engine NISSAN PULSAR 1987 Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1987, Model line: PULSAR, Model: NISSAN PULSAR 1987Pages: 238, PDF Size: 28.91 MB

Page 216 of 238

216 Electrical System

NOTE: While checking the operation of the

fusible link, loosely connect the battery-

terminal only, to safeguard against damage

to the wiring harness.

(5) If the circuit is still inoperative or the fusible

link burns out again, refer the problem to an auto-

motive electrician.

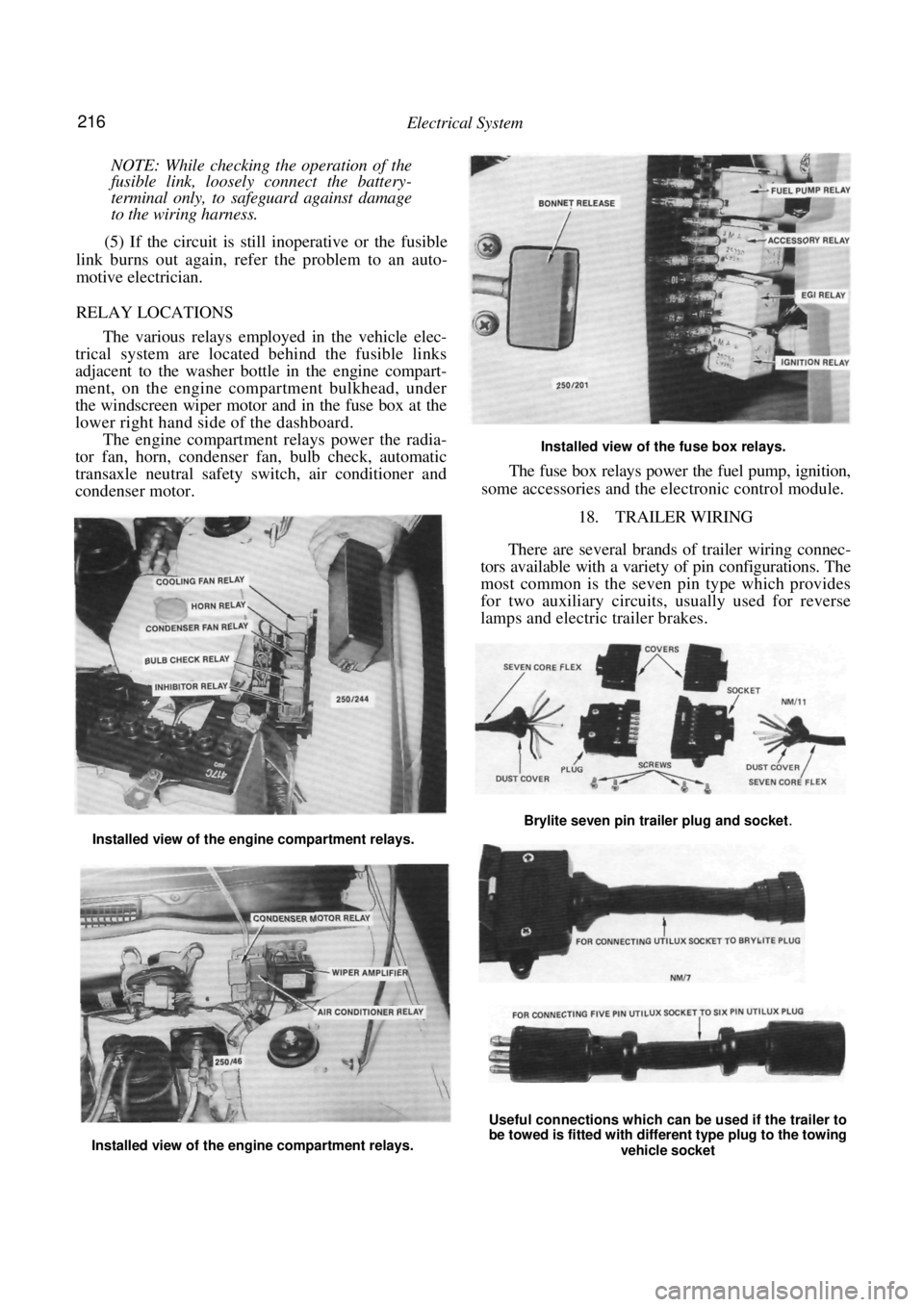

RELAY LOCATIONS

The various relays employed in the vehicle elec-

trical system are located behind the fusible links

adjacent to the washer bottle in the engine compart-

ment, on the engine compartment bulkhead, under

the windscreen wiper motor and in the fuse box at the

lower right hand side of the dashboard.

The engine compartment relays power the radia-

tor fan, horn, condenser fan, bulb check, automatic

transaxle neutral safety switch, air conditioner and

condenser motor.

Installed view of the fuse box relays.

The fuse box relays power the fuel pump, ignition,

some accessories and the el ectronic control module.

18. TRAILER WIRING

There are several brands of trailer wiring connec-

tors available with a variet y of pin configurations. The

most common is the seven pin type which provides

for two auxiliary circuits, usually used for reverse

lamps and electric trailer brakes.

Installed view of the engine compartment relays.

Installed view of the engine compartment relays.

Useful connections which can be used if the trailer to

be towed is fitted with different type plug to the towing

vehicle socket

Brylite seven pin trailer plug and socket.

Page 219 of 238

Electrical System 219

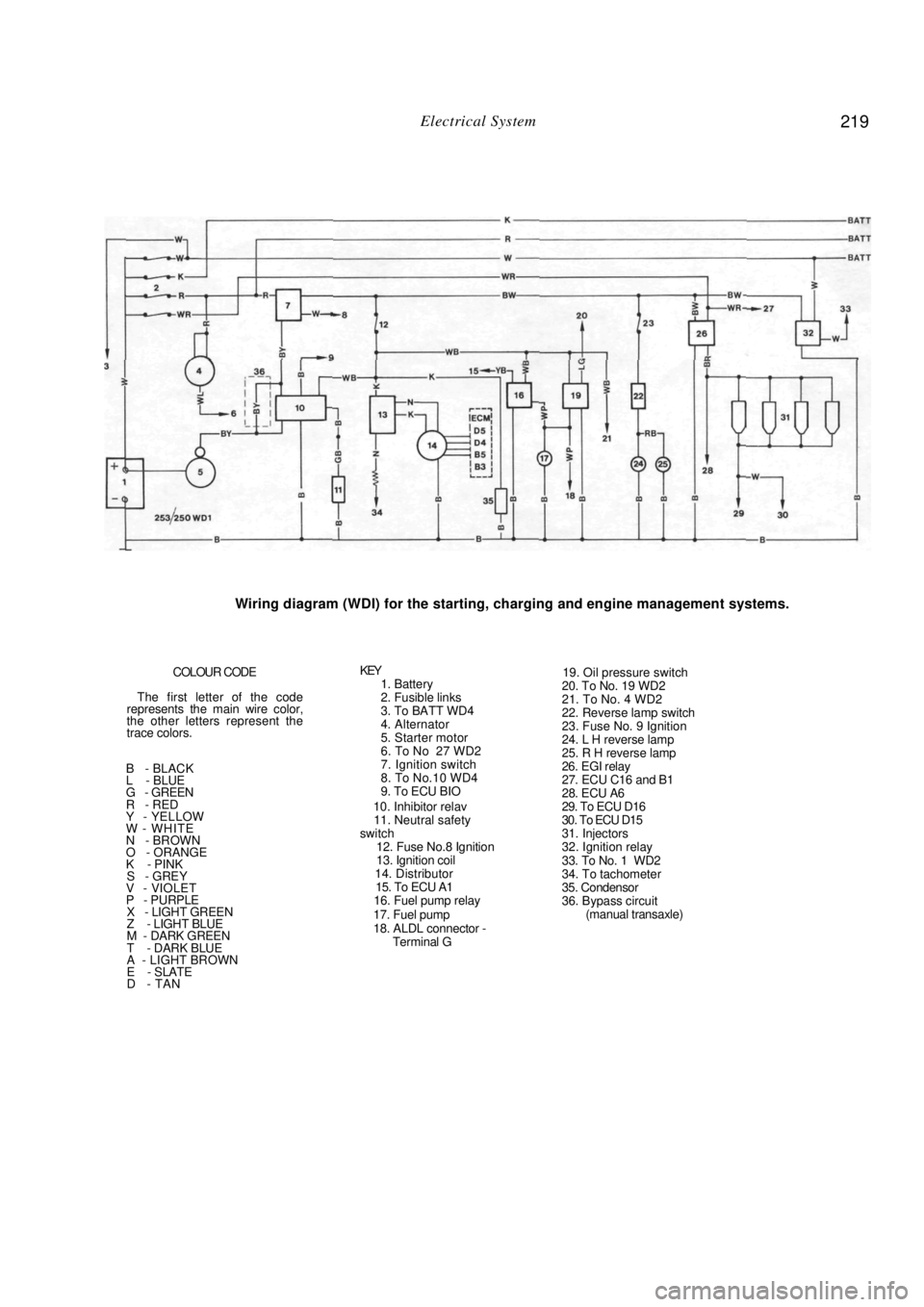

Wiring diagram (WDI) for the starting, charging and engine management systems.

COLOUR CODE

The first letter of the code

represents the main wire color,

the other letters represent the

trace colors.

B - BLACK

L - BLUE

G - GREEN

R - RED

Y - YELLOW

W - WHITE

N - BROWN

O - ORANGE

K - PINK

S - GREY V - VIOLET

P - PURPLE X - LIGHT GREEN

Z - LIGHT BLUE

M - DARK GREEN

T - DARK BLUE

A - LIGHT BROWN

E - SLATE

D - TAN

KEY 1. Battery

2. Fusible links

3. To BATT WD4

4. Alternator

5. Starter motor

6. To No 27 WD2

7. Ignition switch

8. To No.10 WD4

9. To ECU BIO

10. Inhibitor relav

11. Neutral safety

switch

12. Fuse No.8 Ignition

13. Ignition coil

14. Distributor

15. To ECU A1

16. Fuel pump relay

17. Fuel pump

18. ALDL connector - Terminal G

19. Oil pressure switch

20. To No. 19 WD2

21. To No. 4 WD2

22. Reverse lamp switch

23. Fuse No. 9 Ignition

24. L H reverse lamp

25. R H reverse lamp

26. EGI relay

27. ECU C16 and B1

28. ECU A6

29. To ECU D16

30. To ECU D15

31. Injectors

32. Ignition relay

33. To No. 1 WD2

34. To tachometer

35. Condensor

36. Bypass circuit (manual transaxle)

Page 231 of 238

Body 231

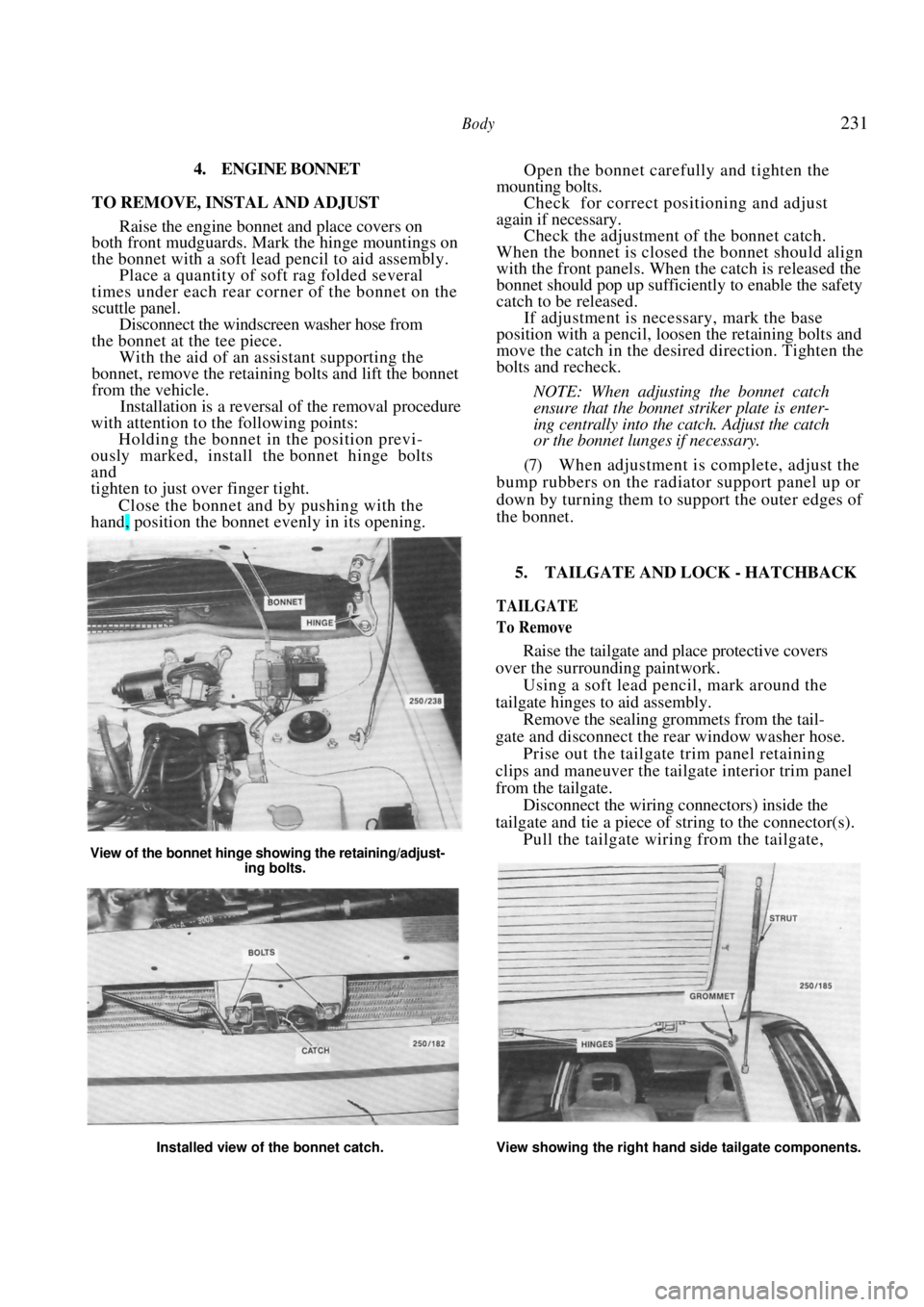

4. ENGINE BONNET

TO REMOVE, INSTAL AND ADJUST

Raise the engine bonnet and place covers on

both front mudguards. Mark the hinge mountings on

the bonnet with a soft lead pencil to aid assembly.

Place a quantity of soft rag folded several

times under each rear corner of the bonnet on the

scuttle panel. Disconnect the windscreen washer hose from

the bonnet at the tee piece. With the aid of an assistant supporting the

bonnet, remove the retaining bolts and lift the bonnet

from the vehicle. Installation is a reversal of the removal procedure

with attention to the following points:

Holding the bonnet in the position previ-

ously marked, install the bonnet hinge bolts

and

tighten to just over finger tight.

Close the bonnet and by pushing with the

hand, position the bonnet evenly in its opening.

Open the bonnet carefully and tighten the

mounting bolts. Check for correct positioning and adjust

again if necessary. Check the adjustment of the bonnet catch.

When the bonnet is closed the bonnet should align

with the front panels. When the catch is released the

bonnet should pop up sufficiently to enable the safety

catch to be released. If adjustment is necessary, mark the base

position with a pencil, loosen the retaining bolts and

move the catch in the desired direction. Tighten the

bolts and recheck.

NOTE: When adjusting the bonnet catch

ensure that the bonnet striker plate is enter-

ing centrally into the catch. Adjust the catch

or the bonnet lunges if necessary.

(7) When adjustment is complete, adjust the

bump rubbers on the radiator support panel up or

down by turning them to support the outer edges of

the bonnet.

View of the bonnet hinge showing the retaining/adjust-

ing bolts.

5. TAILGATE AND LOCK - HATCHBACK

TAILGATE

To Remove

Raise the tailgate and place protective covers

over the surrounding paintwork.

Using a soft lead pencil, mark around the

tailgate hinges to aid assembly. Remove the sealing grommets from the tail-

gate and disconnect the rear window washer hose. Prise out the tailgate trim panel retaining

clips and maneuver the tailgate interior trim panel

from the tailgate.

Disconnect the wiring connectors) inside the

tailgate and tie a piece of st ring to the connector(s).

Pull the tailgate wiring from the tailgate,

Installed view of the bonnet catch. View showing the right hand side tailgate components.