jack points NISSAN PULSAR 1987 Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1987, Model line: PULSAR, Model: NISSAN PULSAR 1987Pages: 238, PDF Size: 28.91 MB

Page 10 of 238

10 General Information

If tools are to be stored for any length of time, it is

good policy to wipe them with an oily cloth.

Bladed screwdrivers should be checked for dam-

age to the tip. If necessary, the tip can be returned to

its original profile by careful grinding. Do not grind

screwdriver tips to a sharp point.

Hammer heads should be secure on their handles

and should be regularly checked for cracking or other

damage.

Chisels and punches should be checked for dam-

age or 'mushrooming' of the head. Any faults should

be rectified by grinding.

Hydraulic jacks should be regularly checked for

fluid leaks. Chassis stands and car ramps should be

checked for damage and cracks. Any equipment that

is suspect should not be used.

STORES

For routine maintenance, stores of automotive

oils, greases and additives should be kept on hand.

The following is a suggested list.

Engine oil.

Brake fluid.

Manual transmission or automatic transmission

oil — automatic transmission oil is also used in

the power steering system.

Rear axle oil.

Cooling system corrosion inhibitor/antifreeze.

Chassis grease.

High melting point grease, for hub bearings etc.

Penetrating oil or spray.

Kerosene or similar cleaning solvent.

Methylated spirits.

Oils and greases are available in handy pack size for

do-it-yourself lube jobs.

2. SAFETY

PERSONAL SAFETY

Safety when working on a motor vehicle is basical-

ly a matter of commonsense. Some safety precautions

to prevent personal in juries are as follows.

Raising a Vehicle

Always jack a vehicle on firm, level ground and at

the specified jacking points . Ensure that the wheels

remaining on the ground are fully chocked.

After raising the vehicle, place chassis stands

underneath and allow the weight of the vehicle to rest

on them. Do not use bricks, blocks of wood or similar

material.

NOTE: Never work under a vehicle which is

only supported by a jack.

Electrical System

Always disconnect the negative battery terminal

when working on any electrical components. Avoid

wearing metal watches, rings and chains which may

short across live terminals.

As battery gases are explosive, keep naked flames

and sparks clear of the work area. When connecting

and disconnecting jumper leads, use extreme caution

to avoid sparking.

Electronic Ignition Systems

Electronic ignition systems produce dangerous

high tension voltages in bo th the primary and second-

ary circuits which can be fatal. Exercise extreme

caution when working on or near any ignition system

components. Do not disconnect high tension leads

while the engine is running.

Work Area

Do not run the engine in a confined space. Ensure

that the work area is adequately ventilated.

Spilt oil or water should be cleaned immediately

to avoid the possibility of slipping.

Fuel System

Always disconnect the negative battery terminal

when working on any fuel components. Do not smoke.

Keep naked flames and sparks clear of the work area.

Do not siphon fuel using the mouth. Use a hand

pump or suitable siphon.

Do not attempt to repair a fuel tank by welding it.

This is an extremely hazardous procedure and should

be entrusted to a specialist.

Cooling System

To avoid scalding, use caution when releasing the

radiator cap on an engine wh ich is at normal operating

temperature. Turn the cap anti-clockwise to the first

stop and allow any pressure in the system to release.

When the pressure is released, remove the cap from

the radiator.

Brakes

As asbestos is used in some brake lining material,

avoid inhaling brake dust. Do not use compressed air

to remove the dust. Gentle brushing with a small

brush or using a vacuum cleaner with a hose attach-

ment are the safest methods of cleaning the brakes.

The above precautions also apply to the clutch plate

lining material.

Page 14 of 238

14

LUBRICATION AND MAINTENANCE

SPECIFICATIONS

CAPACITY AND GRADE

Engine:

Lubricant........................................... 15W-50 SF

Sump capacity including filter ........... 3.3 liters

Cooling system capacity............................ 6.0 liters

Manual transaxle:

Lubricant....................................... 80W-90 GL-4

Capacity ............................................... 2.7 liters

Automatic transaxle:

Lubricant.............................................. Dexron II

Capacity ............................................... 6.0 liters

Power steering:

Lubricant.............................................. Dexron II

Capacity ............................................... 1.0 liters

Manual steering lubricant ........ Castrol EPLl grease

Brake fluid type ................................................ Dot 4

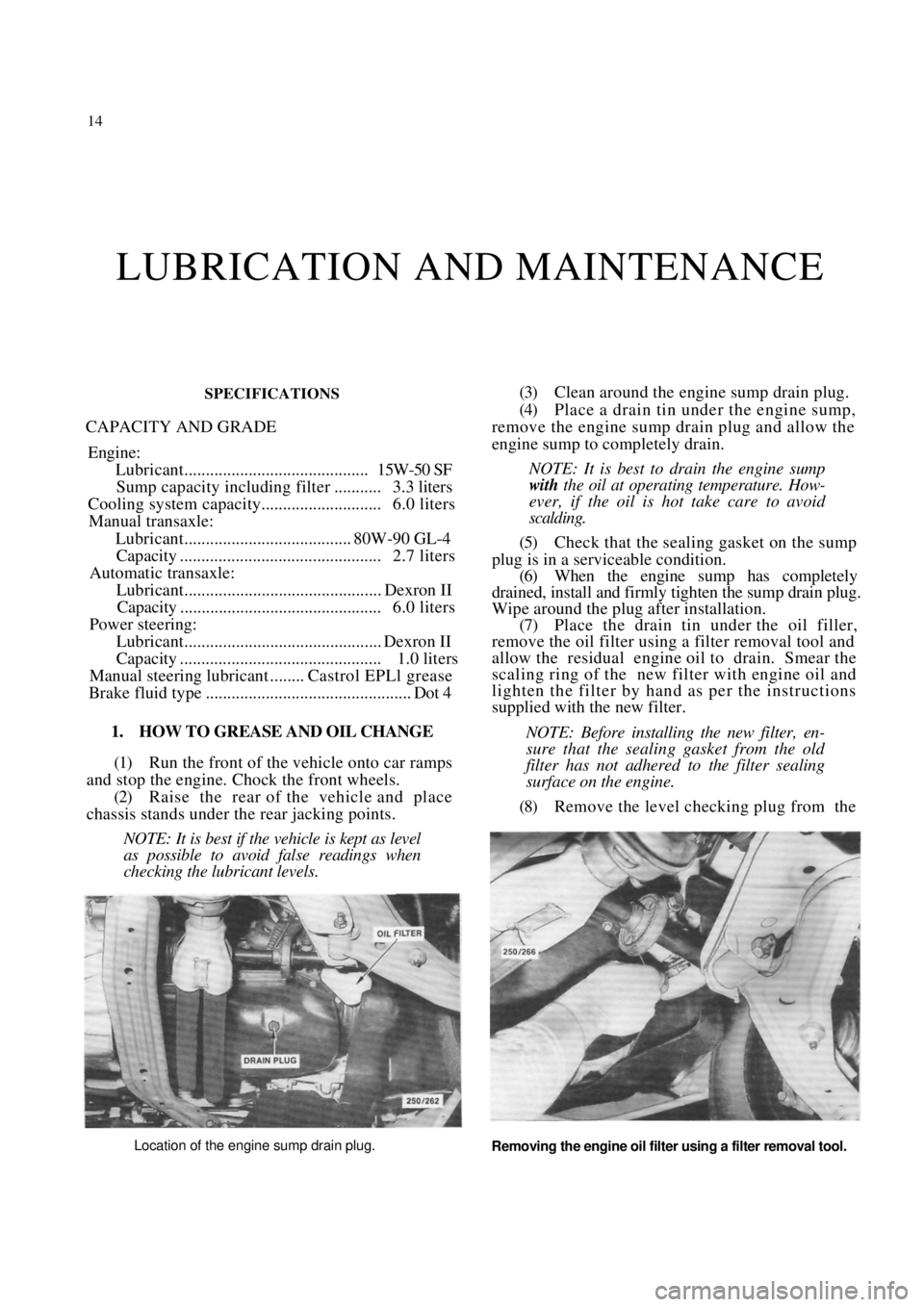

1. HOW TO GREASE AND OIL CHANGE

(1) Run the front of the vehicle onto car ramps

and stop the engine. Chock the front wheels. (2) Raise the rear of the vehicle and place

chassis stands under the rear jacking points.

NOTE: It is best if the vehicle is kept as level

as possible to avoi d false readings when

checking the lubricant levels.

(3) Clean around the engine sump drain plug.

(4) Place a drain tin under the engine sump,

remove the engine sump drain plug and allow the

engine sump to completely drain.

NOTE: It is best to drain the engine sump

with the oil at operating temperature. How-

ever, if the oil is hot take care to avoid

scalding.

(5) Check that the sealing gasket on the sump

plug is in a serviceable condition. (6) When the engine sump has completely

drained, install and firmly tighten the sump drain plug.

Wipe around the plug after installation. (7) Place the drain tin under the oil filler,

remove the oil filter using a filter removal tool and

allow the residual engine oil to drain. Smear the

scaling ring of the new filter with engine oil and

lighten the filter by hand as per the instructions

supplied with the new filter.

NOTE: Before installing the new filter, en-

sure that the sealing gasket from the old

filter has not adhered to the filter sealing

surface on the engine.

(8) Remove the level checking plug from the

Location of the engine sump drain plug.

Removing the engine oil filter using a filter removal tool.

Page 21 of 238

WHEELS AND TYRES

SPECIFICATIONS

TYRES PRESSURES

Front:

Normal load ............................................ 200 kPa

Heavy load or high speed ......................230 kPa

Rear:

Normal load............................................ 180 kPa

Heavy load or high speed ...................... 210 kPa

NOTE: The above pressures are measured

cold and are meant as a guide only. Always

refer to the tire placard positioned on the

inside of the glove compartment lid and the

tire manufacturers recommendations first.

TORQUE WRENCH SETTINGS

Wheel nut torque .............................................98 Nm

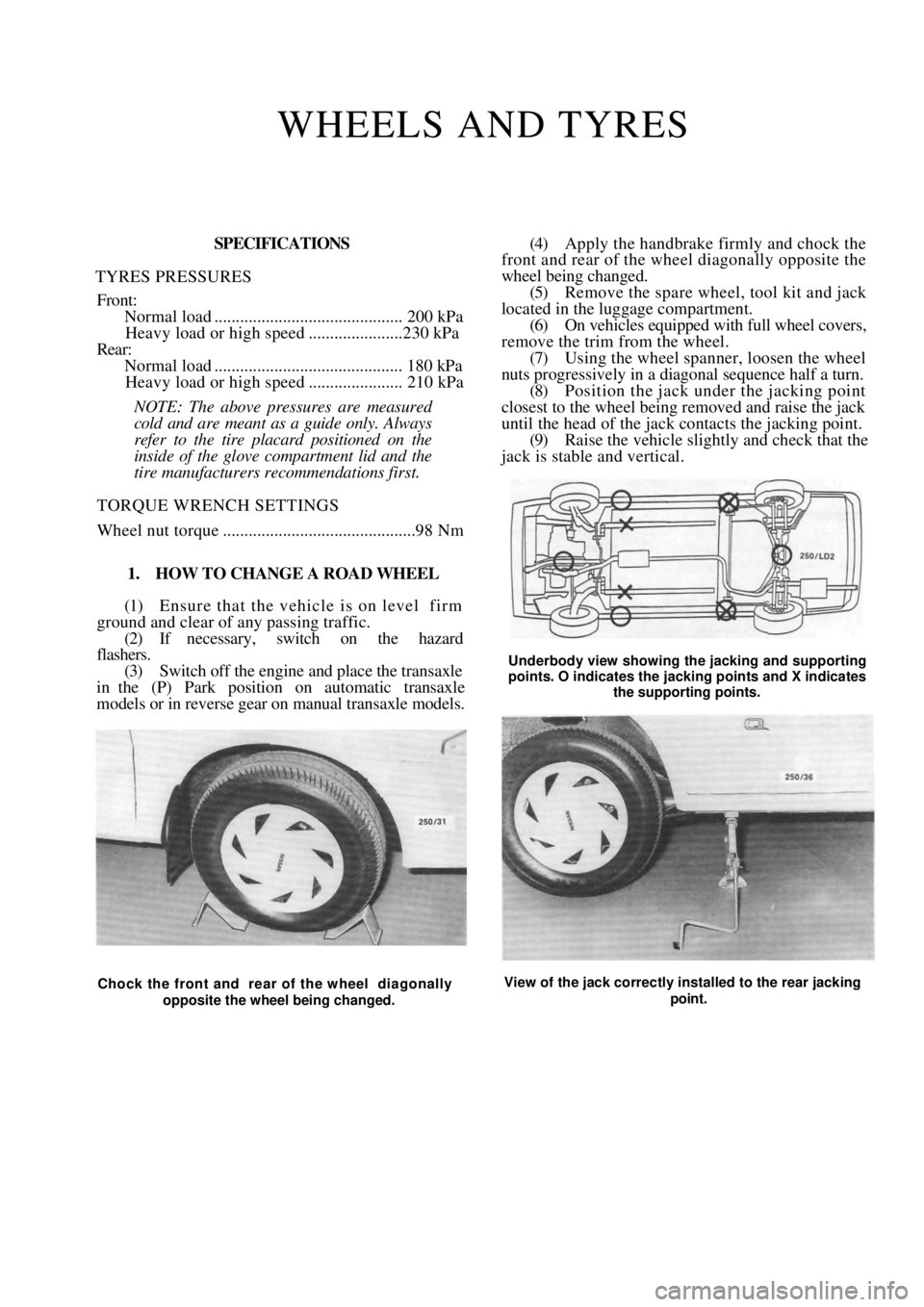

1. HOW TO CHANGE A ROAD WHEEL

(1) Ensure that the vehicle is on level firm

ground and clear of any passing traffic. (2) If necessary, switch on the hazard

flashers.

(3) Switch off the engine a nd place the transaxle

in the (P) Park position on automatic transaxle

models or in reverse gear on manual transaxle models.

(4) Apply the handbrake firmly and chock the

front and rear of the wheel diagonally opposite the

wheel being changed.

(5) Remove the spare wheel, tool kit and jack

located in the luggage compartment. (6) On vehicles equipped with full wheel covers,

remove the trim from the wheel. (7) Using the wheel spanner, loosen the wheel

nuts progressively in a diagonal sequence half a turn.

(8) Position the jack und er the jacking point

closest to the wheel being removed and raise the jack

until the head of the jack contacts the jacking point.

(9) Raise the vehicle slightly and check that the

jack is stable and vertical.

Underbody view showing the jacking and supporting

points. O indicates the jacking points and X indicates

the supporting points.

Chock the front and rear of the wheel diagonally

opposite the wheel being changed. View of the jack correctly installed to the rear jacking

point.

Page 64 of 238

64 Engine

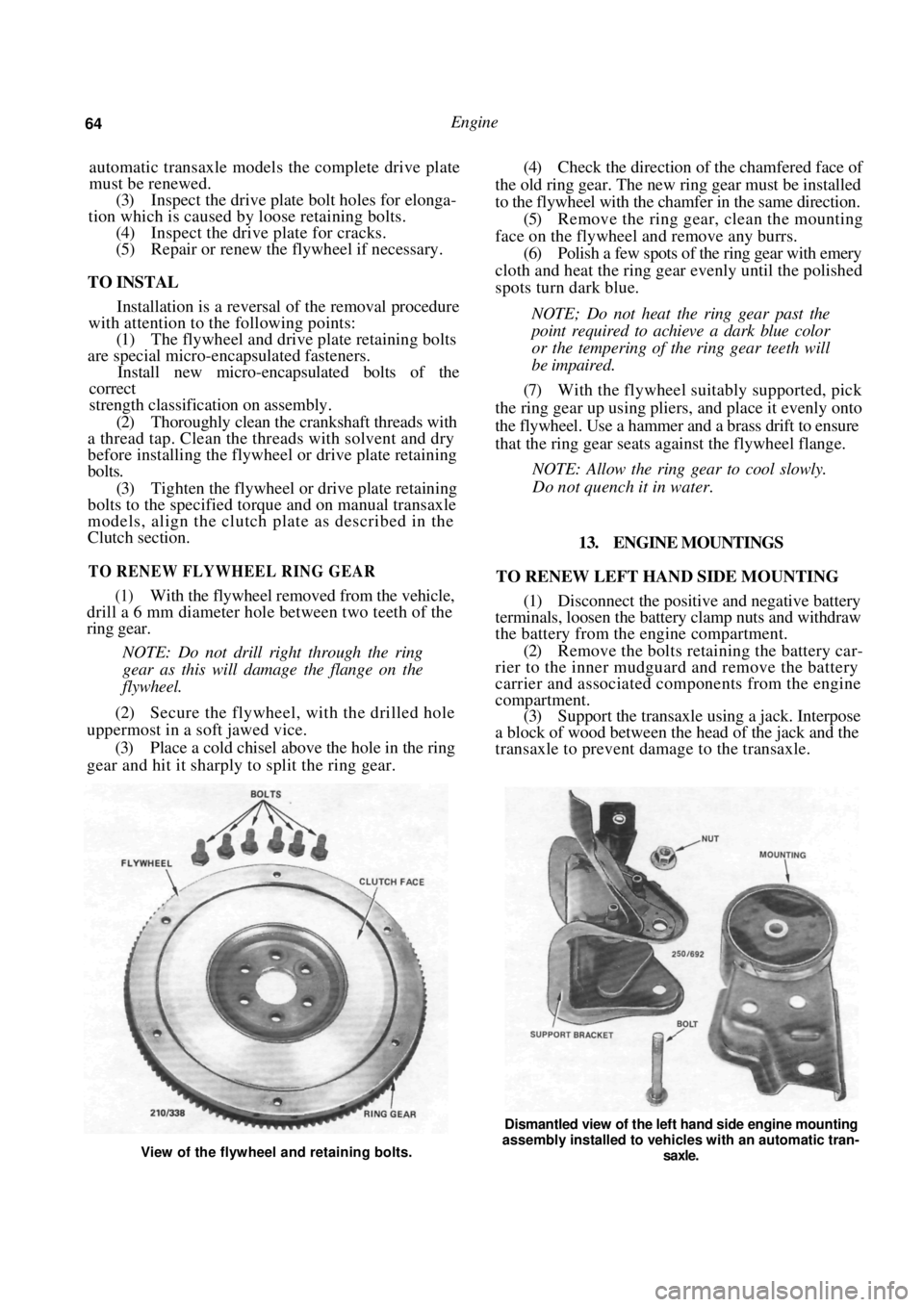

automatic transaxle models the complete drive plate

must be renewed.

(3) Inspect the drive plate bolt holes for elonga-

tion which is caused by loose retaining bolts.

(4) Inspect the drive plate for cracks.

(5) Repair or renew the flywheel if necessary.

TO INSTAL

Installation is a reversal of the removal procedure

with attention to the following points:

(1) The flywheel and drive plate retaining bolts

are special micro-encapsulated fasteners.

Install new micro-encapsulated bolts of the

correct

strength classification on assembly.

(2) Thoroughly clean the crankshaft threads with

a thread tap. Clean the threads with solvent and dry

before installing the flywh eel or drive plate retaining

bolts.

(3) Tighten the flywheel or drive plate retaining

bolts to the specified torque and on manual transaxle

models, align the clutch plate as described in the

Clutch section.

TO RENEW FLYWHEEL RING GEAR

(1) With the flywheel removed from the vehicle,

drill a 6 mm diameter hole between two teeth of the

ring gear.

NOTE: Do not drill right through the ring

gear as this will damage the flange on the

flywheel.

(2) Secure the flywheel, with the drilled hole

uppermost in a soft jawed vice.

(3) Place a cold chisel above the hole in the ring

gear and hit it sharply to split the ring gear.

(4) Check the direction of the chamfered face of

the old ring gear. The new ring gear must be installed

to the flywheel with the chamfer in the same direction. (5) Remove the ring gear, clean the mounting

face on the flywheel and remove any burrs. (6) Polish a few spots of the ring gear with emery

cloth and heat the ring gear evenly until the polished

spots turn dark blue.

NOTE; Do not heat the ring gear past the

point required to achieve a dark blue color

or the tempering of the ring gear teeth will

be impaired.

(7) With the flywheel suitably supported, pick

the ring gear up using plie rs, and place it evenly onto

the flywheel. Use a hammer and a brass drift to ensure

that the ring gear seats ag ainst the flywheel flange.

NOTE: Allow the ring gear to cool slowly.

Do not quench it in water.

13. ENGINE MOUNTINGS

TO RENEW LEFT HAND SIDE MOUNTING

(1) Disconnect the positive and negative battery

terminals, loosen the battery clamp nuts and withdraw

the battery from the engine compartment.

(2) Remove the bolts retaining the battery car-

rier to the inner mudguard and remove the battery

carrier and associ ated components from the engine

compartment. (3) Support the transaxle using a jack. Interpose

a block of wood between the head of the jack and the

transaxle to prevent damage to the transaxle.

View of the flywheel and retaining bolts.

Dismantled view of the left hand side engine mounting

assembly installed to vehicles with an automatic tran-

saxle.

Page 76 of 238

Cooling and Heating Systems

7. THERMOSTAT HOUSING

Special Equipment Required:

To Adjust Camshaft Drive Belt — Adjusting tool

TO REMOVE AND INSTAL

(1) Disconnect the negative battery terminal.

(2) On 1.6 liter models, remove the air cleaner

assembly from the engine. Refer to the Fuel and

Engine Management section if necessary. (3) Drain the cooling system as previously de-

scribed. (4) Remove the camshaft drive belt as described

in the Engine section under the heading Camshaft

Drive Belt. (5) Remove the bolts retaining the camshaft

drive belt rear cover to the cylinder block and remove

the rear cover.

\ COOLANT TEMPERATURE SENSOR TEMPERATURE SENDER SWITCH

View of the thermostat housing and

components.

(6) Disconnect the top radi ator hose, the heater

hose and the inlet manifold heater hose from the

thermostat housing.

(7) Disconnect the wire from the temperature

sender switch and the coolant temperature sensor. (8) Remove the bolts retaining the thermostat

housing to the cylinder head and remove the thermo-

stat housing and the O ring from the cylinder head. Installation is a reversal of the removal procedure

with attention to the following points:

(1) Ensure that all mounting faces are clean.

(2) Renew the O ring on installation.

NOTE; Ensure that the O ring is not

twisted. Do not use sealant.

(3) Tighten the thermostat housing retaining

bolts to the specified torque. (4) Adjust the camshaft drive belt tension as

described in the Engine section under the heading

Camshaft Drive Belt. (5) Fill the cooling system as previously de-

scribed and check for coolant leaks. 8. WATER PUMP

Special Equipment Required:

To Adjust Camshaft Drive Belt — Adjusting tool

TO REMOVE AND INSTAL

NOTE: The water pump is non-repairable

and if faulty must be renewed as a complete

assembly.

(1)

Drain the cooling system as previously de-

scribed.

(2) Remove the camshaft drive belt as described

in the Engine section under the heading Camshaft

Drive Belt. (3) Remove the water pump retaining bolts and

remove the water pump and the O ring from the

engine. Installation is a reversal of the removal procedure

with attention to the following points:

View of the water pump and components removed

from the vehicle.

(1) Ensure that all mounting faces are clean.

(2) Use a new O ring and smear it with a liberal

amount of silicone grease.

(3) Install the water pump to the engine but

do

not tighten the retaining bolts until the camshaft drive

belt has been installed and tensioned correctly as

described in the Engine section under the heading

Camshaft Drive Belt.

(4) Fill the cooling system as previously de-

scribed in this section and check for coolant leaks.

9. WELCH PLUGS

To facilitate the casting of the cylinder block and

cylinder head passages and water jackets, a number of

openings had to be ma de at manufacture.

Page 129 of 238

Manual Transaxle and Drive Shafts 129

renewed as individual units. The C.V. joints are

lubricated in manufacture and need no attention in

service unless one of the r ubber boots is damaged. In

this case the joint can be cl eaned and repacked with

the recommended grease and a new boot installed.

From July 1989, Pulsar Q and Vector SSS manual

transaxle models are equipped with a limited slip

differential incorporating a viscous coupling. The

coupling is not repairable and must be renewed as an

assembly if unserviceable. A test procedure for the

viscous coupling is included in the text in this section.

3. TRANSAXLE ASSEMBLY

Special Equipment Required:

To Dismantle and Assemble — Puller set, press

and press plates, dial gauge

To Measure Mainshaft Turning Torque —

Suitable slotted adaptor and torque gauge

TO REMOVE AND INSTAL

(1) Raise the front of the vehicle and support it

on chassis stands.

(2) Remove the battery as described in the

Electrical System section. (3) Remove the drive shafts as described later in

this section. (4) Disconnect and remove the starter motor as

described in the Elect rical System section.

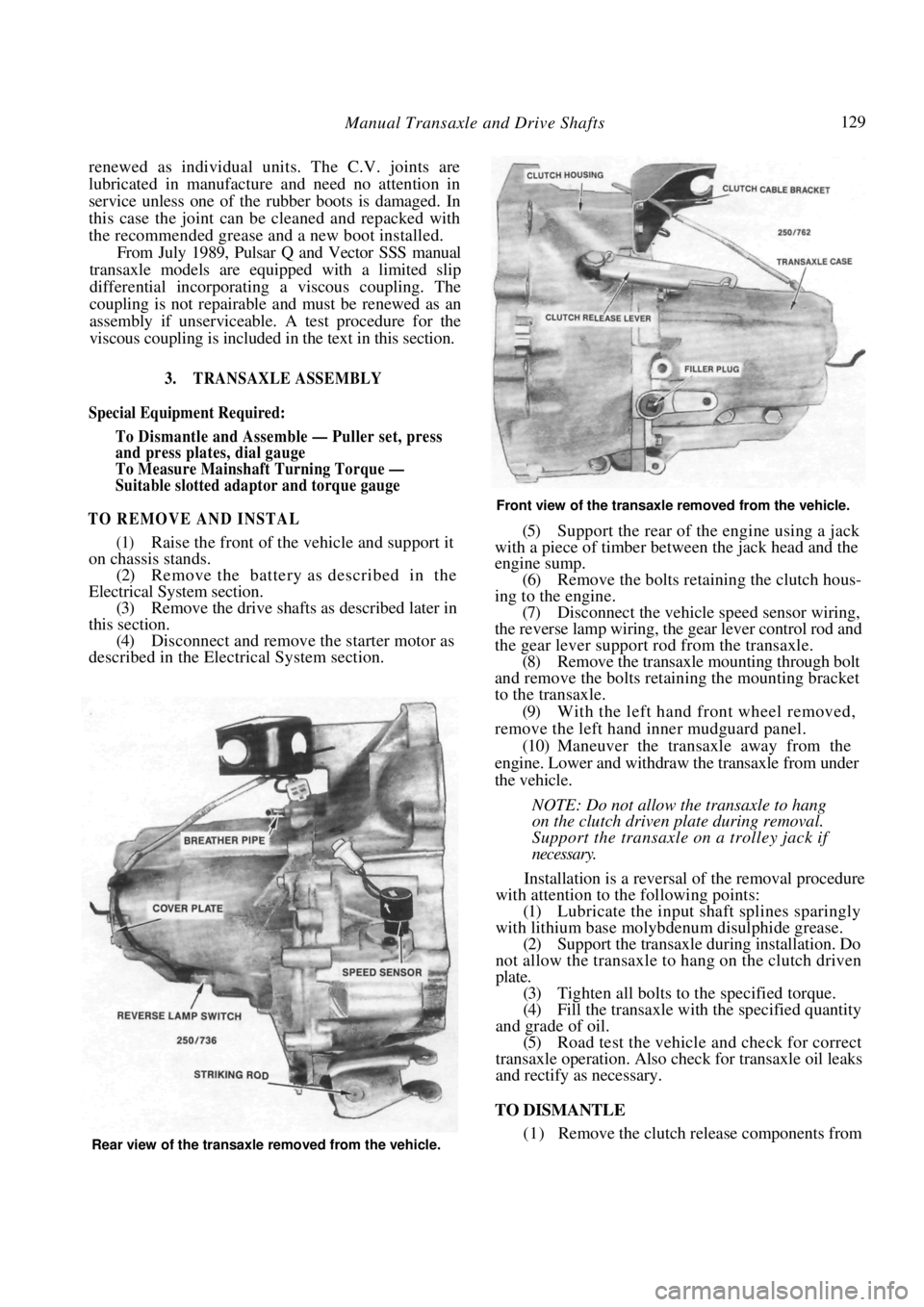

Front view of the transaxle removed from the vehicle.

(5) Support the rear of the engine using a jack

with a piece of timber between the jack head and the

engine sump.

(6) Remove the bolts retaining the clutch hous-

ing to the engine. (7) Disconnect the vehicle speed sensor wiring,

the reverse lamp wiring, the gear lever control rod and

the gear lever support rod from the transaxle. (8) Remove the transaxle mounting through bolt

and remove the bolts retaining the mounting bracket

to the transaxle.

(9) With the left hand front wheel removed,

remove the left hand inner mudguard panel. (10) Maneuver the transaxle away from the

engine. Lower and withdraw the transaxle from under

the vehicle.

NOTE: Do not allow the transaxle to hang

on the clutch driven plate during removal.

Support the transaxle on a trolley jack if

necessary.

Installation is a reversal of the removal procedure

with attention to the following points:

(1) Lubricate the input shaft splines sparingly

with lithium base molybdenum disulphide grease. (2) Support the transaxle during installation. Do

not allow the transaxle to hang on the clutch driven

plate. (3) Tighten all bolts to the specified torque.

(4) Fill the transaxle with the specified quantity

and grade of oil. (5) Road test the vehicle and check for correct

transaxle operation. Also ch eck for transaxle oil leaks

and rectify as necessary.

TO DISMANTLE

(1) Remove the clutch release components from Rear view of the transaxle removed from the vehicle.

Page 137 of 238

Manual Transaxle and Drive Shafts 137

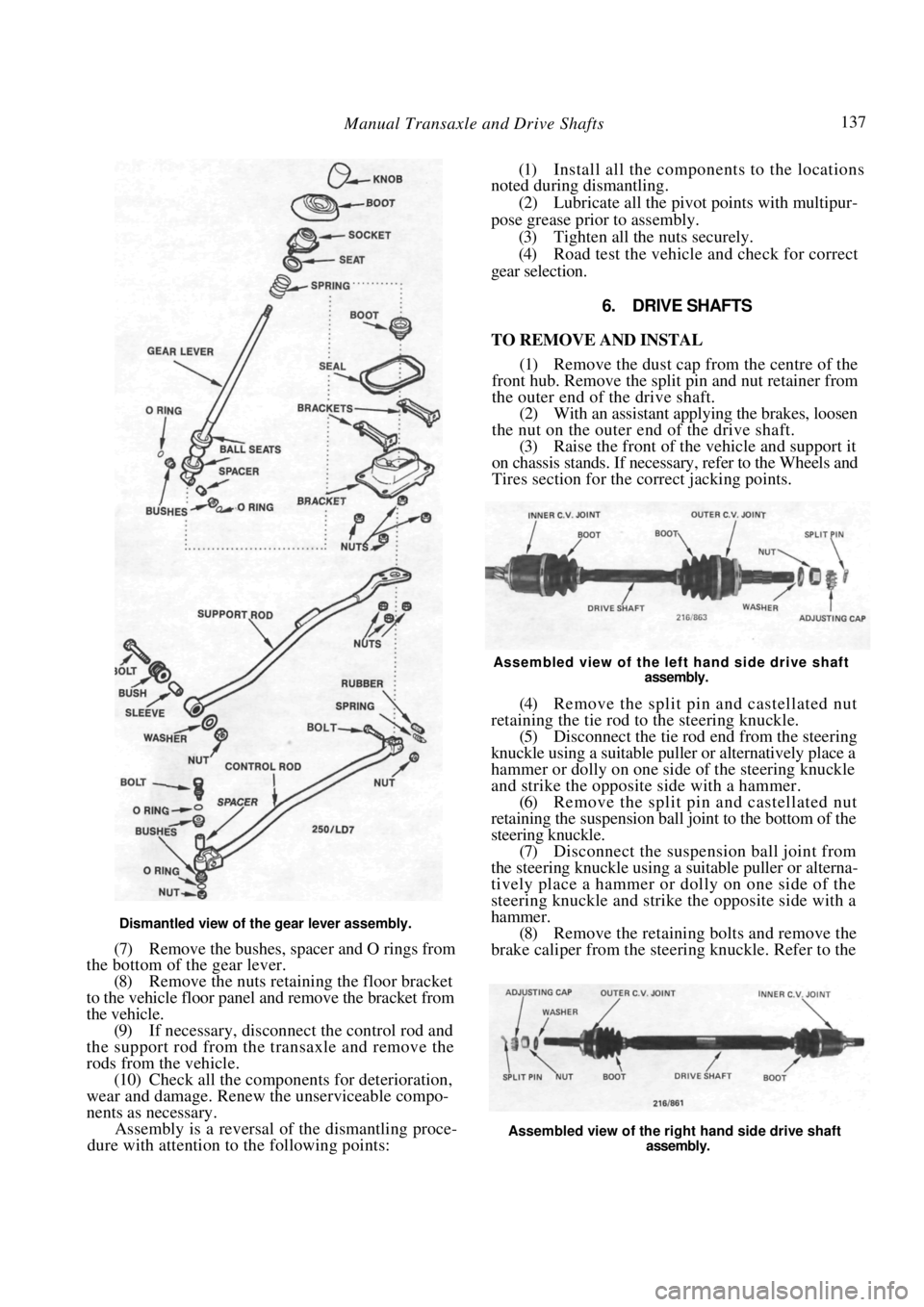

Dismantled view of the gear lever assembly.

(7) Remove the bushes, spacer and O rings from

the bottom of the gear lever.

(8) Remove the nuts retaining the floor bracket

to the vehicle floor panel and remove the bracket from

the vehicle. (9) If necessary, disconnect the control rod and

the support rod from the transaxle and remove the

rods from the vehicle. (10) Check all the components for deterioration,

wear and damage. Renew the unserviceable compo-

nents as necessary. Assembly is a reversal of the dismantling proce-

dure with attention to the following points:

(1) Install all the components to the locations

noted during dismantling.

(2) Lubricate all the pivot points with multipur-

pose grease prior to assembly. (3) Tighten all the nuts securely.

(4) Road test the vehicle and check for correct

gear selection.

6. DRIVE SHAFTS

TO REMOVE AND INSTAL

(1) Remove the dust cap from the centre of the

front hub. Remove the split pin and nut retainer from

the outer end of the drive shaft. (2) With an assistant applying the brakes, loosen

the nut on the outer end of the drive shaft.

(3) Raise the front of the vehicle and support it

on chassis stands. If necessary, refer to the Wheels and

Tires section for the correct jacking points.

Assembled view of the left hand side drive shaft

assembly.

(4) Remove the split pin and castellated nut

retaining the tie rod to the steering knuckle. (5) Disconnect the tie rod end from the steering

knuckle using a suitable puller or alternatively place a

hammer or dolly on one side of the steering knuckle

and strike the opposite side with a hammer.

(6) Remove the split pin and castellated nut

retaining the suspension ball joint to the bottom of the

steering knuckle. (7) Disconnect the suspension ball joint from

the steering knuckle using a suitable puller or alterna-

tively place a hammer or dolly on one side of the

steering knuckle and strike the opposite side with a

hammer. (8) Remove the retaining bolts and remove the

brake caliper from the stee ring knuckle. Refer to the

Assembled view of the right hand side drive shaft

assembly.

Page 143 of 238

Automatic Transaxle 143

facing towards the radiator support panel at the front

of the vehicle.

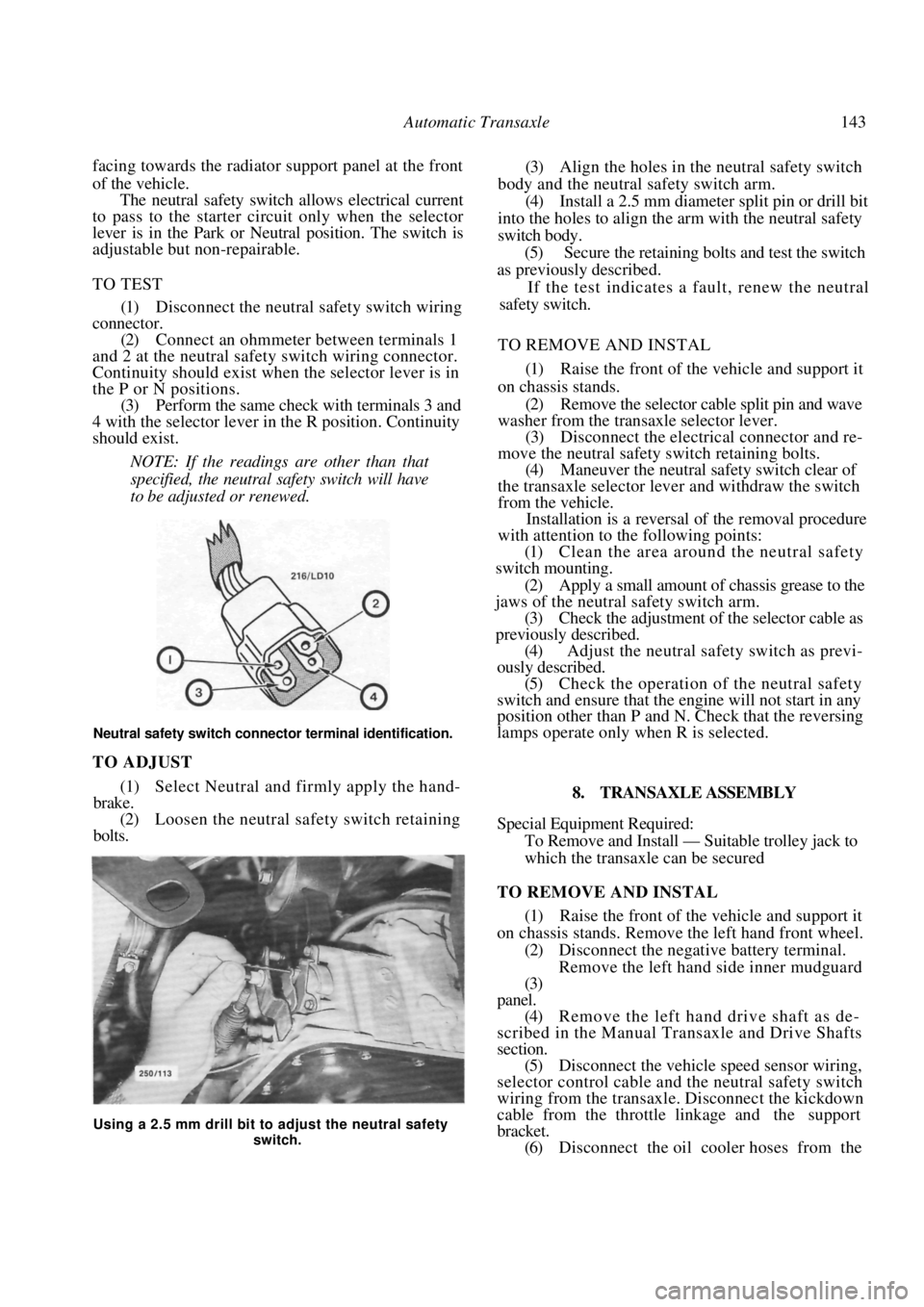

The neutral safety switch allows electrical current

to pass to the starter circ uit only when the selector

lever is in the Park or Neutral position. The switch is

adjustable but non-repairable.

TO TEST

(1) Disconnect the neutral safety switch wiring

connector.

(2) Connect an ohmmeter between terminals 1

and 2 at the neutral safety switch wiring connector.

Continuity should exist when the selector lever is in

the P or N positions. (3) Perform the same check with terminals 3 and

4 with the selector lever in the R position. Continuity

should exist.

NOTE: If the readings are other than that

specified, the neutral safety switch will have

to be adjusted or renewed.

Neutral safety switch connector terminal identification.

TO ADJUST

(1) Select Neutral and firmly apply the hand-

brake. (2) Loosen the neutral safety switch retaining

bolts.

(3) Align the holes in the neutral safety switch

body and the neutral safety switch arm. (4) Install a 2.5 mm diameter split pin or drill bit

into the holes to align the arm with the neutral safety

switch body. (5) Secure the retaining bolts and test the switch

as previously described.

If the test indicates a fault, renew the neutral

safety switch.

TO REMOVE AND INSTAL

(1) Raise the front of the vehicle and support it

on chassis stands. (2) Remove the selector cable split pin and wave

washer from the transaxle selector lever.

(3) Disconnect the electric al connector and re-

move the neutral safety switch retaining bolts. (4) Maneuver the neutral safety switch clear of

the transaxle selector lever and withdraw the switch

from the vehicle. Installation is a reversal of the removal procedure

with attention to the following points:

(1) Clean the area around the neutral safety

switch mounting.

(2) Apply a small amount of chassis grease to the

jaws of the neutral safety switch arm. (3) Check the adjustment of the selector cable as

previously described. (4) Adjust the neutral safety switch as previ-

ously described.

(5) Check the operation of the neutral safety

switch and ensure that the engine will not start in any

position other than P and N. Check that the reversing

lamps operate only when R is selected.

8. TRANSAXLE ASSEMBLY

Special Equipment Required:

To Remove and Install — Suitable trolley jack to

which the transaxle can be secured

TO REMOVE AND INSTAL

(1) Raise the front of the vehicle and support it

on chassis stands. Remove the left hand front wheel.

(2) Disconnect the negative battery terminal. Remove the left hand side inner mudguard

(3)

panel.

(4) Remove the left hand drive shaft as de-

scribed in the Manual Tran saxle and Drive Shafts

section. (5) Disconnect the vehicle speed sensor wiring,

selector control cable and the neutral safety switch

wiring from the transaxle. Disconnect the kickdown

cable from the throttle linkage and the support

bracket. (6) Disconnect the oil cooler hoses from the

Using a 2.5 mm drill bit to adjust the neutral safety

switch.

Page 144 of 238

144 Automatic Transaxle

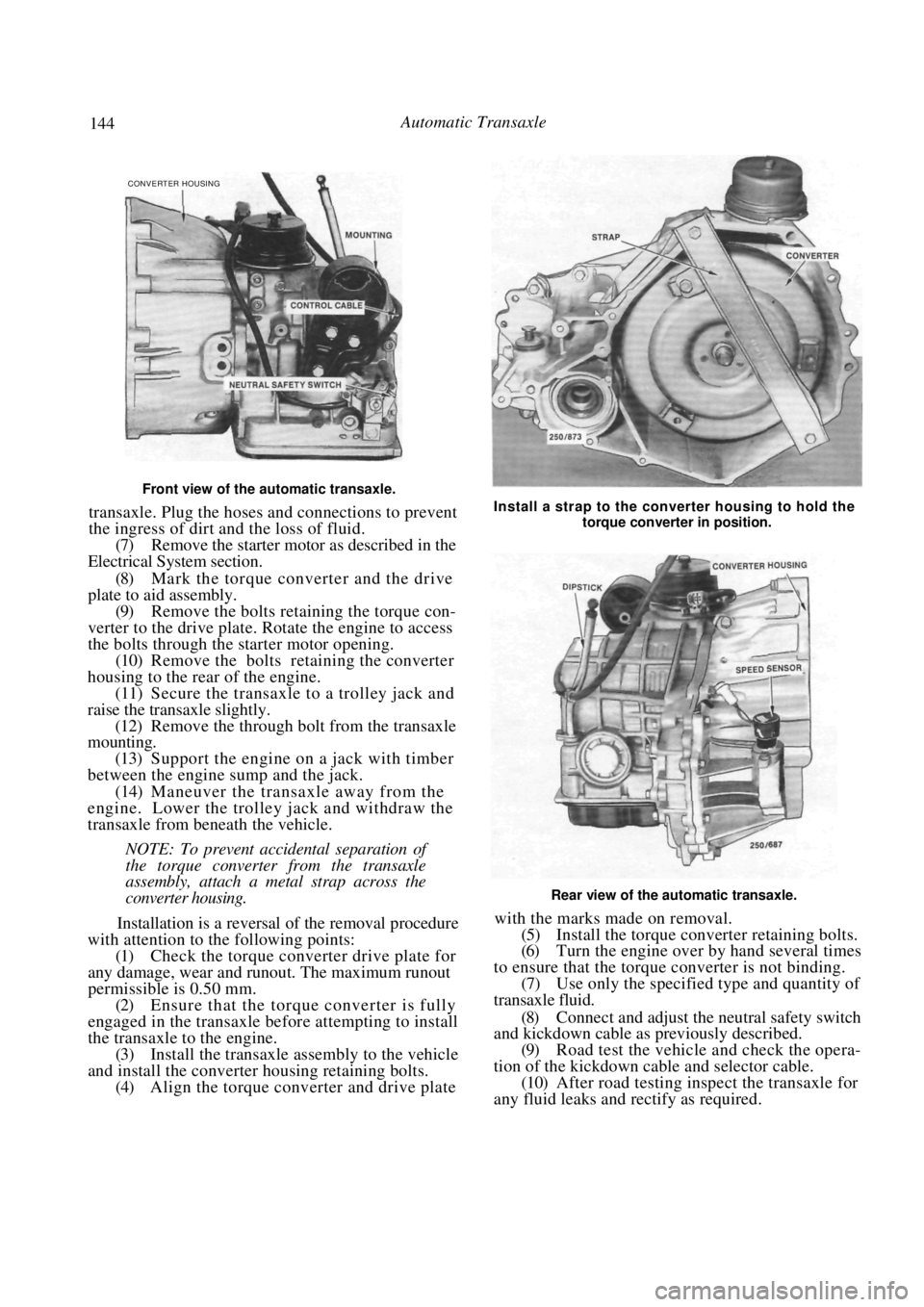

Front view of the automatic transaxle.

transaxle. Plug the hoses and connections to prevent

the ingress of dirt and the loss of fluid.

(7) Remove the starter motor as described in the

Electrical System section.

(8) Mark the torque converter and the drive

plate to aid assembly.

(9) Remove the bolts retaining the torque con-

verter to the drive plate. Rotate the engine to access

the bolts through the starter motor opening. (10) Remove the bolts retaining the converter

housing to the rear of the engine. (11) Secure the transaxle to a trolley jack and

raise the transaxle slightly. (12) Remove the through bolt from the transaxle

mounting.

(13) Support the engine on a jack with timber

between the engine sump and the jack. (14) Maneuver the transaxle away from the

engine. Lower the trolley jack and withdraw the

transaxle from beneath the vehicle.

NOTE: To prevent accidental separation of

the torque converter from the transaxle

assembly, attach a metal strap across the

converter housing.

Installation is a reversal of the removal procedure

with attention to the following points:

(1) Check the torque converter drive plate for

any damage, wear and runout. The maximum runout

permissible is 0.50 mm.

(2) Ensure that the torque converter is fully

engaged in the transaxle be fore attempting to install

the transaxle to the engine. (3) Install the transaxle assembly to the vehicle

and install the converter housing retaining bolts. (4) Align the torque converter and drive plate

Install a strap to the converter housing to hold the

torque converter in position.

Rear view of the automatic transaxle.

with the marks made on removal.

(5) Install the torque converter retaining bolts.

(6) Turn the engine over by hand several times

to ensure that the torque converter is not binding. (7) Use only the specified type and quantity of

transaxle fluid.

(8) Connect and adjust the neutral safety switch

and kickdown cable as previously described.

(9) Road test the vehicle and check the opera-

tion of the kickdown cable and selector cable. (10) After road testing inspect the transaxle for

any fluid leaks and rectify as required.

CONVERTER HOUSING

Page 150 of 238

150 Steering — Part 2

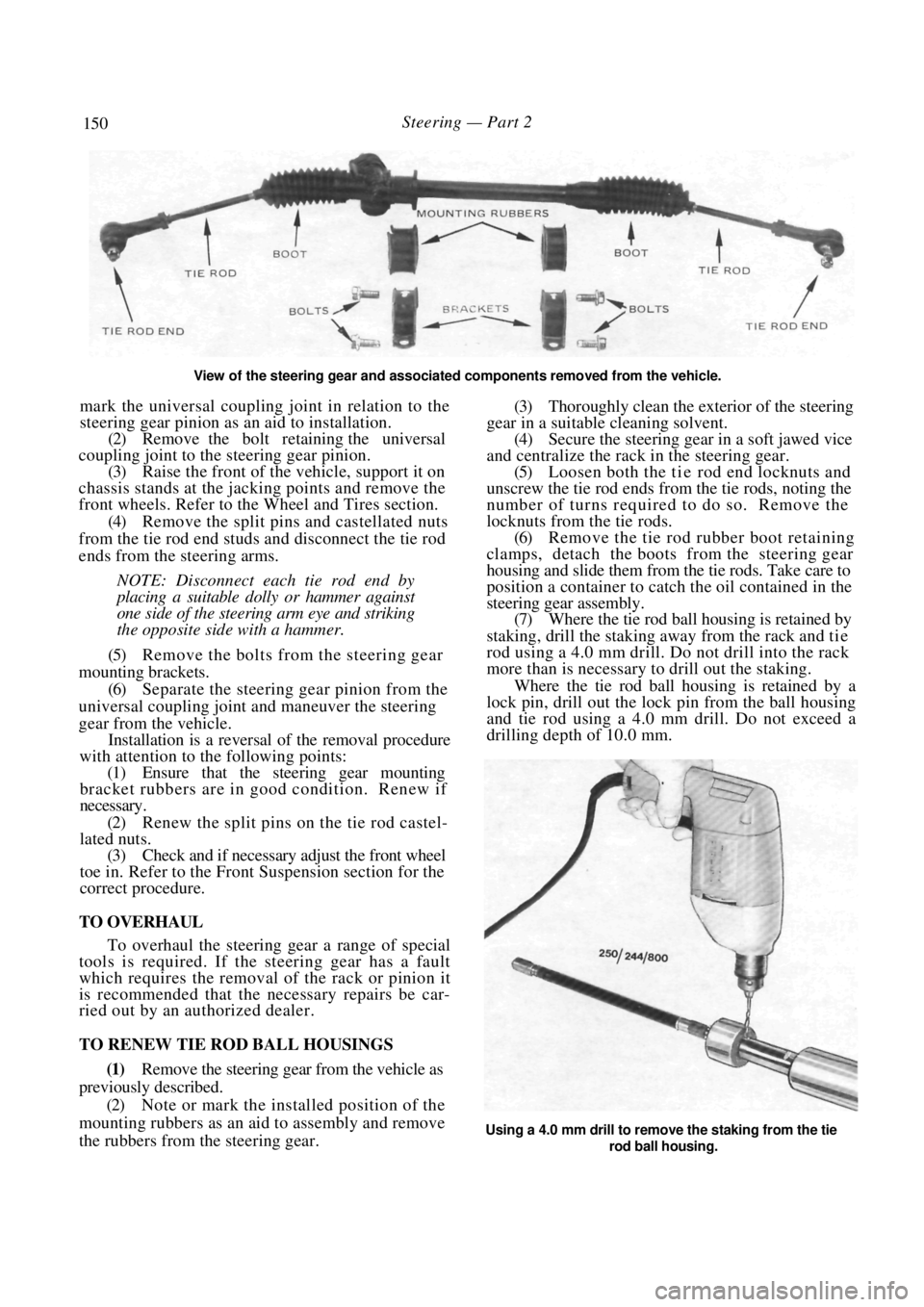

View of the steering gear and associated components removed from the vehicle.

mark the universal coupling joint in relation to the

steering gear pinion as an aid to installation.

(2) Remove the bolt retaining the universal

coupling joint to the steering gear pinion. (3) Raise the front of the vehicle, support it on

chassis stands at the jack ing points and remove the

front wheels. Refer to the Wheel and Tires section.

(4) Remove the split pins and castellated nuts

from the tie rod end studs and disconnect the tie rod

ends from the steering arms.

NOTE: Disconnect each tie rod end by

placing a suitable dolly or hammer against

one side of the steer ing arm eye and striking

the opposite side with a hammer.

(5) Remove the bolts from the steering gear

mounting brackets. (6) Separate the steering gear pinion from the

universal coupling joint and maneuver the steering

gear from the vehicle. Installation is a reversal of the removal procedure

with attention to the following points:

(1) Ensure that the steering gear mounting

bracket rubbers are in good condition. Renew if

necessary.

(2) Renew the split pins on the tie rod castel-

lated nuts.

(3) Check and if necessary adjust the front wheel

toe in. Refer to the Front Suspension section for the

correct procedure.

TO OVERHAUL

To overhaul the steering gear a range of special

tools is required. If the steering gear has a fault

which requires the removal of the rack or pinion it

is recommended that the necessary repairs be car-

ried out by an authorized dealer.

TO RENEW TIE ROD BALL HOUSINGS

(1) Remove the steering gear from the vehicle as

previously described.

(2) Note or mark the installed position of the

mounting rubbers as an aid to assembly and remove

the rubbers from the steering gear.

(3) Thoroughly clean the exterior of the steering

gear in a suitable cleaning solvent.

(4) Secure the steering gear in a soft jawed vice

and centralize the rack in the steering gear. (5) Loosen both the ti e rod end locknuts and

unscrew the tie rod ends from the tie rods, noting the

number of turns required to do so. Remove the

locknuts from the tie rods. (6) Remove the tie rod rubber boot retaining

clamps, detach the boot s from the steering gear

housing and slide them from the tie rods. Take care to

position a container to catch the oil contained in the

steering gear assembly. (7) Where the tie rod ball housing is retained by

staking, drill the staking away from the rack and t i e

rod using a 4.0 mm drill. Do not drill into the rack

more than is necessary to drill out the staking.

Where the tie rod ball housing is retained by a

lock pin, drill out the lock pin from the ball housing

and tie rod using a 4.0 mm drill. Do not exceed a

drilling depth of 10.0 mm.

Using a 4.0 mm drill to remove the staking from the tie

rod ball housing.