handbrake NISSAN PULSAR 1987 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1987, Model line: PULSAR, Model: NISSAN PULSAR 1987Pages: 238, PDF Size: 28.91 MB

Page 173 of 238

Brakes 173

Inspect the handbrake cable for chafing or fraying.

(4) Seized handbrake cables: Renew the hand-

brake cables.

NOTE: Raise the vehicle and spin the

wheels one at a time to check for binding. If

the wheels are not binding, have an assistant

apply and release the brakes. Check if the

brakes release immediately. A clogged mas-

ter cylinder port will cause binding on the

two wheels fed by that particular circuit

from the master cylinder. Open the bleeder

valve on one of the o ffending wheels to check

if pressure build up is the cause of the

binding. A seized handbrake cable will usu-

ally cause binding on a rear wheel. Discon-

nect the handbrake cable and check if the

wheel will then turn freely.

LOW SPONGY BRAKE PEDAL

(1) Incorrectly adjusted brake shoes: Check and

adjust the brake shoes.

(2) Insufficient fluid in the system: Check for

leaks, replenish the fluid to the specified level and

bleed the hydraulic system.

(3) Air in the brake hydraulic system: Bleed the

hydraulic system. (4) Master cylinder faulty: Repair or renew as

necessary.

NOTE: A spongy brake pedal in most cases

is caused by air in the hydraulic system. For

air to enter the system one or more of the

sealing rubbers or brake lines must be

sucking in air. Always rectify the cause of

the trouble before bleeding the hydraulic

system. Faulty components usually show up

as fluid leakage.

BRAKES LOCK ON APPLICATION

(1) Gummy linings or brake pads due to oil or

fluid contamination: Renew the linings or brake pads

and rectify the source of contamination. (2) Scored or eccentric brake drum or warped

disc: Check and machine or renew the drum or disc as

necessary.

(3) Incorrect or distorted linings or disc pads:

Check and renew as necessary. (4) Brake servo unit faulty: Repair or renew the

brake servo unit. (5) Broken or stretched brake shoe return

springs: Check and renew th e faulty brake springs.

(6) Faulty brake pressure proportioning valve:

Renew the brake pressure proportioning valve.

NOTE: If this condition arises, remove all

the wheels and check the condition of the

friction material for oil contamination and

excessive wear. Check the shoe return

springs for stretching by comparing their

free length with new sp rings. An eccentric-

brake drum or warped disc will be indicated

by pulsating of the brake pedal when the

brakes are lightly applied.

BRAKE PEDAL PULSATES

(1) Eccentric brake drums or warped disc: Check

and machine or renew the drum or disc as required.

(2) Loose or worn hub bearings: Renew the hub

bearings as necessary.

NOTE: Brake drums or discs that are run-

ning out must be machined. This job is best

entrusted to a brake specialist who will also

be able to determine if a new disc or drum

needs to be installed.

BRAKE FADE

(1) Incorrect shoe adjustment: Check and adjust

the shoe to drum clearance. (2) Eccentric brake drum: Check and machine or

renew the brake drum.

Check the brake hoses for deterioration, chafing and

leaks.

Page 174 of 238

174 Brakes

(3) Linings saturated with hydraulic fluid: Re-

new the linings in sets. (4) Incorrect linings installed: Check and install

the recommended linings in sets.

NOTE: In most cases brake fade is caused

by overuse of the footbrake, which in turn

causes a build up of heat at the friction

material and drums or disc. Once this

excessive build up of heat is allowed to

dissipate the brakes should again function

normally.

BRAKES OVERHEAT

(1) Incorrect shoe adjustment: Check and adjust

the shoe to drum clearance.

(2) Broken shoe return springs: Renew any

faulty springs.

(3) Faulty handbrake cables or incorrect adjust-

ment: Check and renew or adjust the cables. (4) Frozen wheel cylinder or caliper pistons:

Overhaul the cylinders or calipers. (5) Obstructed or damaged hydraulic hose or

line: Remove the obstruction or renew the hydraulic

hose or line.

(6) Obstructed master cylinder compensating

port: Clean the compensating port. (7) Blocked vent in the master cylinder reservoir

cap; Check and remove the obstruction in the vent. (8) Overuse of footbrake: Revise driving habits.

NOTE: To check for brake binding raise the

vehicle and spin each wheel in turn by hand.

If it is found that one wheel cylinder or

caliper piston is sti cking it is advisable to

overhaul all the wheel cylinders and calipers.

BRAKE FAILURE

(1) Faulty master cylinder: Remove and over-

haul the master cylinder. (2) Loss of fluid due to a leaking wheel cylinder:

Overhaul or renew the wheel cylinders and bleed the

hydraulic system.

(3) Loss of fluid due to a leaking caliper: Over-

haul or renew the caliper assemblies and bleed the

hydraulic system. (4) Loss of fluid due to a fractured pipe or faulty

union: Renew the faulty components as necessary and

bleed the hydraulic system. (5) Air in the hydraulic system: Locate the

source of the air leak, rectify the problem and bleed

the hydraulic system. (6) Water in the hydraulic fluid: Drain, flush,

refill and bleed the hydraulic system.

NOTE: To locate the source of a fluid leak,

fill the master cylinder reservoir with fluid

and check for obvious signs of external

leakage while an assistant pumps the brake

pedal.

Check the brake pipe unions for leaks.

BRAKE NOISE

(1) Brakes squeal on application: Glazed friction

material or missing or da maged disc pad anti-squeal

shims. (2) Grinding noise on application: Friction ma-

terial worn out. Check the friction material and

discs/drums. Renew the brake pads/shoes and ma-

chine or renew the brake discs/drums as necessary.

Inspect the brake discs for scoring and wear.

2. DESCRIPTION

The brakes are operated by hydraulic pressure in

two independent circuits by means of a tandem dual

circuit master cylinder coupled to a brake servo unit

mounted on the bulkhead between the brake pedal

and master cylinder.

The brake circuits are sp lit diagonally. The left

hand front and right hand rear brakes are connected

to the primary circuit, and the right hand front and

left hand rear brakes are connected to the secondary

circuit. Should a malfunction occur in one circuit, the

remaining circuit is capable of stopping the vehicle.

Page 175 of 238

Brakes 175

A pressure proportioning valve is incorporated in

each circuit to prevent premature locking of the rear

wheels during severe braking.

The four wheel hydraulically operated brakes

utilize disc brakes on each front wheel and disc brakes

or leading and trailing drum brake shoes on each rear

wheel.

The front disc brakes comprise a disc attached to

the hub assembly and a caliper bolted to the steering

knuckle.

The rear disc brakes comprise a disc and hub

assembly attached to the rear stub axle and a caliper

and anchor plate bolted to the backing plate.

The front and rear calipers are of the sliding type.

As pad wear takes place, the caliper piston is allowed

to slide outwards through the seal to take up a new

position in the caliper bore. Elastic deformation of the

seal takes place when the brakes are applied, which

returns the piston slightly when the brakes are re-

leased. Thus a constant clearance is maintained

between the pads and the disc when the brakes are in

the off position.

The disc brakes do not require periodical adjust-

ment in service to compensate for pad wear as they

are self adjusting.

The leading and trailing shoe drum brakes on the

rear wheels use a double ended wheel cylinder to

operate both brake shoes at the top. The lower end of

each brake shoe abuts a fixed anchor point. The brake

shoes are automatically adju sted when the brakes are

operated.

The handbrake operates the rear brakes via a

cable arrangement.

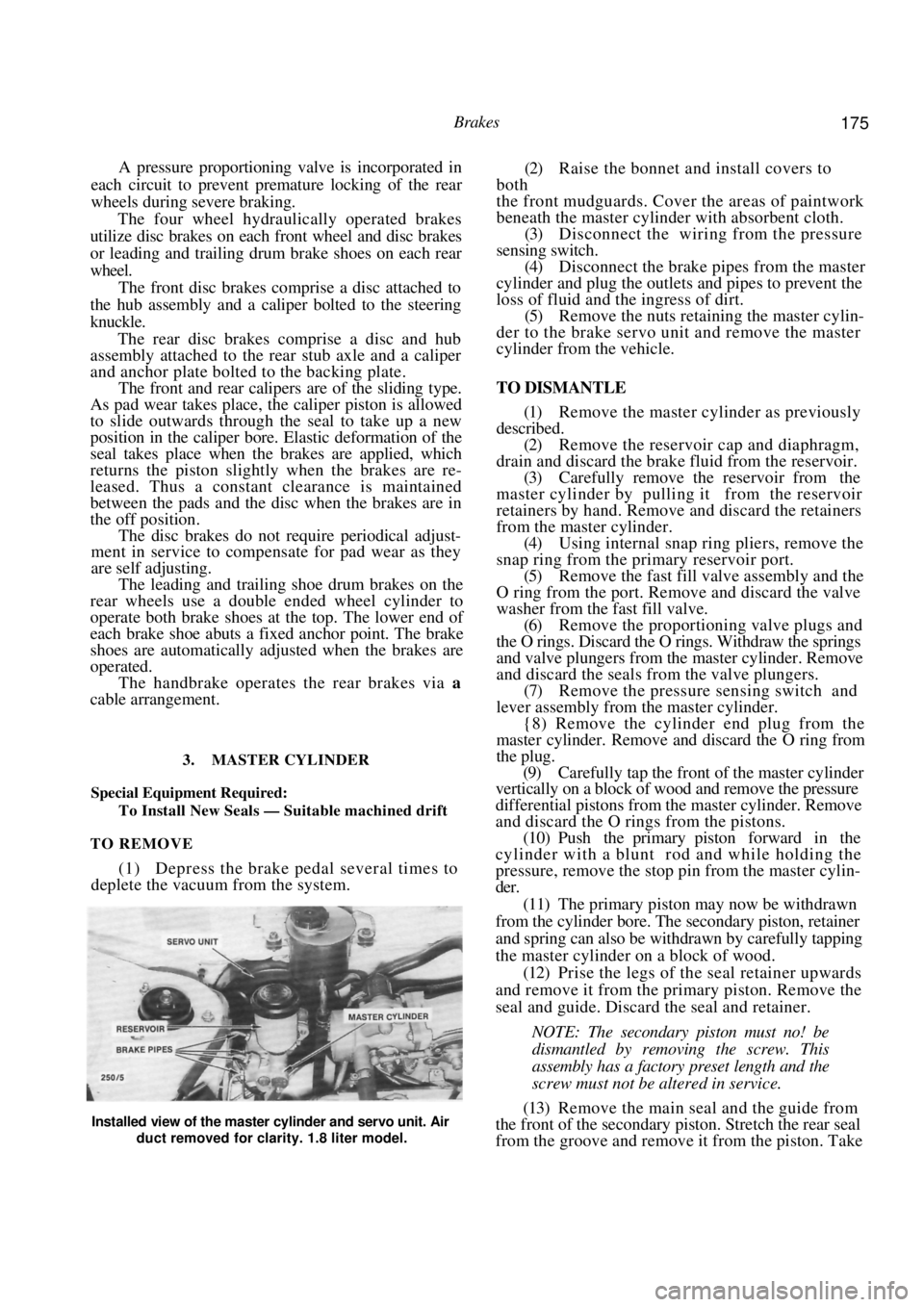

3. MASTER CYLINDER

Special Equipment Required:

To Install New Seals — Suitable machined drift

TO REMOVE

(1) Depress the brake pedal several times to

deplete the vacuum from the system.

(2) Raise the bonnet and install covers to

both

the front mudguards. Cover the areas of paintwork

beneath the master cylinder with absorbent cloth.

(3) Disconnect the wiring from the pressure

sensing switch. (4) Disconnect the brake pipes from the master

cylinder and plug the outlets and pipes to prevent the

loss of fluid and the ingress of dirt.

(5) Remove the nuts retaining the master cylin-

der to the brake servo unit and remove the master

cylinder from the vehicle.

TO DISMANTLE

(1) Remove the master cylinder as previously

described. (2) Remove the reservoir cap and diaphragm,

drain and discard the brake fluid from the reservoir. (3) Carefully remove the reservoir from the

master cylinder by pulling it from the reservoir

retainers by hand. Remove and discard the retainers

from the master cylinder. (4) Using internal snap ring pliers, remove the

snap ring from the primary reservoir port. (5) Remove the fast fill valve assembly and the

O ring from the port. Remove and discard the valve

washer from the fast fill valve.

(6) Remove the proportioning valve plugs and

the O rings. Discard the O rings. Withdraw the springs

and valve plungers from the master cylinder. Remove

and discard the seals from the valve plungers. (7) Remove the pressure sensing switch and

lever assembly from the master cylinder. {8) Remove the cylinder end plug from the

master cylinder. Remove and discard the O ring from

the plug.

(9) Carefully tap the front of the master cylinder

vertically on a block of wo od and remove the pressure

differential pistons from the master cylinder. Remove

and discard the O rings from the pistons. (10) Push the primary piston forward in the

cylinder with a blunt rod and while holding the

pressure, remove the stop pin from the master cylin-

der.

(11) The primary piston may now be withdrawn

from the cylinder bore. The secondary piston, retainer

and spring can also be withdrawn by carefully tapping

the master cylinder on a block of wood. (12) Prise the legs of the seal retainer upwards

and remove it from the primary piston. Remove the

seal and guide. Discard the seal and retainer.

NOTE: The secondary piston must no! be

dismantled by removing the screw. This

assembly has a factory p reset length and the

screw must not be altered in service.

(13) Remove the main seal and the guide from

the front of the secondary piston. Stretch the rear seal

from the groove and remove it from the piston. Take

Installed view of the master cylinder and servo unit. Air

duct removed for clarity. 1.8 liter model.

Page 182 of 238

182 Brakes

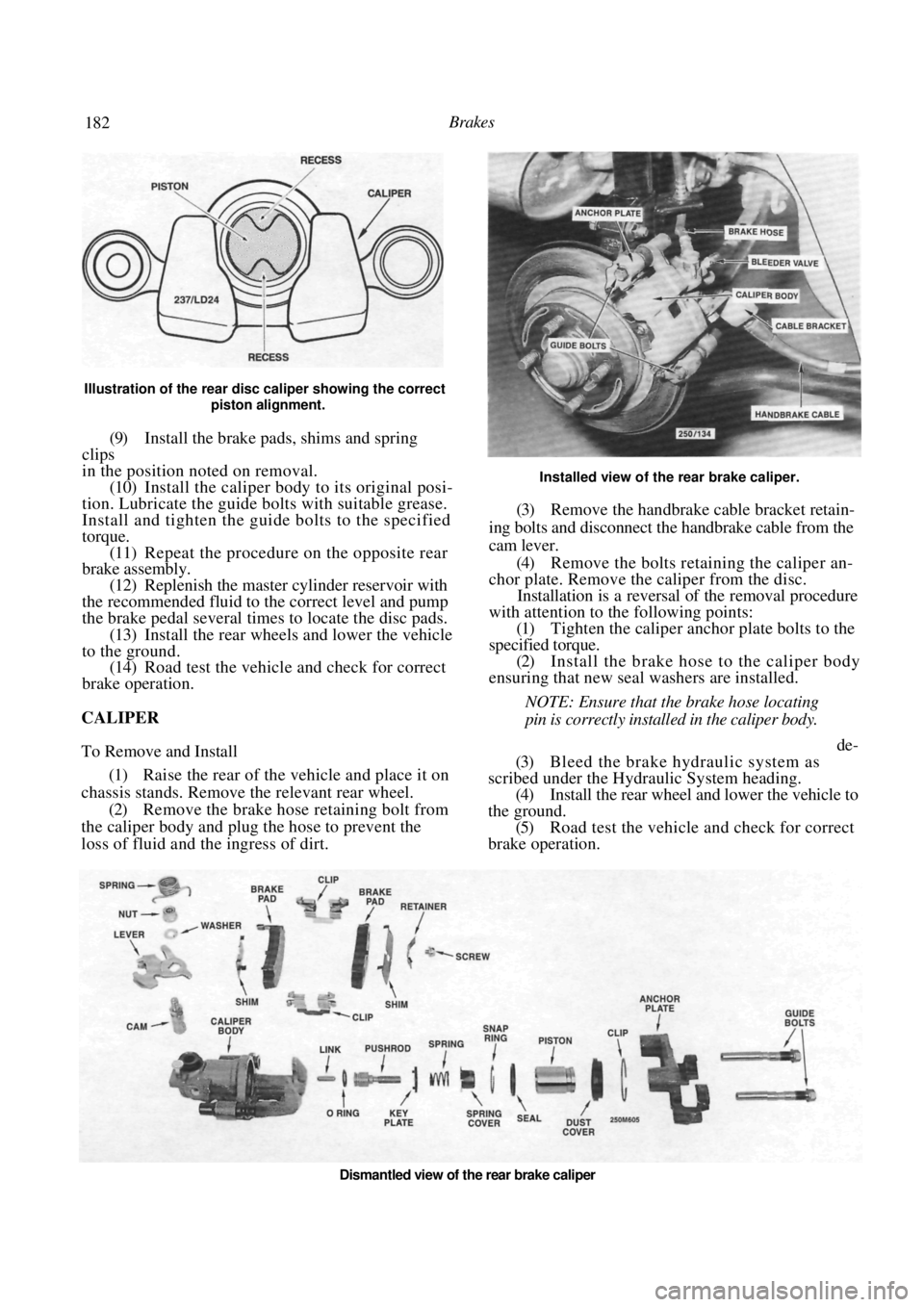

Illustration of the rear disc caliper showing the correct

piston alignment.

(9) Install the brake pads, shims and spring

clips

in the position noted on removal. (10) Install the caliper body to its original posi-

tion. Lubricate the guide bolts with suitable grease.

Install and tighten the guide bolts to the specified

torque. (11) Repeat the procedure on the opposite rear

brake assembly.

(12) Replenish the master cylinder reservoir with

the recommended fluid to the correct level and pump

the brake pedal several times to locate the disc pads. (13) Install the rear wheels and lower the vehicle

to the ground. (14) Road test the vehicle and check for correct

brake operation.

CALIPER

To Remove and Install

(1) Raise the rear of the vehicle and place it on

chassis stands. Remove the relevant rear wheel. (2) Remove the brake hose retaining bolt from

the caliper body and plug the hose to prevent the

loss of fluid and the ingress of dirt.

Installed view of the rear brake caliper.

(3) Remove the handbrake cable bracket retain-

ing bolts and disconnect the handbrake cable from the

cam lever. (4) Remove the bolts retaining the caliper an-

chor plate. Remove the caliper from the disc. Installation is a reversal of the removal procedure

with attention to the following points:

(1) Tighten the caliper anch or plate bolts to the

specified torque. (2) Install the brake hose to the caliper body

ensuring that new seal washers are installed.

NOTE: Ensure that the brake hose locating

pin is correctly installed in the caliper body.

de-

(3) Bleed the brake hydraulic system as

scribed under the Hydraulic System heading. (4) Install the rear wheel and lower the vehicle to

the ground. (5) Road test the vehicle and check for correct

brake operation.

Dismantled view of the rear brake caliper

Page 183 of 238

Brakes 183

To Dismantle

(1) Raise the rear of the vehicle and place it on

chassis stands. Remove the relevant rear wheel.

(2) Remove the brake hose retaining bolt from

the caliper body and plug the hose to prevent the loss

of fluid and the ingress of dirt. (3) Remove the handbrake cable bracket retain-

ing bolt and disconnect the handbrake cable from the

cam lever.

(4) Remove the guide bolts and slide the caliper

body off the pads. (5) Using a pair of long nose pliers with the nose

located in the recesses of the piston, rotate the piston

anticlockwise to remove it from the caliper body.

(6) Remove the dust cover retaining clip and dust

cover. Discard the dust cover. (7) Using a thin blunt probe, preferably made

from wood or plastic, remove and discard the piston

seal from the groove in the caliper bore. (8) Using internal snap ring pliers, remove the

snap ring from the caliper bore. (9) Withdraw the spring cover, spring, key plate,

pushrod and link from the caliper bore. Do not mix

these components from the left and right hand sides as

they differ. (10) Remove and discard the O ring from the

pushrod. (11) Remove the spring, nut and washer from the

cam lever. Remove the cam lever and cam from the

caliper body. (12) Remove the cam seal from the caliper using a

screwdriver.

(13) Clean all the caliper components in methy-

lated spirits and arrange the components in order on a

clean dry surface to aid assembly.

To Inspect

(1) Inspect the caliper bore and piston for pit-

ting, wear or damage. Renew the caliper assembly or

piston if damage is evident.

NOTE: Slight rust spots in the caliper bore

may be removed with fine emery paper. The

piston must not be polished as the plated

surface will be damaged.

(2) Inspect the guide bolts for wear or damage

and renew as necessary.

(3) Inspect the threads of the pushrod for wear or

damage and renew as necessary. (4) Inspect the nut inside the piston for wear,

damage and security. Renew the piston if any damage

is evident. (5) Inspect the cam for wear, damage or pitting,

renew as necessary. (6) Inspect the cam bearing in the caliper body

for wear, damage or pitting and renew the seal and

bearing as necessary. (7) Inspect the guide bolt rubbers for deteriora-

tion, wear or damage. Renew as required. To Assemble

(1)

Lubricate the cam bearing with multipurpose

grease and install the seal. (2) Install the cam and cam lever to the

caliper

body. Install the cam lever spring, washer and nut, and

tighten the nut to the specified torque. (3) Install a new O ring to the pushrod and

install

the link, pushrod, key plate, spring and spring cover to

the caliper body. The key plate must engage the caliper

body. Secure the assembly with the snap ring. (4) Dip a new piston seal in clean hydraulic brake

fluid. Insert the seal into the groove in the caliper bore

ensuring that the seal is correctly seated and not

twisted. (5) Install a new dust cover to the piston prior

to

installing the piston to the caliper bore.

(6) Coat the piston and caliper bore with clean

hydraulic brake fluid and using long nose pliers rotate

the piston clockwise into the caliper bore. (7) Locate the dust seal in the groove of the

caliper body and install the retaining clip.

(8) Lubricate the guide bolts using a suitable

grease. Install the caliper body and tighten the guide

bolts to the specified torque. (9) Replenish the master cylinder reservoir with

the recommended fluid and bleed the brakes as

described under the Hydraulic System heading. (10) Install the rear wheel and lower the vehicle to

the ground. (11) Road test the vehicle and check for correct

brake operation.

BRAKE DISC

To Check Runout

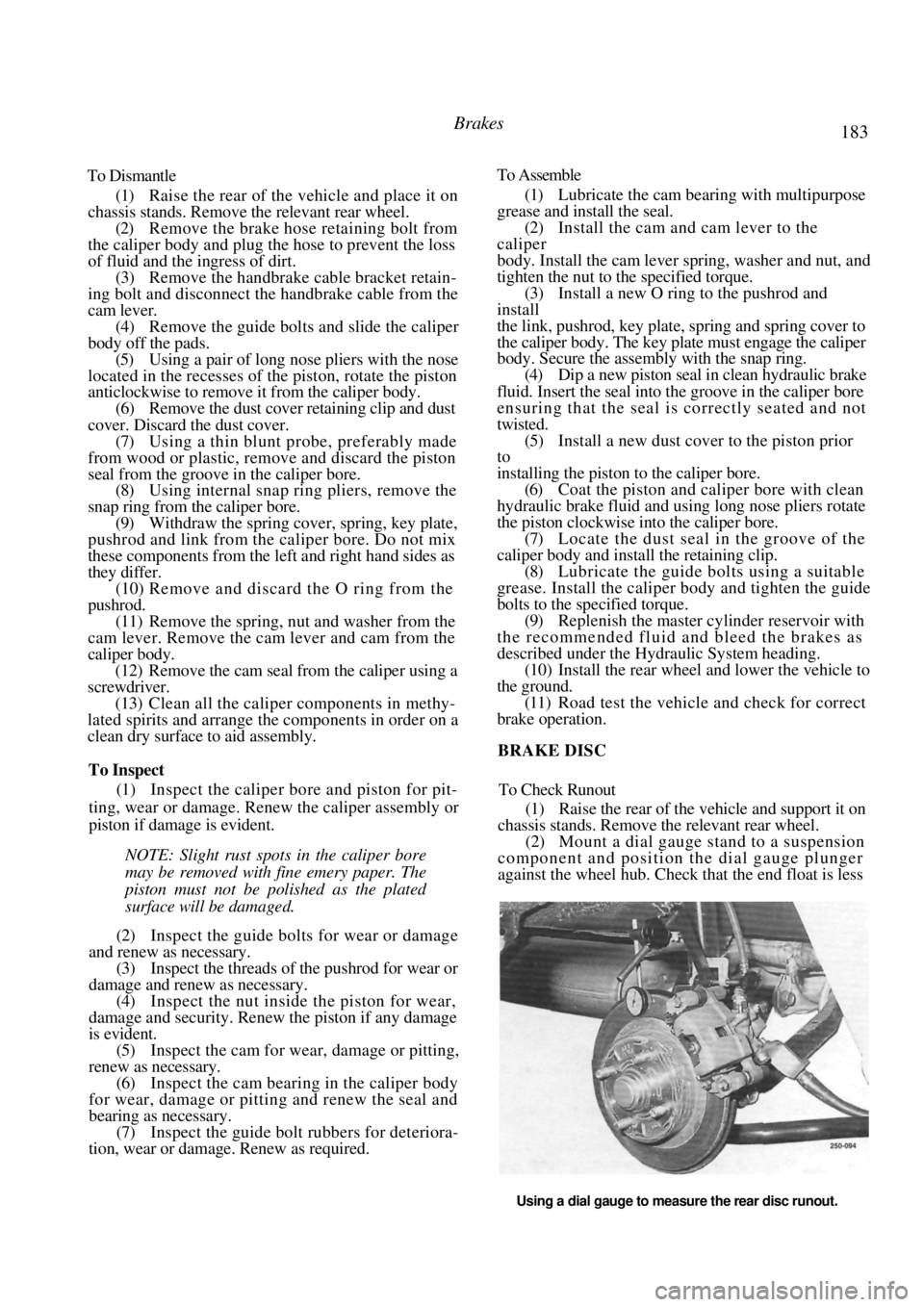

(1) Raise the rear of the vehicle and support it on

chassis stands. Remove the relevant rear wheel.

(2) Mount a dial gauge stand to a suspension

component and position the dial gauge plunger

against the wheel hub. Check that the end float is less

Using a dial gauge to measure the rear disc runout.

Page 184 of 238

184 Brakes

than 0.05 mm. If the wheel hub end float exceeds

Specifications, the bearing must be renewed as de-

scribed in the Rear Suspension section.

(3) Position the dial gauge plunger against the

centre of the brake disc contact area. Rotate the hub

and measure the runout. Ma ximum allowable runout

is 0.07 mm. (4) If the runout exceeds the specified amount,

machine or renew the brake disc. (5) Install the rear wheel and lower the vehicle to

the ground. (6) Road test the vehicle and check for correct

brake operation.

To Remove and Install

(1) Raise the rear of the vehicle and support it

on chassis stands. Remove the relevant rear wheel.

(2) Remove the clip securing the brake hose to

the suspension unit and disengage the hose. (3) Remove the bolts retaining the caliper an-

chor plate. (4) Slide the caliper from the brake disc and

suspend the caliper clear of the work area using wire

or cord.

NOTE: Do not allow the caliper to hang on

the brake hose.

(5) Remove the grease cap from the rear hub.

(6) Remove the split pin, nut retainer, hub nut

and washer from the stub axle. (7) Remove the hub assembly from the stud

axle. Installation is a reversal of the removal procedure

with attention to the following points:

(1) Tighten the rear hub to the specified torque.

(2) Install the brake caliper and tighten all the

bolts to the specified torque. (3) Rotate the hub and check for roughness. If

the hub does not rotate smoothly, renew the hub

bearing as described in the Rear Suspension section. (4) Install the rear wheel and lower the vehicle to

the ground.

(5) Road test the vehicle and check for correct

brake operation.

To Inspect

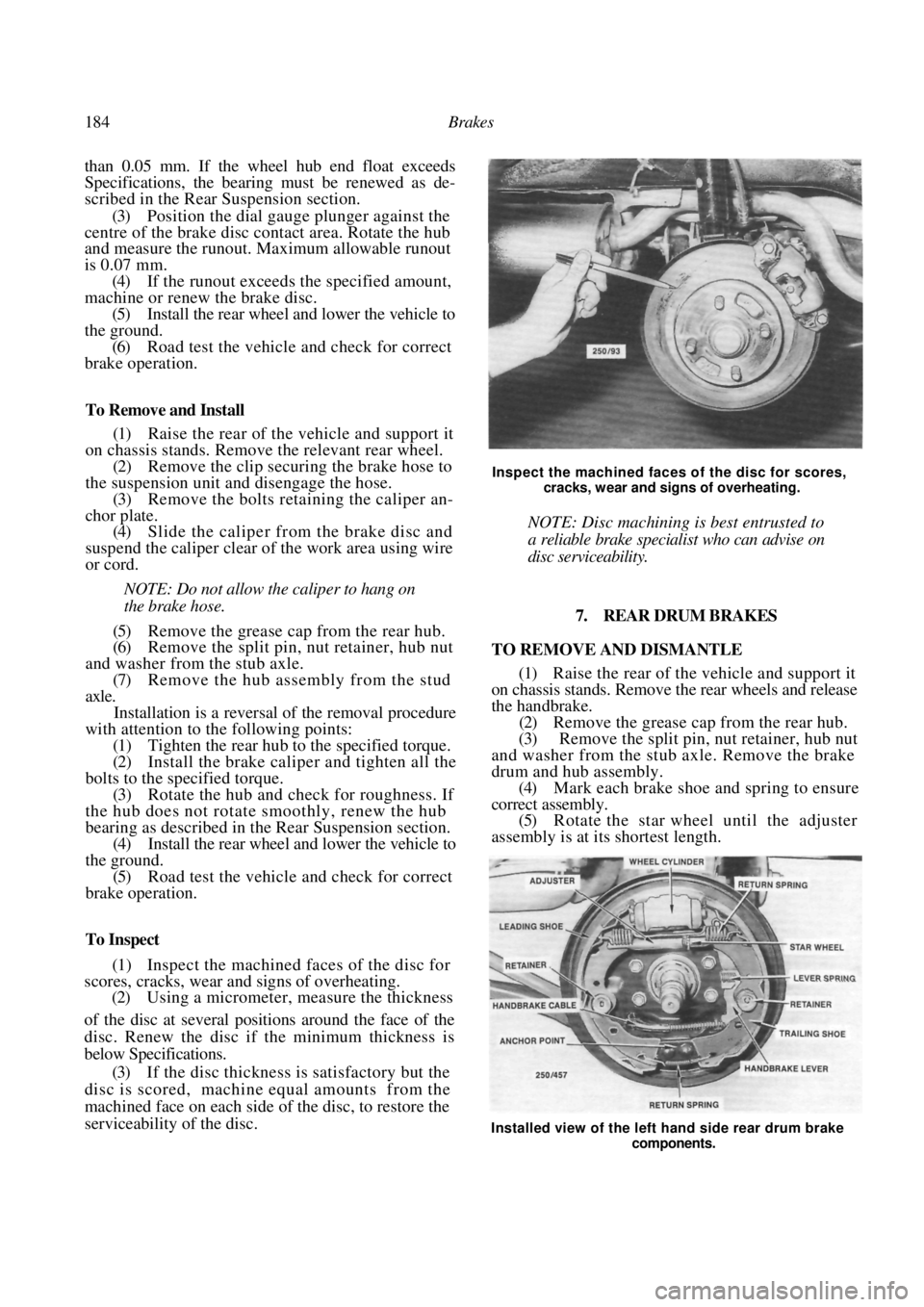

(1) Inspect the machined faces of the disc for

scores, cracks, wear and signs of overheating. (2) Using a micrometer, measure the thickness

of the disc at several posit ions around the face of the

disc. Renew the disc if the minimum thickness is

below Specifications.

(3) If the disc thickness is satisfactory but the

disc is scored, machine equal amounts from the

machined face on each side of the disc, to restore the

serviceability of the disc.

Inspect the machined faces of the disc for scores,

cracks, wear and signs of overheating.

NOTE: Disc machining is best entrusted to

a reliable brake specialist who can advise on

disc serviceability.

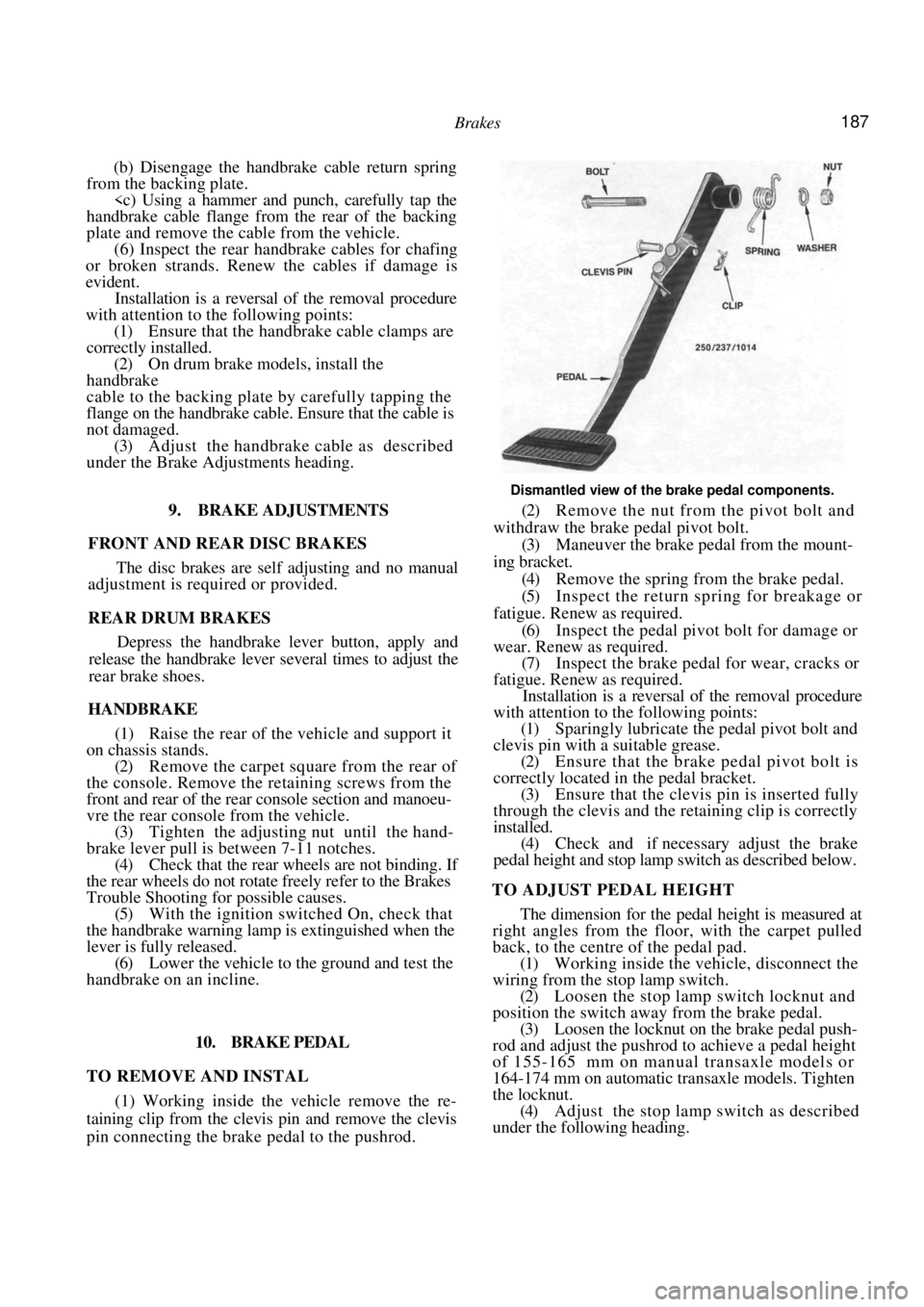

7. REAR DRUM BRAKES

TO REMOVE AND DISMANTLE

(1) Raise the rear of the vehicle and support it

on chassis stands. Remove th e rear wheels and release

the handbrake.

(2) Remove the grease cap from the rear hub.

(3) Remove the split pin, nut retainer, hub nut

and washer from the stub axle. Remove the brake

drum and hub assembly.

(4) Mark each brake shoe and spring to ensure

correct assembly. (5) Rotate the star wheel until the adjuster

assembly is at its shortest length.

Installed view of the left hand side rear drum brake

components.

Page 185 of 238

Brakes 185

(6) Using a suitable pair of pliers, disengage the

upper and lower return springs from the leading shoe,

and then remove them from the trailing shoe. (7) Using a pair of pliers, compress the leading

shoe retainer, turn through ninety degrees and remove

the retainer, spring and pin. Remove the leading shoe

from the backing plate. (8) Using the same procedure, remove the trail-

ing shoe retainer. (9) Lift the trailing shoe from the backing plate

and disconnect the handbrake cable from the hand-

brake lever. Remove the trailing shoe assembly from

the backing plate.

(10) If the brake shoes are to be renewed, remove

the C clip from the trailing shoe and remove the

handbrake lever assembly. (11) If the wheel cylinder is to be overhauled,

proceed as follows:

(a) Disconnect the brake pipe from the rear of

the wheel cylinder and plug the pipe to prevent the

loss of fluid and the ingress of dirt. (b) Remove the bolts retaining the wheel cylin-

der to the backing plate and withdraw the wheel

cylinder from the vehicle. (c) Remove the rubber boots, pistons and spring

from the wheel cylinder bore. Remove the seals from

the pistons. Discard th e rubber boots and seals.

(d) Remove the rubber boot and bleeder valve

from the wheel cylinder.

TO CLEAN AND INSPECT

(1) Thoroughly clean all the brake components,

except the brake shoes in methylated spirits.

(2) Inspect the brake shoe linings. If the thick-

ness of the lining on one or more of the shoes is less

than 1.5 mm thick or contaminated with fluid or

grease, the brake shoes must be renewed as a set. (3) Inspect the wheel cylinder bore and piston

for pitting, wear or damage. Renew the wheel cylinder

assembly if any damage is evident. (4) Check the brake drums for cracks, scoring or

out of round. Renew or machine the brake drums as

necessary.

(5) Inspect the springs and handbrake lever for

fatigue and distortion. Renew as required. (6) Operate the handbrake lever and check for.

smooth operation of the handbrake cable. Renew as

required under the Hand brake Cable and Lever

Assembly heading. (7) Check the bleeder valve for blockage.

(8) Clean and lubricate the adjuster rod.

(9) Clean and inspect the backing plate for

cracks, damage and wear. Renew as required.

TO ASSEMBLE AND INSTAL

(1) If the wheel cylinder was overhauled, pro-

ceed as follows:

(a) Lubricate the pistons and seats with brake

fluid and install the seals on to the pistons so that the

l i p on the seals will be facing towards the centre of the

cylinder.

(b) Install the spring, pistons and rubber boots to

the wheel cylinder ensuring that the rubber boots are

securely located in the cy linder. If necessary, use a

clamp to hold the pistons in the cylinder.

(c) Position the wheel cylinder in the backing

plate and install the brake pi pe to the cylinder. Do not

fully tighten the pipe at this stage. (d) Install the wheel cylinder retaining bolts and

tighten the retaining bolts and brake pipe securely.

Install and tighten the bleeder valve. Install the

valve

boot.

Dismantled view of the right hand rear drum brake

components. Dismantled view of the rear wheel cylinder.

(2) Sparingly lubricate the brake shoe moving

contact surfaces on the backing plate and the adjuster

assembly with a high melting point grease.

(3) If necessary, position the adjusting lever

on

the handbrake lever. (4) If necessary, position the handbrake lever

assembly and washer on the trailing shoe and secure it

with the C clip.

(5) Ensure that the adjuster assembly is adjusted

to its shortest length. (6) Install the adjusting lever return spring to

the

trailing shoe.

Page 186 of 238

186 Brakes

(7) Using a pair of pliers, compress the hand-

brake cable spring and install the cable to the hand-

brake lever.

(8) Position the trailing shoe on the backing

plate with the upper end located on the wheel cylinder

piston and the lower end on the anchor plate. (9) Install the adjuster assembly to the

trailing

shoe ensuring that the adjuster fork is correctly

located on the upper end of the shoe. (10) Install the pin, spring and retainer to the

trailing shoe, turn the reta iner through 90 degrees and

secure the brake shoe to the backing plate. (11) Connect the upper and lower return springs

to the trailing shoe as noted on removal. (12) Position the leading shoe on the backing

plate with the upper end located on the wheel cylinder

piston and the lower end on the anchor plate. Ensure

that the adjuster assembly is correctly located on the

upper end of the shoe. (13) Install the pin, spring and retainer to the

leading shoe, turn the retainer through 90 degrees and

secure the shoe to the backing plate. (14) Connect the upper and lower return springs

to the leading shoe.

(15) By alternatively adjust ing the automatic ad-

juster manually and sliding the brake drum on and off

the brake shoe assembly, adjust the brakes until the

brake drum will just slide over the brake shoes. Ensure

that the adjuster lever contacts the adjuster star wheel.

Install the brake drum and operate the handbrake

several times to adjust the brake shoes. (16) Install the rear wheels and rotate each wheel

to ensure that the brake shoe linings are not dragging.

(17) Bleed the hydraulic system as described

under the Hydraulic System heading. (18) Adjust the handbrake as described under the

Brake Adjustments heading.

8. HANDBRAKE CABLE AND LEVER

ASSEMBLY

HANDBRAKE LEVER AND FRONT CABLE

ASSEMBLY

To Remove and Install

(1) Raise the vehicle and support it on chassis

stands. Release the handbrake.

(2) Working beneath the vehicle, remove the

exhaust pipe centre heat shield retaining bolts and

maneuver the shield from the vehicle. (3) Remove the rear handbrake cable front

clamp retaining nuts and disconnect the rear hand-

brake cable from the equalizer. (4) Working within the vehicle, remove the

carpet square from the rear of the console. Remove

the retaining screw from the front and rear of the rear

console section and maneuver the rear console from

the vehicle.

Dismantled view of the handbrake lever components.

(5) Disconnect the handbrake warning lamp

switch wiring. (6) Remove the handbrake lever assembly re-

taining bolts and remove the handbrake lever and

front cable assembly. (7) If necessary slide the boot and cover towards

the equalizer, straighten the tang on the lower edge of

the lever and remove the adjuster nut and washer.

(8) Withdraw the front cable from the lever and

remove the boot and cover. Inspect the cable for

chafing or broken strands. Renew the cable if damage

is evident. (9) Check the handbrake lever ratchet and pawl

for wear and renew as necessary. Installation is a reversal of the removal procedure

with attention to the following points:

(1) Apply lubricant to all the working parts prior

to installation. (2) Ensure that the handbrake cable clamp is

correctly installed. (3) Adjust the handbrake cable as described

under the Brake Adjustments heading.

REAR HANDBRAKE CABLES

TO Remove and Install

(1) Raise the rear of the vehicle and support it

on chassis stands. Remove th e rear wheels and release

the handbrake.

(2) Working beneath the vehicle, remove the

exhaust pipe centre and rear heat shield retaining

bolts and maneuver the heat shields from the

vehicle.

(3) Remove the bolts and nuts retaining the

handbrake cable clamps to the underbody and discon-

nect the rear handbrake cable from the equalizer.

(4) On disc brake models, remove the handbrake

cable to bracket retaining clip on the rear of the

caliper and disconnect the handbrake cable from the

cam lever. Remove the cable from the vehicle.

(5) On drum brake models , proceed as follows:

(a) Remove and dismantle the rear brakes as

previously described.

Page 187 of 238

Brakes 187

(b) Disengage the handbrake cable return spring

from the backing plate.

plate and remove the cable from the vehicle.

(6) Inspect the rear handbrake cables for chafing

or broken strands. Renew the cables if damage is

evident.

Installation is a reversal of the removal procedure

with attention to the following points:

(1) Ensure that the handbrake cable clamps are

correctly installed. (2) On drum brake models, install the

handbrake

cable to the backing plate by carefully tapping the

flange on the handbrake cable. Ensure that the cable is

not damaged. (3) Adjust the handbrake cable as described

under the Brake Adjustments heading.

9. BRAKE ADJUSTMENTS

FRONT AND REAR DISC BRAKES

The disc brakes are self adjusting and no manual

adjustment is required or provided.

REAR DRUM BRAKES

Depress the handbrake lever button, apply and

release the handbrake lever several times to adjust the

rear brake shoes.

HANDBRAKE

(1) Raise the rear of the vehicle and support it

on chassis stands. (2) Remove the carpet square from the rear of

the console. Remove the retaining screws from the

front and rear of the rear console section and manoeu-

vre the rear console from the vehicle. (3) Tighten the adjusting nut until the hand-

brake lever pull is between 7-11 notches. (4) Check that the rear wheels are not binding. If

the rear wheels do not rotate freely refer to the Brakes

Trouble Shooting for possible causes.

(5) With the ignition switched On, check that

the handbrake warning lamp is extinguished when the

lever is fully released. (6) Lower the vehicle to the ground and test the

handbrake on an incline.

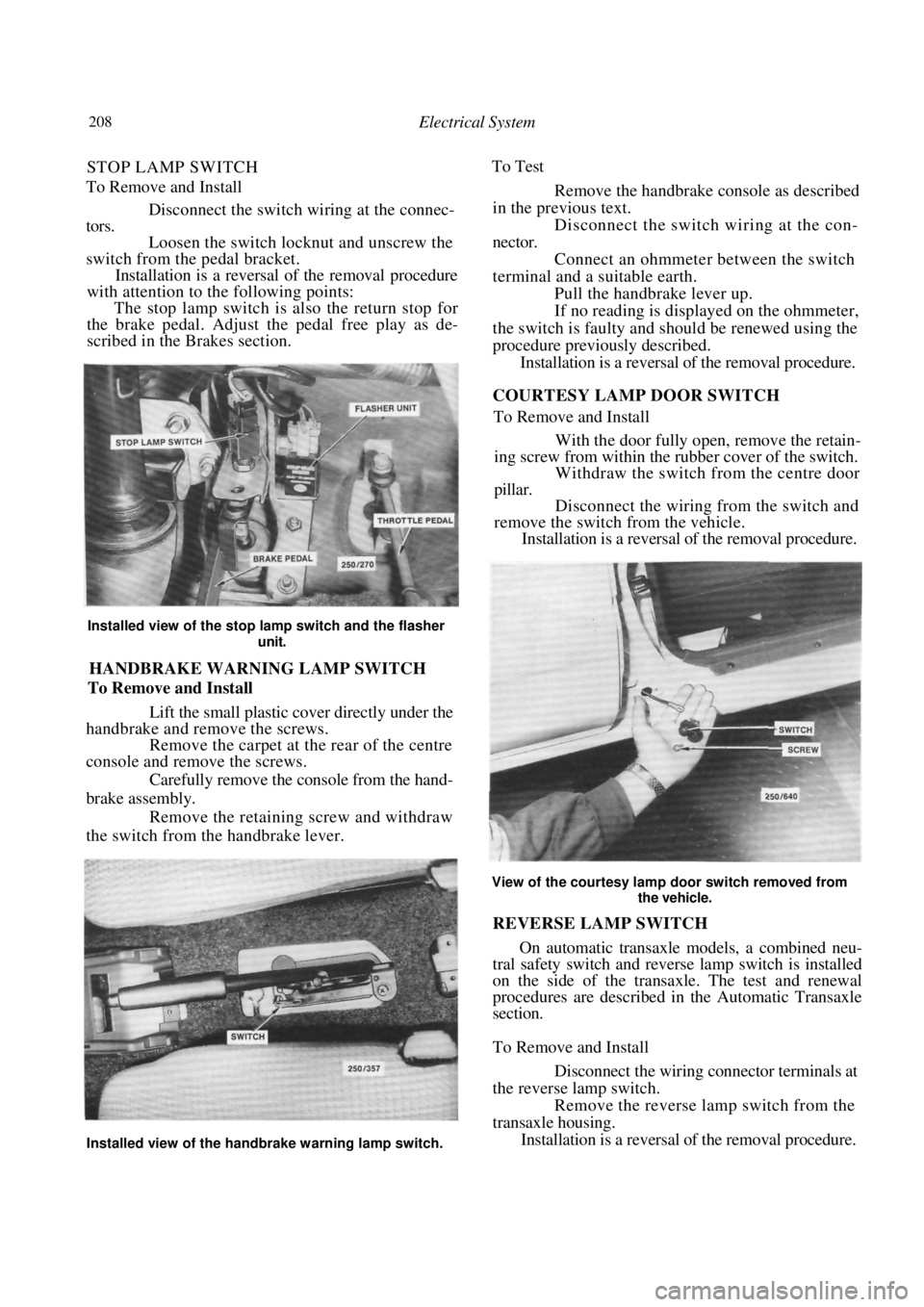

10. BRAKE PEDAL

TO REMOVE AND INSTAL

(1) Working inside the vehicle remove the re-

taining clip from the clevis pin and remove the clevis

pin connecting the brake pedal to the pushrod.

Dismantled view of the brake pedal components.

(2) Remove the nut from the pivot bolt and

withdraw the brake pedal pivot bolt.

(3) Maneuver the brake pedal from the mount-

ing bracket. (4) Remove the spring from the brake pedal.

(5) Inspect the return spring for breakage or

fatigue. Renew as required.

(6) Inspect the pedal pivot bolt for damage or

wear. Renew as required. (7) Inspect the brake pedal for wear, cracks or

fatigue. Renew as required. Installation is a reversal of the removal procedure

with attention to the following points:

(1) Sparingly lubricate the pedal pivot bolt and

clevis pin with a suitable grease. (2) Ensure that the brake pedal pivot bolt is

correctly located in the pedal bracket. (3) Ensure that the clevis pin is inserted fully

through the clevis and the retaining clip is correctly

installed. (4) Check and if necessary adjust the brake

pedal height and stop lamp switch as described below.

TO ADJUST PEDAL HEIGHT

The dimension for the pedal height is measured at

right angles from the floor, with the carpet pulled

back, to the centre of the pedal pad.

(1) Working inside the ve hicle, disconnect the

wiring from the stop lamp switch.

(2) Loosen the stop lamp switch locknut and

position the switch away from the brake pedal. (3) Loosen the locknut on the brake pedal push-

rod and adjust the pushrod to achieve a pedal height

of 155-165 mm on manual transaxle models or

164-174 mm on automatic transaxle models. Tighten

the locknut. (4) Adjust the stop lamp switch as described

under the following heading.

Page 208 of 238

208 Electrical System

STOP LAMP SWITCH

To Remove and Install

Disconnect the switch wi ring at the connec-

tors.

Loosen the switch locknut and unscrew the

switch from the pedal bracket.

Installation is a reversal of the removal procedure

with attention to the following points:

The stop lamp switch is also the return stop for

the brake pedal. Adjust the pedal free play as de-

scribed in the Brakes section.

Installed view of the stop lamp switch and the flasher

unit.

HANDBRAKE WARNING LAMP SWITCH

To Remove and Install

Lift the small plastic cover directly under the

handbrake and remove the screws.

Remove the carpet at the rear of the centre

console and remove the screws.

Carefully remove the console from the hand-

brake assembly. Remove the retaining screw and withdraw

the switch from the handbrake lever. To Test

Remove the handbrake console as described

in the previous text.

Disconnect the switch wiring at the con-

nector. Connect an ohmmeter between the switch

terminal and a suitable earth. Pull the handbrake lever up.

If no reading is displayed on the ohmmeter,

the switch is faulty and should be renewed using the

procedure previously described. Installation is a reversal of the removal procedure.

COURTESY LAMP DOOR SWITCH

To Remove and Install

With the door fully open, remove the retain-

ing screw from within the rubber cover of the switch. Withdraw the switch from the centre door

pillar.

Disconnect the wiring from the switch and

remove the switch from the vehicle. Installation is a reversal of the removal procedure.

View of the courtesy lamp door switch removed from

the vehicle.

REVERSE LAMP SWITCH

On automatic transaxle models, a combined neu-

tral safety switch and reverse lamp switch is installed

on the side of the transaxle. The test and renewal

procedures are described in the Automatic Transaxle

section.

To Remove and Install

Disconnect the wiring connector terminals at

the reverse lamp switch. Remove the reverse lamp switch from the

transaxle housing. Installation is a reversal of the removal procedure.

Installed view of the handbrake warning lamp switch.