timing belt NISSAN PULSAR 1987 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1987, Model line: PULSAR, Model: NISSAN PULSAR 1987Pages: 238, PDF Size: 28.91 MB

Page 56 of 238

56 Engine

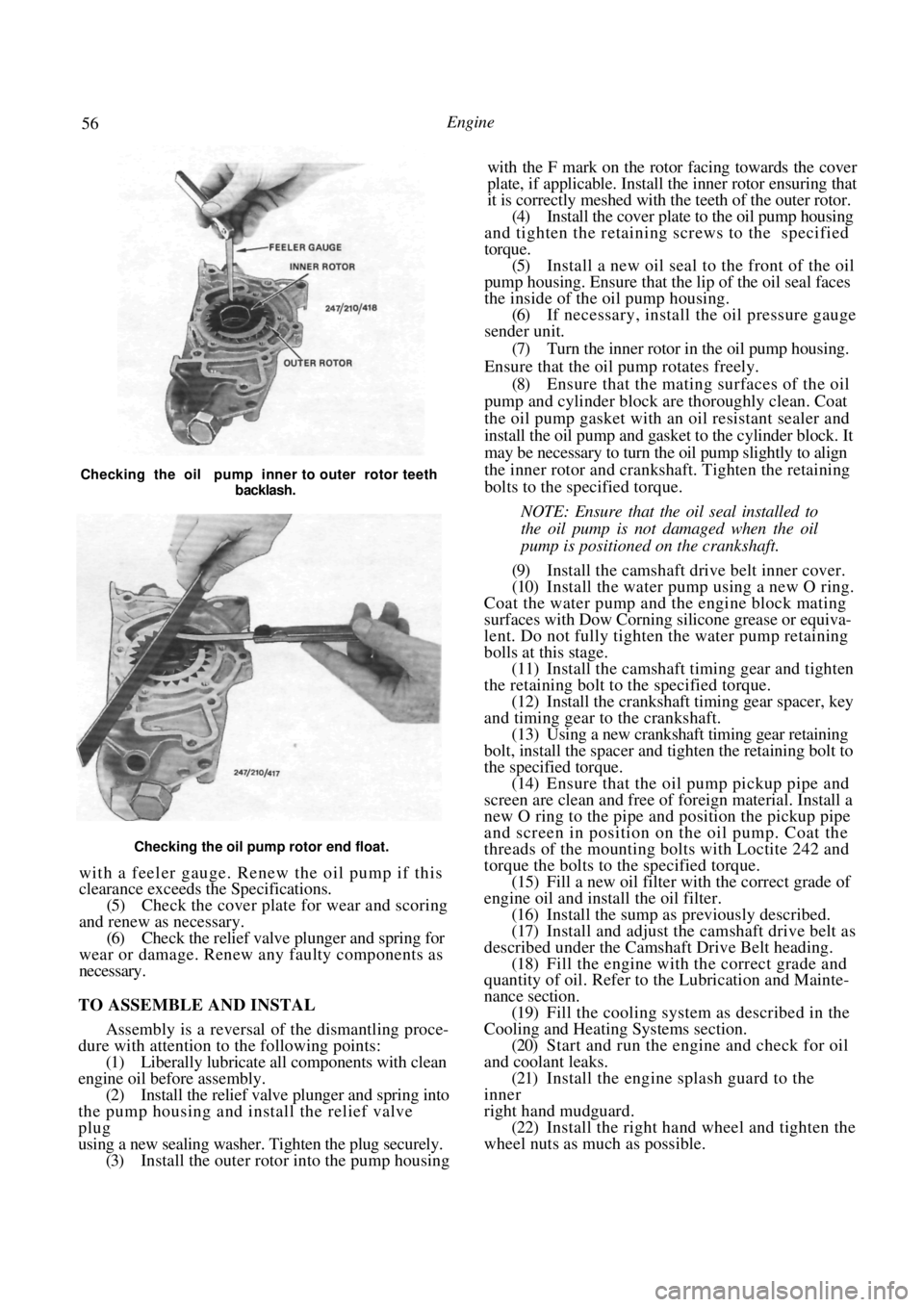

Checking the oil pump rotor end float.

with a feeler gauge. Renew the oil pump if this

clearance exceeds the Specifications.

(5) Check the cover plate for wear and scoring

and renew as necessary. (6) Check the relief valve plunger and spring for

wear or damage. Renew any faulty components as

necessary.

TO ASSEMBLE AND INSTAL

Assembly is a reversal of the dismantling proce-

dure with attention to the following points:

(1) Liberally lubricate all components with clean

engine oil before assembly. (2) Install the relief valve plunger and spring into

the pump housing and install the relief valve

plug

using a new sealing washer. Tighten the plug securely. (3) Install the outer rotor into the pump housing with the F mark on the rotor facing towards the cover

plate, if applicable. Install the inner rotor ensuring that

it is correctly meshed with the teeth of the outer rotor.

(4)

Install the cover plate to the oil pump housing

and tighten the retaining screws to the specified

torque. (5) Install a new oil seal to the front of the oil

pump housing. Ensure that the lip of the oil seal faces

the inside of the oil pump housing. (6) If necessary, install the oil pressure gauge

sender unit.

(7) Turn the inner rotor in the oil pump housing.

Ensure that the oil pump rotates freely. (8) Ensure that the mating surfaces of the oil

pump and cylinder block are thoroughly clean. Coat

the oil pump gasket with an oil resistant sealer and

install the oil pump and gasket to the cylinder block. It

may be necessary to turn the oil pump slightly to align

the inner rotor and crankshaft. Tighten the retaining

bolts to the specified torque.

NOTE: Ensure that the oil seal installed to

the oil pump is not damaged when the oil

pump is positioned on the crankshaft.

(9) Install the camshaft drive belt inner cover.

(10) Install the water pump using a new O ring.

Coat the water pump and the engine block mating

surfaces with Dow Corning silicone grease or equiva-

lent. Do not fully tighten the water pump retaining

bolls at this stage. (11) Install the camshaft timing gear and tighten

the retaining bolt to the specified torque.

(12) Install the crankshaft timing gear spacer, key

and timing gear to the crankshaft. (13) Using a new crankshaft timing gear retaining

bolt, install the spacer and tighten the retaining bolt to

the specified torque. (14) Ensure that the oil pump pickup pipe and

screen are clean and free of foreign material. Install a

new O ring to the pipe and position the pickup pipe

and screen in position on the oil pump. Coat the

threads of the mounting bolts with Loctite 242 and

torque the bolts to the specified torque. (15) Fill a new oil filter with the correct grade of

engine oil and install the oil filter. (16) Install the sump as previously described.

(17) Install and adjust the camshaft drive belt as

described under the Camshaft Drive Belt heading. (18) Fill the engine with the correct grade and

quantity of oil. Refer to the Lubrication and Mainte-

nance section.

(19) Fill the cooling system as described in the

Cooling and Heating Systems section. (20) Start and run the engine and check for oil

and coolant leaks. (21) Install the engine splash guard to the

inner

right hand mudguard. (22) Install the right hand wheel and tighten the

wheel nuts as much as possible.

Checking the oil pump inner to outer rotor teeth

backlash.

Page 63 of 238

Engine

edge of the bearing cap to cylinder block joint. Install

the bearing cap bolts and tighten to the specified

torque.

(17) Lubricate the l i p of the new oil seal with

lithium grease and carefully install the seal into

position over the crankshaft . Insert the seal as far as

possible using finger pressure and then fully install the

sea! using a tubular drift. Ensure that the seal is not

damaged during installation and that the seal is

mounted square to the block face.

(18) Install the remainder of the engine

compo-

nents by referring to the relevant headings in

this

section.

TO RENEW CRANKSHAFT OIL SEALS

Front

(1) Remove the camshaft drive belt as previ-

ously described.

(2) Disconnect the lower radiator hose and drain

the cooling system. (3) Select fifth gear on manual transaxle models

and firmly apply the handbrake. (4) On automatic transaxle models, remove the

torque converter inspection cover to allow access to

the ring gear. Have an assi stant hold the ring gear

using a suitable lever. (5) Remove the crankshaft timing gear retaining

bolt and discard. (6) Remove the crankshaft timing gear from the

crankshaft. It may be necessary to lever the gear from

the crankshaft using two screwdrivers. Remove the

key and spacer from the crankshaft. (7) Using a centre punch, tap a small hole in the

front face of the oil seal. (8) Insert a self tapping screw into the hole.

(9) Remove the seal from the oil pump by

gripping and pulling the end of the screw with a pair

of pliers. (10) Coat the l i p of a new seal with multi-purpose

grease. (11) Install the oil seal to the oil pump using a

tubular drift. Ensure that the lip of the oil seal faces

the inside of the housing.

(12) Install the remaining components in the re-

verse order of removal, usi ng a new crankshaft timing

gear retaining bolt and referring to the relevant

headings in this section as necessary.

Rear

(1) Remove the automatic transaxle or manual

transaxle as described in the appropriate section. (2) Remove the flywheel/drive plate as described

under the following heading. (3) Lever the oil seal from the rear of the

crankcase being careful not to damage the crankshaft.

(4) Coat the lip of a new seal with Lithium

grease.

(5) Install the oil seal over the crankshaft. Ensure

that the li p of the oil sea l faces towards the engine.

(6) Insert the seal as far as possible using finger

pressure, and then fully seat the seal using a tubular

drift. (7) Install the remaining components in the

re-

verse order of removal, referring to the relevant

headings in this section as necessary.

12. FLYWHEEL/DRIVE PLATE

Special Equipment Required:

To Renew Ring Gear — Suitable heat source

TO REMOVE

(1) Remove the transaxle from the vehicle as

described in the Manual or Automatic Transaxle

sections, whichever is applicable. (2) On manual transaxle models, mark the fly-

wheel and the clutch pressure plate cover to ensure

correct assembly.

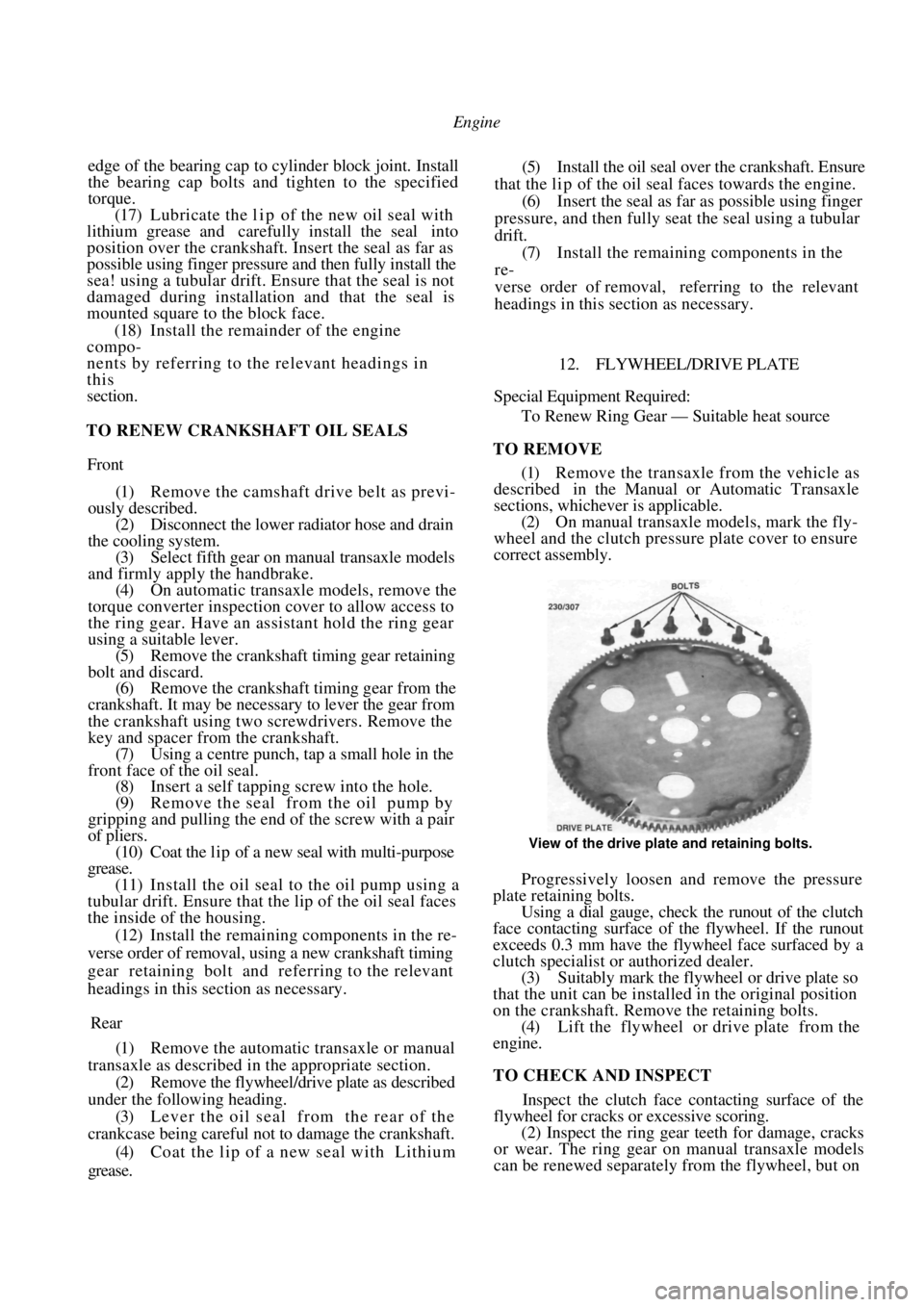

View of the drive plate and retaining bolts.

Progressively loosen and remove the pressure

plate retaining bolts.

Using a dial gauge, check the runout of the clutch

face contacting surface of the flywheel. If the runout

exceeds 0.3 mm have the flywheel face surfaced by a

clutch specialist or authorized dealer.

(3) Suitably mark the flywheel or drive plate so

that the unit can be installed in the original position

on the crankshaft. Remove the retaining bolts. (4) Lift the flywheel or drive plate from the

engine.

TO CHECK AND INSPECT

Inspect the clutch face contacting surface of the

flywheel for cracks or excessive scoring.

(2) Inspect the ring gear teeth for damage, cracks

or wear. The ring gear on manual transaxle models

can be renewed separately from the flywheel, but on

Page 91 of 238

Fuel and Engine Management 91

components, erase the self diagnosis memory as

described under the following heading.

(7) Repeat the self diagnosis test procedure and

ensure that code 12 is displayed.

To Erase Memory

(1) With the ignition Off, remove the fusible link

that is positioned third from the front of the fusible

link connecting block located at the rear of the

battery. (2) Install the fusible link after 10 seconds.

View showing the location of the fusible links.

TO CHECK AND ADJUST IGNITION TIMING

(1) Connect a timing light to the engine as

previously described under the Service Precautions

and Procedures heading.

(2) Start the engine and allow it to reach normal

operating temperature. (3) Connect a jumper lead between terminals A

and B on the diagnostic link connector. (4) With the engine idling at the specified speed,

check the ignition timing with the timing light.

The timing mark on the crankshaft pulley should

be aligned with the pointer on the inner liming belt

cover.

(5) If necessary, loosen the distributor body

retaining nuts and turn the distributor until the timing

marks are aligned. (6) Tighten the distributor body retaining nuts

and check that the timing is correct. (7) Remove the jumper lead from the diagnostic

link connector and disconnect the timing light from

the engine.

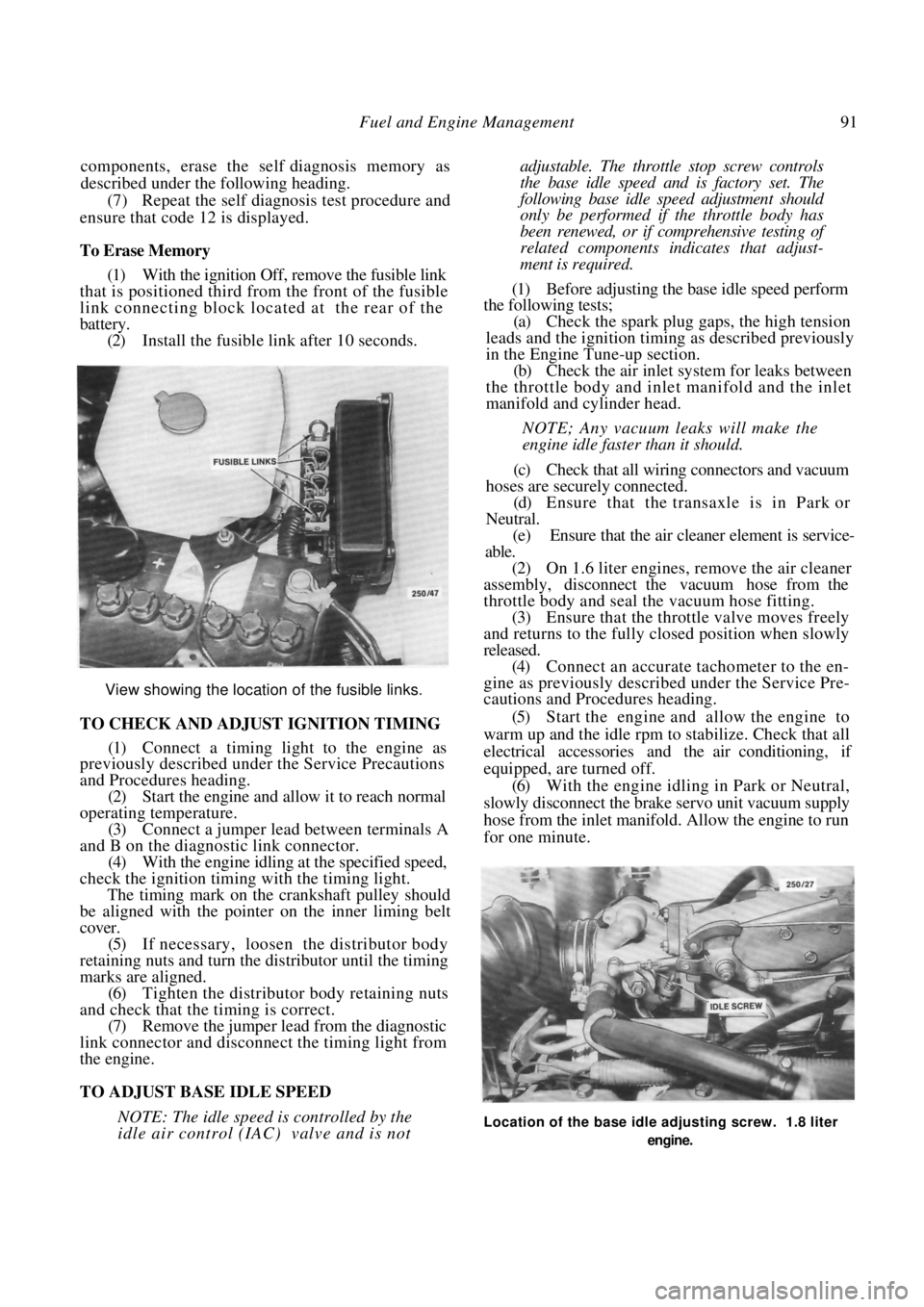

TO ADJUST BASE IDLE SPEED

NOTE: The idle speed is controlled by the

idle air control (IAC) valve and is not

adjustable. The throttle stop screw controls

the base idle speed a nd is factory set. The

following base idle speed adjustment should

only be performed if the throttle body has

been renewed, or if comprehensive testing of

related components indicates that adjust-

ment is required.

(1) Before adjusting the base idle speed perform

the following tests;

(a) Check the spark plug gaps, the high tension

leads and the ignition timin g as described previously

in the Engine Tune-up section.

(b) Check the air inlet syst em for leaks between

the throttle body and inlet manifold and the inlet

manifold and cylinder head.

NOTE; Any vacuum leaks will make the

engine idle faster than it should.

(c) Check that all wiring connectors and vacuum

hoses are securely connected. (d) Ensure that the transaxle is in Park or

Neutral. (e) Ensure that the air cleaner element is service-

able.

(2) On 1.6 liter engines, remove the air cleaner

assembly, disconnect the vacuum hose from the

throttle body and seal the vacuum hose fitting.

(3) Ensure that the throttle valve moves freely

and returns to the fully closed position when slowly

released. (4) Connect an accurate tachometer to the en-

gine as previously descri bed under the Service Pre-

cautions and Procedures heading.

(5) Start the engine and allow the engine to

warm up and the idle rpm to stabilize. Check that all

electrical accessories and the air conditioning, if

equipped, are turned off. (6) With the engine idling in Park or Neutral,

slowly disconnect the brake servo unit vacuum supply

hose from the inlet manifold. Allow the engine to run

for one minute.

Location of the base idle adjusting screw. 1.8 liter

engine.