brake NISSAN QASHQAI 2016 Owner´s Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: QASHQAI, Model: NISSAN QASHQAI 2016Pages: 338, PDF Size: 4.87 MB

Page 247 of 338

In case of a flat tyre, follow the instructions as de-

scribed below:

STOPPING THE VEHICLE

WARNING

•Make sure that the parking brake is securely

applied.

•For Manual Transmission (MT) models: Make

sure the shift lever is in the R (Reverse) posi-

tion.

For XTRONIC models: Make sure that the shift

lever is in the P (Park) position.

•Never change tyres when the vehicle is on a

slope, ice or a slippery area. This is hazard-

ous.

•Never change tyres if oncoming traffic is close

to your vehicle. Wait for professional road as-

sistance.

1. Safely move the vehicle off the road, away from

traffic.

2. Switch on the hazard warning flashers.

3. Park on a level surface.

4. Apply the parking brake.

5. Shift the shift lever (MT models) into the R (Re-

verse) position [XTRONIC models, move the shift

lever to the P (Park) position].

6. Turn off the engine.7. Open the bonnet (for details, see “Bonnet

release” in the “3. Pre-driving checks and

adjustments” section) in order to:

•Warn other traffic.

•Signal to professional road assistance that

you require assistance.

8. Have all passengers exit the vehicle and stand in

a safe place, away from traffic and clear of the

vehicle.

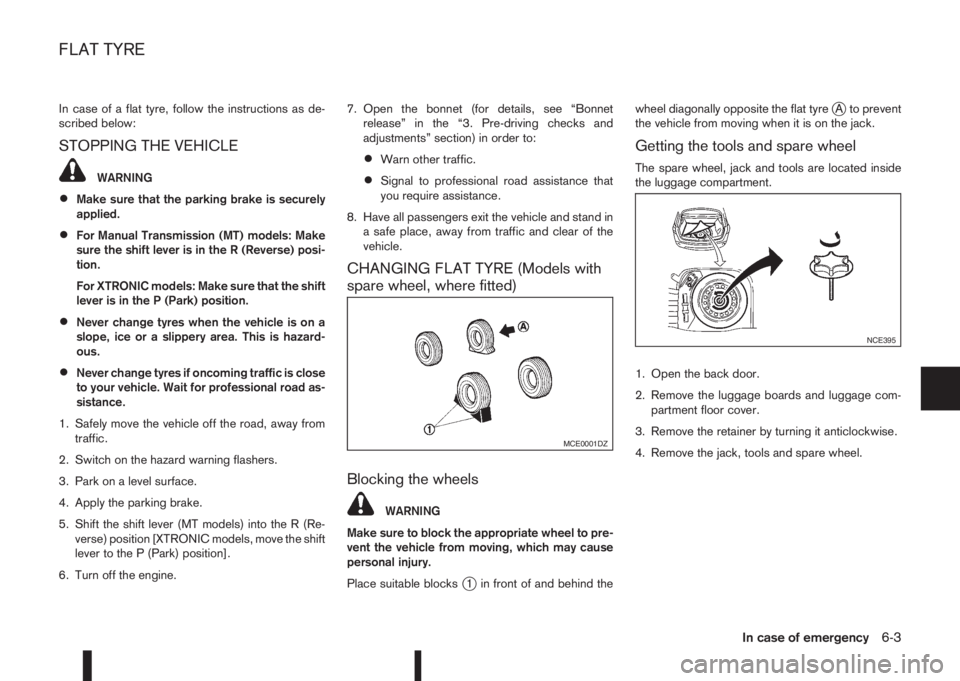

CHANGING FLAT TYRE (Models with

spare wheel, where fitted)

Blocking the wheels

WARNING

Make sure to block the appropriate wheel to pre-

vent the vehicle from moving, which may cause

personal injury.

Place suitable blocks

j1 in front of and behind thewheel diagonally opposite the flat tyre

jA to prevent

the vehicle from moving when it is on the jack.

Getting the tools and spare wheel

The spare wheel, jack and tools are located inside

the luggage compartment.

1. Open the back door.

2. Remove the luggage boards and luggage com-

partment floor cover.

3. Remove the retainer by turning it anticlockwise.

4. Remove the jack, tools and spare wheel.

MCE0001DZ

NCE395

FLAT TYRE

In case of emergency6-3

Page 255 of 338

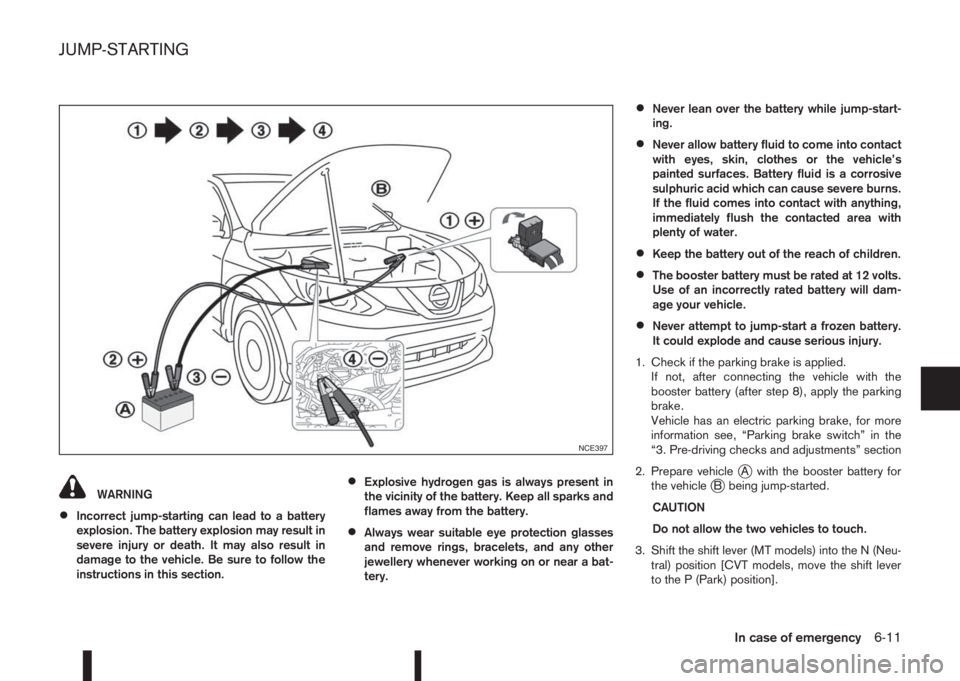

WARNING

•Incorrect jump-starting can lead to a battery

explosion. The battery explosion may result in

severe injury or death. It may also result in

damage to the vehicle. Be sure to follow the

instructions in this section.

•Explosive hydrogen gas is always present in

the vicinity of the battery. Keep all sparks and

flames away from the battery.

•Always wear suitable eye protection glasses

and remove rings, bracelets, and any other

jewellery whenever working on or near a bat-

tery.

•Never lean over the battery while jump-start-

ing.

•Never allow battery fluid to come into contact

with eyes, skin, clothes or the vehicle’s

painted surfaces. Battery fluid is a corrosive

sulphuric acid which can cause severe burns.

If the fluid comes into contact with anything,

immediately flush the contacted area with

plenty of water.

•Keep the battery out of the reach of children.

•The booster battery must be rated at 12 volts.

Use of an incorrectly rated battery will dam-

age your vehicle.

•Never attempt to jump-start a frozen battery.

It could explode and cause serious injury.

1. Check if the parking brake is applied.

If not, after connecting the vehicle with the

booster battery (after step 8), apply the parking

brake.

Vehicle has an electric parking brake, for more

information see, “Parking brake switch” in the

“3. Pre-driving checks and adjustments” section

2. Prepare vehicle

jA with the booster battery for

the vehiclejB being jump-started.

CAUTION

Do not allow the two vehicles to touch.

3. Shift the shift lever (MT models) into the N (Neu-

tral) position [CVT models, move the shift lever

to the P (Park) position].

NCE397

JUMP-STARTING

In case of emergency6-11

Page 257 of 338

CAUTION

•Three-way catalyst equipped models (where

fitted) should not be started by pushing the

vehicle as the three-way catalyst may be dam-

aged.

•XTRONIC transmission (CVT) models cannot

be started by pushing the vehicle. This may

cause transmission damage.

•Never try to start the vehicle by towing it; when

the engine starts, the forward surge could

cause the vehicle to collide with the tow ve-

hicle.

WARNING

•Never continue driving if the engine of your

vehicle overheats. Doing so could cause a ve-

hicle fire.

•Never open the bonnet if steam is coming

out.

•Never remove engine coolant reservoir cap

when the engine is hot. If the engine coolant

reservoir cap is removed while the engine is

hot, pressurised hot water will spurt out and

possibly cause burning, scalding or serious

injury.

•If steam or coolant is coming out of the en-

gine, stand clear of the vehicle to prevent get-

ting injured.

•The engine cooling fan will start whenever the

coolant temperature exceeds preset degrees.

•Be careful not to allow your hands, hair, jewel-

lery or clothing to come into contact with, or

get caught in, the cooling fan or drive belts.

If the engine of your vehicle is overheating (indi-

cated by the engine coolant temperature gauge) or

if you feel a lack of engine power, detect unusual

noise, etc., proceed as follows:

1. Move and park the vehicle safely off the road and

away from traffic.

2. Turn on the hazard warning flasher lights.

3. Apply the parking brake.4. Shift the shift lever (MT models) into the N (Neu-

tral) position, XTRONIC transmission (CVT)

models: move the shift lever to the P (Park) posi-

tion.

DO NOT STOP THE ENGINE.

5. Open all windows.

6. Switch off the air conditioner system (where fit-

ted).

7. Set the heater or air conditioner temperature

control to maximum “HOT” and fan speed con-

trol to maximum speed.

8. Exit the vehicle.

9. Visually inspect and listen for steam or coolant

escaping from the radiator before opening the

bonnet. Wait until no steam or coolant can be

seen before proceeding.

10. Open the bonnet. For details, see “Bonnet

release” in the “3. Pre-driving checks and

adjustments” section.

11. Visually check if the cooling fan is running.

12. Visually check the radiator and radiator hoses

for leakage.

WARNING

If coolant is leaking, the cooling fan belt is

missing or loose or the cooling fan is not run-

ning, stop the engine.

PUSH-STARTING ENGINE OVERHEAT

In case of emergency6-13

Page 258 of 338

13. After the engine cools down, check the coolant

level in the engine coolant reservoir with the

engine running.

14. If the level is low, remove the engine coolant

reservoir cap and add coolant slowly into the

reservoir. After refilling the reservoir to the MAX

level, install the reservoir cap.

WARNING

Before removing the engine coolant reservoir

cap and to avoid the danger of being scalded,

cover the reservoir cap with a rag and loosen

the reservoir cap to the first notch to allow the

steam to escape.

15. Close the bonnet.

Have your vehicle inspected or repaired by a

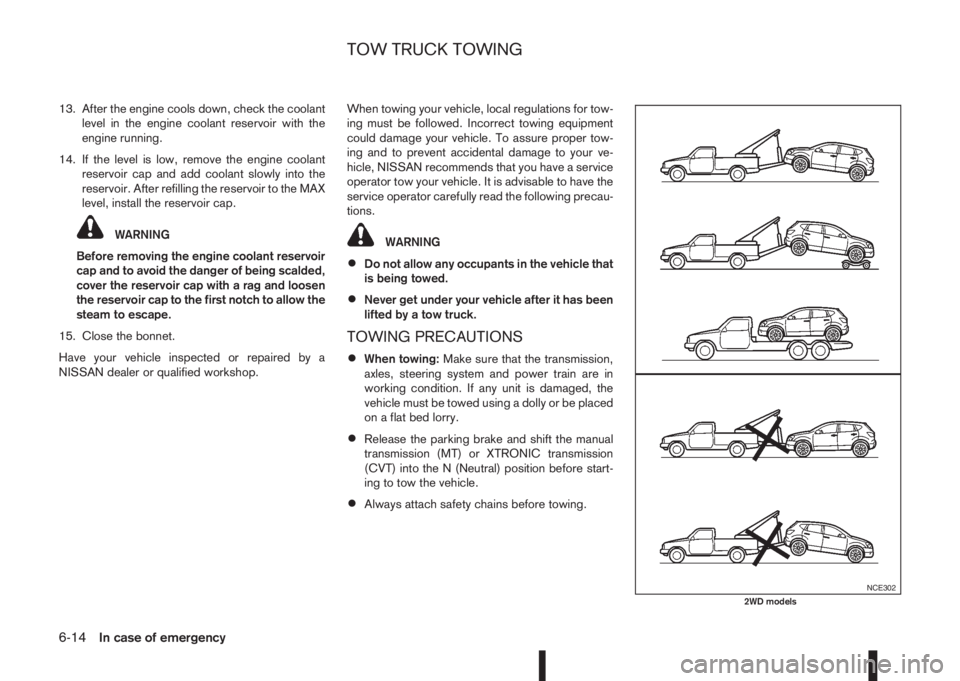

NISSAN dealer or qualified workshop.When towing your vehicle, local regulations for tow-

ing must be followed. Incorrect towing equipment

could damage your vehicle. To assure proper tow-

ing and to prevent accidental damage to your ve-

hicle, NISSAN recommends that you have a service

operator tow your vehicle. It is advisable to have the

service operator carefully read the following precau-

tions.WARNING

•Do not allow any occupants in the vehicle that

is being towed.

•Never get under your vehicle after it has been

lifted by a tow truck.

TOWING PRECAUTIONS

•When towing:Make sure that the transmission,

axles, steering system and power train are in

working condition. If any unit is damaged, the

vehicle must be towed using a dolly or be placed

on a flat bed lorry.

•Release the parking brake and shift the manual

transmission (MT) or XTRONIC transmission

(CVT) into the N (Neutral) position before start-

ing to tow the vehicle.

•Always attach safety chains before towing.

NCE3022WD models

TOW TRUCK TOWING

6-14In case of emergency

Page 266 of 338

Corrosion will also accelerate in areas where the

temperatures stay above freezing.

Air pollution

Industrial pollution, the presence of salt in the air in

coastal areas, or heavy road salt use will accelerate

the corrosion process. Road salt will also acceler-

ate the disintegration of paint surfaces.

TO PROTECT YOUR VEHICLE FROM

CORROSION

•Wash and wax your vehicle often to keep the

vehicle clean.

•Always check for minor damage to the paint sur-

face and if any exists, repair it as soon as pos-

sible.

•Keep the drain holes at the bottom of the doors

and back door opened to avoid water accumula-

tion.

•Check the vehicle underbody for accumulation

of sand, dirt or salt. If present, wash with water

as soon as possible.

CAUTION

•Never remove dirt, sand or other debris from

the passenger compartment by washing it out

with a hose. Remove dirt with a vacuum

cleaner or broom.

•Never allow water or other liquids to come in

contact with electronic components inside the

vehicle as this may damage them.

Chemicals used for road surface de-icing are ex-tremely corrosive. They accelerate corrosion and

deterioration of underbody components such as the

exhaust system, fuel and brake lines, brake cables,

floor pan and fenders.

In the winter, the underbody must be cleaned

periodically.

For additional protection against rust and corrosion,

which may be required in some areas, consult a

NISSAN dealer or qualified workshop.

7-6Appearance and care

Page 268 of 338

8Maintenance and do-it-yourselfMaintenance and do-it-yourself

Maintenance requirements ....................................... 8-2

Scheduled maintenance...................................... 8-2

General maintenance .......................................... 8-2

Where to go for service ...................................... 8-2

General maintenance ............................................... 8-2

Explanation of general maintenance items ........... 8-2

Maintenance precautions ......................................... 8-4

Engine compartment ................................................ 8-5

Engine cooling system ............................................. 8-6

Checking engine coolant level............................. 8-6

Changing engine coolant .................................... 8-6

Engine oil................................................................. 8-8

Checking engine oil level .................................... 8-8

Changing engine oil ............................................ 8-9

Changing engine oil filter .................................... 8-10

Protect the environment ...................................... 8-12

Fuel filter (Diesel engine models) ............................. 8-13

Draining water .................................................... 8-13

Bleeding the fuel system ..................................... 8-13

XTRONIC Continuously variable transmission

(CVT) fluid ............................................................... 8-13

Brakes ..................................................................... 8-13

Checking parking brake ...................................... 8-13

Checking brake pedal......................................... 8-13

Brake booster ..................................................... 8-14

Brake and clutch fluid .............................................. 8-14

Window washer fluid/headlight cleaner fluid

(where fitted) ........................................................... 8-15

Battery..................................................................... 8-16

Vehicle battery .................................................... 8-16Jump-starting ...................................................... 8-18

Integrated keyfob/Intelligent Key battery

replacement........................................................ 8-18

Drive belts ............................................................... 8-20

Spark plugs (Petrol engine models).......................... 8-21

Air duct removal....................................................... 8-21

Air cleaner filter........................................................ 8-23

Viscous paper type ............................................. 8-23

Dry paper type (where fitted) .............................. 8-23

Wiper blades ........................................................... 8-24

Cleaning ............................................................. 8-24

Front window wiper replacement ........................ 8-24

Back door window wiper replacement ................ 8-24

Windscreen washer nozzle ................................. 8-25

Fuses ...................................................................... 8-25

Passenger compartment ..................................... 8-25

Engine compartment ........................................... 8-26

Lights ...................................................................... 8-27

Headlights .......................................................... 8-28

Exterior lights ...................................................... 8-29

Interior lights....................................................... 8-29

Light locations .................................................... 8-30

Wheels and tyres ..................................................... 8-33

Tyre inflation pressure......................................... 8-33

Types of tyres ..................................................... 8-33

Snow chains....................................................... 8-34

Tyre rotation ....................................................... 8-34

Tyre wear and damage ....................................... 8-35

Tyre age ............................................................. 8-35

Changing tyres and wheels................................. 8-35

Page 271 of 338

Lights*:

Clean the headlights on a regular basis. Make sure

that the headlights, stop lights, tail lights, turn signal

lights, and other lights are all operating properly and

installed securely. Also check headlight aim.

Tyres*:

Check the pressure with a gauge periodically when

at a service station (including the spare) and adjust

to the specified pressure if necessary. Check care-

fully for damage, cuts or excessive wear.

Tyre rotation*:

Tyres should be rotated every 10,000 km (6,000

miles) for Two-Wheel Drive (2WD) models and

5,000 km (3,000 miles) for Four-Wheel Drive (4WD)

models. However, the timing for tyre rotation may

vary according to your driving habits and road sur-

face conditions.

Tyre Pressure Monitoring System (TPMS)

transmitter components (where fitted):

Replace the TPMS transmitter grommet seal, valve

core and cap when the tyres are replaced due to

wear or age.

Wheel alignment and balance:

If the vehicle pull to either side while driving on a

straight and level road, or if you detect uneven or

abnormal tyre wear, there may be a need for wheel

alignment. If the steering wheel or seat vibrates at

normal highway speeds, wheel balancing may be

needed.Wheel nuts:

When checking the tyres, make sure no wheel nuts

are missing, and check for any loose wheel nuts.

Tighten if necessary.

Windscreen:

Clean the windscreen on a regular basis. Check the

windscreen at least every six months for cracks or

other damage. Have a damaged windscreen re-

paired by a qualified repair facility.

Wiper blades*:

Check for cracks or wear if they do not wipe prop-

erly.

Under the bonnet and vehicle

The maintenance items listed here should be

checked periodically, e.g. each time you check the

engine oil or refuel.

Battery*:

Check if the green indicator on the top of the main-

tenance free battery is visible. If it is not visible,

replace the battery as soon as possible.

Vehicles operated in high temperatures or under

severe conditions, check the fluid level frequently.

Brake and clutch fluid level*:

Make sure that the brake and clutch fluid level is

between the MAX and MIN lines on the reservoir.

Engine coolant level*:

Check the coolant level when the engine is cold.Engine drive belts*:

Make sure that the drive belts are not frayed, worn,

cracked or oily.

Engine oil level*:

Check the level after parking the vehicle on a level

surface and turning off the engine.

Fluid leaks:

Check under the vehicle for fuel, oil, water or other

fluid leaks after the vehicle has been parked for a

while. Water dripping from the air conditioner after

use is normal. If you should notice any leaks or if

petrol fumes are evident, check for the cause and

have it corrected immediately.

Window washer fluid*:

Check that there is adequate fluid in the tank.

Inside the vehicle

The maintenance items listed here should be

checked on a regular basis, such as when perform-

ing periodic maintenance, cleaning the vehicle, etc.

Accelerator pedal:

Check the pedal for smooth operation and make

sure that the pedal does not catch or require uneven

effort. Keep the floor mats away from the pedal.

Brake pedal*:

Check the pedal for smooth operation. If the brake

pedal suddenly goes down further than normal, the

pedal feels spongy or the vehicle seems to take

Maintenance and do-it-yourself8-3

Page 272 of 338

longer to stop, contact a NISSAN dealer or qualified

workshop immediately. Keep the floor mat away

from the pedal.

Parking brake*:

Confirm that your vehicle is held securely on a fairly

steep hill with only the parking brake applied.

Seats:

Check seat position controls such as seat adjust-

ers, seatback recliner, etc. to ensure they operate

smoothly and all latches lock securely in every posi-

tion. Check that the head restraints move up and

down smoothly and the locks hold securely in all

latched positions.

Seat belts:

Check that all parts of the seat belt system (e.g.

buckles, anchors, adjusters and retractors) operate

properly and smoothly, and are installed securely.

Check the belt webbing for cuts, fraying, wear or

damage. See “Seat belts” in the “1. Safety — Seats,

Seat belts and Supplemental Restraint System” sec-

tion for further details.

Steering wheel:

Check for any change in the steering conditions,

such as excessive free play, hard steering or strange

noises.

Warning lights and audible reminders:

Make sure that all warning/indicator lights and au-

dible reminders are operating properly.Windscreen defogger:

Check that the air comes out of the defogger outlets

properly when operating the heater or air condi-

tioner.

Windscreen wiper and washer*:

Check that the wipers and washer operate properly

and that the wipers do not streak.When performing any inspection or maintenance

work on your vehicle, always take care to prevent

serious accidental injury to yourself or damage to

the vehicle. The following are general precautions

which should be closely observed.

•Park the vehicle on a level surface, apply the

parking brake securely and block the wheels

to prevent the vehicle from moving. For

manual transmission models, move the shift

lever to N (Neutral) position.For continuously

variable transmission models: move the shift

lever to P (Park) position.

•Do not work under the engine bonnet while

the engine is hot. Turn off the engine and wait

until it cools down.

•Be sure to turn the ignition switch to the “OFF”

or LOCK position.

When the ignition switch is in the ON or Acc

position, the cooling fan may start to operate

suddenly even when the engine is not run-

ning. To avoid injury, always disconnect the

negative battery cable before working near

the engine.

•If you must work with the engine running,

keep your hands, clothing, hair and tools away

from moving fans, belts and any other moving

parts.

•It is advisable to remove ties and any jewel-

lery, such as rings, watches, etc. before work-

ing on your vehicle.

MAINTENANCE PRECAUTIONS

8-4Maintenance and do-it-yourself

Page 276 of 338

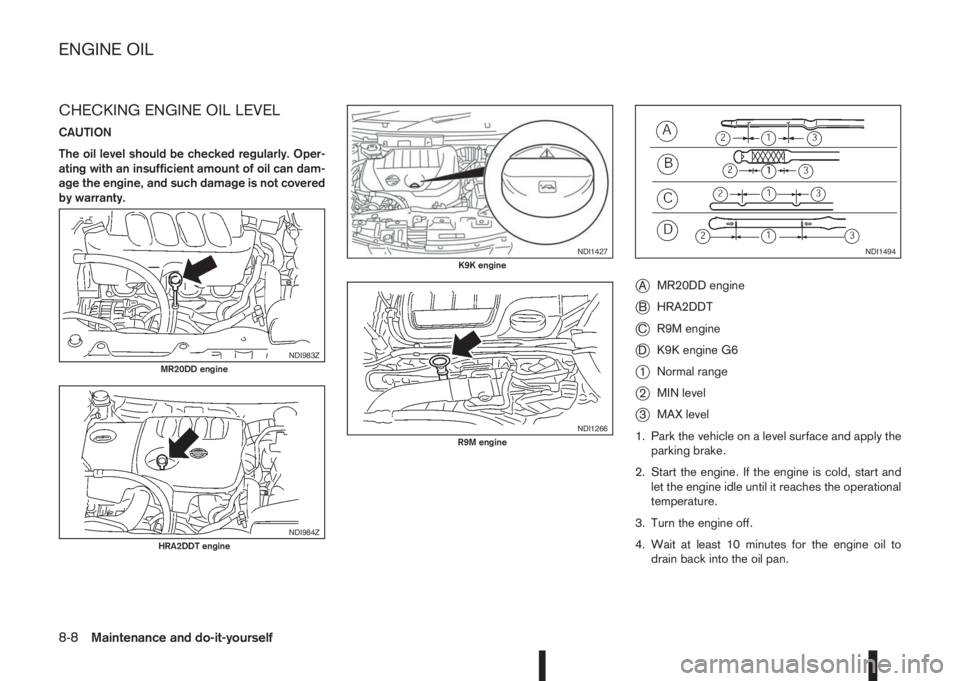

CHECKING ENGINE OIL LEVEL

CAUTION

The oil level should be checked regularly. Oper-

ating with an insufficient amount of oil can dam-

age the engine, and such damage is not covered

by warranty.

jAMR20DD engine

jBHRA2DDT

jCR9M engine

jDK9K engine G6

j1Normal range

j2MIN level

j3MAX level

1. Park the vehicle on a level surface and apply the

parking brake.

2. Start the engine. If the engine is cold, start and

let the engine idle until it reaches the operational

temperature.

3. Turn the engine off.

4. Wait at least 10 minutes for the engine oil to

drain back into the oil pan.

NDI983ZMR20DD engine

NDI984ZHRA2DDT engine

NDI1427K9K engine

NDI1266R9M engine

NDI1494

ENGINE OIL

8-8Maintenance and do-it-yourself

Page 278 of 338

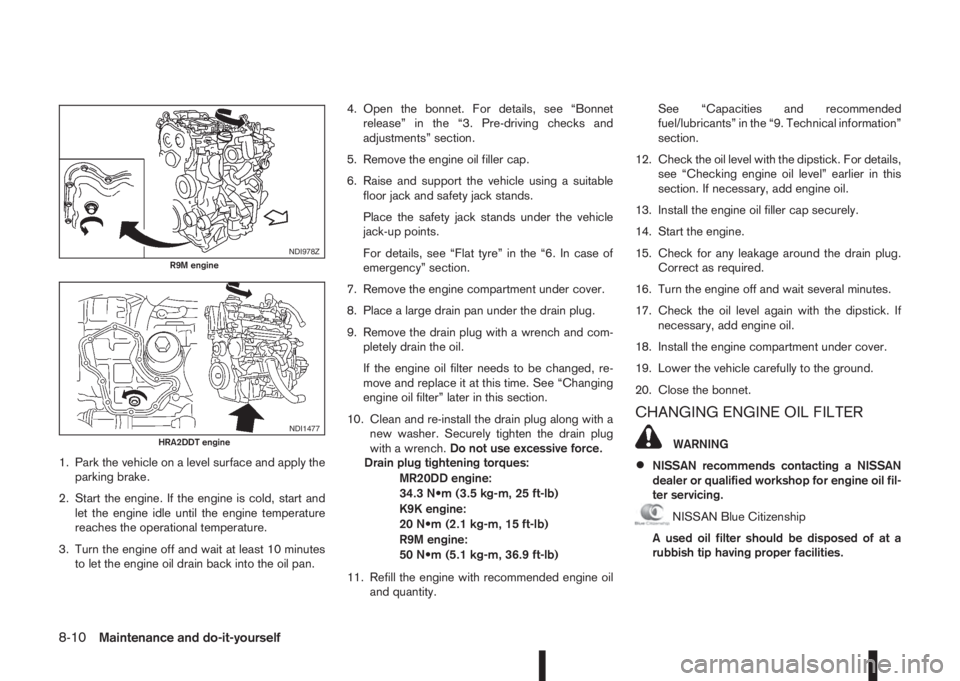

1. Park the vehicle on a level surface and apply the

parking brake.

2. Start the engine. If the engine is cold, start and

let the engine idle until the engine temperature

reaches the operational temperature.

3. Turn the engine off and wait at least 10 minutes

to let the engine oil drain back into the oil pan.4. Open the bonnet. For details, see “Bonnet

release” in the “3. Pre-driving checks and

adjustments” section.

5. Remove the engine oil filler cap.

6. Raise and support the vehicle using a suitable

floor jack and safety jack stands.

Place the safety jack stands under the vehicle

jack-up points.

For details, see “Flat tyre” in the “6. In case of

emergency” section.

7. Remove the engine compartment under cover.

8. Place a large drain pan under the drain plug.

9. Remove the drain plug with a wrench and com-

pletely drain the oil.

If the engine oil filter needs to be changed, re-

move and replace it at this time. See “Changing

engine oil filter” later in this section.

10. Clean and re-install the drain plug along with a

new washer. Securely tighten the drain plug

with a wrench.Do not use excessive force.

Drain plug tightening torques:

MR20DD engine:

34.3 N•m (3.5 kg-m, 25 ft-lb)

K9K engine:

20 N•m (2.1 kg-m, 15 ft-lb)

R9M engine:

50 N•m (5.1 kg-m, 36.9 ft-lb)

11. Refill the engine with recommended engine oil

and quantity.See “Capacities and recommended

fuel/lubricants” in the “9. Technical information”

section.

12. Check the oil level with the dipstick. For details,

see “Checking engine oil level” earlier in this

section. If necessary, add engine oil.

13. Install the engine oil filler cap securely.

14. Start the engine.

15. Check for any leakage around the drain plug.

Correct as required.

16. Turn the engine off and wait several minutes.

17. Check the oil level again with the dipstick. If

necessary, add engine oil.

18. Install the engine compartment under cover.

19. Lower the vehicle carefully to the ground.

20. Close the bonnet.

CHANGING ENGINE OIL FILTER

WARNING

•NISSAN recommends contacting a NISSAN

dealer or qualified workshop for engine oil fil-

ter servicing.

NISSAN Blue Citizenship

A used oil filter should be disposed of at a

rubbish tip having proper facilities.

NDI978ZR9M engine

NDI1477HRA2DDT engine

8-10Maintenance and do-it-yourself