maintenance NISSAN PULSAR 1987 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1987, Model line: PULSAR, Model: NISSAN PULSAR 1987Pages: 238, PDF Size: 28.91 MB

Page 20 of 238

20 Lubrication and Maintenance

This Section Removed

Page 23 of 238

Wheels and Tires 23

(3) Excessive play in the front suspension ball

joints: Check and renew the ball joints.

(4) Excessive play in the hub bearing assembly:

Check and renew the hub bearing assembly.

WORN SPOTS ON CENTRE OF TREAD

(1) Static unbalance of the wheel and tire asem-

bly: Check the balance of the wheel and tire assembly

(2) Radial run out (eccentricity) of the wheel:

Check and renew the wheel.

FEATHERED EDGES ON TREAD PATTERN

(1) Excessive speed when cornering: Revise driv-

ing habits. (2) Excessive toe-in or toe-out: Check and adjust

the wheel alignment.

(3) Bent, loose or worn suspension components:

Check and renew any faulty components.

NOTE: To preserve tire life it is good policy

to periodically have the front wheel balanced

and the steering geometry checked on a

reliable wheel alignment machine.

Under no circumstances mix radial ply

and conventional ply tire s. Install only tires

of the same construction to all four wheels.

3. CARE AND MAINTENANCE

STEEL WHEELS

Steel wheels should be regularly cleaned of all

foreign matter, such as dirt and mud. If foreign matter

is allowed to build up it will affect the balance of the

wheel and may cause vibrations and uneven tire wear.

If the paint has been chipped or scratched it should be

touched up as soon as possible to prevent rust.

Any minor damage to the wheel rim can usually

be repaired using a suitable hammer after the wheel

has been removed from the vehicle. However, any

major rim damage or buckling of the wheel will

necessitate the renewal of the wheel. It is good policy

to occasionally remove the wheels from the vehicle

and inspect them for damage, cracks or corrosion.

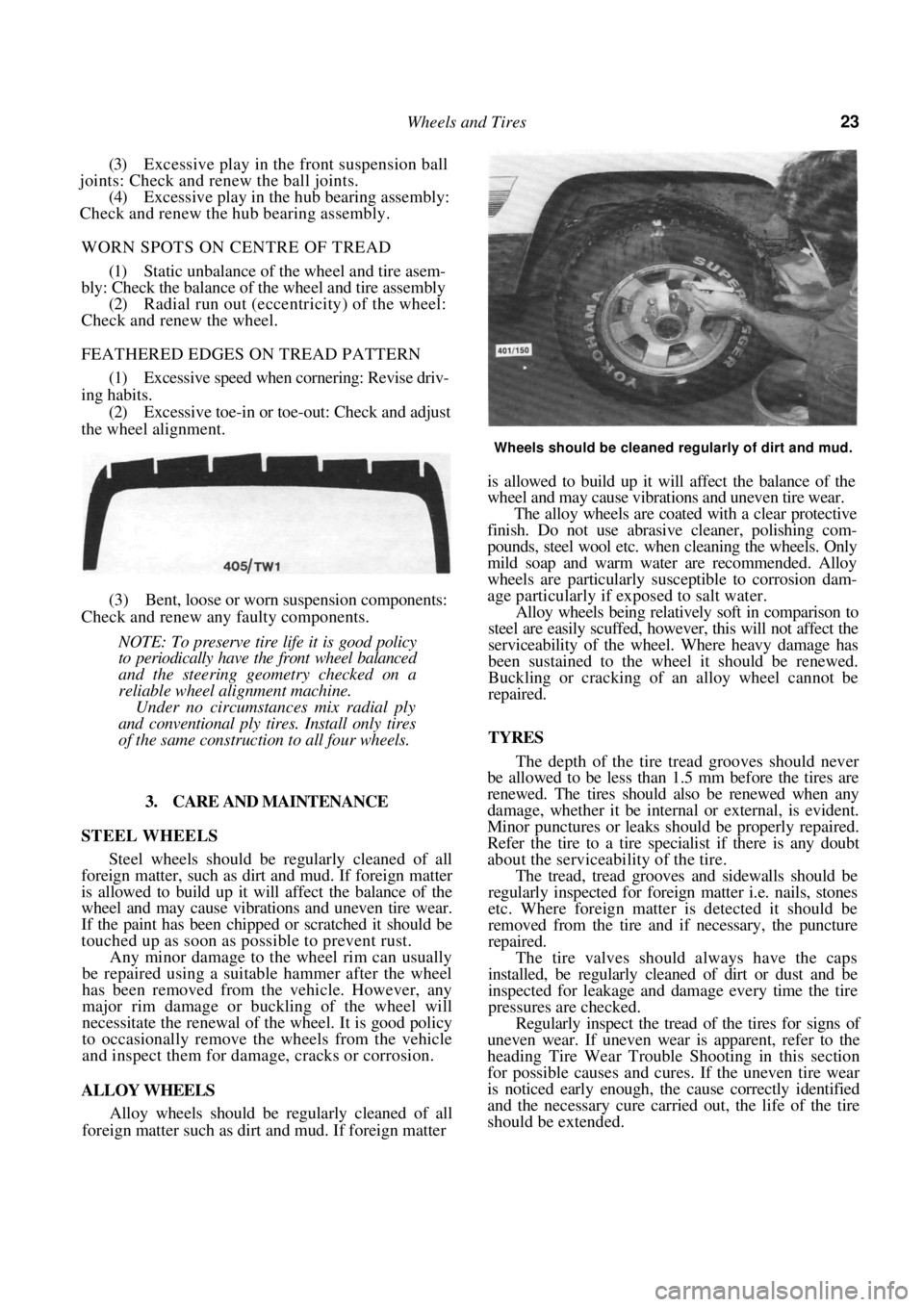

ALLOY WHEELS

Alloy wheels should be regularly cleaned of all

foreign matter such as dirt and mud. If foreign matter

Wheels should be cleaned regularly of dirt and mud.

is allowed to build up it will affect the balance of the

wheel and may cause vibrations and uneven tire wear.

The alloy wheels are coated with a clear protective

finish. Do not use abrasive cleaner, polishing com-

pounds, steel wool etc. when cleaning the wheels. Only

mild soap and warm wate r are recommended. Alloy

wheels are particularly su sceptible to corrosion dam-

age particularly if exposed to salt water.

Alloy wheels being relatively soft in comparison to

steel are easily scuffed, however, this will not affect the

serviceability of the wheel. Where heavy damage has

been sustained to the wheel it should be renewed.

Buckling or cracking of an alloy wheel cannot be

repaired.

TYRES

The depth of the tire tread grooves should never

be allowed to be less than 1.5 mm before the tires are

renewed. The tires should also be renewed when any

damage, whether it be internal or external, is evident.

Minor punctures or leaks s hould be properly repaired.

Refer the tire to a tire spec ialist if there is any doubt

about the serviceability of the tire.

The tread, tread grooves and sidewalls should be

regularly inspected for foreign matter i.e. nails, stones

etc. Where foreign matter is detected it should be

removed from the tire and if necessary, the puncture

repaired.

The tire valves should always have the caps

installed, be regularly cleaned of dirt or dust and be

inspected for leakage and damage every time the tire

pressures are checked.

Regularly inspect the tread of the tires for signs of

uneven wear. If uneven wear is apparent, refer to the

heading Tire Wear Trouble Shooting in this section

for possible causes and cures. If the uneven tire wear

is noticed early enough, the cause correctly identified

and the necessary cure carried out, the life of the tire

should be extended.

Page 29 of 238

Engine Tune-up 29

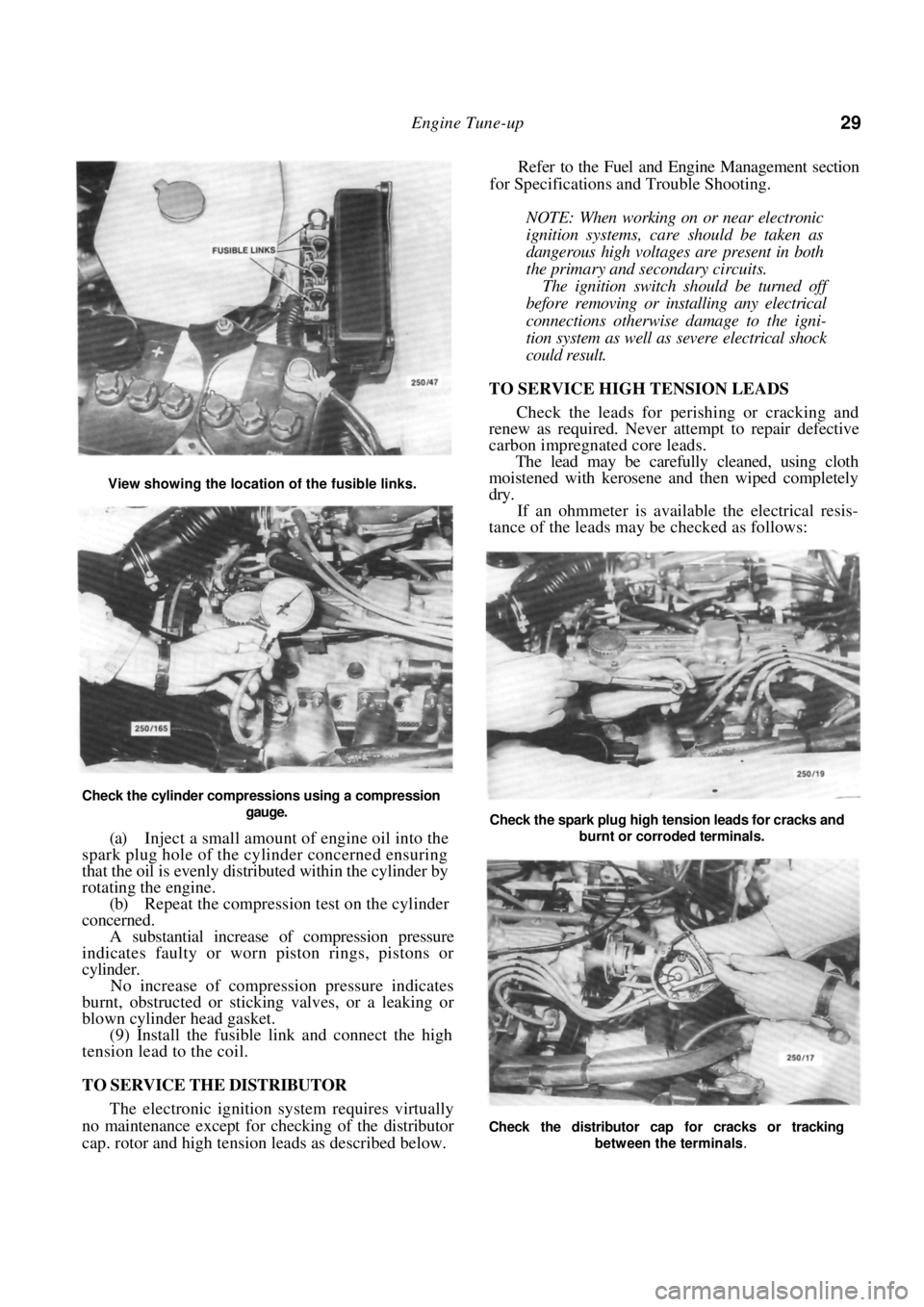

Check the cylinder compressions using a compression gauge.

(a) Inject a small amount of engine oil into the

spark plug hole of the cylinder concerned ensuring

that the oil is evenly distributed within the cylinder by

rotating the engine.

(b) Repeat the compression test on the cylinder

concerned.

A substantial increase of compression pressure

indicates faulty or worn piston rings, pistons or

cylinder.

No increase of compression pressure indicates

burnt, obstructed or sticking valves, or a leaking or

blown cylinder head gasket.

(9) Install the fusible li nk and connect the high

tension lead to the coil.

TO SERVICE THE DISTRIBUTOR

The electronic ignition system requires virtually

no maintenance except for checking of the distributor

cap. rotor and high tension leads as described below.

Refer to the Fuel and Engine Management section

for Specifications and Trouble Shooting.

NOTE: When working on or near electronic

ignition systems, care should be taken as

dangerous high voltages are present in both

the primary and secondary circuits.

The ignition switch should be turned off

before removing or inst alling any electrical

connections otherwise damage to the igni-

tion system as well as severe electrical shock

could result.

TO SERVICE HIGH TENSION LEADS

Check the leads for perishing or cracking and

renew as required. Never a ttempt to repair defective

carbon impregnated core leads.

The lead may be carefully cleaned, using cloth

moistened with kerosene a nd then wiped completely

dry.

If an ohmmeter is available the electrical resis-

tance of the leads may be checked as follows:

View showing the location of the fusible links.

Check the spark plug high tension leads for cracks and

burnt or corroded terminals.

Check the distributor cap for cracks or tracking

between the terminals

.

Page 54 of 238

54 Engine

in the valve stem groove before releasing the spring

compressor. A sharp tap to the top of the valve stem

with a soft faced hammer will ensure that the collets

are correctly seated.

(7) Install the inlet and exhaust manifolds using

new gaskets and tighten the mounting nuts to the

specified torque as previously described. (8) Install a new sealing ring to the

thermostat

housing, install the housing to the cylinder head and

tighten the mounting bolts to the specified torque.

(9) Ensure that the lappet assemblies are filled

with clean engine oil and install the tappets in

their

respective bores in the cylinder head. (10) Install the thrust pads to the top of each

valve

assembly, ensuring that they are returned to their

original locations. (11) Coat the contact surfaces of the rocker arms

with molybdenum disulphide grease and install the

rocker arms to their origin al locations on the cylinder

head. (12) Install the cylinder head to the engine as

previously described.

8. ENGINE SUMP AND OIL PUMP PICKUP . PIPE

TO REMOVE

(1) Disconnect the negative battery terminal.

(2) Raise the front of the vehicle and support it

on chassis stands. Refer to the Wheels and Tires

section for the correct procedure.

(3) Remove the sump plug and drain the engine

oil into a container. Install and tighten the plug

after the oil has been drained.

(4)

Remove the engine pipe as described at the

end of this section.

(5) Remove the nuts and bolts retaining the

engine crossmember to the vehicle underbody and

withdraw the crossmember from the vehicle. On

automatic transaxle models, it will be necessary to

release the selector cable from the crossmember

bracket.

(6) Remove the sump retaining bolts and wash-

ers and if necessary firmly bump the sump with the

palm of the hand and remove it from the engine. (7) Remove the bolts retaining the oil pump

pickup pipe to the oil pump and disconnect the

pickup pipe from the support bracket. Remove the

pickup pipe and discard the O ring seal. (8) Remove the scraper and gasket from the

engine. (9) Clean the gasket material from the sump,

engine block and the scraper.

NOTE: If the scraper assembly is damaged

it should be renewed.

TO INSTAL

(1) Wash the inside of the sump to remove

carbon and sludge deposits. Check for any metal

deposits which may indicate an imminent component

failure. (2) Inspect the sump for dents and cracks.

Ensure that the gasket sea ling face is not distorted or

damaged. (3) Clean the pickup pipe screen with solvent

and a brush. (4) Using a new O ring seal, install the pickup

pipe. Coat the pipe retain ing bolts with Loctite 242

and tighten to the specified torque. (5) Apply a bead of KP510-00150 sealer or

equivalent to the oil pump to cylinder block mating

joint area. (6) Ensure that the sump gasket is correctly

located on the scraper and install the sump to

the

engine. Apply Loctite 242 to the threads of the sump

bolts and tighten the bolts to the specified torque.

(7) Install the front exhaust pipe using a

new

gasket and coat the threads of the flange nuts with an

anti-seize compound before tightening the nuts to the

specified torque. (8) Install the engine crossmember and

tighten

the nuts and bolts securely. If applicable, connect the

automatic transaxle selector cable to the crossmember

bracket. (9) Ensure that the sump drain plug is secure

and lower the vehicle to the ground. (10) Fill the engine with the specified amount and

grade of engine oil. Refer to the Lubrication and

Maintenance section if necessary. (11) Start and run the engine and check for oil

leaks.

View of the sump, oil pump pickup, gasket and scraper

removed from the engine.

Page 81 of 238

Cooling and Heating Systems 81

continuous stream of bubbles indicates that the refriger-

ant charge is low.

A large number of bubbles or foam indicates that

the refrigerant charge is very low.

No bubbles or the presen ce of oil streaks in the

sight glass indicate that the system is completely

empty.

NOTE: If the outside air temperature is

high, a certain number of bubbles may be

observed in the sight gl ass, even though the

system is fully charged.

If the system requires recharging, the vehicle

should be taken to an authorized dealer for evacu-

ation, leak testing and recharging.

Do not operate the system if it is known that the

refrigerant charge is low as damage may result.

MAINTENANCE

The air conditioning system requires l i t t l e main-

tenance other than the following. Where applicable,

refer to the Lubrication an d Maintenance section for

the recommended service intervals.

(1) Check the refrigerant charge level in the

receiver/dryer sight glass. Recharge the system as

necessary. It is considered normal for the system to

require periodic recharging. (2) Inspect the air conditioner pipes and hoses

for leaks, deterioration and alignment. Evidence of oil

leakage is an indication of refrigerant leakage. Repair

or renew as necessary.

(3) Inspect the evaporator drain tube and the

condenser cooling fins for blockage. Clean as neces-

sary.

(4) Check the drive belt for deterioration and for

correct tension. Refer to the Engine Tune-up section

for the correct procedure.

(5) Operate the system at least once a week for

approximately 15 minutes to keep the compressor

seals lubricated.

Page 117 of 238

117

EMISSION CONTROL

INTRODUCTION

To reduce the output level of the three primary

automotive emissions, carbon monoxide (CO), hydro-

carbons (HC) and oxides of nitrogen (NOx), and thus

comply with legislation on the maintenance of clean

air, several different emissi on control systems are used

in the Pulsar range of vehicles covered by this manual.

The systems will be discussed under the headings

( 1 ) Crankcase Ventilation System, (2) Evaporative

Control System, (3) Air Preheat System — 1.6 Liter

Engine and (4) Exhaust Control System.

1. CRANKCASE VENTILATION SYSTEM

DESCRIPTION

The crankcase ventilation system is of the closed

type and is designed to prevent crankcase vapors

being emitted into the atmosphere. Crankcase

vapors are caused by gases escaping past the piston

rings into the crankcase during the combustion pro-

cess.

The crankcase vapors are collected in the cam-

shaft housing from the cra nkcase via the various oil

drain passages and the pipe from the side of the

crankcase.

The crankcase vapors are then drawn into the

engine via a branched hose connected to the camshaft

housing oil baffle and the throttle body (1.8 liter

engines) or inlet manifold (1.6 liter engines).

At idle speed, vapors are drawn through the

small branch of the hose and into the engine.

As the engine speed increases, vapors are also

drawn into the engine via the main hose.

TO SERVICE THE SYSTEM

(1) At intervals of 40 000 km, disconnect the

small engine ventilation hose from the throttle body

or inlet manifold and check that the metering orifice

is not blocked.

If necessary, clean the orifice using compressed air

and solvent.

(2) Disconnect all the engine ventilation hoses

and check for blocking, collapsing and deterioration.

Renew the hoses as necessary.

2. EVAPORATIVE CONTROL SYSTEM

Special Equipment Required:

To Test Purge Valve — Hand vacuum pump

DESCRIPTION

The evaporative control system reduces the

amount of hydrocarbons emitted to the atmosphere

through fuel evaporation.

The vehicles covered by this manual use an

absorption regeneration system to reduce vapor loss.

The system utilizes a canister of activated charcoal to

trap and hold the fuel vapors until they can be fed

into the induction system for burning in the combus-

tion chambers.

The basic components of the evaporative control

system are a fuel tank with a sealed filler cap, a

charcoal canister with a pur ge control valve, a fuel

check valve and pipes a nd hoses to connect the

various components.

NOTE: The fuel tank filler cap is not vented

to the atmosphere but is equipped with a one

way relief valve to prevent a vacuum form-

ing in the fuel tank.

View of the engine ventilation hoses and pipe. 1.8 liter

engine.

Page 120 of 238

120 Emission Control

If the flap does not operate as described, renew

the air cleaner housing.

(2) Disconnect the vacuum hose from the servo

unit and connect it to a vacuum gauge.

(3) Start and run the engine at approximately

1 200 rpm. If the engine is cold there should be

vacuum. (4) As the engine temperature increases the

vacuum should decrease to zero. If the vacuum gauge does not read as described,

check that the vacuum supply hose is connected to the

thermal vacuum valve and the throttle body.

If no fault is found, renew the thermal vacuum

valve.

4. EXHAUST CONTROL SYSTEM

DESCRIPTION

The exhaust system is the greatest source of

pollutant emission from the internal combustion

engine.

On the Pulsar range of vehicles covered by this

manual, the exhaust control system consists of a

catalytic converter and the engine management sys-

tem. The engine management system constantly mon-

itors the exhaust gases via an oxygen sensor located in

the exhaust system. Fuel injection is then adjusted

accordingly to give the minimum amount of exhaust

emissions. Refer to the Fuel and Engine Management

section for further information.

CATALYTIC CONVERTER

The catalytic converter, which is located in the

exhaust system, converts hydrocarbons, oxides of

nitrogen and carbon monoxide present in the exhaust

gases into carbon dioxide, nitrogen, water and heat.

The catalytic converter does not require periodic

maintenance or replacement under normal circum-

stances. However, it can be damaged or poisoned by

excessively high exhaust gas temperatures, raw fuel

and the use of leaded fuel.

Installed view of the catalytic converter.

To prevent the use of leaded fuel, a small diam-

eter fuel filler neck with a spring loaded trap door is

used.

To prevent damage to the catalytic converter, the

following precautions sh ould be observed.

(1) Do not operate the vehicle on leaded fuel.

(2) Do not push or tow start the vehicle.

(3) Do not allow the engine to idle for prolonged

periods. (4) Do not operate the vehicle if the engine is

misfiring.

(5) Avoid running the vehicle out of fuel.

(6) Ensure that the engine oil is formulated to

contain low phosphorous levels.

To Inspect Catalytic Converter

(1) Inspect the converter for dents and damage.

If the converter is damaged, it should be renewed. (2) Inspect the converter heat shield for damage

and ensure that it is positioned correctly. Renew the

converter heat shield if necessary.

To Remove and Install

To remove and install the catalytic converter,

refer

to the Exhaust System heading in the Engine section.

Page 142 of 238

142 Automatic Transaxle

(8) Install the dipstick and start the engine and

recheck the fluid level.

NOTE; Do not overfill the transaxle or

foaming and unsatisfactory operation of the

transaxle will result.

TO DRAIN AND REFILL

This is not a normal maintenance and lubrication

procedure. It is only necessary to drain the complete

system, including the torq ue converter and the oil

cooler, when the transaxle assembly is removed for

overhaul or the renewal of transaxle components such

as bearings, clutches or as semblies. When this condi-

tion arises, the torque converter and the cooler should

be cleaned and flushed to remove any dirt or sludge.

After transaxle overhaul, install approximately 6

liters of new transaxle fluid, and top up as previously

described.

4. BRAKE BAND

Band adjustment is not a normal maintenance

procedure.

The adjustment entails removal of the valve body

and for this reason the vehicle should be taken to an

authorized dealer.

5. KICKDOWN CABLE

TO ADJUST

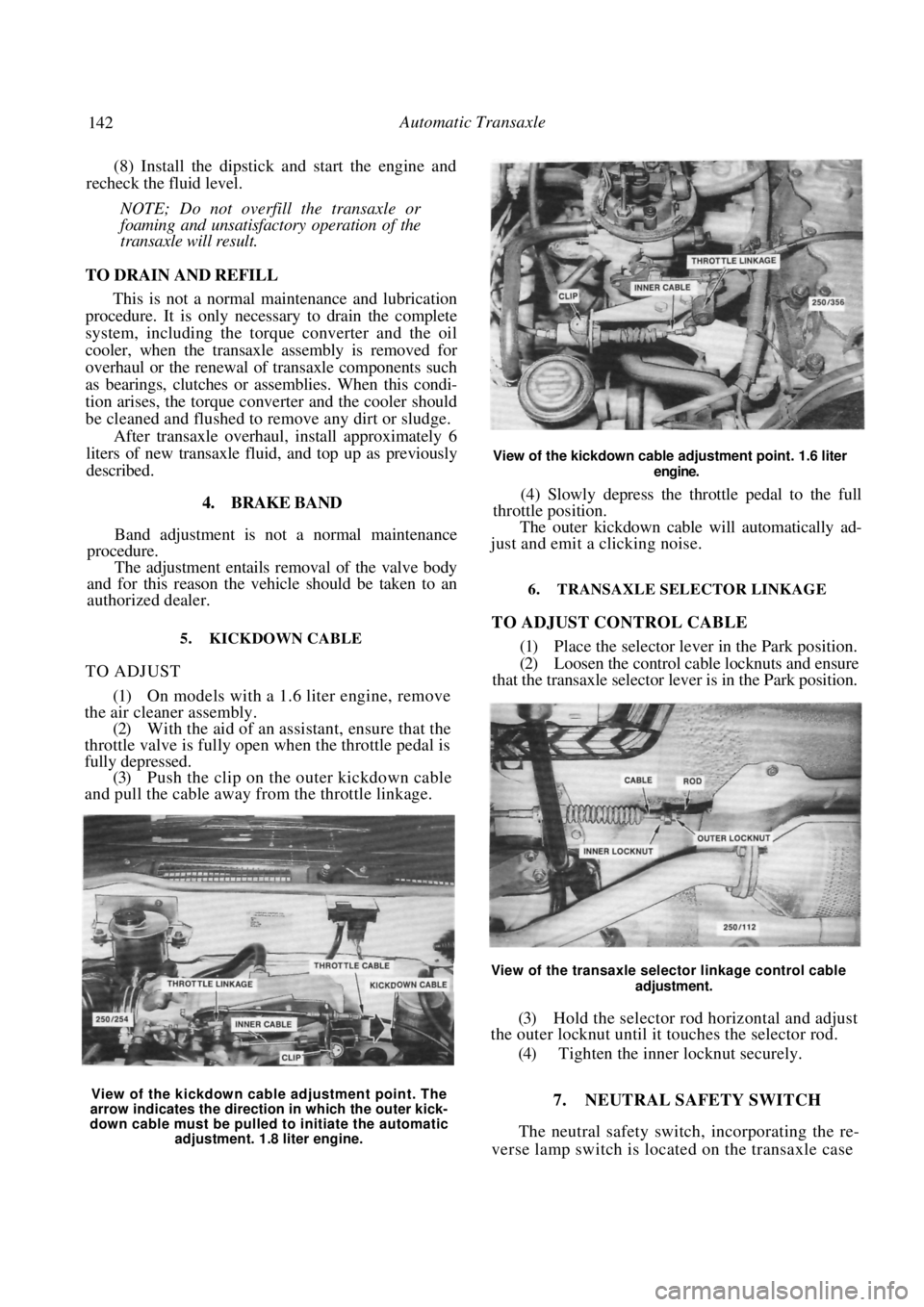

(1) On models with a 1.6 liter engine, remove

the air cleaner assembly. (2) With the aid of an assistant, ensure that the

throttle valve is fully open when the throttle pedal is

fully depressed. (3) Push the clip on the outer kickdown cable

and pull the cable away from the throttle linkage.

View of the kickdown cable adjustment point. 1.6 liter

engine.

(4) Slowly depress the throttle pedal to the full

throttle position.

The outer kickdown cable will automatically ad-

just and emit a clicking noise.

6. TRANSAXLE SELECTOR LINKAGE

TO ADJUST CONTROL CABLE

(1) Place the selector lever in the Park position.

(2) Loosen the control cable locknuts and ensure

that the transaxle selector lever is in the Park position.

View of the transaxle selector linkage control cable

adjustment.

(3) Hold the selector rod horizontal and adjust

the outer locknut until it touches the selector rod.

(4) Tighten the inner locknut securely.

7. NEUTRAL SAFETY SWITCH

The neutral safety switch, incorporating the re-

verse lamp switch is located on the transaxle case

View of the kickdown cable adjustment point. The

arrow indicates the direction in which the outer kick-

down cable must be pulled to initiate the automatic adjustment. 1.8 liter engine.

Page 195 of 238

Electrical System 195

(2) Remove the battery holding clamp and lift

the battery from the vehicle.

Installation is a reversal of the removal procedure

with attention to the following points:

Ensure that the terminals and posts are

clean. When connecting the l eads to the battery,

ensure that the polarity is correct. Connect the

positive lead first. Do not over tighten the terminal clamp

nuts.

Apply petroleum jelly to the battery termi-

nals to prevent corrosion.

MAINTENANCE

Battery maintenance should be performed at the

scheduled services.

NOTE: Keep naked flames away from the

battery as the battery gases are highly

explosive.

(1) Keep the battery and the surrounding area

clean and dry. In particular, ensure that the top of the

battery is free from dirt and moisture to prevent a

voltage drop between the terminals.

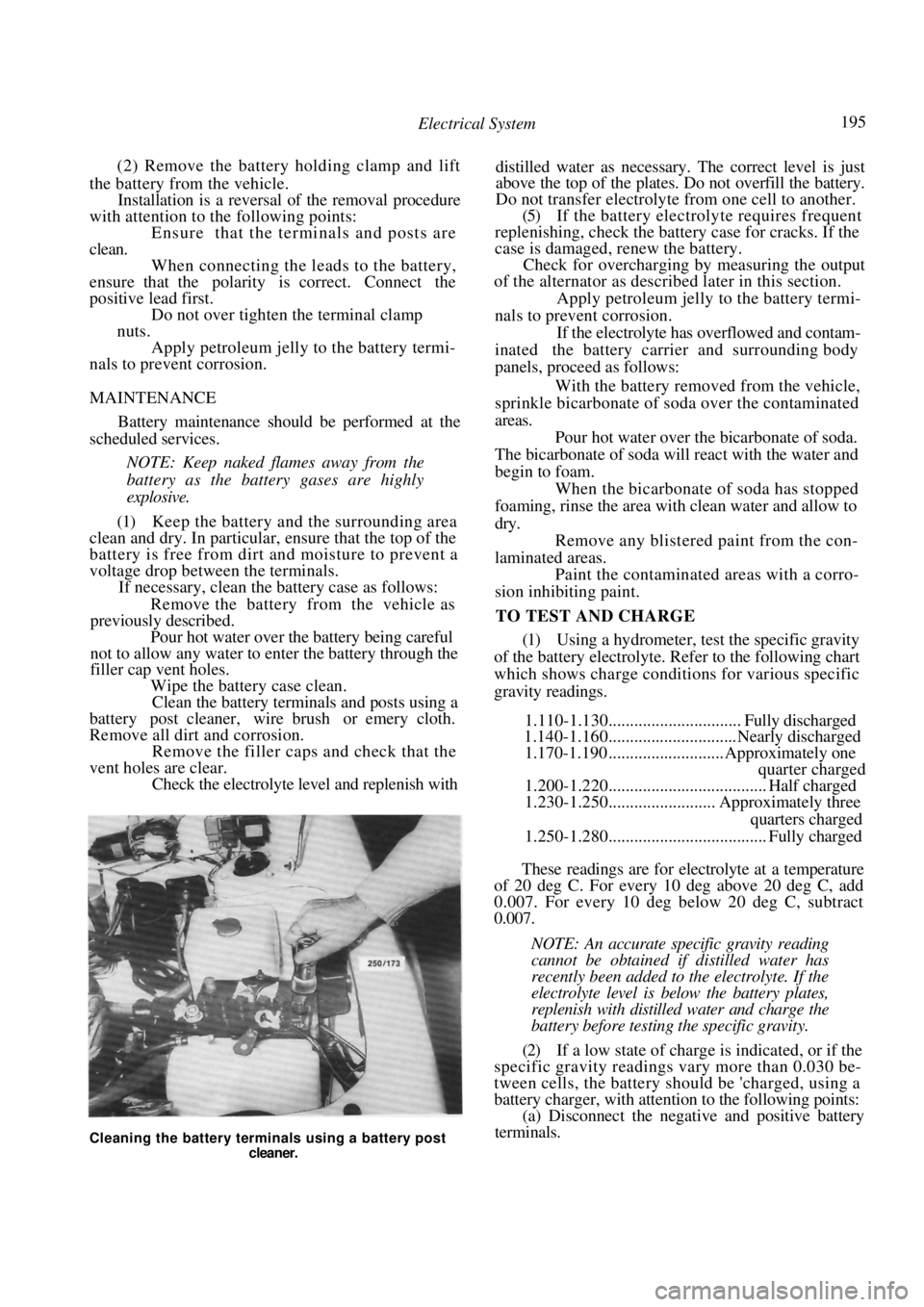

If necessary, clean the battery case as follows:

Remove the battery from the vehicle as

previously described.

Pour hot water over the battery being careful

not to allow any water to enter the battery through the

filler cap vent holes. Wipe the battery case clean.

Clean the battery terminals and posts using a

battery post cleaner, wire brush or emery cloth.

Remove all dirt and corrosion.

Remove the filler caps and check that the

vent holes are clear. Check the electrolyte le vel and replenish with distilled water as necessary. The correct level is just

above the top of the plates. Do not overfill the battery.

Do not transfer electrolyte from one cell to another.

(5) If the battery electrolyte requires frequent

replenishing, check the batt ery case for cracks. If the

case is damaged, renew the battery.

Check for overcharging by measuring the output

of the alternator as described later in this section.

Apply petroleum jelly to the battery termi-

nals to prevent corrosion. If the electrolyte has overflowed and contam-

inated the battery carrier and surrounding body

panels, proceed as follows:

With the battery removed from the vehicle,

sprinkle bicarbonate of soda over the contaminated

areas.

Pour hot water over the bicarbonate of soda.

The bicarbonate of soda will react with the water and

begin to foam. When the bicarbonate of soda has stopped

foaming, rinse the area with clean water and allow to

dry. Remove any blistered paint from the con-

laminated areas. Paint the contaminated areas with a corro-

sion inhibiting paint.

TO TEST AND CHARGE

(1) Using a hydrometer, test the specific gravity

of the battery electrolyte. Refer to the following chart

which shows charge conditi ons for various specific

gravity readings.

1.110-1.130............................... Fully discharged

1.140-1.160..............................Nearly discharged

1.170-1.190 ........................... Approximately one

quarter charged

1.200-1.220..................................... Half charged

1.230-1.250......................... Approximately three

quarters charged

1.250-1.280..................................... Fully charged

These readings are for electrolyte at a temperature

of 20 deg C. For every 10 deg above 20 deg C, add

0.007. For every 10 deg below 20 deg C, subtract

0.007.

NOTE: An accurate specific gravity reading

cannot be obtained if distilled water has

recently been added to the electrolyte. If the

electrolyte level is below the battery plates,

replenish with distilled water and charge the

battery before testing the specific gravity.

(2) If a low state of charge is indicated, or if the

specific gravity readings vary more than 0.030 be-

tween cells, the battery s hould be 'charged, using a

battery charger, with attention to the following points:

(a) Disconnect the negati ve and positive battery

terminals.

Cleaning the battery terminals using a battery post

cleaner.