service schedule NISSAN PULSAR 1987 Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1987, Model line: PULSAR, Model: NISSAN PULSAR 1987Pages: 238, PDF Size: 28.91 MB

Page 3 of 238

CONTENTS

INTRODUCTION........................................ 5

VEHICLE IDENTIFICATION AND

GENERAL SPECIFICATIONS................. 7

GENERAL INFORMATION...................... 8

Tools and equipment ............................................. 8 Safety .................................................................... 10

General repair procedures..................................... 11

LUBRICATION AND MAINTENANCE... 14

Specifications......................................................... 14

How to grease and oil change .............................. 14

Service schedule ................................................... 17

WHEELS AND TYRES............................. 21

Specifications......................................................... 21

How to change a road wheel ................................ 21

Tire wear troubl e shooting ..................................... 22

Care and main tenance ......................................... 23

ENGINE TUNE-UP.................................... 25

Tune-up specifications ........................................... 25

Tune-up operat ions............................................... 25

ROADSIDE TROUBLE SHOOTING....... 32

Trouble shoot ing.................................................... 32

To check ignition and el ectrical system ................ 33

To check fuel system ............................................ 34

To check mechani cal system ................................ 35

ENGINE....................................................... 37

Specifications ........................................................ 37

Engine mechanical tr ouble shooting ...................... 39

Description ............................................................ 41

Engine and transaxle assembly ........................... 42

Manifolds ............................................................... 44 Camshaft, rocker arms and tappets..................... 48

Cylinder head........................................................ 50

Engine sump and oil pum p pickup pipe................ 54

Oil pump ............................................................... 55

Pistons, connecting rods and cylinder bores ........ 57

Crankshaft and bearings ...................................... 60

Flywheel /drive plate............................................... 63

Engine mountings.................................................. 64

Exhaust system .................................................... 66

COOLING AND HEATING SYSTEMS.... 68

Specifications ........................................................ 68 Cooling system trouble shooting ........................... 68

Heater and air conditioner trouble shooting ......... 69 Description ............................................................ 70

Radiator ................................................................ 70

Cooling fan ............................................................ 73

Thermost at............................................................ 75

Thermostat housing .............................................. 76

Water pump .......................................................... 76

Welch plugs .......................................................... 76

Heater unit, water valv e and controls ................... 77

Blower fan ............................................................. 80

Air condition ing ..................................................... 80

FUEL AND ENGINE MANAGEMENT ... 82

Specifications ........................................................ 82 Fuel and engine management trouble shooting ... 82

Description ............................................................ 84

Service precautions and procedures

..................... 86

System diagnosis and adjustments ...................... 89

Fuel supply components ....................................... 92

Air flow components .............................................. 98

Electronic components .......................................... 104

EMISSION CONTROL............................. 117

Introduction ........................................................... 117

Crankcase ventilati on system............................... 117

Evaporate control system..................................... 117

Air preheat system — 1.6 liter engines ................ 119

Exhaust control system ........................................ 120

CLUTCH...................................................... 121

Specifications........................................................ 121

Clutch trouble shooting......................................... 121

Description ............................................................ 122

Clutch unit and release mechanism..................... 123

Clutch pedal ......................................................... 124

Clutch c able.......................................................... 124

Clutch adjustments ............................................... 125

MANUAL TRANSAXLE AND

DRIVE SHAFTS......................................... 126

Specifications ........................................................ 126

Manual transaxle and drive shaft trouble shooting 126

Description............................................................ 128

Transaxle assembly.............................................. 129

Differential and final drive assembly ..................... 135

Gear lever assembly ............................................ 136

Drive shafts .......................................................... 137

AUTOMATIC TRANSAXLE....................... 140

Specifications........................................................ 140

Automatic transaxle trouble shooting.................... 140

Description............................................................ 141

Transaxle fluid ...................................................... 141

Brake band........................................................... 142

Kickdown cable .................................................... 142

Transaxle select or linkage ................................... 142

Neutral safety switch ............................................ 142

Transaxle assembly .............................................. 143

STEERING................................................. 145

PART 1. STEERING TROUBLE SHOOTING....145

Faults, causes and remedies................................ 145

PART 2. MANUA L STEERING......................... 147

Specifications ........................................................ 147

Description............................................................ 147

Steering wheel ...................................................... 147

Steering column.................................................... 148

Steering gear assembly ....................................... 149

PART 3. POWE R STEERING .......................... 152

Specifications........................................................ 152

Description............................................................ 152

In car adjustments, checks and minor repairs ..... 152

Steering wheel ...................................................... 153

Steering column.................................................... 153 Power steering pump ........................................... 153

Power steering gear assembly............................. 154

Page 16 of 238

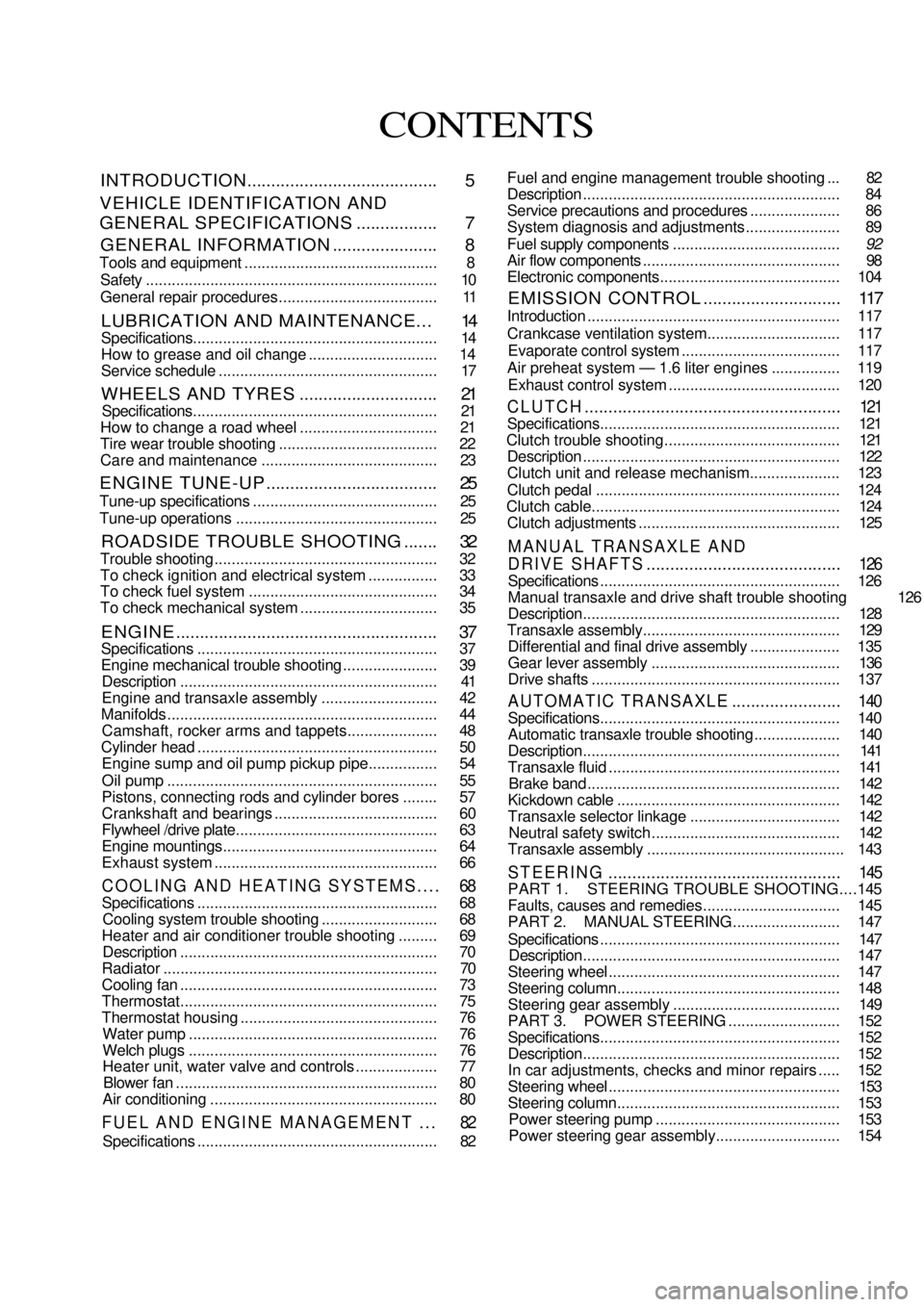

16 Lubrication and Maintenance

Underbonnet view of the 1.6 liter engine. Manual transaxle model.

oil into the engine in one go as sometimes

the amounts specified are only approximate.

If is best to hold back at least half a liter and

top up the level after the engine has been run

for a few minutes.

(10) Check thoroughly for oil leaks at the engine

sump drain plug and oil filter if a new filter was

installed.

(11) Referring to the service schedule, lubricate

and check all other items which coincide with the

grease and oil change intervals.

(12) Lower the vehicle to the ground.

Page 17 of 238

Lubrication and Maintenance 17

2. SERVICE SCHEDULE

This Section Removed

Page 195 of 238

Electrical System 195

(2) Remove the battery holding clamp and lift

the battery from the vehicle.

Installation is a reversal of the removal procedure

with attention to the following points:

Ensure that the terminals and posts are

clean. When connecting the l eads to the battery,

ensure that the polarity is correct. Connect the

positive lead first. Do not over tighten the terminal clamp

nuts.

Apply petroleum jelly to the battery termi-

nals to prevent corrosion.

MAINTENANCE

Battery maintenance should be performed at the

scheduled services.

NOTE: Keep naked flames away from the

battery as the battery gases are highly

explosive.

(1) Keep the battery and the surrounding area

clean and dry. In particular, ensure that the top of the

battery is free from dirt and moisture to prevent a

voltage drop between the terminals.

If necessary, clean the battery case as follows:

Remove the battery from the vehicle as

previously described.

Pour hot water over the battery being careful

not to allow any water to enter the battery through the

filler cap vent holes. Wipe the battery case clean.

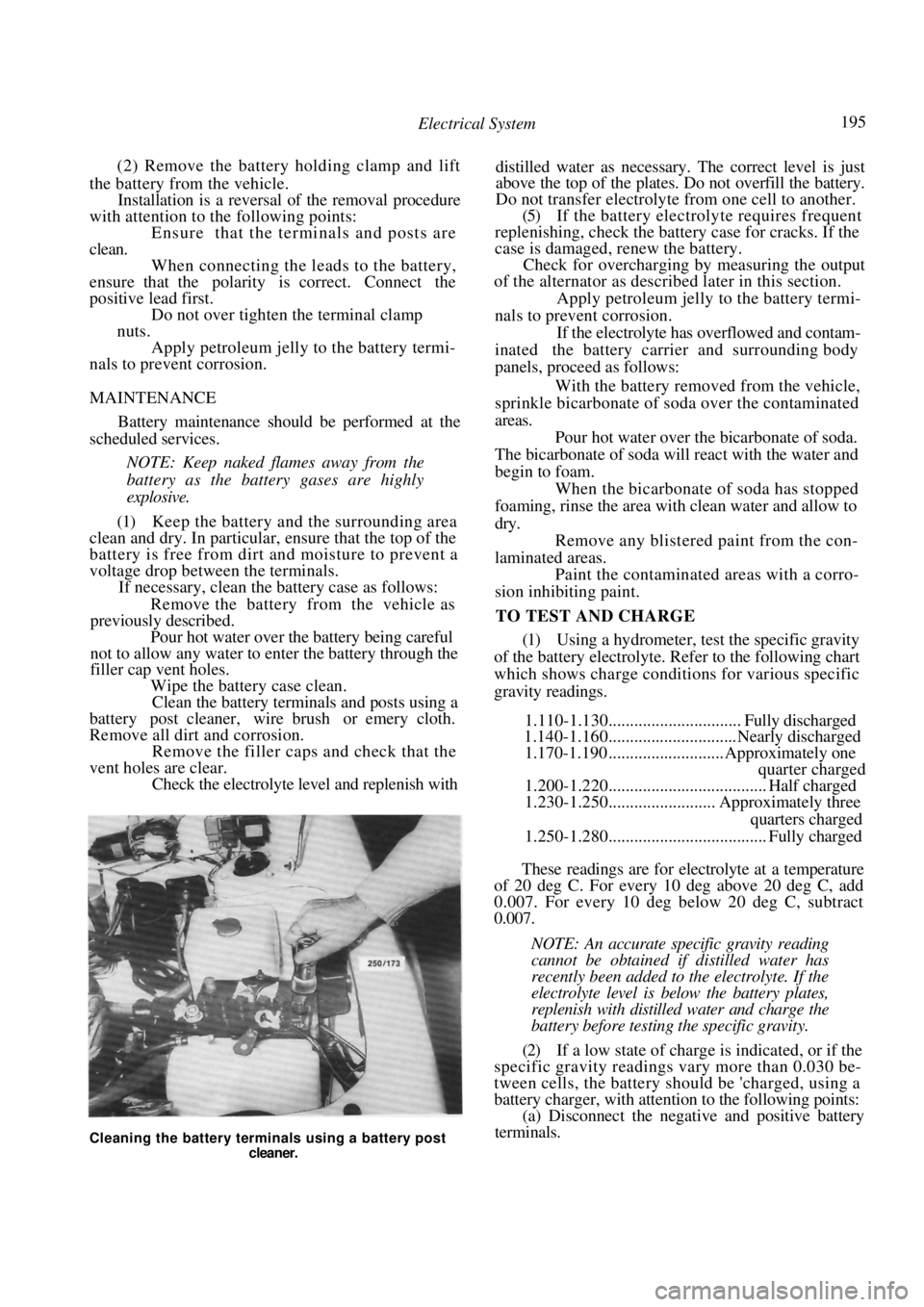

Clean the battery terminals and posts using a

battery post cleaner, wire brush or emery cloth.

Remove all dirt and corrosion.

Remove the filler caps and check that the

vent holes are clear. Check the electrolyte le vel and replenish with distilled water as necessary. The correct level is just

above the top of the plates. Do not overfill the battery.

Do not transfer electrolyte from one cell to another.

(5) If the battery electrolyte requires frequent

replenishing, check the batt ery case for cracks. If the

case is damaged, renew the battery.

Check for overcharging by measuring the output

of the alternator as described later in this section.

Apply petroleum jelly to the battery termi-

nals to prevent corrosion. If the electrolyte has overflowed and contam-

inated the battery carrier and surrounding body

panels, proceed as follows:

With the battery removed from the vehicle,

sprinkle bicarbonate of soda over the contaminated

areas.

Pour hot water over the bicarbonate of soda.

The bicarbonate of soda will react with the water and

begin to foam. When the bicarbonate of soda has stopped

foaming, rinse the area with clean water and allow to

dry. Remove any blistered paint from the con-

laminated areas. Paint the contaminated areas with a corro-

sion inhibiting paint.

TO TEST AND CHARGE

(1) Using a hydrometer, test the specific gravity

of the battery electrolyte. Refer to the following chart

which shows charge conditi ons for various specific

gravity readings.

1.110-1.130............................... Fully discharged

1.140-1.160..............................Nearly discharged

1.170-1.190 ........................... Approximately one

quarter charged

1.200-1.220..................................... Half charged

1.230-1.250......................... Approximately three

quarters charged

1.250-1.280..................................... Fully charged

These readings are for electrolyte at a temperature

of 20 deg C. For every 10 deg above 20 deg C, add

0.007. For every 10 deg below 20 deg C, subtract

0.007.

NOTE: An accurate specific gravity reading

cannot be obtained if distilled water has

recently been added to the electrolyte. If the

electrolyte level is below the battery plates,

replenish with distilled water and charge the

battery before testing the specific gravity.

(2) If a low state of charge is indicated, or if the

specific gravity readings vary more than 0.030 be-

tween cells, the battery s hould be 'charged, using a

battery charger, with attention to the following points:

(a) Disconnect the negati ve and positive battery

terminals.

Cleaning the battery terminals using a battery post

cleaner.