key NISSAN PRIMERA 1999 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 8 of 2267

IWhen connecting or disconnecting pin connectors into or

from TCM, take care not to damage pin terminals (bend or

break).

Make sure that there are not any bends or breaks on TCM

pin terminal, when connecting pin connectors.

IBefore replacing TCM, perform TCM input/output signal

inspection and make sure whether TCM functions prop-

erly or not. (See page AT-41.)

IAfter performing each TROUBLE DIAGNOSIS, perform

ªDTC (Diagnostic Trouble Code) CONFIRMATION PROCE-

DUREº.

The DTC should not be displayed in the ªDTC CONFIRMA-

TION PROCEDUREº if the repair is completed.

IIt is very important to perform functional tests whenever they

are indicated.

IExtreme care should be taken to avoid damage to O-rings,

seals and gaskets when assembling.

IWhen the CVT drain plug is removed, only some of the fluid is

drained. Old CVT fluid will remain in torque converter and CVT

fluid cooling system.

Always follow the procedures under ªChanging CVT Fluidº in

the MA section when changing CVT fluid.

Service Notice or PrecautionsNCAT0004FAIL-SAFENCAT0004S01The TCM has an electronic Fail-Safe (limp home mode). This allows the vehicle to be driven even if a major

electrical input/output device circuit is damaged.

Under Fail-Safe, the vehicle always runs even with a shift lever position of ªLº or ªDº. The customer may com-

plain of sluggish or poor acceleration.

When the ignition key is turned ªONº following Fail-Safe operation, CVT or SPORT indicator lamp blinks for

about 8 seconds. [For ªTCM SELF-DIAGNOSTIC PROCEDURE (No Tools)º, refer to AT-25.]

Fail-Safe may occur without electrical circuit damage if the vehicle is driven under extreme conditions (such

as excessive wheel spin followed by sudden braking). To recover normal shift pattern, turn the ignition key

ªOFFº for 5 seconds, then ªONº.

SEF291H

MEF040DA Perform TCM

input/output signal

inspection before

replacement.

SAT652J

PRECAUTIONS

Precautions (Cont'd)

AT-6

Page 32 of 2267

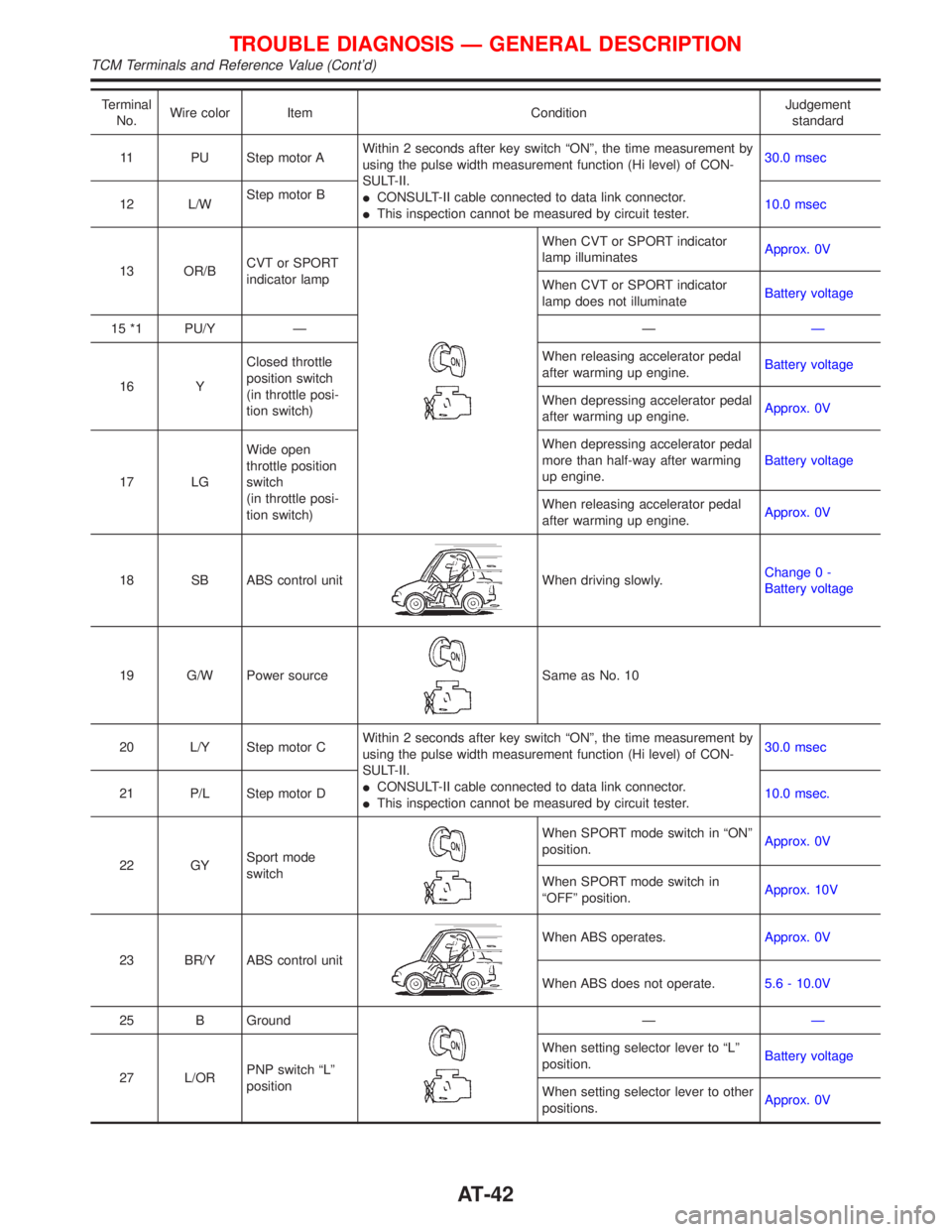

DIAGNOSTIC WORKSHEET=NCAT0023S01Information from CustomerNCAT0023S0101KEY POINTS

WHAT..... Vehicle & CVT model

WHEN..... Date, Frequencies

WHERE..... Road conditions

HOW..... Operating conditions, Symptoms

Customer name MR/MS Model & Year VIN

Trans. model Engine Mileage

Incident Date Manuf. Date In Service Date

FrequencylContinuouslIntermittent ( times a day)

lVehicle does not move. (lAny positionlParticular position)

SymptomslLockup malfunction

lShift point too high or too low.

lShift shock or slip (lN,DlLockuplAny drive position)

lNoise or vibration

lNo pattern select

lOthers

()

SPORT indicator lamp or CVT

indicator (warning) lampBlinks for about 8 seconds.

lContinuously litlNot lit

Malfunction indicator (MI)lContinuously litlNot lit

TROUBLE DIAGNOSIS Ð INTRODUCTION

Introduction (Cont'd)

AT-30

Page 44 of 2267

Terminal

No.Wire color Item ConditionJudgement

standard

11 PU Step motor AWithin 2 seconds after key switch ªONº, the time measurement by

using the pulse width measurement function (Hi level) of CON-

SULT-II.

ICONSULT-II cable connected to data link connector.

IThis inspection cannot be measured by circuit tester.30.0 msec

12 L/WStep motor B

10.0 msec

13 OR/BCVT or SPORT

indicator lamp

When CVT or SPORT indicator

lamp illuminatesApprox. 0V

When CVT or SPORT indicator

lamp does not illuminateBattery voltage

15 *1 PU/Y Ð ÐÐ

16 YClosed throttle

position switch

(in throttle posi-

tion switch)When releasing accelerator pedal

after warming up engine.Battery voltage

When depressing accelerator pedal

after warming up engine.Approx. 0V

17 LGWide open

throttle position

switch

(in throttle posi-

tion switch)When depressing accelerator pedal

more than half-way after warming

up engine.Battery voltage

When releasing accelerator pedal

after warming up engine.Approx. 0V

18 SB ABS control unit

When driving slowly.Change 0 -

Battery voltage

19 G/W Power source

Same as No. 10

20 L/Y Step motor CWithin 2 seconds after key switch ªONº, the time measurement by

using the pulse width measurement function (Hi level) of CON-

SULT-II.

ICONSULT-II cable connected to data link connector.

IThis inspection cannot be measured by circuit tester.30.0 msec

21 P/L Step motor D10.0 msec.

22 GYSport mode

switch

When SPORT mode switch in ªONº

position.Approx. 0V

When SPORT mode switch in

ªOFFº position.Approx. 10V

23 BR/Y ABS control unit

When ABS operates.Approx. 0V

When ABS does not operate.5.6 - 10.0V

25 B Ground

ÐÐ

27 L/ORPNP switch ªLº

positionWhen setting selector lever to ªLº

position.Battery voltage

When setting selector lever to other

positions.Approx. 0V

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTION

TCM Terminals and Reference Value (Cont'd)

AT-42

Page 88 of 2267

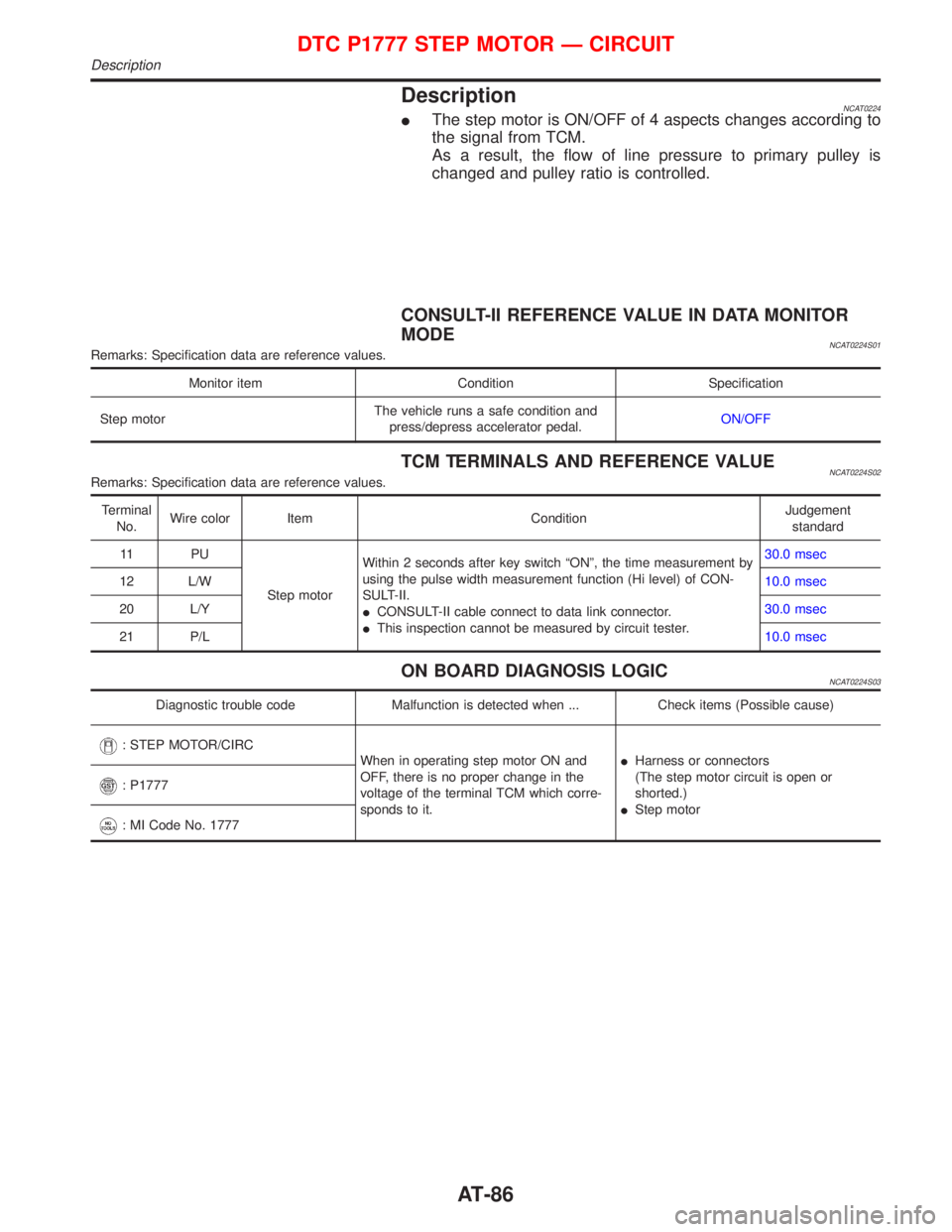

DescriptionNCAT0224IThe step motor is ON/OFF of 4 aspects changes according to

the signal from TCM.

As a result, the flow of line pressure to primary pulley is

changed and pulley ratio is controlled.

CONSULT-II REFERENCE VALUE IN DATA MONITOR

MODE

NCAT0224S01Remarks: Specification data are reference values.

Monitor item Condition Specification

Step motorThe vehicle runs a safe condition and

press/depress accelerator pedal.ON/OFF

TCM TERMINALS AND REFERENCE VALUENCAT0224S02Remarks: Specification data are reference values.

Terminal

No.Wire color Item ConditionJudgement

standard

11 P U

Step motorWithin 2 seconds after key switch ªONº, the time measurement by

using the pulse width measurement function (Hi level) of CON-

SULT-II.

ICONSULT-II cable connect to data link connector.

IThis inspection cannot be measured by circuit tester.30.0 msec

12 L/W10.0 msec

20 L/Y30.0 msec

21 P/L10.0 msec

ON BOARD DIAGNOSIS LOGICNCAT0224S03

Diagnostic trouble code Malfunction is detected when ... Check items (Possible cause)

: STEP MOTOR/CIRC

When in operating step motor ON and

OFF, there is no proper change in the

voltage of the terminal TCM which corre-

sponds to it.IHarness or connectors

(The step motor circuit is open or

shorted.)

IStep motor

: P1777

: MI Code No. 1777

DTC P1777 STEP MOTOR Ð CIRCUIT

Description

AT-86

Page 149 of 2267

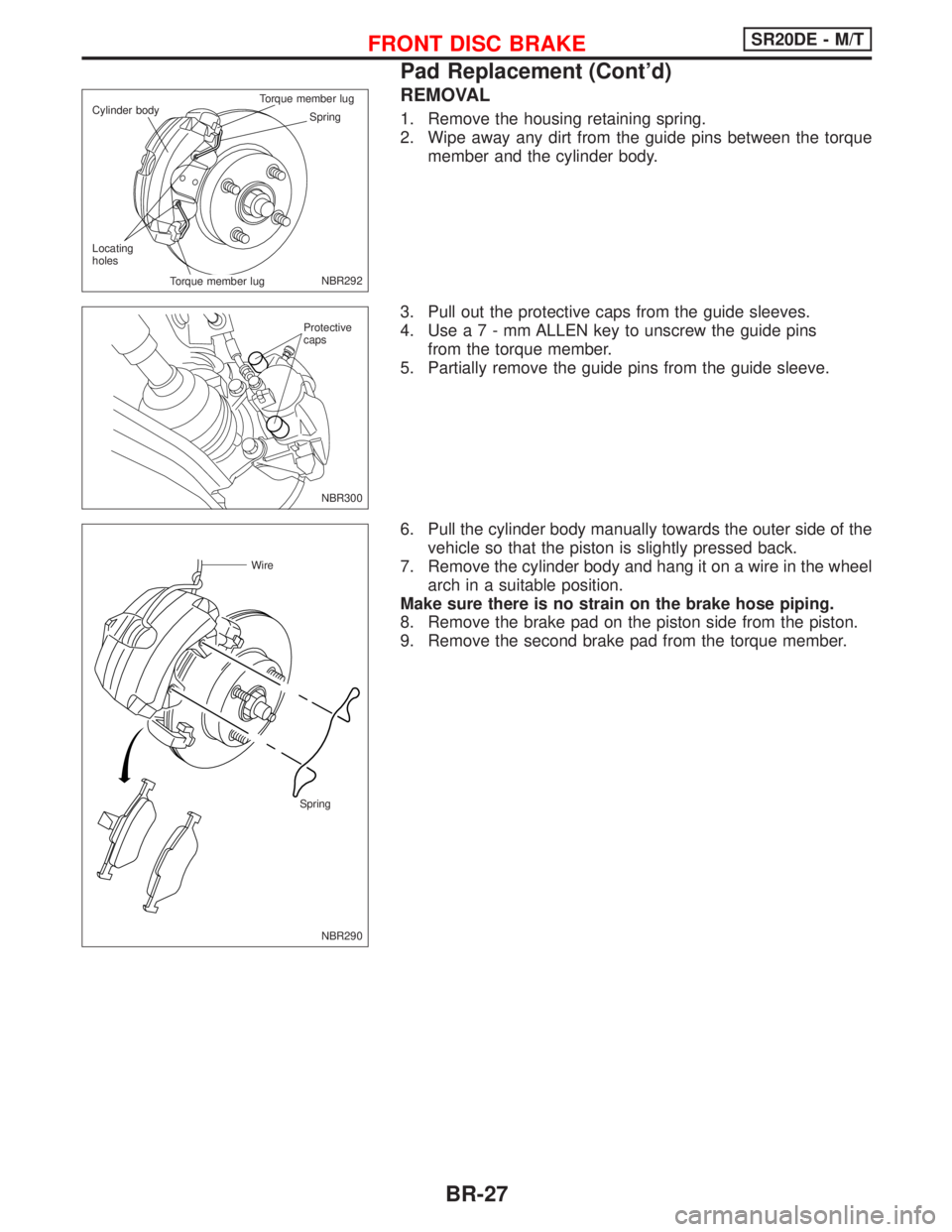

REMOVAL

1. Remove the housing retaining spring.

2. Wipe away any dirt from the guide pins between the torque

member and the cylinder body.

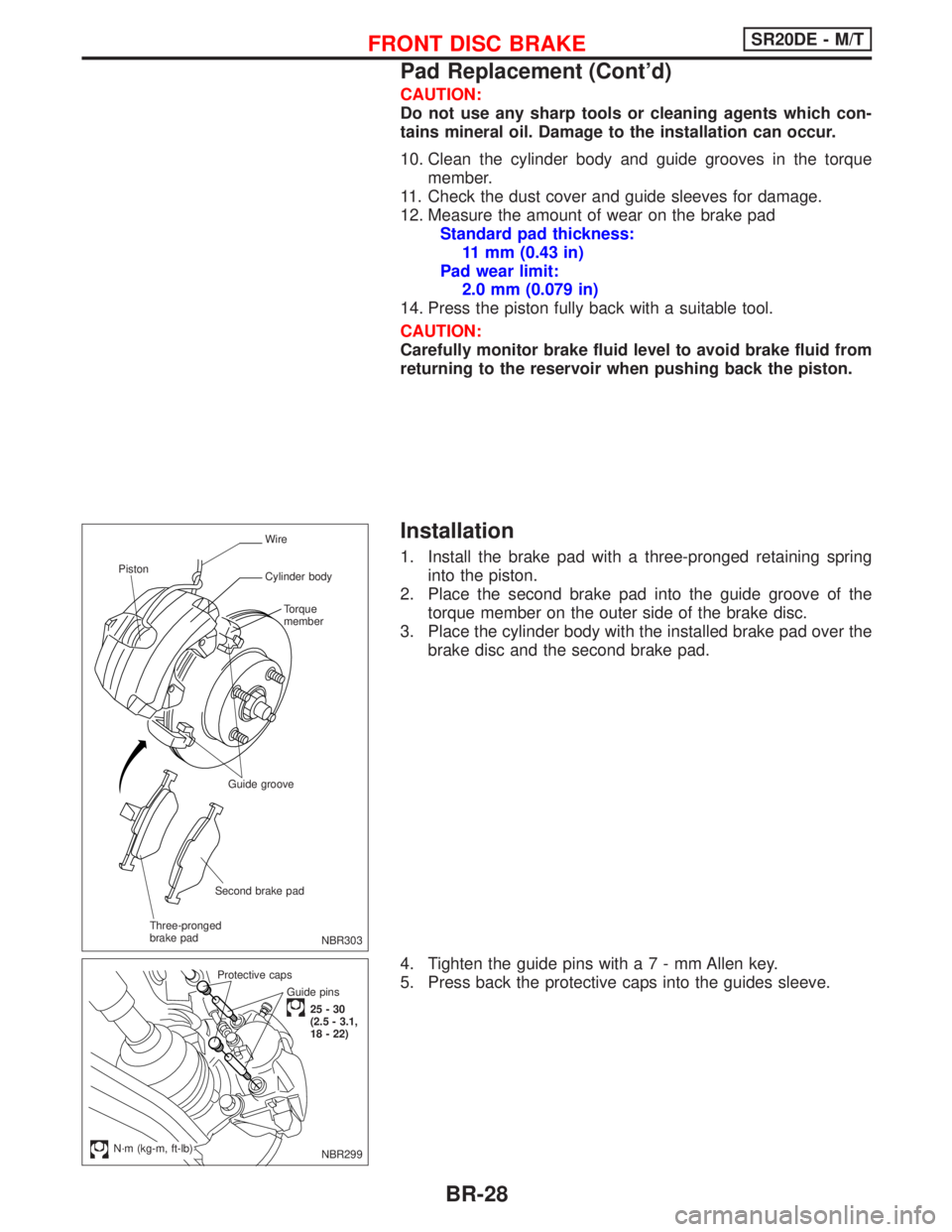

3. Pull out the protective caps from the guide sleeves.

4. Usea7-mmALLEN key to unscrew the guide pins

from the torque member.

5. Partially remove the guide pins from the guide sleeve.

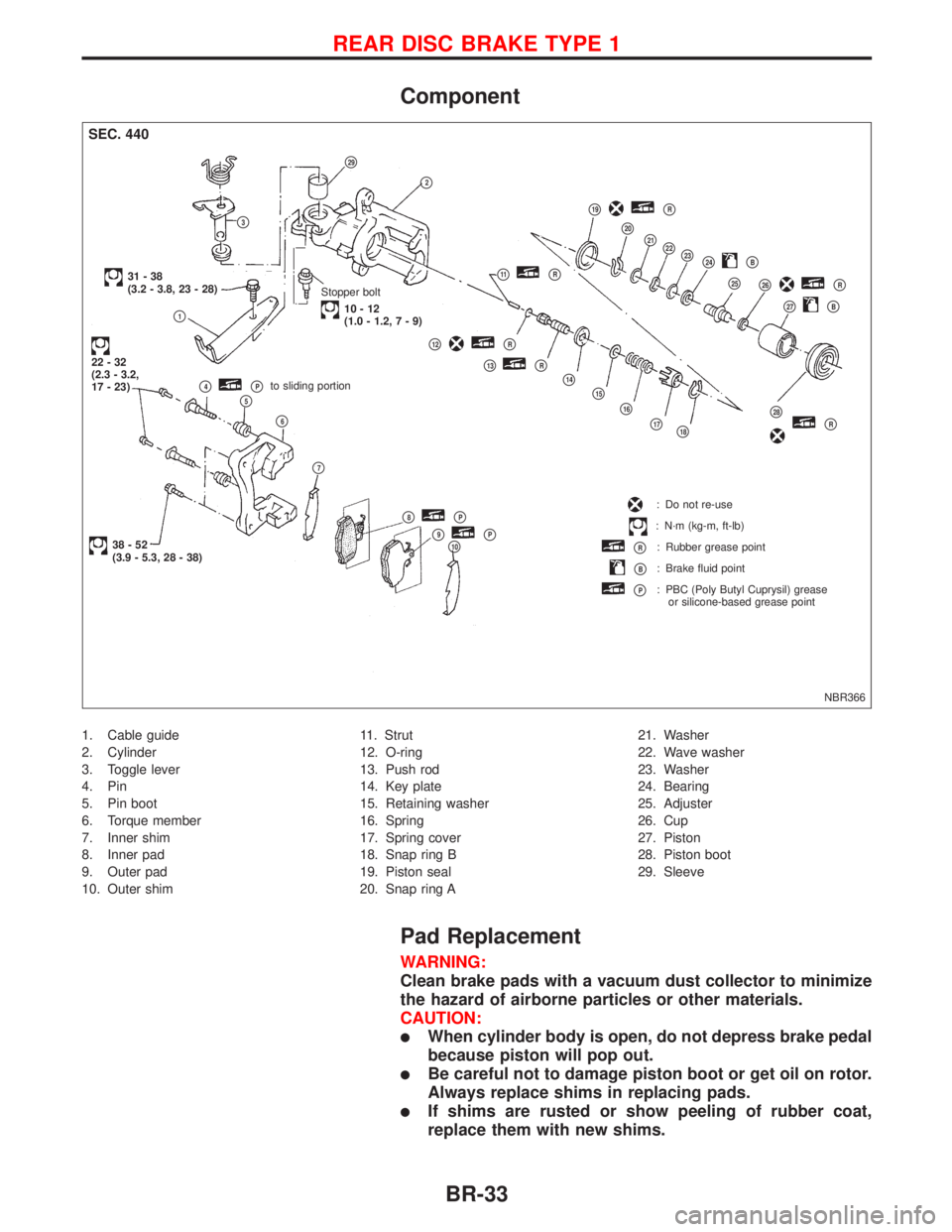

6. Pull the cylinder body manually towards the outer side of the

vehicle so that the piston is slightly pressed back.

7. Remove the cylinder body and hang it on a wire in the wheel

arch in a suitable position.

Make sure there is no strain on the brake hose piping.

8. Remove the brake pad on the piston side from the piston.

9. Remove the second brake pad from the torque member.

NBR292 Spring Cylinder bodyTorque member lug.Torque member lug Locating

holes

NBR300 Protective

caps

NBR290

Wire

Spring

FRONT DISC BRAKESR20DE - M/T

Pad Replacement (Cont'd)

BR-27

Page 150 of 2267

CAUTION:

Do not use any sharp tools or cleaning agents which con-

tains mineral oil. Damage to the installation can occur.

10. Clean the cylinder body and guide grooves in the torque

member.

11. Check the dust cover and guide sleeves for damage.

12. Measure the amount of wear on the brake pad

Standard pad thickness:

11 mm (0.43 in)

Pad wear limit:

2.0 mm (0.079 in)

14. Press the piston fully back with a suitable tool.

CAUTION:

Carefully monitor brake fluid level to avoid brake fluid from

returning to the reservoir when pushing back the piston.

Installation

1. Install the brake pad with a three-pronged retaining spring

into the piston.

2. Place the second brake pad into the guide groove of the

torque member on the outer side of the brake disc.

3. Place the cylinder body with the installed brake pad over the

brake disc and the second brake pad.

4. Tighten the guide pins witha7-mmAllen key.

5. Press back the protective caps into the guides sleeve.

NBR303

Wire

Cylinder body

Torque

member

Guide groove

Second brake pad

Three-pronged

brake pad Piston

Guide pins

25-30

(2.5 - 3.1,

18 - 22) Protective caps

.N´m (kg-m, ft-lb)NBR299

FRONT DISC BRAKESR20DE - M/T

Pad Replacement (Cont'd)

BR-28

Page 155 of 2267

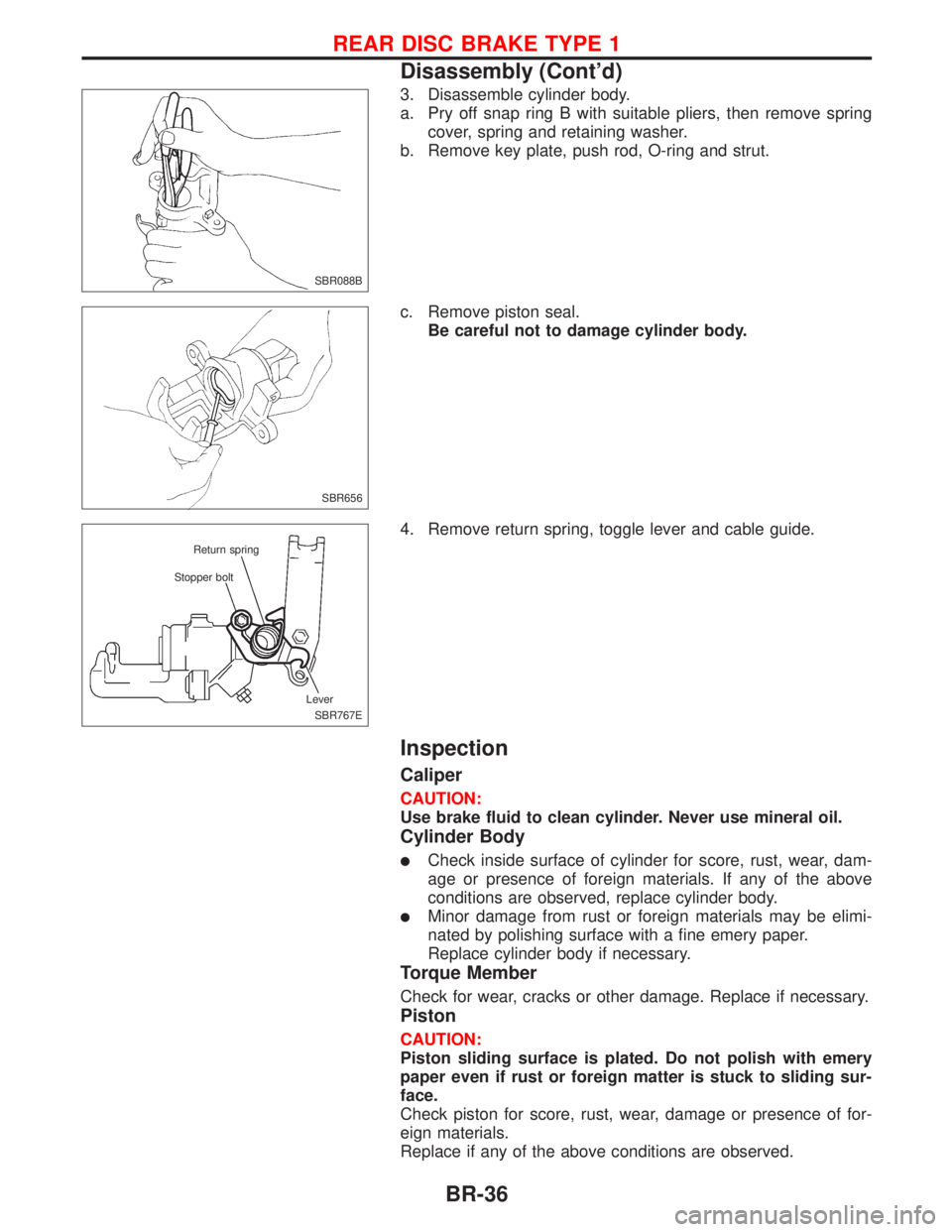

Component

1. Cable guide

2. Cylinder

3. Toggle lever

4. Pin

5. Pin boot

6. Torque member

7. Inner shim

8. Inner pad

9. Outer pad

10. Outer shim11. Strut

12. O-ring

13. Push rod

14. Key plate

15. Retaining washer

16. Spring

17. Spring cover

18. Snap ring B

19. Piston seal

20. Snap ring A21. Washer

22. Wave washer

23. Washer

24. Bearing

25. Adjuster

26. Cup

27. Piston

28. Piston boot

29. Sleeve

Pad Replacement

WARNING:

Clean brake pads with a vacuum dust collector to minimize

the hazard of airborne particles or other materials.

CAUTION:

lWhen cylinder body is open, do not depress brake pedal

because piston will pop out.

lBe careful not to damage piston boot or get oil on rotor.

Always replace shims in replacing pads.

lIf shims are rusted or show peeling of rubber coat,

replace them with new shims.

NBR366

SEC. 440

Stopper bolt

10-12

(1.0-1.2,7-9)

31-38

(3.2 - 3.8, 23 - 28)

p1

22-32

(2.3 - 3.2,

17 - 23)

38-52

(3.9 - 5.3, 28 - 38)p10p9pPp8pP

p7

p6

p5p4pPto sliding portion

p12pR

p13pR

p14

p15

p16

p17p18

p28pR

: Do not re-use

: N´m (kg-m, ft-lb)

pR: Rubber grease point

pB: Brake fluid point

pP: PBC (Poly Butyl Cuprysil) grease

or silicone-based grease point

p23

p27pB

p26pRp25

p24pBp22p21p20

p19pR

p11pR

p3

p2

p29

REAR DISC BRAKE TYPE 1

BR-33

Page 158 of 2267

3. Disassemble cylinder body.

a. Pry off snap ring B with suitable pliers, then remove spring

cover, spring and retaining washer.

b. Remove key plate, push rod, O-ring and strut.

c. Remove piston seal.

Be careful not to damage cylinder body.

4. Remove return spring, toggle lever and cable guide.

Inspection

Caliper

CAUTION:

Use brake fluid to clean cylinder. Never use mineral oil.

Cylinder Body

lCheck inside surface of cylinder for score, rust, wear, dam-

age or presence of foreign materials. If any of the above

conditions are observed, replace cylinder body.

lMinor damage from rust or foreign materials may be elimi-

nated by polishing surface with a fine emery paper.

Replace cylinder body if necessary.

Torque Member

Check for wear, cracks or other damage. Replace if necessary.

Piston

CAUTION:

Piston sliding surface is plated. Do not polish with emery

paper even if rust or foreign matter is stuck to sliding sur-

face.

Check piston for score, rust, wear, damage or presence of for-

eign materials.

Replace if any of the above conditions are observed.

SBR088B

SBR656

SBR767E Stopper boltReturn spring

Lever

REAR DISC BRAKE TYPE 1

Disassembly (Cont'd)

BR-36

Page 160 of 2267

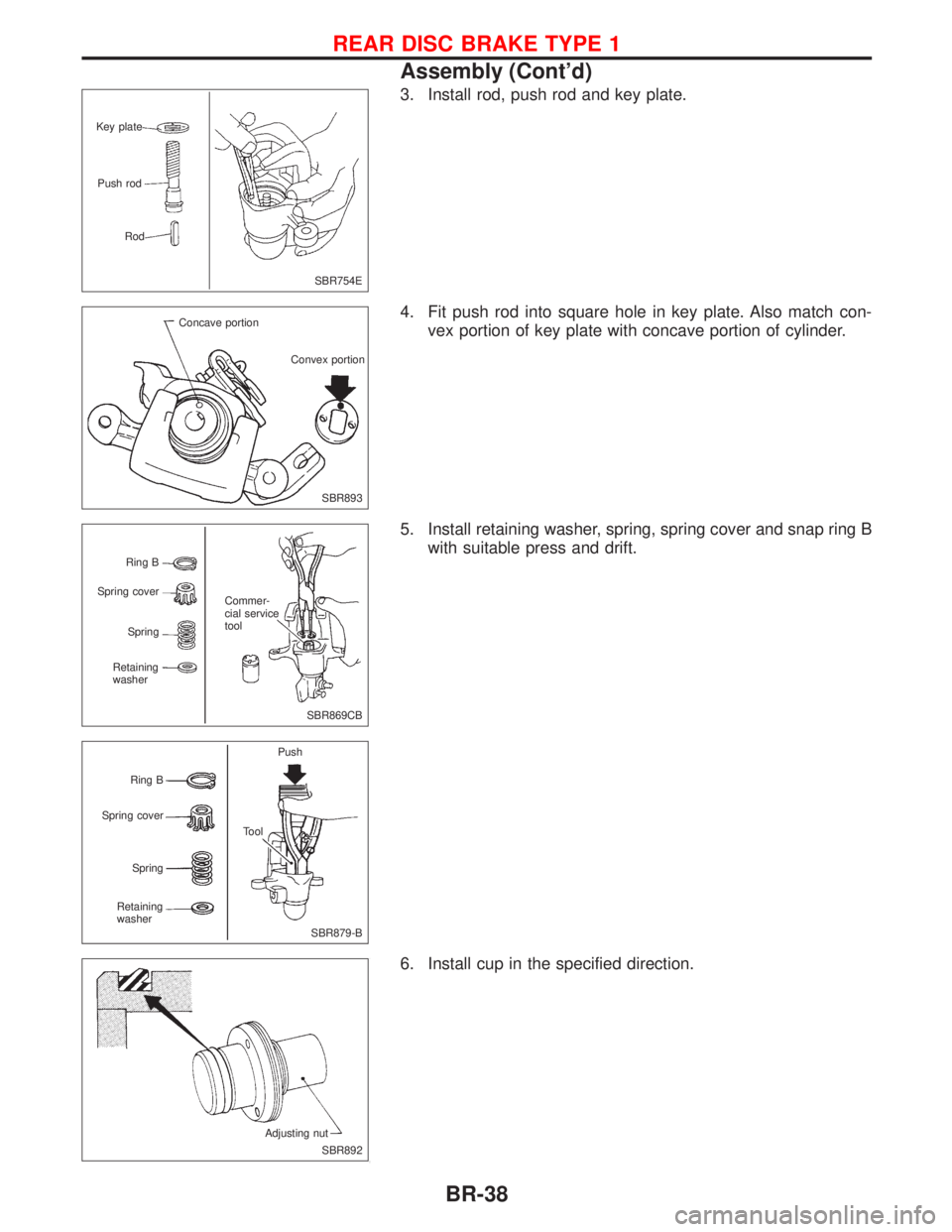

3. Install rod, push rod and key plate.

4. Fit push rod into square hole in key plate. Also match con-

vex portion of key plate with concave portion of cylinder.

5. Install retaining washer, spring, spring cover and snap ring B

with suitable press and drift.

6. Install cup in the specified direction.

SBR754E Key plate

Push rod

Rod

SBR893 Concave portion

Convex portion

SBR869CB Ring B

Spring cover

Spring

Retaining

washerCommer-

cial service

tool

SBR879-B Ring B

Spring cover

Spring

Retaining

washerPush

Tool

SBR892 Adjusting nut

REAR DISC BRAKE TYPE 1

Assembly (Cont'd)

BR-38

Page 196 of 2267

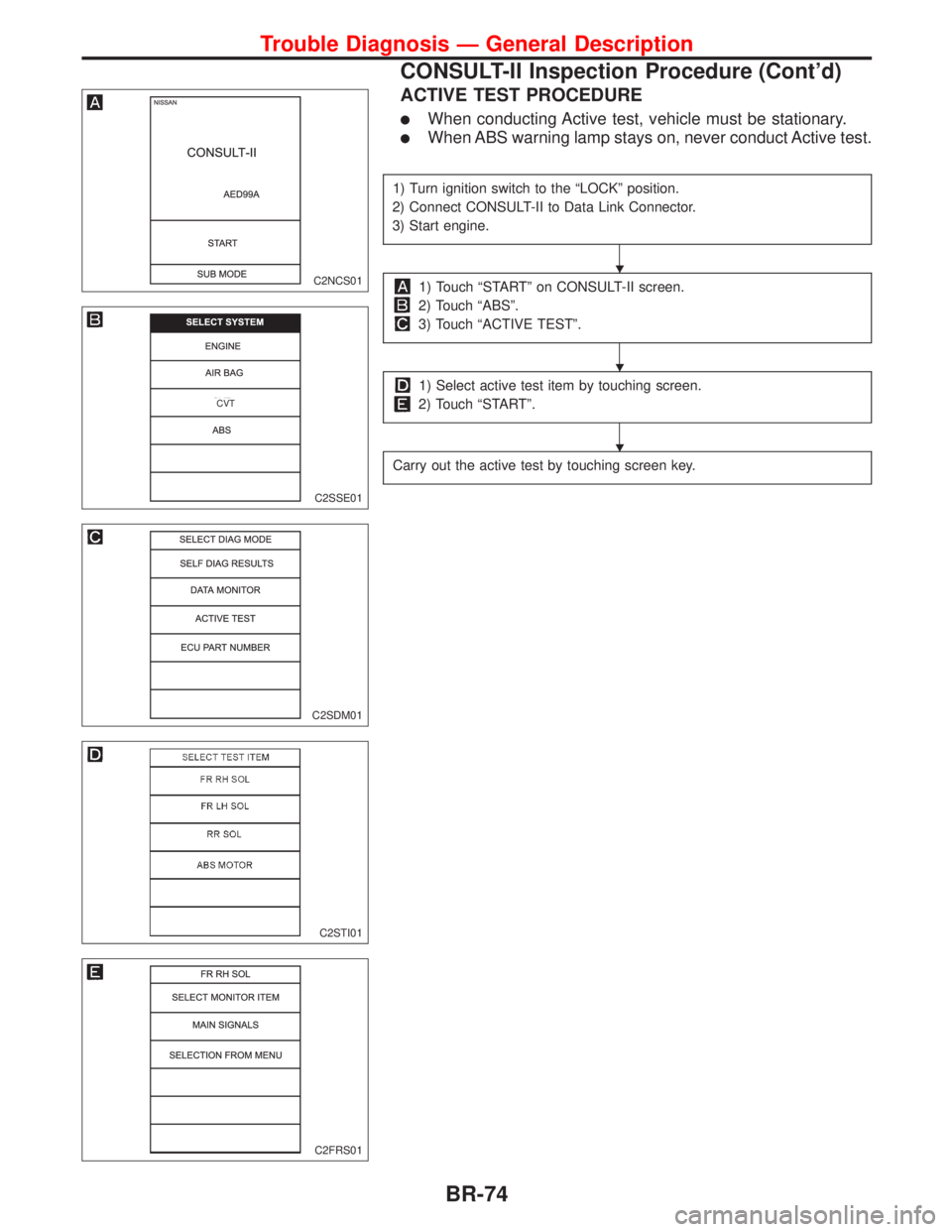

ACTIVE TEST PROCEDURE

lWhen conducting Active test, vehicle must be stationary.

lWhen ABS warning lamp stays on, never conduct Active test.

1) Turn ignition switch to the ªLOCKº position.

2) Connect CONSULT-II to Data Link Connector.

3) Start engine.

1) Touch ªSTARTº on CONSULT-II screen.

2) Touch ªABSº.

3) Touch ªACTIVE TESTº.

1) Select active test item by touching screen.

2) Touch ªSTARTº.

Carry out the active test by touching screen key.

C2NCS01

C2SSE01

.CVT

C2SDM01

C2STI01

C2FRS01

H

H

H

Trouble Diagnosis Ð General Description

CONSULT-II Inspection Procedure (Cont'd)

BR-74