lug pattern NISSAN PRIMERA 1999 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 8 of 2267

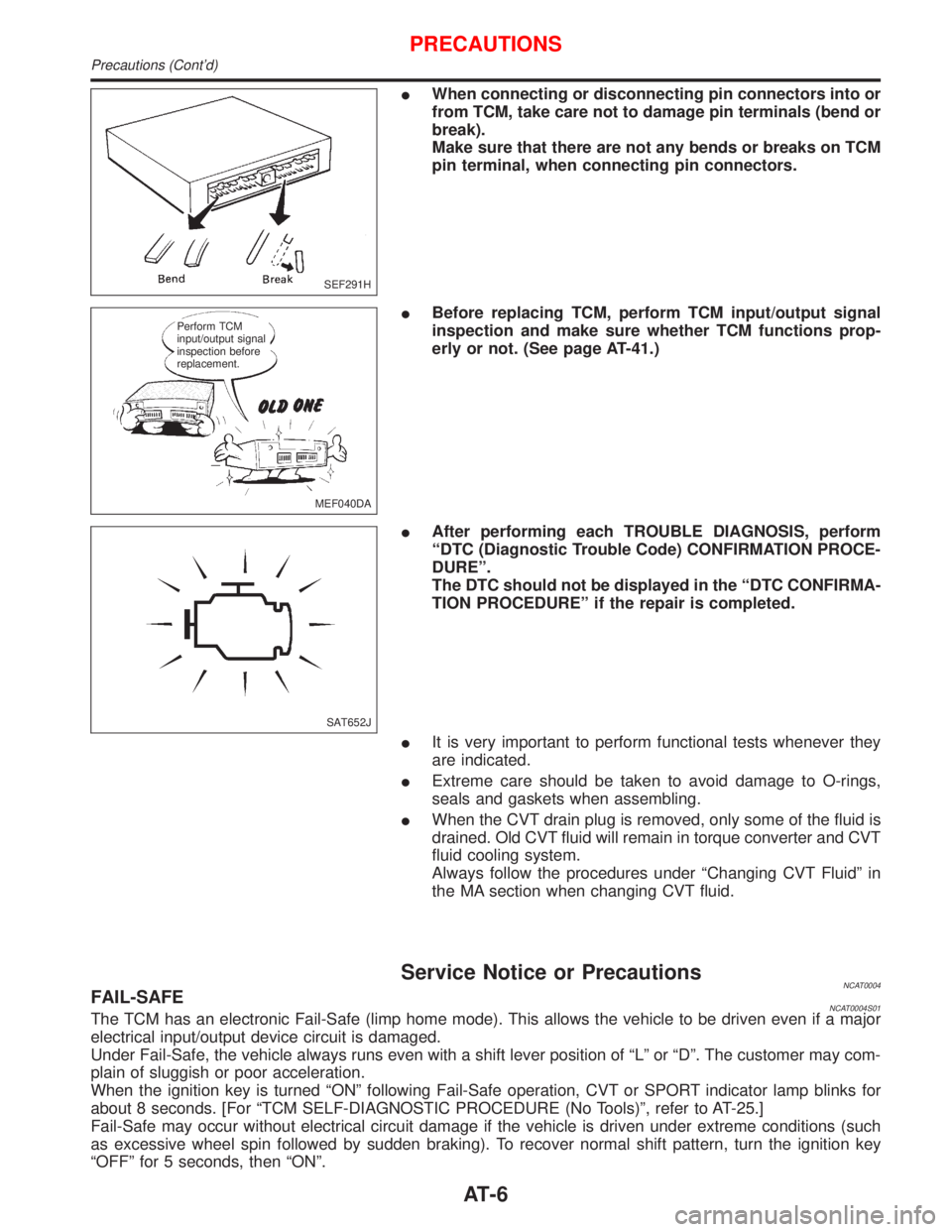

IWhen connecting or disconnecting pin connectors into or

from TCM, take care not to damage pin terminals (bend or

break).

Make sure that there are not any bends or breaks on TCM

pin terminal, when connecting pin connectors.

IBefore replacing TCM, perform TCM input/output signal

inspection and make sure whether TCM functions prop-

erly or not. (See page AT-41.)

IAfter performing each TROUBLE DIAGNOSIS, perform

ªDTC (Diagnostic Trouble Code) CONFIRMATION PROCE-

DUREº.

The DTC should not be displayed in the ªDTC CONFIRMA-

TION PROCEDUREº if the repair is completed.

IIt is very important to perform functional tests whenever they

are indicated.

IExtreme care should be taken to avoid damage to O-rings,

seals and gaskets when assembling.

IWhen the CVT drain plug is removed, only some of the fluid is

drained. Old CVT fluid will remain in torque converter and CVT

fluid cooling system.

Always follow the procedures under ªChanging CVT Fluidº in

the MA section when changing CVT fluid.

Service Notice or PrecautionsNCAT0004FAIL-SAFENCAT0004S01The TCM has an electronic Fail-Safe (limp home mode). This allows the vehicle to be driven even if a major

electrical input/output device circuit is damaged.

Under Fail-Safe, the vehicle always runs even with a shift lever position of ªLº or ªDº. The customer may com-

plain of sluggish or poor acceleration.

When the ignition key is turned ªONº following Fail-Safe operation, CVT or SPORT indicator lamp blinks for

about 8 seconds. [For ªTCM SELF-DIAGNOSTIC PROCEDURE (No Tools)º, refer to AT-25.]

Fail-Safe may occur without electrical circuit damage if the vehicle is driven under extreme conditions (such

as excessive wheel spin followed by sudden braking). To recover normal shift pattern, turn the ignition key

ªOFFº for 5 seconds, then ªONº.

SEF291H

MEF040DA Perform TCM

input/output signal

inspection before

replacement.

SAT652J

PRECAUTIONS

Precautions (Cont'd)

AT-6

Page 1861 of 2267

Refrigeration Cycle

REFRIGERANT FLOW

The refrigerant flow is in the standard pattern. Refrigerant flows through the compressor, condenser, liquid

tank, evaporator, and back to the compressor.

The refrigerant evaporation through the evaporator coil is controlled by an externally equalized expansion

valve, located inside the evaporator case.

FREEZE PROTECTION

Variable displacement (CSV613)

Under normal operating conditions, when the A/C is switched on, the compressor runs continuously, and the

evaporator pressure, therefore temperature, is controlled by the CSV613 variable displacement compressor

to prevent freeze up.

Vane rotary (CR-14)

The compressor cycles on and off to maintain the evaporator temperature within a specified range. When

the evaporator coil temperature falls below a specified point, the thermo control amplifier interrupts the

compressor operation. When the evaporator coil temperature rises above the specification, the thermo con-

trol amplifier allows compressor operation.

REFRIGERANT SYSTEM PROTECTION

Dual-pressure switch (System with CR-14 compressor)

The refrigerant system is protected against excessively high or low pressure by the dual-pressure switch,

located on the liquid tank. If the system pressure rises above, or falls below the specifications, the dual-

pressure switch opens to interrupt the compressor operation.

Pressure sensor (System with CSV613 compressor)

The pressure sensor is located on the liquid tank. It converts the system pressure into a voltage value witch

is then input into ECM.

If the system pressure rises above, or falls below the specifications, ECM interrupt the compressor opera-

tion.

Fusible plug

Open at temperatures above 105ÉC (221ÉF), thereby discharging refrigerant to the atmosphere. If this plug

is melted and opened, check the refrigerant line and replace liquid tank.

Pressure relief valve (CSV613 compressor)

The refrigerant system is also protected by a pressure relief valve, located in the rear head of the compres-

sor. When the pressure of refrigerant in the system increases to an abnormal level [more than 3,727 kPa

(38 kg/cm

2, 540 psi)], the release port on the pressure relief valve automatically opens and releases refrig-

erant into the atmosphere.

DESCRIPTION

HA-12