steering NISSAN PULSAR 1987 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1987, Model line: PULSAR, Model: NISSAN PULSAR 1987Pages: 238, PDF Size: 28.91 MB

Page 179 of 238

Brakes 179

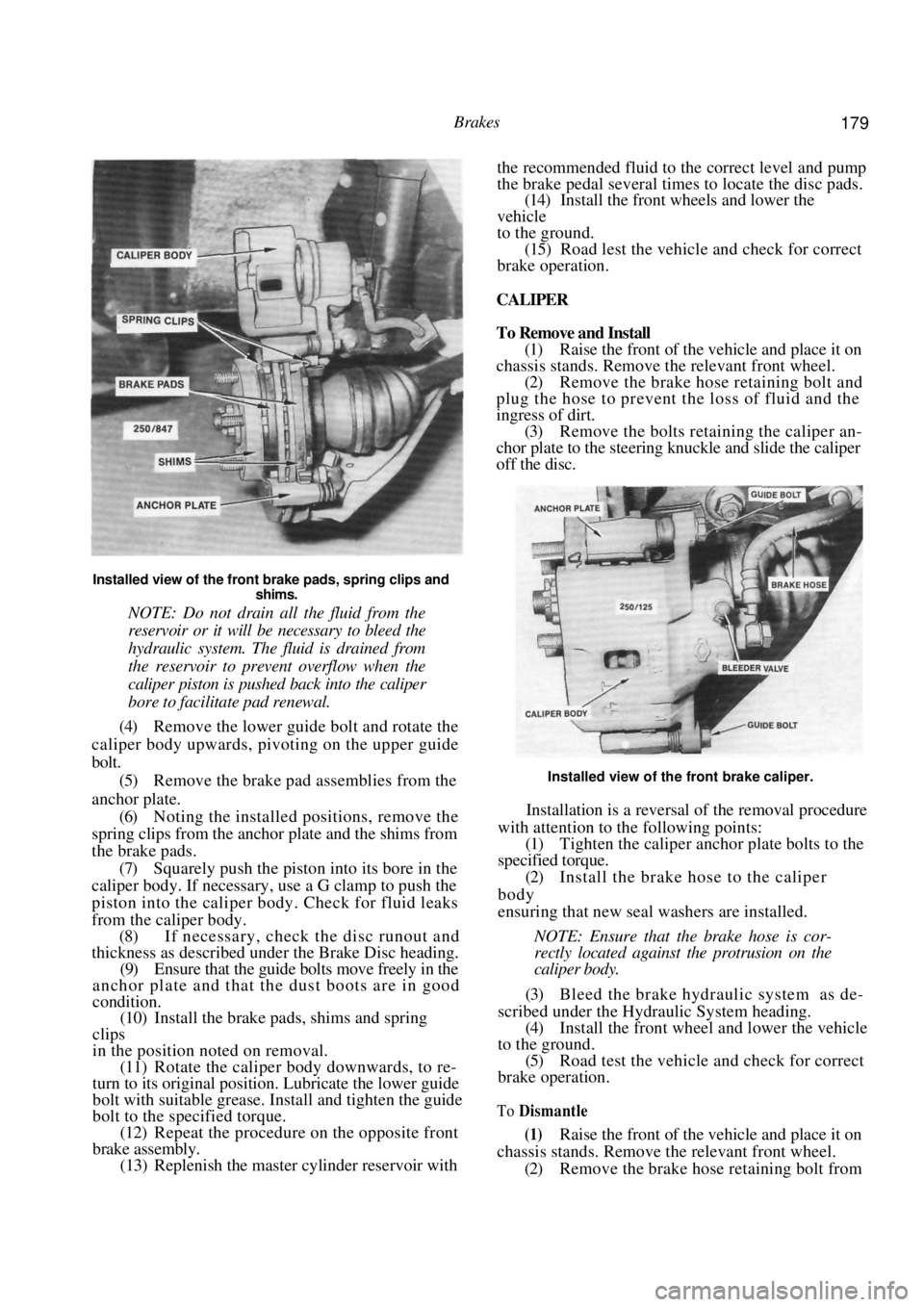

Installed view of the front brake pads, spring clips and shims.

NOTE: Do not drain all the fluid from the

reservoir or it will be necessary to bleed the

hydraulic system. The fluid is drained from

the reservoir to prevent overflow when the

caliper piston is pushed back into the caliper

bore to facilitate pad renewal.

(4) Remove the lower guide bolt and rotate the

caliper body upwards, pivoting on the upper guide

bolt.

(5) Remove the brake pad assemblies from the

anchor plate. (6) Noting the installed positions, remove the

spring clips from the anchor plate and the shims from

the brake pads.

(7) Squarely push the piston into its bore in the

caliper body. If necessary, us e a G clamp to push the

piston into the caliper b ody. Check for fluid leaks

from the calip er body.

(8) If necessary, check the disc runout and

thickness as described under the Brake Disc heading.

(9) Ensure that the guide bolts move freely in the

anchor plate and that the dust boots are in good

condition. (10) Install the brake pads, shims and spring

clips

in the position noted on removal. (11) Rotate the caliper body downwards, to re-

turn to its original position. Lubricate the lower guide

bolt with suitable grease. In stall and tighten the guide

bolt to the specified torque. (12) Repeat the procedure on the opposite front

brake assembly. (13) Replenish the master cylinder reservoir with the recommended fluid to the correct level and pump

the brake pedal several times to locate the disc pads.

(14)

Install the front wheels and lower the

vehicle

to the ground. (15) Road lest the vehicle and check for correct

brake operation.

CALIPER

To Remove and Install

(1) Raise the front of the vehicle and place it on

chassis stands. Remove the relevant front wheel. (2) Remove the brake hose retaining bolt and

plug the hose to prevent the loss of fluid and the

ingress of dirt. (3) Remove the bolts retaining the caliper an-

chor plate to the steering knuckle and slide the caliper

off the disc.

Installed view of the front brake caliper.

Installation is a reversal of the removal procedure

with attention to the following points:

(1) Tighten the caliper anch or plate bolts to the

specified torque.

(2) Install the brake hose to the caliper

body

ensuring that new seal washers are installed.

NOTE: Ensure that the brake hose is cor-

rectly located against the protrusion on the

caliper body.

(3) Bleed the brake hydraulic system as de-

scribed under the Hydraulic System heading. (4) Install the fron t wheel and lower the vehicle

to the ground. (5) Road test the vehicle and check for correct

brake operation.

To Dismantle

(1) Raise the front of the vehicle and place it on

chassis stands. Remove the relevant front wheel.

(2) Remove the brake hose retaining bolt from

Page 181 of 238

Brakes 181

chor plate to the steering knuckle and slide the caliper

off the brake disc. Suspend the caliper clear of the

work area using wire or cord.

(3) Suitably mark the location of the disc in

relation to the hub.

(4) Slide the disc off the hub. If the disc is

difficult to remove, install two M8 x 1.25 mm bolts in

the disc and by alternatively tightening the bolts,

remove the disc.

Do not use a hammer to remove the disc.

Installation is a reversal of the removal procedure

ensuring that the mating face s of the disc and hub are

clean and free from burrs and that the marks made on

removal are aligned.

To Inspect

(1) Inspect the machined faces of the disc for

scores, cracks, wear and signs of overheating. (2) Using a micrometer, measure the thickness

of the disc at several positi ons around the face of the

disc. Renew the disc if the minimum thickness is

below Specifications.

Inspect the brake discs for scoring and wear.

(3) If the disc thickness is satisfactory but the

disc is scored, machine equal amounts from the

machined face on each side of the disc, to restore the

serviceability of the disc.

NOTE: Disc machining is best entrusted to

a reliable brake specialist who can advise on

disc serviceability.

6. REAR DISC BRAKES

Special Equipment Required:

To Check Disc Runout — Dial gauge

To Check Disc Thickness — Micrometer

TO CHECK AND RENEW BRAKE PADS

( 1 ) Raise the rear of the vehicle and place it on

chassis stands. Remove the rear wheels.

Renew the rear brake pads if the friction material is less

than 2 mm thick.

(2) Inspect the brake pads on both sides of the

vehicle. If the friction material on one or more of the

pads is less than 2 mm thick or contaminated with

fluid or grease, renew the brake pad as a set as follows.

NOTE: If the brake pads are contaminated

trace and rectify the cause prior to installing

the new set of pads.

(3) Drain approximately two thirds of the brake

fluid from the master cylinder reservoir. This can be

done by loosening the bleeder valve on the caliper and

allowing the fluid to drai n into a container. Discard

this fluid.

NOTE: Do not drain all the fluid from the

reservoir otherwise it will be necessary to

bleed the hydraulic system. The fluid is

drained from the reservoir to prevent over-

flow when the caliper piston is pushed back

into the caliper bore to facilitate pad re-

newal.

(4) Remove the guide bolts and lift the caliper

body clear of the disc.

NOTE: Do not allow the caliper to hang on

the brake hose.

(5) Noting the installed positions, remove the

brake pads, shims and spring clips from the anchor

plate.

(6) Using a pair of long nosed pliers with the

nose located in the recesses of the piston, rotate the

piston clockwise to retract it into the cylinder body.

Align the recesses between the brake pad retaining

lugs on the caliper body. Refer to the illustration. (7) If necessary, check the disc runout and

thickness as described under the Brake Disc heading.

(8) Ensure that the guide bolts move freely in the

caliper body and that the dust boots are in good

condition.

Page 206 of 238

206 Electrical System

Install the armature and yoke to the drive end

bracket rotating the drive to align the reduction gears.

Do not use force.

Install the retaining through bolts to the

commutator end bracket and lighten the through bolts

and armature end cover retaining screws securely. Install the solenoid to the drive end bracket,

install the retaining screws and tighten them securely.

Install the brush connector strap and

install

the retaining nut and washer and tighten securely.

9 . IGNITION SYSTEM

The testing and repair procedures for the ignition

system are fully covered in the Fuel and Engine

Management section.

10. STEERING WHEEL

The removal and installation procedures for the

steering wheel and horn pad are fully covered in the

Steering section.

11. SWITCHES AND CONTROLS

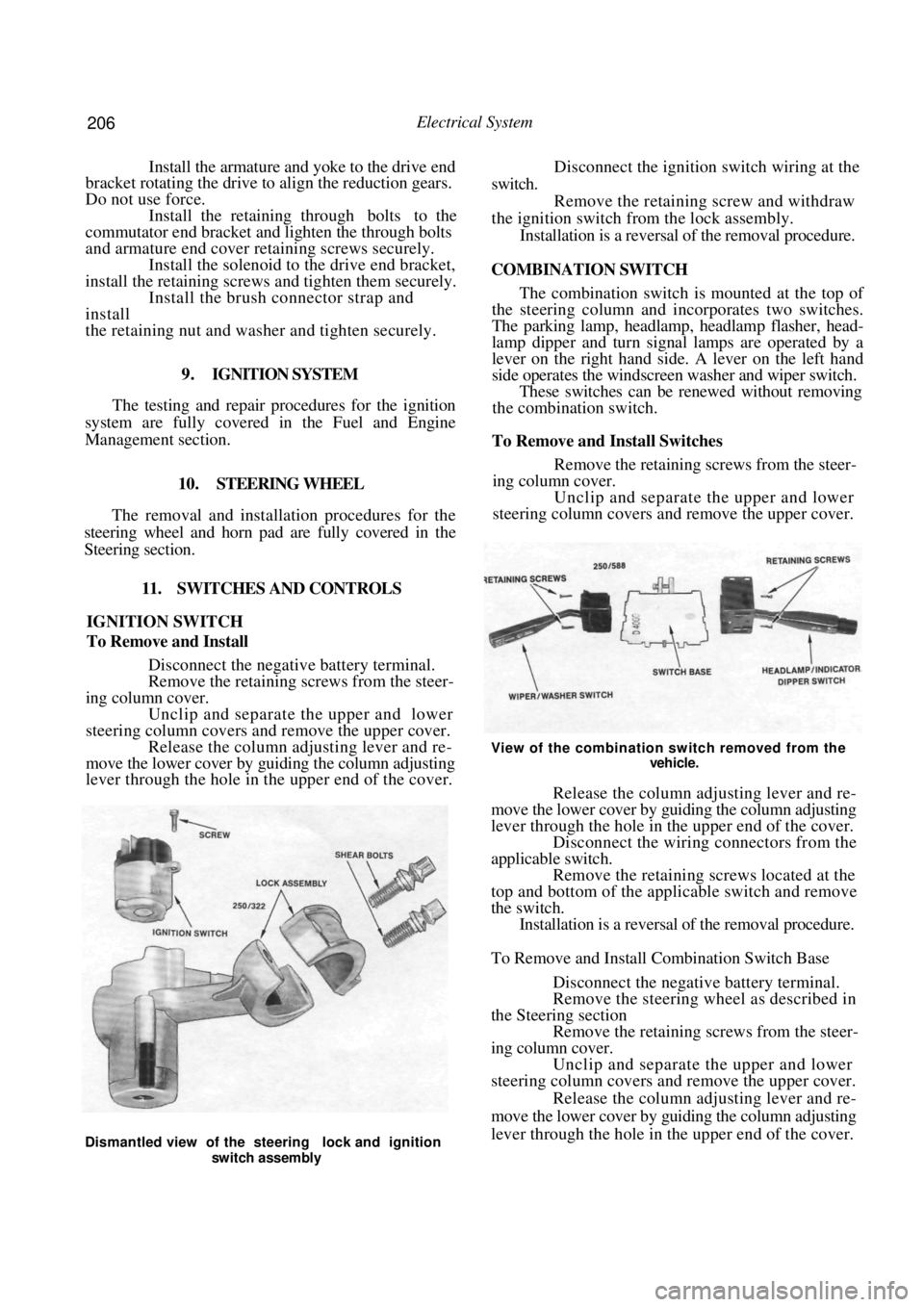

IGNITION SWITCH

To Remove and Install

Disconnect the negative battery terminal.

Remove the retaining screws from the steer-

ing column cover. Unclip and separate the upper and lower

steering column covers and remove the upper cover. Release the column adjusting lever and re-

move the lower cover by guiding the column adjusting

lever through the hole in the upper end of the cover.

Disconnect the ignition switch wiring at the

switch. Remove the retaining screw and withdraw

the ignition switch fr om the lock assembly.

Installation is a reversal of the removal procedure.

COMBINATION SWITCH

The combination switch is mounted at the top of

the steering column and incorporates two switches.

The parking lamp, headlamp, headlamp flasher, head-

lamp dipper and turn signal lamps are operated by a

lever on the right hand side. A lever on the left hand

side operates the windscreen washer and wiper switch.

These switches can be re newed without removing

the combination switch.

To Remove and Install Switches

Remove the retaining screws from the steer-

ing column cover.

Unclip and separate the upper and lower

steering column covers and remove the upper cover.

View of the combination switch removed from the

vehicle.

Release the column adjusting lever and re-

move the lower cover by guiding the column adjusting

lever through the hole in the upper end of the cover. Disconnect the wiring connectors from the

applicable switch. Remove the retaining screws located at the

top and bottom of the applicable switch and remove

the switch. Installation is a reversal of the removal procedure.

To Remove and Install Combination Switch Base

Disconnect the negative battery terminal.

Remove the steering wheel as described in

the Steering section Remove the retaining screws from the steer-

ing column cover. Unclip and separate the upper and lower

steering column covers and remove the upper cover.

Release the column adjusting lever and re-

move the lower cover by guiding the column adjusting

lever through the hole in the upper end of the cover.

Dismantled view of the steering lock and ignition

switch assembly

Page 207 of 238

Electrical System 207

Disconnect the wiring connectors from the

rear of the combination switch.

Loosen the clamping screw located at the left

hand side of the combination switch. Push, turn and slide the combination switch

from the steering column. Installation is a reversal of the removal procedure.

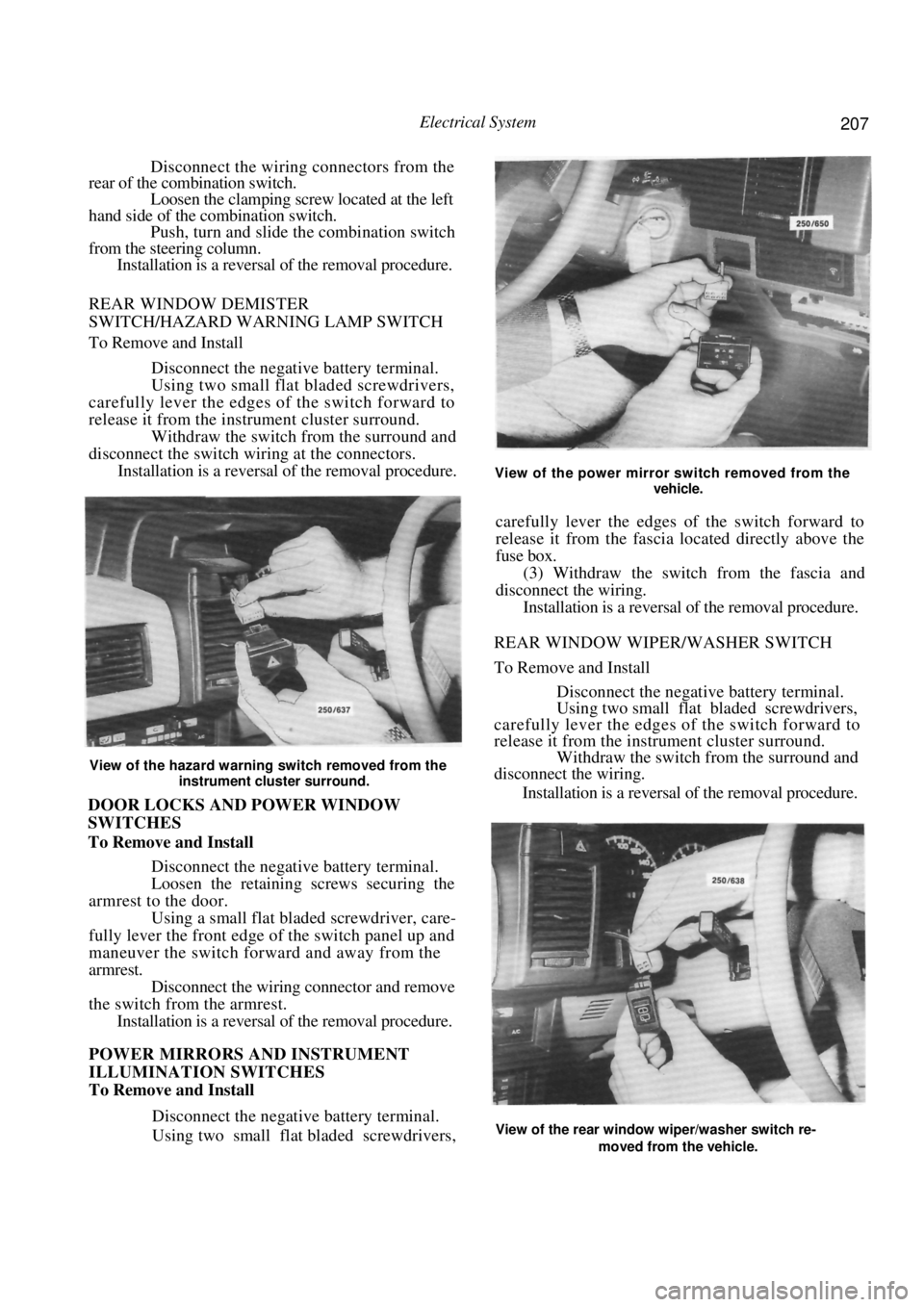

REAR WINDOW DEMISTER

SWITCH/HAZARD WARNING LAMP SWITCH

To Remove and Install

Disconnect the negative battery terminal.

Using two small flat bladed screwdrivers,

carefully lever the edges of the switch forward to

release it from the instrument cluster surround.

Withdraw the switch from the surround and

disconnect the switch wiri ng at the connectors.

Installation is a reversal of the removal procedure.

View of the hazard warning switch removed from the

instrument cluster surround.

DOOR LOCKS AND POWER WINDOW

SWITCHES

To Remove and Install

Disconnect the negative battery terminal.

Loosen the retaining screws securing the

armrest to the door. Using a small flat bladed screwdriver, care-

fully lever the front edge of the switch panel up and

maneuver the switch forward and away from the

armrest. Disconnect the wiring connector and remove

the switch from the armrest. Installation is a reversal of the removal procedure.

POWER MIRRORS AND INSTRUMENT

ILLUMINATION SWITCHES

To Remove and Install

Disconnect the negative battery terminal.

Using two small flat bladed screwdrivers,

View of the power mirror switch removed from the

vehicle.

carefully lever the edges of the switch forward to

release it from the fascia lo cated directly above the

fuse box.

(3) Withdraw the switch from the fascia and

disconnect the wiring.

Installation is a reversal of the removal procedure.

REAR WINDOW WIPER/WASHER SWITCH

To Remove and Install

Disconnect the negative battery terminal.

Using two small flat bladed screwdrivers,

carefully lever the edges of the switch forward to

release it from the instrument cluster surround. Withdraw the switch from the surround and

disconnect the wiring.

Installation is a reversal of the removal procedure.

View of the rear window wiper/washer switch re-

moved from the vehicle.

Page 235 of 238

Body 235

lever and remove the screws underneath. Withdraw

the rear console.

On manual transaxle models, unscrew the

gear lever knob and prise out the gear lever rubber

boot. On automatic transaxle models, prise out the

panel around the selector lever and maneuver the

panel over the lever. Remove the screws retaining the front of the

console to the floor panel and withdraw the console

from the vehicle. Installation is a reversal of the removal procedure.

9, DASHBOARD

TO REMOVE AND INSTAL

Disconnect the negative battery terminal.

Remove the centre console as previously

described in this section. Remove the steering wheel as described in

the Steering section. Remove the upper and lower steering col-

umn shrouds and remove the combination switch.

Refer to the Electrical System section if necessary. Remove the retaining screws and withdraw

the lower trim panel from underneath the steering

column. Remove the screws from underneath the

bonnet lock handle and slide the bonnet lock handle

downwards out of the dashboard. Remove the screws retaining the centre fas-

cia panel, two upper and two lower, withdraw the

fascia panel slightly and disconnect the wiring to the

cigarette lighter.

Dismantled view of the centre console assembly. Au-

tomatic transaxle model.

Remove the radio/cassette bracket retaining

screws. Disconnect the aerial and the wiring and

withdraw the radio/cassette from the centre bracket. Remove the heater control knobs and re-

move the heater fascia panel screws. Carefully remove

the heater fascia panel leaving the heater controls in

place.

Loosen the bolt retaining the large wiring

connector at the lower right hand side of the dash-

board. As the bolt is loosened it will force the

connector apart. Using a screwdriver, carefully prise out the

demister ducts from th e top of the dashboard.

Using a suitable socket, remove the bolts

from underneath the demister ducts. Remove the bolts from the outer lower edges

and the lower part of th e centre bracket assembly.

NOTE: Refer to the illustration for the

location of the dashboard retaining bolts.

(14) With the aid of an assistant lift the dash-

board straight up at the door pillar brackets. Tilt the

View of the dashboard removed from the vehicle. The arrows indicate the location of the retaining bolts.