run flat NISSAN PULSAR 1987 Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1987, Model line: PULSAR, Model: NISSAN PULSAR 1987Pages: 238, PDF Size: 28.91 MB

Page 12 of 238

12 General Information

Damaged threads can be repaired using a die nut

on studs and bolts, and a tap on nuts and threaded

holes in castings. If the threads of a threaded hole are

damaged beyond repair, it will be necessary to drill

and tap the hole to a larger size. Alternatively, a

Helicoil insert can be used to Testore the hole to the

original thread size.

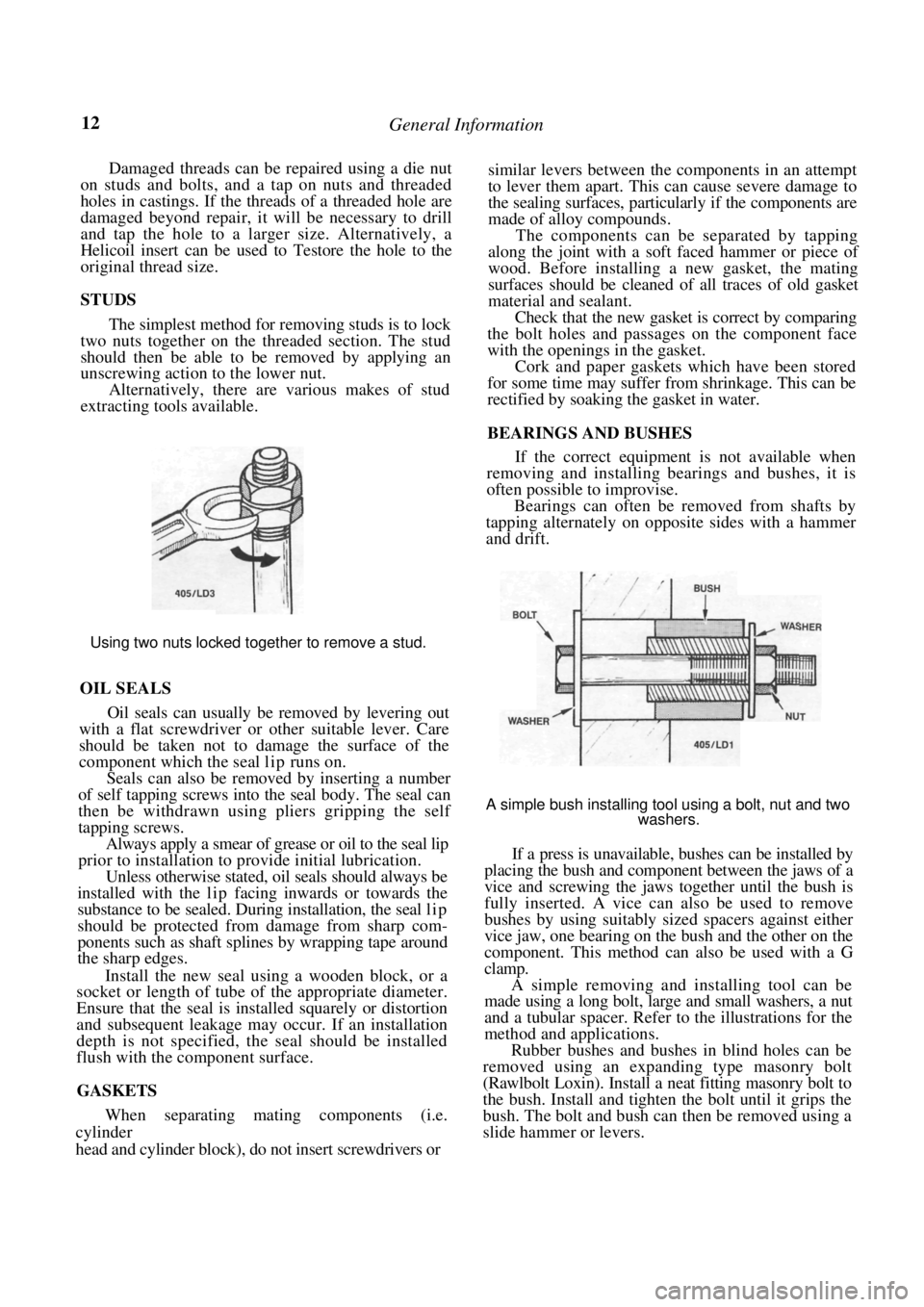

STUDS

The simplest method for removing studs is to lock

two nuts together on the threaded section. The stud

should then be able to be removed by applying an

unscrewing action to the lower nut.

Alternatively, there are various makes of stud

extracting tools available.

Using two nuts locked together to remove a stud.

OIL SEALS

Oil seals can usually be removed by levering out

with a flat screwdriver or other suitable lever. Care

should be taken not to damage the surface of the

component which the seal lip runs on.

Seals can also be removed by inserting a number

of self tapping screws into the seal body. The seal can

then be withdrawn using pliers gripping the self

tapping screws.

Always apply a smear of grease or oil to the seal lip

prior to installation to provide initial lubrication.

Unless otherwise stated, oil seals should always be

installed with the lip facing inwards or towards the

substance to be sealed. Duri ng installation, the seal l i p

should be protected from damage from sharp com-

ponents such as shaft splines by wrapping tape around

the sharp edges.

Install the new seal using a wooden block, or a

socket or length of tube of the appropriate diameter.

Ensure that the seal is installed squarely or distortion

and subsequent leakage may occur. If an installation

depth is not specified, th e seal should be installed

flush with the component surface.

GASKETS

When separating mating components (i.e.

cylinder

head and cylinder block), do not insert screwdrivers or

similar levers between the components in an attempt

to lever them apart. This can cause severe damage to

the sealing surfaces, particularly if the components are

made of alloy compounds.

The components can be separated by tapping

along the joint with a soft faced hammer or piece of

wood. Before installing a new gasket, the mating

surfaces should be cleaned of all traces of old gasket

material and sealant.

Check that the new gasket is correct by comparing

the bolt holes and passages on the component face

with the openings in the gasket.

Cork and paper gaskets which have been stored

for some time may suffer from shrinkage. This can be

rectified by soaking the gasket in water.

BEARINGS AND BUSHES

If the correct equipment is not available when

removing and installing bearings and bushes, it is

often possible to improvise.

Bearings can often be removed from shafts by

tapping alternately on opposite sides with a hammer

and drift.

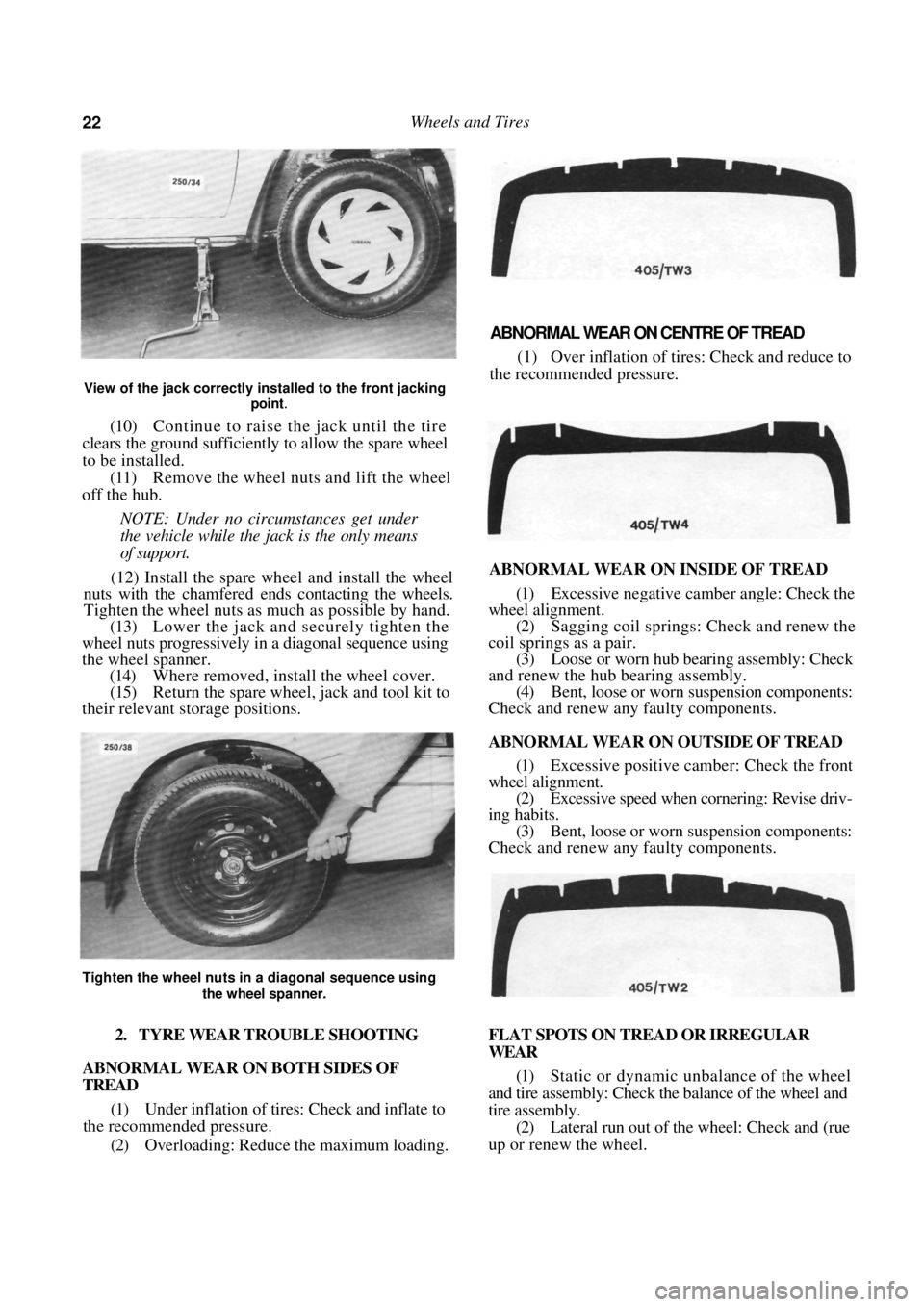

A simple bush installing tool using a bolt, nut and two

washers.

If a press is unavailable, bushes can be installed by

placing the bush and component between the jaws of a

vice and screwing the jaws together until the bush is

fully inserted. A vice can also be used to remove

bushes by using suitably sized spacers against either

vice jaw, one bearing on the bush and the other on the

component. This method can also be used with a G

clamp.

A simple removing and installing tool can be

made using a long bolt, large and small washers, a nut

and a tubular spacer. Refer to the illustrations for the

method and applications.

Rubber bushes and bushes in blind holes can be

removed using an expanding type masonry bolt

(Rawlbolt Loxin). Install a neat fitting masonry bolt to

the bush. Install and tighten the bolt until it grips the

bush. The bolt and bush can then be removed using a

slide hammer or levers.

Page 22 of 238

22 Wheels and Tires

View of the jack correctly installed to the front jacking point

.

(10) Continue to raise the jack until the tire

clears the ground sufficiently to allow the spare wheel

to be installed.

(11) Remove the wheel nuts and lift the wheel

off the hub.

NOTE: Under no circumstances get under

the vehicle while the jack is the only means

of support.

(12) Install the spare wh eel and install the wheel

nuts with the chamfered e nds contacting the wheels.

Tighten the wheel nuts as much as possible by hand.

(13) Lower the jack and securely tighten the

wheel nuts progressively in a diagonal sequence using

the wheel spanner. (14) Where removed, install the wheel cover.

(15) Return the spare wheel, jack and tool kit to

their relevant storage positions.

ABNORMAL WEAR ON CENTRE OF TREAD

(1) Over inflation of tires: Check and reduce to

the recommended pressure.

ABNORMAL WEAR ON INSIDE OF TREAD

(1) Excessive negative camber angle: Check the

wheel alignment. (2) Sagging coil springs: Check and renew the

coil springs as a pair. (3) Loose or worn hub bearing assembly: Check

and renew the hub bearing assembly. (4) Bent, loose or worn suspension components:

Check and renew any faulty components.

ABNORMAL WEAR ON OUTSIDE OF TREAD

(1) Excessive positive camber: Check the front

wheel alignment.

(2) Excessive speed when cornering: Revise driv-

ing habits. (3) Bent, loose or worn suspension components:

Check and renew any faulty components.

2. TYRE WEAR TROUBLE SHOOTING

ABNORMAL WEAR ON BOTH SIDES OF

TREAD

(1) Under inflation of tires: Check and inflate to

the recommended pressure.

(2) Overloading: Reduce the maximum loading. FLAT SPOTS ON TREAD OR IRREGULAR

WEAR

(1)

Static or dynamic unbalance of the wheel

and tire assembly: Check the balance of the wheel and

tire assembly. (2) Lateral run out of the wheel: Check and (rue

up or renew the wheel.

Tighten the wheel nuts in a diagonal sequence using

the wheel spanner.

Page 28 of 238

Engine Tune-up

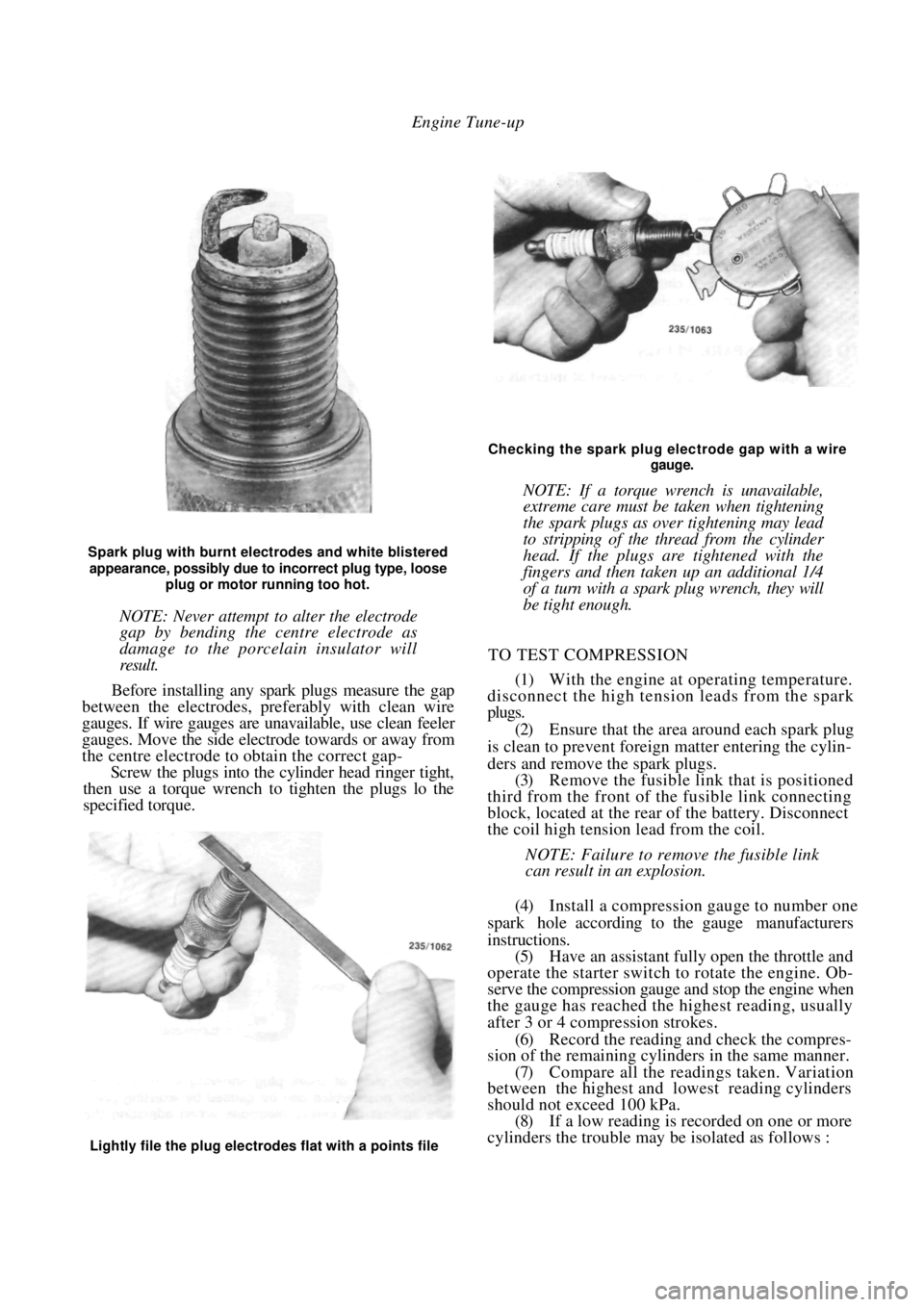

Spark plug with burnt electrodes and white blistered

appearance, possibly due to incorrect plug type, loose

plug or motor running too hot.

NOTE: Never attempt to alter the electrode

gap by bending the centre electrode as

damage to the porcelain insulator will

result.

Before installing any spark plugs measure the gap

between the electrodes, pref erably with clean wire

gauges. If wire gauges are una vailable, use clean feeler

gauges. Move the side electrode towards or away from

the centre electrode to obtain the correct gap-

Screw the plugs into the cylinder head ringer tight,

then use a torque wrench to tighten the plugs lo the

specified torque.

Checking the spark plug electrode gap with a wire

gauge.

NOTE: If a torque wrench is unavailable,

extreme care must be taken when tightening

the spark plugs as over tightening may lead

to stripping of the thread from the cylinder

head. If the plugs are tightened with the

fingers and then taken up an additional 1/4

of a turn with a spark plug wrench, they will

be tight enough.

TO TEST COMPRESSION

(1) With the engine at operating temperature.

disconnect the high tension leads from the spark

plugs.

(2) Ensure that the area around each spark plug

is clean to prevent foreign matter entering the cylin-

ders and remove the spark plugs. (3) Remove the fusible link that is positioned

third from the front of th e fusible link connecting

block, located at the rear of the battery. Disconnect

the coil high tension lead from the coil.

NOTE: Failure to remove the fusible link

can result in an explosion.

(4) Install a compression gauge to number one

spark hole according to the gauge manufacturers

instructions. (5) Have an assistant fully open the throttle and

operate the starter switch to rotate the engine. Ob-

serve the compression gauge and stop the engine when

the gauge has reached the highest reading, usually

after 3 or 4 compression strokes.

(6) Record the reading a nd check the compres-

sion of the remaining cylinders in the same manner.

(7) Compare all the readings taken. Variation

between the highest and lowest reading cylinders

should not exceed 100 kPa. (8) If a low reading is recorded on one or more

cylinders the trouble may be isolated as follows :

Lightly file the plug electrodes flat with a points file

Page 33 of 238

Roadside Trouble Shooting

(5) Place the vent caps loosely over the cell

apertures.

(6) Connect one end of the red jumper lead to

the positive ( + ) battery terminal of the booster

battery and the other end of the red lead to the

positive (+) battery terminal of the discharged bat-

tery.

NOTE: The battery emits hydrogen gas

which is explosive. Do not expose the battery

to naked /lames or sparks.

Do not lean over the battery when con-

necting the jumper leads.

Do not allow the ends of the jumper leads

to touch one another or any part of the

engine.

(7) Connect one end of the black juniper lead to

the negative (-) battery terminal of the booster

battery and the other end of the black lead to a good

earthing point on the engine of the vehicle with the

discharged battery.

NOTE: Do not connect the jumper lead

directly to the negative (-) battery terminal

of the discharged battery.

(8) Start the engine on the vehicle with the

booster battery and run the engine at a moderate

speed. (9) Start the engine on the vehicle with the

discharged battery.

(10) If possible, leave the engines of both vehi-

cles running for 10 minutes.

(11) Disconnect the jumper leads in the reverse

order of the sequence in which they were connected.

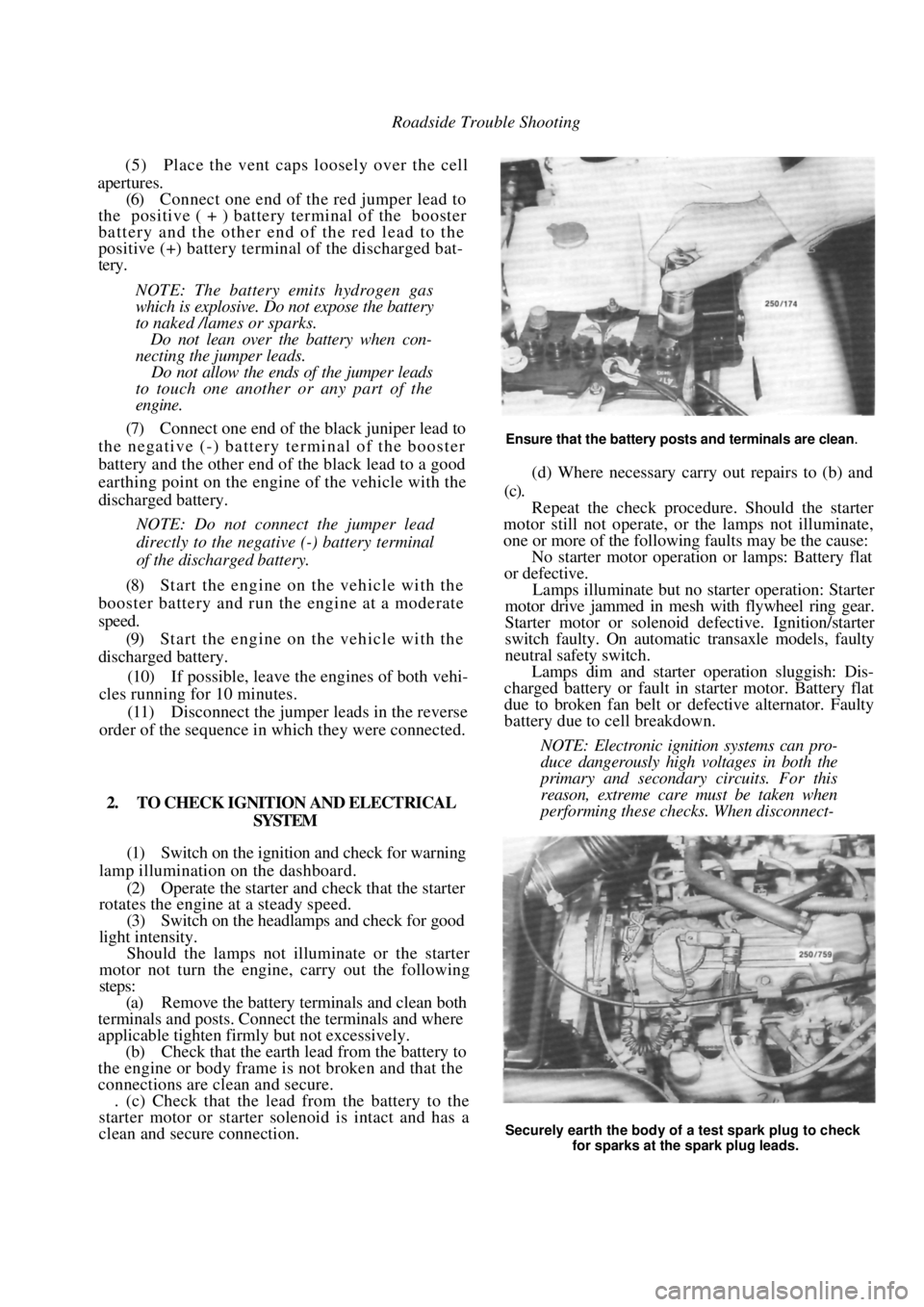

2. TO CHECK IGNITION AND ELECTRICAL SYSTEM

(1) Switch on the ignition and check for warning

lamp illumination on the dashboard. (2) Operate the starter and check that the starter

rotates the engine at a steady speed.

(3) Switch on the headlamps and check for good

light intensity. Should the lamps not illum inate or the starter

motor not turn the engine, carry out the following

steps:

(a) Remove the battery terminals and clean both

terminals and posts. Connect the terminals and where

applicable tighten firmly but not excessively.

(b) Check that the earth lead from the battery to

the engine or body frame is not broken and that the

connections are clean and secure. . (c) Check that the lead from the battery to the

starter motor or starter solenoid is intact and has a

clean and secure connection.

Ensure that the battery posts and terminals are clean.

(d) Where necessary carry out repairs to (b) and

(c).

Repeat the check procedur e. Should the starter

motor still not operate, or the lamps not illuminate,

one or more of the following faults may be the cause:

No starter motor operation or lamps: Battery flat

or defective.

Lamps illuminate but no starter operation: Starter

motor drive jammed in mesh with flywheel ring gear.

Starter motor or solenoid defective. Ignition/starter

switch faulty. On automatic transaxle models, faulty

neutral safety switch.

Lamps dim and starter operation sluggish: Dis-

charged battery or fault in starter motor. Battery flat

due to broken fan belt or de fective alternator. Faulty

battery due to cell breakdown.

NOTE: Electronic ignition systems can pro-

duce dangerously high voltages in both the

primary and secondary circuits. For this

reason, extreme care must be taken when

performing these checks. When disconnect-

Securely earth the body of a test spark plug to check

for sparks at the spark plug leads.

Page 180 of 238

180 Brakes

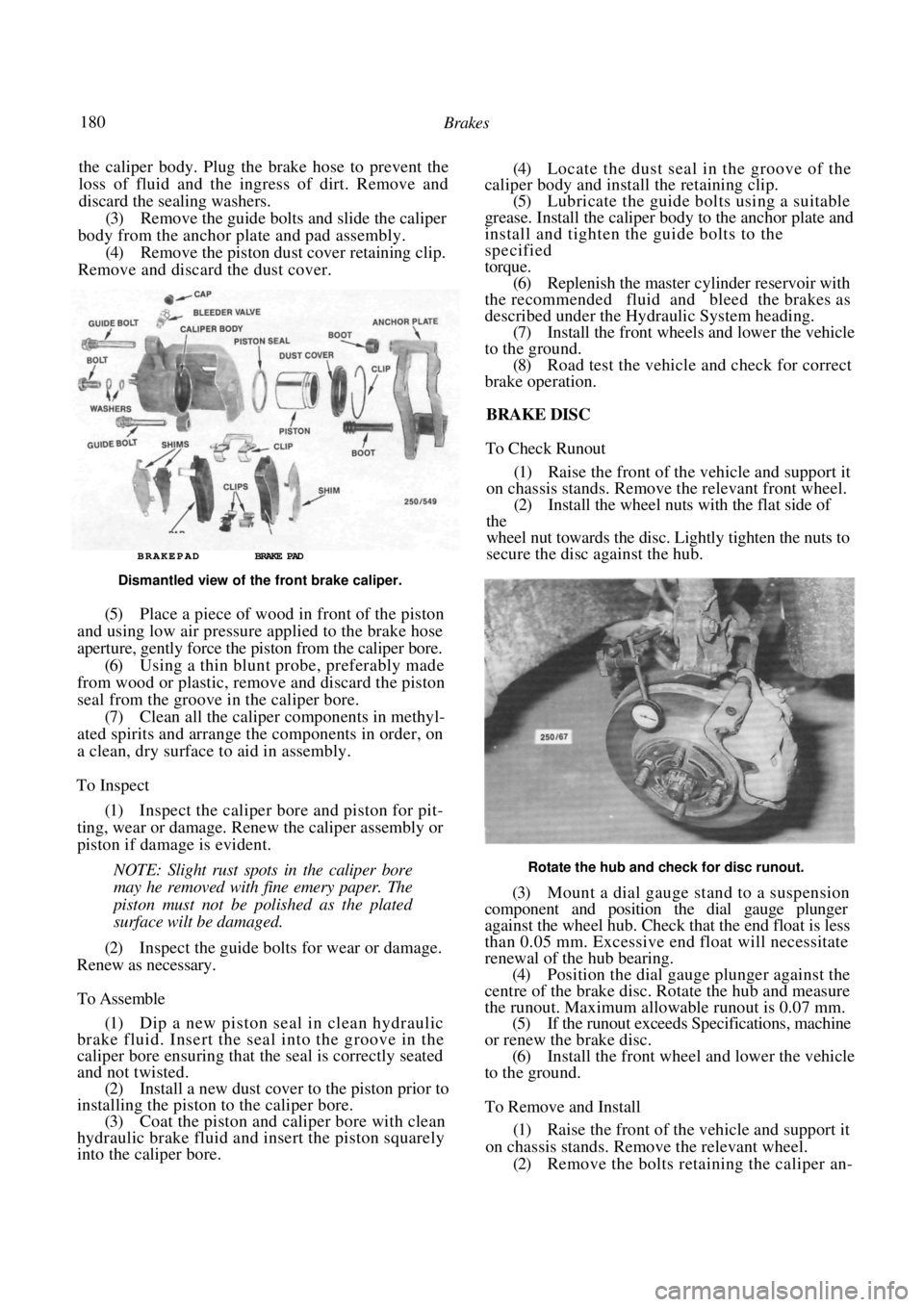

the caliper body. Plug the brake hose to prevent the

loss of fluid and the ingress of dirt. Remove and

discard the sealing washers.

(3) Remove the guide bolts and slide the caliper

body from the anchor plate and pad assembly. (4) Remove the piston dust cover retaining clip.

Remove and discard the dust cover.

BRAKEPAD BRAKE PAD

Dismantled view of the front brake caliper.

(5) Place a piece of wood in front of the piston

and using low air pressure applied to the brake hose

aperture, gently force the piston from the caliper bore.

(6) Using a thin blunt probe, preferably made

from wood or plastic, remove and discard the piston

seal from the groove in the caliper bore. (7) Clean all the caliper components in methyl-

ated spirits and arrange the components in order, on

a clean, dry surface to aid in assembly.

To Inspect

(1) Inspect the caliper bore and piston for pit-

ting, wear or damage. Renew the caliper assembly or

piston if damage is evident.

NOTE: Slight rust spots in the caliper bore

may he removed with fine emery paper. The

piston must not be polished as the plated

surface wilt be damaged.

(2) Inspect the guide bolts for wear or damage.

Renew as necessary.

To Assemble

(1) Dip a new piston seal in clean hydraulic

brake fluid. Insert the seal into the groove in the

caliper bore ensuring that the seal is correctly seated

and not twisted.

(2) Install a new dust cover to the piston prior to

installing the piston to the caliper bore. (3) Coat the piston and caliper bore with clean

hydraulic brake fluid and insert the piston squarely

into the caliper bore.

(4) Locate the dust seal in the groove of the

caliper body and install the retaining clip.

(5) Lubricate the guide bolts using a suitable

grease. Install the caliper body to the anchor plate and

install and tighten the guide bolts to the

specified

torque. (6) Replenish the master cylinder reservoir with

the recommended fluid and bleed the brakes as

described under the Hydr aulic System heading.

(7) Install the front wheels and lower the vehicle

to the ground. (8) Road test the vehicle and check for correct

brake operation.

BRAKE DISC

To Check Runout

(1) Raise the front of the vehicle and support it

on chassis stands. Remove the relevant front wheel. (2) Install the wheel nuts with the flat side of

the

wheel nut towards the disc. Lightly tighten the nuts to

secure the disc against the hub.

Rotate the hub and check for disc runout.

(3) Mount a dial gauge stand to a suspension

component and position the dial gauge plunger

against the wheel hub. Check that the end float is less

than 0.05 mm. Excessive e nd float will necessitate

renewal of the hub bearing. (4) Position the dial gauge plunger against the

centre of the brake disc. Ro tate the hub and measure

the runout. Maximum allowable runout is 0.07 mm. (5) If the runout exceeds Specifications, machine

or renew the brake disc. (6) Install the fron t wheel and lower the vehicle

to the ground.

To Remove and Install

(1) Raise the front of the vehicle and support it

on chassis stands. Remove the relevant wheel. (2) Remove the bolts retaining the caliper an-