turn signal NISSAN PULSAR 1987 Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1987, Model line: PULSAR, Model: NISSAN PULSAR 1987Pages: 238, PDF Size: 28.91 MB

Page 4 of 238

FRONT SUSPENSION............................ 156

Specifications......................................................... 156

Front suspension tr ouble shooting ........................ 156

Description ............................................................ 157

Steering knuckle.................................................... 157

Suspension unit..................................................... 159

Control arm ........................................................... 161

Stabiliser bar ........................................................ 162

Suspension and steering angles .......................... 163

REAR SUSPENSION................................ 164

Specifications ........................................................ 164

Rear suspension tr ouble shooting ........................ 164

Description ............................................................ 165

Rear hub ............................................................... 166

Suspension unit .................................................... 167

Control arm ........................................................... 169

Knuckle assembly.................................................. 170

Stabiliser bar ........................................................ 170

Rear wheel alignment ........................................... 171

BRAKES...................................................... 172

Specifications......................................................... 172

Brakes trouble shooting ........................................ 172

Description ............................................................ 174

Master cyli nder...................................................... 175

Brake servo unit .................................................... 177

Front brakes ......................................................... 178

Rear disc brakes................................................... 181

Rear drum brakes ................................................. 184

Handbrake cable and le ver assembly ................... 186

Brake adjustments ................................................ 187

Brake pedal ........................................................... 187

Hydraulic system................................................... 188

ELECTRICAL SYSTEM............................ 190

Specifications......................................................... 190

Battery and charging system trouble shooting ....... 190

Battery and starting system trouble shooting ........ 191

Lighting system trouble shooting ........................... 192

Turn signal lamp trouble shooting ........................ 192

Test equipment and so me applications................. 193

Battery ................................................................... 194

Alternator ............................................................... 196

Starter motor ......................................................... 201

Ignition system ...................................................... 206

Steering wheel ....................................................... 206

Switches and controls........................................... 206

Instrument cluster.................................................. 209

Blower fan .............................................................. 209

Radio/cassette...................................................... 209

lamp units ............................................................ 210

Windscreen wiper ................................................. 213

Fuses, fusible links and relays ............................. 215

Trailer wiring ......................................................... 216

Wiring diagrams ................................................... 218

BODY........................................................... 225

Windscreen and re ar glass .................................. 225

Front doors ........................................................... 225

Rear doors............................................................ 228

Engine bonnet...................................................... 231

Tailgate and lock — hatchback ............................ 231

Luggage compartment lid and lock — sedan ........ 233

Radiator grille.............................................................. 234

Centre console...................................................... 234 Dashboard ............................................................ 235

Scat belts ............................................................. 236

Seats .................................................................... 236

Vehicle cleaning ........................................................... 237

CONVERSION TABLES.......................... 238

Page 85 of 238

Fuel and Engine Management 85

View of the 1.6 liter engine showing the engine management components. Air cleaner removed for clarity.

series of tests on various components in the system

and records the results, If a fault is discovered, the

ECM warning lamp on the instrument cluster will

illuminate while the engine is running. When the self

diagnosis mode is activated, the ECM warning lamp

will flash codes indicating the area in which the fault

has occurred.

This function is very useful in locating system

faults, particularly intermittent problems. However,

the self diagnosis mode does not provide comprehen-

sive testing of the EFI system, and therefore should

always be used in conjunction with the other test

procedures described later in this section in order to

accurately locate system faults.

The high energy electronic ignition system con-

sists of a distributor and an ignition coil.

The distributor has two functions. The first is to

produce and distribute secondary high tension voltage

to the spark plugs.

The second function is to provide the control unit

with information on engine speed and crankshaft

position.

The ignition timing is constantly adjusted by the

control unit to suit varying engine and vehicle oper-

ating conditions.

In the fuel injection system, a metered amount of

fuel is sprayed into the air stream. The air/fuel

mixture then enters the combustion chamber via the

inlet valves.

On 1.6 liter engines, the fuel is injected by a single

injector, located above the throttle valve within the

throttle body assembly. The injector fires twice per

engine revolution under most operating conditions.

On 1.8 liter engines, four injectors are used. The

fuel is distributed to the injectors via the fuel rail. All

injectors fire simultaneous ly once per engine revolu-

tion under most operating conditions.

Under conditions of high load the control unit

may signal the injector(s) to fire more often. However,

if the engine speed exceeds 6 700 rpm the control unit

will cease firing the injectors until the engine speed is

below 6 200 rpm.

Fuel is supplied under pressu re by an electric fuel

pump mounted in the fuel tank and the pressure is

regulated by a pressure regulator.

On 1.6 liter engines, the regulator consists of a

spring tensioned diaphragm which is mounted to the

side of the throttle body assembly. The fuel pressure is

regulated by the tension of the spring against the

diaphragm, opening and closing the fuel return port.

On 1.8 liter engines, the pressure regulator is

mounted adjacent to the fuel rail and consists of a

diaphragm with fuel pressu re acting on one side and

spring tension and manifold vacuum acting on the

Page 104 of 238

104 Fuel and Engine Management

(3) Gently pull the outer throttle cable until the

inner cable remains taut without moving the throttle

linkage. (4) Install the snap ring into the groove

posi-

tioned second from the insulator.

(5) Depress the throttle pedal and check that the

throttle valve opens fully and returns to the idle

position when the pedal is released. (6) On 1.6 liter engines, install the air

cleaner

assembly.

7. ELECTRONIC COMPONENTS

NOTE: Before proceeding with any of the

operations in this section, refer to the Ser-

vice Precautions and Procedures heading.

TO CHECK IGNITION SYSTEM

(1) Perform the test procedure described in the

Roadside Trouble Shooting section. Repair or renew

components as necessary. (2) Perform the self diagnosis test procedure as

previously described and rectify any faults. If there is

no spark, proceed as follows. (3) Disconnect the 4 pin wiring connector from

the distributor and check for spark at a spark plug

high tension lead using the test spark plug. If there is a spark, renew the pickup coil in the

distributor.

If there is no spark, proceed as follows.

(4) Connect the coil high tension lead to the test

spark plug and check for spark.

If there is a spark, check the distributor cap and

rotor for cracks and moisture. Repair or renew as

necessary.

If there is no spark, proceed as follows.

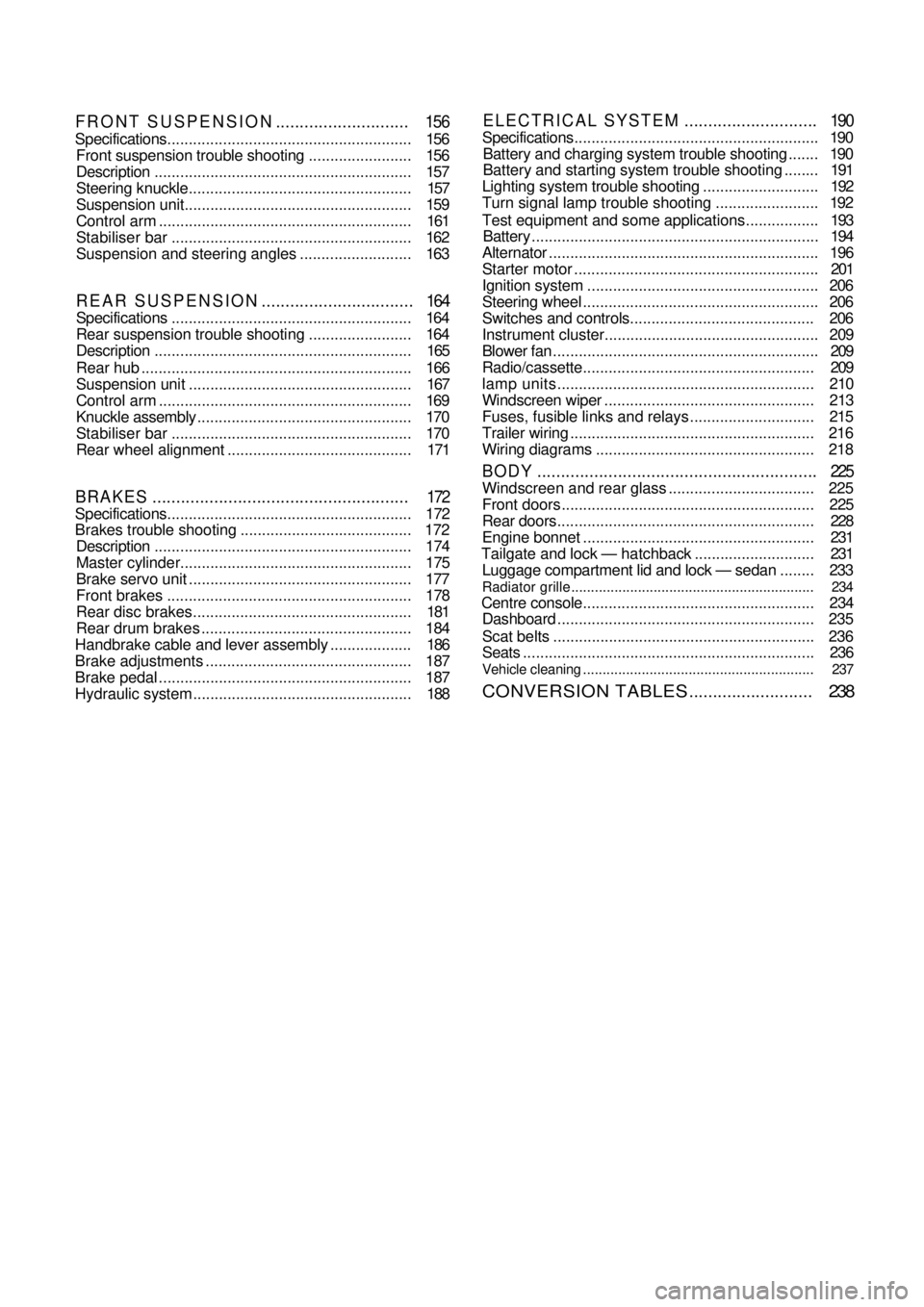

(5) Disconnect the 2 pin wiring connector from

the distributor. (6) With the ignition switched On. measure the

voltage at terminals A and B on the distributor 2 pin

wiring connector. If the voltage at terminal B only is under 10 volts,

check the wiring harness for continuity between

terminal B on the distributor 2 pin wiring connector

and terminal 2 on the black ignition coil wiring

connector. Repair or renew the wiring harness as

necessary. If no fault is found, renew the ignition coll.

If the voltages at both terminals is under 10 volts,

check the wiring harness between terminal A on the

distributor 2 pin wiring connector and terminal 1 on

the black ignition coil wiring connector for continuity.

Also check the fuel pump fuse and the wiring harness

between the ignition switch and the ignition coil.

Repair or renew the wiring harness as necessary.

If the voltage at both terminals is 10 volts or

more, proceed as follows.

(7) Connect the 2 pin wiring connector to the

distributor. (8) With the ignition switched On, measure the

voltage at the tachometer signal wire.

Illustration identifying the 2 and 4 pin distributor wiring

connector terminals.

If the voltage is under 1 volt, check the tacho-

meter signal wire for continuity from the ignition coil.

Repair or renew the wiring harness as necessary.

If the voltage is 1-10 volts, renew the distributor

control module. If there is still no spark, renew the

ignition coil also.

If the voltage is over 10 volts, proceed as follows.

(9) With the ignition switch in the Start position,

check for voltage at the tachometer signal wire using

a test lamp.

If the test lamp flashes, replace the ignition coil

with a known serviceable un it. If there is still no

spark, install the original coil and renew the control

module.

If the test lamp remains illuminated, proceed as

follows.

(10) Remove the distributor cap and disconnect

the pickup coil wiring co nnector from the control

module. (11) Connect a voltmeter between the tachometer

signal wire and earth. (12) Connect the lead of a test lamp to a power

supply of 1.5-8 volts. (13) With the ignition switched On, momentarily

connect the probe of the test lamp to terminal P on

the control module and note the voltage. The voltage

should decrease to 7-9 volts. If there is no voltage decrease, check the control

module earth. If the earth is satisfactory, renew the

control module.

If the voltage decreases , proceed as follows.

(14) Check for spark at the coil high tension lead

as the test lamp is disconnected from terminal P on

the control module.

If there is no spark, proceed to operation (15).

If there is a spark, check that the steel rotor on the

distributor shaft is magnetized. If it is not renew the

distributor shaft assembly.

If the steel rotor is magnetized, check that the

resistance between the pickup coil leads is 500-1 500

ohms and not earthed. Renew the pickup coil as

necessary.

(15) Renew the ignition coil and check for spark.

If there is no spark check the coil high tension

lead. If no fault can be found, renew the control

module.

Page 116 of 238

116 Fuel and Engine Management

Rear view of the instrument cluster showing the flexible printed circuit.

If the voltage is under 5 volts proceed as follows.

(17) Check the wiring harness for continuity or

shorts to earth between th e red wire terminal on the

speed sensor harness connector and the green and

black wire terminal on th e instrument cluster wiring

connector.

If no fault can be found check the instrument

cluster printed circuit for continuity or shorts. If no

fault can be found, renew the speedometer and the

signal divider circuit board.

(18) Remove the instrument cluster as described

in the Electrical System se ction and repeat operation

(16).

If the voltage is under 1 volt, check the flexible

printed circuit on the rear of the instrument cluster for

continuity or shorts and re new as necessary. If no fault

can be found, renew the speedometer and the signal

divider circuit board.

(19) Connect the harness connector to the vehicle

speed sensor wiring connector. (20) Raise the front of the vehicle and support it on chassis stands. Place the transaxle in Neutral.

(21) With the aid of assistants, slowly spin the

front wheels by hand while backprobing the brown

wire terminal on the vehicle speed sensor wiring

connector with a voltmeter to earth.

The voltage should alternate between approxi-

mately 1 and 7 volts.

If the voltage is as specif ied, check the flexible

printed circuit on the rear of the instrument cluster for

continuity or shorts. If no fault can be found, renew

the speedometer and the signal divider circuit board.

If the voltage is not as specified, proceed as

follows.

(22) Disconnect the vehicle speed sensor wiring

connector and unscrew the sensor from the speedom-

eter drive housing. (23) Rotate both front wheels in the same direc-

tion and check that the speedometer drive shaft is

turning and does not slip. If the drive shaft does not operate as described,

renew the drive assembly as described in the Manual

or Automatic Transaxle section.

If the drive shaft operates satisfactorily, renew the

vehicle speed sensor.

To Remove and Install

(1) Disconnect the negative battery terminal.

(2) Disconnect the vehicle speed sensor wiring

connector. (3) Unscrew the vehicle speed sensor from the

speedometer drive housing.

Installation is a reversal of the removal procedure

with attention to the following points:

(1) Align the cut-out in the speedometer drive

shaft with the notch in the vehicle speed sensor shaft.

(2) Tighten the vehicle speed sensor securely.

Page 147 of 238

147

PART 2. MANUAL STEERING

SPECIFICATIONS

Steering gear type ............................ Rack and pinion

Steering column type ...................... Energy absorbing

collapsible and tilt adjustable

Steering wheel free play

(maximum ) ...................................................... 35 mm

Linkage........................... Direct from rack ends to t i e

rods and steering knuckles

Turns lock to lock ................................................. 3.6

Steering column length .................. 534.7-537.3 mm

Steering gear lubricant.............. Castrol EPL 1 grease

TORQUE WRENCH SETTINGS

Steering wheel retaining nut ............................ 39 Nm

Steering gear to bulkhead

mounting bolts .............................................. 108 Nm

Tie rod to steering knuckle nut...................... 98 Nm

Tie rod to tie rod end locknut ....................... 98 Nm

Tie rod ball housing to rack............................ 88 Nm

Steering column to mounting

bracket bolt ...................................................... 14 Nm

Steering column universal

coupling joint pinch bolts ............................... 29 Nm

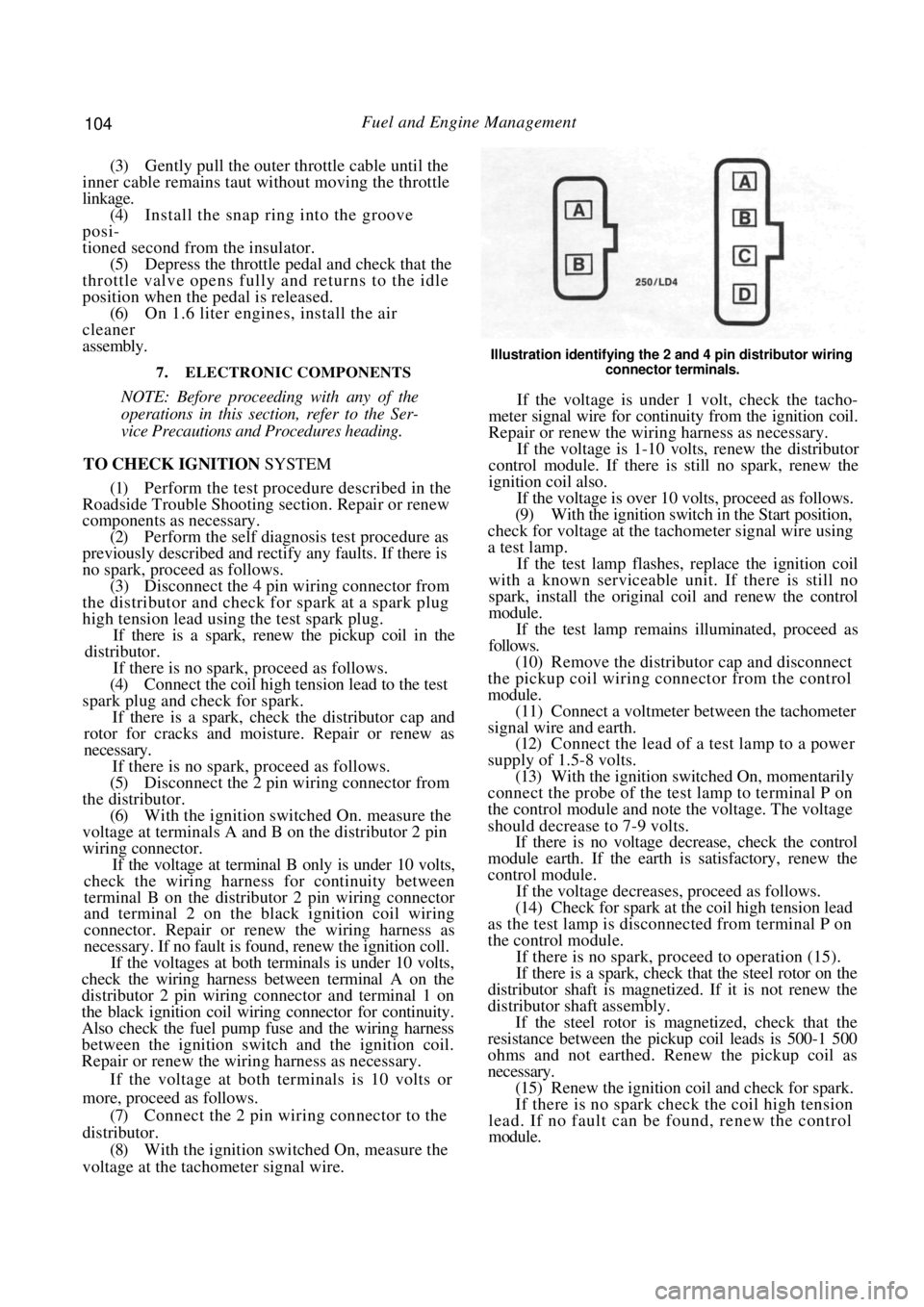

2. STEERING WHEEL

Special Equipment Required:

To Remove Steering Wheel - Steering wheel

puller

TO REMOVE AND INSTAL

(1) Disconnect the negative battery terminal.

(2) Using a small screwdriver, carefully prise the

centre ornament from the steering wheel.

View of the steering wheel removed from the vehicle.

Steering wheels may vary between models.

1. DESCRIPTION

The steering gear is a rack and p i n i o n type

which is mounted on the lower section of the engine

compartment bulkhead by rubber mountings and

brackets.

The design of this assembly requires a range of

special tools to dismantle and assemble the steering

gear. If the steering gear is found to have a fault which

requires overhaul of the rack and pinion, it is recom-

mended that this be performed by an authorized work-

shop or steering specialist.

However, the procedures for the removal and

installation of the steering gear and the renewal of the

tie rods, the tie rod ends and the rubber boots are fully

covered in this section.

The rack and pinion assembly requires no lubri-

cation during service.

The steering column is of the energy absorbing

type designed to compress in the event of a severe

front end collision. The energy absorbing units are the

outer steering column, the tilt bracket and the steering

shaft. All these units shoul d be handled with extreme

care if service operations are performed on the

steering column assembly.

(3) Remove the steering wh eel retaining nut and

mark the steering shaft and steering wheel hub in

relation to each other as an aid to assembly.

(4) Remove the steering wheel from the steering

shaft.

NOTE: If the steering wheel will not sepa-

rate from the steering shaft, loosen the horn

pad retaining screws at the rear of the

steering wheel and withdraw the horn pad

after disconnecting the wire. A puller can

now be used to pull the steering wheel from

the steering shaft. Do not strike the end of

the steering shaft as sharp blows can cause

irreparable damage to the collapsible steer-

ing shaft.

(5) If necessary the steering wheel can be dis-

mantled as shown in the illustration.

Installation is a reversal of the removal procedure

with attention to the following points:

(1) Apply a light coat of multipurpose grease to

the horn slip ring and the turn signal canceling pins.

(2) Ensure that the marks on the steering wheel

and steering shaf t are aligned.

(3) Tighten the steering wheel retaining nut to

the specified torque.

Page 192 of 238

192 Electrical System

transaxle models, check for a faulty or incorrectly

adjusted neutral safety switch.

1. Discharged battery: Check for a fault or short

circuit in the system. 2. Battery fully charged but will not crank

engine. Check for a locked drive and ring gear,

internal starter faul t or seized engine.

3. Fusible link blown: Check and repair the

cause and renew as necessary.

NOTE: Rotate the engine by hand to ensure

that the starter drive is not locked with the

flywheel ring gear and t hat the engine is not

seized. Ensure that the ignition key is

turned off before rotating the engine.

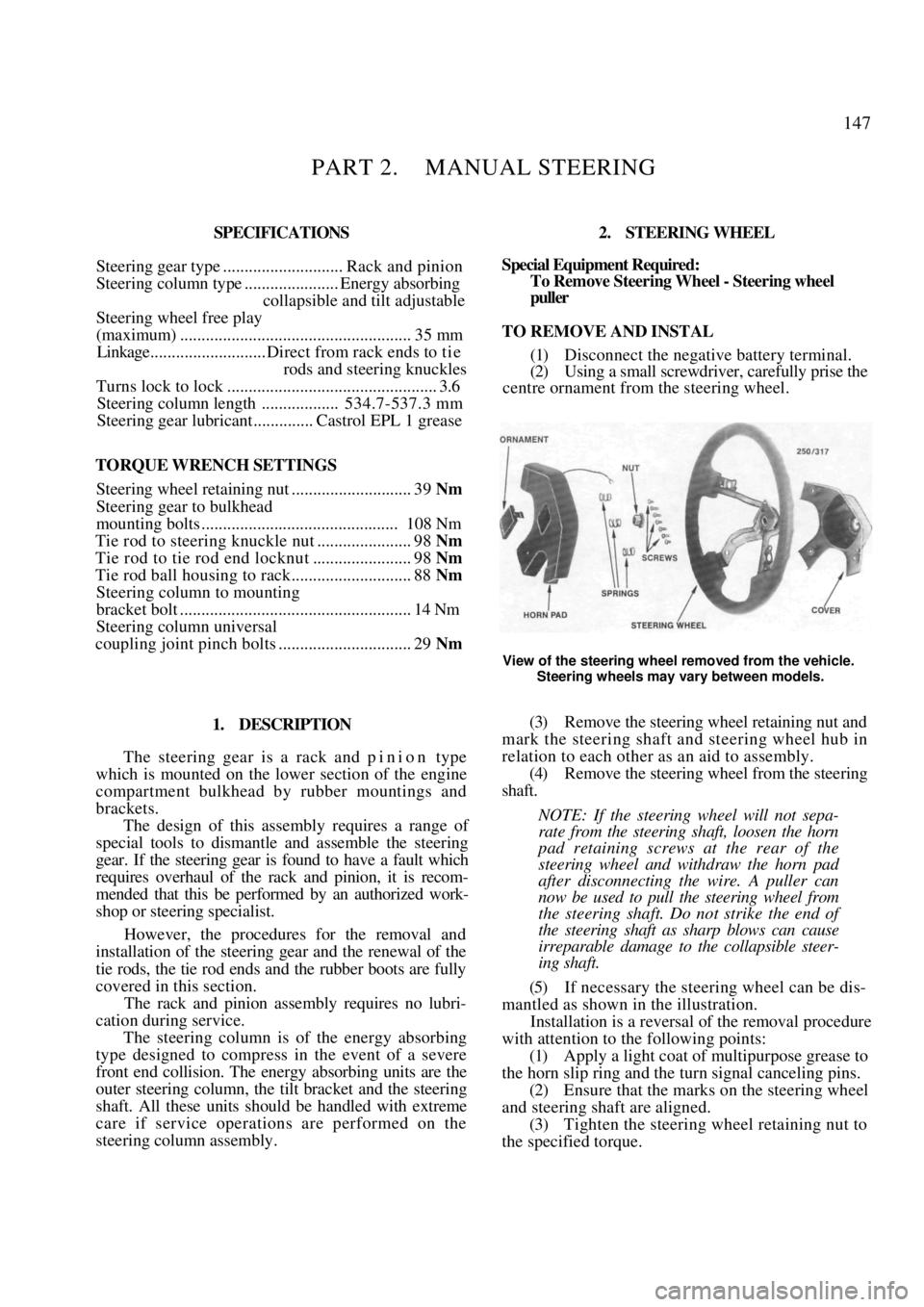

3. LIGHTING SYSTEM TROUBLE SHOOTING

LAMP OR LAMPS FAIL TO LIGHT

1. Faulty bulb(s): Check and renew the faulty

bulb(s). 2. Open circuit in the wiring or connections:

Check the lamp circuits and rectify as necessary.

1. Faulty lamp switch: Check and if necessary

renew the lamp switch. 2. Faulty fuse or fuse connection: Repair the

fuse connection or renew the fuse. 3. Lamp relay faulty: Check and renew as

necessary.

NOTE: Switch on the lamps concerned and

using a test lamp, check that the lamp

circuits are operating. This is best done by

starting at the lamp wiring connector or

bulb holder and work ing back to the power

source.

LAMP OR LAMPS INCORRECTLY

ILLUMINATED

1. Lamp or lamps incorrectly earthed: Check

the lamp earth for loosene ss or clean the contact,

either at the lamp body or wire.

2. Incorrect bulbs installe d: Check the bulb

wattage and voltage and renew with the correct type if

necessary. 3. Dirty or damaged lamp reflector: Clean or

renew the lamp reflector. 4. Faulty bulb: Check with a known serviceable

bulb and renew if necessary. 5. Dirty lamp lens: Clean or renew the lamp

lens. 6. High resistance or faulty connections be-

tween the alternator and battery: Check the circuit

and rectify th e condition.

7. Poor earth connection between the battery

and the engine or alternat or: Check the battery earth

lead and the strap between the engine and the body. 8. Voltage regulator faulty: Check and renew

the voltage regulator.

NOTE: The most common cause for this

condition is dirty t erminals on the earth

leads. Check all earth leads at their earthing

points.

4. TURN SIGNAL LAMP TROUBLE SHOOTING

TURN SIGNAL LAMP DOES NOT LIGHT AND

NO AUDIBLE NOISE FROM FLASHER UNIT

(1) Fuse blown: Rectify the fault and renew the

fuse.

(2) The Flasher unit is faulty: Renew the unit

(3) Turn signal switch faulty: Renew the switch

(4) Fault in the wiring circuit: Check and repair

the fault.

TURN SIGNAL WARNING LAMP DOES NOT

FLASH BUT AUDIBLE CLICKING FROM

FLASHER UNIT

(1) Warning lamp bulb blown: Check and renew

the bulb.

Checking the rear combination lamp circuit using a test

lamp.

Checking the headlamp circuit using a test lamp.

Page 193 of 238

Electrical System 193

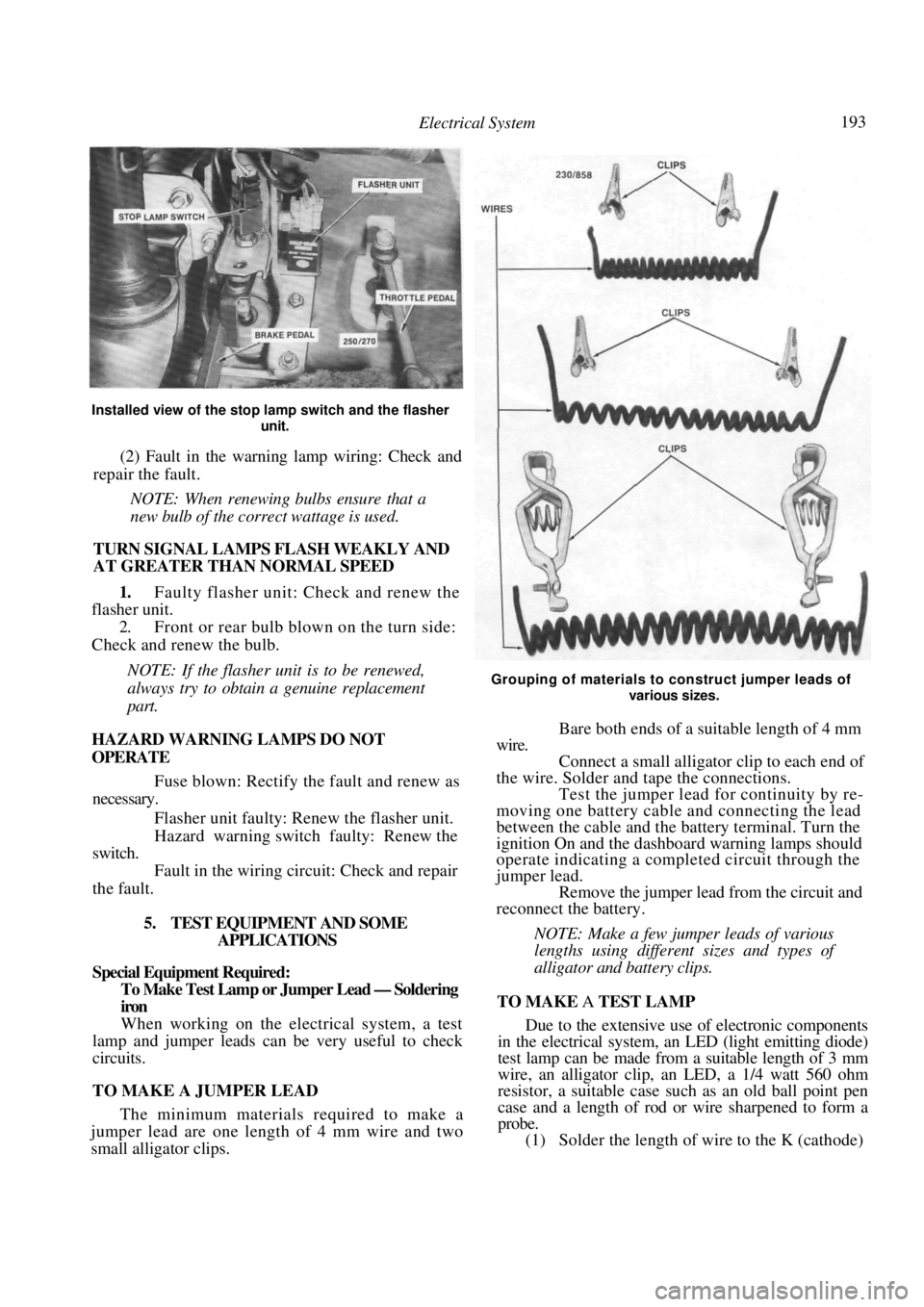

Installed view of the stop lamp switch and the flasher

unit.

(2) Fault in the warning lamp wiring: Check and

repair the fault.

NOTE: When renewing bulbs ensure that a

new bulb of the correct wattage is used.

TURN SIGNAL LAMPS FLASH WEAKLY AND

AT GREATER THAN NORMAL SPEED

1. Faulty flasher unit: Check and renew the

flasher unit.

2. Front or rear bulb blown on the turn side:

Check and renew the bulb.

NOTE: If the flasher unit is to be renewed,

always try to obtain a genuine replacement

part.

HAZARD WARNING LAMPS DO NOT

OPERATE

Fuse blown: Rectify the fault and renew as

necessary.

Flasher unit faulty: Re new the flasher unit.

Hazard warning switch faulty: Renew the

switch.

Fault in the wiring circuit: Check and repair

the fault.

5. TEST EQUIPMENT AND SOME APPLICATIONS

Special Equipment Required:

To Make Test Lamp or Jumper Lead — Soldering

iron

When working on the electrical system, a test

lamp and jumper leads can be very useful to check

circuits.

TO MAKE A JUMPER LEAD

The minimum materials required to make a

jumper lead are one length of 4 mm wire and two

small alligator clips.

Grouping of materials to construct jumper leads of

various sizes.

Bare both ends of a suitable length of 4 mm

wire. Connect a small alligato r clip to each end of

the wire. Solder and tape the connections. Test the jumper lead for continuity by re-

moving one battery cable and connecting the lead

between the cable and the battery terminal. Turn the

ignition On and the dashboard warning lamps should

operate indicating a completed circuit through the

jumper lead. Remove the jumper lead from the circuit and

reconnect the battery.

NOTE: Make a few jumper leads of various

lengths using different sizes and types of

alligator and battery clips.

TO MAKE A TEST LAMP

Due to the extensive use of electronic components

in the electrical system, an LED (light emitting diode)

test lamp can be made from a suitable length of 3 mm

wire, an alligator clip, an LED, a 1/4 watt 560 ohm

resistor, a suitable case such as an old ball point pen

case and a length of rod or wire sharpened to form a

probe.

(1) Solder the length of wire to the K (cathode)

Page 206 of 238

206 Electrical System

Install the armature and yoke to the drive end

bracket rotating the drive to align the reduction gears.

Do not use force.

Install the retaining through bolts to the

commutator end bracket and lighten the through bolts

and armature end cover retaining screws securely. Install the solenoid to the drive end bracket,

install the retaining screws and tighten them securely.

Install the brush connector strap and

install

the retaining nut and washer and tighten securely.

9 . IGNITION SYSTEM

The testing and repair procedures for the ignition

system are fully covered in the Fuel and Engine

Management section.

10. STEERING WHEEL

The removal and installation procedures for the

steering wheel and horn pad are fully covered in the

Steering section.

11. SWITCHES AND CONTROLS

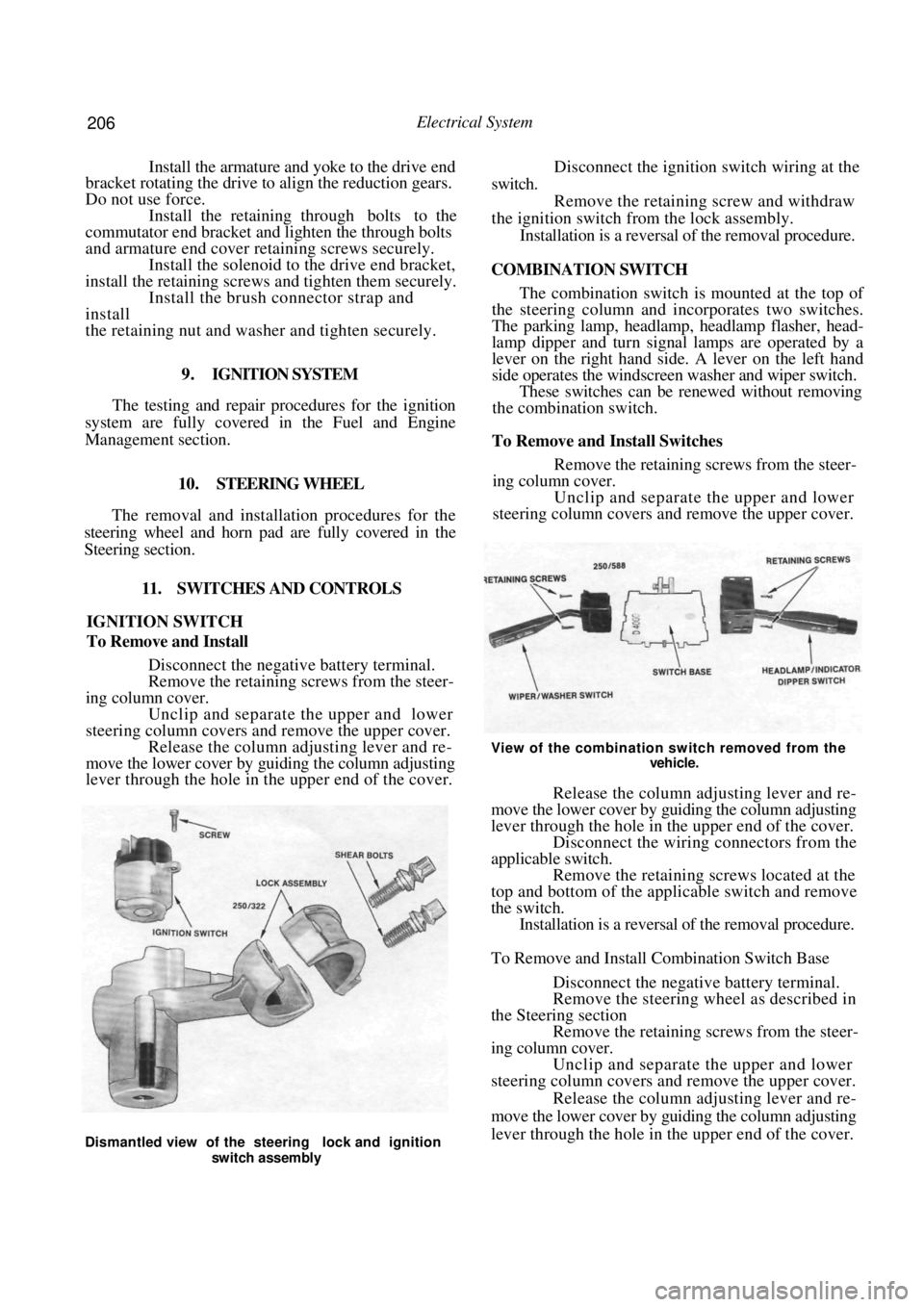

IGNITION SWITCH

To Remove and Install

Disconnect the negative battery terminal.

Remove the retaining screws from the steer-

ing column cover. Unclip and separate the upper and lower

steering column covers and remove the upper cover. Release the column adjusting lever and re-

move the lower cover by guiding the column adjusting

lever through the hole in the upper end of the cover.

Disconnect the ignition switch wiring at the

switch. Remove the retaining screw and withdraw

the ignition switch fr om the lock assembly.

Installation is a reversal of the removal procedure.

COMBINATION SWITCH

The combination switch is mounted at the top of

the steering column and incorporates two switches.

The parking lamp, headlamp, headlamp flasher, head-

lamp dipper and turn signal lamps are operated by a

lever on the right hand side. A lever on the left hand

side operates the windscreen washer and wiper switch.

These switches can be re newed without removing

the combination switch.

To Remove and Install Switches

Remove the retaining screws from the steer-

ing column cover.

Unclip and separate the upper and lower

steering column covers and remove the upper cover.

View of the combination switch removed from the

vehicle.

Release the column adjusting lever and re-

move the lower cover by guiding the column adjusting

lever through the hole in the upper end of the cover. Disconnect the wiring connectors from the

applicable switch. Remove the retaining screws located at the

top and bottom of the applicable switch and remove

the switch. Installation is a reversal of the removal procedure.

To Remove and Install Combination Switch Base

Disconnect the negative battery terminal.

Remove the steering wheel as described in

the Steering section Remove the retaining screws from the steer-

ing column cover. Unclip and separate the upper and lower

steering column covers and remove the upper cover.

Release the column adjusting lever and re-

move the lower cover by guiding the column adjusting

lever through the hole in the upper end of the cover.

Dismantled view of the steering lock and ignition

switch assembly

Page 211 of 238

Electrical System 211

When using an aiming board, position the

vehicle five meters from and square to the aiming

board. Gently rock the vehi cle and allow the suspen-

sion to stabilize. Mark a reference line on the board to

correspond with the horizontal centre line of the

headlamp low beam bulbs. Mark two reference lines on the board to

correspond with the vertical centre lines of

the

headlamp low beam bulbs. Switch on the headlamps and select low

beam. Adjust the headlamps by turning the adjust-

ing screws located at the rear of the headlamp

assemblies. Adjust the headlamps to comply with local

regulations. As a guide, adjust the lamps so that the

low beam pattern strikes the aiming board with the

horizontal cut off point 50 mm below the headlamp

bulb horizontal centre line and the point where the

beam raises from the horizontal is on the headlamp

low beam bulb vertical centre line.

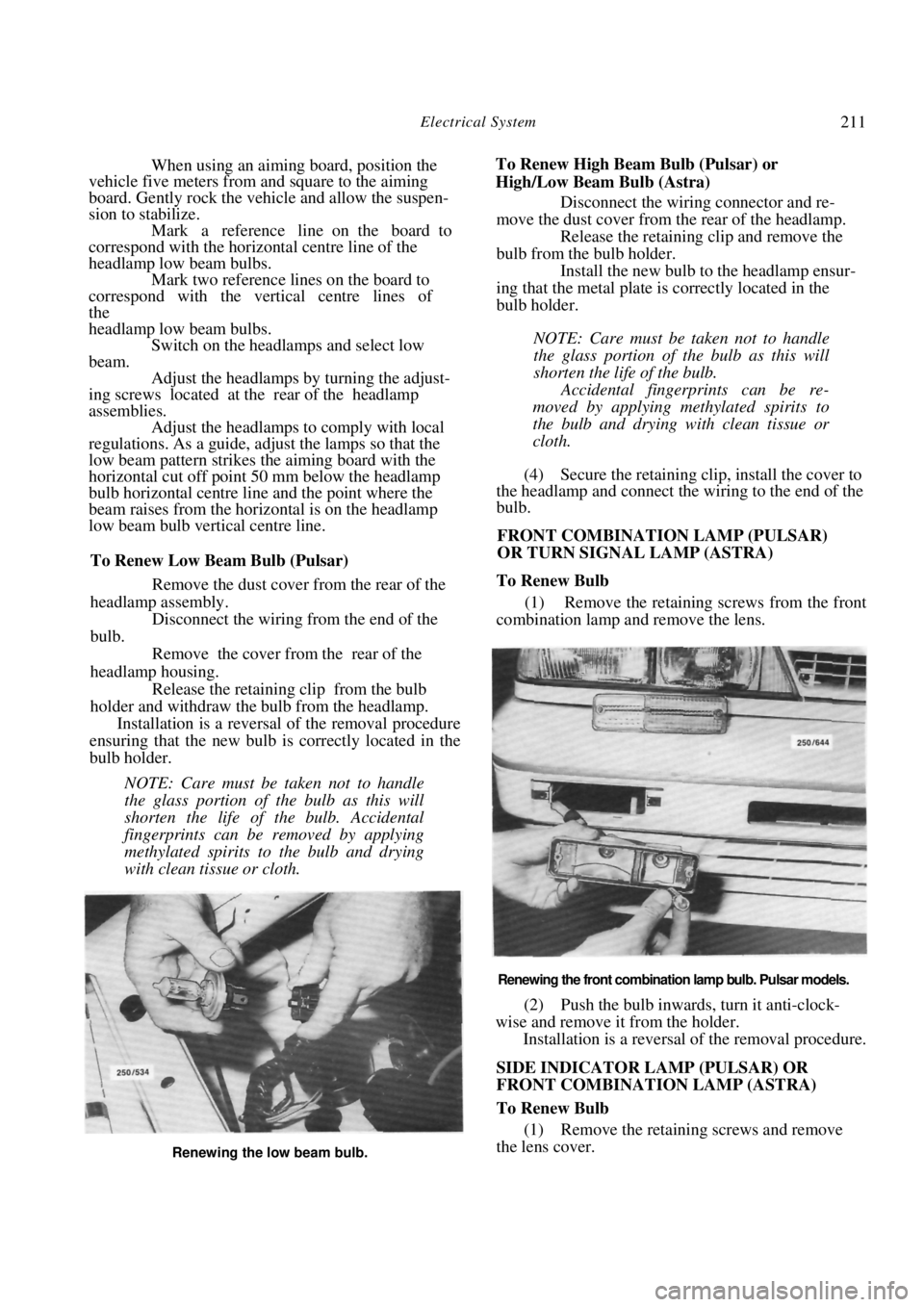

To Renew Low Beam Bulb (Pulsar)

Remove the dust cover from the rear of the

headlamp assembly.

Disconnect the wiring from the end of the

bulb.

Remove the cover from the rear of the

headlamp housing. Release the retaining clip from the bulb

holder and withdraw the bulb from the headlamp. Installation is a reversal of the removal procedure

ensuring that the new bulb is correctly located in the

bulb holder.

NOTE: Care must be taken not to handle

the glass portion of the bulb as this will

shorten the life of the bulb. Accidental

fingerprints can be removed by applying

methylated spirits to the bulb and drying

with clean tissue or cloth.

To Renew High Beam Bulb (Pulsar) or

High/Low Beam Bulb (Astra) Disconnect the wiring connector and re-

move the dust cover from the rear of the headlamp. Release the retaining clip and remove the

bulb from the bulb holder. Install the new bulb to the headlamp ensur-

ing that the metal plate is correctly located in the

bulb holder.

NOTE: Care must be taken not to handle

the glass portion of the bulb as this will

shorten the life of the bulb.

Accidental fingerprints can be re-

moved by applying methylated spirits to

the bulb and drying with clean tissue or

cloth.

(4) Secure the retaining clip, install the cover to

the headlamp and connect the wiring to the end of the

bulb.

FRONT COMBINATION LAMP (PULSAR)

OR TURN SIGNAL LAMP (ASTRA)

To Renew Bulb

(1) Remove the retaining screws from the front

combination lamp and remove the lens.

Renewing the front combination lamp bulb. Pulsar models.

(2) Push the bulb inwards, turn it anti-clock-

wise and remove it from the holder. Installation is a reversal of the removal procedure.

SIDE INDICATOR LAMP (PULSAR) OR

FRONT COMBINATION LAMP (ASTRA)

To Renew Bulb

(1) Remove the retaining screws and remove

the lens cover.

Renewing the low beam bulb.

Page 217 of 238

Electrical System 217

When installing a trailer socket, it may be neces-

sary to replace the original vehicle flasher unit with a

heavy duty unit to maintain the flash rate in accor-

dance with local regulations. Local regulations may

also require the installation of a dashboard mounted

repeater lamp.

Should the trailer socket and plug not be matched,

adaptors can be made or obtained to facilitate con-

nection.

TO INSTAL TRAILER SOCKET.

The minimum materials required are a trailer

socket, mounting bracket, seven core flex, insulated

wiring connectors and a rubber grommet.

(1) Disconnect the negative battery terminal.

(2)Locate the wiring harness for the lamps at

the rear of the vehicle.

For five pin sockets and plugs, use the following

standard trailer wiring code:

Terminal No.CircuitColor2 Left turn signal lampYellow

3Earth White

5 Ri

ght turn signal lampGreen

6Stop lamp Red

7 Tail lam

p Brown

Minimum material needed for wiring up a trailer.

Utilux trailer socket and plug shown.

(3) Identify the wires for the right turn signal

lamp, left turn signal lamp, tail lamp, stop lamp,

reverse lamp and earth. Use the vehicle wiring

diagram in this section to determine the wire color

for each lamp circuit.

(4)Connect the seven core flex to the various

lamp wires using insulated connectors.

For seven pin sockets and plugs, use the following

standard trailer wiring code:

Terminal No.CircuitColor1 Left turn signal lamp Yellow

2 Reversing lamp Black

3EarthWhite

4 Right turn signal Green

lamp

5Electric brakesBlue

6 Stop lampRed

7

Tail lampBrown

For six pin sockets and pl ugs, use the following

standard trailer wiring code:

Terminal No.CircuitColor1 Tail LampBrown

2 Left Turn Signal Lamp Yellow

3Right Turn Signal LampGreen

4 Stop LampRed

5AuxilaryBlue

6 Earth White

(5) Drill a suitably si

zed hole through the vehicle

floor and install a rubber grommet to the hole.

NOTE: Before drilling the hole, check

whether there is an existing hole which may-

be used. Ensure that a rubber grommet is

installed to prevent chafing of the wires.

Pass the seven core flex through the rubber

grommet. Cut the seven core flex to the required length

and slide the dust cover onto the flex. Remove approximately 15 mm of insulation

from each wire in the flex.

Connect the wires of the seven core flex to

the terminals of the socket, using the standard wiring

code and following the socket manufacturers connec-

tion procedure. Assemble the socket and install the dust cover

to the rear of the socket. Install the mounting bracket as close as

possible to the tow bar ball and high enough to

maintain vehicle ground clearance. Install the socket to the mounting bracket.

Connect a trailer plug to the socket and test

for correct lamp operation.

TO INSTAL TRAILER PLUG

The minimum materials required are a trailer

plug, seven core flex and insulated wiring connectors.

The installation procedure for the trailer plug is

similar to that for the socket with attention to the

following points:

Connect the trailer wiring to the plug accord-

ing to the standard wiring color code and the plug

manufacturers instructions. Use a suitable length of

seven core flex and insulated connectors should the

trailer wiring not be long enough.

If the trailer wiring does not conform to the

standard color code, identify each circuit as follows: (a) Locate the trailer earth wire.

PLUG