change wheel NISSAN PULSAR 1987 Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1987, Model line: PULSAR, Model: NISSAN PULSAR 1987Pages: 238, PDF Size: 28.91 MB

Page 3 of 238

CONTENTS

INTRODUCTION........................................ 5

VEHICLE IDENTIFICATION AND

GENERAL SPECIFICATIONS................. 7

GENERAL INFORMATION...................... 8

Tools and equipment ............................................. 8 Safety .................................................................... 10

General repair procedures..................................... 11

LUBRICATION AND MAINTENANCE... 14

Specifications......................................................... 14

How to grease and oil change .............................. 14

Service schedule ................................................... 17

WHEELS AND TYRES............................. 21

Specifications......................................................... 21

How to change a road wheel ................................ 21

Tire wear troubl e shooting ..................................... 22

Care and main tenance ......................................... 23

ENGINE TUNE-UP.................................... 25

Tune-up specifications ........................................... 25

Tune-up operat ions............................................... 25

ROADSIDE TROUBLE SHOOTING....... 32

Trouble shoot ing.................................................... 32

To check ignition and el ectrical system ................ 33

To check fuel system ............................................ 34

To check mechani cal system ................................ 35

ENGINE....................................................... 37

Specifications ........................................................ 37

Engine mechanical tr ouble shooting ...................... 39

Description ............................................................ 41

Engine and transaxle assembly ........................... 42

Manifolds ............................................................... 44 Camshaft, rocker arms and tappets..................... 48

Cylinder head........................................................ 50

Engine sump and oil pum p pickup pipe................ 54

Oil pump ............................................................... 55

Pistons, connecting rods and cylinder bores ........ 57

Crankshaft and bearings ...................................... 60

Flywheel /drive plate............................................... 63

Engine mountings.................................................. 64

Exhaust system .................................................... 66

COOLING AND HEATING SYSTEMS.... 68

Specifications ........................................................ 68 Cooling system trouble shooting ........................... 68

Heater and air conditioner trouble shooting ......... 69 Description ............................................................ 70

Radiator ................................................................ 70

Cooling fan ............................................................ 73

Thermost at............................................................ 75

Thermostat housing .............................................. 76

Water pump .......................................................... 76

Welch plugs .......................................................... 76

Heater unit, water valv e and controls ................... 77

Blower fan ............................................................. 80

Air condition ing ..................................................... 80

FUEL AND ENGINE MANAGEMENT ... 82

Specifications ........................................................ 82 Fuel and engine management trouble shooting ... 82

Description ............................................................ 84

Service precautions and procedures

..................... 86

System diagnosis and adjustments ...................... 89

Fuel supply components ....................................... 92

Air flow components .............................................. 98

Electronic components .......................................... 104

EMISSION CONTROL............................. 117

Introduction ........................................................... 117

Crankcase ventilati on system............................... 117

Evaporate control system..................................... 117

Air preheat system — 1.6 liter engines ................ 119

Exhaust control system ........................................ 120

CLUTCH...................................................... 121

Specifications........................................................ 121

Clutch trouble shooting......................................... 121

Description ............................................................ 122

Clutch unit and release mechanism..................... 123

Clutch pedal ......................................................... 124

Clutch c able.......................................................... 124

Clutch adjustments ............................................... 125

MANUAL TRANSAXLE AND

DRIVE SHAFTS......................................... 126

Specifications ........................................................ 126

Manual transaxle and drive shaft trouble shooting 126

Description............................................................ 128

Transaxle assembly.............................................. 129

Differential and final drive assembly ..................... 135

Gear lever assembly ............................................ 136

Drive shafts .......................................................... 137

AUTOMATIC TRANSAXLE....................... 140

Specifications........................................................ 140

Automatic transaxle trouble shooting.................... 140

Description............................................................ 141

Transaxle fluid ...................................................... 141

Brake band........................................................... 142

Kickdown cable .................................................... 142

Transaxle select or linkage ................................... 142

Neutral safety switch ............................................ 142

Transaxle assembly .............................................. 143

STEERING................................................. 145

PART 1. STEERING TROUBLE SHOOTING....145

Faults, causes and remedies................................ 145

PART 2. MANUA L STEERING......................... 147

Specifications ........................................................ 147

Description............................................................ 147

Steering wheel ...................................................... 147

Steering column.................................................... 148

Steering gear assembly ....................................... 149

PART 3. POWE R STEERING .......................... 152

Specifications........................................................ 152

Description............................................................ 152

In car adjustments, checks and minor repairs ..... 152

Steering wheel ...................................................... 153

Steering column.................................................... 153 Power steering pump ........................................... 153

Power steering gear assembly............................. 154

Page 14 of 238

14

LUBRICATION AND MAINTENANCE

SPECIFICATIONS

CAPACITY AND GRADE

Engine:

Lubricant........................................... 15W-50 SF

Sump capacity including filter ........... 3.3 liters

Cooling system capacity............................ 6.0 liters

Manual transaxle:

Lubricant....................................... 80W-90 GL-4

Capacity ............................................... 2.7 liters

Automatic transaxle:

Lubricant.............................................. Dexron II

Capacity ............................................... 6.0 liters

Power steering:

Lubricant.............................................. Dexron II

Capacity ............................................... 1.0 liters

Manual steering lubricant ........ Castrol EPLl grease

Brake fluid type ................................................ Dot 4

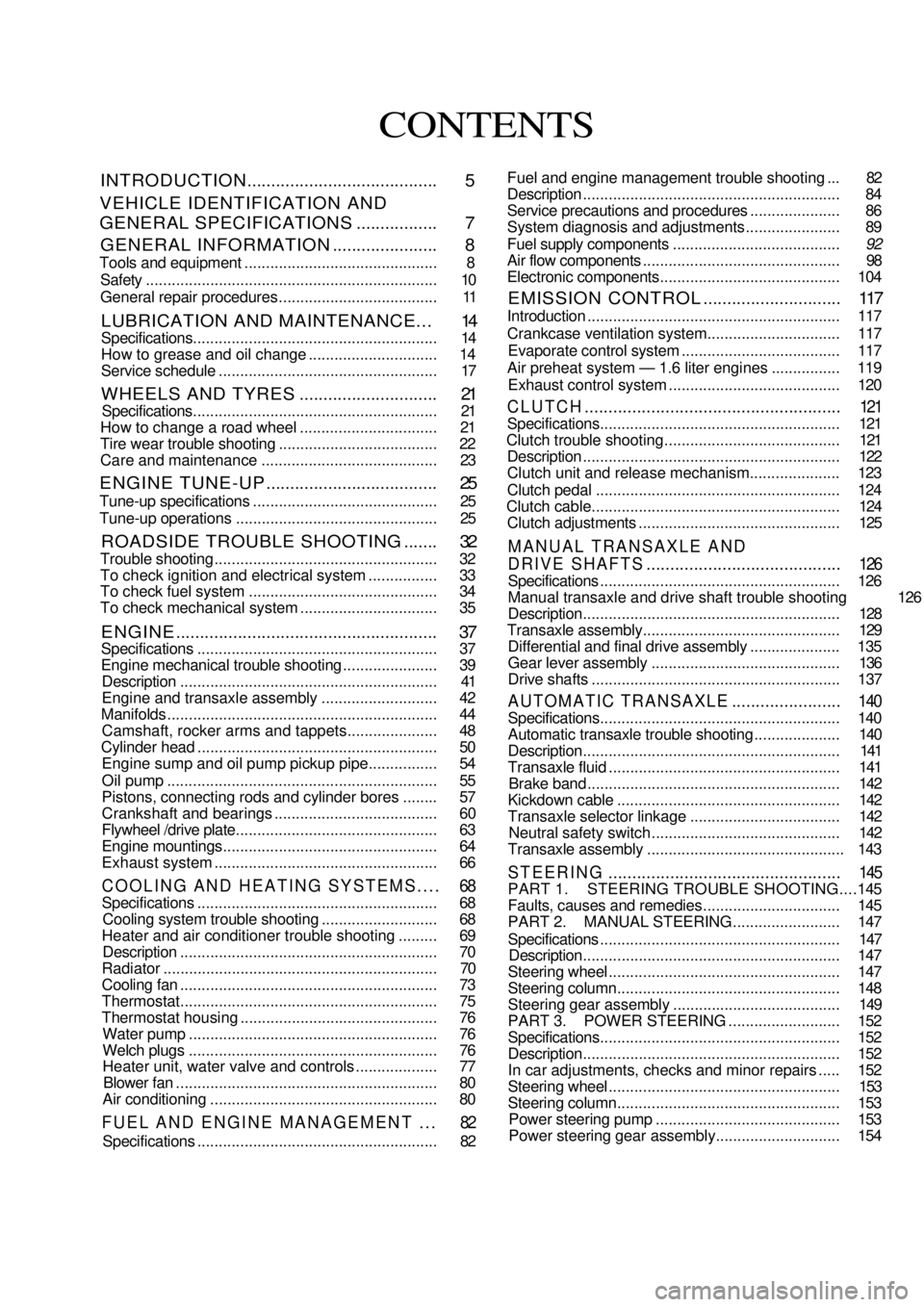

1. HOW TO GREASE AND OIL CHANGE

(1) Run the front of the vehicle onto car ramps

and stop the engine. Chock the front wheels. (2) Raise the rear of the vehicle and place

chassis stands under the rear jacking points.

NOTE: It is best if the vehicle is kept as level

as possible to avoi d false readings when

checking the lubricant levels.

(3) Clean around the engine sump drain plug.

(4) Place a drain tin under the engine sump,

remove the engine sump drain plug and allow the

engine sump to completely drain.

NOTE: It is best to drain the engine sump

with the oil at operating temperature. How-

ever, if the oil is hot take care to avoid

scalding.

(5) Check that the sealing gasket on the sump

plug is in a serviceable condition. (6) When the engine sump has completely

drained, install and firmly tighten the sump drain plug.

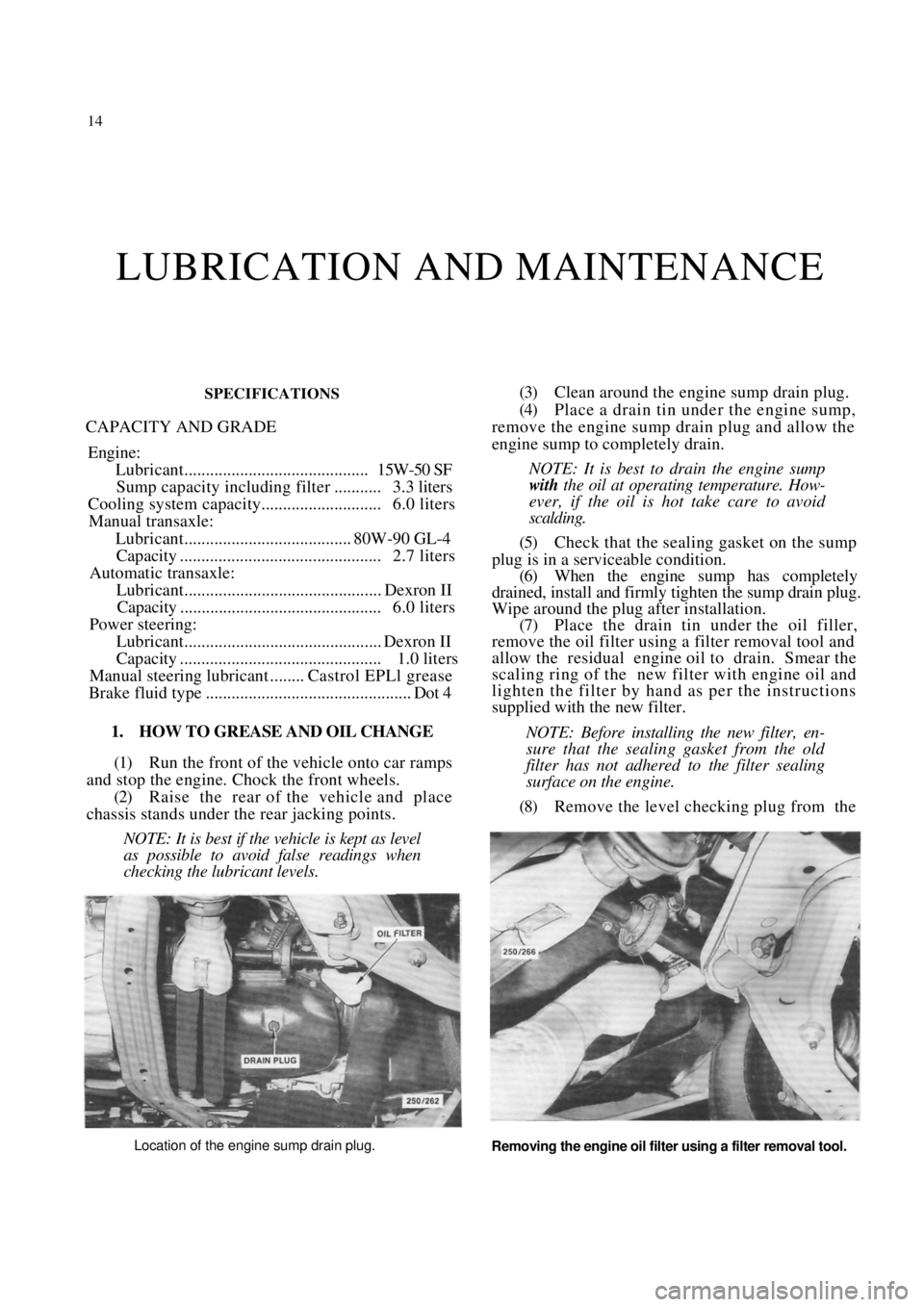

Wipe around the plug after installation. (7) Place the drain tin under the oil filler,

remove the oil filter using a filter removal tool and

allow the residual engine oil to drain. Smear the

scaling ring of the new filter with engine oil and

lighten the filter by hand as per the instructions

supplied with the new filter.

NOTE: Before installing the new filter, en-

sure that the sealing gasket from the old

filter has not adhered to the filter sealing

surface on the engine.

(8) Remove the level checking plug from the

Location of the engine sump drain plug.

Removing the engine oil filter using a filter removal tool.

Page 21 of 238

WHEELS AND TYRES

SPECIFICATIONS

TYRES PRESSURES

Front:

Normal load ............................................ 200 kPa

Heavy load or high speed ......................230 kPa

Rear:

Normal load............................................ 180 kPa

Heavy load or high speed ...................... 210 kPa

NOTE: The above pressures are measured

cold and are meant as a guide only. Always

refer to the tire placard positioned on the

inside of the glove compartment lid and the

tire manufacturers recommendations first.

TORQUE WRENCH SETTINGS

Wheel nut torque .............................................98 Nm

1. HOW TO CHANGE A ROAD WHEEL

(1) Ensure that the vehicle is on level firm

ground and clear of any passing traffic. (2) If necessary, switch on the hazard

flashers.

(3) Switch off the engine a nd place the transaxle

in the (P) Park position on automatic transaxle

models or in reverse gear on manual transaxle models.

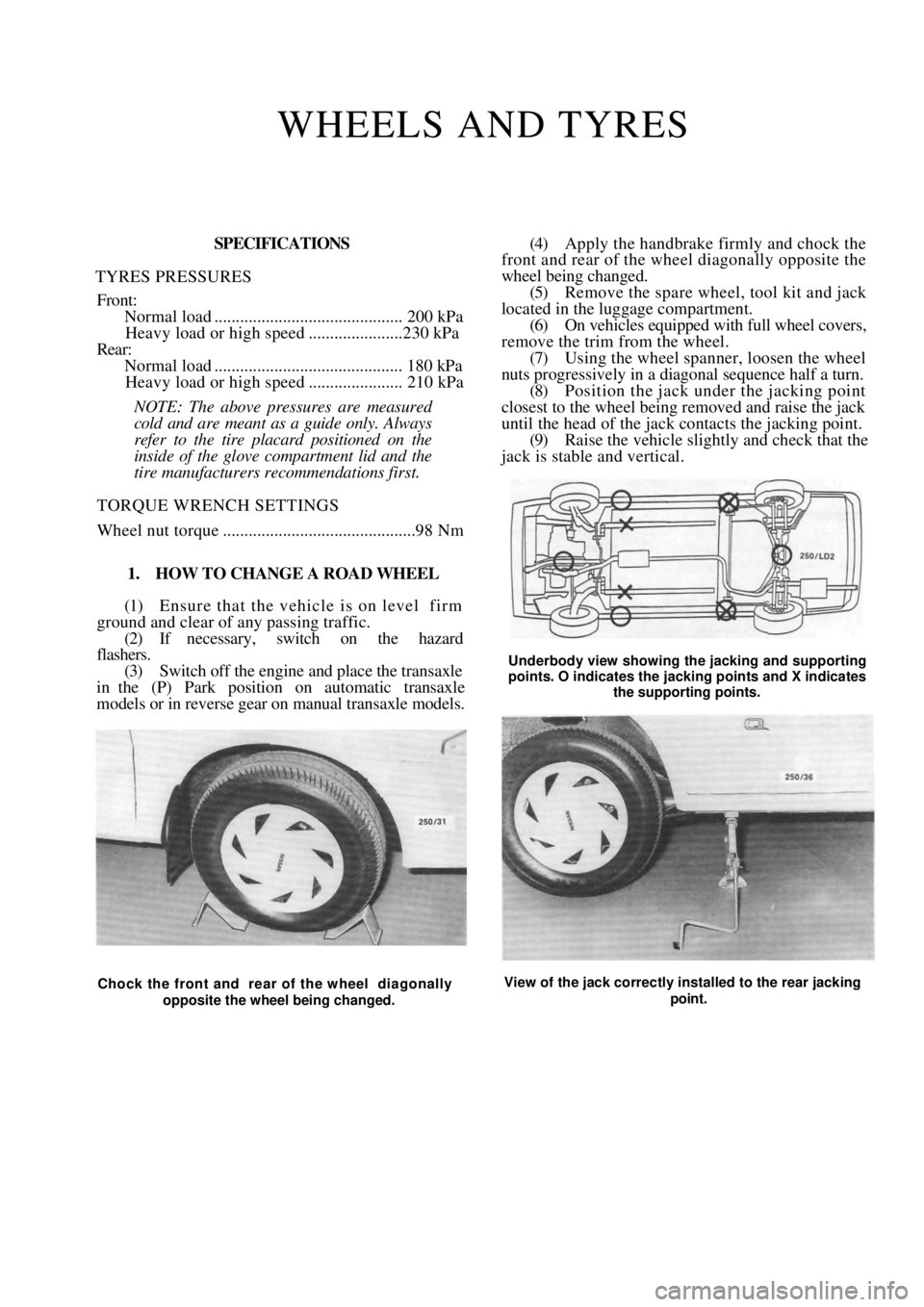

(4) Apply the handbrake firmly and chock the

front and rear of the wheel diagonally opposite the

wheel being changed.

(5) Remove the spare wheel, tool kit and jack

located in the luggage compartment. (6) On vehicles equipped with full wheel covers,

remove the trim from the wheel. (7) Using the wheel spanner, loosen the wheel

nuts progressively in a diagonal sequence half a turn.

(8) Position the jack und er the jacking point

closest to the wheel being removed and raise the jack

until the head of the jack contacts the jacking point.

(9) Raise the vehicle slightly and check that the

jack is stable and vertical.

Underbody view showing the jacking and supporting

points. O indicates the jacking points and X indicates

the supporting points.

Chock the front and rear of the wheel diagonally

opposite the wheel being changed. View of the jack correctly installed to the rear jacking

point.

Page 24 of 238

24 Wheels and Tires

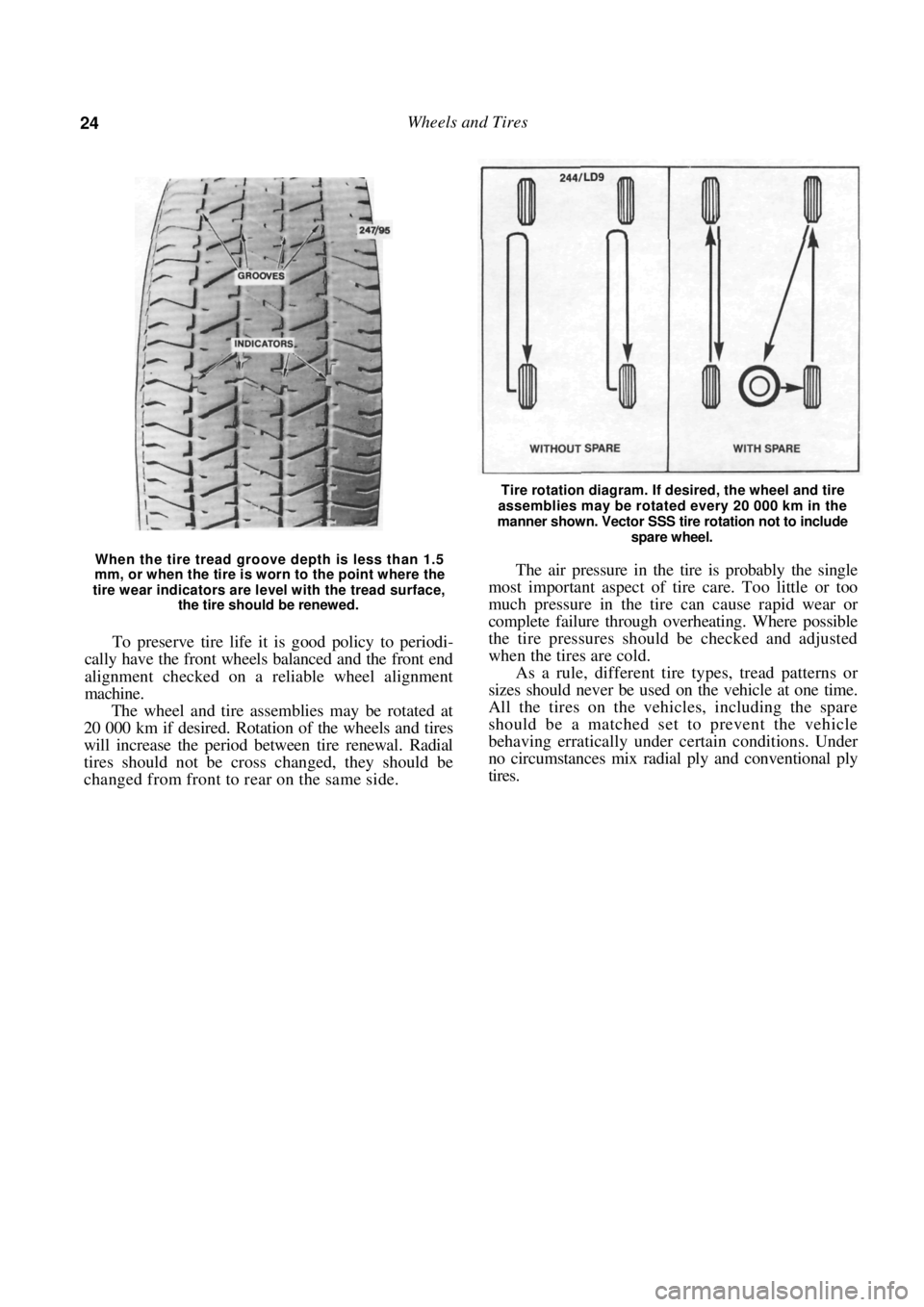

When the tire tread groove depth is less than 1.5

mm, or when the tire is worn to the point where the

tire wear indicators are level with the tread surface,

the tire should be renewed.

To preserve tire life it is good policy to periodi-

cally have the front wheels balanced and the front end

alignment checked on a reliable wheel alignment

machine.

The wheel and tire assemblies may be rotated at

20 000 km if desired. Rotation of the wheels and tires

will increase the period between tire renewal. Radial

tires should not be cross changed, they should be

changed from front to rear on the same side.

Tire rotation diagram. If desired, the wheel and tire

assemblies may be rotated every 20 000 km in the

manner shown. Vector SSS tire rotation not to include

spare wheel.

The air pressure in the tire is probably the single

most important aspect of tire care. Too little or too

much pressure in the tire can cause rapid wear or

complete failure through overheating. Where possible

the tire pressures should be checked and adjusted

when the tires are cold.

As a rule, different tire types, tread patterns or

sizes should never be used on the vehicle at one time.

All the tires on the vehicles, including the spare

should be a matched set to prevent the vehicle

behaving erratically under certain conditions. Under

no circumstances mix radial ply and conventional ply

tires.

Page 41 of 238

Engine 41

DROP IN OIL PRESSURE

(1) Oil level low in the sump: Check and replen-

ish the oil to the full mark on the dipstick.

(2) Thin or diluted oil: Change to the correct oil

grade and rectify the source of dilution. (3) Oil pump relief valve stuck or spring broken;

Free up the relief valve or renew the broken relief

valve spring. (4) Excessive bearing clearance: Renew the bear-

ing shells or recondition the crankshaft journals as

necessary.

(5) Excessive wear of the oil pump components:

Renew or recondition the oil pump.

NOTE: If the vehicle is not equipped with an

oil pressure gauge re move the oil sender unit

and connect a pressure gauge into the oil

gallery. Check the oil pressure with the

engine cold and hot. If the oil pump or relief

valve are faulty. low pressure will be indi-

cated with the engine both hot and cold.

However, if the bearings are at fault a fairly

high oil pressure will be indicated when the

engine is cold, but a marked drop in pressure

will occur when the engine is hot.

ENGINE WILL NOT ROTATE

(1) Starter motor drive jammed: Remove the

starter motor. Check and renew the damaged drive

and/or flywheel ring gear.

(2) Engine overheated an d seized: Remove and

dismantle the engine. Check and renew any damaged

components. See the following note.

(3) Water in the cylinder due to a blown head

gasket or cracked cylinder block or head: Remove the

cylinder head. If the gasket is blown, check for

cylinder block and head distortion and reface if

necessary. Renew the cylinder head and/or cylinder

block if cracked.

(4) Broken crankshaft, connecting rod. piston

etc. due to overheating, fatigue etc: Remove and

dismantle the engine. Examine and renew any com-

ponents as necessary. (5) Valve head broken off due to overheating,

fatigue etc: Remove the cylinder head and check the

head, piston and cylinder bore for damage. Repair or

renew as necessary.

NOTE: Invariably when an engine seizes

because of overheating due to lack of oil

and/or water, damage is done to the bear-

ings, pistons etc. Although there may be

instances where an engine will start and run

after it has cooled down and the oil and

water have been replenished, it will usually

be found that oil consumption increases, oil

pressure decreases and the engine will be

noisier, depending on the degree of damage.

When a cylinder head gasket blows allow-

ing water into the cylinders, or compression

loss between the cylinders, it is essential to

check the gasket faces on the cylinder block

and head for distortion. Sufficient water can

enter a cylinder because of a blown head

gasket, cracked cylinder or head to prevent

an engine from rotating.

This is normally preceded by difficult

starting, misfiring, excessive steam from the

exhaust and loss of water from the radiator.

Frequent jamming of the starter motor

drive with the flywheel ring gear can be due

to a bent starter armature shaft or damaged

teeth on the drive and/or ring gear. With the

starter motor removed, the flywheel ring

gear teeth can be examined through the

starter motor mounting aperture. Renewal

of the ring gear requires removal of the

transaxle, clutch and flywheel on manual

transaxle models and the removal of the

transaxle and drive plate on automatic

transaxle models. To check for a bent arma-

ture shaft, rotate the shaft by hand while

holding the end in close proximity to a fixed

object.

2. DESCRIPTION

The 1.6 and 1.8 liter engines are basically identi-

cal in design.

Both engines share the same stroke. The 1.8 liter

engine has a larger bore thus giving it increased

capacity.

The engine is a four cylinder, inline, overhead

camshaft design transversely mounted in the front of

the vehicle.

The camshaft runs in five integral support bear-

ings in the camshaft housing which in turn is mounted

directly on to the cylinder head and retained by the

cylinder head bolts.

Camshaft end float is controlled by a retaining

plate engaged in a groove machined in the rear

camshaft journal. The camshaft is driven by the

crankshaft timing gear vi a a reinforced rubber belt.

The aluminum cross flow cylinder head houses

the tappets, rocker arms a nd valve assemblies. An oil

pressure relief valve is installed to the cylinder head to

maintain oil pressure to the hydraulic tappets at a

predetermined setting.

The exhaust valve springs are equipped with

rotators mounted below the valve springs which rotate

the exhaust valve assemblies. The rocker arms pivot

on hydraulic tappet assemblies and locate in notched

lash pads mounted on the valve stems. The camshaft

lobes bear directly onto the rocker arms and due to

the characteristics of the hydraulic tappet assemblies,

no provision is made for tappet clearance adjustment.

Page 188 of 238

188 Brakes

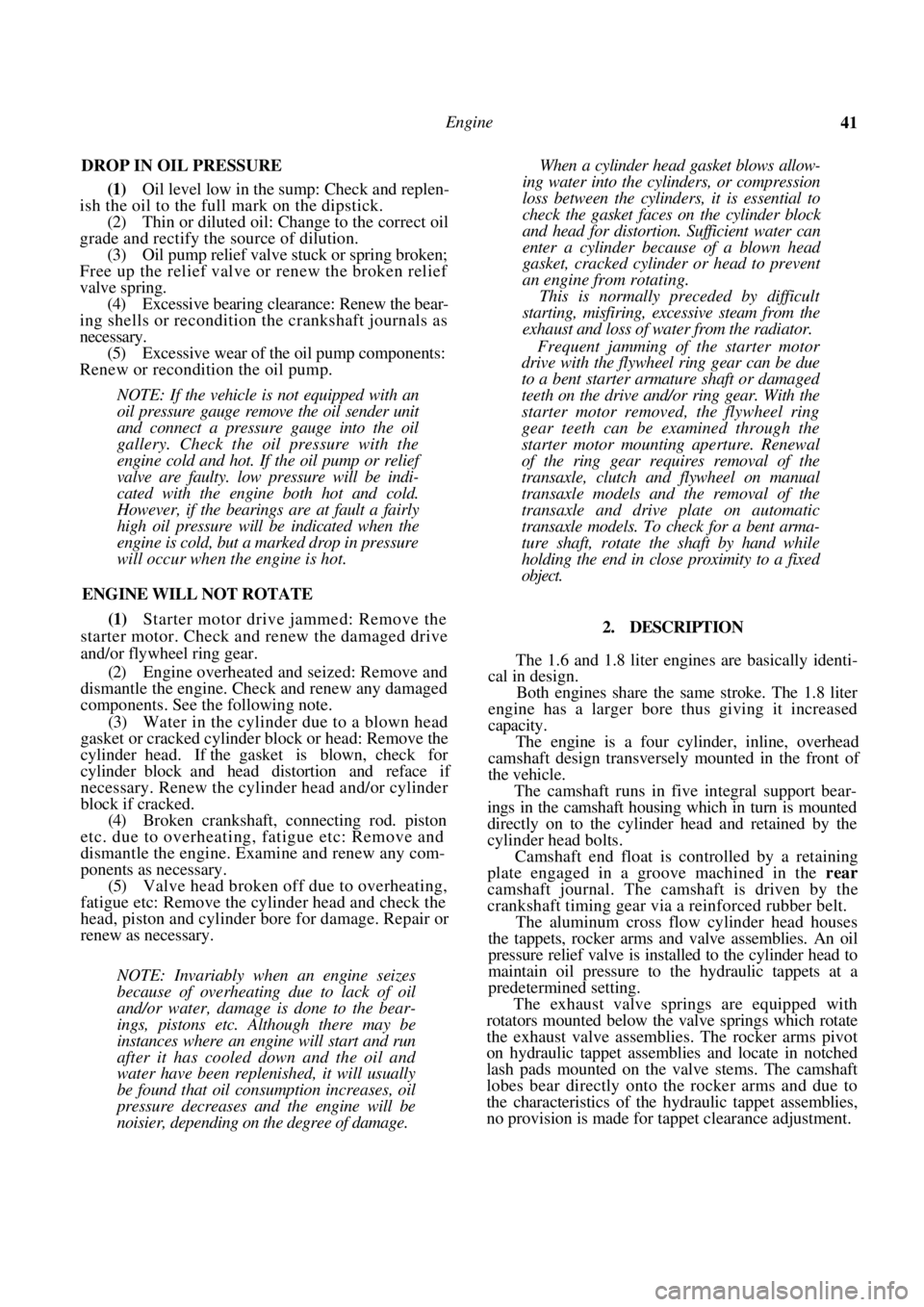

Illustration showing the brake pedal adjustments. Di-

mension H = brake pedal height, Dimension C = stop

lamp switch clearance, Dimension F - brake pedal free

play.

TO ADJUST STOP LAMP SWITCH

(1) Loosen the stop lamp switch locknut and

disconnect the wiring from the switch.

(2) Adjust the stop lamp switch to achieve a

clearance of 0.3-1.0 mm between the pedal stop and

the threaded end of the switch. (3) Tighten the locknut and connect the wiring

to the switch. Ensure that the stop lamps are off when

the pedal is released.

(4) Ensure that the pedal free play is 1.0-3.00

mm after adjustments have been completed.

11. HYDRAULIC SYSTEM

TO BLEED

Bleeding the hydraulic system should only be

necessary when some portion of the hydraulic system

has been disconnected or fluid has been drained,

allowing air to enter the system.

The brake fluid in the hydraulic system should be

changed every 30 000 km or 18 months. The proce-

dure for changing the brake fluid and bleeding the

hydraulic system are simila r with attention to the

notes in the text.

There are four points in the system where bleeder

valves are installed, one on each front caliper and one

on each rear wheel cylinder or rear caliper.

14. Fill the fluid reservoir with clean hydraulic

brake fluid and maintain at least one third full

throughout the entire operation. 15. Attach a transparent hose to the bleeder

valve on the left rear cali per and immerse the other

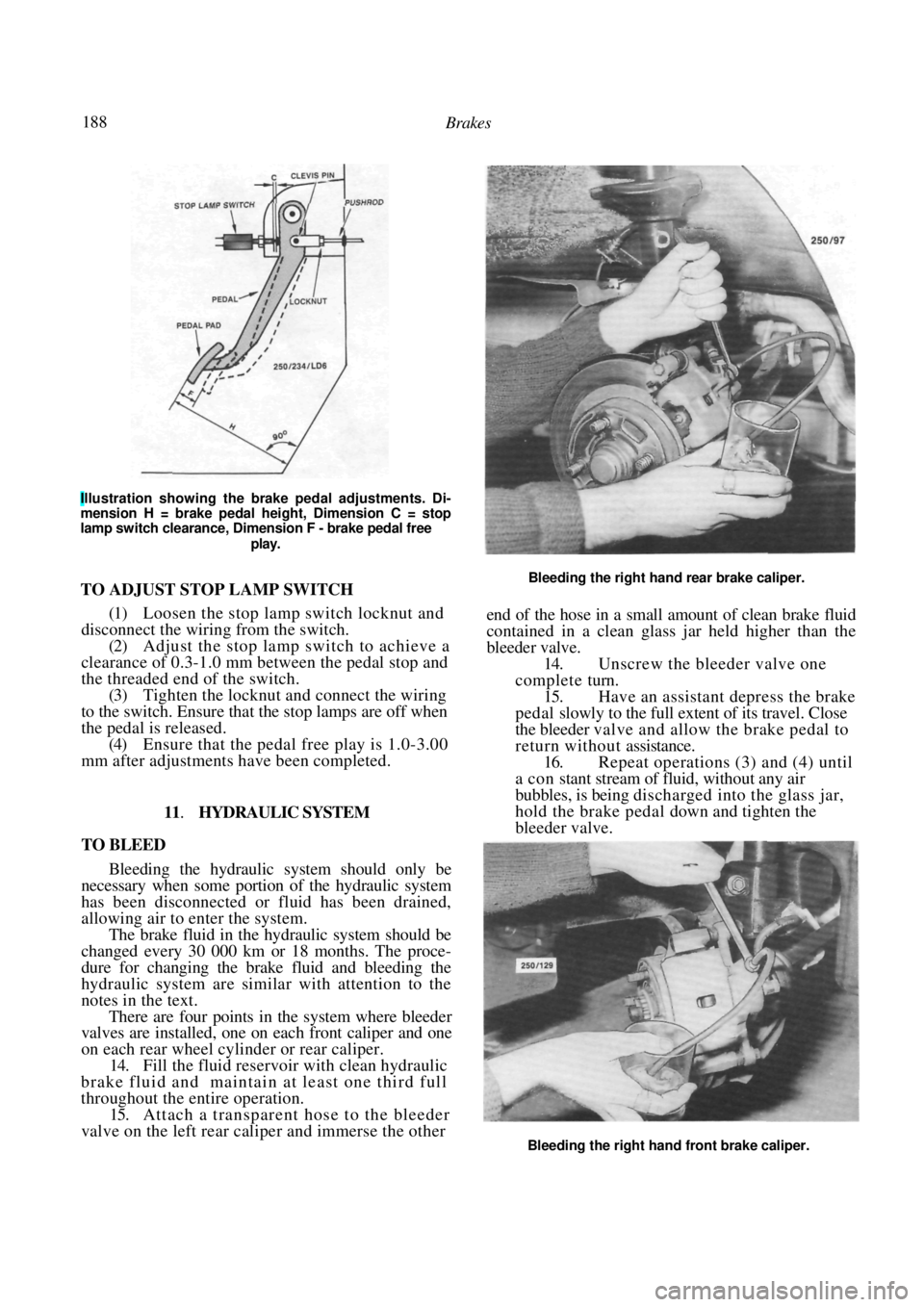

Bleeding the right hand rear brake caliper.

end of the hose in a small amount of clean brake fluid

contained in a clean glass jar held higher than the

bleeder valve.

14. Unscrew the bleeder valve one

complete turn.

15. Have an assistant depress the brake

pedal slowly to the full extent of its travel. Close

the bleeder valve and allow the brake pedal to

r e t u r n w i t h o u t assistance. 16. Repeat operations (3) and (4) until

a con stant stream of fluid, without any air

bubbles, is being discharged into the gl ass jar,

hold the brake pedal down and tighten the

bleeder valve.

Bleeding the right hand front brake caliper.