length NISSAN PULSAR 1987 Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1987, Model line: PULSAR, Model: NISSAN PULSAR 1987Pages: 238, PDF Size: 28.91 MB

Page 200 of 238

200 Electrical System

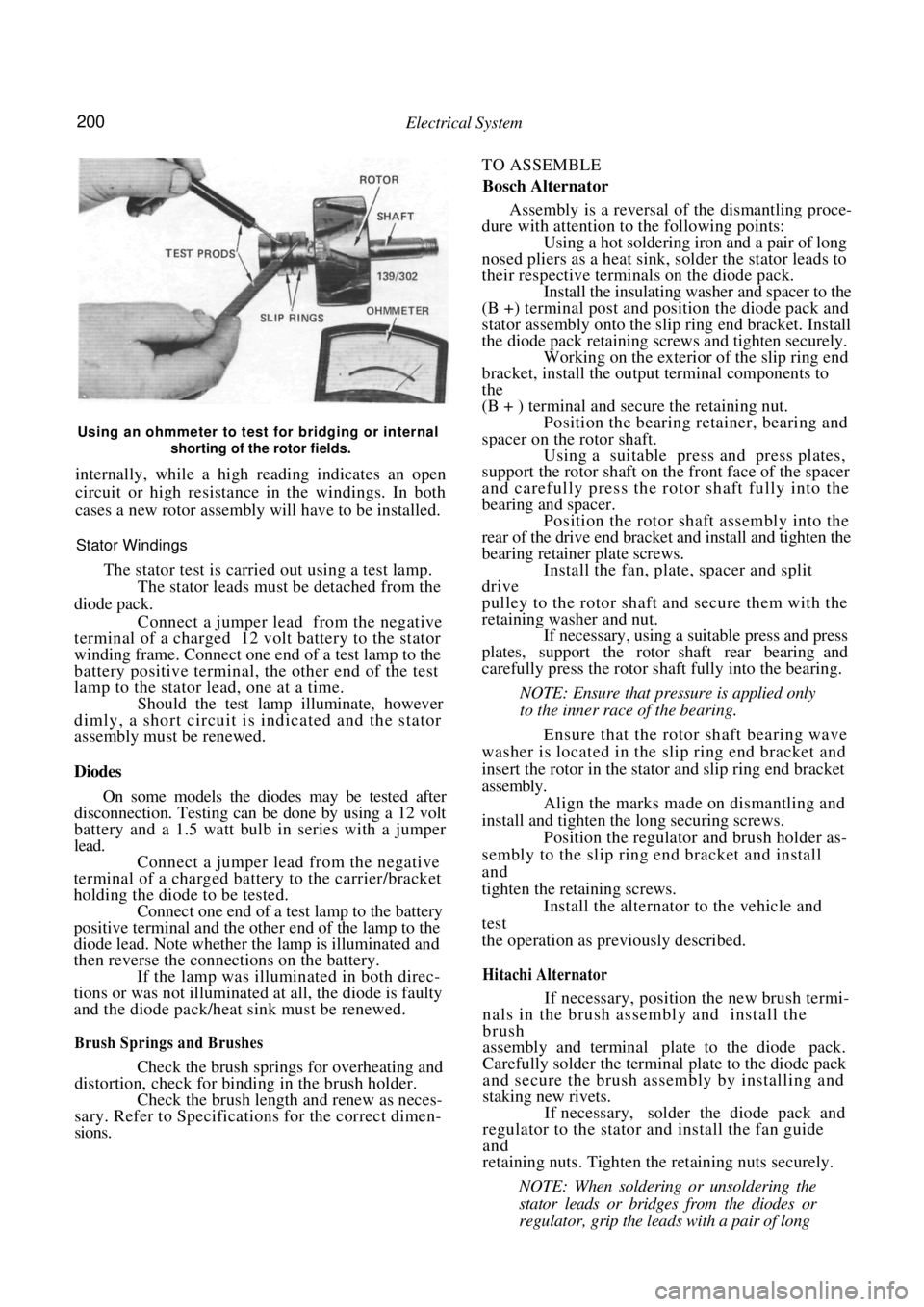

Using an ohmmeter to test for bridging or internal shorting of the rotor fields.

internally, while a high reading indicates an open

circuit or high resistance in the windings. In both

cases a new rotor assembly will have to be installed.

Stator Windings

The stator test is carried out using a test lamp.

The stator leads must be detached from the

diode pack.

Connect a jumper lead from the negative

terminal of a charged 12 volt battery to the stator

winding frame. Connect one en d of a test lamp to the

battery positive terminal, the other end of the test

lamp to the stator lead, one at a time. Should the test lamp illuminate, however

dimly, a short circuit is indicated and the stator

assembly must be renewed.

Diodes

On some models the diod es may be tested after

disconnection. Testing can be done by using a 12 volt

battery and a 1.5 watt bulb in series with a jumper

lead.

Connect a jumper lead from the negative

terminal of a charged battery to the carrier/bracket

holding the diode to be tested. Connect one end of a test lamp to the battery

positive terminal and the other end of the lamp to the

diode lead. Note whether the lamp is illuminated and

then reverse the connections on the battery. If the lamp was illuminated in both direc-

tions or was not illuminated at all, the diode is faulty

and the diode pack/heat sink must be renewed.

Brush Springs and Brushes

Check the brush spring s for overheating and

distortion, check for binding in the brush holder.

Check the brush length and renew as neces-

sary. Refer to Specifications for the correct dimen-

sions. TO ASSEMBLE

Bosch Alternator

Assembly is a reversal of the dismantling proce-

dure with attention to the following points:

Using a hot soldering iron and a pair of long

nosed pliers as a heat sink, solder the stator leads to

their respective terminals on the diode pack. Install the insulating washer and spacer to the

(B +) terminal post and position the diode pack and

stator assembly onto the slip ring end bracket. Install

the diode pack retaining screws and tighten securely. Working on the exterior of the slip ring end

bracket, install the output terminal components to

the

(B + ) terminal and secure the retaining nut.

Position the bearing retainer, bearing and

spacer on the rotor shaft. Using a suitable press and press plates,

support the rotor sh aft on the front face of the spacer

and carefully press the rotor shaft fully into the

bearing and spacer. Position the rotor shaft assembly into the

rear of the drive end bracket and install and tighten the

bearing retainer plate screws. Install the fan, plate, spacer and split

drive

pulley to the rotor shaft and secure them with the

retaining washer and nut. If necessary, using a suitable press and press

plates, support the rotor shaft rear bearing and

carefully press the rotor shaft fully into the bearing.

NOTE: Ensure that pressure is applied only

to the inner race of the bearing.

Ensure that the rotor shaft bearing wave

washer is located in the slip ring end bracket and

insert the rotor in the stator and slip ring end bracket

assembly. Align the marks made on dismantling and

install and tighten the long securing screws.

Position the regulator and brush holder as-

sembly to the slip ring end bracket and install

and

tighten the retaining screws. Install the alternator to the vehicle and

test

the operation as prev iously described.

Hitachi Alternator

If necessary, position the new brush termi-

nals in the brush assembly and install the

brush

assembly and terminal plate to the diode pack.

Carefully solder the terminal plate to the diode pack

and secure the brush assembly by installing and

staking new rivets.

If necessary, solder the diode pack and

regulator to the stator and install the fan guide

and

retaining nuts. Tighten the retaining nuts securely.

NOTE: When soldering or unsoldering the

stator leads or bridges from the diodes or

regulator, grip the leads with a pair of long

Page 202 of 238

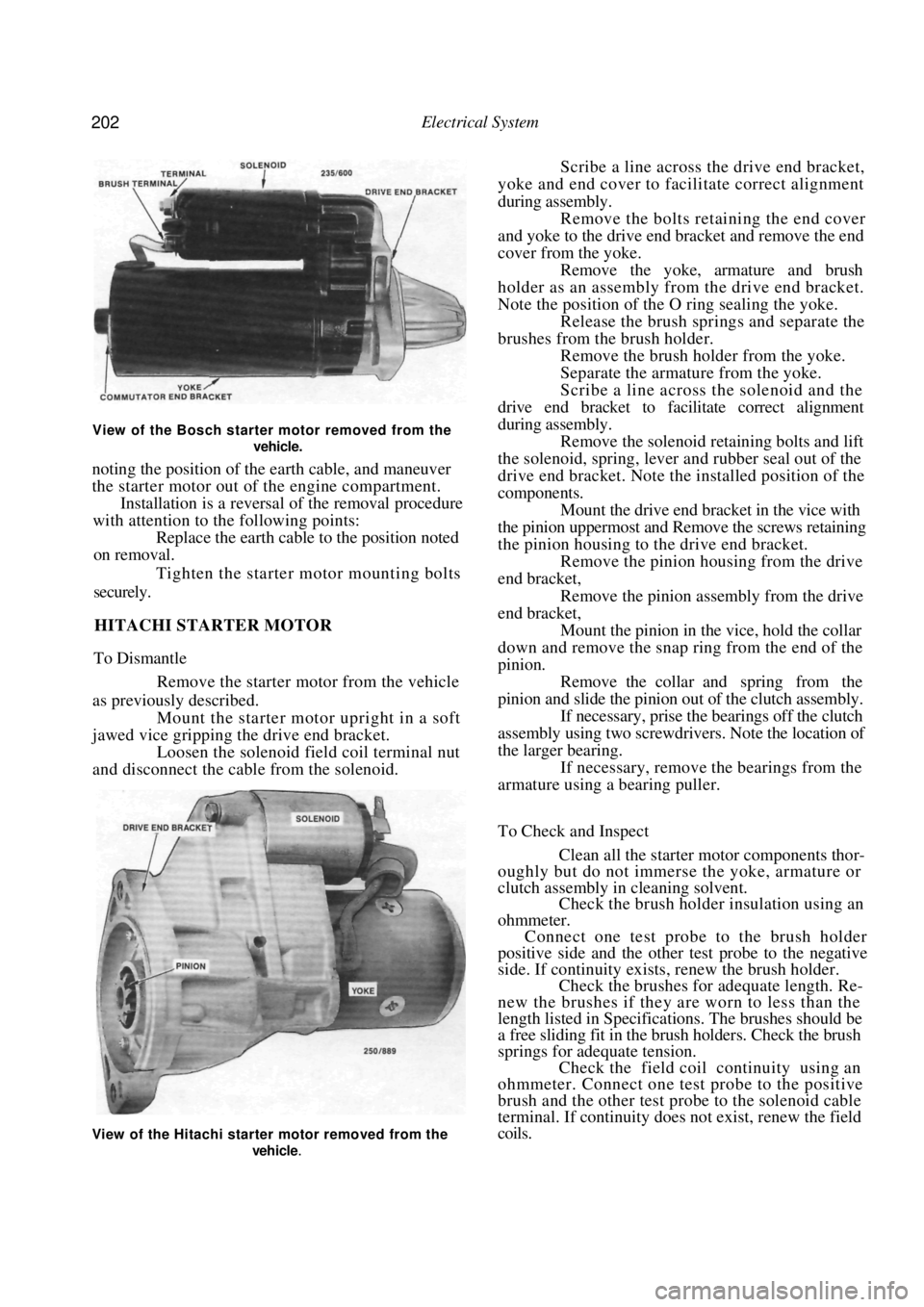

202 Electrical System

View of the Bosch starter motor removed from the

vehicle.

noting the position of the earth cable, and maneuver

the starter motor out of the engine compartment.

Installation is a reversal of the removal procedure

with attention to the following points:

Replace the earth cable to the position noted

on removal.

Tighten the starter motor mounting bolts

securely.

HITACHI STARTER MOTOR

To Dismantle

Remove the starter motor from the vehicle

as previously described. Mount the starter motor upright in a soft

jawed vice gripping the drive end bracket. Loosen the solenoid field coil terminal nut

and disconnect the cable from the solenoid.

Scribe a line across the drive end bracket,

yoke and end cover to facilitate correct alignment

during assembly. Remove the bolts retaining the end cover

and yoke to the drive end bracket and remove the end

cover from the yoke. Remove the yoke, armature and brush

holder as an assembly from the drive end bracket.

Note the position of the O ring sealing the yoke. Release the brush spri ngs and separate the

brushes from the brush holder. Remove the brush holder from the yoke.

Separate the armature from the yoke.

Scribe a line across the solenoid and the

drive end bracket to facilitate correct alignment

during assembly. Remove the solenoid retaining bolts and lift

the solenoid, spring, lever an d rubber seal out of the

drive end bracket. Note the installed position of the

components. Mount the drive end bracket in the vice with

the pinion uppermost and Remove the screws retaining

the pinion housing to the drive end bracket. Remove the pinion housing from the drive

end bracket,

Remove the pinion assembly from the drive

end bracket, Mount the pinion in the vice, hold the collar

down and remove the snap ring from the end of the

pinion. Remove the collar and spring from the

pinion and slide the pinion out of the clutch assembly. If necessary, prise the bearings off the clutch

assembly using two screwdri vers. Note the location of

the larger bearing. If necessary, remove the bearings from the

armature using a bearing puller.

To Check and Inspect

Clean all the starter motor components thor-

oughly but do not immerse the yoke, armature or

clutch assembly in cleaning solvent.

Check the brush holder insulation using an

ohmmeter. Connect one test probe to the brush holder

positive side and the other test probe to the negative

side. If continuity exists , renew the brush holder.

Check the brushes for adequate length. Re-

new the brushes if they are worn to less than the

length listed in Specifications. The brushes should be

a free sliding fit in the brush holders. Check the brush

springs for adequate tension.

Check the field coil continuity using an

ohmmeter. Connect one test probe to the positive

brush and the other test probe to the solenoid cable

terminal. If continuity does not exist, renew the field

coils.

View of the Hitachi starter motor removed from the

vehicle

.

Page 205 of 238

Electrical System 205

Dismantled view of the brush holder assembly. Bosch

starter motor.

side and the other lead to the negative side. If there is

any indication of leakage the ohmmeter will show a

reading other than infinity. Repair or renew the brush

holder if leakage is evident.

(2) Check the brushes for adequate length.

Brushes should be renewed when their length is below

Specifications. They should be a free sliding fit in the

brush holders.

NOTE: Due to the difficulty involved in

removing and installing the brushes in the

Bosch starter motor, it is recommended that

the brush holder be renewed as an assembly.

(3) Check that the commutator is free from

pitting and burning. Clean with a petrol moistened

cloth and polish with a strip of fine glass paper.

A badly worn commutator may be repaired by

mounting in a lathe, spi nning at high speed, and

taking a light cut with a very sharp tool. After turning,

undercut the insulation between the segments.

(4) Check the armature for short circuit using an

ohmmeter.

Place one of the test lead s on the armature shaft

or core and move the other lead around the circum-

ference of the commutator. If the ohmmeter shows a

reading at any point the armature is faulty and should

be renewed.

Check the drive assembly clutch pinion teeth

for wear, scoring or chipping. A clutch in good

condition should take up the drive in one direction

only. It should rotate easily and smoothly in the

non-drive direction and the assembly should move

smoothly along the armature or drive shaft helical

splines.

Check the armature shaft bushes for wear

and renew as necessary. The old bushes must be

removed and the new ones pressed into the end

brackets using a polished mandrel of the exact diam-

eter of the armature shaft. NOTE: The new bushes must not be reamed

to size, as reaming will impair the porosity

of the bushes and cause early failure. New

bushes should be allowed to stand immersed

in clean light engine oil for one hour before

installation.

To Assemble

Assembly is a reversal of the dismantling proce-

dure with attention to the following points:

Lubricate the helix of the drive shaft lightly

with graphite grease and install the drive assembly

to

the drive shaft. Install the stop collar and snap ring, slide the

stop collar over the snap ring to lock the snap ring in

position.

Lubricate the bushes in both end brackets

sparingly with engine oil. Install the engaging lever and gear set into the

drive end bracket. Install the centre rear bracket and the engag-

ing lever seal into the drive end bracket.

Slide the brush holder assembly into position

on the commutator ensuring that the brush holders

are correctly positioned in the anchor points. Install the commutator end bracket to

the

armature, install the shims and C clip. Check that the armature end float is satisfac-

tory and adjust as necessary using shims of the correct

thickness.

Align the slot in the commutator end bracket

with the cut out on the wiring seal and install the

armature end cover to the commutator end bracket.

Install the cover retaini ng screws but do not tighten.

Ensure that the permanent magnets in the

yoke have not picked up any debris and slide the yoke

over the armature ensuring that the wiring seal locates

correctly in the slot in the yoke.

View showing the planetary gear set. Bosch starter

motor.

Page 217 of 238

Electrical System 217

When installing a trailer socket, it may be neces-

sary to replace the original vehicle flasher unit with a

heavy duty unit to maintain the flash rate in accor-

dance with local regulations. Local regulations may

also require the installation of a dashboard mounted

repeater lamp.

Should the trailer socket and plug not be matched,

adaptors can be made or obtained to facilitate con-

nection.

TO INSTAL TRAILER SOCKET.

The minimum materials required are a trailer

socket, mounting bracket, seven core flex, insulated

wiring connectors and a rubber grommet.

(1) Disconnect the negative battery terminal.

(2)Locate the wiring harness for the lamps at

the rear of the vehicle.

For five pin sockets and plugs, use the following

standard trailer wiring code:

Terminal No.CircuitColor2 Left turn signal lampYellow

3Earth White

5 Ri

ght turn signal lampGreen

6Stop lamp Red

7 Tail lam

p Brown

Minimum material needed for wiring up a trailer.

Utilux trailer socket and plug shown.

(3) Identify the wires for the right turn signal

lamp, left turn signal lamp, tail lamp, stop lamp,

reverse lamp and earth. Use the vehicle wiring

diagram in this section to determine the wire color

for each lamp circuit.

(4)Connect the seven core flex to the various

lamp wires using insulated connectors.

For seven pin sockets and plugs, use the following

standard trailer wiring code:

Terminal No.CircuitColor1 Left turn signal lamp Yellow

2 Reversing lamp Black

3EarthWhite

4 Right turn signal Green

lamp

5Electric brakesBlue

6 Stop lampRed

7

Tail lampBrown

For six pin sockets and pl ugs, use the following

standard trailer wiring code:

Terminal No.CircuitColor1 Tail LampBrown

2 Left Turn Signal Lamp Yellow

3Right Turn Signal LampGreen

4 Stop LampRed

5AuxilaryBlue

6 Earth White

(5) Drill a suitably si

zed hole through the vehicle

floor and install a rubber grommet to the hole.

NOTE: Before drilling the hole, check

whether there is an existing hole which may-

be used. Ensure that a rubber grommet is

installed to prevent chafing of the wires.

Pass the seven core flex through the rubber

grommet. Cut the seven core flex to the required length

and slide the dust cover onto the flex. Remove approximately 15 mm of insulation

from each wire in the flex.

Connect the wires of the seven core flex to

the terminals of the socket, using the standard wiring

code and following the socket manufacturers connec-

tion procedure. Assemble the socket and install the dust cover

to the rear of the socket. Install the mounting bracket as close as

possible to the tow bar ball and high enough to

maintain vehicle ground clearance. Install the socket to the mounting bracket.

Connect a trailer plug to the socket and test

for correct lamp operation.

TO INSTAL TRAILER PLUG

The minimum materials required are a trailer

plug, seven core flex and insulated wiring connectors.

The installation procedure for the trailer plug is

similar to that for the socket with attention to the

following points:

Connect the trailer wiring to the plug accord-

ing to the standard wiring color code and the plug

manufacturers instructions. Use a suitable length of

seven core flex and insulated connectors should the

trailer wiring not be long enough.

If the trailer wiring does not conform to the

standard color code, identify each circuit as follows: (a) Locate the trailer earth wire.

PLUG

Page 236 of 238

236 Body

top of the dashboard rearwards and maneuver the

dashboard through the front door opening.

Installation is a reversal of the removal procedure

with attention to the following points:

With the aid of an assistant, ensure that the

outer edges of the dashboard engage properly with the

door pillar brackets.

Hold the dashboard in position and loosely

install all retaining bolts. Align the dashboard

and

tighten all screws and bolts securely.

10. SEAT BELTS

The front and outer rear seats are equipped with

lap/sash inertia reel seat belts, which are designed to

lock with any sudden change in vehicle motion.

The centre rear seat is equipped with a manually

adjustable lap seat belt.

Child restraint anchorages are located on the

parcel shelf behind the rear seat on Sedan models and

at the rear of the lugg age compartment floor on

Hatchback models. These anchorages must be used if

a child's seat or capsule is installed to the vehicle. The

anchorages should not be used for adult scat bells or

harnesses.

The seat belts should be periodically inspected as

described below. Any seat belt assembly that is worn

or damaged, or has been subjected to abnormal

loadings in a collision, should be renewed as a

complete assembly.

Only mild soap and water should be used to clean

the webbing. Contamination wi th polish, oil, bleaches

and other chemicals should be avoided.

TO INSPECT

(1) Check the seat belt webbing for fraying, cuts,

burns or other damage. On inertia reel belts, slowly

pull the belt from the reel to allow the entire length to

be examined. If the webbing is damaged or worn,

renew the seat belt assembly.

Check the seat belt webbing for fraying, cuts, burns or

other damage.

Ensure that the belts are not twisted.

Check all retaining nuts and bolts for secu-

rity.

Inspect the belt buckles for correct and

secure engagement. If the buckles are damaged or do

not function correctly, renew the seat belt assembly. On inertia reel seat belts, check the retractor

mechanism as follows:

Pull the belt slowly from the reel and check

for smooth operation. Release the belt and ensure that

it retracts fully.

Pull the belt rapidly from the reel. The reel

should lock.

Drive the vehicle at walking pace and at-

tempt to withdraw the belt slowly while braking

sharply. The reel should lock. If the retractor mechanism does not function

correctly, renew the seat belt assembly.

11. SEATS

FRONT SEAT

To Remove and Install

Adjust the seat to the most forward position.

Remove the mounting bolts from the rear of

the seat.

Adjust the seat to allow access to the mount-

ing bolts at the front of the seat. Remove the mounting bolts and withdraw

the seat from the vehicle.

Installed view of the fron t seat belt with the door pillar

trim removed showing the mounting points.