bolt pattern NISSAN PULSAR 1987 Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1987, Model line: PULSAR, Model: NISSAN PULSAR 1987Pages: 238, PDF Size: 28.91 MB

Page 45 of 238

Engine 45

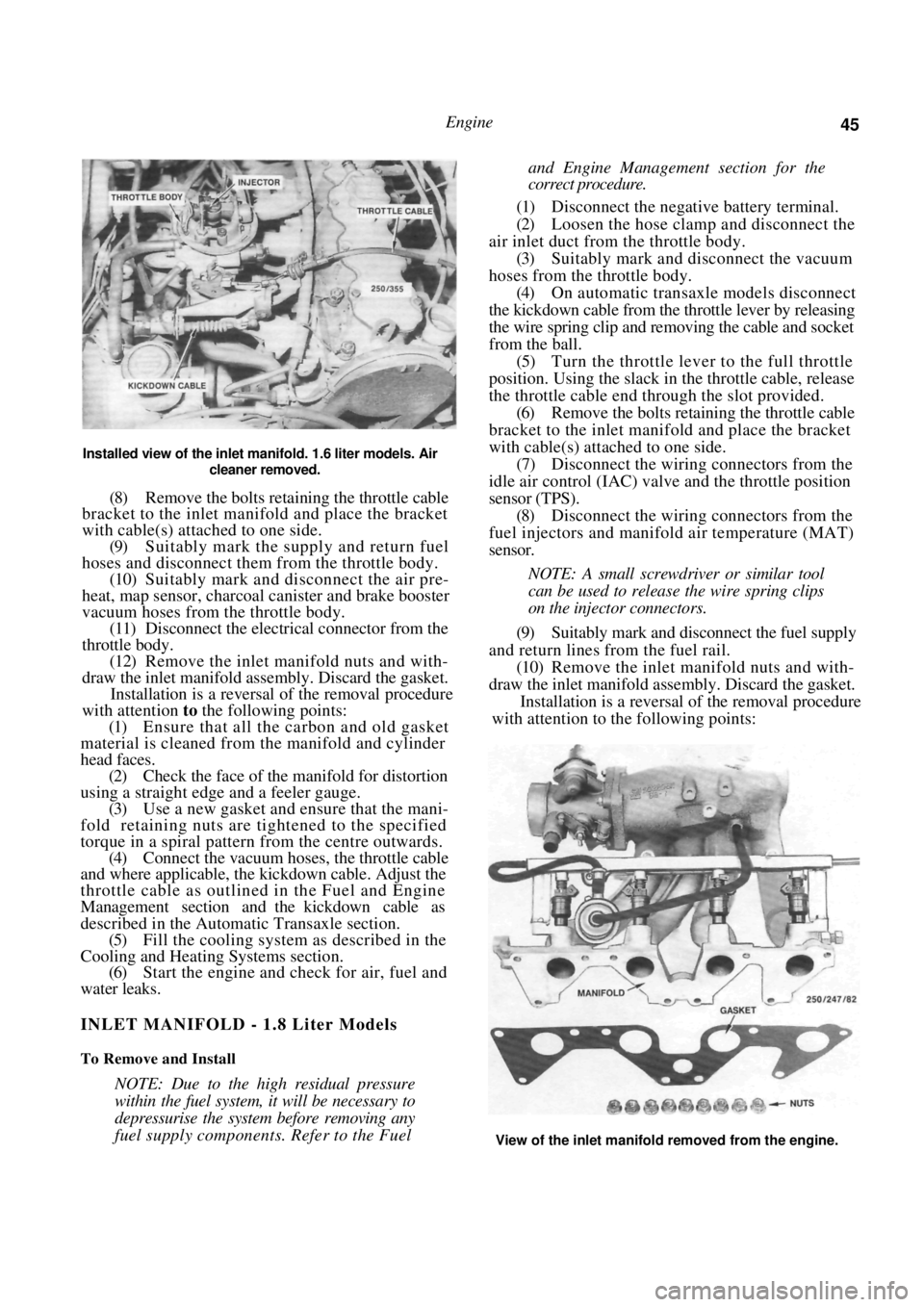

Installed view of the inlet manifold. 1.6 liter models. Air

cleaner removed.

(8) Remove the bolts retaining the throttle cable

bracket to the inlet manifold and place the bracket

with cable(s) attached to one side.

(9) Suitably mark the supply and return fuel

hoses and disconnect them from the throttle body.

(10) Suitably mark and disconnect the air pre-

heat, map sensor, charcoal canister and brake booster

vacuum hoses from the throttle body. (11) Disconnect the electrical connector from the

throttle body. (12) Remove the inlet manifold nuts and with-

draw the inlet manifold assembly. Discard the gasket. Installation is a reversal of the removal procedure

with attention to the following points:

(1) Ensure that all the carbon and old gasket

material is cleaned from the manifold and cylinder

head faces. (2) Check the face of the manifold for distortion

using a straight edge and a feeler gauge. (3) Use a new gasket and ensure that the mani-

fold retaining nuts are tightened to the specified

torque in a spiral pattern from the centre outwards. (4) Connect the vacuum hoses, the throttle cable

and where applicable, the kickdown cable. Adjust the

throttle cable as outlined in the Fuel and Engine

Management section and the kickdown cable as

described in the Automatic Transaxle section. (5) Fill the cooling system as described in the

Cooling and Heating Systems section. (6) Start the engine and check for air, fuel and

water leaks.

INLET MANIFOLD - 1.8 Liter Models

To Remove and Install

NOTE: Due to the high residual pressure

within the fuel system, it will be necessary to

depressurise the system before removing any

fuel supply components. Refer to the Fuel

and Engine Management section for the

correct procedure.

(1) Disconnect the negative battery terminal.

(2) Loosen the hose clamp and disconnect the

air inlet duct from the throttle body. (3) Suitably mark and disconnect the vacuum

hoses from the throttle body. (4) On automatic transaxle models disconnect

the kickdown cable from the throttle lever by releasing

the wire spring clip and re moving the cable and socket

from the ball. (5) Turn the throttle lever to the full throttle

position. Using the slack in the throttle cable, release

the throttle cable end thr ough the slot provided.

(6) Remove the bolts retaining the throttle cable

bracket to the inlet manifold and place the bracket

with cable(s) attached to one side. (7) Disconnect the wiring connectors from the

idle air control (IAC) valve and the throttle position

sensor (TPS).

(8) Disconnect the wiring connectors from the

fuel injectors and manifold air temperature (MAT)

sensor.

NOTE: A small screwdriver or similar tool

can be used to release the wire spring clips

on the injector connectors.

(9) Suitably mark and disconnect the fuel supply

and return lines from the fuel rail. (10) Remove the inlet manifold nuts and with-

draw the inlet manifold assembly. Discard the gasket. Installation is a reversal of the removal procedure

with attention to the following points:

View of the inlet manifold removed from the engine.

Page 46 of 238

46 Engine

(1) Ensure that all carbon and old gasket mate-

rial is cleaned from the manifold and cylinder head

faces. (2) Check the face of the manifold for distortion

using a straight edge and a feeler gauge. (3) Use a new gasket and ensure that the mani-

fold retaining nuts are tightened to the specified

torque in a spiral pattern from the centre outwards. (4) Adjust the throttle cabl e as described in the

Fuel and Engine Management section and the kick-

down cable as described in the Automatic Transaxle

section.

(5) Start the engine and check for air, fuel and

water leaks.

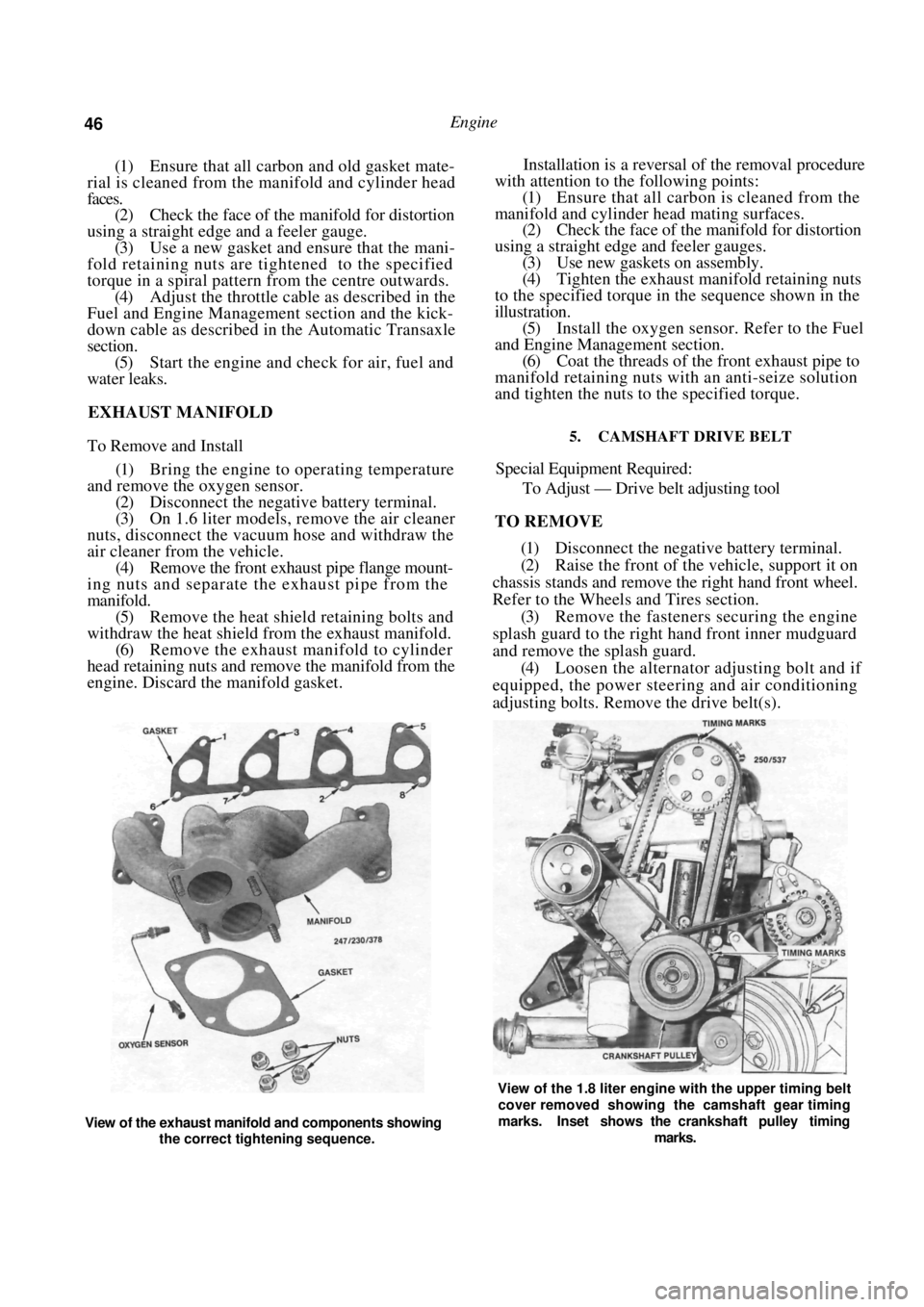

EXHAUST MANIFOLD

To Remove and Install

(1) Bring the engine to operating temperature

and remove the oxygen sensor.

(2) Disconnect the negative battery terminal.

(3) On 1.6 liter models, remove the air cleaner

nuts, disconnect the vacuum hose and withdraw the

air cleaner from the vehicle. (4) Remove the front exhaust pipe flange mount-

ing nuts and separate the exhaust pipe from the

manifold. (5) Remove the heat shield retaining bolts and

withdraw the heat shield from the exhaust manifold. (6) Remove the exhaust manifold to cylinder

head retaining nuts and remove the manifold from the

engine. Discard the manifold gasket. Installation is a reversal of the removal procedure

with attention to the following points:

(1) Ensure that all carbon is cleaned from the

manifold and cylinder head mating surfaces. (2) Check the face of the manifold for distortion

using a straight edge and feeler gauges. (3) Use new gaskets on assembly.

(4) Tighten the exhaust manifold retaining nuts

to the specified torque in the sequence shown in the

illustration. (5) Install the oxygen sensor. Refer to the Fuel

and Engine Management section. (6) Coat the threads of the front exhaust pipe to

manifold retaining nuts with an anti-seize solution

and tighten the nuts to the specified torque.

5. CAMSHAFT DRIVE BELT

Special Equipment Required:

To Adjust — Drive belt adjusting tool

TO REMOVE

(1) Disconnect the negative battery terminal.

(2) Raise the front of the vehicle, support it on

chassis stands and remove the right hand front wheel.

Refer to the Wheels and Tires section. (3) Remove the fasteners securing the engine

splash guard to the right hand front inner mudguard

and remove the splash guard. (4) Loosen the alternator adjusting bolt and if

equipped, the power steering and air conditioning

adjusting bolts. Remove the drive belt(s).

View of the exhaust manifold and components showing

the correct tightening sequence.

View of the 1.8 liter engine with the upper timing belt

cover removed showing the camshaft gear timing

marks. Inset shows the crankshaft pulley timing

marks.

Page 210 of 238

210 Electrical System

Using the radio/cassette removal tools during removal of the unit.

Construct the special tools as illustrated,

insert both tools into the release holes on the radio/

cassette and carefully withdraw the radio/cassette

from the mounting bracket.

Disconnect the wiring harness terminal plug

and remove the radio/cassette.

Installation is a reversal of the removal procedure

with attention to the following points:

Remove the special tools from the radio/

cassette, connect the wiring harness terminal and push

the radio/cassette into the mounting bracket. Install the release hole covers on each side

of

the radio/cassette.

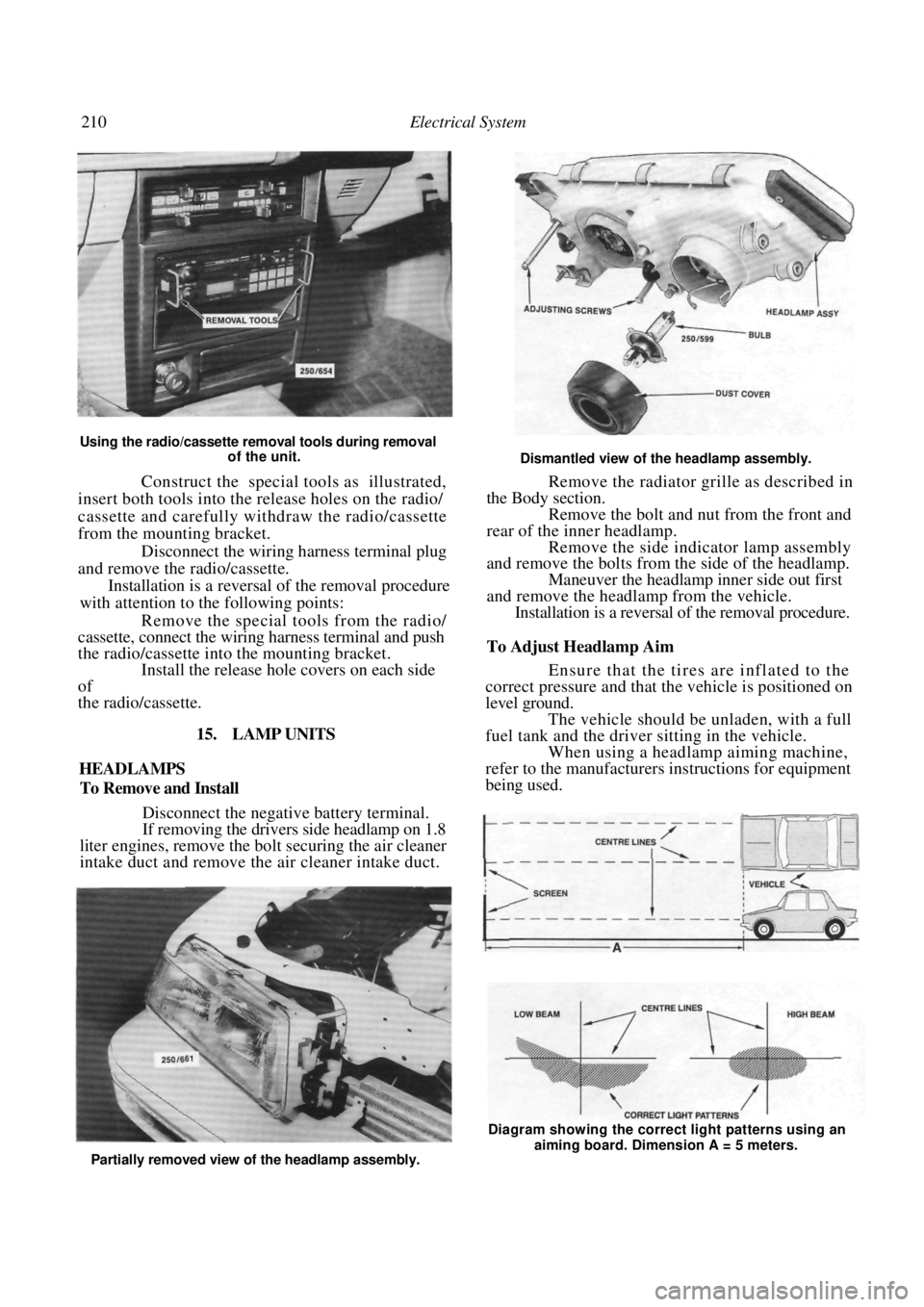

15. LAMP UNITS

HEADLAMPS

To Remove and Install

Disconnect the negative battery terminal.

If removing the drivers side headlamp on 1.8

liter engines, remove the bo lt securing the air cleaner

intake duct and remove the air cleaner intake duct.

Dismantled view of the headlamp assembly.

Remove the radiator grille as described in

the Body section. Remove the bolt and nut from the front and

rear of the inner headlamp. Remove the side indicator lamp assembly

and remove the bolts from the side of the headlamp.

Maneuver the headlamp inner side out first

and remove the headlamp from the vehicle. Installation is a reversal of the removal procedure.

To Adjust Headlamp Aim

Ensure that the tires are inflated to the

correct pressure and that the vehicle is positioned on

level ground.

The vehicle should be unladen, with a full

fuel tank and the driver sitting in the vehicle. When using a headlamp aiming machine,

refer to the manufacturers instructions for equipment

being used.

Partially removed view of the headlamp assembly. Diagram showing the correct light patterns using an

aiming board. Dimension A = 5 meters.