coolant temperature NISSAN PULSAR 1987 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1987, Model line: PULSAR, Model: NISSAN PULSAR 1987Pages: 238, PDF Size: 28.91 MB

Page 82 of 238

82

FUEL AND ENGINE MANAGEMENT

CAUTION: To prevent severe electrical shock, extreme care must be taken when

working on or near the electronic ignition system as dangerous high tension voltages

are produced in both the primary and secondary circuits. See the text fo\

r

precautionary notes.

SPECIFICATIONS

FUEL INJECTION

Type:

1.6 liter engine .................................. Single point

1.8 liter engine................................... Multi point

FUEL PUMP

Type ................................................................ Electric

Pressure at idle:

1.6 liter engine ..................................... 62-90 kPa

1.8 liter engine ................................ 190-230 kPa

FUEL FILTER

Type ................................................ Inline, disposable

AIR FILTER

Type ................................... Disposable paper element

DISTRIBUTOR

Make ........................................................ Delco Remy

Advance contro l .......................................... Electronic

Rotation of rotor .................................. Anti-clockwise

Firing order....................................................1 -3-4-2

ADJUSTMENTS

Base idle speed ..................................... 550-650 rpm

Ignition timing.......................................... 10° BTDC

TORQUE WRENCH SETTINGS

Throttle body nuts.......................................... 10 Nm

*Throttle body bolts ........................................ 12 Nm

*Fuel hose fittings............................................ 35 Nm

Fuel rail bolts ....................................................8 Nm

Fuel tank drain plug ........................................ 24 Nm

Coolant temperature sensor ............................ 12 Nm

Oxygen sensor .................................................. 40 Nm

MAT sensor..................................................... 14 Nm

*1.6 liter engine

l . 8 liter engine

1. FUEL AND ENGINE MANAGEMENT

TROUBLE SHOOTING

NOTE: The following Trouble Shooting pro-

cedures are basic checks only. If these pro-

cedures fail to locate the fault, refer to the

System Diagnosis and Adjustments heading

for more thorough testing.

Prior to performing any of the following

operations, refer to the Service Precautions

and Procedures heading.

ENGINE WILL NOT START OR HARD TO

START

(1) Water in the fuel: Dr ain the fuel from the

system and renew the fuel filter.

(2) Fault in the power supply: Check the battery,

fusible links and fuses. Check for clean, secure con-

nections, particularly the earth connections. Check the

EG1 and fuel pump relays.

NOTE: If the fuel pump relay fails, power

will be supplied to the fuel pump via the oil

pressure switch. When starting the engine,

Check that the MAP sensor hose is not blocked or split

and ensure that all electrical connections are clean and

secure.

Page 83 of 238

Fuel and Engine Management 83

the fuel pump will not operate until the oil

pressure is sufficient to extinguish the oil

pressure warning lamp. Therefore it will be

necessary to operate the starter motor for a

longer period than usual to start the engine.

(3) Faulty EFI component wiring connections:

Check that all component wiring connections are

clean and secure.

(4) Manifold absolute pressure (MAP) sensor

vacuum hose blocked or disconnected: Clear or recon-

nect the vacuum hose. (5) Fault in the ignition system: Check the

primary and secondary ignition circuits.

(6) Engine flooded: Fully depress the throttle

pedal until the engine starts. Check the coolant

temperature sensor. Check th e injector(s) for leakage.

ENGINE STARTS THEN STALLS

(1) Water in the fuel: Dr ain the fuel from the

system and renew the fuel filter.

(2) Air leakage at the inlet manifold: Check all

joints and hoses for air leaks. (3) Faulty EFI wiring connections: Check that

all component wiring connections are clean and

secure.

(4) Ignition timing incorrectly set: Check and

adjust the timing. (5) MAP sensor faulty or supply hose discon-

nected or blocked: Check the vacuum supply hose.

Check the operation of the MAP sensor.

ENGINE MISFIRES

(1) Faulty, dirty or incorrectly adjusted spark

plugs: Renew or clean and adjust the spark plugs.

(2) Condensation in the distributor cap: Dry and

examine the cap for cracks. (3) Faulty high tension leads: Check and renew

the high tension leads.

Testing the fuel system pressure using a pressure

gauge.

(4) Faulty ignition coil: Check and renew the

ignition coil.

(5) Fuel blockage: Check for blockage in the fuel

filter, lines and injector(s). (6) Low fuel pressure: Check the fuel pump and

fuel pressure regulator. (7) Water in the fuel: Dr ain the fuel from the

system and renew the fuel filter. (8) Loose fuel supply wiring connectors: Check

all connectors for tightness. (9) Faulty fuel injector: Check the connections

and test the condition of the fuel injectors.

ENGINE LACKS POWER

(1) Ignition timing incorrectly set: Check and

adjust the timing.

(2) Water in the fuel: Dr ain the fuel from the

system and renew the fuel filter.

(3) Incorrectly adjusted throttle cable: Adjust the

throttle cable.

Check the distributor cap for cracks or tracking be- tween the terminals. The air filter element should be renewed at 40 000 km

intervals. 1.8 liter engine.

Page 84 of 238

Fuel and Engine Management

(4) MAP sensor faulty or supply hose discon-

nected or blocked: Check the vacuum supply hose.

Check the operation of the MAP sensor.

EXCESSIVE FUEL CONSUMPTION

(1) Blocked air cleaner element: Check the ele-

ment and clean or renew as necessary.

(2) Incorrect fuel pressure: Check the fuel pump

and fuel pressure regulator. (3) Faulty coolant temperature sensor: Check

the connections and operation.

(4) Leaks in the fuel supply system: Check the

connections and components for leakage. (5) Leaking fuel injector(s): Clean or renew the

faulty injector(s). (6) Engine operating temperature too low:

Check the thermostat and electric cooling fan as

described in the Cooling an d Heating Systems section.

2. DESCRIPTION

The engine management system on the range of

vehicles covered by this manual controls the opera-

tion of the ignition system and the fuel system.

The central component of the engine management

system is the electronic control unit (ECU). The con-

trol unit is a micro-computer which controls the igni-

tion timing and the amount of fuel injected according

to signals received from various sensors. As changes

are detected in engine load and speed, coolant tem-

perature, barometric pressure, air temperature (1.8

liter engine), throttle position and vehicle speed, the

control unit alters the ignition timing and the fuel

injection amount to achieve optimum engine effi-

ciency.

The control unit incorporates a self diagnosis

mode which stores and displays codes relating to

certain system malfunctions. Whenever power is sup-

plied to the control unit, the control unit performs a

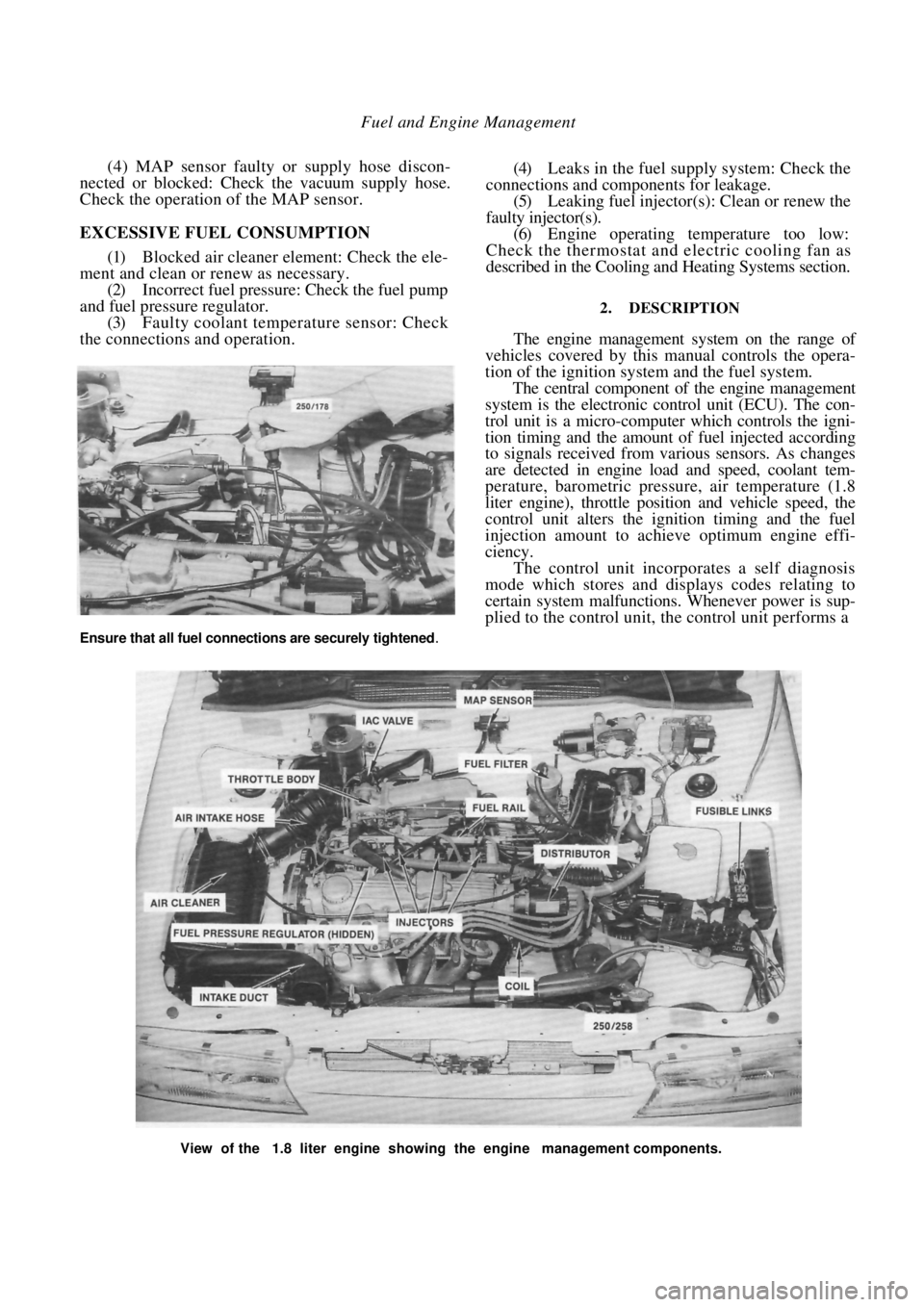

View of the 1.8 liter engine showing the engine management components.

Ensure that all fuel connections are securely tightened.

Page 90 of 238

90 Fuel and Engine Management

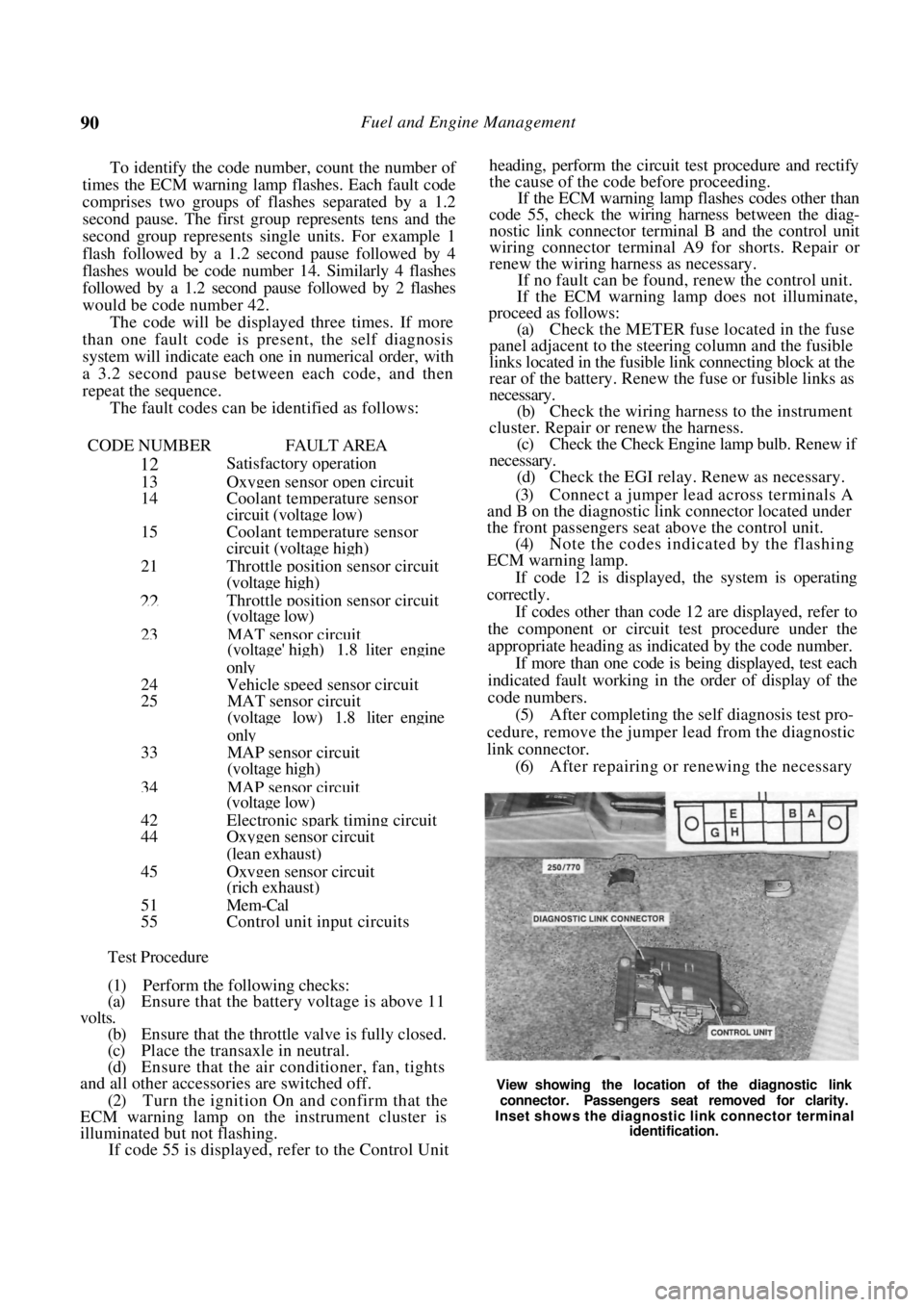

To identify the code number, count the number of

times the ECM warning lamp flashes. Each fault code

comprises two groups of flashes separated by a 1.2

second pause. The first group represents tens and the

second group represents single units. For example 1

flash followed by a 1.2 second pause followed by 4

flashes would be code number 14. Similarly 4 flashes

followed by a 1.2 second pause followed by 2 flashes

would be code number 42.

The code will be displayed three times. If more

than one fault code is present, the self diagnosis

system will indicate each one in numerical order, with

a 3.2 second pause between each code, and then

repeat the sequence.

The fault codes can be identified as follows:

CODE NUMBER FAULT AREA

12 Satisfactory operation

13 Oxygen sensor open circuit

14 Coolant temperature sensor circuit (voltage low)

15 Coolant temperature sensor circuit (voltage high)

21 Throttle position sensor circuit (voltage high)

22Throttle position sensor circuit (voltage low)

23MAT sensor circuit (voltage' high) 1.8 liter engine

only

24 Vehicle speed sensor circuit

25 MAT sensor circuit

(voltage low) 1.8 liter engine

only

33 MAP sensor circuit

(voltage high)

34MAP sensor circuit (voltage low)

42 Electronic spark timing circuit

44

Oxygen sensor circuit

(lean exhaust)

45Oxygen sensor circuit (rich exhaust)

51 Mem-Cal

55 Control unit input circuits

Test Procedure

(1) Perform the following checks:

(a) Ensure that the battery voltage is above 11

volts. (b) Ensure that the throttle valve is fully closed.

(c) Place the transaxle in neutral.

(d) Ensure that the air conditioner, fan, tights

and all other accessories are switched off.

(2) Turn the ignition On and confirm that the

ECM warning lamp on the instrument cluster is

illuminated but not flashing.

If code 55 is displayed, refer to the Control Unit

heading, perform the circuit test procedure and rectify

the cause of the code before proceeding.

If the ECM warning lamp flashes codes other than

code 55, check the wiring harness between the diag-

nostic link connector terminal B and the control unit

wiring connector terminal A9 for shorts. Repair or

renew the wiring harness as necessary.

If no fault can be found, renew the control unit.

If the ECM warning lamp does not illuminate,

proceed as follows:

(a) Check the METER fuse located in the fuse

panel adjacent to the steering column and the fusible

links located in the fusible link connecting block at the

rear of the battery. Renew the fuse or fusible links as

necessary. (b) Check the wiring harness to the instrument

cluster. Repair or renew the harness. (c) Check the Check Engine lamp bulb. Renew if

necessary. (d) Check the EGI relay. Renew as necessary.

(3) Connect a jumper lead across terminals A

and B on the diagnostic link connector located under

the front passengers seat above the control unit.

(4) Note the codes indicated by the flashing

ECM warning lamp.

If code 12 is displayed, the system is operating

correctly.

If codes other than code 12 are displayed, refer to

the component or circuit test procedure under the

appropriate heading as indicated by the code number.

If more than one code is being displayed, test each

indicated fault working in the order of display of the

code numbers.

(5) After completing the self diagnosis test pro-

cedure, remove the jumper lead from the diagnostic

link connector. (6) After repairing or renewing the necessary

View showing the location of the diagnostic link

connector. Passengers seat removed for clarity.

Inset shows the diagnostic link connector terminal identification.

Page 101 of 238

Fuel and Engine Management 101

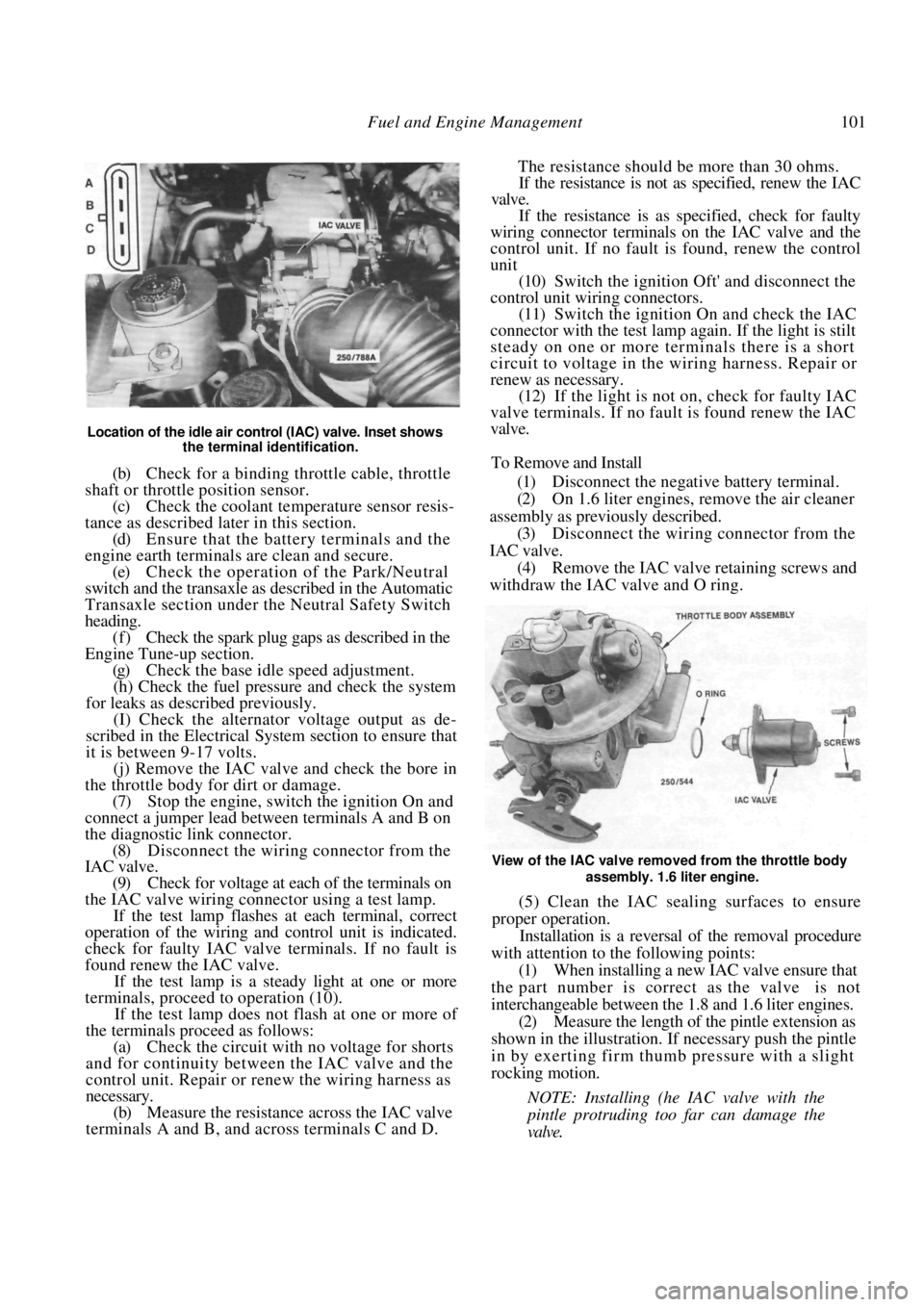

Location of the idle air control (IAC) valve. Inset shows the terminal identification.

(b) Check for a binding throttle cable, throttle

shaft or throttle position sensor. (c) Check the coolant temperature sensor resis-

tance as described later in this section. (d) Ensure that the battery terminals and the

engine earth terminals are clean and secure.

(e) Check the operation of the Park/Neutral

switch and the transaxle as described in the Automatic

Transaxle section under the Neutral Safety Switch

heading. (f) Check the spark plug gaps as described in the

Engine Tune-up section.

(g) Check the base idle speed adjustment.

(h) Check the fuel pressure and check the system

for leaks as described previously.

(I) Check the alternator voltage output as de-

scribed in the Electrical System section to ensure that

it is between 9-17 volts.

(j) Remove the IAC valve and check the bore in

the throttle body for dirt or damage.

(7) Stop the engine, switch the ignition On and

connect a jumper lead between terminals A and B on

the diagnostic link connector. (8) Disconnect the wiring connector from the

IAC valve.

(9) Check for voltage at each of the terminals on

the IAC valve wiring connector using a test lamp. If the test lamp flashes at each terminal, correct

operation of the wiring and control unit is indicated.

check for faulty IAC valve terminals. If no fault is

found renew the IAC valve.

If the test lamp is a steady light at one or more

terminals, proceed to operation (10).

If the test lamp does not flash at one or more of

the terminals proceed as follows:

(a) Check the circuit with no voltage for shorts

and for continuity between the IAC valve and the

control unit. Repair or renew the wiring harness as

necessary.

(b) Measure the resistance across the IAC valve

terminals A and B, and across terminals C and D. The resistance should be more than 30 ohms.

If the resistance is not as specified, renew the IAC

valve.

If the resistance is as specified, check for faulty

wiring connector terminals on the IAC valve and the

control unit. If no fault is found, renew the control

unit

(10) Switch the ignition Oft' and disconnect the

control unit wiring connectors. (11) Switch the ignition On and check the IAC

connector with the test lamp again. If the light is stilt

steady on one or more terminals there is a short

circuit to voltage in the wiring harness. Repair or

renew as necessary. (12) If the light is not on, check for faulty IAC

valve terminals. If no fault is found renew the IAC

valve.

To Remove and Install

(1) Disconnect the negative battery terminal.

(2) On 1.6 liter engines, remove the air cleaner

assembly as previously described. (3) Disconnect the wiring connector from the

IAC valve. (4) Remove the IAC valve retaining screws and

withdraw the IAC valve and O ring.

View of the IAC valve removed from the throttle body

assembly. 1.6 liter engine.

(5) Clean the IAC sealing surfaces to ensure

proper operation.

Installation is a reversal of the removal procedure

with attention to the following points:

(1) When installing a new IAC valve ensure that

the part number is correct as the valve is not

interchangeable between the 1.8 and 1.6 liter engines.

(2) Measure the length of the pintle extension as

shown in the illustration. If necessary push the pintle

in by exerting firm thum b pressure with a slight

rocking motion.

NOTE: Installing (he IAC valve with the

pintle protruding too far can damage the

valve.

Page 109 of 238

Fuel and Engine Management 109

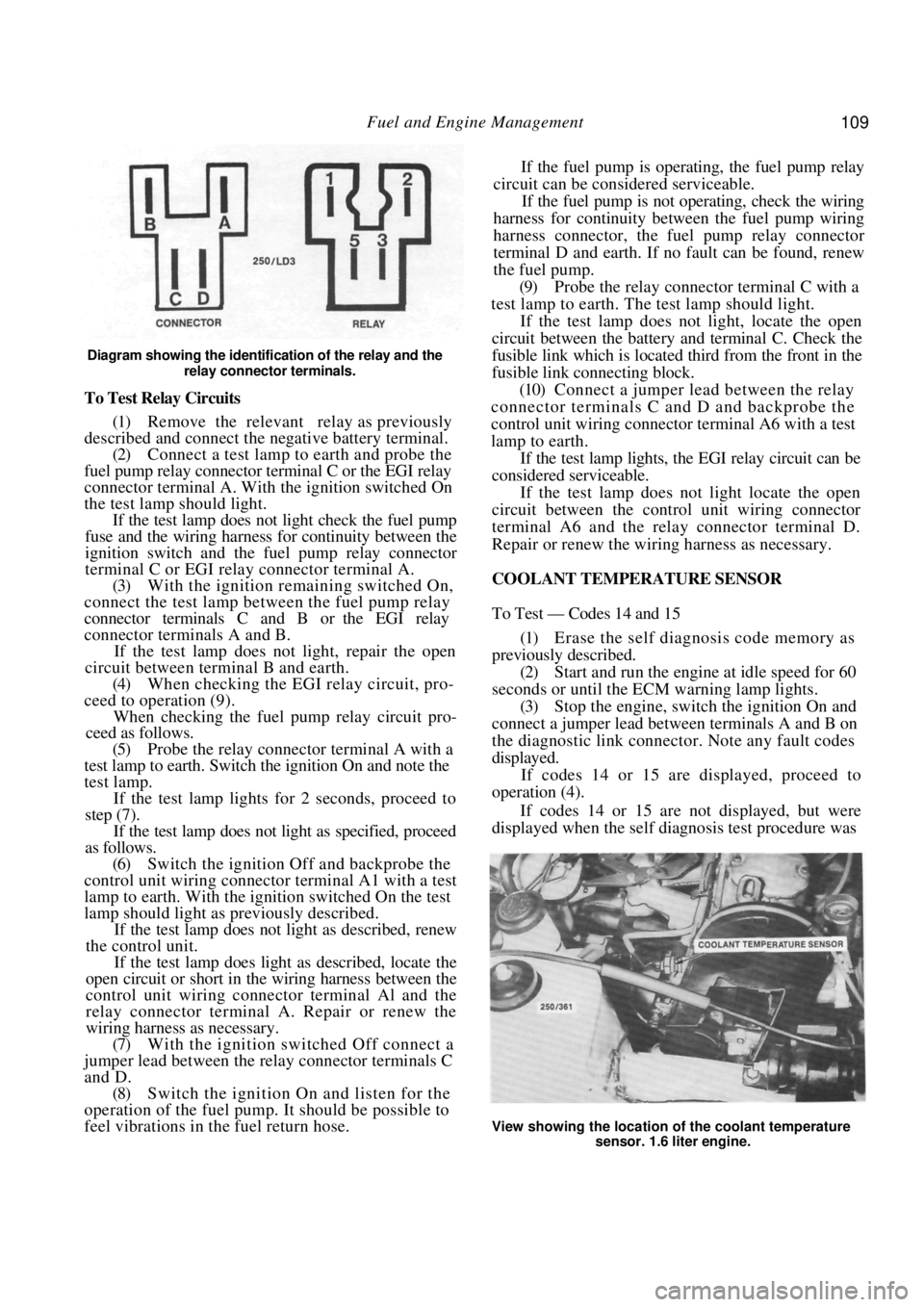

Diagram showing the identification of the relay and the relay connector terminals.

To Test Relay Circuits

(1) Remove the relevant relay as previously

described and connect the ne gative battery terminal.

(2) Connect a test lamp to earth and probe the

fuel pump relay connector terminal C or the EGI relay

connector terminal A. With the ignition switched On

the test lamp should light. If the test lamp does not light check the fuel pump

fuse and the wiring harness for continuity between the

ignition switch and the fuel pump relay connector

terminal C or EGI rela y connector terminal A.

(3) With the ignition remaining switched On,

connect the test lamp between the fuel pump relay

connector terminals C and B or the EGI relay

connector terminals A and B.

If the test lamp does not light, repair the open

circuit between terminal B and earth.

(4) When checking the EGI relay circuit, pro-

ceed to operation (9).

When checking the fuel pu mp relay circuit pro-

ceed as follows.

(5) Probe the relay connector terminal A with a

test lamp to earth. Switch the ignition On and note the

test lamp.

If the test lamp lights for 2 seconds, proceed to

step (7).

If the test lamp does not light as specified, proceed

as follows.

(6) Switch the ignition Off and backprobe the

control unit wiring connector terminal A1 with a test

lamp to earth. With the ignition switched On the test

lamp should light as previously described.

If the test lamp does not light as described, renew

the control unit.

If the test lamp does light as described, locate the

open circuit or short in the wiring harness between the

control unit wiring connector terminal Al and the

relay connector terminal A. Repair or renew the

wiring harness as necessary.

(7) With the ignition switched Off connect a

jumper lead between the relay connector terminals C

and D. (8) Switch the ignition On and listen for the

operation of the fuel pump. It should be possible to

feel vibrations in the fuel return hose. If the fuel pump is operating, the fuel pump relay

circuit can be considered serviceable.

If the fuel pump is not operating, check the wiring

harness for continuity between the fuel pump wiring

harness connector, the fuel pump relay connector

terminal D and earth. If no fault can be found, renew

the fuel pump.

(9) Probe the relay connector terminal C with a

test lamp to earth. The test lamp should light.

If the test lamp does not light, locate the open

circuit between the battery and terminal C. Check the

fusible link which is located third from the front in the

fusible link connecting block.

(10) Connect a jumper lead between the relay

connector terminals C and D and backprobe the

control unit wiring connector terminal A6 with a test

lamp to earth.

If the test lamp lights, the EGI relay circuit can be

considered serviceable.

If the test lamp does not light locate the open

circuit between the contro l unit wiring connector

terminal A6 and the relay connector terminal D.

Repair or renew the wiring harness as necessary.

COOLANT TEMPERATURE SENSOR

To Test — Codes 14 and 15

(1) Erase the self diagnosis code memory as

previously described. (2) Start and run the engine at idle speed for 60

seconds or until the ECM warning lamp lights.

(3) Stop the engine, switch the ignition On and

connect a jumper lead between terminals A and B on

the diagnostic link connect or. Note any fault codes

displayed. If codes 14 or 15 are displayed, proceed to

operation (4).

If codes 14 or 15 are not displayed, but were

displayed when the self diagnosis test procedure was

View showing the location of the coolant temperature

sensor. 1.6 liter engine.

Page 110 of 238

110 Fuel and Engine Management

originally performed, an intermittent fault is indi-

cated. Proceed as follows:

(a) Check for faulty wiri ng connections. Check

that all wiring connectors are clean and secure. (b) Check that all earth wires are secure.

(4) Disconnect the wiring connector from the

coolant temperature sensor. (5) With the ignition switched On, measure the

voltage across the terminals on the coolant tempera-

ture sensor wiring connector. The voltage should be

4-6 volts.

If the voltage is below 4 volts, proceed to opera-

tion (9).

If the voltage is as specified, proceed as follows.

(6) Remove the coolant temperature sensor

from the vehicle. (7) Connect an ohmmeter to the coolant temper-

ature sensor terminals. (8) Immerse the meta1 end of the coolant

tem-

perature sensor in a 50/50 mixture of glycol and iced

water at a temperature of 0 deg C. The resistance

should be 6 000 ohms. Slowly heat the mixture and measure the resis-

tance of the coolant temperature sensor at the follow-

ing temperatures. Compare the results with the spec-

ified values:

0 d e g C ................................................. 6 000 ohms

20 deg C .................................................. 2 500 ohms

30 deg C .................................................. 1 800 ohms

40 deg C.................................................. 1 200 ohms

70 deg C .......................................................450 ohms

90 degC .......................................................250 ohms

100 deg C.....................................................190 ohms

110 deg C.....................................................110 ohms

If the resistances obtained are not as specified at

any of the given temperatures, renew the coolant

temperature sensor and retest for fault codes.

(9) Disconnect the control unit wiring connec-

tors.

(10) Check the wiring harness for shorts and

continuity between the coolant temperature sensor

wiring connector terminals and the control unit wiring

connector terminals C10 and D2. Repair or renew the

wiring harness as necessary.

Also check the control unit terminals for damage.

If no fault is found, renew the control unit and

retest for fault codes.

To Remove and Install

(1) Disconnect the negative battery terminal.

(2) Disconnect the wiring connector from the

coolant temperature sensor.

(3) Drain the coolant as described in the Cooling

and Heating Systems section to a level below the

sensor.

(4) Unscrew the sensor from the thermostat

housing. Installation is a reversal of the removal procedure

with attention to the following points;

(1) Apply Loctite 675 or a similar conductive

sealer to the threads of th e sensor. Tighten the sensor

to the specified torque.

(2) Fill the cooling system with the correct

mixture of water and inhibitor as described in the

Cooling and Heating Systems section. (3) Ensure that the wiring connector is clean and

secure.

THROTTLE POSITION SENSOR

To Test - Codes 21 and 22

NOTE: The following test procedure as-

sumes that fault codes 21 or 22 have been

displayed during the se lf diagnosis test pro-

cedure. If no codes have been displayed but

the operation of the throttle position sensor

is suspect, begin the test procedure at oper-

ation (24).

(1) Erase the self diagnosis code memory as

previously described.

(2) Start and run the engine at idle speed for 60

seconds or until the ECM warning lamp lights. If the engine will not start, disconnect the throttle

position sensor wiring co nnector and proceed to

operation (8). .

(3) With the engine id ling, quickly increase the

engine speed to 3 000 rpm and return to idle.

If the ECM warning lamp remains illuminated,

proceed to operation (4).

If the ECM warning lamp extinguishes, an inter-

mittent fault is indicated. Proceed as follows:

(a) Check for faulty wiri ng connections. Check

that all wiring connectors are clean and secure. (b) Check that all earth wires are secure.

(4) Stop the engine, switch the ignition On and

connect a jumper lead between terminals A and B on

the diagnostic link connect or. Note any fault codes

displayed.

If codes 21 or 22 are displayed, proceed as

follows.

(5) Remove the jumper lead from the diagnostic

link connector. (6) Erase the self diagnosis codes as previously

described. (7) Disconnect the wiring connector from the

throttle position sensor. If code 22 was displayed in operation (4), proceed

to operation (13).

If code 21 was displayed in operation (4), proceed

as follows.

(8) Start and run the engine at idle speed for 2

minutes or until the ECM warning lamp lights. If the

engine will not start, pr oceed to operation (11).

(9) Stop the engine, switch the ignition On and

connect a jumper lead between terminals A and B on