brake NISSAN SENTRA 1997 B14 / 4.G Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1997, Model line: SENTRA, Model: NISSAN SENTRA 1997 B14 / 4.GPages: 194, PDF Size: 1.62 MB

Page 144 of 194

normal, it may be due to a lack of adjust-

ment of the rear drum brakes. Apply the

parking brake several times.

WARNING

See your NISSAN dealer and have it

checked if the brake pedal height does

not return to normal.

Brake pad wear indicators

The disc brake pads on your vehicle have

audible wear indicators. When a brake pad

requires replacement, it makes a high

pitched scraping or screeching sound when

the vehicle is in motion whether or not the

brake pedal is depressed. Have the brakes

checked as soon as possible if the wear

indicator sound is heard.

Under some driving or climate conditions,

occasional brake squeak, squeal or other

noise may be heard. Occasional brake

noise during light to moderate stops is nor-

mal and does not affect the function or

performance of the brake system.

The rear drum brakes (if so equipped) do

not have audible wear indicators. Should

you ever hear an unusually loud noise fromthe rear drum brakes, have them inspected

as soon as possible by your NISSAN

dealer.

Proper brake inspection intervals should

be followed.For more information regard-

ing brake inspections, see the appropriate

maintenance schedule information in the

``Maintenance Schedule'' section of this

manual.Check the brake booster function as fol-

lows:

1. With the engine off, press and release

the brake pedal several times. When

brake pedal movement (distance of

travel) remains the same from one pedal

application to the next, continue on to the

next step.

2. While depressing the brake pedal, start

the engine. The pedal height should drop

a little.

3. With the brake pedal depressed, stop the

engine. Keeping the pedal depressed for

about 30 seconds, the pedal height

should not change.

4. Run the engine for one minute without

depressing the brake pedal, then turn it

off. Depress the brake pedal several

times. The pedal travel distance will de-

crease gradually with each depression

as the vacuum is released from the

booster.

If the brakes do not operate properly, see

your NISSAN dealer.

BRAKE BOOSTER

7-22

ZX

Page 157 of 194

cIf the wheels are changed for any

reason, always replace with

wheelswhich have the same offset

dimension. Wheels of a different off-

set could cause early tire wear, poor

vehicle handling characteristics

and/or interference with the brake

discs/drums. Such interference can

lead to decreased braking efficiency

and/or early brake pad/shoe wear.

cDo not install a deformed wheel or

tire even if it has been repaired. Such

wheels or tires could have structural

damage and could fail without warn-

ing.

Wheel balance

Unbalanced wheels may affect vehicle han-

dling and tire life. Even with regular use,

wheels can get out of balance. Therefore,

they should be balanced as required.

Wheel balance service should be per-

formed with the wheels off the vehicle. Spin

balancing the front wheels on the vehicle

could lead to transmission damage.

Care of wheels

cWash the wheels when washing the

vehicle to maintain their appearance.

cClean the inner side of the wheels when

the wheel is changed or the underside of

the vehicle is washed.

cDo not use abrasive cleaners when

washing the wheels.

cInspect wheel rims regularly for dents or

corrosion. Such damage may cause

loss of pressure or poor seal at the tire

bead.

cNISSAN recommends waxing the road

wheels to protect against road salt in

areas where it is used during winter.

Spare tire (T-type spare tire)

Observe the following precautions if the T-type

spare tire must be used, otherwise your vehicle

could be damaged or involved in an accident:

CAUTION

cThe T-type spare tire should be used

only for emergency. It should be re-

placed by the standard tire at the

first opportunity.cDrive carefully while the T-type

spare tire is installed. Avoid sharp

turns and abrupt braking while

driving.

cPeriodically check tire inflation pres-

sure, and always keep it at 60 psi

(420 kPa, 4.2 bar).

cDo not drive your vehicle at speeds

faster than 50 MPH (80 km/h).

cDo not use tire chains on a T-type

spare tire. Tire chains will not fit

properly on the T-type spare tire and

may cause damage to the vehicle.

cWhen driving on roads covered with

snow or ice, the T-type spare tire

should be used on the rear wheel

and the original tire used on the front

wheels (drive wheels). Use tire

chains only on the front two original

tires.

cTire tread of the T-type spare tire will

wear at a faster rate than the original

tire. Replace the T-type spare tire as

soon as the tread wear indicators

appear.

7-35

ZX

Page 161 of 194

Tire rotation* ÐTires should be rotated

every 7,500 miles (12,000 km).

Wheel alignment and balance ÐIf the

vehicle should pull to either side while driv-

ing on a straight and level road, or if you

detect uneven or abnormal tire wear, there

may be a need for wheel alignment.

If the steering wheel or seat vibrates at

normal highway speeds, wheel balancing

may be needed.

Windshield wiper blades* ÐCheck for

cracks or wear if they do not wipe properly.

Doors and engine hood ÐCheck that all

doors and the engine hood operate prop-

erly. Also ensure that all latches lock se-

curely. Lubricate hinges, latches, rollers and

links if necessary. Make sure the secondary

latch keeps the hood from opening when

the primary latch is released.

When driving in areas using road salt or

other corrosive materials, check lubrication

frequently.

Lights* ÐMake sure the headlights, stop

lights, tail lights, turn signal lights, and other

lights are all operating properly and installed

securely. Also check headlight aim.INSIDE THE VEHICLE

The maintenance items listed here should

be checked on a regular basis, such as

when performing periodic maintenance,

cleaning the vehicle, etc.

Additional information on the following

items with ``*'' is found in the ``Do-it-

yourself operations'' section.

Warning lights and chimes ÐMake sure

all warning lights and chimes are operating

properly.

Windshield wiper and washer* ÐCheck

that the wipers and washer operate properly

and that the wipers do not streak.

Windshield defroster ÐCheck that the air

comes out of the defroster outlets properly

and in sufficient quantity when operating the

heater or air conditioner.

Steering wheel ÐCheck for changes in

the steering conditions, such as excessive

freeplay, hard steering or strange noises.

Seats ÐCheck seat position controls such

as seat adjusters, seatback recliner, etc. to

ensure they operate smoothly and all

latches lock securely in every position.

Check that the head restraints move up anddown smoothly and the locks hold securely

in all latched positions.

Seat belts ÐCheck that all parts of the seat

belt system (e.g., buckles, anchors, adjust-

ers and retractors) operate properly and

smoothly, and are installed securely. Check

the belt webbing for cuts, fraying, wear or

damage.

Accelerator pedal ÐCheck the pedal for

smooth operation and make sure the pedal

does not catch or require uneven effort.

Keep the floor mats away from the pedal.

Clutch pedal* ÐMake sure the pedal

operates smoothly and check that it has the

proper free travel.

Brakes ÐCheck that the brakes do not pull

the vehicle to one side when applied.

Brake pedal* ÐCheck the pedal for

smooth operation and make sure it has the

proper distance under it when depressed

fully. Check the brake booster function. Be

certain to keep floor mats away from the

pedal.

Parking brake* ÐCheck that the lever has

the proper travel and confirm that your

vehicle is held securely on a fairly steep hill

8-3

ZX

Page 162 of 194

with only the parking brake applied.

Automatic transmission ``Park'' mecha-

nism ÐOn a fairly steep hill check that your

vehicle is held securely with the selector

lever in the P position without applying any

brakes.

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should

be checked periodically, such as each time

you check the engine oil or refuel.

Additional information on the following

items with ``*'' is found in the ``Do-it-

yourself operations'' section.

Windshield washer fluid* ÐCheck for

adequate fluid in the tank.

Engine coolant level* ÐCheck the cool-

ant level when the engine is cold.

Radiator and hoses ÐCheck the front of

the radiator and clean off any dirt, insects,

leaves, etc., that may have accumulated.

Make sure the hoses have no cracks, de-

formation, rot or loose connections.

Brake fluid level* ÐMake sure the brake

and clutch fluid level is between the MAX

and MIN lines on the reservoir.Battery* ÐCheck the fluid level in each

cell.

Engine drive belts* ÐMake sure no belt is

frayed, worn, cracked or oily.

Engine oil level* ÐCheck the level after

parking the vehicle on a level spot and

turning off the engine. Wait a few minutes

for the oil to drain back into the oil pan.

Power steering fluid level* and lines Ð

Check the level when the fluid is cold and

the engine is turned off. Check the lines for

proper attachment, leaks, cracks, etc.

Automatic transmission fluid level* Ð

Check the level after putting the selector

lever in P with the engine idling.

Exhaust system ÐMake sure there are no

cracks, holes, loose joints or supports. If the

sound of the exhaust seems unusual or

there is a smell of exhaust fumes, immedi-

ately have the exhaust system inspected by

a qualified individual. (See the carbon mon-

oxide warning in the ``Starting and driving''

section.)

Underbody ÐThe underbody is frequently

exposed to corrosive substances such as

those used on icy roads or to control dust. Itis very important to remove these sub-

stances, otherwise rust forms on the floor

pan, frame, fuel lines and around the ex-

haust system. At the end of winter, the

underbody should be thoroughly flushed

with plain water, being careful to clean

those areas where mud and dirt may accu-

mulate. See the ``Appearance and interior

care'' section for additional information.

Fluid leaks ÐCheck under the vehicle for

fuel, oil, water or other fluid leaks after the

vehicle has been parked for awhile. Water

dripping from the air conditioner after use is

normal. If you should notice any leaks or if

gasoline fumes are evident, check for the

cause and have it corrected immediately.

8-4

ZX

Page 165 of 194

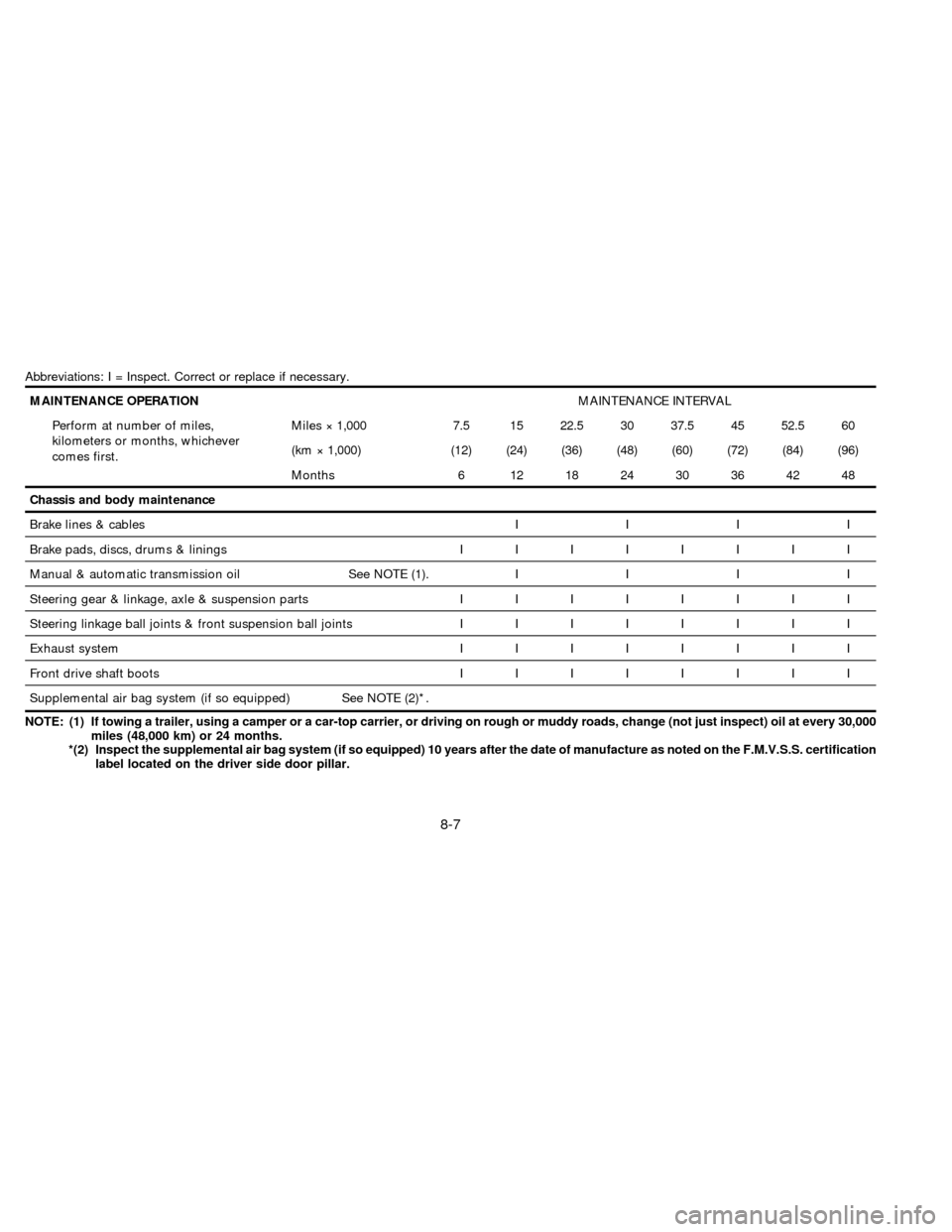

Abbreviations: I = Inspect. Correct or replace if necessary.

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Perform at number of miles,

kilometers or months, whichever

comes first.Miles ý 1,000 7.5 15 22.5 30 37.5 45 52.5 60

(km ý 1,000) (12) (24) (36) (48) (60) (72) (84) (96)

Months 6 12 18 24 30 36 42 48

Chassis and body maintenance

Brake lines & cablesIIII

Brake pads, discs, drums & liningsIIIIIIII

Manual & automatic transmission oil See NOTE (1).IIII

Steering gear & linkage, axle & suspension partsIIIIIIII

Steering linkage ball joints & front suspension ball jointsIIIIIIII

Exhaust systemIIIIIIII

Front drive shaft bootsIIIIIIII

Supplemental air bag system (if so equipped) See NOTE (2)*.

NOTE: (1) If towing a trailer, using a camper or a car-top carrier, or driving on rough or muddy roads, change (not just inspect) oil at every 30,000

miles (48,000 km) or 24 months.

*(2) Inspect the supplemental air bag system (if so equipped) 10 years after the date of manufacture as noted on the F.M.V.S.S. certification

label located on the driver side door pillar.

8-7

ZX

Page 167 of 194

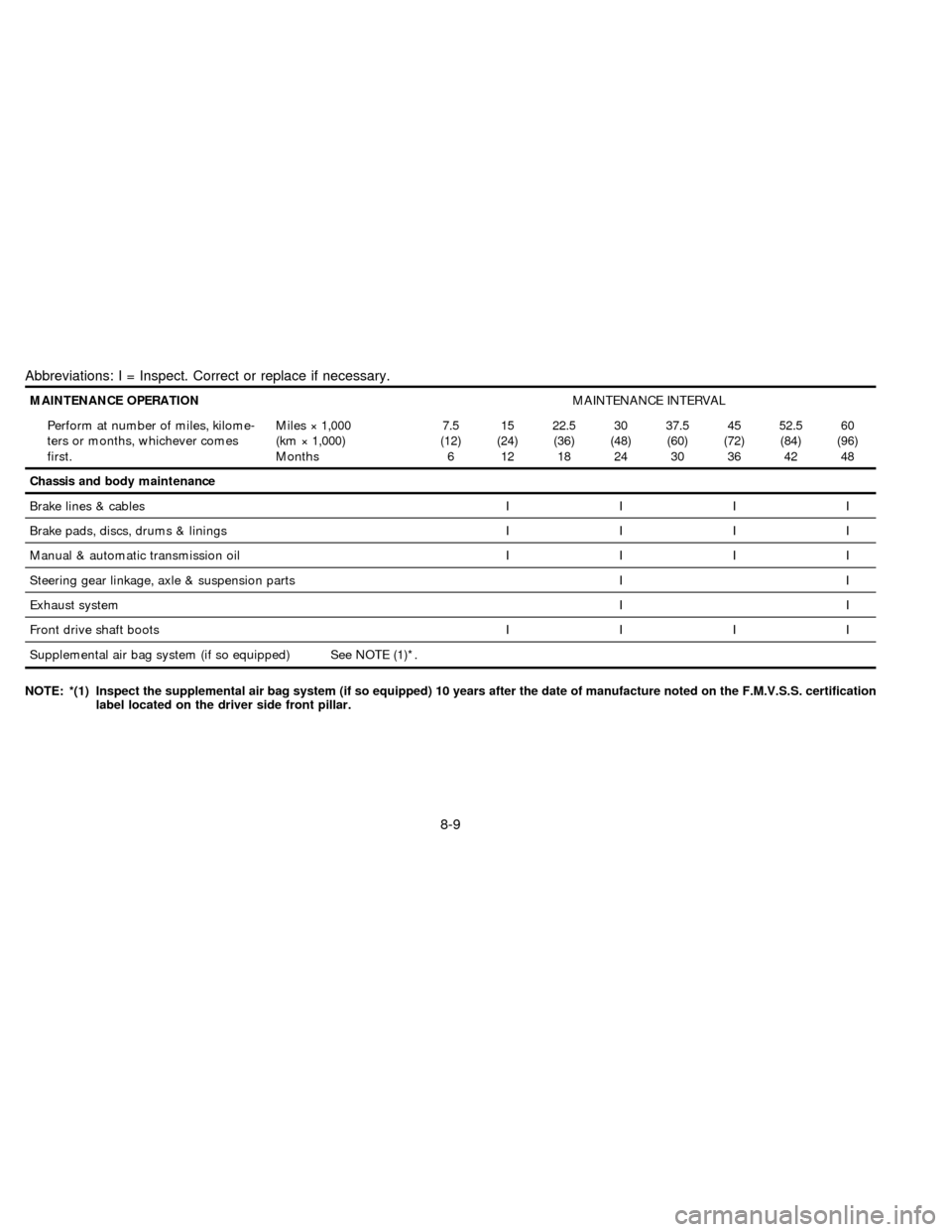

Abbreviations: I = Inspect. Correct or replace if necessary.

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Perform at number of miles, kilome-

ters or months, whichever comes

first.Miles ý 1,000

(km ý 1,000)

Months7.5

(12)

615

(24)

1222.5

(36)

1830

(48)

2437.5

(60)

3045

(72)

3652.5

(84)

4260

(96)

48

Chassis and body maintenance

Brake lines & cablesIIII

Brake pads, discs, drums & liningsIIII

Manual & automatic transmission oilIIII

Steering gear linkage, axle & suspension parts I I

Exhaust systemII

Front drive shaft bootsIIII

Supplemental air bag system (if so equipped) See NOTE (1)*.

NOTE: *(1) Inspect the supplemental air bag system (if so equipped) 10 years after the date of manufacture noted on the F.M.V.S.S. certification

label located on the driver side front pillar.

8-9

ZX

Page 168 of 194

Additional information on the following

items with ``*'' is found in the ``Do-it-

yourself operations'' section.

Emission control system

maintenance

Drive belts* ÐCheck drive belts for wear,

fraying or cracking and also for proper tension.

Replace the drive belts if found damaged.

Air cleaner filter ÐUnder normal driving

conditions, the air cleaner filter should be

replaced in accordance with the maintenance

schedule. However, driving the vehicle in

dusty areas may cause more rapid clogging

of the element. Consequently, the element

may have to be replaced more frequently.

Vapor lines ÐCheck vapor lines and con-

nections for failure or looseness. If leaks are

found, replace them.

Fuel lines ÐCheck the fuel hoses, piping

and connections for leaks, looseness or

deterioration. Replace any parts if they are

damaged.

Fuel filter ÐIf the vehicle is operated under

extremely adverse weather conditions or in

areas where ambient temperatures are ei-

ther extremely low or extremely high, thefilter might become clogged. In such an

event, replace the filter immediately.

Engine coolant* ÐDrain and flush the

cooling system.

Engine oil & oil filter* ÐUnder normal

driving conditions, the engine oil and oil filter

should be replaced in accordance with the

maintenance schedule. However, under se-

vere driving conditions, they may have to be

replaced more frequently.

Spark plugs* ÐReplace with new plugs

having the correct heat range.

Intake & exhaust valve clearance Ð

Check and adjust the valve clearance.

Chassis and body maintenance

Brake lines & cables ÐCheck the brake

lines and hoses (including brake booster

vacuum hoses, connections & check valve)

and parking brake cables for proper attach-

ment, leaks, cracks, chafing, abrasion, de-

terioration, etc.

Brake pads, discs, drums & linings Ð

Check these and the other neighboring brake

components for wear, deterioration and

leaks. Under severe driving conditions, they

may have to be inspected more frequently.

Manual & automatic transmission fluid*

ÐCheck the fluid level and visually inspect

for signs of leakage.

Under severe driving conditions, the fluid

should be replaced at the specified interval.

Steering gear & linkage, axle & suspen-

sion parts, and drive shaft boots Ð

Check for damage, looseness and leakage

of oil or grease. Under severe driving con-

ditions, more frequent inspection should be

performed.

Steering linkage ball joints & front sus-

pension ball joints ÐCheck the ball joints

for damage, looseness and grease leakage.

Exhaust system ÐVisually check the ex-

haust pipes, muffler, and hangers for proper

attachment, leaks, cracks, chafing, abra-

sion, deterioration, etc. Under severe

driving conditions, inspection should be per-

formed more frequently.

Supplemental air bag system (if so

equipped) ÐCheck the supplemental air

bag system components for proper attach-

ment, damage, deformities, cracks, rust,

etc. Work around and on the supplemental

air bag system should be done by an autho-

rized NISSAN dealer.

EXPLANATION OF

MAINTENANCE ITEMS

8-10

ZX

Page 170 of 194

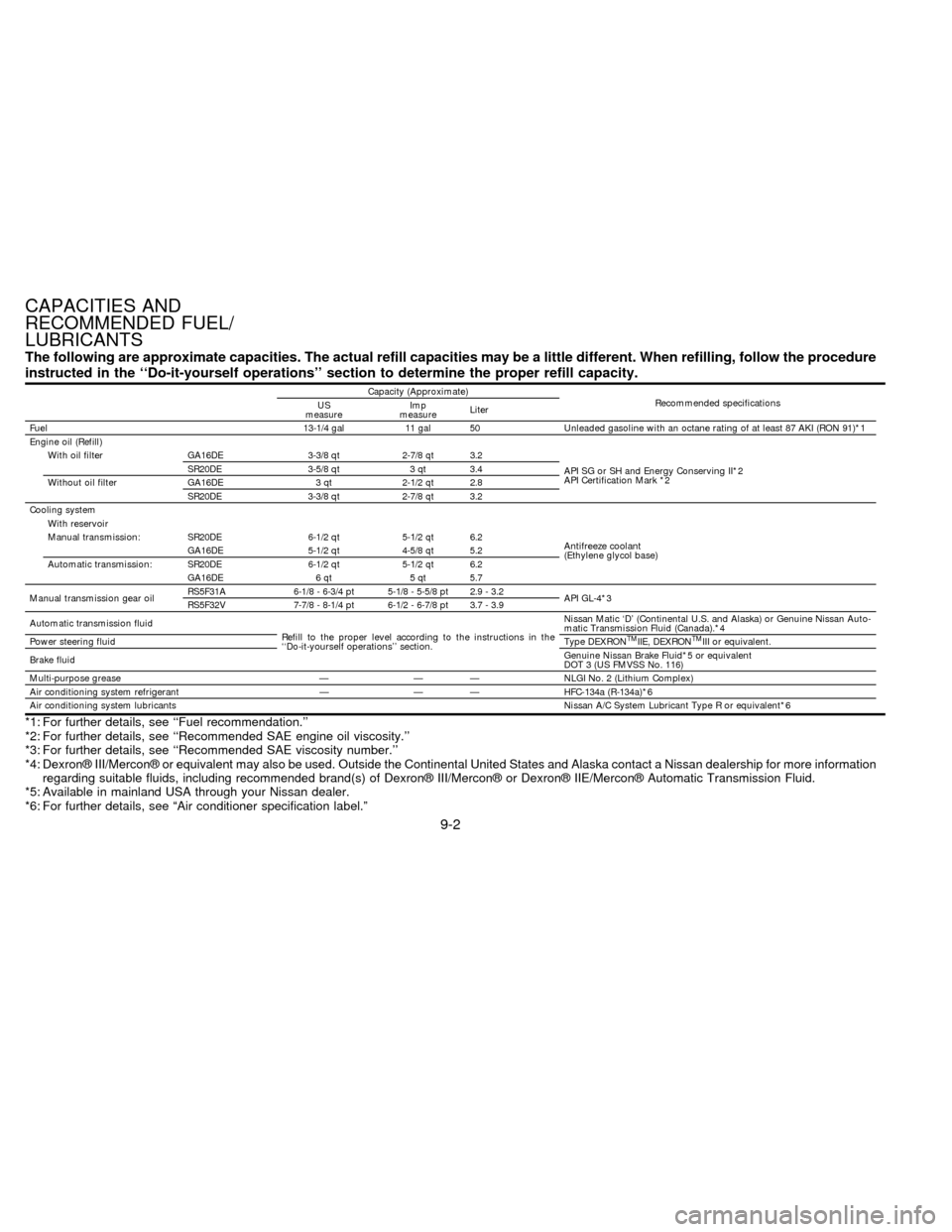

The following are approximate capacities. The actual refill capacities may be a little different. When refilling, follow the procedure

instructed in the ``Do-it-yourself operations'' section to determine the proper refill capacity.

Capacity (Approximate)

Recommended specifications

US

measureImp

measureLiter

Fuel 13-1/4 gal 11 gal 50 Unleaded gasoline with an octane rating of at least 87 AKI (RON 91)*1

Engine oil (Refill)

With oil filter GA16DE 3-3/8 qt 2-7/8 qt 3.2

API SG or SH and Energy Conserving II*2

API Certification Mark *2 SR20DE 3-5/8 qt 3 qt 3.4

Without oil filter GA16DE 3 qt 2-1/2 qt 2.8

SR20DE 3-3/8 qt 2-7/8 qt 3.2

Cooling system

With reservoir

Antifreeze coolant

(Ethylene glycol base) Manual transmission: SR20DE 6-1/2 qt 5-1/2 qt 6.2

GA16DE 5-1/2 qt 4-5/8 qt 5.2

Automatic transmission: SR20DE 6-1/2 qt 5-1/2 qt 6.2

GA16DE 6 qt 5 qt 5.7

Manual transmission gear oilRS5F31A 6-1/8 - 6-3/4 pt 5-1/8 - 5-5/8 pt 2.9 - 3.2

API GL-4*3

RS5F32V 7-7/8 - 8-1/4 pt 6-1/2 - 6-7/8 pt 3.7 - 3.9

Automatic transmission fluid

Refill to the proper level according to the instructions in the

``Do-it-yourself operations'' section.Nissan Matic `D' (Continental U.S. and Alaska) or Genuine Nissan Auto-

matic Transmission Fluid (Canada).*4

Power steering fluidType DEXRON

TMIIE, DEXRONTMIII or equivalent.

Brake fluidGenuine Nissan Brake Fluid*5 or equivalent

DOT 3 (US FMVSS No. 116)

Multi-purpose grease Ð Ð Ð NLGI No. 2 (Lithium Complex)

Air conditioning system refrigerant Ð Ð Ð HFC-134a (R-134a)*6

Air conditioning system lubricantsNissan A/C System Lubricant Type R or equivalent*6

*1: For further details, see ``Fuel recommendation.''

*2: For further details, see ``Recommended SAE engine oil viscosity.''

*3: For further details, see ``Recommended SAE viscosity number.''

*4: Dexronž III/Merconž or equivalent may also be used. Outside the Continental United States and Alaska contact a Nissan dealership for more information

regarding suitable fluids, including recommended brand(s) of Dexronž III/Merconž or Dexronž IIE/Merconž Automatic Transmission Fluid.

*5: Available in mainland USA through your Nissan dealer.

*6: For further details, see ªAir conditioner specification label.º

CAPACITIES AND

RECOMMENDED FUEL/

LUBRICANTS

9-2

ZX

Page 183 of 194

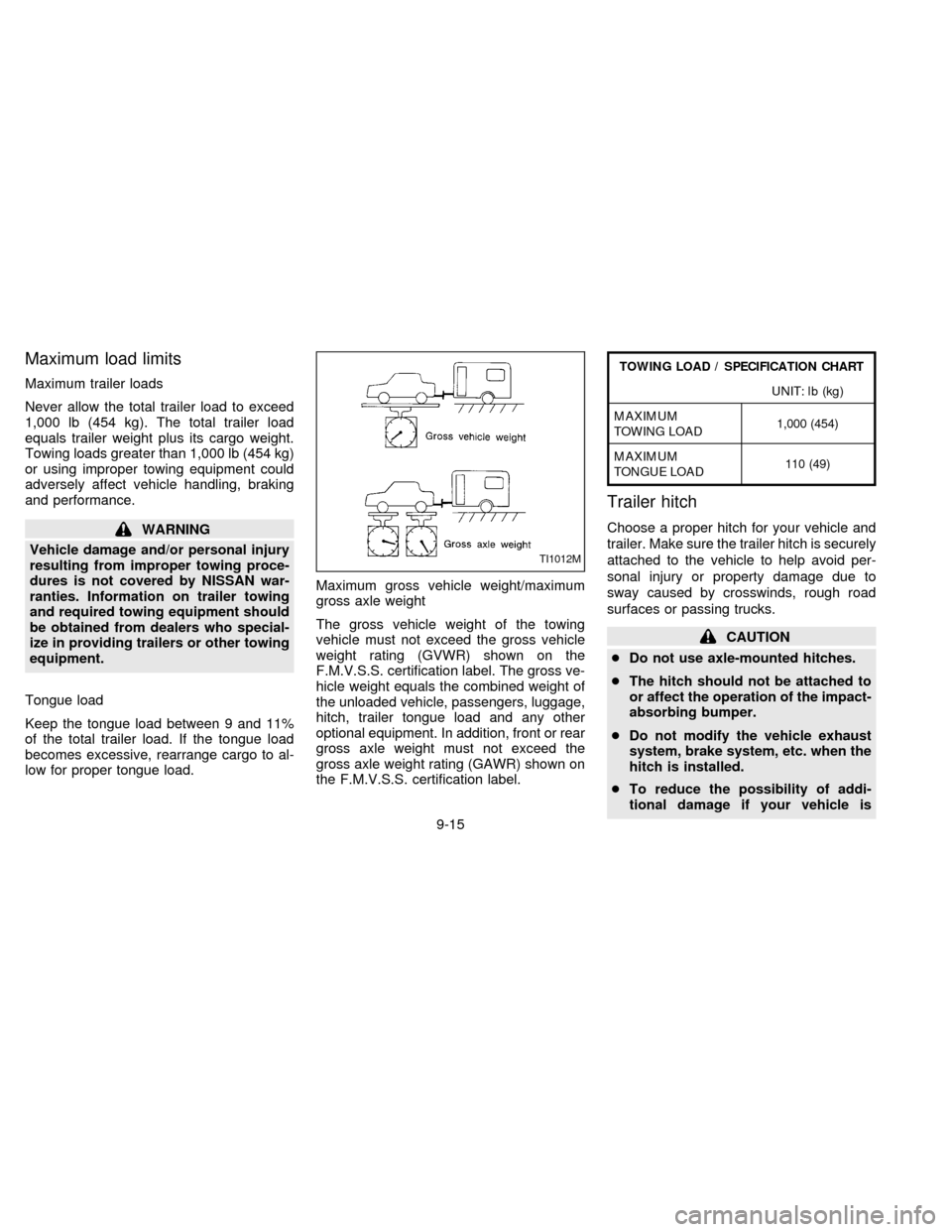

Maximum load limits

Maximum trailer loads

Never allow the total trailer load to exceed

1,000 lb (454 kg). The total trailer load

equals trailer weight plus its cargo weight.

Towing loads greater than 1,000 lb (454 kg)

or using improper towing equipment could

adversely affect vehicle handling, braking

and performance.

WARNING

Vehicle damage and/or personal injury

resulting from improper towing proce-

dures is not covered by NISSAN war-

ranties. Information on trailer towing

and required towing equipment should

be obtained from dealers who special-

ize in providing trailers or other towing

equipment.

Tongue load

Keep the tongue load between 9 and 11%

of the total trailer load. If the tongue load

becomes excessive, rearrange cargo to al-

low for proper tongue load.Maximum gross vehicle weight/maximum

gross axle weight

The gross vehicle weight of the towing

vehicle must not exceed the gross vehicle

weight rating (GVWR) shown on the

F.M.V.S.S. certification label. The gross ve-

hicle weight equals the combined weight of

the unloaded vehicle, passengers, luggage,

hitch, trailer tongue load and any other

optional equipment. In addition, front or rear

gross axle weight must not exceed the

gross axle weight rating (GAWR) shown on

the F.M.V.S.S. certification label.

TOWING LOAD / SPECIFICATION CHART

UNIT: lb (kg)

MAXIMUM

TOWING LOAD1,000 (454)

MAXIMUM

TONGUE LOAD110 (49)

Trailer hitch

Choose a proper hitch for your vehicle and

trailer. Make sure the trailer hitch is securely

attached to the vehicle to help avoid per-

sonal injury or property damage due to

sway caused by crosswinds, rough road

surfaces or passing trucks.

CAUTION

cDo not use axle-mounted hitches.

cThe hitch should not be attached to

or affect the operation of the impact-

absorbing bumper.

cDo not modify the vehicle exhaust

system, brake system, etc. when the

hitch is installed.

cTo reduce the possibility of addi-

tional damage if your vehicle is

TI1012M

9-15

ZX

Page 184 of 194

struck from the rear, where practical

remove the hitch when not in use.

Remove receiver when not in use.

cAfter the hitch is removed, seal the

bolt holes to prevent exhaust fumes,

water or dust from entering the pas-

senger compartment.

cRegularly check that all hitch mount-

ing bolts are securely mounted.

Tire pressures

cWhen towing a trailer, inflate the vehicle

tires to the recommended cold tire pres-

sure indicated on the tire placard (lo-

cated on the driver side center pillar).

cTrailer tire condition, size, load rating

and proper inflation pressure should be

in accordance with the trailer and tire

manufacturers' specifications.

Safety chain

Always use a suitable chain between your

vehicle and the trailer. The chain should be

crossed and should be attached to the hitch,

not to the vehicle bumper or axle. Be sure to

leave enough slack in the chain to permit

turning corners.

Trailer lights

Trailer lights should comply with federal

and/ or local regulations. When wiring the

vehicle for towing, connect the stop and tail

light pickup into the vehicle electrical circuit.

Trailer brakes

If your trailer is equipped with a braking

system, make sure it conforms to federal

and/or local regulations and that it is prop-

erly installed.

WARNING

Never connect a trailer brake system

directly to the vehicle brake system.

Pre-towing tips

cBe certain your vehicle maintains a level

position when a loaded and/or unloaded

trailer is hitched. Do not drive the vehicle if

it has an abnormal nose-up or nose- down

condition; check for improper tongue load,

overload, worn suspension or other pos-

sible causes of either condition.

cAlways secure items in the trailer to

prevent load shifts while driving.cBe certain your rear view mirrors con-

form to all federal, state or local regula-

tions. If not, install any mirrors required

for towing before driving the vehicle.

Trailer towing tips

In order to gain skill and an understanding

of the vehicle's behavior, you should prac-

tice turning, stopping and backing up in an

area which is free from traffic. Steering,

stability, and braking performance are

somewhat different than under normal driv-

ing conditions.

cAlways secure items in the trailer to

prevent load shift while driving.

c

Avoid abrupt starts, acceleration or stops.

cAvoid sharp turns or lane changes.

cAlways drive your vehicle at a moderate

speed.

c

Always block the wheels on both vehicle

and trailer when parking. Parking on a

slope is not recommended; however, if

you must do so, and if your vehicle is

equipped with automatic transmission,

first block the wheels and apply the park-

ing brake, and then move the transmis-

sion shift lever into the P position. If you

move the shift lever to the P position

before blocking the wheels and applying

9-16

ZX