dimensions NISSAN PULSAR 1987 Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1987, Model line: PULSAR, Model: NISSAN PULSAR 1987Pages: 238, PDF Size: 28.91 MB

Page 47 of 238

Engine 47

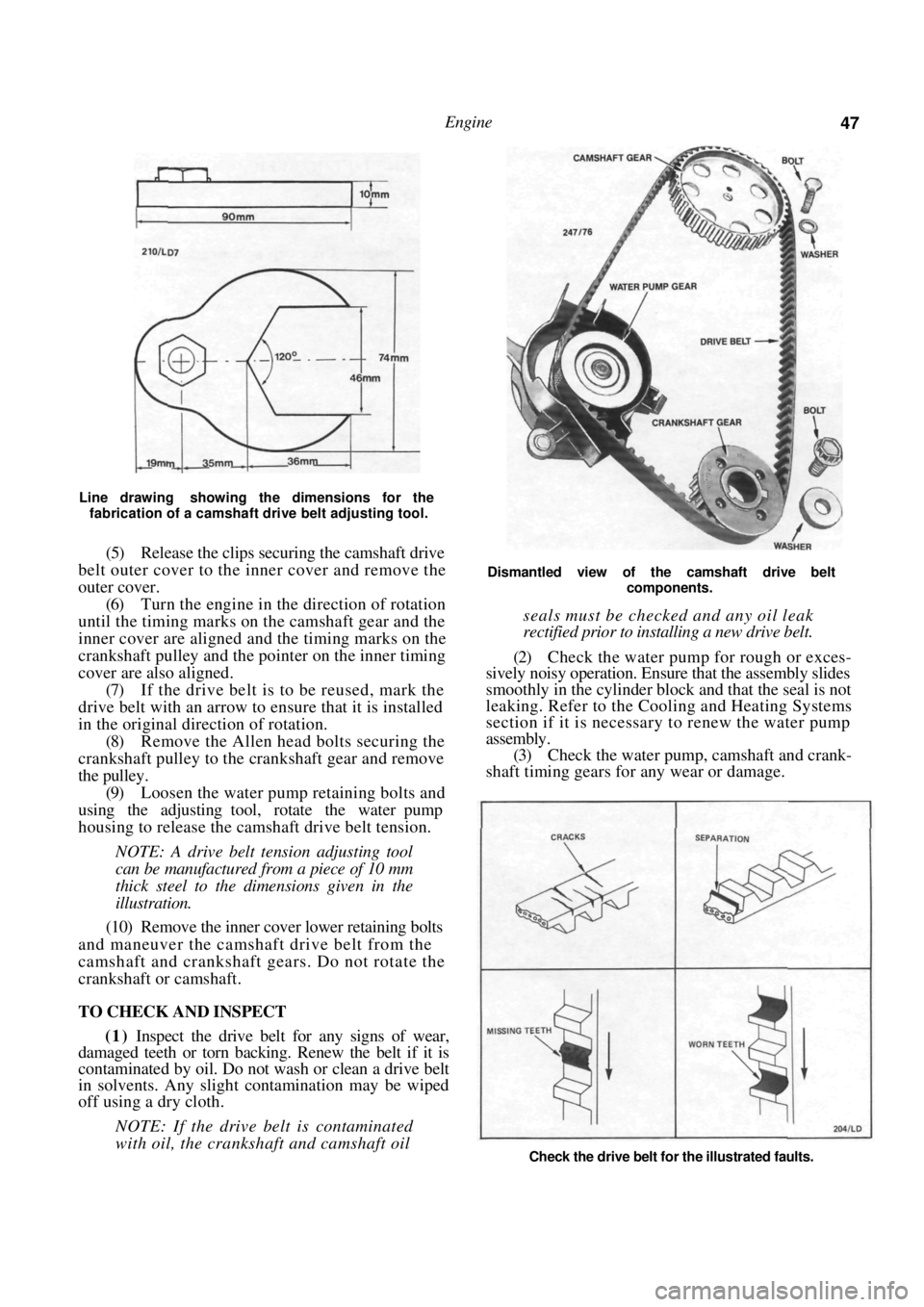

Line drawing showing the dimensions for the fabrication of a camshaft drive belt adjusting tool.

(5) Release the clips securing the camshaft drive

belt outer cover to the inner cover and remove the

outer cover.

(6) Turn the engine in the direction of rotation

until the timing marks on the camshaft gear and the

inner cover are aligned and the timing marks on the

crankshaft pulley and the pointer on the inner timing

cover are also aligned.

(7) If the drive belt is to be reused, mark the

drive belt with an arrow to ensure that it is installed

in the original direction of rotation. (8) Remove the Allen head bolts securing the

crankshaft pulley to the crankshaft gear and remove

the pulley. (9) Loosen the water pump retaining bolts and

using the adjusting tool, rotate the water pump

housing to release the camsh aft drive belt tension.

NOTE: A drive belt tension adjusting tool

can be manufactured from a piece of 10 mm

thick steel to the dimensions given in the

illustration.

(10) Remove the inner cover lower retaining bolts

and maneuver the camshaft drive belt from the

camshaft and crankshaft gears. Do not rotate the

crankshaft or camshaft.

TO CHECK AND INSPECT

(1) Inspect the drive belt for any signs of wear,

damaged teeth or torn backing. Renew the belt if it is

contaminated by oil. Do not wash or clean a drive belt

in solvents. Any slight contamination may be wiped

off using a dry cloth.

NOTE: If the drive belt is contaminated

with oil, the crankshaft and camshaft oil

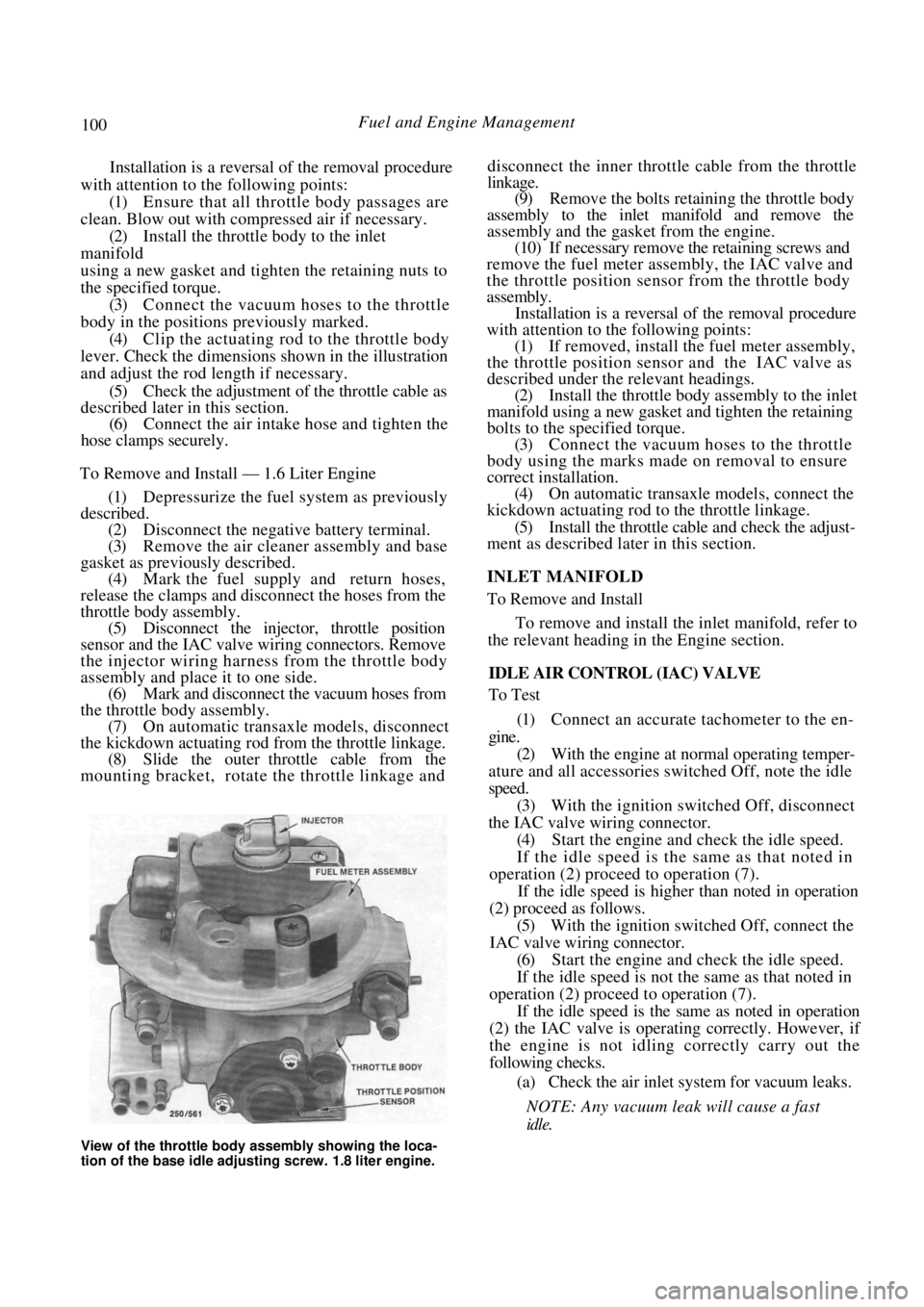

Dismantled view of the camshaft drive belt

components.

seals must be checked and any oil leak

rectified prior to installing a new drive belt.

(2) Check the water pump for rough or exces-

sively noisy operation. Ensure that the assembly slides

smoothly in the cylinder bloc k and that the seal is not

leaking. Refer to the Cooling and Heating Systems

section if it is necessary to renew the water pump

assembly. (3) Check the water pump, camshaft and crank-

shaft timing gears for any wear or damage.

Check the drive belt for the illustrated faults.

Page 100 of 238

100 Fuel and Engine Management

Installation is a reversal of the removal procedure

with attention to the following points:

(1) Ensure that all throttle body passages are

clean. Blow out with compressed air if necessary. (2) Install the throttle body to the inlet

manifold

using a new gasket and tighten the retaining nuts to

the specified torque. (3) Connect the vacuum hoses to the throttle

body in the positions previously marked. (4) Clip the actuating rod to the throttle body

lever. Check the dimensions shown in the illustration

and adjust the rod length if necessary.

(5) Check the adjustment of the throttle cable as

described later in this section.

(6) Connect the air intake hose and tighten the

hose clamps securely.

To Remove and Install — 1.6 Liter Engine

(1) Depressurize the fuel system as previously

described. (2) Disconnect the negative battery terminal.

(3) Remove the air cleane r assembly and base

gasket as previously described. (4) Mark the fuel supply and return hoses,

release the clamps and disconnect the hoses from the

throttle body assembly. (5) Disconnect the injector, throttle position

sensor and the IAC valve wiring connectors. Remove

the injector wiring harness from the throttle body

assembly and place it to one side.

(6) Mark and disconnect the vacuum hoses from

the throttle body assembly. (7) On automatic transaxle models, disconnect

the kickdown actuating rod from the throttle linkage.

(8) Slide the outer throttle cable from the

mounting bracket, rotate the throttle linkage and disconnect the inner throttle cable from the throttle

linkage.

(9)

Remove the bolts retaining the throttle body

assembly to the inlet manifold and remove the

assembly and the gasket from the engine. (10) If necessary remove the retaining screws and

remove the fuel meter assembly, the IAC valve and

the throttle position sensor from the throttle body

assembly. Installation is a reversal of the removal procedure

with attention to the following points:

(1) If removed, install the fuel meter assembly,

the throttle position sensor and the IAC valve as

described under the relevant headings. (2) Install the throttle body assembly to the inlet

manifold using a new gasket and tighten the retaining

bolts to the specified torque. (3) Connect the vacuum ho ses to the throttle

body using the marks made on removal to ensure

correct installation. (4) On automatic transaxle models, connect the

kickdown actuating rod to the throttle linkage.

(5) Install the throttle cable and check the adjust-

ment as described later in this section.

INLET MANIFOLD

To Remove and Install

To remove and install the inlet manifold, refer to

the relevant heading in the Engine section.

IDLE AIR CONTROL (IAC) VALVE

To Test

(1) Connect an accurate tachometer to the en-

gine. (2) With the engine at normal operating temper-

ature and all accessories switched Off, note the idle

speed.

(3) With the ignition switched Off, disconnect

the IAC valve wiring connector. (4) Start the engine and check the idle speed.

If the idle speed is the same as that noted in

operation (2) proceed to operation (7).

If the idle speed is higher than noted in operation

(2) proceed as follows.

(5) With the ignition switched Off, connect the

IAC valve wiring connector.

(6) Start the engine and check the idle speed.

If the idle speed is not the same as that noted in

operation (2) proceed to operation (7).

If the idle speed is the same as noted in operation

(2) the IAC valve is operating correctly. However, if

the engine is not idling correctly carry out the

following checks.

(a) Check the air inlet system for vacuum leaks.

NOTE: Any vacuum leak will cause a fast

idle.

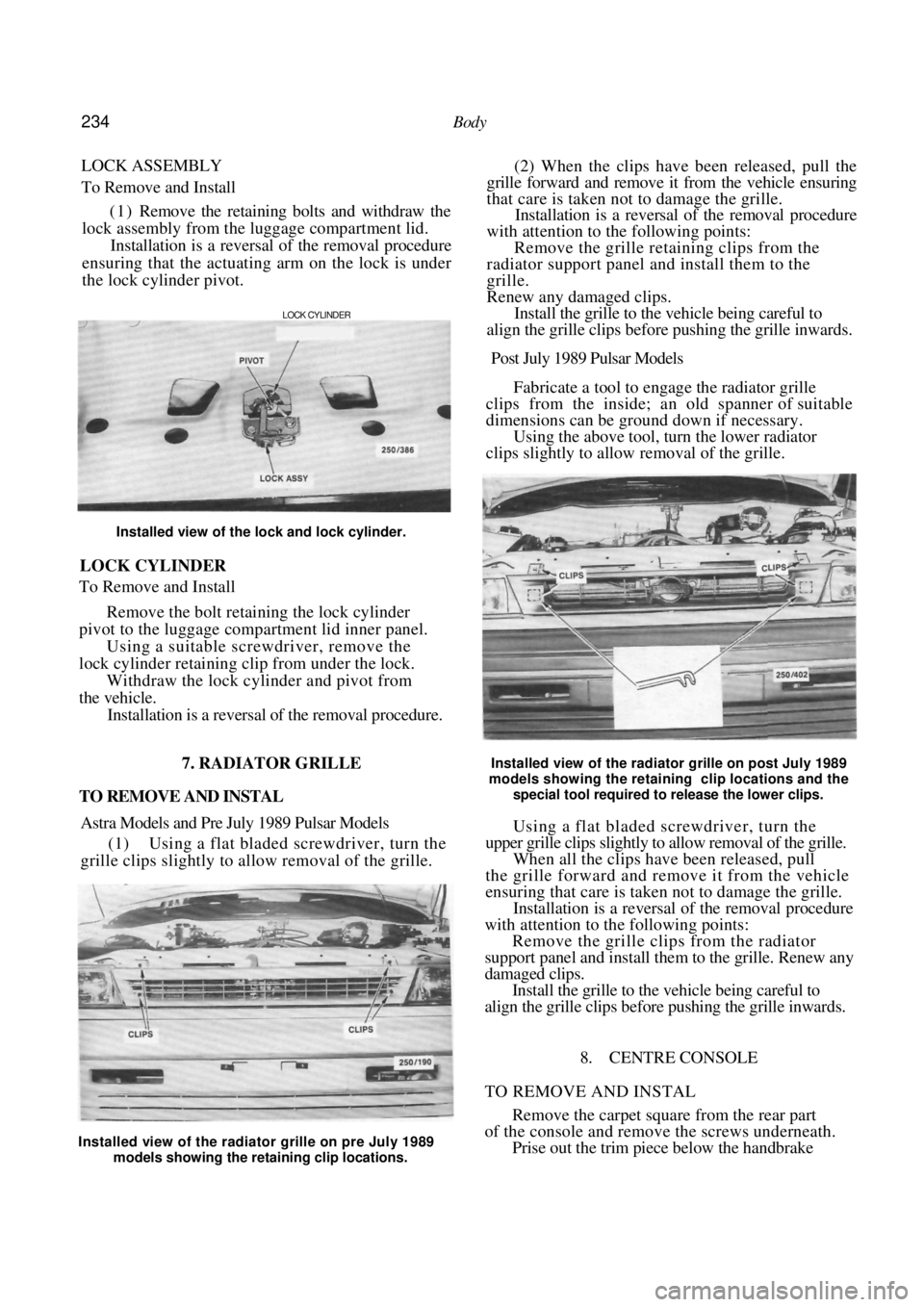

View of the throttle body assembly showing the loca-

tion of the base idle adjusting screw. 1.8 literengine.

Page 209 of 238

Electrical System 209

12. INSTRUMENT CLUSTER

TO REMOVE AND INSTAL

Disconnect the negative battery terminal.

Remove the retaining screws from the instru-

ment cluster surround. Carefully withdraw the instrument cluster

surround from the instrument panel sufficiently to

enable the wiring to be disconnected. Remove the

surround from the vehicle.

.

FLEXIBLE PRINTED

CIRCUIT

Rear view of the instrument cluster removed from the

vehicle.

(4) Remove the instrument cluster assembly

retaining screws and gently ease the assembly from the

instrument panel sufficiently to enable the wiring to be

disconnected.

If necessary, remove the instruments as follows:

Carefully depress the retaining clips on the

front lens and remove the front lens. On models equipped with a tachometer, slide

the plastic rib from between the speedometer and the

tachometer. Remove the screws retaining the speedome-

ter and the tachometer or fuel/temperature gauges

from the rear of the instrument cluster.

CLUSTER ASSEMBLY

(d) Withdraw both instruments from the front of

the instrument cluster being careful as these instru-

ments are held by protruding pin terminals.

NOTE: Do not touch the faces of the instru-

ment dials as they mark easily.

(e) On models equipped with a tachometer,

remove the retaining nuts and remove the tempera-

ture and/or the fuel gauge from the cluster assembly.

Installation is a reversal of the removal procedure

ensuring that all electrical connectors are correctly

installed.

13. BLOWER FAN

The removal and installation procedure for the

blower fan is described in the Cooling and Heating

Systems section.

14. RADIO/CASSETTE

TO REMOVE AND INSTAL

Disconnect the negative battery terminal.

Remove the release hole covers on each side

of the radio/cassette.

Dismantled view of the instrument cluster.

Illustration of the radio/cass ette removal tool showing

the required dimensions.

BULB HOLDERS

BULB HOLDERS

Removing the release hole covers from the radio/cas-

sette.

Page 234 of 238

234 Body

LOCK ASSEMBLY

To Remove and Install

( 1 ) Remove the retaining bolts and withdraw the

lock assembly from the luggage compartment lid.

Installation is a reversal of the removal procedure

ensuring that the actuating arm on the lock is under

the lock cylinder pivot.

LOCK CYLINDER

Installed view of the lock and lock cylinder.

LOCK CYLINDER

To Remove and Install

Remove the bolt retaining the lock cylinder

pivot to the luggage compartment lid inner panel. Using a suitable screwdriver, remove the

lock cylinder retaining clip from under the lock. Withdraw the lock cylinder and pivot from

the vehicle. Installation is a reversal of the removal procedure.

(2) When the clips have been released, pull the

grille forward and remove it from the vehicle ensuring

that care is taken not to damage the grille.

Installation is a reversal of the removal procedure

with attention to the following points:

Remove the grille retaining clips from the

radiator support panel and install them to the

grille.

Renew any damaged clips. Install the grille to the vehicle being careful to

align the grille clips before pushing the grille inwards.

Post July 1989 Pulsar Models

Fabricate a tool to engage the radiator grille

clips from the inside; an old spanner of suitable

dimensions can be ground down if necessary.

Using the above tool, turn the lower radiator

clips slightly to allow removal of the grille.

7. RADIATOR GRILLE

TO REMOVE AND INSTAL

Astra Models and Pre July 1989 Pulsar Models

(1) Using a flat bladed screwdriver, turn the

grille clips slightly to allow removal of the grille.

Installed view of the radiator grille on pre July 1989

models showing the retaining clip locations. Installed view of the radiator grille on post July 1989

models showing the retaining clip locations and the

special tool required to release the lower clips.

Using a flat bladed screwdriver, turn the

upper grille clips slightly to allow removal of the grille. When all the clips have been released, pull

the grille forward and remove it from the vehicle

ensuring that care is taken not to damage the grille.

Installation is a reversal of the removal procedure

with attention to the following points:

Remove the grille clips from the radiator

support panel and install them to the grille. Renew any

damaged clips.

Install the grille to the vehicle being careful to

align the grille clips before pushing the grille inwards.

8. CENTRE CONSOLE

TO REMOVE AND INSTAL

Remove the carpet square from the rear part

of the console and remove the screws underneath. Prise out the trim piece below the handbrake