distributor NISSAN PRIMERA 1999 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 801 of 2267

ENGINE CONTROL SYSTEM

SECTION

EC

CONTENTS

SR20DE

TROUBLE DIAGNOSIS - INDEX....................................6

Alphabetical & P No. Index for DTC ...........................6

PRECAUTIONS.............................................................10

Supplemental Restraint System (SRS)²AIR

BAG²and²SEAT BELT PRE-TENSIONER².............10

Precautions for On Board Diagnostic (OBD)

System of Engine and CVT .......................................10

Engine Fuel & Emission Control System .................. 11

Precautions ................................................................12

Wiring Diagrams and Trouble Diagnosis ...................13

PREPARATION.............................................................14

Special Service Tools ................................................14

Commercial Service Tool ...........................................14

ENGINE AND EMISSION CONTROL OVERALL

SYSTEM.........................................................................15

Engine Control Component Parts Location ...............15

Circuit Diagram ..........................................................19

System Diagram ........................................................20

Vacuum Hose Drawing ..............................................21

System Chart .............................................................22

ENGINE AND EMISSION BASIC CONTROL

SYSTEM DESCRIPTION...............................................23

Multiport Fuel Injection (MFI) System .......................23

Distributor Ignition (DI) System .................................25

Air Conditioning Cut Control ......................................26

Fuel Cut Control (at no load & high engine

speed) ........................................................................27

Evaporative Emission System ...................................27

Positive Crankcase Ventilation ..................................30

BASIC SERVICE PROCEDURE...................................31

Fuel Pressure Release ..............................................31

Fuel Pressure Check .................................................31

Fuel Pressure Regulator Check ................................32

Injector .......................................................................32

Idle Speed/Ignition Timing/Idle Mixture Ratio

Adjustment .................................................................34Idle Air Volume Learning ...........................................46

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION...............................................................48

Introduction ................................................................48

Two Trip Detection Logic ...........................................48

Emission-related Diagnostic Information ...................49

Malfunction Indicator (MI) ..........................................58

OBD System Operation Chart ...................................63

CONSULT-II ...............................................................68

Generic Scan Tool (GST) ..........................................78

TROUBLE DIAGNOSIS - INTRODUCTION..................80

Introduction ................................................................80

Work Flow ..................................................................82

TROUBLE DIAGNOSIS - BASIC INSPECTION...........84

Basic Inspection.........................................................84

TROUBLE DIAGNOSIS - GENERAL

DESCRIPTION...............................................................92

DTC Inspection Priority Chart....................................92

Fail-safe Chart ...........................................................93

Symptom Matrix Chart ...............................................94

CONSULT-II Reference Value in Data Monitor

Mode ..........................................................................98

Major Sensor Reference Graph in Data Monitor

Mode ........................................................................100

ECM Terminals and Reference Value .....................103

TROUBLE DIAGNOSIS - SPECIFICATION VALUE.. 110

Description ............................................................... 110

Testing Condition ..................................................... 110

Inspection Procedure ............................................... 110

Diagnostic Procedure .............................................. 111

TROUBLE DIAGNOSIS FOR INTERMITTENT

INCIDENT..................................................................... 114

Description ............................................................... 114

Diagnostic Procedure .............................................. 114

TROUBLE DIAGNOSIS FOR POWER SUPPLY........ 115

Main Power Supply and Ground Circuit .................. 115

EC

Page 815 of 2267

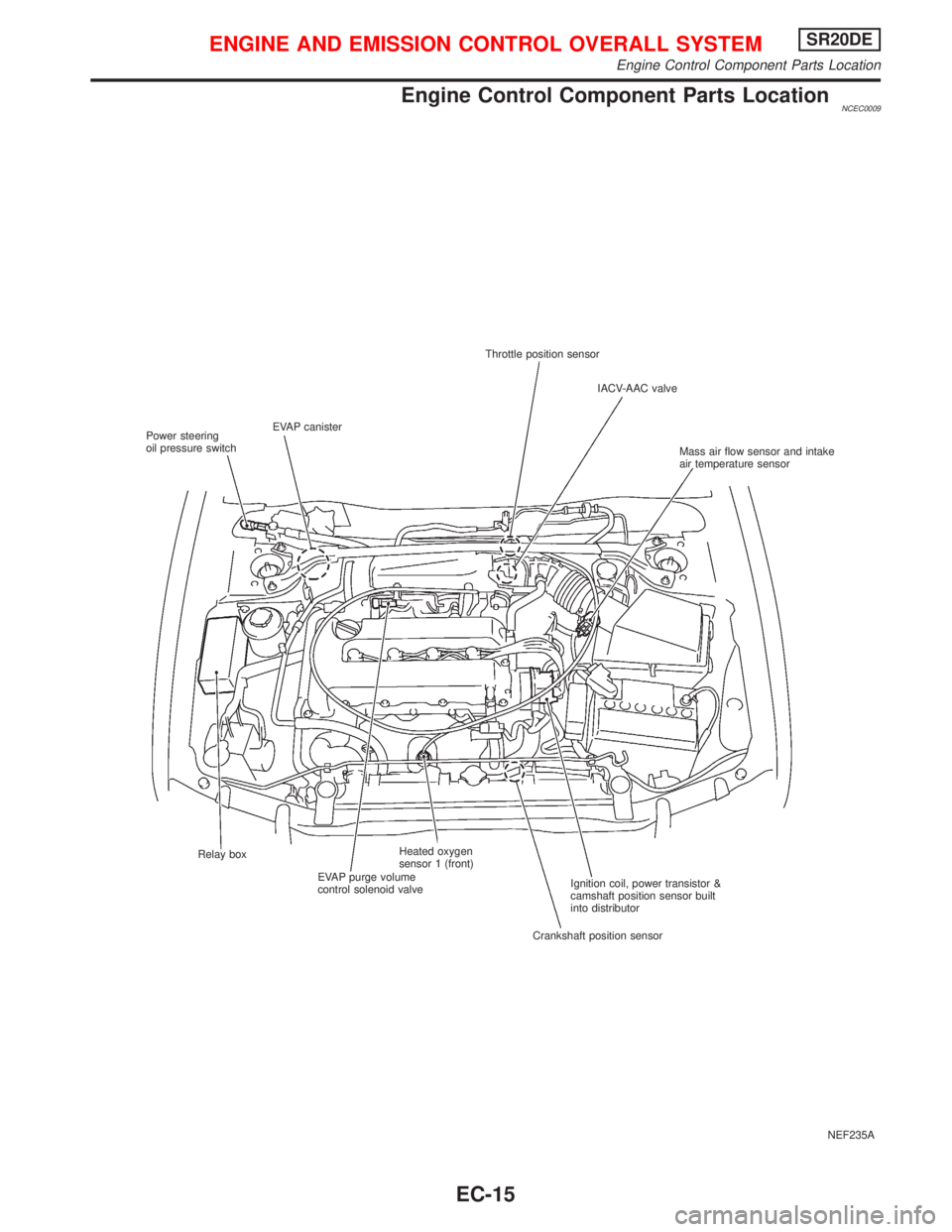

Engine Control Component Parts LocationNCEC0009

NEF235A Throttle position sensor

IACV-AAC valve

Mass air flow sensor and intake

air temperature sensor

Ignition coil, power transistor &

camshaft position sensor built

into distributor

Crankshaft position sensor Relay box

EVAP purge volume

control solenoid valveHeated oxygen

sensor 1 (front) EVAP canister

Power steering

oil pressure switch

ENGINE AND EMISSION CONTROL OVERALL SYSTEMSR20DE

Engine Control Component Parts Location

EC-15

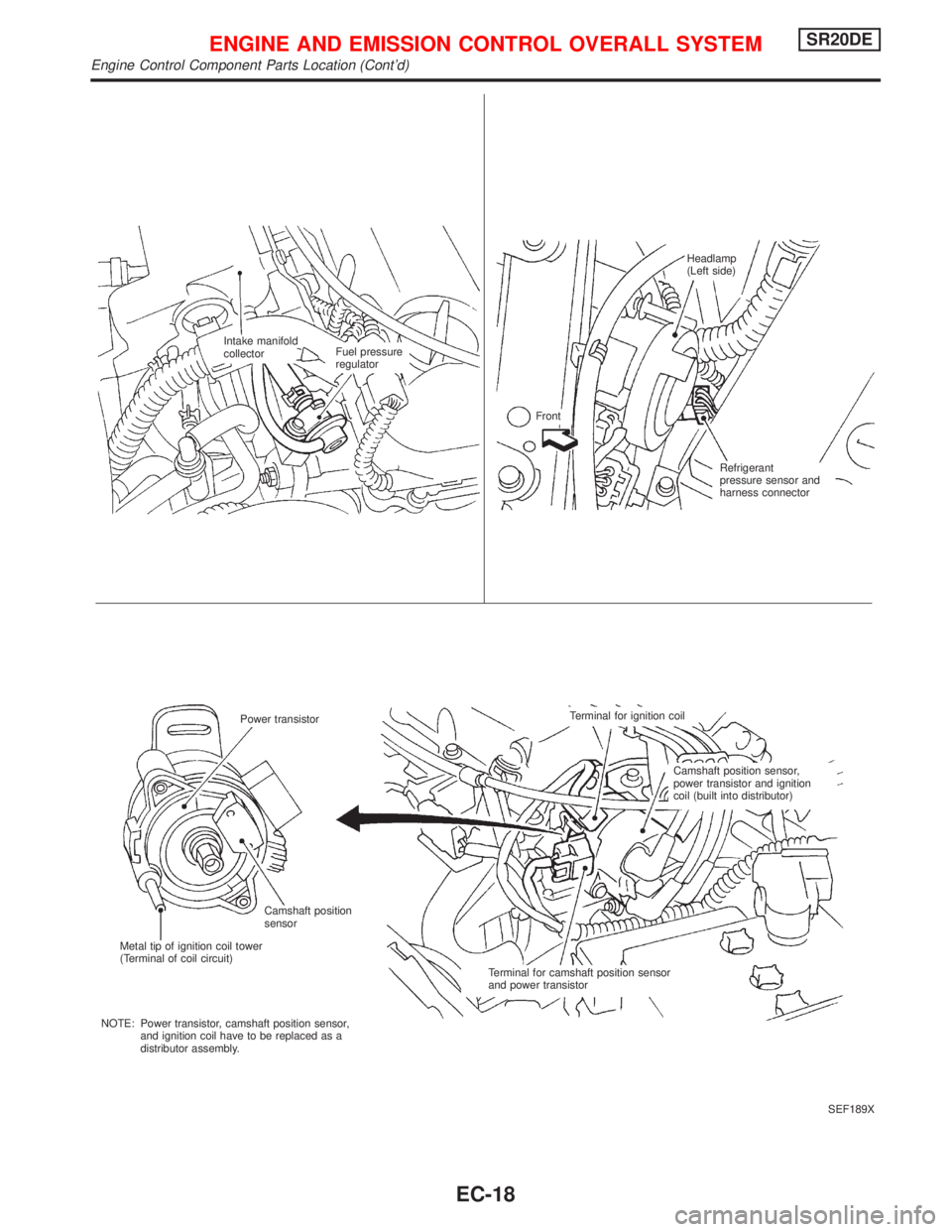

Page 818 of 2267

SEF189X Intake manifold

collectorFuel pressure

regulatorHeadlamp

(Left side)

Front

Refrigerant

pressure sensor and

harness connector

Power transistorTerminal for ignition coil

Camshaft position sensor,

power transistor and ignition

coil (built into distributor)

Terminal for camshaft position sensor

and power transistor Camshaft position

sensor

Metal tip of ignition coil tower

(Terminal of coil circuit)

NOTE: Power transistor, camshaft position sensor,

and ignition coil have to be replaced as a

distributor assembly.

ENGINE AND EMISSION CONTROL OVERALL SYSTEMSR20DE

Engine Control Component Parts Location (Cont'd)

EC-18

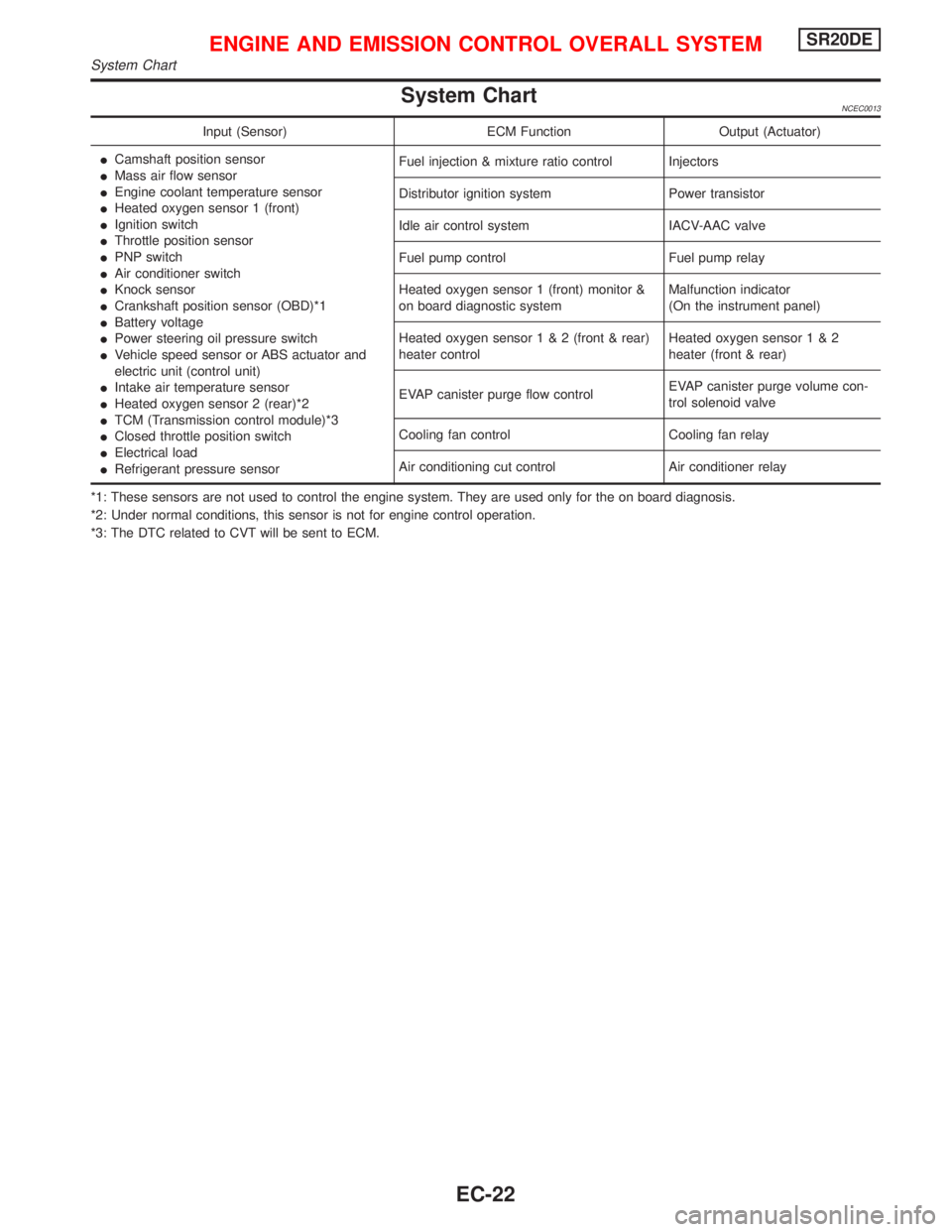

Page 822 of 2267

System ChartNCEC0013

Input (Sensor) ECM Function Output (Actuator)

ICamshaft position sensor

IMass air flow sensor

IEngine coolant temperature sensor

IHeated oxygen sensor 1 (front)

IIgnition switch

IThrottle position sensor

IPNP switch

IAir conditioner switch

IKnock sensor

ICrankshaft position sensor (OBD)*1

IBattery voltage

IPower steering oil pressure switch

IVehicle speed sensor or ABS actuator and

electric unit (control unit)

IIntake air temperature sensor

IHeated oxygen sensor 2 (rear)*2

ITCM (Transmission control module)*3

IClosed throttle position switch

IElectrical load

IRefrigerant pressure sensorFuel injection & mixture ratio control Injectors

Distributor ignition system Power transistor

Idle air control system IACV-AAC valve

Fuel pump control Fuel pump relay

Heated oxygen sensor 1 (front) monitor &

on board diagnostic systemMalfunction indicator

(On the instrument panel)

Heated oxygen sensor1&2(front & rear)

heater controlHeated oxygen sensor1&2

heater (front & rear)

EVAP canister purge flow controlEVAP canister purge volume con-

trol solenoid valve

Cooling fan control Cooling fan relay

Air conditioning cut control Air conditioner relay

*1: These sensors are not used to control the engine system. They are used only for the on board diagnosis.

*2: Under normal conditions, this sensor is not for engine control operation.

*3: The DTC related to CVT will be sent to ECM.

ENGINE AND EMISSION CONTROL OVERALL SYSTEMSR20DE

System Chart

EC-22

Page 825 of 2267

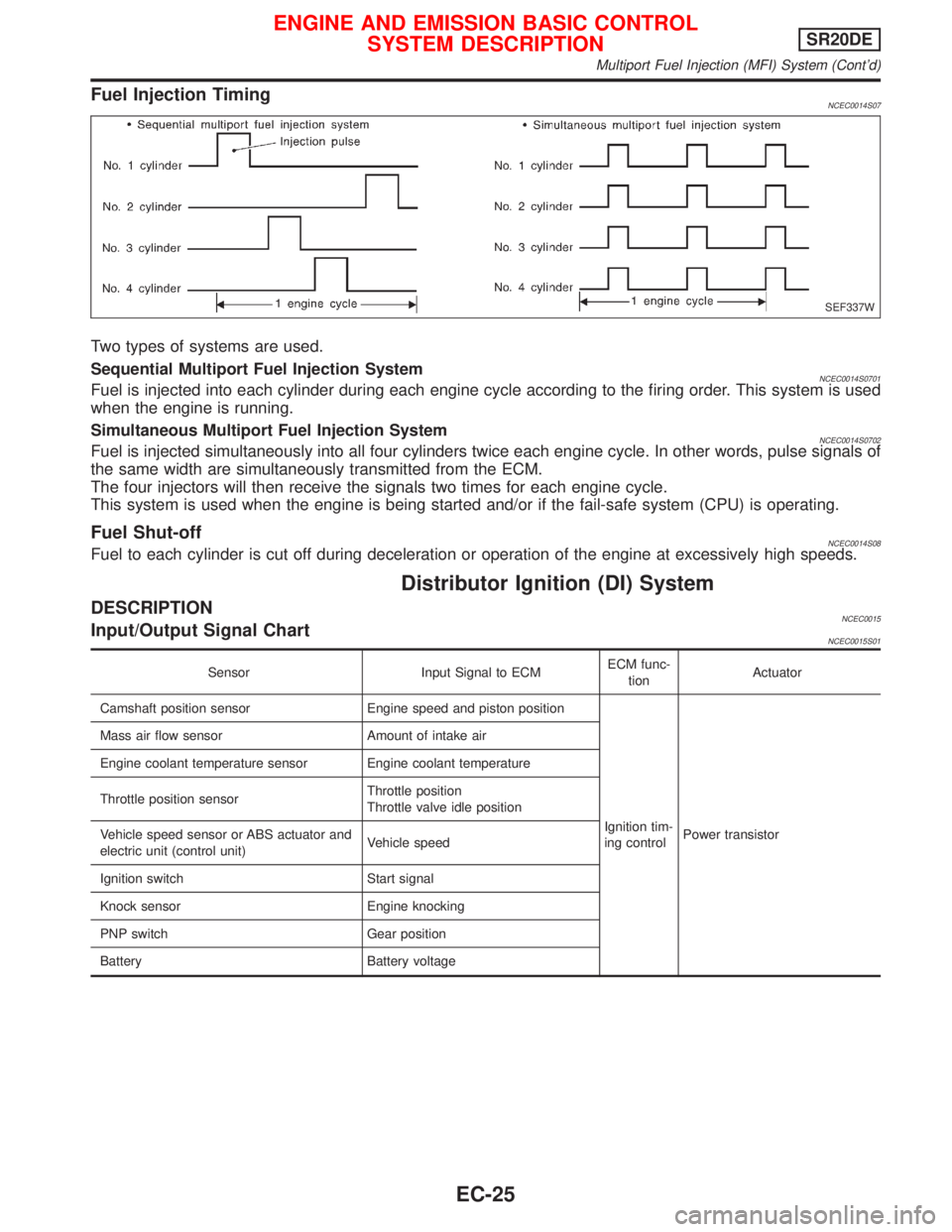

Fuel Injection TimingNCEC0014S07

Two types of systems are used.

Sequential Multiport Fuel Injection System

NCEC0014S0701Fuel is injected into each cylinder during each engine cycle according to the firing order. This system is used

when the engine is running.

Simultaneous Multiport Fuel Injection System

NCEC0014S0702Fuel is injected simultaneously into all four cylinders twice each engine cycle. In other words, pulse signals of

the same width are simultaneously transmitted from the ECM.

The four injectors will then receive the signals two times for each engine cycle.

This system is used when the engine is being started and/or if the fail-safe system (CPU) is operating.

Fuel Shut-offNCEC0014S08Fuel to each cylinder is cut off during deceleration or operation of the engine at excessively high speeds.

Distributor Ignition (DI) System

DESCRIPTIONNCEC0015Input/Output Signal ChartNCEC0015S01

Sensor Input Signal to ECMECM func-

tionActuator

Camshaft position sensor Engine speed and piston position

Ignition tim-

ing controlPower transistor Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Throttle position sensorThrottle position

Throttle valve idle position

Vehicle speed sensor or ABS actuator and

electric unit (control unit)Vehicle speed

Ignition switch Start signal

Knock sensor Engine knocking

PNP switch Gear position

Battery Battery voltage

SEF337W

ENGINE AND EMISSION BASIC CONTROL

SYSTEM DESCRIPTIONSR20DE

Multiport Fuel Injection (MFI) System (Cont'd)

EC-25

Page 826 of 2267

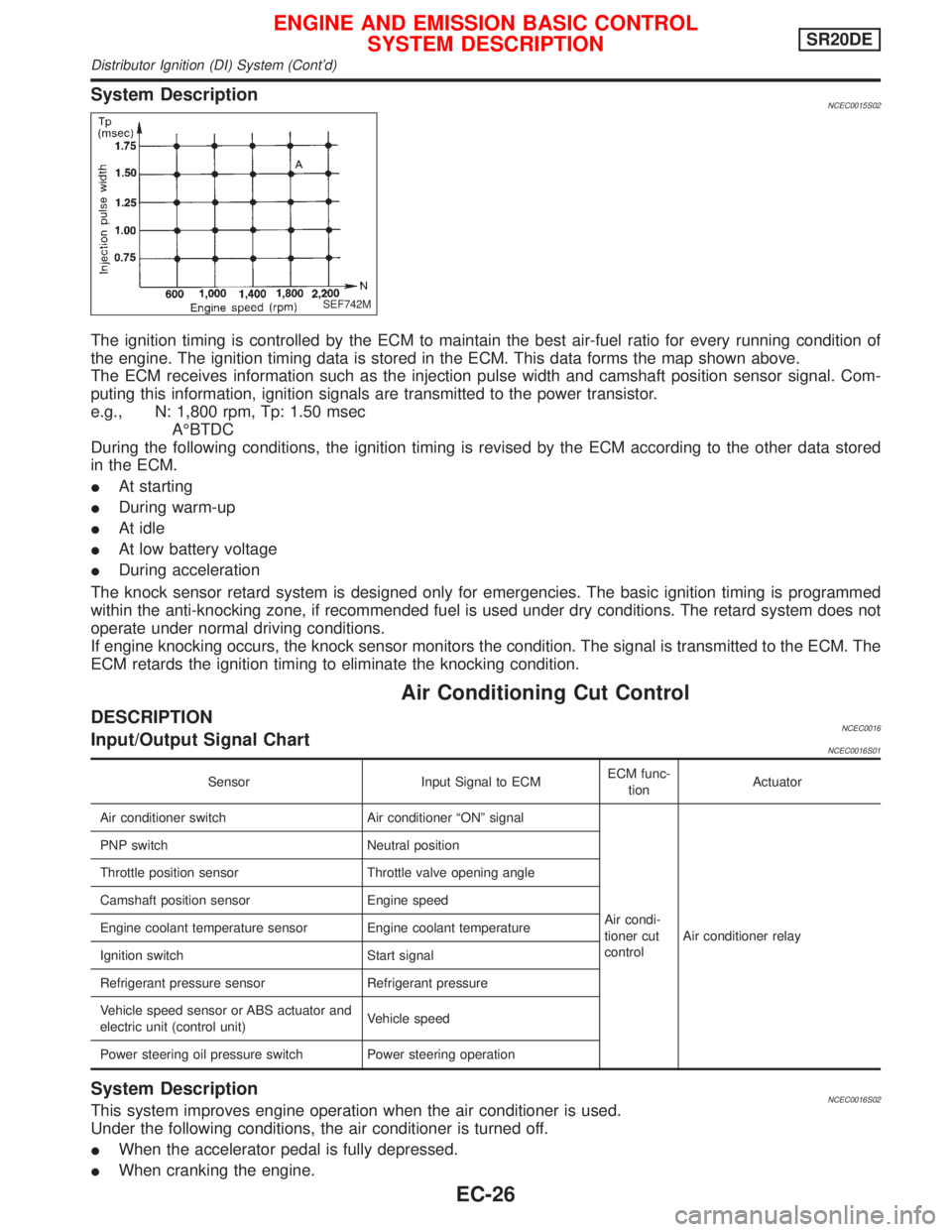

System DescriptionNCEC0015S02

The ignition timing is controlled by the ECM to maintain the best air-fuel ratio for every running condition of

the engine. The ignition timing data is stored in the ECM. This data forms the map shown above.

The ECM receives information such as the injection pulse width and camshaft position sensor signal. Com-

puting this information, ignition signals are transmitted to the power transistor.

e.g., N: 1,800 rpm, Tp: 1.50 msec

AÉBTDC

During the following conditions, the ignition timing is revised by the ECM according to the other data stored

in the ECM.

IAt starting

IDuring warm-up

IAt idle

IAt low battery voltage

IDuring acceleration

The knock sensor retard system is designed only for emergencies. The basic ignition timing is programmed

within the anti-knocking zone, if recommended fuel is used under dry conditions. The retard system does not

operate under normal driving conditions.

If engine knocking occurs, the knock sensor monitors the condition. The signal is transmitted to the ECM. The

ECM retards the ignition timing to eliminate the knocking condition.

Air Conditioning Cut Control

DESCRIPTIONNCEC0016Input/Output Signal ChartNCEC0016S01

Sensor Input Signal to ECMECM func-

tionActuator

Air conditioner switch Air conditioner ªONº signal

Air condi-

tioner cut

controlAir conditioner relay PNP switch Neutral position

Throttle position sensor Throttle valve opening angle

Camshaft position sensor Engine speed

Engine coolant temperature sensor Engine coolant temperature

Ignition switch Start signal

Refrigerant pressure sensor Refrigerant pressure

Vehicle speed sensor or ABS actuator and

electric unit (control unit)Vehicle speed

Power steering oil pressure switch Power steering operation

System DescriptionNCEC0016S02This system improves engine operation when the air conditioner is used.

Under the following conditions, the air conditioner is turned off.

IWhen the accelerator pedal is fully depressed.

IWhen cranking the engine.

SEF742M

ENGINE AND EMISSION BASIC CONTROL

SYSTEM DESCRIPTIONSR20DE

Distributor Ignition (DI) System (Cont'd)

EC-26

Page 839 of 2267

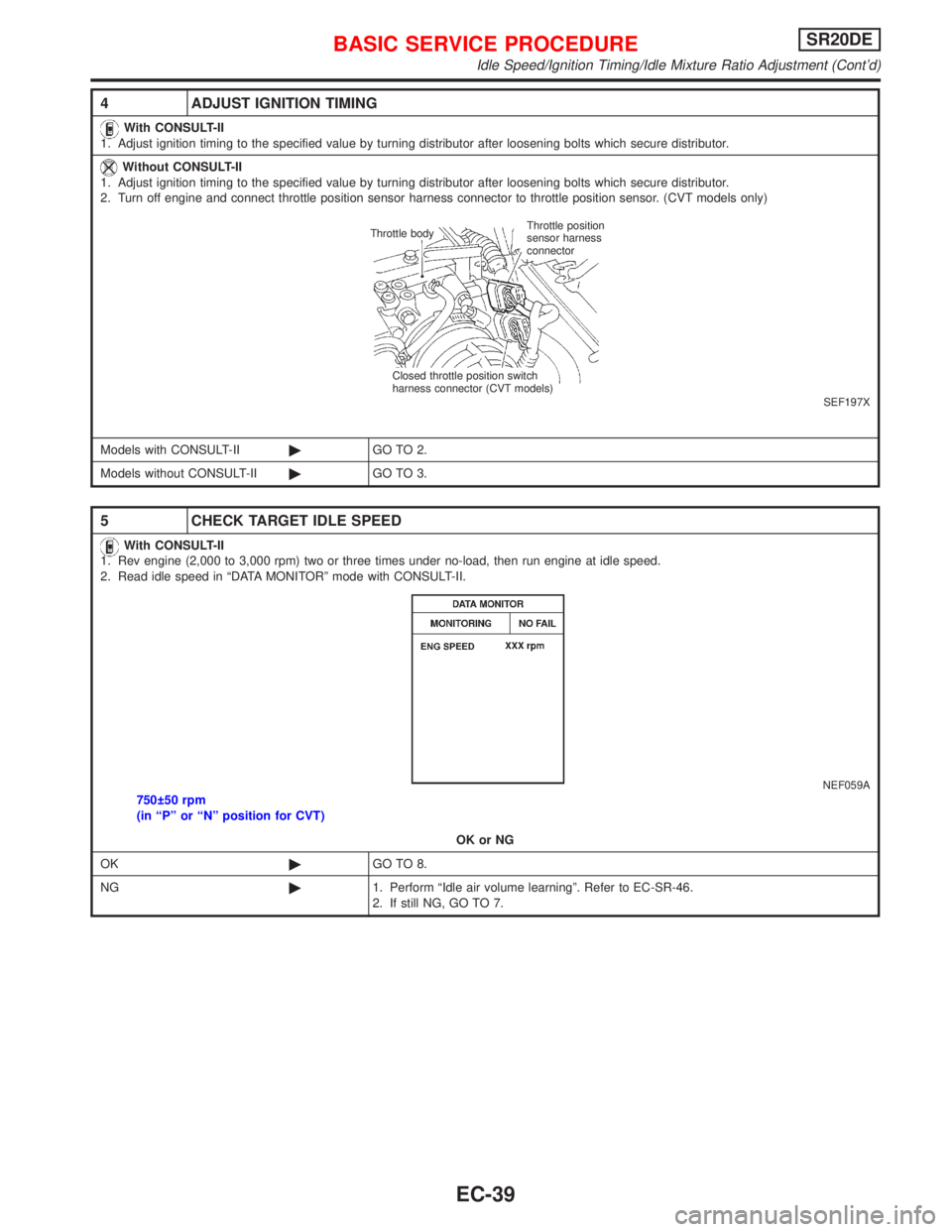

4 ADJUST IGNITION TIMING

With CONSULT-II

1. Adjust ignition timing to the specified value by turning distributor after loosening bolts which secure distributor.

Without CONSULT-II

1. Adjust ignition timing to the specified value by turning distributor after loosening bolts which secure distributor.

2. Turn off engine and connect throttle position sensor harness connector to throttle position sensor. (CVT models only)

SEF197X

Models with CONSULT-II©GO TO 2.

Models without CONSULT-II©GO TO 3.

5 CHECK TARGET IDLE SPEED

With CONSULT-II

1. Rev engine (2,000 to 3,000 rpm) two or three times under no-load, then run engine at idle speed.

2. Read idle speed in ªDATA MONITORº mode with CONSULT-II.

NEF059A750 50 rpm

(in ªPº or ªNº position for CVT)

OK or NG

OK©GO TO 8.

NG©1. Perform ªIdle air volume learningº. Refer to EC-SR-46.

2. If still NG, GO TO 7.

Throttle position

sensor harness

connector Throttle body

Closed throttle position switch

harness connector (CVT models)

BASIC SERVICE PROCEDURESR20DE

Idle Speed/Ignition Timing/Idle Mixture Ratio Adjustment (Cont'd)

EC-39

Page 1024 of 2267

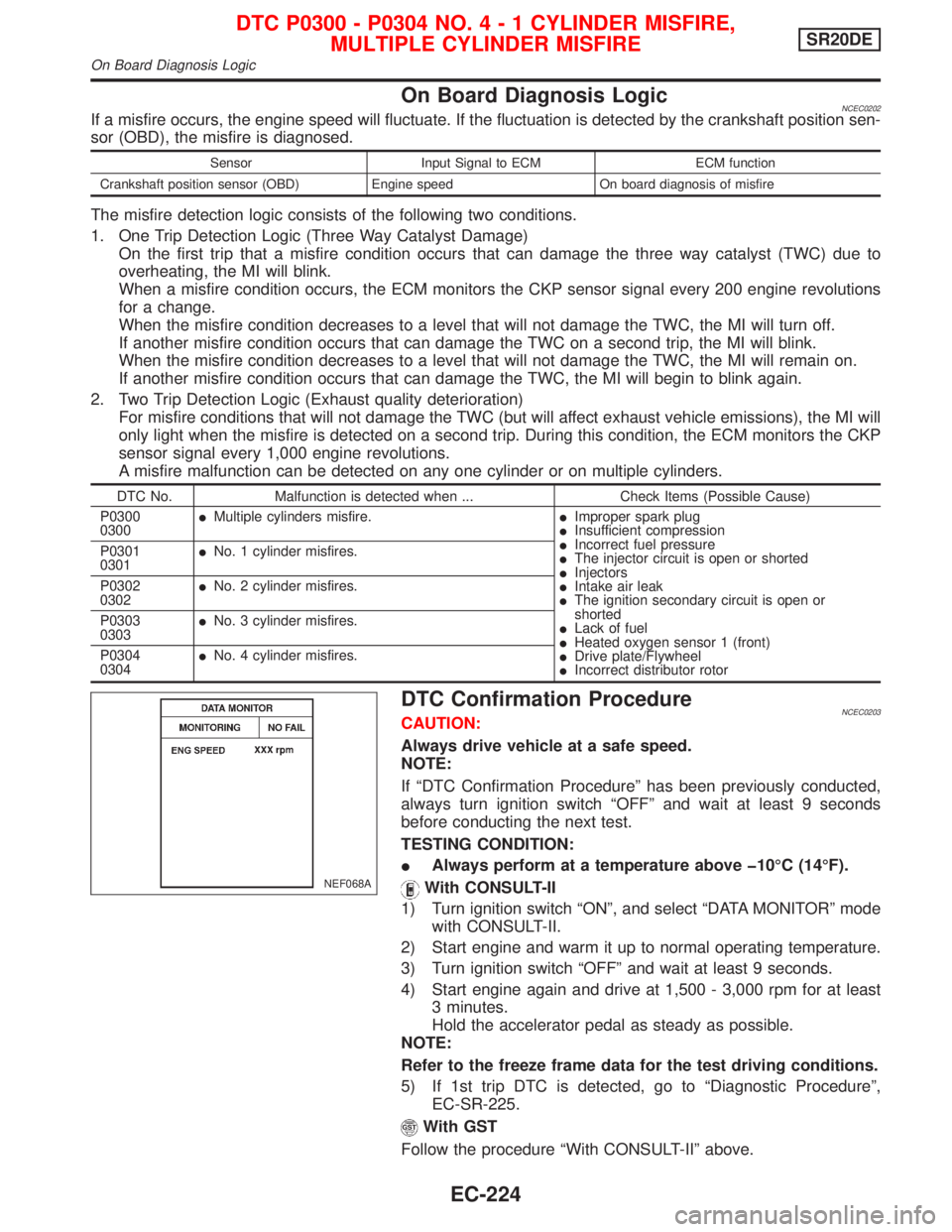

On Board Diagnosis LogicNCEC0202If a misfire occurs, the engine speed will fluctuate. If the fluctuation is detected by the crankshaft position sen-

sor (OBD), the misfire is diagnosed.

Sensor Input Signal to ECM ECM function

Crankshaft position sensor (OBD) Engine speed On board diagnosis of misfire

The misfire detection logic consists of the following two conditions.

1. One Trip Detection Logic (Three Way Catalyst Damage)

On the first trip that a misfire condition occurs that can damage the three way catalyst (TWC) due to

overheating, the MI will blink.

When a misfire condition occurs, the ECM monitors the CKP sensor signal every 200 engine revolutions

for a change.

When the misfire condition decreases to a level that will not damage the TWC, the MI will turn off.

If another misfire condition occurs that can damage the TWC on a second trip, the MI will blink.

When the misfire condition decreases to a level that will not damage the TWC, the MI will remain on.

If another misfire condition occurs that can damage the TWC, the MI will begin to blink again.

2. Two Trip Detection Logic (Exhaust quality deterioration)

For misfire conditions that will not damage the TWC (but will affect exhaust vehicle emissions), the MI will

only light when the misfire is detected on a second trip. During this condition, the ECM monitors the CKP

sensor signal every 1,000 engine revolutions.

A misfire malfunction can be detected on any one cylinder or on multiple cylinders.

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P0300

0300IMultiple cylinders misfire.IImproper spark plug

IInsufficient compression

IIncorrect fuel pressure

IThe injector circuit is open or shorted

IInjectors

IIntake air leak

IThe ignition secondary circuit is open or

shorted

ILack of fuel

IHeated oxygen sensor 1 (front)

IDrive plate/Flywheel

IIncorrect distributor rotor P0301

0301INo. 1 cylinder misfires.

P0302

0302INo. 2 cylinder misfires.

P0303

0303INo. 3 cylinder misfires.

P0304

0304INo. 4 cylinder misfires.

DTC Confirmation ProcedureNCEC0203CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 9 seconds

before conducting the next test.

TESTING CONDITION:

IAlways perform at a temperature above þ10ÉC (14ÉF).

With CONSULT-II

1) Turn ignition switch ªONº, and select ªDATA MONITORº mode

with CONSULT-II.

2) Start engine and warm it up to normal operating temperature.

3) Turn ignition switch ªOFFº and wait at least 9 seconds.

4) Start engine again and drive at 1,500 - 3,000 rpm for at least

3 minutes.

Hold the accelerator pedal as steady as possible.

NOTE:

Refer to the freeze frame data for the test driving conditions.

5) If 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-SR-225.

With GST

Follow the procedure ªWith CONSULT-IIº above.

NEF068A

DTC P0300 - P0304 NO.4-1CYLINDER MISFIRE,

MULTIPLE CYLINDER MISFIRESR20DE

On Board Diagnosis Logic

EC-224

Page 1026 of 2267

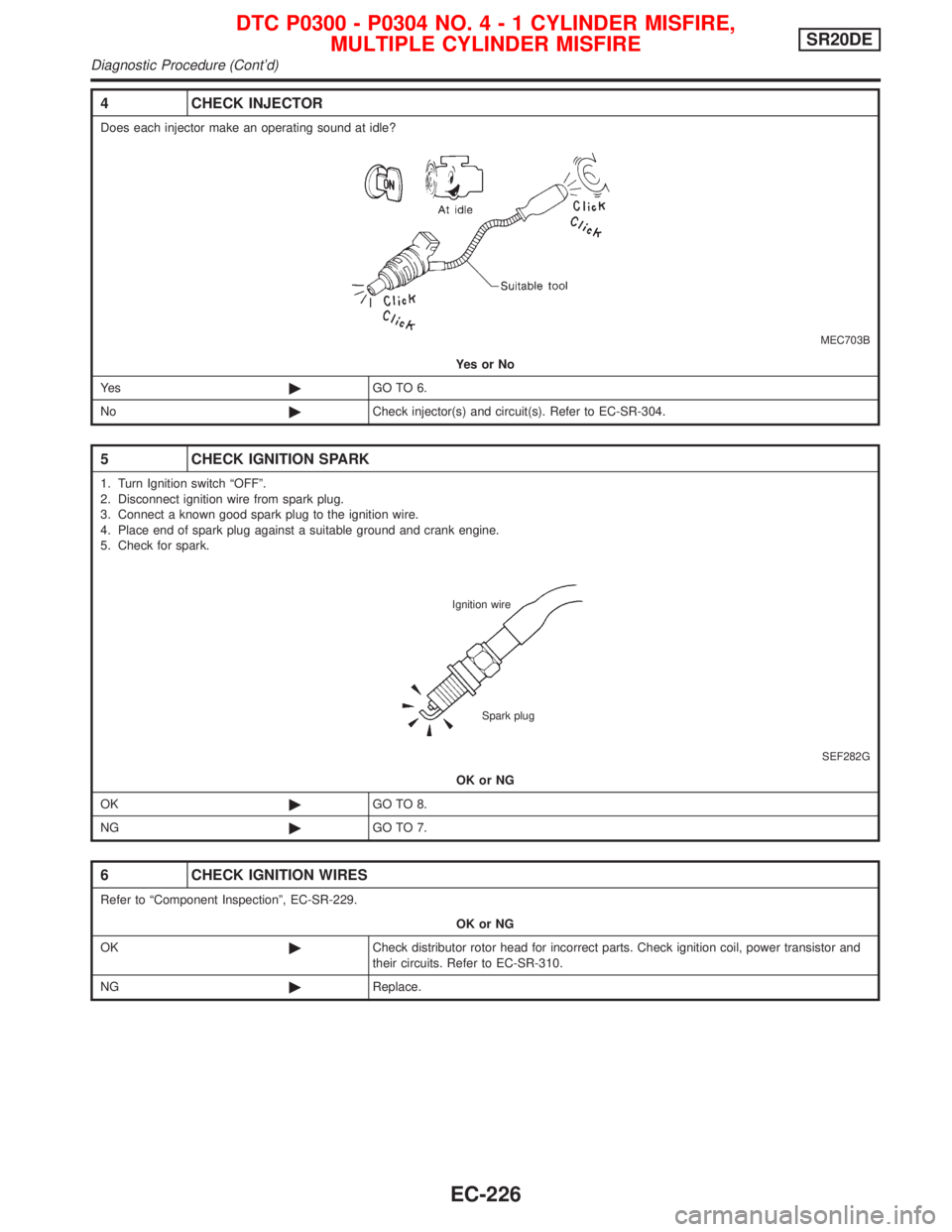

4 CHECK INJECTOR

Does each injector make an operating sound at idle?

MEC703B

YesorNo

Ye s©GO TO 6.

No©Check injector(s) and circuit(s). Refer to EC-SR-304.

5 CHECK IGNITION SPARK

1. Turn Ignition switch ªOFFº.

2. Disconnect ignition wire from spark plug.

3. Connect a known good spark plug to the ignition wire.

4. Place end of spark plug against a suitable ground and crank engine.

5. Check for spark.

SEF282G

OK or NG

OK©GO TO 8.

NG©GO TO 7.

6 CHECK IGNITION WIRES

Refer to ªComponent Inspectionº, EC-SR-229.

OK or NG

OK©Check distributor rotor head for incorrect parts. Check ignition coil, power transistor and

their circuits. Refer to EC-SR-310.

NG©Replace.

Ignition wire

Spark plug

DTC P0300 - P0304 NO.4-1CYLINDER MISFIRE,

MULTIPLE CYLINDER MISFIRESR20DE

Diagnostic Procedure (Cont'd)

EC-226

Page 1029 of 2267

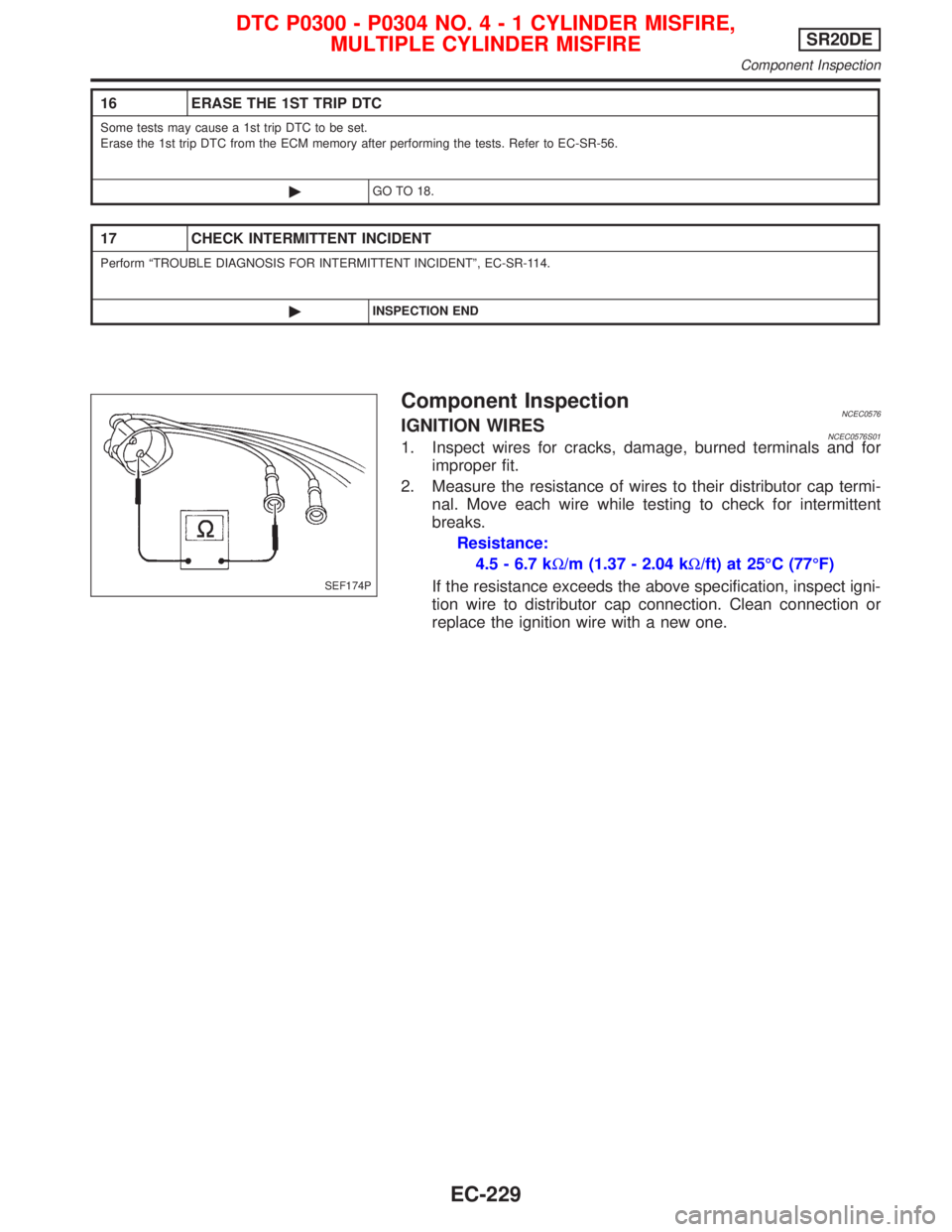

Component InspectionNCEC0576IGNITION WIRESNCEC0576S011. Inspect wires for cracks, damage, burned terminals and for

improper fit.

2. Measure the resistance of wires to their distributor cap termi-

nal. Move each wire while testing to check for intermittent

breaks.

Resistance:

4.5 - 6.7 kW/m (1.37 - 2.04 kW/ft) at 25ÉC (77ÉF)

If the resistance exceeds the above specification, inspect igni-

tion wire to distributor cap connection. Clean connection or

replace the ignition wire with a new one.

16 ERASE THE 1ST TRIP DTC

Some tests may cause a 1st trip DTC to be set.

Erase the 1st trip DTC from the ECM memory after performing the tests. Refer to EC-SR-56.

©GO TO 18.

17 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-SR-114.

©INSPECTION END

SEF174P

DTC P0300 - P0304 NO.4-1CYLINDER MISFIRE,

MULTIPLE CYLINDER MISFIRESR20DE

Component Inspection

EC-229