boot NISSAN PULSAR 1987 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1987, Model line: PULSAR, Model: NISSAN PULSAR 1987Pages: 238, PDF Size: 28.91 MB

Page 150 of 238

150 Steering — Part 2

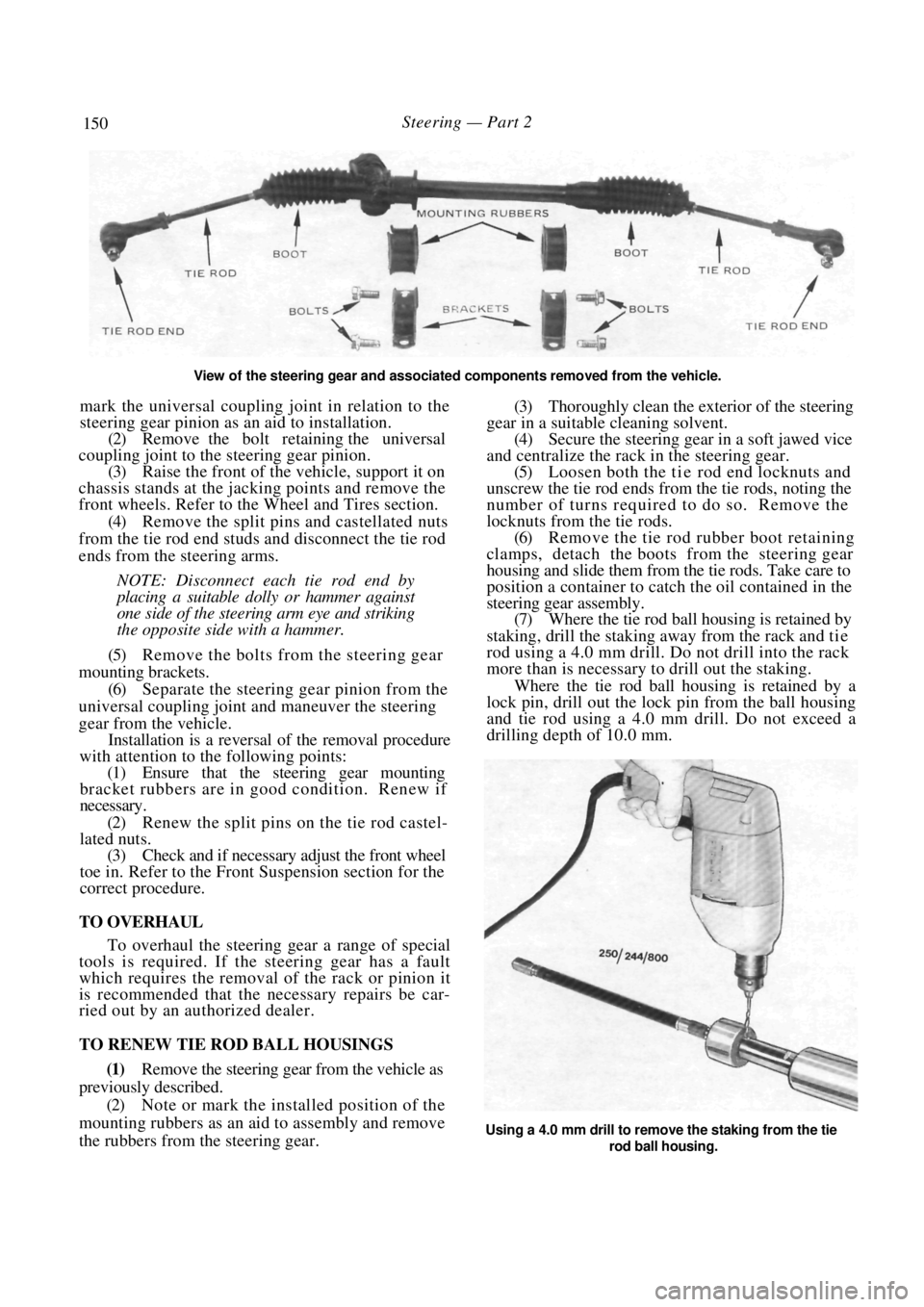

View of the steering gear and associated components removed from the vehicle.

mark the universal coupling joint in relation to the

steering gear pinion as an aid to installation.

(2) Remove the bolt retaining the universal

coupling joint to the steering gear pinion. (3) Raise the front of the vehicle, support it on

chassis stands at the jack ing points and remove the

front wheels. Refer to the Wheel and Tires section.

(4) Remove the split pins and castellated nuts

from the tie rod end studs and disconnect the tie rod

ends from the steering arms.

NOTE: Disconnect each tie rod end by

placing a suitable dolly or hammer against

one side of the steer ing arm eye and striking

the opposite side with a hammer.

(5) Remove the bolts from the steering gear

mounting brackets. (6) Separate the steering gear pinion from the

universal coupling joint and maneuver the steering

gear from the vehicle. Installation is a reversal of the removal procedure

with attention to the following points:

(1) Ensure that the steering gear mounting

bracket rubbers are in good condition. Renew if

necessary.

(2) Renew the split pins on the tie rod castel-

lated nuts.

(3) Check and if necessary adjust the front wheel

toe in. Refer to the Front Suspension section for the

correct procedure.

TO OVERHAUL

To overhaul the steering gear a range of special

tools is required. If the steering gear has a fault

which requires the removal of the rack or pinion it

is recommended that the necessary repairs be car-

ried out by an authorized dealer.

TO RENEW TIE ROD BALL HOUSINGS

(1) Remove the steering gear from the vehicle as

previously described.

(2) Note or mark the installed position of the

mounting rubbers as an aid to assembly and remove

the rubbers from the steering gear.

(3) Thoroughly clean the exterior of the steering

gear in a suitable cleaning solvent.

(4) Secure the steering gear in a soft jawed vice

and centralize the rack in the steering gear. (5) Loosen both the ti e rod end locknuts and

unscrew the tie rod ends from the tie rods, noting the

number of turns required to do so. Remove the

locknuts from the tie rods. (6) Remove the tie rod rubber boot retaining

clamps, detach the boot s from the steering gear

housing and slide them from the tie rods. Take care to

position a container to catch the oil contained in the

steering gear assembly. (7) Where the tie rod ball housing is retained by

staking, drill the staking away from the rack and t i e

rod using a 4.0 mm drill. Do not drill into the rack

more than is necessary to drill out the staking.

Where the tie rod ball housing is retained by a

lock pin, drill out the lock pin from the ball housing

and tie rod using a 4.0 mm drill. Do not exceed a

drilling depth of 10.0 mm.

Using a 4.0 mm drill to remove the staking from the tie

rod ball housing.

Page 151 of 238

Steering — Part 2 151

(8) Slide the rack out of the housing slightly so

that an adjustable spanner can be used to hold the

rack. (9) Using a Stillsons wrench, unscrew the ball

housings in turn using care not to allow the rack to

rotate. Keep all the tie rod parts in order. (10) Inspect the rack boots for cracks and deteri-

oration and renew as necessary. (11) Inspect the tie rod ends for wear and damage

and renew as necessary.

Dismantled view of the tie rod ball housing and the tie

rod end assemblies removed from the steering gear.

Assembly is a reversal of the dismantling proce-

dure with attention to the following points:

(1) Using large Stillsons and a large adjustable

spanner, install the tie rod and ball housing

assemblies

to the rack. Tighten the ball housings to the specified

torque.

NOTE: To avoid damage to the rack or

pinion the adjustable spanner must be

firmly tightened over the rack teeth and the

rack must not be allowed to rotate when

installing the ball housings.

(2) Measure a point 9 mm in from the rear face

of the ball housing of the rack and at 90 deg to the

rack teeth. Centre punch this point.

(3) At this point drill a 4 mm hole, 10 mm deep

through the rack and into the ball housing thread.

(4) Place a locking pin above the hole and drive

it into position.

(5) Lubricate the rack, rack teeth and t i e rod

boot groove with suitable EPL 1 grease. (6) Install the rack boots and secure with the

clamps. Renew the clamps if necessary. (7) Install the tie rod end locknuts and then the

tie rod ends, ensuring that they are screwed on the

same number of turns as was necessary to remove

them.

(8) Tighten the locknuts to the specified torque.

(9) Install the mounting rubbers and brackets

to

the steering gear as noted on removal. (10) Install the steering gear assembly to

the

vehicle as previously described. (11) Check and if necessary adjust the front wheel toe in as described in the Front Suspension section

under the appropriate heading.

TO RENEW TIE ROD END

(1)

Raise the front of the vehicle and support it

on chassis stands. (2) Remove the relevant front wheel.

(3) Loosen the tie rod end locknut and remove

the tie rod end castellated nut. Disconnect the tie rod

from the steering arm by plac ing a suitable dolly or

hammer against one side of the steering arm eye and

striking the opposite side with a hammer. (4) Unscrew the tie rod end from the tie rod,

noting the number of turns necessary to remove it.

(5) Screw the new tie rod end onto the t i e rod

the same number of turn s noted during removal.

(6) Connect the t i e rod to the steering arm and

install the castellated nut. Tighten the nut to the

specified torque and secure it with a new split pin.

(7) Install the front wheel and lower the vehicle

to the ground. (8) Check and if necessary, adjust the front

wheel toe in as described in the Front Suspension

section. Ensure that the rubber boots are not distorted

or twisted on the tie rod when the adjustment is

completed.

TO RENEW RUBBER BOOT

(1) Raise the front of the vehicle and support it

on chassis stands. (2) Remove the relevant t i e rod end as previ-

ously described. (3) Release the clamps securi ng the boot to the

tie rod and steering gear housing. (4) Unscrew and remove the locknut from the

tie rod. (5) Remove the rubber boot together with the

outer retaining clamp from the t i e rod. (6) Sparingly lubricate th e tie rod boot groove

with EPL 1 grease, install the new boot to the t i e

rod

and push it onto the steering gear rack housing. Install

and secure the inner and outer retaining clamps.

(7) Install the tie rod end locknut and screw

the

tie rod end onto the tie ro d the same number of turns

noted during removal. (8) Connect the tie rod to the steering arm and

install the castellated nut. Tighten the nut to the

specified torque and secure it with a new split pin. (9) Install the wheel and lower the vehicle to the

ground. (10) Check and if necessary, adjust the front

wheel toe in as described in the Front Suspension

section. Ensure that the rubber boots are not distorted

or twisted when the adjustment is completed.

Page 152 of 238

152

PART 3. POWER STEERING

SPECIFICATIONS

Steering gear type ................Rack and pinion with

integral power cylinder

Steering column type .................... Energy absorbing

collapsible and lilt adjustable

Steering wheel free play ................................. 35 mm

Number of turns lock to lock:

TRW ...............................................................2.82

PR24SA ........................................................... 2.7

Linkage.....................................Direct from rack ends

to ti e rods and steering knuckles

Power steering pump

maximum pr essure.................................... 6 865 kPa

Lubricant ...................................................... Dexron II

TORQUE WRENCH SETTINGS

Steering gear to bulkhead mounting bolts... 108 Nm

Tie rod to steering knuckle nut ...................... 98 Nm

Tie rod to tie rod end locknut....................... 98 Nm

Tie rod ball housing to rack............................ 88 Nm

Power steering pump pulley nut ..................... 68 Nm

1. DESCRIPTION

The vehicles covered by this manual are equipped

with either a TRW power steering system or a

Japanese PR24SA power steering system.

Both types are similar in construction and appear-

ance.

The power steering is a rack and pinion type

which is mounted on the lower section of the engine

compartment bulkhead by rubber mountings and

brackets.

Hydraulic pressure is supplied to the power

steering gear by a pump driven by a drive belt from

the engine.

The power steering pump has a separate fluid

reservoir located on the righ t side of the bulkhead.

No lubrication of the steering gear or steering

pump is required in service and in the event of the

loss of power assistance, the steering will continue to

operate but will require a greatly increased effort.

However, as the steering gear and pump are lubricated

by the power steering fluid, the cause of the loss of

power steering or fluid loss must be determined and

repaired promptly to prevent damage to the steering

pump and to a lesser extent, the steering gear.

The t i e rod ends and rubb er boots can be renewed

without removing the steering gear from the vehicle.

To renew the integral t i e rod and tie rod ball housings,

the steering gear must be removed.

As specialist knowledge and equipment are re-

quired to overhaul the power steering gear and the

hydraulic pump, it is recommended that these op-

erations be carried out by an authorized dealer.

However, procedures for the removal and installa-

tion of the steering gear and pump are fully de-

scribed in this section.

The steering column is of the energy absorbing

type and is designed to collapse in the event of a

severe front end collision. The energy absorbing com-

ponents are the column tu bes, steering shaft and tilt

bracket breakaway capsules. All these components

should be handled with extr eme care if service opera-

tions are to be carried out on the steering column

assembly.

2. IN CAR ADJUSTMENTS, CHECKS AND

MINOR REPAIRS

If the power steering system becomes partially or

fully inoperative it is most important that the follow-

ing preliminary inspection and testing procedure be

performed prior to undertaking any trouble shooting

or repair operations.

PUMP DRIVE BELT

Inspect the pump drive belt for breakage, glazing

or wear. If any of these characteristics are evident,

renew the belt using only a genuine replacement.

If the belt is loose but still serviceable, adjust it

using the procedure outlined in the Engine Tune-up

section.

NOTE: In most cases a loose drive belt can

be heard squealing when a load is placed on

the pump as the steering wheel is turned or

as the engine speed is increased.

Checking the power steering pump drive belt for

deterioration.

Page 154 of 238

154 Steering —

(2) Remove the air inlet duct from the air

cleaner and throttle body. (3) Position a container or a piece of cloth

beneath the steering pump reservoir and disconnect

the fluid return and power steering pump supply hose

from the reservoir.

(4) Loosen the steering pump drive belt as

described in the Engi ne Tune-up section.

(5) Loosen the return hose clamp and the supply

union and disconnect the hoses from the power

steering pump. Plug the hoses to prevent the loss of

fluid.

(6) Loosen the retaining bolts and withdraw the

pump. (7) Thoroughly clean the exterior of the steering

pump and inspect it for cracks, damage and signs of

leakage.

Installation is a reversal of the removal procedure

with attention to the following points:

(1) Install the pump and retaining bolts.

(2) Install the drive belt and adjust it as de-

scribed in the Engine Tune-up section. (3) Install the hoses to the power steering pump

and tighten securely. (4) Top up the pump reservoir and purge the

power steering system of air as previously described.

TO OVERHAUL

As specialist knowledge and equipment arc re-

quired to overhaul the power steering pump, it is

recommended that this operation be performed by an

authorized dealer or steering specialist.

6. POWER STEERING GEAR ASSEMBLY

Special Equipment Required:

To Renew Tie Rod Ball Housings — Large Still-

sons

TO REMOVE AND INSTAL

The procedures for removing and installing the

power steering gear are similar to those carried out in

the Manual Steering section under the Steering Gear

Assembly heading except fo r the following differences.

(1) Place a container under the pressure and

return pipes that are conn ected to the steering gear

valve housing. Remove the pipes and allow the fluid

to drain into the container. (2) Suitably seal the pipes and the steering gear

to prevent the entry of di rt whilst the pipes are

removed.

(3) Upon removal of the power steering gear,

thoroughly clean the steering gear except the tie rod

ends in a suitable solvent. Be careful not to allow the

solvent to enter the apertu res where the pressure and

return pipes were removed. (4) Check the pipes and co nnections for cracks,

damage or obstructions and renew as necessary.

Installed view of the power steering gear with the

engine removed.

Installation is a reversal of the removal procedure

with attention to the following points:

(1) Install the pressure and return pipes to the

steering gear valve housing and tighten securely. (2) Fill the power steering reservoir to the cor-

rect level and bleed the system as described previously

under the heading In Car Adjustments. Checks and

Minor Repairs. (3) Check all power steering pipe connections

for leaks and repair as necessary. (4) Check, and if necessary, adjust the front

wheel toe in as described in the Front Suspension

section. After adjustment ensure that the rubber boots

are not distorted or twisted and the rubber boot

clamps and clips are facing downward.

TO OVERHAUL

As specialist knowledge and equipment are re-

quired to overhaul the power steering gear, it is rec-

ommended that this opera tion be performed by an

authorized dealer or steering specialist.

TO RENEW TIE ROD BALL HOUSINGS

TRW Steering Gear

The renewal of the tie rod ball housings is the

same as for the manual steering gear. Refer to Part 2.

Manual Steering section.

PR24SA Steering Gear

(1) Remove the power steering gear assembly

from the vehicle as previously described.

(2) Carefully mount the power steering gear in a

vice equipped with soft jaws. Loosen the tie rod end

locknuts without disturbing the location of the tie rod

ends and unscrew the tie rod ends, taking note of the

number of turns required to remove them. Unscrew

and remove the locknuts from the tie rod. (3) Remove the clamps from the rubber boots

and remove the boots.

Page 155 of 238

Steering — Part 3 155

(4) Support the rack carefully and lever back the

tabs of the ball housing lock washers. To prevent

damage to the steering gear, avoid any impact to the

steering rack.

(5) Holding the rack with an adjustable spanner,

unscrew the ball housings from the rack using a

Stillsons wrench. Remove and discard the lock wash-

ers. Installation is a reversal of the removal procedure

with attention to the following points:

(1) Install the new lock washer to the

rack,

ensuring that the lockwasher tangs are located in the

rack end. (2) Install the ball housing as semblies to the rack.

Tighten the ball housings to the specified torque and

secure by bending the lock washer. (3) Before installing the rubber boots ensure that

the vent holes, located towards each end of the rack

near the ball housings, are clear. If necessary clear the

hole with a suitable probe. (4) Apply sealant to the la rge end of the rubber

boot and grease to the small end. and install the boots,

being careful not to damage or twist them. Secure the boots with the clamps and clip

s ensuring that the clips

are facing downwards.

(5) Install the t i e rod end locknuts and tie rod

ends to the t i e rod. Install the t i e rod ends the same

number of turns noted on removal. Tighten the lock-

nuts to the specified torque.

Install the power steerin g gear assembly to the

vehicle as described under the previous heading and

bleed the system as described under the heading In

Car Adjustments, Checks and Minor Repairs.

TO RENEW RUBBER BOOTS

The procedure to renew the rubber boots is fully

covered in the Manual Steering section under the

Steering Gear Assembly heading.

TO RENEW TIE ROD ENDS

The procedure to renew the t i e rod ends is fully

covered in the Manual Steering section under the

Steering Gear Assembly heading.

Page 156 of 238

156

FRONT SUSPENSION

SPECIFICATIONS

Type.................. Independent MacPherson strut with

coil springs and control arms

Shock absorber .................. Hydraulic, non-repairable

Hub bearing end float (maximum) ............. 0.05 mm

Ball joint axial play (maximum) ....................0.7 mm

Ball joint turning torque (used)...............0.5-4.9 Nm

Wheel alignment:

Toe in ..................................................... 0-2 mm

Camber ........................................- 0 ° 1 0 ' ± 4 5 '

Caster ..............................................1 ° 1 0 ' ± 4 5 '

King pin inclination..................... 1 3 ° 5 5 ' ± 4 5 '

TORQUE WRENCH SETTINGS

Hub bearing nut..................................... 196-235 Nm

Suspension unit to steering knuckle nut ...... 118 Nm

Suspension unit to body nuts ......................... 29 Nm

Piston rod nut .................................................. 72 Nm

Brake caliper to steering knuckle bolts ........... 52 Nm

Ball joint to steering knuckle bolt ................... 86 Nm

Control arm bracket bolts ............................... 98 Nm

Control arm pivot bolt ................................ 118 Nm

Stabiliser bar link nuts..................................... 44 Nm

Stabiliser bar bracket bolts .............................. 21 Nm

1. FRONT SUSPENSION TROUBLE

SHOOTING

FRONT END NOISE

(1) Loose upper suspension mounting or piston

rod: Tighten the mounting or piston rod nuts. (2) Loose or worn suspension unit lower ball

joint: Tighten or renew the lower ball joint.

(3) Noise in the suspension unit: Renew the

faulty suspension unit, preferably in pairs.

(4) Worn or loose steering gear: Overhaul the

steering gear assembly. (5) Worn front hub bearings: Renew the hub

bearings:

(6) Loose or defective stab ilizer bar, control arm

or mountings: Check, tighten or renew the mounting

rubbers.

Check the ball joints for wear and deterioration.

(7) Worn stabilizer bar link ball joints: Renew

the stabilizer bar links.

(8) Drive shafts worn or insufficiently lubri-

cated: Check the lubricant and the dust boots and

renew as necessary. (9) Drive shaft splines in the hub or the

differential worn or dama ged: Check and renew as

necessary.

NOTE: To check the front suspension com-

ponents for wear, raise the front of the

vehicle, support it on chassis stands and

allow both front wheel to hang free. With an

assistant pushing and pulling the front

wheels in and out at the top and then at the

bottom, check for excessive looseness at the

front hub bearings and lower control arm

inner pivot bushes. Noise or vibration in the

front end can also be caused by excessive

tire or wheel unbalance. Drive shaft joint

noise is usually more pronounced when

moving slowly with the steering on full lock.

POOR OR ERRATIC ROAD HOLDING

ABILITY

(1) Low or uneven tire pressures: Inflate the

tires to the recommended pressures.

(2) Defective suspension unit: Renew the faulty

unit, preferably in pairs.

Page 158 of 238

158 Front Suspension

Installed view of the front suspension. When using a floor jack locate the head of the jack on the crossmember.

(2) Remove the cap, split pin, castellated re-

tainer and with the aid of an assistant applying the

brakes, loosen and remove the hub nut.

(3) Remove the split pin and the castellated nut

retaining the tie rod end to the steering knuckle. (4) Disconnect the tie rod end from the steering

knuckle using a suitable puller. Alternatively place a

suitable dolly or hammer against one side of the

steering knuckle eye and strike the opposite side with

a hammer.

(5) Remove the brake caliper anchor plate bolts,

withdraw the caliper from the disc and support it with

a piece of wire inside the inner mudguard. Ensure that

the brake hose is not twisted.

(6) Withdraw the brake disc from the hub.

(7) Loosely install the hub nut and tap on the nut

with a soft faced hammer to separate the drive shaft

from the hub. (8) Place a mark on the suspension unit to

steering knuckle cam head bolt to ensure correct wheel

alignment on assembly. (9) Remove the steering knuckle to suspension

unit nuts and bolts. (10) Remove the split pin and the castellated nut

retaining the lower ball joint stud to the steering

knuckle. (11) Disconnect the ball joint stud from the steering knuckle using a suitable puller or alternatively

place a suitable dolly or hammer against one side of

the steering knuckle eye and strike the opposite side

with a hammer.

(12)

Withdraw the steering knuckle from the

vehicle taking care not to drop the drive shaft or

damage its boot. (13) Clean and check the steering knuckle for

wear, cracks and damage. (14) If necessary, dismantle the hub and check

the bearing assembly using the dismantling procedure

described later in this section. Installation is a reversal of the removal procedure

with attention to the following points:

(1) Install the steering knuckle and hub assembly

over the drive shaft and loosely install the ball joint

stud nut and the suspension unit to knuckle bolts and

nuts.

(2) Ensure that the suspension unit to steering

knuckle cam head bolt mark s are aligned and tighten

the retaining nuts to the specified torque.

NOTE: If the cam head bolt is not installed

in its original position, a wheel alignment

should be performed.

(3) Tighten the ball joint to steering knuckle stud

bolt to the specified torque.

Page 160 of 238

160 Front Suspension

(2) Disconnect the flexible brake hoses from the

suspension unit bracket.

(3) Using quick drying paint, place mating

marks on the camber adjustin g cam head bolt and the

suspension unit lower mounti ng as an aid to installa-

tion. (4) Remove the bolts and nuts retaining the

suspension unit lower mounting to the steering

knuckle. (5) Open the bonnet and remove the nuts

retaining the suspension unit upper mounting to the

inner mudguard panel and remove the suspension

unit assembly from the vehicle. Use care when

removing not to damage the drive shaft boot.

(6) Remove the dust cover and loosen the piston

rod nut but do not remove it at this stage. (7) Install a spring compressor to the

suspension

unit assembly. Compress the coil spring and remove

the piston rod nut. (8) Remove the washer, upper mounting assem-

bly, the thrust washer, spring seat, insulator, coil

spring, bump rubber and dust cover from the suspen-

sion unit. (9) Check the operation of the suspension unit.

With the suspension unit in a vertical position, move

the piston rod up and down a number of times. A

Dismantled view of the front suspension unit.

uniform resistance should be felt with no abnormal

slack spots or noise evident. If the suspension unit is

defective, it should be renewed.

NOTE: It is recommended that the suspen-

sion unit on the opposite side be renewed at

the same time.

(10) Check the upper mounting assembly for

damage and fatigue. Check the thrust washer for wear.

Check all rubber components, the spring seat and

insulator for wear, damage and deterioration. Renew

worn or damaged components. (11) Check the coil spring for fatigue by compar-

ison with a new spring. Al so check the spring for

cracks and damage. If the coil spring is defective, it is

recommended that the springs on both sides be

renewed.

TO ASSEMBLE AND INSTAL

Assembly and installation is a reversal of the

removal and dismantling procedure with attention to

the following points:

View of the front suspension unit with the spring

compressor installed.

Page 163 of 238

Front Suspension 163

(2) Ensure that the stabilizer bar links are in

good condition. Renew if necessary.

(3) When installing the stabilizer bar ensure that

the links are installed perpendicular to the control arm

with the ball joint socket face parallel to the end of the

stabilizer bar. (4) Ensure that the brackets are installed with

the flat portion facing towards the front of the vehicle.

Tighten the retaining bolts securely.

7. SUSPENSION AND STEERING ANGLES

ADJUSTMENT

NOTE: Extensive knowledge and special-

ised equipment are required to measure and

correct the suspension and steering angles

with the exception of the front wheel toe in.

Therefore, as it is not a viable proposition

for the average person to carry out a com-

plete wheel alignment, the vehicle should be

taken to a wheel alignment specialist.

Prior to carrying out a wheel alignment, a thor-

ough inspection of the steering linkage, front hub

bearings, ball joints and suspension units should be

carried out. Faulty components should be renewed or

repaired as necessary.

The tread of the front ti res should be examined

for excessive or uneven wear as certain conditions of

tire wear are indicative of damaged or worn compo-

nents in the suspension, stee ring linkage and/or wheels

and bearings. Refer to the heading Tire Wear Trouble

Shooting in the Wheels and Tires section. If the tires

are found to be defective, renew them with serviceable

lyres.

TO CHECK AND ADJUST TOE IN/OUT

NOTE: The vehicle s hould be unladen ex-

cept for the normal amount of fuel and with

the tires inflated to the correct pressures.

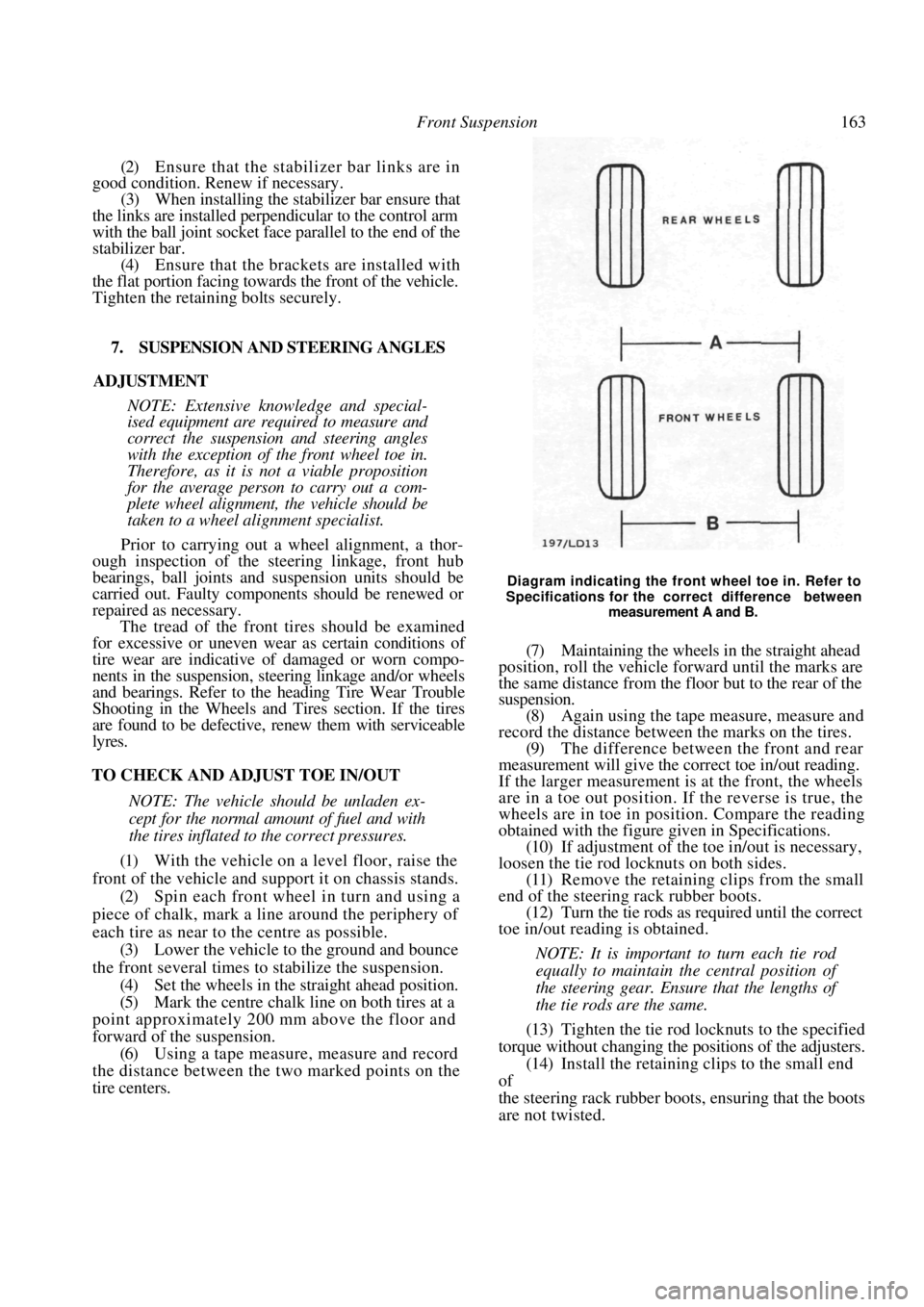

(1) With the vehicle on a level floor, raise the

front of the vehicle and s upport it on chassis stands.

(2) Spin each front wheel in turn and using a

piece of chalk, mark a line around the periphery of

each tire as near to the centre as possible. (3) Lower the vehicle to the ground and bounce

the front several times to stabilize the suspension. (4) Set the wheels in the straight ahead position.

(5) Mark the centre chalk line on both tires at a

point approximately 200 mm above the floor and

forward of the suspension. (6) Using a tape measure, measure and record

the distance between the two marked points on the

tire centers.

Diagram indicating the front wheel toe in. Refer to

Specifications for the correct difference between

measurement A and B.

(7) Maintaining the wheels in the straight ahead

position, roll the vehicle forward until the marks are

the same distance from the floor but to the rear of the

suspension. (8) Again using the tape measure, measure and

record the distance between the marks on the tires.

(9) The difference between the front and rear

measurement will give the correct toe in/out reading.

If the larger measurement is at the front, the wheels

are in a toe out position. If the reverse is true, the

wheels are in toe in position. Compare the reading

obtained with the figure given in Specifications.

(10) If adjustment of the to e in/out is necessary,

loosen the tie rod locknuts on both sides. (11) Remove the retaining clips from the small

end of the steering rack rubber boots. (12) Turn the tie rods as required until the correct

toe in/out reading is obtained.

NOTE: It is important to turn each tie rod

equally to maintain the central position of

the steering gear. Ensure that the lengths of

the tie rods are the same.

(13) Tighten the tie rod locknuts to the specified

torque without changing the positions of the adjusters.

(14) Install the retaining clips to the small end

of

the steering rack rubber boots, ensuring that the boots

are not twisted.

Page 179 of 238

Brakes 179

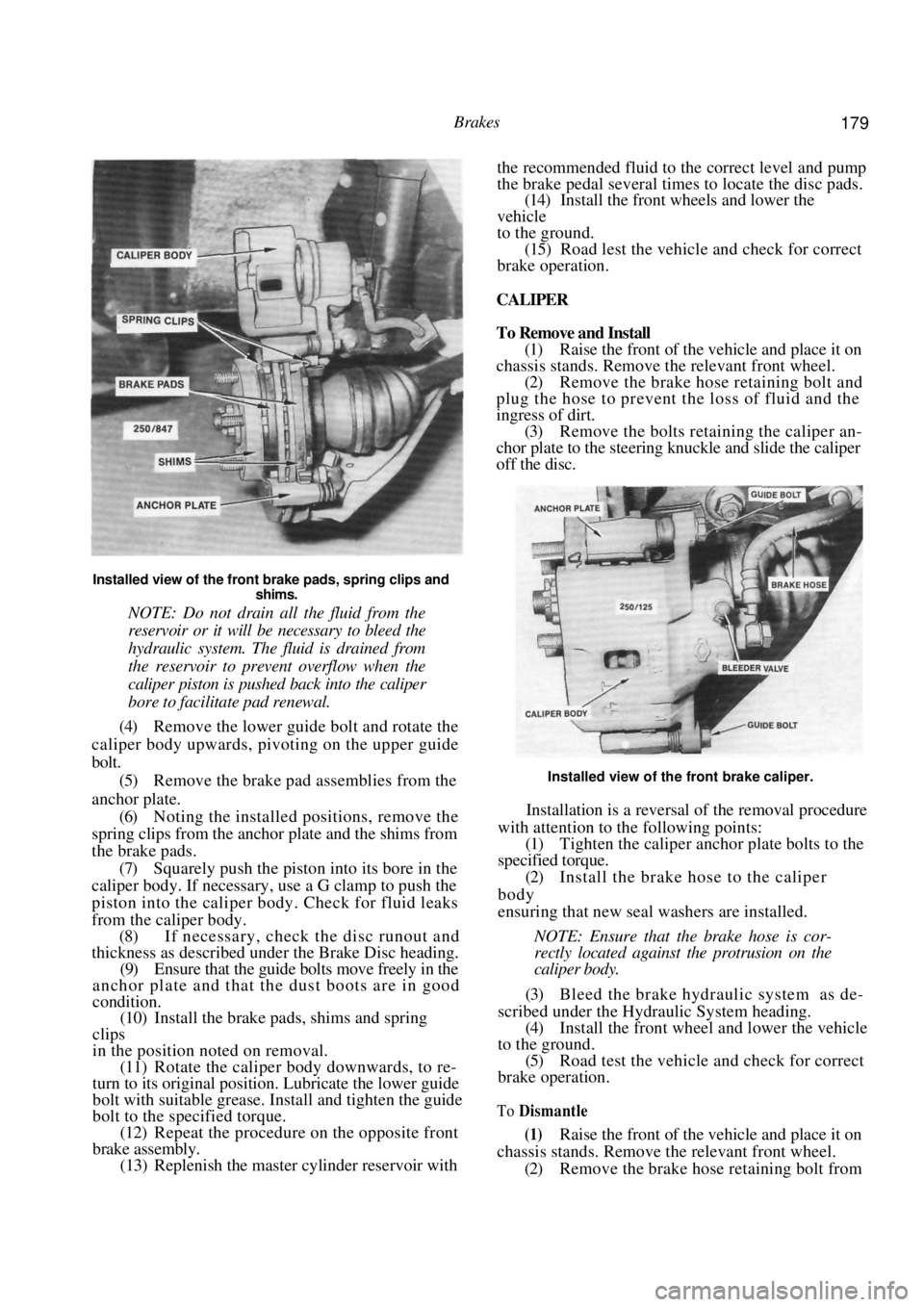

Installed view of the front brake pads, spring clips and shims.

NOTE: Do not drain all the fluid from the

reservoir or it will be necessary to bleed the

hydraulic system. The fluid is drained from

the reservoir to prevent overflow when the

caliper piston is pushed back into the caliper

bore to facilitate pad renewal.

(4) Remove the lower guide bolt and rotate the

caliper body upwards, pivoting on the upper guide

bolt.

(5) Remove the brake pad assemblies from the

anchor plate. (6) Noting the installed positions, remove the

spring clips from the anchor plate and the shims from

the brake pads.

(7) Squarely push the piston into its bore in the

caliper body. If necessary, us e a G clamp to push the

piston into the caliper b ody. Check for fluid leaks

from the calip er body.

(8) If necessary, check the disc runout and

thickness as described under the Brake Disc heading.

(9) Ensure that the guide bolts move freely in the

anchor plate and that the dust boots are in good

condition. (10) Install the brake pads, shims and spring

clips

in the position noted on removal. (11) Rotate the caliper body downwards, to re-

turn to its original position. Lubricate the lower guide

bolt with suitable grease. In stall and tighten the guide

bolt to the specified torque. (12) Repeat the procedure on the opposite front

brake assembly. (13) Replenish the master cylinder reservoir with the recommended fluid to the correct level and pump

the brake pedal several times to locate the disc pads.

(14)

Install the front wheels and lower the

vehicle

to the ground. (15) Road lest the vehicle and check for correct

brake operation.

CALIPER

To Remove and Install

(1) Raise the front of the vehicle and place it on

chassis stands. Remove the relevant front wheel. (2) Remove the brake hose retaining bolt and

plug the hose to prevent the loss of fluid and the

ingress of dirt. (3) Remove the bolts retaining the caliper an-

chor plate to the steering knuckle and slide the caliper

off the disc.

Installed view of the front brake caliper.

Installation is a reversal of the removal procedure

with attention to the following points:

(1) Tighten the caliper anch or plate bolts to the

specified torque.

(2) Install the brake hose to the caliper

body

ensuring that new seal washers are installed.

NOTE: Ensure that the brake hose is cor-

rectly located against the protrusion on the

caliper body.

(3) Bleed the brake hydraulic system as de-

scribed under the Hydraulic System heading. (4) Install the fron t wheel and lower the vehicle

to the ground. (5) Road test the vehicle and check for correct

brake operation.

To Dismantle

(1) Raise the front of the vehicle and place it on

chassis stands. Remove the relevant front wheel.

(2) Remove the brake hose retaining bolt from