key NISSAN PULSAR 1987 Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1987, Model line: PULSAR, Model: NISSAN PULSAR 1987Pages: 238, PDF Size: 28.91 MB

Page 36 of 238

36 Roadside Trouble Shooting

Check the engine oil for level and dilution on the dipstick.

turn creamy. The oil level will also have increased. If

the oil is emulsified, proceed to operation (5).

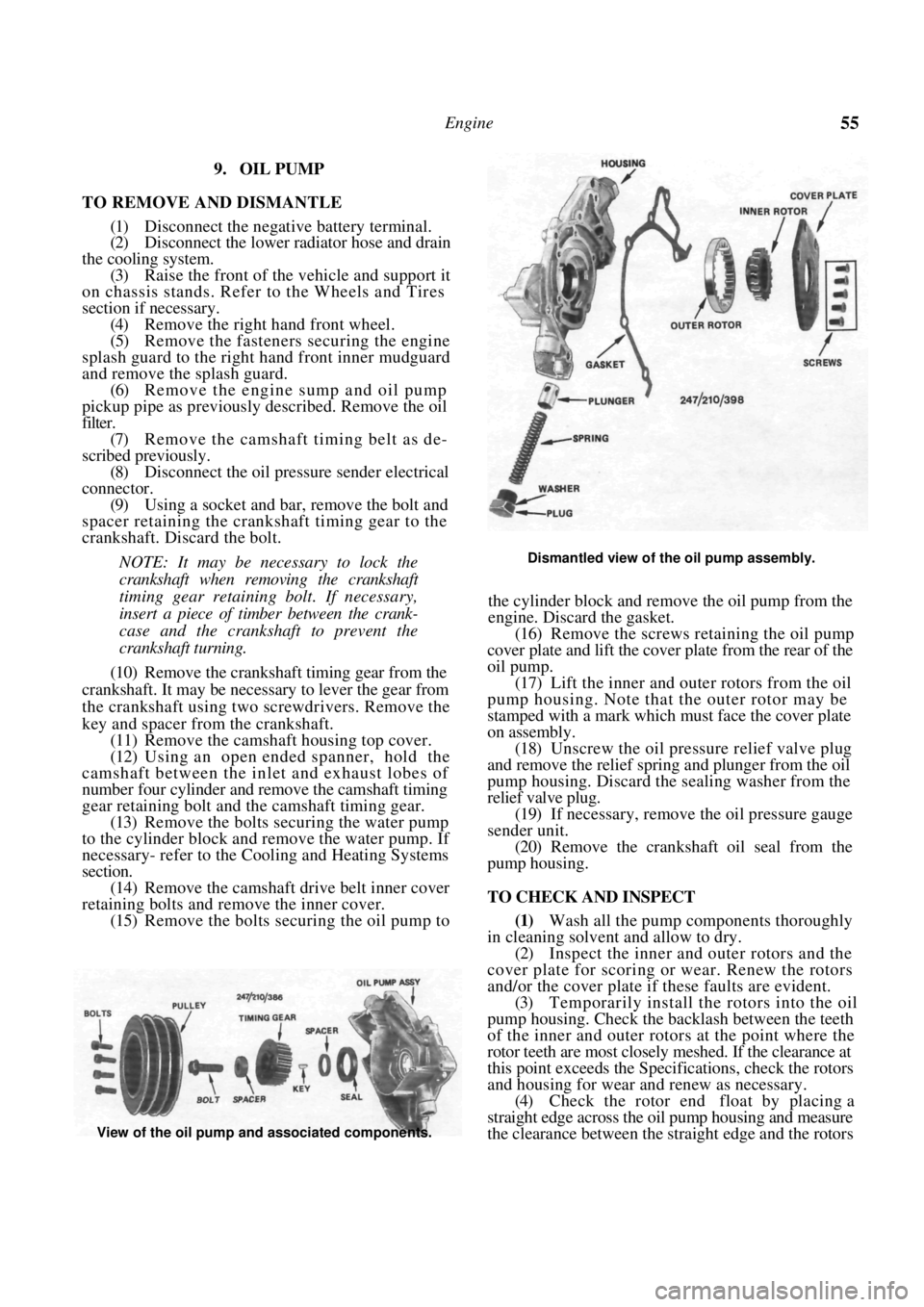

(2) Remove the fusible link that is positioned

third from the front of th e fusible link connection

block, located at the rear of the battery. Disconnect

the coil high tension lead from the coil. (3) Remove all of the spark plugs except one.

(4) Have an assistant operate the ignition switch

to rotate the engine and listen to the sound made by

the engine as it is being turned over. Move the spark

plug to a different cylinder and repeat the lest. By performing the same test on all cylinders, a

rough comparison can be made to determine if there

is any loss of compression in any cylinder. This will be

apparent by the different sound made by the engine as

it is being turned over.

Normally, if the compression is satisfactory the

cylinder with the spark plug installed will create a

resistance to the rotating engine.

However, if the compression is low in a particular

cylinder, the engine will tu rn over easily and smoothly

when that spark plug is in place.

(5) If the above checks show a loss of coolant

which is present in the engine oil or on the spark plug,

one or more of the following faults may be the cause:

Blown cylinder head gasket.

Cracked cylinder or cylinder head.

If the compression check showed any weak or

inconsistent compressions, in addition to the above

faults any of the following could also be the cause:

Broken piston{s)

Burnt or broken valve(s).

Provided the previous checks do not indicate an

View showing the location of the fusible links.

internal leakage of coolant, proceed with the follow-

ing:

(6) Remove the distributor cap and, with the aid

of an assistant operating th e starter motor, check that

the rotor arm rotates as the engine turns over. (7) Remove the camshaft hous ing top cover and.

again with an assistant operating the ignition switch,

check that all the valves open and close as the engine

turns over.

If the rotor arm or valves do not operate with

engine rotation, one of the following faults may be the

cause:

Rotor arm does not turn but valves operate:

Distributor drive shaft broken.

Rotor arm and valves do not operate: Broken

camshaft drive belt. Sheare d crankshaft timing gear

drive key. Sheared camshaft liming gear drive dowel.

Provided that all the previous checks have been

performed correctly and the operator is satisfied that

none of the components are at fault, all that remains

is for the ignition and valve timing to be checked. It

should be noted, however, that if loss of valve timing

proves to be the fault, th e cause of this occurrence

must be sought and rectified.

(8) In order to check the valve timing it will be

necessary to remove the distributor cap and the

camshaft housing top cover and turn the engine

clockwise via the crankshaft pulley until No. 1 piston

is at TDC on the compression stroke. In this position

the valves of No. 1 cylinder should be closed, the

valves of No. 4 should be rocking and the distributor

rotor should be pointing to the No. 1 high tension lead

segment in the distributor cap.

Page 55 of 238

Engine 55

9. OIL PUMP

TO REMOVE AND DISMANTLE

(1) Disconnect the negative battery terminal.

(2) Disconnect the lower radiator hose and drain

the cooling system. (3) Raise the front of the vehicle and support it

on chassis stands. Refer to the Wheels and Tires

section if necessary. (4) Remove the right hand front wheel.

(5) Remove the fasteners securing the engine

splash guard to the right hand front inner mudguard

and remove the splash guard. (6) Remove the engine sump and oil pump

pickup pipe as previously described. Remove the oil

filter.

(7) Remove the camshaft timing belt as de-

scribed previously. (8) Disconnect the oil pressure sender electrical

connector. (9) Using a socket and bar, remove the bolt and

spacer retaining the crankshaft timing gear to the

crankshaft. Discard the bolt.

NOTE: It may be necessary to lock the

crankshaft when removing the crankshaft

timing gear retaining bolt. If necessary,

insert a piece of timber between the crank-

case and the crankshaft to prevent the

crankshaft turning.

(10) Remove the crankshaft timing gear from the

crankshaft. It may be necessary to lever the gear from

the crankshaft using two screwdrivers. Remove the

key and spacer from the crankshaft. (11) Remove the camshaft housing top cover.

(12) Using an open ended spanner, hold the

camshaft between the inlet and exhaust lobes of

number four cylinder and remove the camshaft timing

gear retaining bolt and the camshaft timing gear.

(13) Remove the bolts securing the water pump

to the cylinder block and remove the water pump. If

necessary- refer to the Cooling and Heating Systems

section. (14) Remove the camshaft drive belt inner cover

retaining bolts and remove the inner cover. (15) Remove the bolts securing the oil pump to

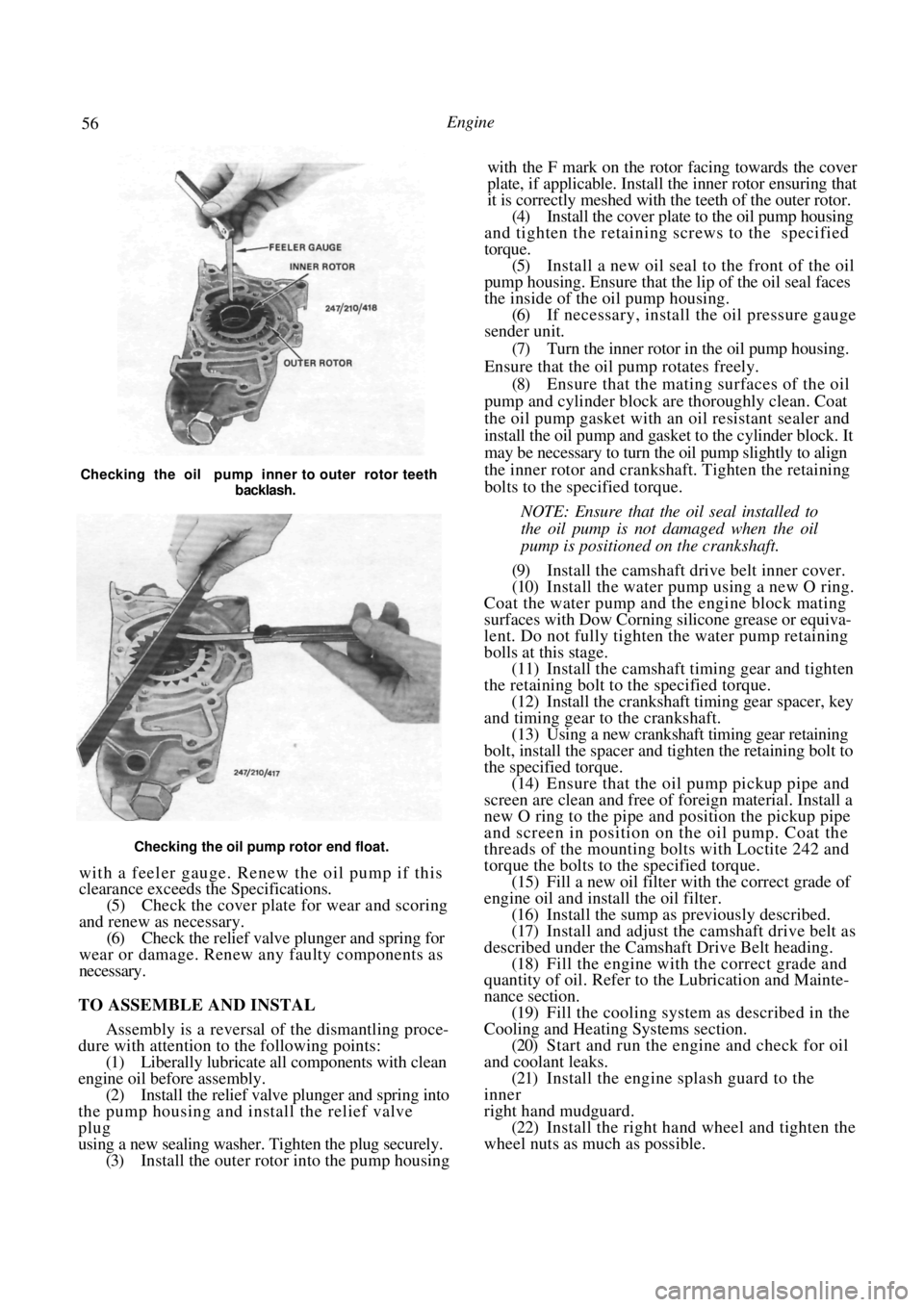

Dismantled view of the oil pump assembly.

the cylinder block and remove the oil pump from the

engine. Discard the gasket.

(16) Remove the screws retaining the oil pump

cover plate and lift the cover plate from the rear of the

oil pump. (17) Lift the inner and outer rotors from the oil

pump housing. Note that the outer rotor may be

stamped with a mark which must face the cover plate

on assembly. (18) Unscrew the oil pressure relief valve plug

and remove the relief spring and plunger from the oil

pump housing. Discard the sealing washer from the

relief valve plug. (19) If necessary, remove the oil pressure gauge

sender unit.

(20) Remove the crankshaft oil seal from the

pump housing.

TO CHECK AND INSPECT

(1) Wash all the pump components thoroughly

in cleaning solvent and allow to dry.

(2) Inspect the inner and outer rotors and the

cover plate for scoring or wear. Renew the rotors

and/or the cover plate if these faults are evident. (3) Temporarily install the rotors into the oil

pump housing. Check the b acklash between the teeth

of the inner and outer rotors at the point where the

rotor teeth are most closely meshed. If the clearance at

this point exceeds the Specif ications, check the rotors

and housing for wear and renew as necessary. (4) Check the rotor end float by placing a

straight edge across the oil pump housing and measure

the clearance between the straight edge and the rotors

View of the oil pump and associated components.

Page 56 of 238

56 Engine

Checking the oil pump rotor end float.

with a feeler gauge. Renew the oil pump if this

clearance exceeds the Specifications.

(5) Check the cover plate for wear and scoring

and renew as necessary. (6) Check the relief valve plunger and spring for

wear or damage. Renew any faulty components as

necessary.

TO ASSEMBLE AND INSTAL

Assembly is a reversal of the dismantling proce-

dure with attention to the following points:

(1) Liberally lubricate all components with clean

engine oil before assembly. (2) Install the relief valve plunger and spring into

the pump housing and install the relief valve

plug

using a new sealing washer. Tighten the plug securely. (3) Install the outer rotor into the pump housing with the F mark on the rotor facing towards the cover

plate, if applicable. Install the inner rotor ensuring that

it is correctly meshed with the teeth of the outer rotor.

(4)

Install the cover plate to the oil pump housing

and tighten the retaining screws to the specified

torque. (5) Install a new oil seal to the front of the oil

pump housing. Ensure that the lip of the oil seal faces

the inside of the oil pump housing. (6) If necessary, install the oil pressure gauge

sender unit.

(7) Turn the inner rotor in the oil pump housing.

Ensure that the oil pump rotates freely. (8) Ensure that the mating surfaces of the oil

pump and cylinder block are thoroughly clean. Coat

the oil pump gasket with an oil resistant sealer and

install the oil pump and gasket to the cylinder block. It

may be necessary to turn the oil pump slightly to align

the inner rotor and crankshaft. Tighten the retaining

bolts to the specified torque.

NOTE: Ensure that the oil seal installed to

the oil pump is not damaged when the oil

pump is positioned on the crankshaft.

(9) Install the camshaft drive belt inner cover.

(10) Install the water pump using a new O ring.

Coat the water pump and the engine block mating

surfaces with Dow Corning silicone grease or equiva-

lent. Do not fully tighten the water pump retaining

bolls at this stage. (11) Install the camshaft timing gear and tighten

the retaining bolt to the specified torque.

(12) Install the crankshaft timing gear spacer, key

and timing gear to the crankshaft. (13) Using a new crankshaft timing gear retaining

bolt, install the spacer and tighten the retaining bolt to

the specified torque. (14) Ensure that the oil pump pickup pipe and

screen are clean and free of foreign material. Install a

new O ring to the pipe and position the pickup pipe

and screen in position on the oil pump. Coat the

threads of the mounting bolts with Loctite 242 and

torque the bolts to the specified torque. (15) Fill a new oil filter with the correct grade of

engine oil and install the oil filter. (16) Install the sump as previously described.

(17) Install and adjust the camshaft drive belt as

described under the Camshaft Drive Belt heading. (18) Fill the engine with the correct grade and

quantity of oil. Refer to the Lubrication and Mainte-

nance section.

(19) Fill the cooling system as described in the

Cooling and Heating Systems section. (20) Start and run the engine and check for oil

and coolant leaks. (21) Install the engine splash guard to the

inner

right hand mudguard. (22) Install the right hand wheel and tighten the

wheel nuts as much as possible.

Checking the oil pump inner to outer rotor teeth

backlash.

Page 63 of 238

Engine

edge of the bearing cap to cylinder block joint. Install

the bearing cap bolts and tighten to the specified

torque.

(17) Lubricate the l i p of the new oil seal with

lithium grease and carefully install the seal into

position over the crankshaft . Insert the seal as far as

possible using finger pressure and then fully install the

sea! using a tubular drift. Ensure that the seal is not

damaged during installation and that the seal is

mounted square to the block face.

(18) Install the remainder of the engine

compo-

nents by referring to the relevant headings in

this

section.

TO RENEW CRANKSHAFT OIL SEALS

Front

(1) Remove the camshaft drive belt as previ-

ously described.

(2) Disconnect the lower radiator hose and drain

the cooling system. (3) Select fifth gear on manual transaxle models

and firmly apply the handbrake. (4) On automatic transaxle models, remove the

torque converter inspection cover to allow access to

the ring gear. Have an assi stant hold the ring gear

using a suitable lever. (5) Remove the crankshaft timing gear retaining

bolt and discard. (6) Remove the crankshaft timing gear from the

crankshaft. It may be necessary to lever the gear from

the crankshaft using two screwdrivers. Remove the

key and spacer from the crankshaft. (7) Using a centre punch, tap a small hole in the

front face of the oil seal. (8) Insert a self tapping screw into the hole.

(9) Remove the seal from the oil pump by

gripping and pulling the end of the screw with a pair

of pliers. (10) Coat the l i p of a new seal with multi-purpose

grease. (11) Install the oil seal to the oil pump using a

tubular drift. Ensure that the lip of the oil seal faces

the inside of the housing.

(12) Install the remaining components in the re-

verse order of removal, usi ng a new crankshaft timing

gear retaining bolt and referring to the relevant

headings in this section as necessary.

Rear

(1) Remove the automatic transaxle or manual

transaxle as described in the appropriate section. (2) Remove the flywheel/drive plate as described

under the following heading. (3) Lever the oil seal from the rear of the

crankcase being careful not to damage the crankshaft.

(4) Coat the lip of a new seal with Lithium

grease.

(5) Install the oil seal over the crankshaft. Ensure

that the li p of the oil sea l faces towards the engine.

(6) Insert the seal as far as possible using finger

pressure, and then fully seat the seal using a tubular

drift. (7) Install the remaining components in the

re-

verse order of removal, referring to the relevant

headings in this section as necessary.

12. FLYWHEEL/DRIVE PLATE

Special Equipment Required:

To Renew Ring Gear — Suitable heat source

TO REMOVE

(1) Remove the transaxle from the vehicle as

described in the Manual or Automatic Transaxle

sections, whichever is applicable. (2) On manual transaxle models, mark the fly-

wheel and the clutch pressure plate cover to ensure

correct assembly.

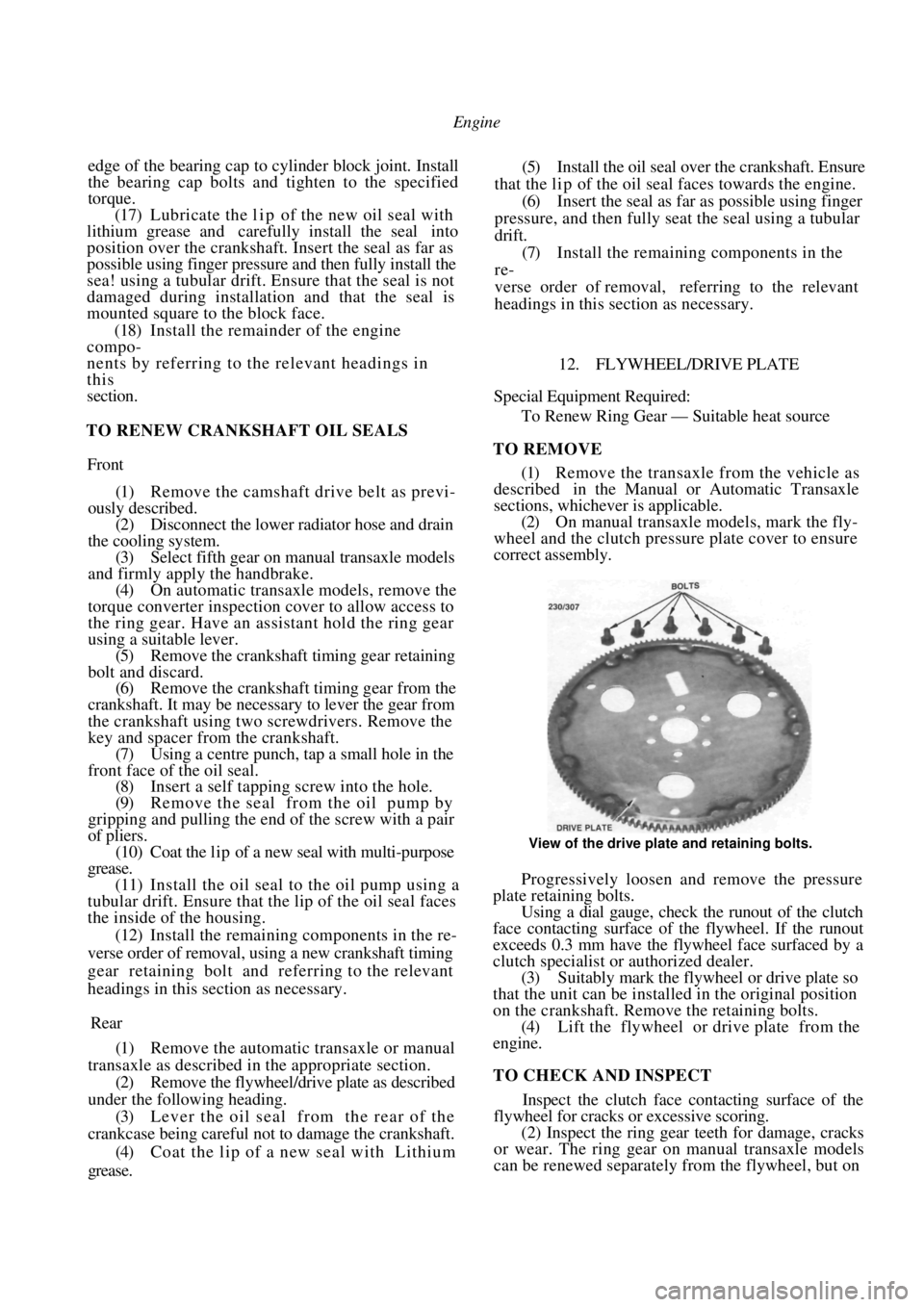

View of the drive plate and retaining bolts.

Progressively loosen and remove the pressure

plate retaining bolts.

Using a dial gauge, check the runout of the clutch

face contacting surface of the flywheel. If the runout

exceeds 0.3 mm have the flywheel face surfaced by a

clutch specialist or authorized dealer.

(3) Suitably mark the flywheel or drive plate so

that the unit can be installed in the original position

on the crankshaft. Remove the retaining bolts. (4) Lift the flywheel or drive plate from the

engine.

TO CHECK AND INSPECT

Inspect the clutch face contacting surface of the

flywheel for cracks or excessive scoring.

(2) Inspect the ring gear teeth for damage, cracks

or wear. The ring gear on manual transaxle models

can be renewed separately from the flywheel, but on

Page 73 of 238

Cooling and Heating Systems 73

(1) Renew all hoses that show signs of cracking

or perishing.

(2) Before finally tightening the hose clips, en-

sure that the hoses are push ed fully onto the radiator

and are not kinked. (3) On automatic transaxle models, ensure that

the oil cooler hoses are correctly installed to the

radiator and show no signs of leakage. Check and top

up the automatic transaxle fluid as necessary.

5. COOLING FAN

The radiator cooling fan is controlled by the

electronic control unit, and on vehicles with air

conditioning, the condenser fan relay. On vehicles

with air conditioning there are two cooling fans, one

is larger than the other. The large fan is for the

radiator and the smaller fan provides extra cooling

when the air conditioning is activated. Each fan is

controlled by a separate system.

TO TEST COOLING FAN AND SYSTEM

(1) With the cooling system cold and the air

conditioning, if applicable, switched off, switch the

ignition On and confirm that the cooling fan is

stationary.

NOTE: Leave the ignition On for all tests

unless otherwise stated.

(2) In the above test, if the cooling fan rotates,

proceed as follows:

(a) Disconnect the cooling fan relay from the

rear of the engine compartment relay box.

(b) If the fan stops, backprobe terminal C1 at

the electronic control unit using an LED test lamp

connected to the positive battery terminal. If no

circuit exists, renew the cooling fan relay.

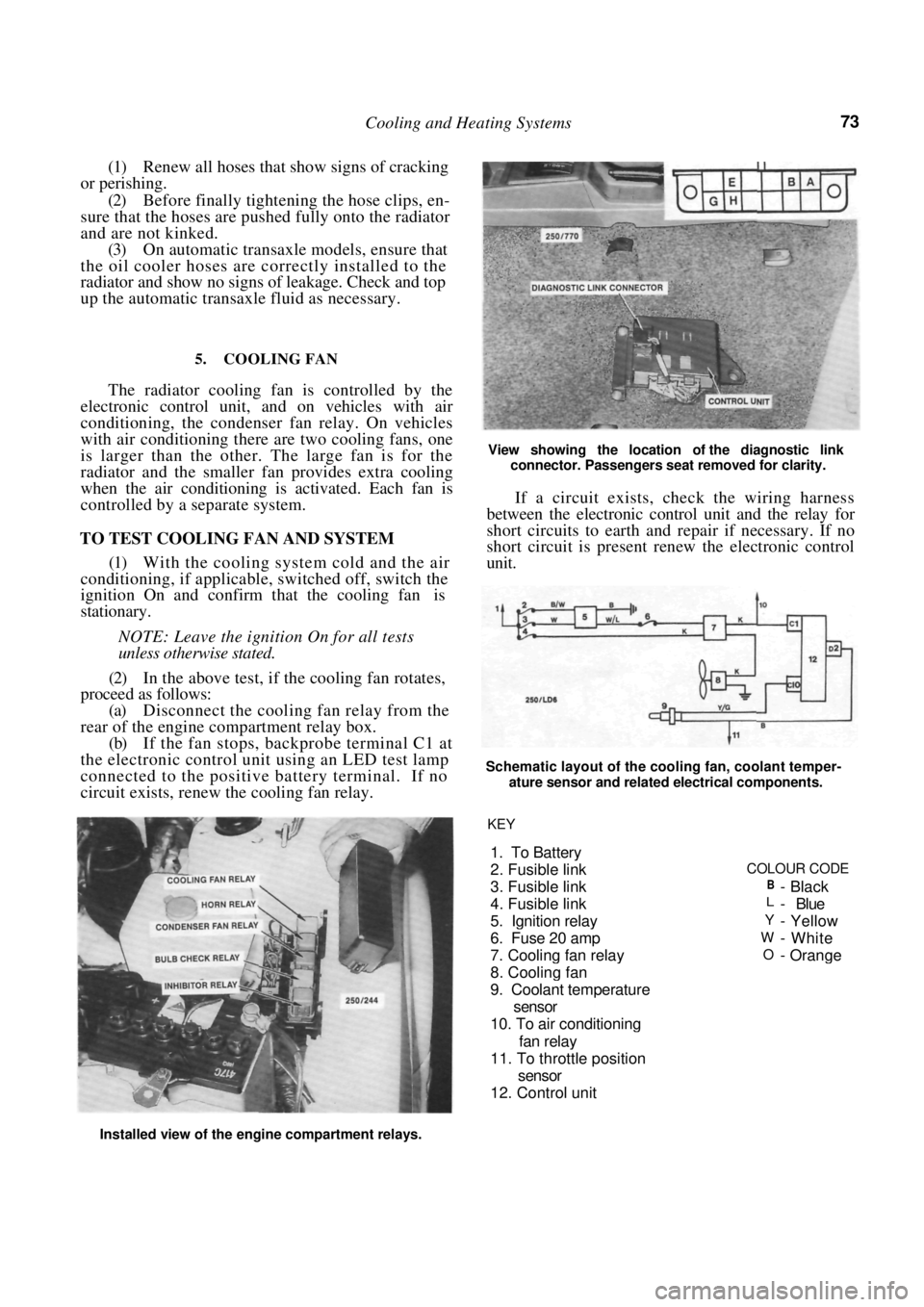

View showing the location of the diagnostic link

connector. Passengers seat removed for clarity.

If a circuit exists, check the wiring harness

between the electronic control unit and the relay for

short circuits to earth and repair if necessary. If no

short circuit is present renew the electronic control

unit.

Schematic layout of the cooling fan, coolant temper-

ature sensor and related electrical components.

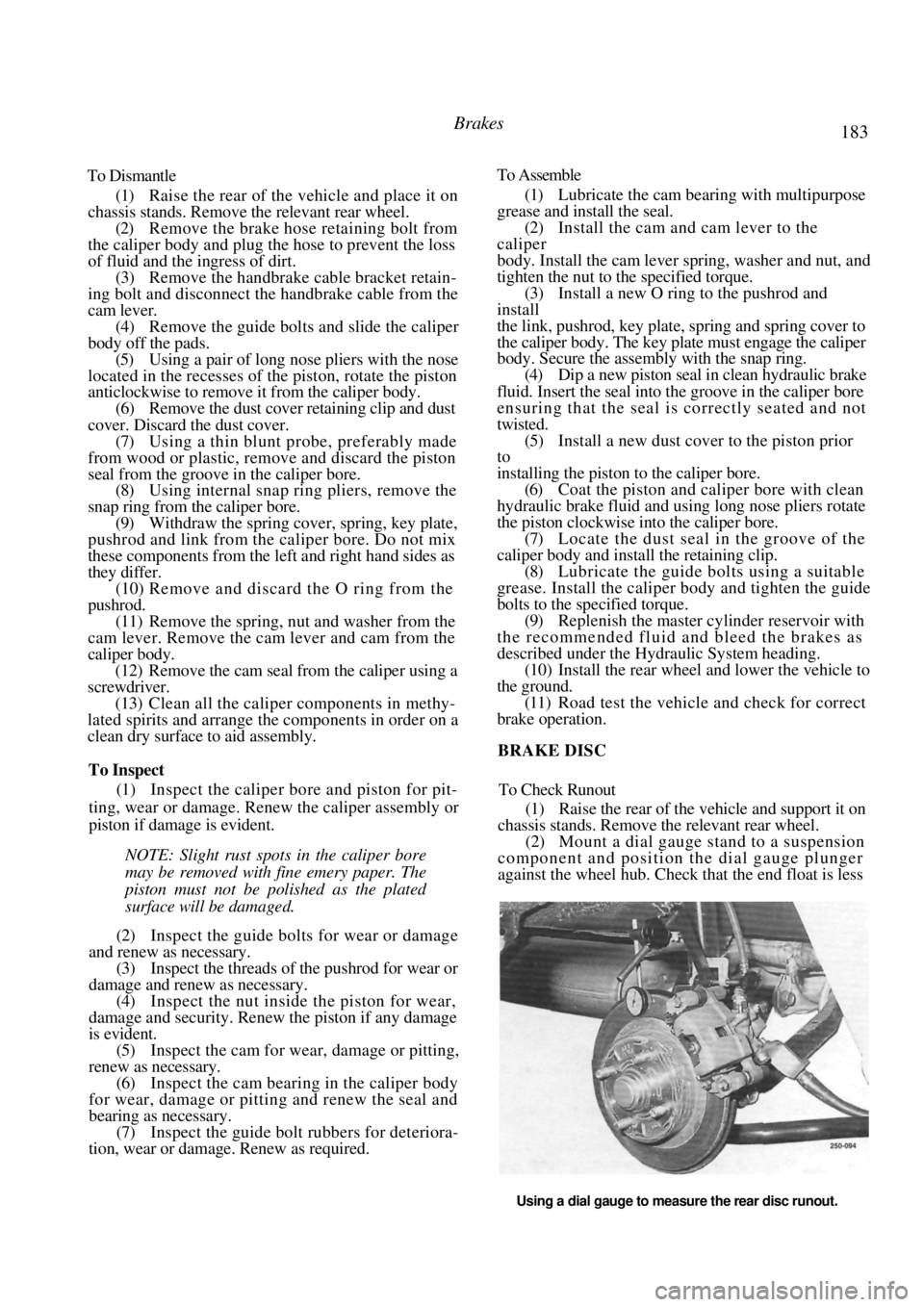

Installed view of the engine compartment relays. KEY

1. To Battery

2. Fusible link

COLOUR CODE

3. Fusible link

B-Black

4. Fusible linkL- Blue

5. I

gnition relayY- Yellow

6. Fuse 20 am

pW-White

7. Coolin

g fan relayO-Orange

8. Coolin

g fan

9. Coolant tem

perature

sensor

10. To air conditionin

g

fan rela

y

11. To throttle

position

sensor

12. Control unit

Page 183 of 238

Brakes 183

To Dismantle

(1) Raise the rear of the vehicle and place it on

chassis stands. Remove the relevant rear wheel.

(2) Remove the brake hose retaining bolt from

the caliper body and plug the hose to prevent the loss

of fluid and the ingress of dirt. (3) Remove the handbrake cable bracket retain-

ing bolt and disconnect the handbrake cable from the

cam lever.

(4) Remove the guide bolts and slide the caliper

body off the pads. (5) Using a pair of long nose pliers with the nose

located in the recesses of the piston, rotate the piston

anticlockwise to remove it from the caliper body.

(6) Remove the dust cover retaining clip and dust

cover. Discard the dust cover. (7) Using a thin blunt probe, preferably made

from wood or plastic, remove and discard the piston

seal from the groove in the caliper bore. (8) Using internal snap ring pliers, remove the

snap ring from the caliper bore. (9) Withdraw the spring cover, spring, key plate,

pushrod and link from the caliper bore. Do not mix

these components from the left and right hand sides as

they differ. (10) Remove and discard the O ring from the

pushrod. (11) Remove the spring, nut and washer from the

cam lever. Remove the cam lever and cam from the

caliper body. (12) Remove the cam seal from the caliper using a

screwdriver.

(13) Clean all the caliper components in methy-

lated spirits and arrange the components in order on a

clean dry surface to aid assembly.

To Inspect

(1) Inspect the caliper bore and piston for pit-

ting, wear or damage. Renew the caliper assembly or

piston if damage is evident.

NOTE: Slight rust spots in the caliper bore

may be removed with fine emery paper. The

piston must not be polished as the plated

surface will be damaged.

(2) Inspect the guide bolts for wear or damage

and renew as necessary.

(3) Inspect the threads of the pushrod for wear or

damage and renew as necessary. (4) Inspect the nut inside the piston for wear,

damage and security. Renew the piston if any damage

is evident. (5) Inspect the cam for wear, damage or pitting,

renew as necessary. (6) Inspect the cam bearing in the caliper body

for wear, damage or pitting and renew the seal and

bearing as necessary. (7) Inspect the guide bolt rubbers for deteriora-

tion, wear or damage. Renew as required. To Assemble

(1)

Lubricate the cam bearing with multipurpose

grease and install the seal. (2) Install the cam and cam lever to the

caliper

body. Install the cam lever spring, washer and nut, and

tighten the nut to the specified torque. (3) Install a new O ring to the pushrod and

install

the link, pushrod, key plate, spring and spring cover to

the caliper body. The key plate must engage the caliper

body. Secure the assembly with the snap ring. (4) Dip a new piston seal in clean hydraulic brake

fluid. Insert the seal into the groove in the caliper bore

ensuring that the seal is correctly seated and not

twisted. (5) Install a new dust cover to the piston prior

to

installing the piston to the caliper bore.

(6) Coat the piston and caliper bore with clean

hydraulic brake fluid and using long nose pliers rotate

the piston clockwise into the caliper bore. (7) Locate the dust seal in the groove of the

caliper body and install the retaining clip.

(8) Lubricate the guide bolts using a suitable

grease. Install the caliper body and tighten the guide

bolts to the specified torque. (9) Replenish the master cylinder reservoir with

the recommended fluid and bleed the brakes as

described under the Hydraulic System heading. (10) Install the rear wheel and lower the vehicle to

the ground. (11) Road test the vehicle and check for correct

brake operation.

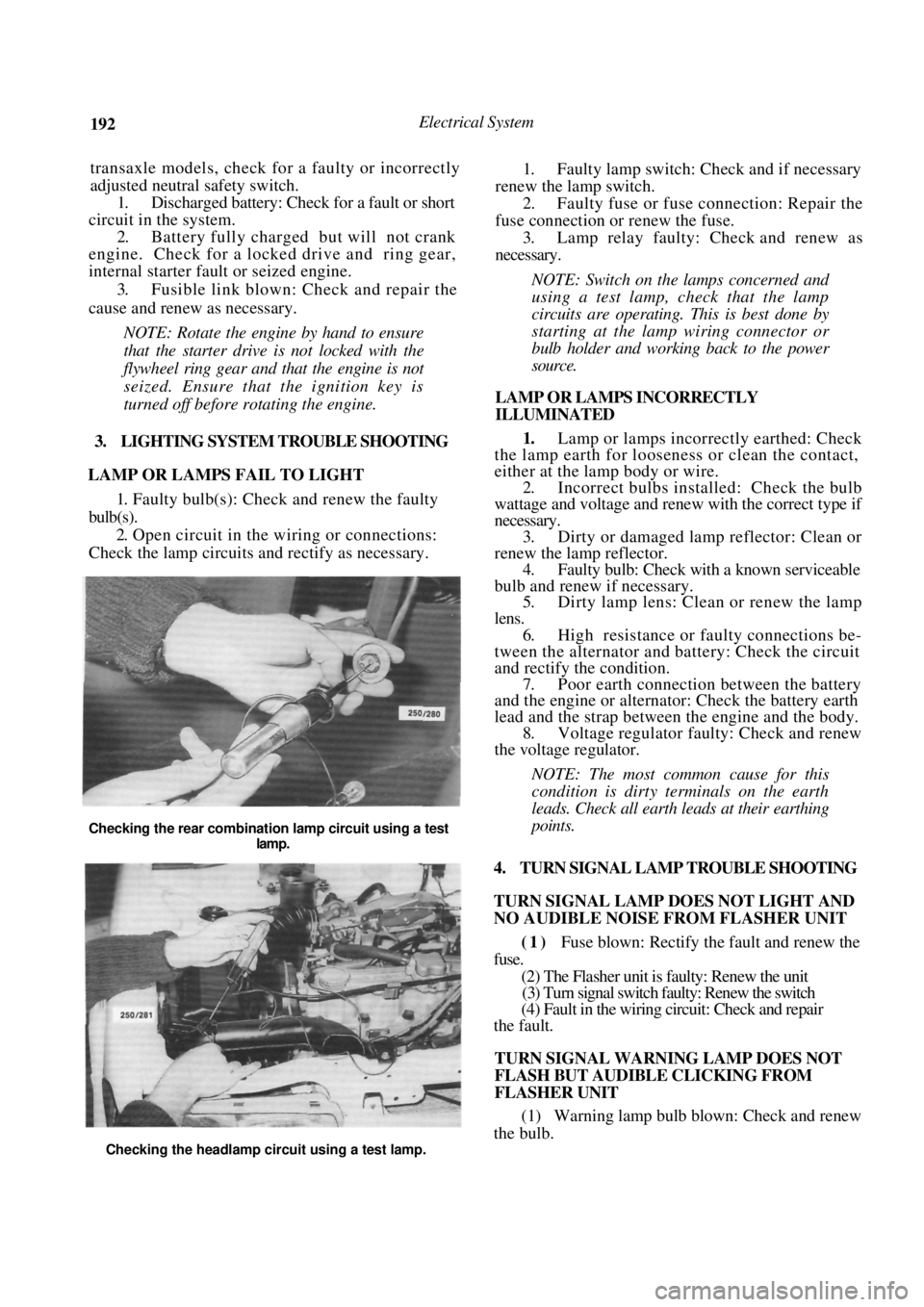

BRAKE DISC

To Check Runout

(1) Raise the rear of the vehicle and support it on

chassis stands. Remove the relevant rear wheel.

(2) Mount a dial gauge stand to a suspension

component and position the dial gauge plunger

against the wheel hub. Check that the end float is less

Using a dial gauge to measure the rear disc runout.

Page 192 of 238

192 Electrical System

transaxle models, check for a faulty or incorrectly

adjusted neutral safety switch.

1. Discharged battery: Check for a fault or short

circuit in the system. 2. Battery fully charged but will not crank

engine. Check for a locked drive and ring gear,

internal starter faul t or seized engine.

3. Fusible link blown: Check and repair the

cause and renew as necessary.

NOTE: Rotate the engine by hand to ensure

that the starter drive is not locked with the

flywheel ring gear and t hat the engine is not

seized. Ensure that the ignition key is

turned off before rotating the engine.

3. LIGHTING SYSTEM TROUBLE SHOOTING

LAMP OR LAMPS FAIL TO LIGHT

1. Faulty bulb(s): Check and renew the faulty

bulb(s). 2. Open circuit in the wiring or connections:

Check the lamp circuits and rectify as necessary.

1. Faulty lamp switch: Check and if necessary

renew the lamp switch. 2. Faulty fuse or fuse connection: Repair the

fuse connection or renew the fuse. 3. Lamp relay faulty: Check and renew as

necessary.

NOTE: Switch on the lamps concerned and

using a test lamp, check that the lamp

circuits are operating. This is best done by

starting at the lamp wiring connector or

bulb holder and work ing back to the power

source.

LAMP OR LAMPS INCORRECTLY

ILLUMINATED

1. Lamp or lamps incorrectly earthed: Check

the lamp earth for loosene ss or clean the contact,

either at the lamp body or wire.

2. Incorrect bulbs installe d: Check the bulb

wattage and voltage and renew with the correct type if

necessary. 3. Dirty or damaged lamp reflector: Clean or

renew the lamp reflector. 4. Faulty bulb: Check with a known serviceable

bulb and renew if necessary. 5. Dirty lamp lens: Clean or renew the lamp

lens. 6. High resistance or faulty connections be-

tween the alternator and battery: Check the circuit

and rectify th e condition.

7. Poor earth connection between the battery

and the engine or alternat or: Check the battery earth

lead and the strap between the engine and the body. 8. Voltage regulator faulty: Check and renew

the voltage regulator.

NOTE: The most common cause for this

condition is dirty t erminals on the earth

leads. Check all earth leads at their earthing

points.

4. TURN SIGNAL LAMP TROUBLE SHOOTING

TURN SIGNAL LAMP DOES NOT LIGHT AND

NO AUDIBLE NOISE FROM FLASHER UNIT

(1) Fuse blown: Rectify the fault and renew the

fuse.

(2) The Flasher unit is faulty: Renew the unit

(3) Turn signal switch faulty: Renew the switch

(4) Fault in the wiring circuit: Check and repair

the fault.

TURN SIGNAL WARNING LAMP DOES NOT

FLASH BUT AUDIBLE CLICKING FROM

FLASHER UNIT

(1) Warning lamp bulb blown: Check and renew

the bulb.

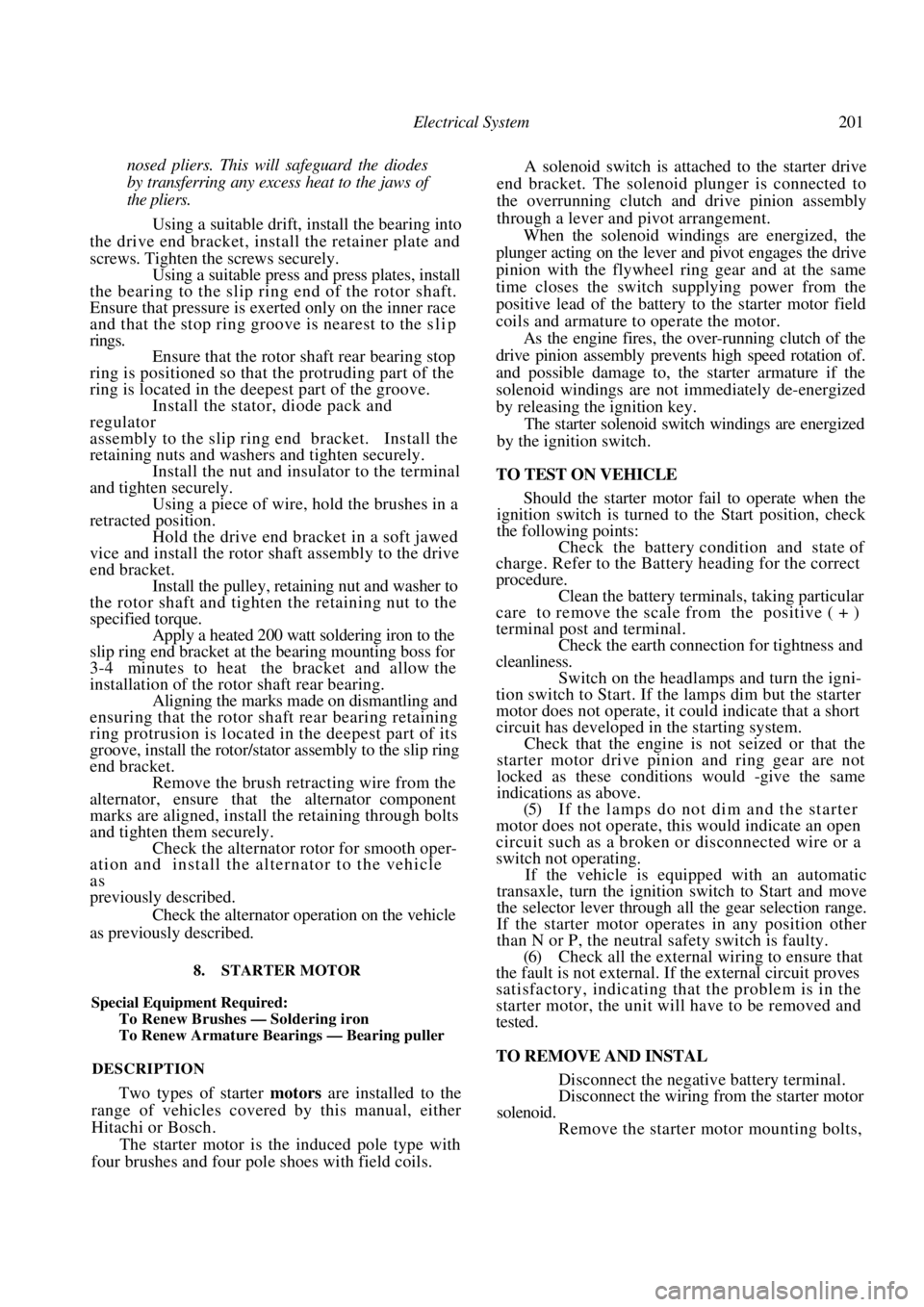

Checking the rear combination lamp circuit using a test

lamp.

Checking the headlamp circuit using a test lamp.

Page 201 of 238

Electrical System 201

nosed pliers. This will safeguard the diodes

by transferring any excess heat to the jaws of

the pliers.

Using a suitable drift, install the bearing into

the drive end bracket, install the retainer plate and

screws. Tighten the screws securely. Using a suitable press and press plates, install

the bearing to the slip ring end of the rotor shaft.

Ensure that pressure is ex erted only on the inner race

and that the stop ring groove is nearest to the sl i p

rings. Ensure that the rotor sh aft rear bearing stop

ring is positioned so that the protruding part of the

ring is located in the deepest part of the groove. Install the stator, diode pack and

regulator

assembly to the slip ring e nd bracket. Install the

retaining nuts and washers and tighten securely. Install the nut and insulator to the terminal

and tighten securely. Using a piece of wire, hold the brushes in a

retracted position. Hold the drive end bracket in a soft jawed

vice and install the rotor shaft assembly to the drive

end bracket. Install the pulley, retaining nut and washer to

the rotor shaft and tighten the retaining nut to the

specified torque. Apply a heated 200 watt soldering iron to the

slip ring end bracket at the bearing mounting boss for

3-4 minutes to heat the bracket and allow the

installation of the rotor shaft rear bearing. Aligning the marks made on dismantling and

ensuring that the rotor sh aft rear bearing retaining

ring protrusion is located in the deepest part of its

groove, install the rotor/stator assembly to the slip ring

end bracket.

Remove the brush retr acting wire from the

alternator, ensure that the alternator component

marks are aligned, install the retaining through bolts

and tighten them securely. Check the alternator rotor for smooth oper-

ation and install the al ternator to the vehicle

as

previously described.

Check the alternator operation on the vehicle

as previously described.

8. STARTER MOTOR

Special Equipment Required:

To Renew Brushes — Soldering iron

To Renew Armature Bearings — Bearing puller

DESCRIPTION

Two types of starter motors are installed to the

range of vehicles covere d by this manual, either

Hitachi or Bosch.

The starter motor is the induced pole type with

four brushes and four pole shoes with field coils.

A solenoid switch is attached to the starter drive

end bracket. The solenoid plunger is connected to

the overrunning clutch and drive pinion assembly

through a lever and pivot arrangement.

When the solenoid windings are energized, the

plunger acting on the lever and pivot engages the drive

pinion with the flywheel ri ng gear and at the same

time closes the switch supplying power from the

positive lead of the battery to the starter motor field

coils and armature to operate the motor.

As the engine fires, the over-running clutch of the

drive pinion assembly prevents high speed rotation of.

and possible damage to, the starter armature if the

solenoid windings are not immediately de-energized

by releasing the ignition key.

The starter solenoid switch windings are energized

by the ignition switch.

TO TEST ON VEHICLE

Should the starter motor fail to operate when the

ignition switch is turned to the Start position, check

the following points:

Check the battery condition and state of

charge. Refer to the Battery heading for the correct

procedure.

Clean the battery terminals, taking particular

care to remove the scale from the positive ( + )

terminal post and terminal. Check the earth connection for tightness and

cleanliness.

Switch on the headlamps and turn the igni-

tion switch to Start. If the lamps dim but the starter

motor does not operate, it could indicate that a short

circuit has developed in the starting system. Check that the engine is not seized or that the

starter motor drive pinion and ring gear are not

locked as these conditions would -give the same

indications as above.

(5) If the lamps do not dim and the starter

motor does not operate, this would indicate an open

circuit such as a broken or disconnected wire or a

switch not operating.

If the vehicle is equipped with an automatic

transaxle, turn the ignition switch to Start and move

the selector lever through all the gear selection range.

If the starter motor operates in any position other

than N or P, the neutral safety switch is faulty.

(6) Check all the external wiring to ensure that

the fault is not external. If the external circuit proves

satisfactory, indicating that the problem is in the

starter motor, the unit will have to be removed and

tested.

TO REMOVE AND INSTAL

Disconnect the negative battery terminal.

Disconnect the wiring from the starter motor

solenoid. Remove the starter motor mounting bolts,

Page 219 of 238

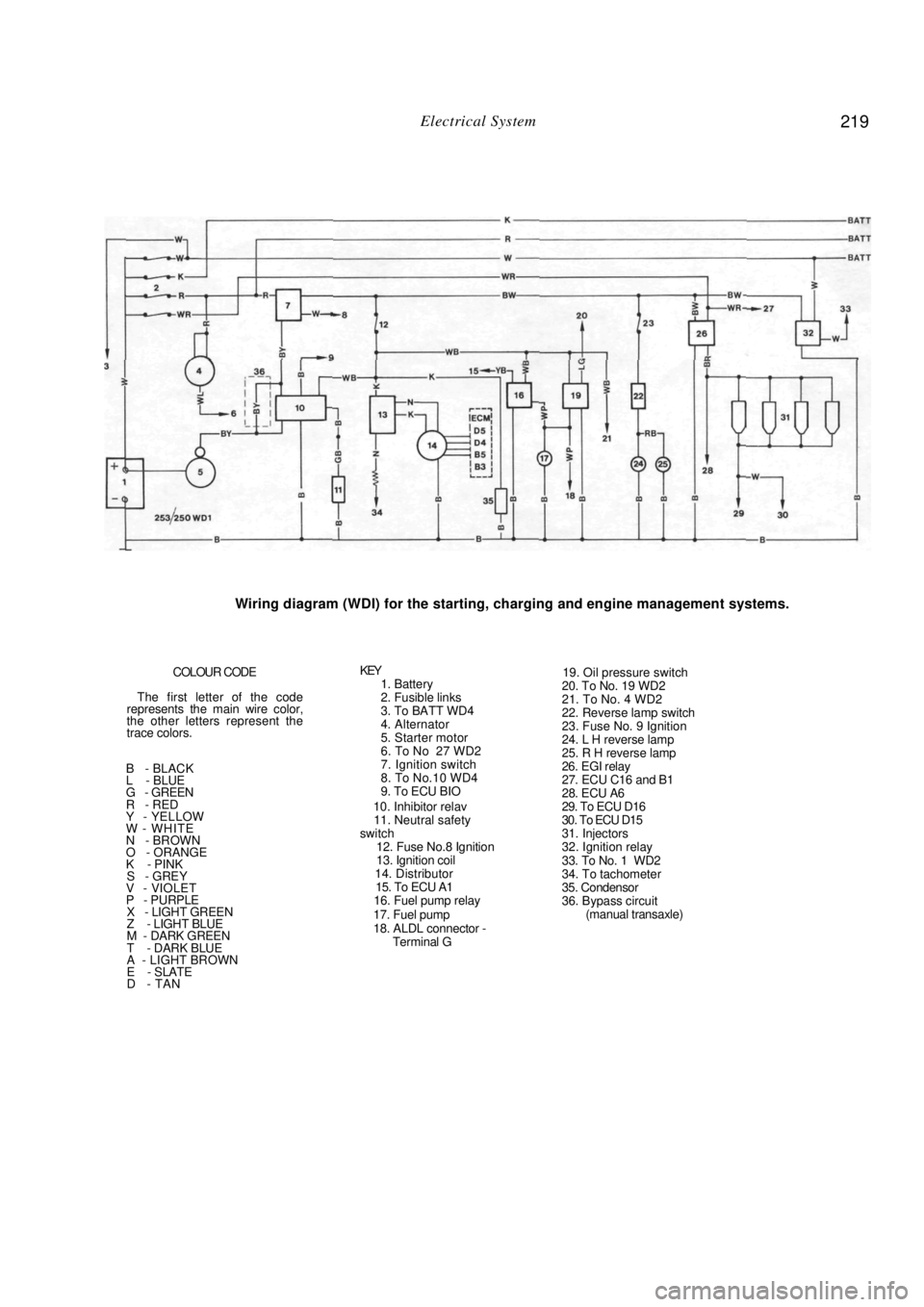

Electrical System 219

Wiring diagram (WDI) for the starting, charging and engine management systems.

COLOUR CODE

The first letter of the code

represents the main wire color,

the other letters represent the

trace colors.

B - BLACK

L - BLUE

G - GREEN

R - RED

Y - YELLOW

W - WHITE

N - BROWN

O - ORANGE

K - PINK

S - GREY V - VIOLET

P - PURPLE X - LIGHT GREEN

Z - LIGHT BLUE

M - DARK GREEN

T - DARK BLUE

A - LIGHT BROWN

E - SLATE

D - TAN

KEY 1. Battery

2. Fusible links

3. To BATT WD4

4. Alternator

5. Starter motor

6. To No 27 WD2

7. Ignition switch

8. To No.10 WD4

9. To ECU BIO

10. Inhibitor relav

11. Neutral safety

switch

12. Fuse No.8 Ignition

13. Ignition coil

14. Distributor

15. To ECU A1

16. Fuel pump relay

17. Fuel pump

18. ALDL connector - Terminal G

19. Oil pressure switch

20. To No. 19 WD2

21. To No. 4 WD2

22. Reverse lamp switch

23. Fuse No. 9 Ignition

24. L H reverse lamp

25. R H reverse lamp

26. EGI relay

27. ECU C16 and B1

28. ECU A6

29. To ECU D16

30. To ECU D15

31. Injectors

32. Ignition relay

33. To No. 1 WD2

34. To tachometer

35. Condensor

36. Bypass circuit (manual transaxle)

Page 220 of 238

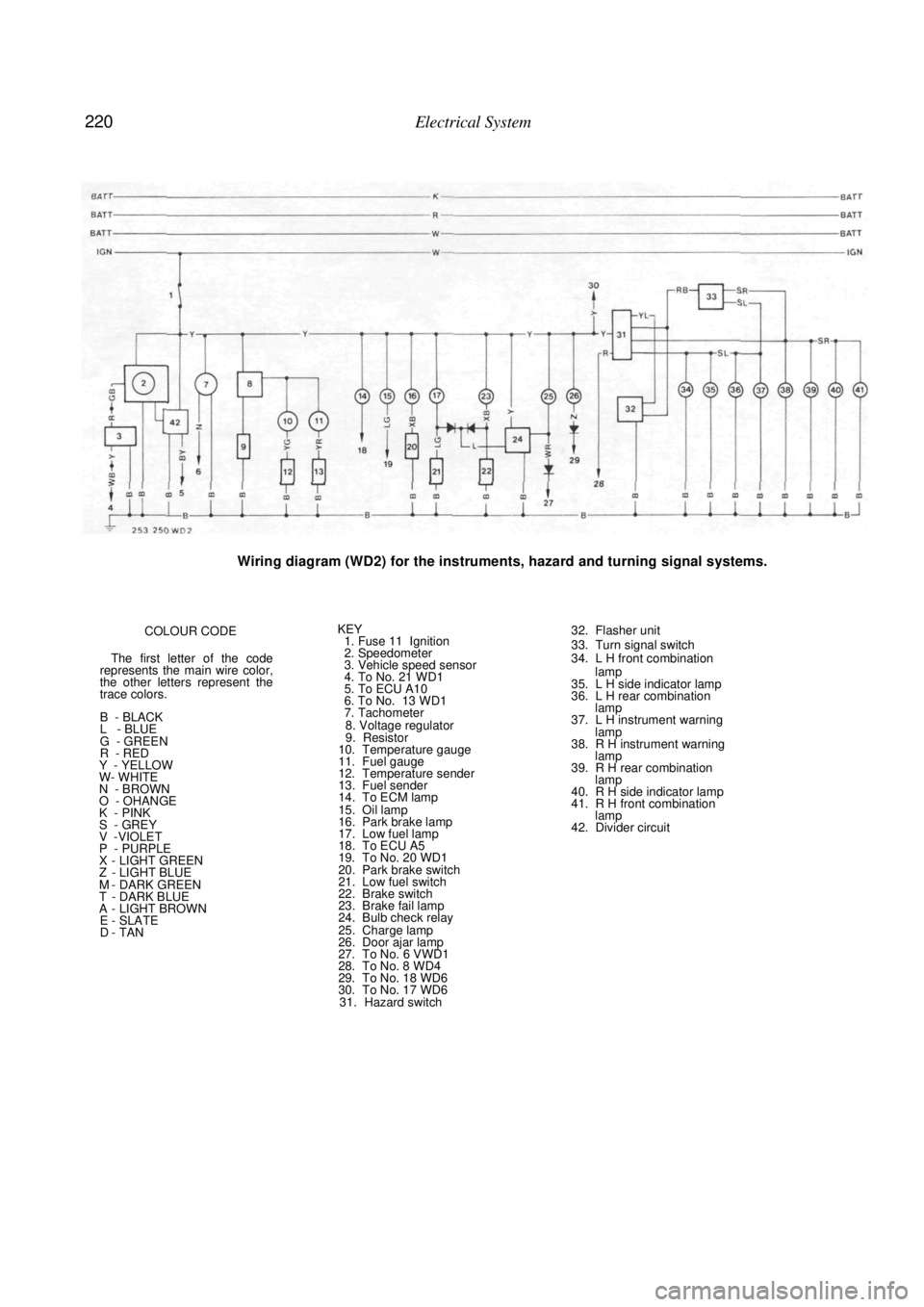

220 Electrical System

Wiring diagram (WD2) for the instruments, hazard and turning signal systems.

COLOUR CODE

The first letter of the code

represents the main wire color,

the other letters represent the

trace colors.

B - BLACK

L - BLUE

G - GREEN

R - RED

Y - YELLOW

W- WHITE

N - BROWN

O - OHANGE

K - PINK

S - GREY V -VIOLET

P - PURPLE X - LIGHT GREEN Z - LIGHT BLUE M - DARK GREEN T - DARK BLUE A - LIGHT BROWN E - SLATE D - TAN

KEY 1. Fuse 11 Ignition

2. Speedometer

3. Vehicle speed sensor

4. To No. 21 WD1

5. To ECU A10

6. To No. 13 WD1

7. Tachometer

8. Voltage regulator

9. Resistor

10. Temperature gauge

11. Fuel gauge

12. Temperature sender

13. Fuel sender

14. To ECM lamp

15. Oil lamp

16. Park brake lamp

17. Low fuel lamp

18. To ECU A5

19. To No. 20 WD1

20. Park brake switch

21. Low fuel switch

22. Brake switch

23. Brake fail lamp

24. Bulb check relay

25. Charge lamp

26. Door ajar lamp

27. To No. 6 VWD1

28. To No. 8 WD4

29. To No. 18 WD6

30. To No. 17 WD6 31. Hazard switch

32. Flasher unit

33. Turn signal switch

34. L H front combination

lamp

35. L H side indicator lamp

36. L H rear combination lamp

37. L H instrument warning

lamp

38. R H instrument warning lamp

39. R H rear combination lamp

40. R H side indicator lamp

41. R H front combination lamp

42. Divider circuit