belt NISSAN PULSAR 1987 Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1987, Model line: PULSAR, Model: NISSAN PULSAR 1987Pages: 238, PDF Size: 28.91 MB

Page 4 of 238

FRONT SUSPENSION............................ 156

Specifications......................................................... 156

Front suspension tr ouble shooting ........................ 156

Description ............................................................ 157

Steering knuckle.................................................... 157

Suspension unit..................................................... 159

Control arm ........................................................... 161

Stabiliser bar ........................................................ 162

Suspension and steering angles .......................... 163

REAR SUSPENSION................................ 164

Specifications ........................................................ 164

Rear suspension tr ouble shooting ........................ 164

Description ............................................................ 165

Rear hub ............................................................... 166

Suspension unit .................................................... 167

Control arm ........................................................... 169

Knuckle assembly.................................................. 170

Stabiliser bar ........................................................ 170

Rear wheel alignment ........................................... 171

BRAKES...................................................... 172

Specifications......................................................... 172

Brakes trouble shooting ........................................ 172

Description ............................................................ 174

Master cyli nder...................................................... 175

Brake servo unit .................................................... 177

Front brakes ......................................................... 178

Rear disc brakes................................................... 181

Rear drum brakes ................................................. 184

Handbrake cable and le ver assembly ................... 186

Brake adjustments ................................................ 187

Brake pedal ........................................................... 187

Hydraulic system................................................... 188

ELECTRICAL SYSTEM............................ 190

Specifications......................................................... 190

Battery and charging system trouble shooting ....... 190

Battery and starting system trouble shooting ........ 191

Lighting system trouble shooting ........................... 192

Turn signal lamp trouble shooting ........................ 192

Test equipment and so me applications................. 193

Battery ................................................................... 194

Alternator ............................................................... 196

Starter motor ......................................................... 201

Ignition system ...................................................... 206

Steering wheel ....................................................... 206

Switches and controls........................................... 206

Instrument cluster.................................................. 209

Blower fan .............................................................. 209

Radio/cassette...................................................... 209

lamp units ............................................................ 210

Windscreen wiper ................................................. 213

Fuses, fusible links and relays ............................. 215

Trailer wiring ......................................................... 216

Wiring diagrams ................................................... 218

BODY........................................................... 225

Windscreen and re ar glass .................................. 225

Front doors ........................................................... 225

Rear doors............................................................ 228

Engine bonnet...................................................... 231

Tailgate and lock — hatchback ............................ 231

Luggage compartment lid and lock — sedan ........ 233

Radiator grille.............................................................. 234

Centre console...................................................... 234 Dashboard ............................................................ 235

Scat belts ............................................................. 236

Seats .................................................................... 236

Vehicle cleaning ........................................................... 237

CONVERSION TABLES.......................... 238

Page 25 of 238

25

ENGINE TUNE-UP

CAUTION: To prevent severe electrical shock, extreme care must be taken when

working on or near the electronic ignition system as dangerous high tension voltages

are produced in both the primary and secondary circuits. See the text fo\

r

precautionary notes.

1. TUNE-UP SPECIFICATIONS

Firing orde r................................................... 1 -3-4-2

Spark plugs:

Type .............................................NGK BPR 6ES

Gap ........................................................... 1.1 mm

Tightening torque...................................... 20 Nm

Ignition timing with diagnostic link

connector jumped........................... 10 deg BTDC

Idle speed (ECU controlled):

Manual transaxle 1.8 liter ............ 850 ± 50 rpm

Manual transaxle 1.6 liter............800 ± 50 rpm

Automatic transaxle

(Park or Neutral).......................... 825 ± 50 rpm

Drive belt deflection:

Alternator ........................................... 14-16 mm

Power steering pump ......................... 14-16 mm

Air conditioner compressor .................. 9-11 mm

NOTE: When performing an engine tune-

up, a/ways compare the above Specifications

with the emission control information label

inside the engine compartment.

2. TUNE-UP OPERATIONS

Special Equipment Required:

To Test Compression — Compression gauge

TO SERVICE AIR CLEANER

The air cleaner is equipped with a paper element.

The element should be regu larly inspected but should

not be cleaned in service.

The element should be renewed every 40 000 km.

This distance is only a guide for normal operating

conditions and should be reduced accordingly if the

vehicle is operating under ex tremely dusty conditions.

NOTE: Paper air cleaner elements should

not be washed in petrol or any other type of

cleaning solvent. If the element has been

washed in solvent or has become oil soaked,

it should be discarded and a new element

installed.

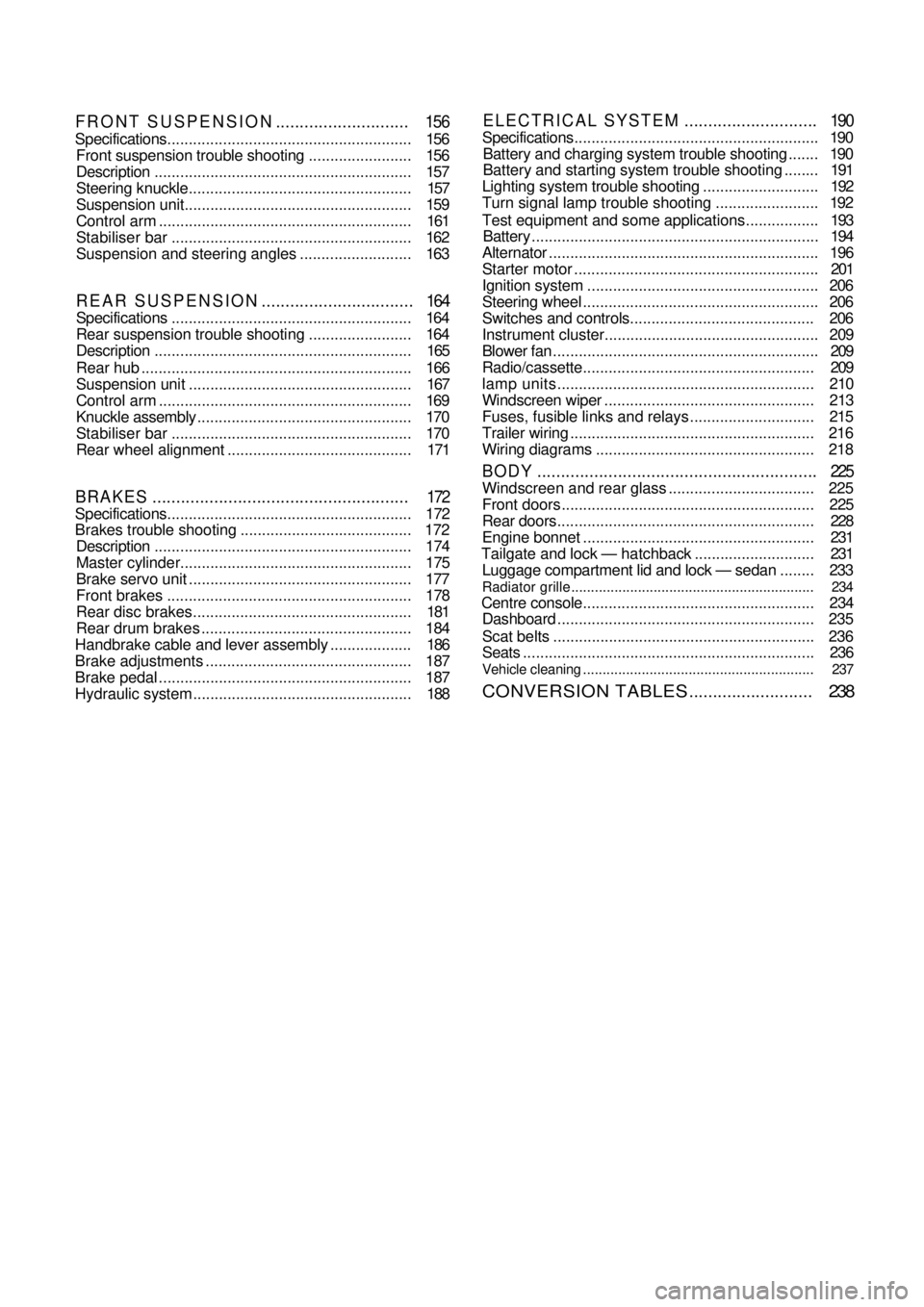

1.8 Liter Engine

(1) Release the clamp securing the air intake

hose to the throttle body and disconnect the throttle

cable from the support bracket. (2) Release the clips reta ining the upper air

cleaner housing to the lowe r air cleaner housing and

raise the upper housing while disconnecting the air

intake hose from the throttle body. Remove the air

cleaner element.

The air cleaner element should be renewed at 40 000

km intervals. 1.8 liter engine.

(3) Clean the inside of the air cleaner housing

using a damp rag to remove all traces of dust and

check the upper housing and air inlet hose for cracks

and air leaks. Renew if necessary. (4) Install a new air cleaner element to the lower

housing ensuring that the element is correctly seated

around the edges. (5) Install the upper housing and lock the clips,

securing it to the lower housing. Connect the air

intake hose to the throttle body and the throttle cable

to the support bracket. Tighten the hose clamp

securely. (6) Start the engine and check the air cleaner

assembly for air leaks.

Page 26 of 238

26 Engine Tune-up

1.6 Liter Engine

(1) Remove the nuts and washers securing the

upper air cleaner housing to the lower air cleaner

housing and release the retaining clips. (2) Remove the air cleaner element.

(3) Clean the inside of the air cleaner housing

using a damp rag to remo ve all traces of dust.

(4) Install a new air cleaner element ensuring that

the element is correctly seated around the edges.

(5) Install the upper housing and secure the

retaining clips. Tighten th e retaining nuts securely.

TO RENEW FUEL FILTER

filter should

The fuel

40 000 km.

(1) Depressurize the fuel system using the fol-

lowing procedure:

(a) Lift the front edge of the rear seat cushion

and remove the cushion from the vehicle.

When depressurizing the fuel system, remove the rear

seat cushion and disconnect the fuel pump wiring

connector.

(b) Disconnect the fuel pump wiring connector.

(c) Start and run the engine until it stalls.

Operate the starter motor for 10 seconds to ensure

that the fuel pressure has dissipated.

(2) Disconnect the negative battery terminal.

(3) Release the hose clamps and disconnect the

fuel hoses from the filter. Remove the filter from the

retaining clamp noting the direction of the arrow on

the filter body. On some models it will be necessary to remove the

screw from the side of the clamp to allow the filler to

be removed.

Installation is a reversal of the removal procedure

with attention to the following points:

(1) Install the fuel filter with the arrow facing the

direction noted on removal, that is, in the direction of

fuel flow.

(2) Ensure that the hose clamps are tightened

securely.

(3) Connect the fuel pump wiring connector and

install the rear seat cushion. (4) Start the engine and check for fuel leaks.

Rectify as necessary.

TO ADJUST DRIVE BELTS

It is essential that all drive belts are adjusted to

the correct tension to prevent slippage or premature

wear of the bearings in the alternator and, if equipped,

the power steering pump and air conditioner compres-

sor.

(1) Push down on the drive belt with a 10 kg

force midway between the pulleys of the drive belt

concerned.

On models with air conditioning, push down on

the upper section of the drive belt between the

compressor and crankshaft pulleys.

If the drive belt deflection is not within Specifi-

cations it will require adjustment as follows.

(2) Loosen the alternator and, if equipped, the

power steering pump pivot and adjusting bolts and

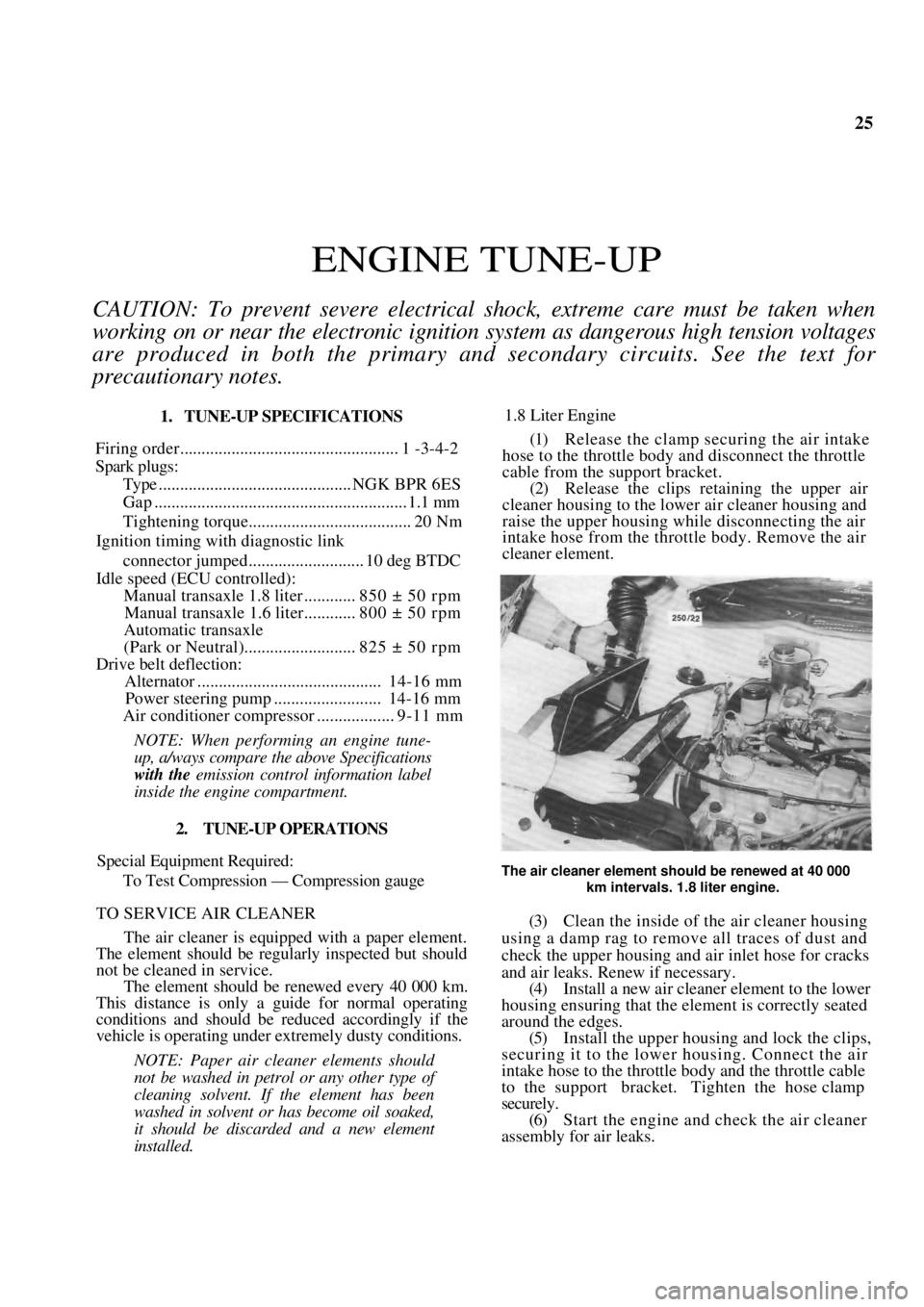

ALTERNATOR

POWER STEERING PUMP

be renewed every

Installed view of the fuel filter. Note the direction of the arrow on the filter prior to removal. Illustration of the alternator, power steering pump and

air conditioner compressor drive belts. The arrows

indicate the deflection measuring points.

Page 27 of 238

Engine Tune-up 27

move the alternator or power steering pump as

required until the drive belt concerned has the

specified deflection.

On models with air conditioning, loosen the nut

in the centre of the idler pulley and turn the adjusting

bolt until the drive belt has the specified deflection.

(3) Tighten the alternator or power steering

pump bolts securely and check the belt tension.

On models with air conditioning, tighten the idler

pulley nut securely.

TO SERVICE SPARK PLUGS

The spark plugs should be renewed at intervals of

40 000 km.

Before removing the spark plugs ensure that the

area around each plug is cl ean to prevent foreign

matter entering the cylinder when the plugs are

removed.

Spark plugs removed from an engine in good

mechanical condition should have a light powdery

deposit ranging from light brown to grayish tan in

color. After considerable service the electrodes will

show signs of wear or no rmal burning. Spark plugs

showing a thick black oily deposit indicate an engine

in poor mechanical condition or possibly, that a plug

with too low a heat range has been installed.

Spark plugs showing a white or yellowish deposit

indicate sustained high speed driving or possibly that

plugs with too high a heat range have been installed,

particularly when these deposits are accompanied by

blistering of the porcelain and burning of the elec-

trodes.

If the spark plugs are to be cleaned, use a

sandblasting machine and blow clean with com-

pressed air. Ensure that all traces of abrasive grit are

removed from the spark plug threads and from the

well in the plug body. Carefully open the electrode gap

a little, by bending the side electrode, and lightly file

the electrodes flat with a points file.

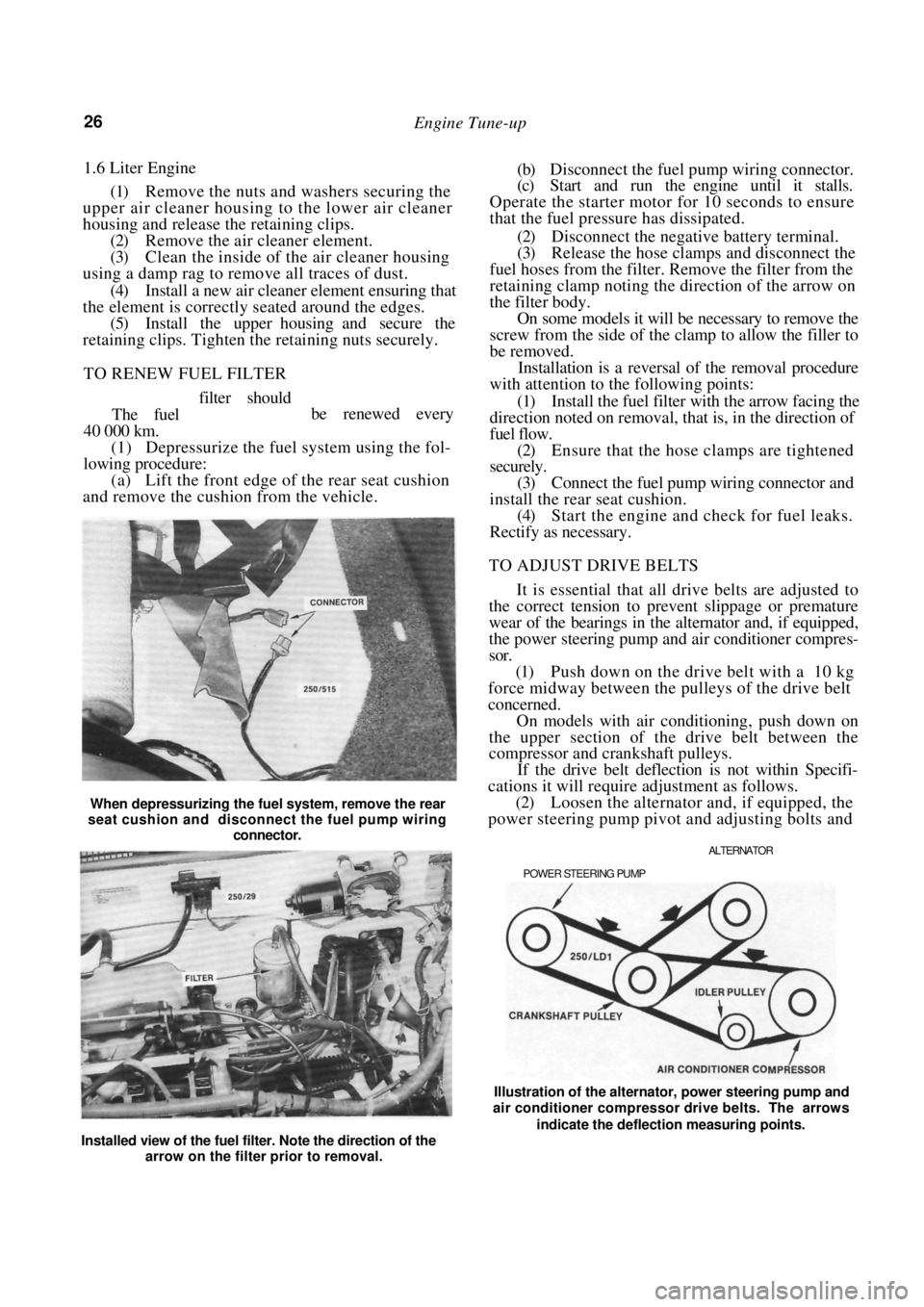

Black damp deposits can be caused by excessive oil

consumption or incorrect plug type. Spark plugs in this

condition are usually not firing.

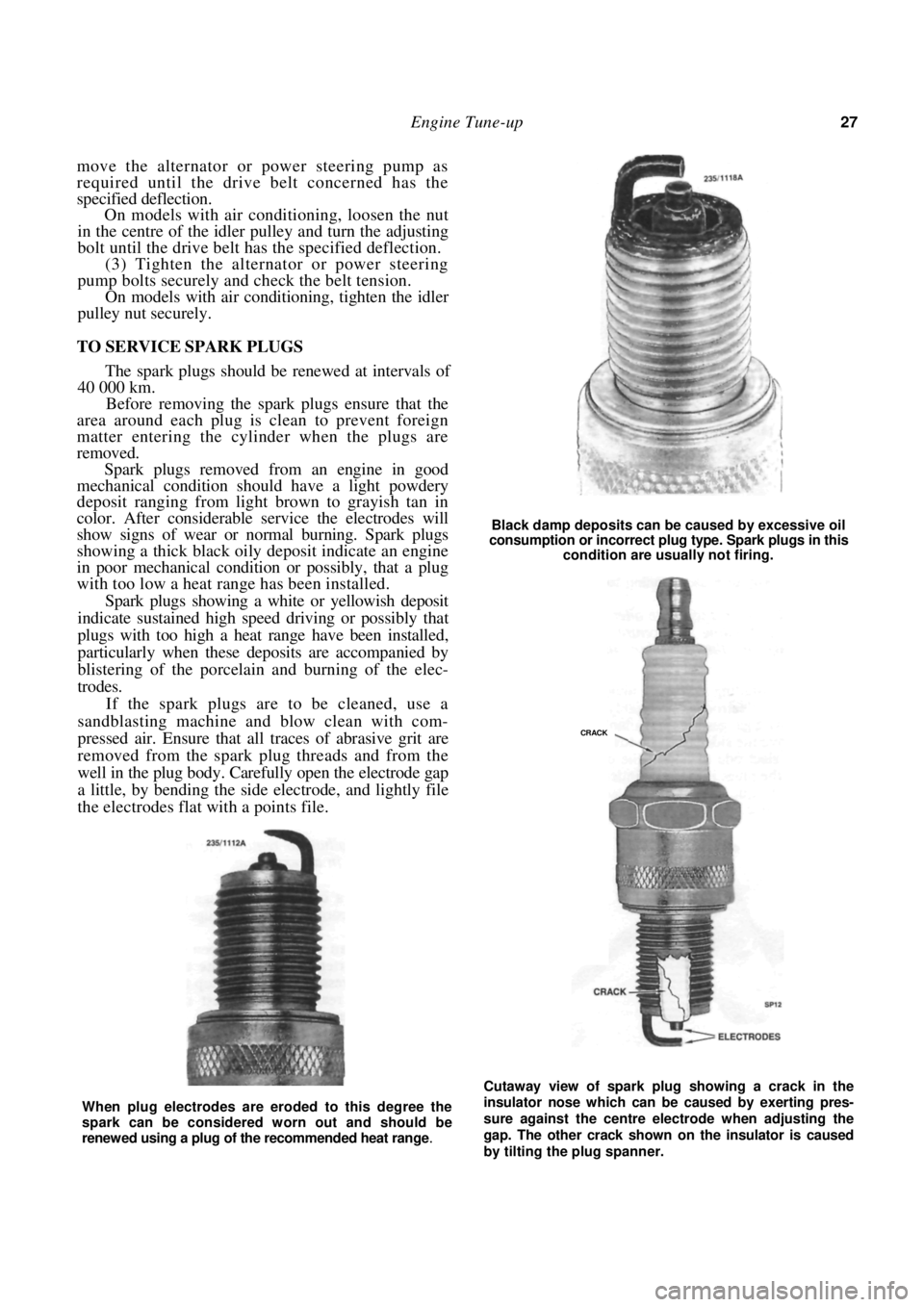

Cutaway view of spark plug showing a crack in the

insulator nose which can be caused by exerting pres-

sure against the centre electrode when adjusting the

gap. The other crack shown on the insulator is caused

by tilting the plug spanner.

When plug electrodes are eroded to this degree the

spark can be considered worn out and should be

renewed using a plug of the recommended heat range

.

CRACK

Page 33 of 238

Roadside Trouble Shooting

(5) Place the vent caps loosely over the cell

apertures.

(6) Connect one end of the red jumper lead to

the positive ( + ) battery terminal of the booster

battery and the other end of the red lead to the

positive (+) battery terminal of the discharged bat-

tery.

NOTE: The battery emits hydrogen gas

which is explosive. Do not expose the battery

to naked /lames or sparks.

Do not lean over the battery when con-

necting the jumper leads.

Do not allow the ends of the jumper leads

to touch one another or any part of the

engine.

(7) Connect one end of the black juniper lead to

the negative (-) battery terminal of the booster

battery and the other end of the black lead to a good

earthing point on the engine of the vehicle with the

discharged battery.

NOTE: Do not connect the jumper lead

directly to the negative (-) battery terminal

of the discharged battery.

(8) Start the engine on the vehicle with the

booster battery and run the engine at a moderate

speed. (9) Start the engine on the vehicle with the

discharged battery.

(10) If possible, leave the engines of both vehi-

cles running for 10 minutes.

(11) Disconnect the jumper leads in the reverse

order of the sequence in which they were connected.

2. TO CHECK IGNITION AND ELECTRICAL SYSTEM

(1) Switch on the ignition and check for warning

lamp illumination on the dashboard. (2) Operate the starter and check that the starter

rotates the engine at a steady speed.

(3) Switch on the headlamps and check for good

light intensity. Should the lamps not illum inate or the starter

motor not turn the engine, carry out the following

steps:

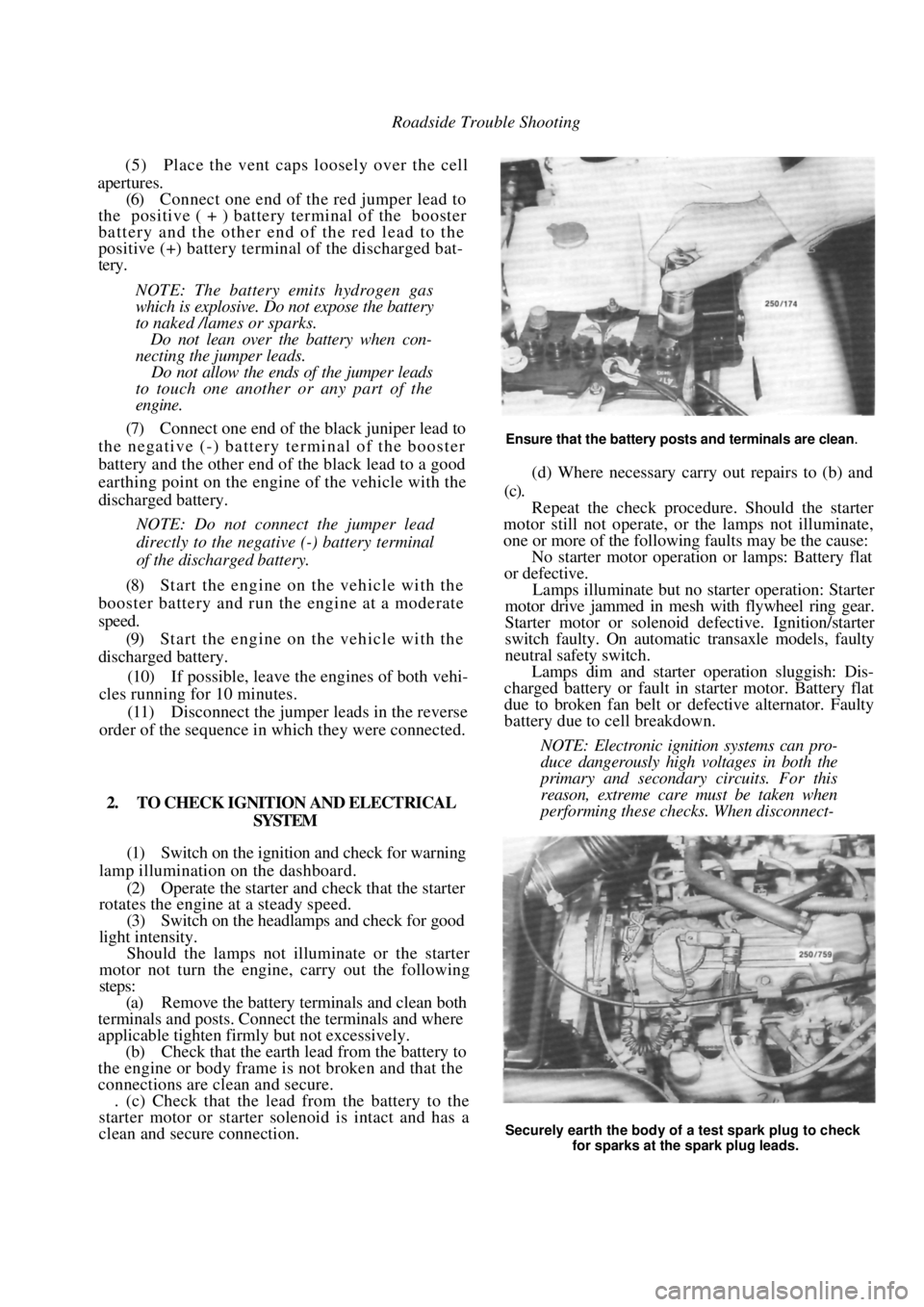

(a) Remove the battery terminals and clean both

terminals and posts. Connect the terminals and where

applicable tighten firmly but not excessively.

(b) Check that the earth lead from the battery to

the engine or body frame is not broken and that the

connections are clean and secure. . (c) Check that the lead from the battery to the

starter motor or starter solenoid is intact and has a

clean and secure connection.

Ensure that the battery posts and terminals are clean.

(d) Where necessary carry out repairs to (b) and

(c).

Repeat the check procedur e. Should the starter

motor still not operate, or the lamps not illuminate,

one or more of the following faults may be the cause:

No starter motor operation or lamps: Battery flat

or defective.

Lamps illuminate but no starter operation: Starter

motor drive jammed in mesh with flywheel ring gear.

Starter motor or solenoid defective. Ignition/starter

switch faulty. On automatic transaxle models, faulty

neutral safety switch.

Lamps dim and starter operation sluggish: Dis-

charged battery or fault in starter motor. Battery flat

due to broken fan belt or de fective alternator. Faulty

battery due to cell breakdown.

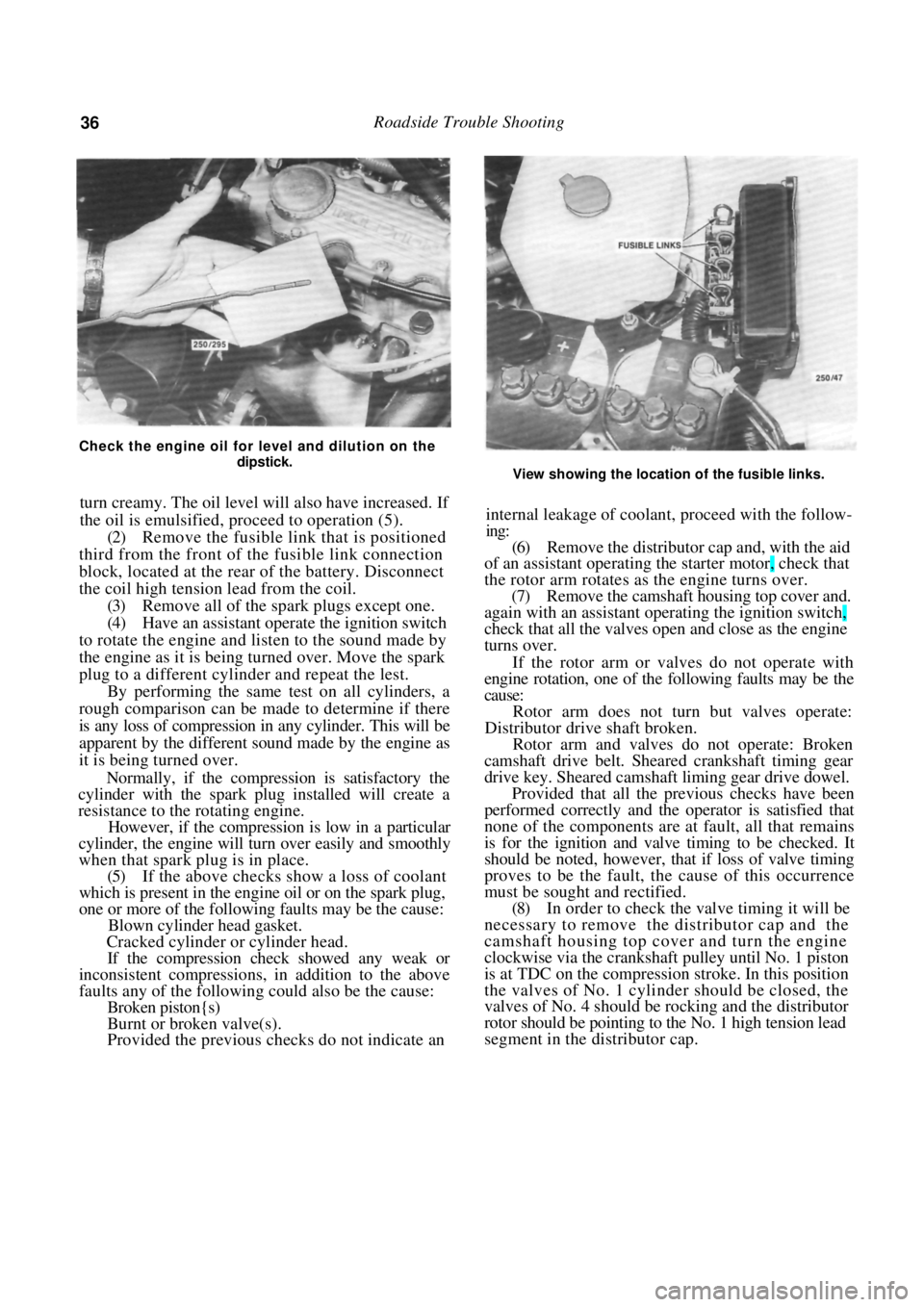

NOTE: Electronic ignition systems can pro-

duce dangerously high voltages in both the

primary and secondary circuits. For this

reason, extreme care must be taken when

performing these checks. When disconnect-

Securely earth the body of a test spark plug to check

for sparks at the spark plug leads.

Page 36 of 238

36 Roadside Trouble Shooting

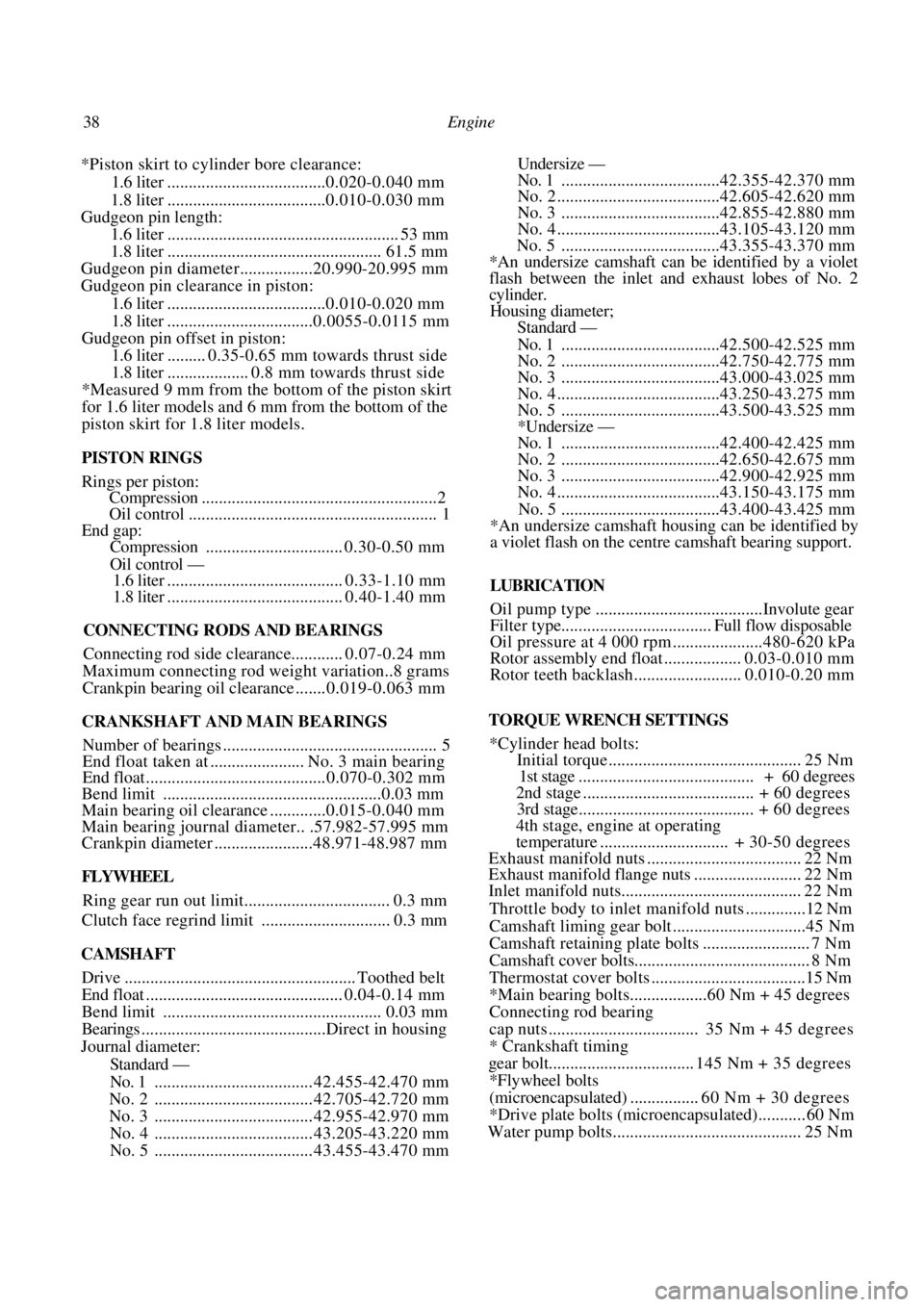

Check the engine oil for level and dilution on the dipstick.

turn creamy. The oil level will also have increased. If

the oil is emulsified, proceed to operation (5).

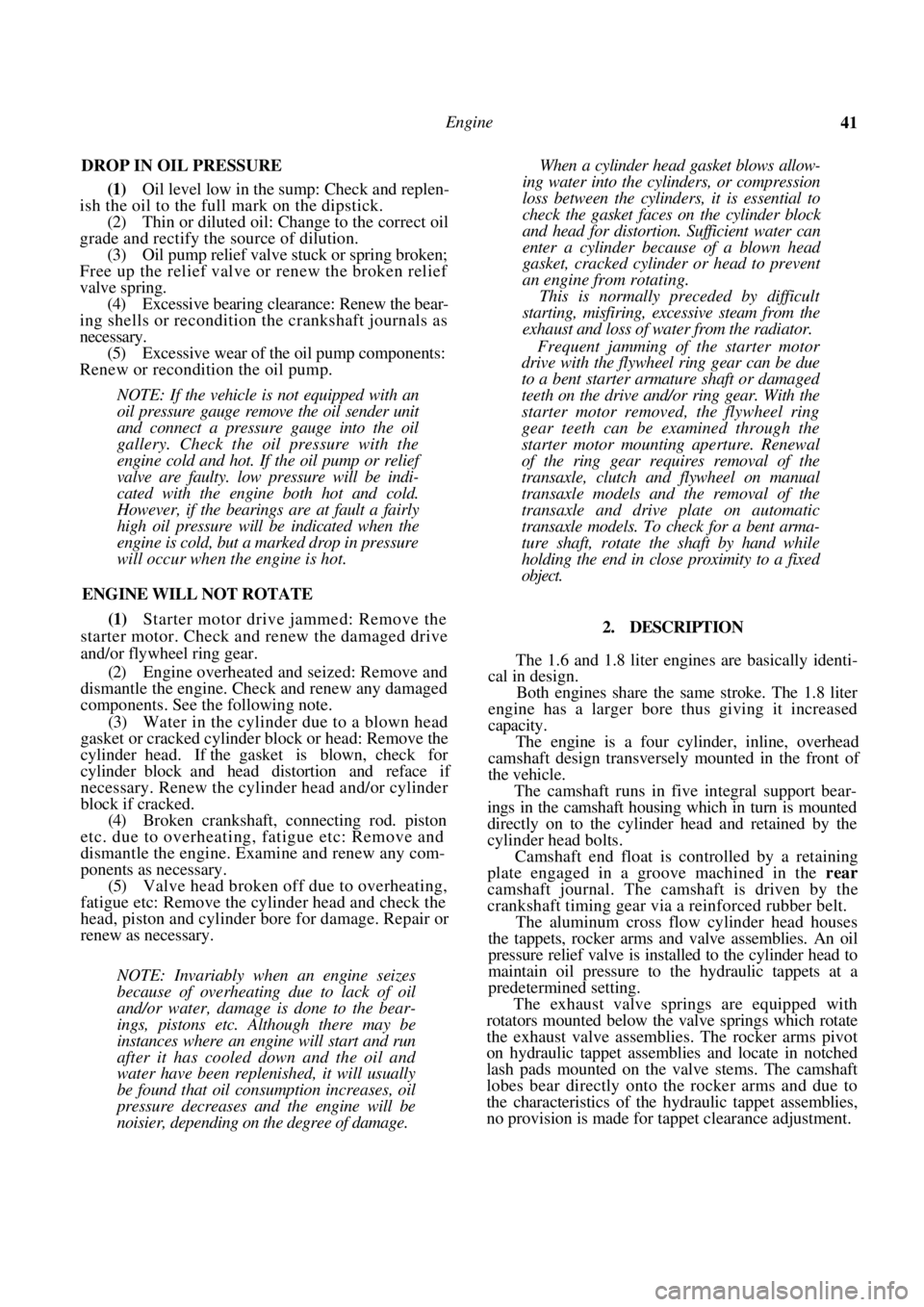

(2) Remove the fusible link that is positioned

third from the front of th e fusible link connection

block, located at the rear of the battery. Disconnect

the coil high tension lead from the coil. (3) Remove all of the spark plugs except one.

(4) Have an assistant operate the ignition switch

to rotate the engine and listen to the sound made by

the engine as it is being turned over. Move the spark

plug to a different cylinder and repeat the lest. By performing the same test on all cylinders, a

rough comparison can be made to determine if there

is any loss of compression in any cylinder. This will be

apparent by the different sound made by the engine as

it is being turned over.

Normally, if the compression is satisfactory the

cylinder with the spark plug installed will create a

resistance to the rotating engine.

However, if the compression is low in a particular

cylinder, the engine will tu rn over easily and smoothly

when that spark plug is in place.

(5) If the above checks show a loss of coolant

which is present in the engine oil or on the spark plug,

one or more of the following faults may be the cause:

Blown cylinder head gasket.

Cracked cylinder or cylinder head.

If the compression check showed any weak or

inconsistent compressions, in addition to the above

faults any of the following could also be the cause:

Broken piston{s)

Burnt or broken valve(s).

Provided the previous checks do not indicate an

View showing the location of the fusible links.

internal leakage of coolant, proceed with the follow-

ing:

(6) Remove the distributor cap and, with the aid

of an assistant operating th e starter motor, check that

the rotor arm rotates as the engine turns over. (7) Remove the camshaft hous ing top cover and.

again with an assistant operating the ignition switch,

check that all the valves open and close as the engine

turns over.

If the rotor arm or valves do not operate with

engine rotation, one of the following faults may be the

cause:

Rotor arm does not turn but valves operate:

Distributor drive shaft broken.

Rotor arm and valves do not operate: Broken

camshaft drive belt. Sheare d crankshaft timing gear

drive key. Sheared camshaft liming gear drive dowel.

Provided that all the previous checks have been

performed correctly and the operator is satisfied that

none of the components are at fault, all that remains

is for the ignition and valve timing to be checked. It

should be noted, however, that if loss of valve timing

proves to be the fault, th e cause of this occurrence

must be sought and rectified.

(8) In order to check the valve timing it will be

necessary to remove the distributor cap and the

camshaft housing top cover and turn the engine

clockwise via the crankshaft pulley until No. 1 piston

is at TDC on the compression stroke. In this position

the valves of No. 1 cylinder should be closed, the

valves of No. 4 should be rocking and the distributor

rotor should be pointing to the No. 1 high tension lead

segment in the distributor cap.

Page 38 of 238

38 Engine

*Piston skirt to cylinder bore clearance:

1.6 liter .....................................0. 020-0.040 mm

1.8 liter .....................................0. 010-0.030 mm

Gudgeon pin length:

1.6 liter ...................................................... 53 mm

1.8 liter .................................................. 61.5 mm

Gudgeon pin diameter.................20.990-20.995 mm

Gudgeon pin clearance in piston:

1.6 liter .....................................0. 010-0.020 mm

1.8 liter ..................................0. 0055-0.0115 mm

Gudgeon pin offset in piston:

1.6 liter......... 0.35-0.65 mm towards thrust side

1.8 liter................... 0.8 mm towards thrust side

*Measured 9 mm from the bottom of the piston skirt

for 1.6 liter models and 6 mm from the bottom of the

piston skirt for 1.8 liter models.

PISTON RINGS

Rings per piston:

Compression .......................................................2

Oil contro l .......................................................... 1

End gap:

Compression ................................ 0.30-0.50 mm

Oil control —

1.6 liter ......................................... 0.33-1.10 mm

1.8 liter ......................................... 0.40-1.40 mm

CONNECTING RODS AND BEARINGS

Connecting rod side clearance............ 0.07-0.24 mm

Maximum connecting rod weight variation..8 grams

Crankpin bearing oil clearance ....... 0. 019-0.063 mm

CRANKSHAFT AND MAIN BEARINGS

Number of bearings .................................................. 5

End float taken at ...................... No. 3 main bearing

End float .......................................... 0.070-0.302 mm

Bend limit ...................................................0.03 mm

Main bearing oil clearance .............0. 015-0.040 mm

Main bearing journal diameter.. .57.982-57.995 mm

Crankpin diameter .......................48.971-48.987 mm

FLYWHEEL

Ring gear run out limit.................................. 0.3 mm

Clutch face regrind limit .............................. 0.3 mm

CAMSHAFT

Drive ...................................................... Toothed belt

End float .............................................. 0.04-0.14 mm

Bend limit ................................................... 0.03 mm

Bearings ...........................................Direct in housing

Journal diameter:

Standard —

No. 1 ..................................... 42. 455-42.470 mm

No. 2 ..................................... 42. 705-42.720 mm

No. 3 ..................................... 42.955-42.970 mm

No. 4 ..................................... 43.205-43.220 mm

No. 5 ..................................... 43.455-43.470 mm

Undersize —

No. 1 .....................................42.355-42.370 mm

No. 2 ......................................42.605-42.620 mm

No. 3 .....................................42.855-42.880 mm

No. 4 ......................................43.105-43.120 mm

No. 5 .....................................43. 355-43.370 mm

*An undersize camshaft can be identified by a violet

flash between the inlet and exhaust lobes of No. 2

cylinder.

Housing diameter;

Standard —

No. 1 .....................................42. 500-42.525 mm

No. 2 .....................................42.750-42.775 mm

No. 3 .....................................43.000-43.025 mm

No. 4 ......................................43.250-43.275 mm

No. 5 .....................................43.500-43.525 mm

*Undersize —

No. 1 .....................................42.400-42.425 mm

No. 2 .....................................42.650-42.675 mm

No. 3 .....................................42.900-42.925 mm

No. 4 ......................................43.150-43.175 mm

No. 5 .....................................43.400-43.425 mm

*An undersize camshaft housing can be identified by

a violet flash on the centre camshaft bearing support.

LUBRICATION

Oil pump type .......................................Involute gear

Filter type................................... Full flow disposable

Oil pressure at 4 000 rpm .....................480-620 kPa

Rotor assembly end float .................. 0.03-0. 010 mm

Rotor teeth backlash ......................... 0.010-0.20 mm

TORQUE WRENCH SETTINGS

*Cylinder head bolts:

Initial torque ............................................. 25 Nm

1st stage ......................................... + 60 degrees

2nd stage ........................................ + 60 degrees

3rd stage......................................... + 60 degrees

4th stage, engine at operating

temperature .............................. + 30-50 degrees

Exhaust manifold nuts .................................... 22 Nm

Exhaust manifold flange nuts ......................... 22 Nm

Inlet manifold nuts.......................................... 22 Nm

Throttle body to inlet manifold nuts ..............12 Nm

Camshaft liming gear bolt ...............................45 Nm

Camshaft retainin g plate bolts ......................... 7 Nm

Camshaft cover bolts......................................... 8 Nm

Thermostat cover bolts ....................................15 Nm

*Main bearing bolts..................60 Nm + 45 degrees

Connecting rod bearing

cap nuts ................................... 35 Nm + 45 degrees

* Crankshaft timing

gear bolt.................................. 145 Nm + 35 degrees

*Flywheel bolts

(microencapsulated) ................ 60 Nm + 30 degrees

*Drive plate bolts (microencapsulated)........... 60 Nm

Water pump bolts............................................ 25 Nm

Page 41 of 238

Engine 41

DROP IN OIL PRESSURE

(1) Oil level low in the sump: Check and replen-

ish the oil to the full mark on the dipstick.

(2) Thin or diluted oil: Change to the correct oil

grade and rectify the source of dilution. (3) Oil pump relief valve stuck or spring broken;

Free up the relief valve or renew the broken relief

valve spring. (4) Excessive bearing clearance: Renew the bear-

ing shells or recondition the crankshaft journals as

necessary.

(5) Excessive wear of the oil pump components:

Renew or recondition the oil pump.

NOTE: If the vehicle is not equipped with an

oil pressure gauge re move the oil sender unit

and connect a pressure gauge into the oil

gallery. Check the oil pressure with the

engine cold and hot. If the oil pump or relief

valve are faulty. low pressure will be indi-

cated with the engine both hot and cold.

However, if the bearings are at fault a fairly

high oil pressure will be indicated when the

engine is cold, but a marked drop in pressure

will occur when the engine is hot.

ENGINE WILL NOT ROTATE

(1) Starter motor drive jammed: Remove the

starter motor. Check and renew the damaged drive

and/or flywheel ring gear.

(2) Engine overheated an d seized: Remove and

dismantle the engine. Check and renew any damaged

components. See the following note.

(3) Water in the cylinder due to a blown head

gasket or cracked cylinder block or head: Remove the

cylinder head. If the gasket is blown, check for

cylinder block and head distortion and reface if

necessary. Renew the cylinder head and/or cylinder

block if cracked.

(4) Broken crankshaft, connecting rod. piston

etc. due to overheating, fatigue etc: Remove and

dismantle the engine. Examine and renew any com-

ponents as necessary. (5) Valve head broken off due to overheating,

fatigue etc: Remove the cylinder head and check the

head, piston and cylinder bore for damage. Repair or

renew as necessary.

NOTE: Invariably when an engine seizes

because of overheating due to lack of oil

and/or water, damage is done to the bear-

ings, pistons etc. Although there may be

instances where an engine will start and run

after it has cooled down and the oil and

water have been replenished, it will usually

be found that oil consumption increases, oil

pressure decreases and the engine will be

noisier, depending on the degree of damage.

When a cylinder head gasket blows allow-

ing water into the cylinders, or compression

loss between the cylinders, it is essential to

check the gasket faces on the cylinder block

and head for distortion. Sufficient water can

enter a cylinder because of a blown head

gasket, cracked cylinder or head to prevent

an engine from rotating.

This is normally preceded by difficult

starting, misfiring, excessive steam from the

exhaust and loss of water from the radiator.

Frequent jamming of the starter motor

drive with the flywheel ring gear can be due

to a bent starter armature shaft or damaged

teeth on the drive and/or ring gear. With the

starter motor removed, the flywheel ring

gear teeth can be examined through the

starter motor mounting aperture. Renewal

of the ring gear requires removal of the

transaxle, clutch and flywheel on manual

transaxle models and the removal of the

transaxle and drive plate on automatic

transaxle models. To check for a bent arma-

ture shaft, rotate the shaft by hand while

holding the end in close proximity to a fixed

object.

2. DESCRIPTION

The 1.6 and 1.8 liter engines are basically identi-

cal in design.

Both engines share the same stroke. The 1.8 liter

engine has a larger bore thus giving it increased

capacity.

The engine is a four cylinder, inline, overhead

camshaft design transversely mounted in the front of

the vehicle.

The camshaft runs in five integral support bear-

ings in the camshaft housing which in turn is mounted

directly on to the cylinder head and retained by the

cylinder head bolts.

Camshaft end float is controlled by a retaining

plate engaged in a groove machined in the rear

camshaft journal. The camshaft is driven by the

crankshaft timing gear vi a a reinforced rubber belt.

The aluminum cross flow cylinder head houses

the tappets, rocker arms a nd valve assemblies. An oil

pressure relief valve is installed to the cylinder head to

maintain oil pressure to the hydraulic tappets at a

predetermined setting.

The exhaust valve springs are equipped with

rotators mounted below the valve springs which rotate

the exhaust valve assemblies. The rocker arms pivot

on hydraulic tappet assemblies and locate in notched

lash pads mounted on the valve stems. The camshaft

lobes bear directly onto the rocker arms and due to

the characteristics of the hydraulic tappet assemblies,

no provision is made for tappet clearance adjustment.

Page 46 of 238

46 Engine

(1) Ensure that all carbon and old gasket mate-

rial is cleaned from the manifold and cylinder head

faces. (2) Check the face of the manifold for distortion

using a straight edge and a feeler gauge. (3) Use a new gasket and ensure that the mani-

fold retaining nuts are tightened to the specified

torque in a spiral pattern from the centre outwards. (4) Adjust the throttle cabl e as described in the

Fuel and Engine Management section and the kick-

down cable as described in the Automatic Transaxle

section.

(5) Start the engine and check for air, fuel and

water leaks.

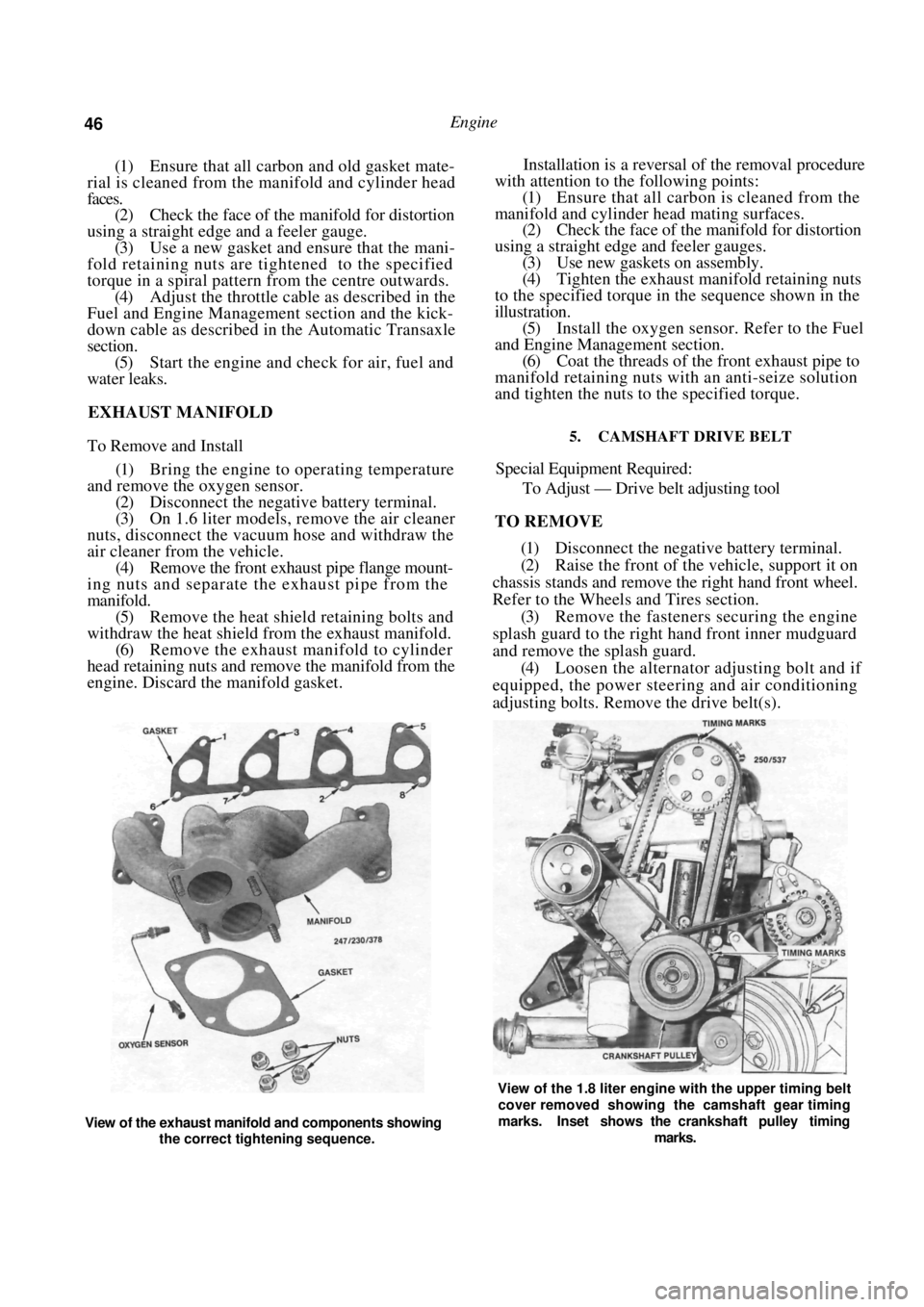

EXHAUST MANIFOLD

To Remove and Install

(1) Bring the engine to operating temperature

and remove the oxygen sensor.

(2) Disconnect the negative battery terminal.

(3) On 1.6 liter models, remove the air cleaner

nuts, disconnect the vacuum hose and withdraw the

air cleaner from the vehicle. (4) Remove the front exhaust pipe flange mount-

ing nuts and separate the exhaust pipe from the

manifold. (5) Remove the heat shield retaining bolts and

withdraw the heat shield from the exhaust manifold. (6) Remove the exhaust manifold to cylinder

head retaining nuts and remove the manifold from the

engine. Discard the manifold gasket. Installation is a reversal of the removal procedure

with attention to the following points:

(1) Ensure that all carbon is cleaned from the

manifold and cylinder head mating surfaces. (2) Check the face of the manifold for distortion

using a straight edge and feeler gauges. (3) Use new gaskets on assembly.

(4) Tighten the exhaust manifold retaining nuts

to the specified torque in the sequence shown in the

illustration. (5) Install the oxygen sensor. Refer to the Fuel

and Engine Management section. (6) Coat the threads of the front exhaust pipe to

manifold retaining nuts with an anti-seize solution

and tighten the nuts to the specified torque.

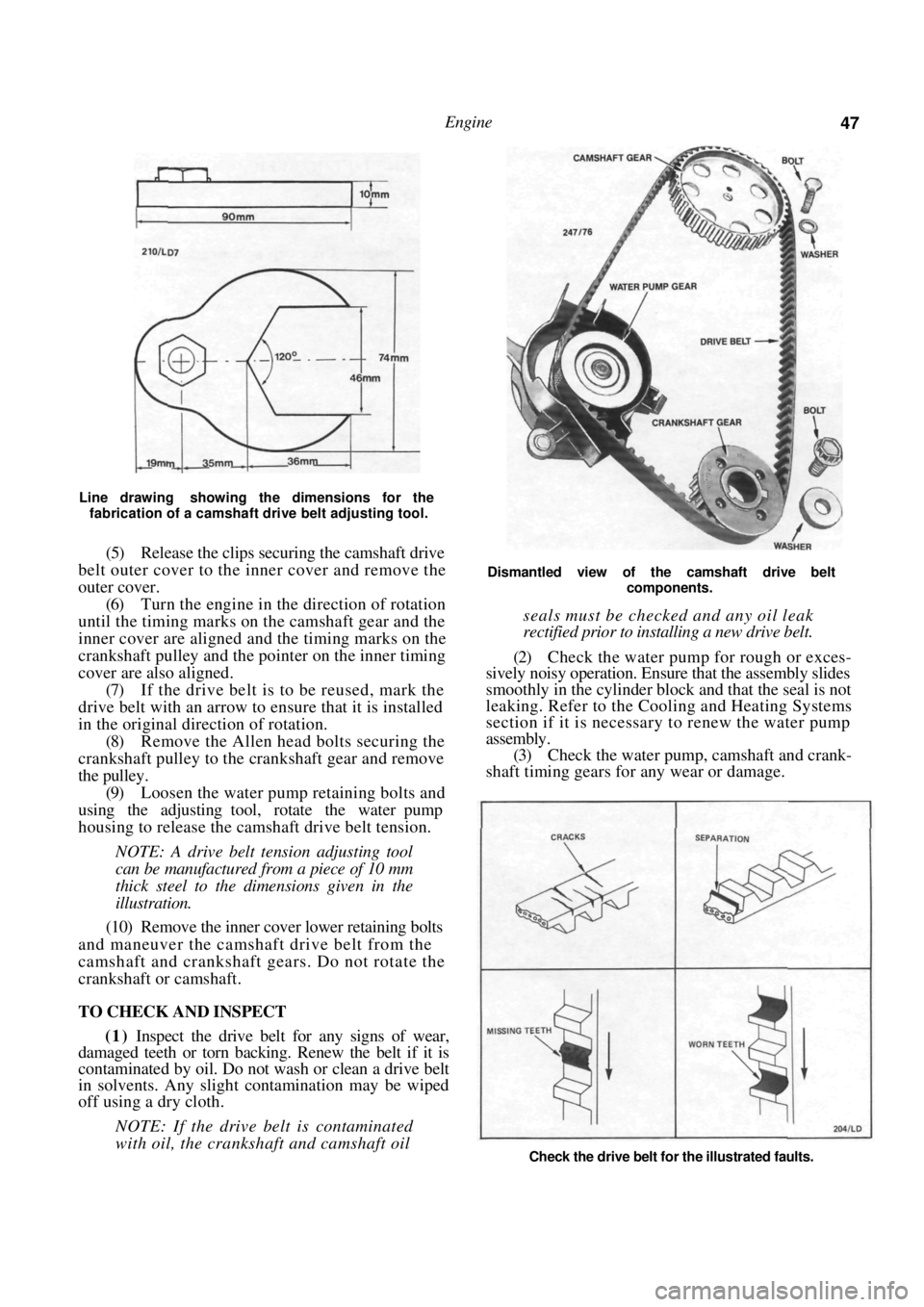

5. CAMSHAFT DRIVE BELT

Special Equipment Required:

To Adjust — Drive belt adjusting tool

TO REMOVE

(1) Disconnect the negative battery terminal.

(2) Raise the front of the vehicle, support it on

chassis stands and remove the right hand front wheel.

Refer to the Wheels and Tires section. (3) Remove the fasteners securing the engine

splash guard to the right hand front inner mudguard

and remove the splash guard. (4) Loosen the alternator adjusting bolt and if

equipped, the power steering and air conditioning

adjusting bolts. Remove the drive belt(s).

View of the exhaust manifold and components showing

the correct tightening sequence.

View of the 1.8 liter engine with the upper timing belt

cover removed showing the camshaft gear timing

marks. Inset shows the crankshaft pulley timing

marks.

Page 47 of 238

Engine 47

Line drawing showing the dimensions for the fabrication of a camshaft drive belt adjusting tool.

(5) Release the clips securing the camshaft drive

belt outer cover to the inner cover and remove the

outer cover.

(6) Turn the engine in the direction of rotation

until the timing marks on the camshaft gear and the

inner cover are aligned and the timing marks on the

crankshaft pulley and the pointer on the inner timing

cover are also aligned.

(7) If the drive belt is to be reused, mark the

drive belt with an arrow to ensure that it is installed

in the original direction of rotation. (8) Remove the Allen head bolts securing the

crankshaft pulley to the crankshaft gear and remove

the pulley. (9) Loosen the water pump retaining bolts and

using the adjusting tool, rotate the water pump

housing to release the camsh aft drive belt tension.

NOTE: A drive belt tension adjusting tool

can be manufactured from a piece of 10 mm

thick steel to the dimensions given in the

illustration.

(10) Remove the inner cover lower retaining bolts

and maneuver the camshaft drive belt from the

camshaft and crankshaft gears. Do not rotate the

crankshaft or camshaft.

TO CHECK AND INSPECT

(1) Inspect the drive belt for any signs of wear,

damaged teeth or torn backing. Renew the belt if it is

contaminated by oil. Do not wash or clean a drive belt

in solvents. Any slight contamination may be wiped

off using a dry cloth.

NOTE: If the drive belt is contaminated

with oil, the crankshaft and camshaft oil

Dismantled view of the camshaft drive belt

components.

seals must be checked and any oil leak

rectified prior to installing a new drive belt.

(2) Check the water pump for rough or exces-

sively noisy operation. Ensure that the assembly slides

smoothly in the cylinder bloc k and that the seal is not

leaking. Refer to the Cooling and Heating Systems

section if it is necessary to renew the water pump

assembly. (3) Check the water pump, camshaft and crank-

shaft timing gears for any wear or damage.

Check the drive belt for the illustrated faults.