NISSAN TEANA 2003 Service Manual

Manufacturer: NISSAN, Model Year: 2003, Model line: TEANA, Model: NISSAN TEANA 2003Pages: 3502, PDF Size: 74.56 MB

Page 201 of 3502

TROUBLE DIAGNOSIS FOR SYMPTOMS

AT-193

D

E

F

G

H

I

J

K

L

MA

B

AT

4. DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT- 2 2 5 , "

Control Valve Assembly and Accumulators" .

2. Check following items:

–Torque converter clutch control valve

–Torque converter clutch solenoid valve

–Torque converter relief valve

–Pilot valve

–Pilot filter

3. Remove A/T. Refer to AT- 2 5 5 , "

Disassembly" .

4. Check the following items:

–Torque converter. Refer to AT-255, "Disassembly" .

OK or NG

OK >> GO TO 5.

NG >> Repair or replace damaged parts.

5. SYMPTOM CHECK

Check again. Refer to AT- 5 0 , "

Cruise Test — Part 1" .

OK or NG

OK >>INSPECTION END

NG >> GO TO 6.

6. CHECK TCM

1. Check TCM input/output signals. Refer to AT- 6 4 , "

TCM Terminals and Reference Value" .

2. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

OK or NG

OK >>INSPECTION END

NG >> Repair or replace damaged parts.

A/T Does Not Hold Lock-up ConditionBCS0014L

SYMPTOM:

A/T does not hold lock-up condition for more than 30 seconds on “Cruise Test — Part 1”.

DIAGNOSTIC PROCEDURE

1. CHECK SELF-DIAGNOSTIC RESULTS

Perform self-diagnosis. Refer to AT- 6 9 , "

SELF-DIAGNOSTIC RESULT MODE" or AT- 7 6 , "Diagnostic Proce-

dure Without CONSULT-II" .

Is any malfunction detected by self-diagnostic results?

YES >> Check the malfunctioning systems. Refer to AT- 6 9 , "SELF-DIAGNOSTIC RESULT MODE" or AT-

77, "Judgement of Self-Diagnosis Code" .

NO >> GO TO 2.

2. CHECK A/T FLUID CONDITION

1. Remove oil pan. Refer to AT- 2 4 6 , "

Components" .

2. Check A/T fluid condition. Refer to AT- 4 3 , "

A/T Fluid Condition Check" .

OK or NG

OK >> GO TO 4.

NG >> GO TO 3.

Page 202 of 3502

AT-194

TROUBLE DIAGNOSIS FOR SYMPTOMS

3. DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT- 2 2 5 , "

Control Valve Assembly and Accumulators" .

2. Check the following items:

–Torque converter clutch control valve

–Torque converter clutch solenoid valve

–Pilot valve

–Pilot filter

3. Disassemble A/T. Refer to AT- 2 5 5 , "

Disassembly" .

4. Check the following items:

–Torque converter. Refer to AT- 2 5 5 , "Disassembly" .

–Oil pump assembly. Refer to AT- 2 7 5 , "Oil Pump" .

OK or NG

OK >> GO TO 5.

NG >> Repair or replace damaged parts.

4. DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT- 2 2 5 , "

Control Valve Assembly and Accumulators" .

2. Check the following items:

–Torque converter clutch control valve

–Torque converter clutch solenoid valve

–Pilot valve

–Pilot filter

OK or NG

OK >> GO TO 5.

NG >> Repair or replace damaged parts.

5. SYMPTOM CHECK

Check again. Refer to AT- 5 0 , "

Cruise Test — Part 1" .

OK or NG

OK >>INSPECTION END

NG >> GO TO 6.

6. CHECK TCM

1. Check TCM input/output signals. Refer to AT- 6 4 , "

TCM Terminals and Reference Value" .

2. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

OK or NG

OK >>INSPECTION END

NG >> Repair or replace damaged parts.

Page 203 of 3502

TROUBLE DIAGNOSIS FOR SYMPTOMS

AT-195

D

E

F

G

H

I

J

K

L

MA

B

AT

Lock-up Is Not ReleasedBCS0014M

SYMPTOM:

Lock-up is not released when accelerator pedal is released on “Cruise Test — Part 1”.

DIAGNOSTIC PROCEDURE

1. CHECK SELF-DIAGNOSTIC RESULTS

Perform self-diagnosis. Refer to EC-82, "

SELF-DIAG RESULTS MODE" (QR engine) or EC-427, "SELF-

DIAG RESULTS MODE" (VQ engine).

Is any malfunction detected by self-diagnostic results?

YES >> Check the malfunctioning systems. Refer to EC-82, "SELF-DIAG RESULTS MODE" (QR engine)

or EC-427, "

SELF-DIAG RESULTS MODE" (VQ engine).

NO >> GO TO 2.

2. SYMPTOM CHECK

Check again. Refer to AT- 5 0 , "

Cruise Test — Part 1" .

OK or NG

OK >>INSPECTION END

NG >> GO TO 3.

3. CHECK TCM

1. Check TCM input/output signals. Refer to AT- 6 4 , "

TCM Terminals and Reference Value" .

2. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

OK or NG

OK >>INSPECTION END

NG >> Repair or replace damaged parts.

Engine Speed Does Not Return To Idle (Light Braking D4 → D3 )BCS0014N

SYMPTOM:

Engine speed does not smoothly return to idle when A/T shifts from D4 to D3 on “Cruise Test — Part

1”.

DIAGNOSTIC PROCEDURE

1. CHECK SELF-DIAGNOSTIC RESULTS

Perform self-diagnosis. Refer to AT- 6 9 , "

SELF-DIAGNOSTIC RESULT MODE" or AT- 7 6 , "Diagnostic Proce-

dure Without CONSULT-II" .

Is any malfunction detected by self-diagnostic results?

YES >> Check the malfunctioning systems. Refer to AT- 6 9 , "SELF-DIAGNOSTIC RESULT MODE" or AT-

77, "Judgement of Self-Diagnosis Code" .

NO >> GO TO 2.

2. CHECK ACCELERATOR PEDAL POSITION SENSOR

Check accelerator pedal position sensor. Refer to EC-272, "

DTC P2138 APP SENSOR" (QR engine) or EC-

652, "DTC P2138 APP SENSOR" (VQ engine).

OK or NG

OK >> GO TO 3.

NG >> Repair or replace accelerator pedal position sensor.

Page 204 of 3502

AT-196

TROUBLE DIAGNOSIS FOR SYMPTOMS

3. CHECK A/T FLUID CONDITION

1. Remove oil pan. Refer to AT- 2 4 6 , "

Components" .

2. Check A/T fluid condition. Refer to AT- 4 3 , "

A/T Fluid Condition Check" .

OK or NG

OK >> GO TO 5.

NG >> GO TO 4.

4. DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT- 2 2 5 , "

Control Valve Assembly and Accumulators" .

2. Check the following items:

–Overrun clutch control valve

–Overrun clutch reducing valve

–Overrun clutch solenoid valve

3. Disassemble A/T. Refer to AT- 2 5 5 , "

Disassembly" .

4. Check the following items:

–Overrun clutch assembly. Refer to AT- 3 0 7 , "Forward and Overrun Clutches" .

OK or NG

OK >> GO TO 6.

NG >> Repair or replace damaged parts.

5. DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT- 2 2 5 , "

Control Valve Assembly and Accumulators" .

2. Check the following items:

–Overrun clutch control valve

–Overrun clutch reducing valve

–Overrun clutch solenoid valve

OK or NG

OK >> GO TO 6.

NG >> Repair or replace damaged parts.

6. SYMPTOM CHECK

Check again. Refer to AT- 5 0 , "

Cruise Test — Part 1" .

OK or NG

OK >>INSPECTION END

NG >> GO TO 7.

7. CHECK TCM

1. Check TCM input/output signals. Refer to AT- 6 4 , "

TCM Terminals and Reference Value" .

2. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

OK or NG

OK >>INSPECTION END

NG >> Repair or replace damaged parts.

Page 205 of 3502

TROUBLE DIAGNOSIS FOR SYMPTOMS

AT-197

D

E

F

G

H

I

J

K

L

MA

B

AT

A/T Does Not Shift: D4 → 33 , When A/T Selector Lever “D” → “3”BCS0014P

SYMPTOM:

A/T does not shift from D4 to 33 when changing A/T selector lever from “D” → “3” position on “Cruise

Te s t — P a r t 3 ” .

DIAGNOSTIC PROCEDURE

1. CHECK CAN COMMUNICATION LINE

Perform the self-diagnosis. Refer to AT- 6 9 , "

SELF-DIAGNOSTIC RESULT MODE" or AT- 7 6 , "Diagnostic Pro-

cedure Without CONSULT-II" .

Is a malfunction in CAN communication indicated in the results?

YES >> Check CAN communication line. Refer to AT- 1 3 3 , "CAN COMMUNICATION LINE" .

NO >> GO TO 2.

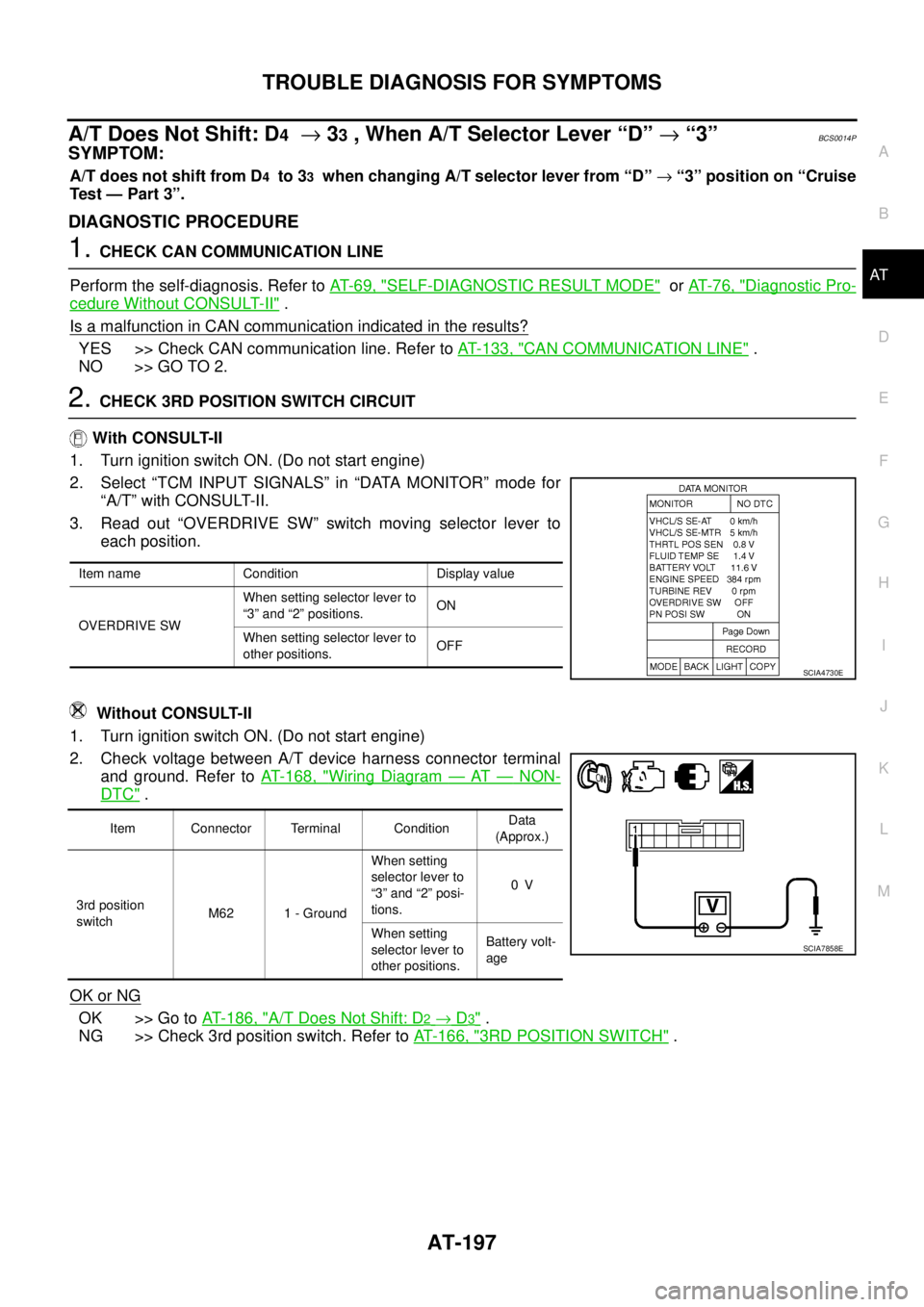

2. CHECK 3RD POSITION SWITCH CIRCUIT

With CONSULT-II

1. Turn ignition switch ON. (Do not start engine)

2. Select “TCM INPUT SIGNALS” in “DATA MONITOR” mode for

“A/T” with CONSULT-II.

3. Read out “OVERDRIVE SW” switch moving selector lever to

each position.

Without CONSULT-II

1. Turn ignition switch ON. (Do not start engine)

2. Check voltage between A/T device harness connector terminal

and ground. Refer to AT- 1 6 8 , "

Wiring Diagram — AT — NON-

DTC" .

OK or NG

OK >> Go to AT- 1 8 6 , "A/T Does Not Shift: D2 → D3" .

NG >> Check 3rd position switch. Refer to AT- 1 6 6 , "

3RD POSITION SWITCH" .

Item name Condition Display value

OVERDRIVE SWWhen setting selector lever to

“3” and “2” positions.ON

When setting selector lever to

other positions.OFF

SCIA4730E

Item Connector Terminal ConditionData

(Approx.)

3rd position

switchM62 1 - GroundWhen setting

selector lever to

“3” and “2” posi-

tions.0V

When setting

selector lever to

other positions.Battery volt-

age

SCIA7858E

Page 206 of 3502

AT-198

TROUBLE DIAGNOSIS FOR SYMPTOMS

A/T Does Not Shift: 33 → 22 , When Selector Lever “3” → “2” PositionBCS0014Q

SYMPTOM:

A/T does not shift from 33 to 22 when changing selector lever from “3” to “2” position on “Cruise Test

— Part 3”.

DIAGNOSTIC PROCEDURE

1. SYMPTOM CHECK

Check symptom. Refer to AT- 5 0 , "

Cruise Test — Part 1" .

Is

“A/T Does No Shift: D1 →D2 or Does Not Kickdown: D4 →D2 ” OK?

YES (With CONSULT-II)>>GO TO 2.

YES (Without CONSULT-II)>>GO TO 3.

NO >> Go to AT- 1 8 4 , "

A/T Does Not Shift: D1 → D2 or Does Not Kickdown: D4 → D2" .

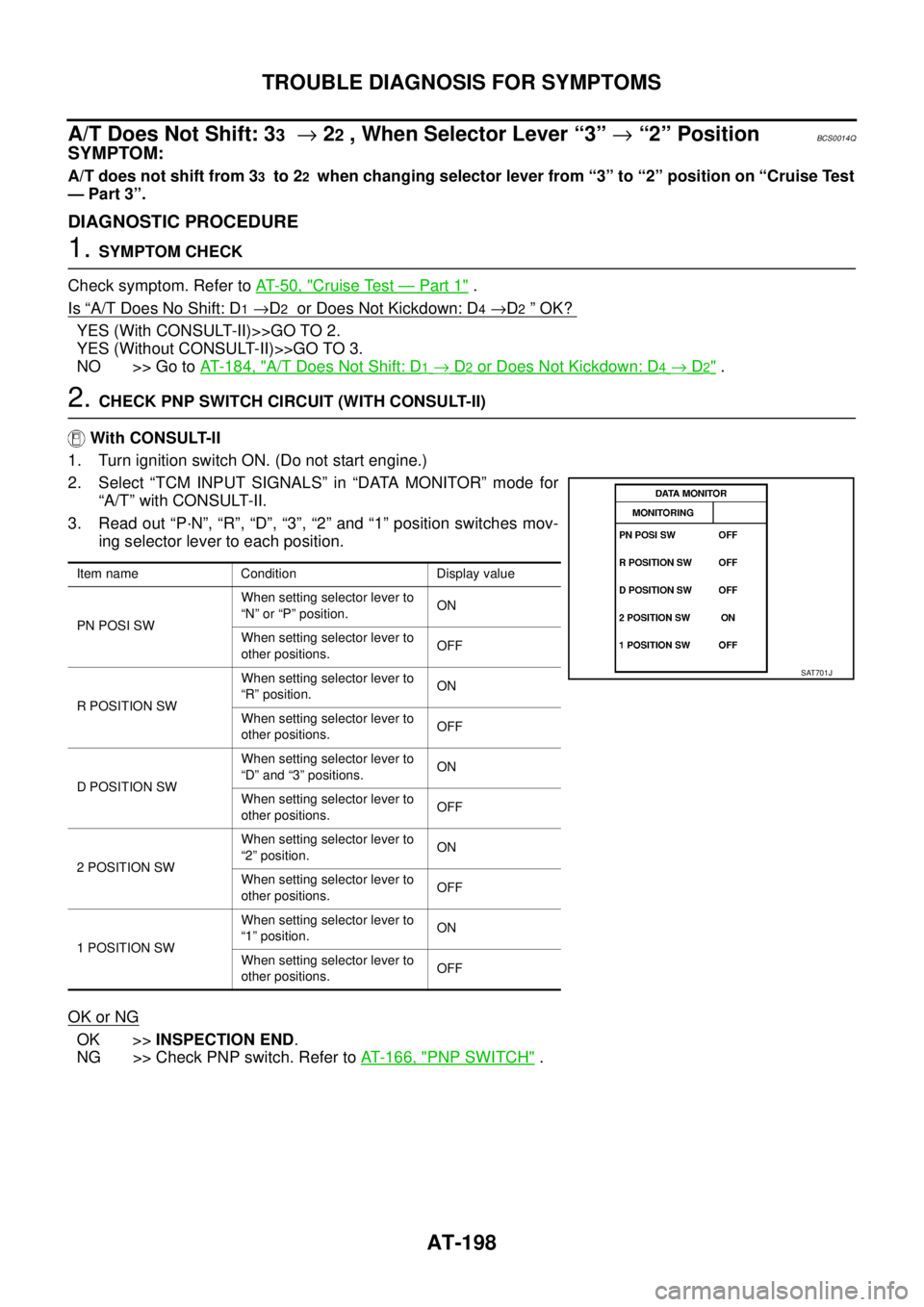

2. CHECK PNP SWITCH CIRCUIT (WITH CONSULT-II)

With CONSULT-II

1. Turn ignition switch ON. (Do not start engine.)

2. Select “TCM INPUT SIGNALS” in “DATA MONITOR” mode for

“A/T” with CONSULT-II.

3. Read out “P·N”, “R”, “D”, “3”, “2” and “1” position switches mov-

ing selector lever to each position.

OK or NG

OK >>INSPECTION END.

NG >> Check PNP switch. Refer to AT- 1 6 6 , "

PNP SWITCH" .

Item name Condition Display value

PN POSI SWWhen setting selector lever to

“N” or “P” position.ON

When setting selector lever to

other positions.OFF

R POSITION SWWhen setting selector lever to

“R” position.ON

When setting selector lever to

other positions.OFF

D POSITION SWWhen setting selector lever to

“D” and “3” positions.ON

When setting selector lever to

other positions.OFF

2 POSITION SWWhen setting selector lever to

“2” position.ON

When setting selector lever to

other positions.OFF

1 POSITION SWWhen setting selector lever to

“1” position.ON

When setting selector lever to

other positions.OFF

SAT701J

Page 207 of 3502

TROUBLE DIAGNOSIS FOR SYMPTOMS

AT-199

D

E

F

G

H

I

J

K

L

MA

B

AT

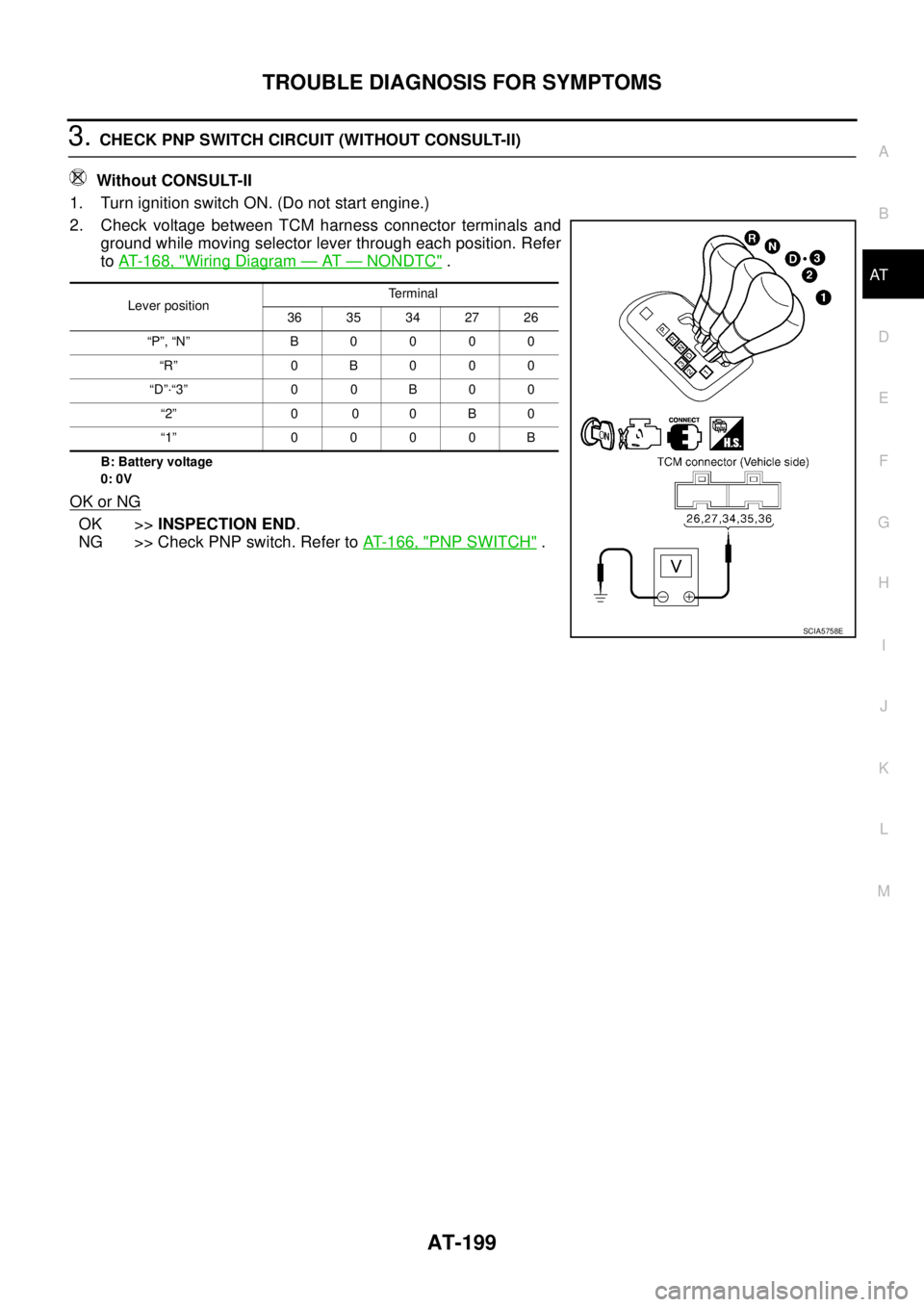

3. CHECK PNP SWITCH CIRCUIT (WITHOUT CONSULT-II)

Without CONSULT-II

1. Turn ignition switch ON. (Do not start engine.)

2. Check voltage between TCM harness connector terminals and

ground while moving selector lever through each position. Refer

to AT- 1 6 8 , "

Wiring Diagram — AT — NONDTC" .

B: Battery voltage

0: 0V

OK or NG

OK >>INSPECTION END.

NG >> Check PNP switch. Refer to AT- 1 6 6 , "

PNP SWITCH" .

Lever positionTerminal

36 35 34 27 26

“P”, “N” B 0 0 0 0

“R” 0 B 0 0 0

“D”·“3” 0 0 B 0 0

“2” 0 0 0 B 0

“1” 0 0 0 0 B

SCIA5758E

Page 208 of 3502

AT-200

TROUBLE DIAGNOSIS FOR SYMPTOMS

A/T Does Not Shift: 22 → 11 , When Selector Lever “2” → “1” PositionBCS0014R

SYMPTOM:

A/T does not shift from 22 to 11 when changing selector lever from “2” to “1” position on “Cruise Test

— Part 3”.

DIAGNOSTIC PROCEDURE

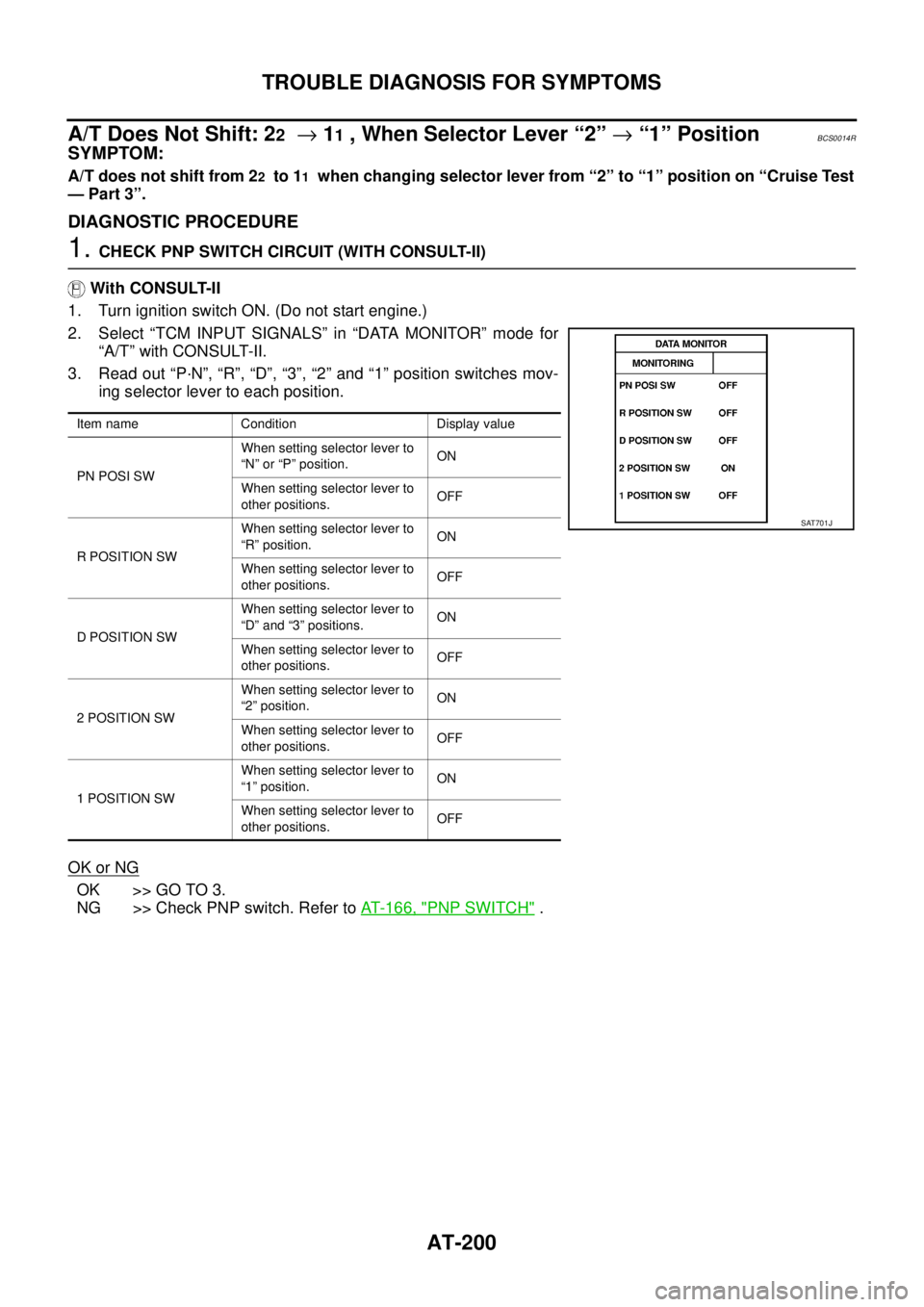

1. CHECK PNP SWITCH CIRCUIT (WITH CONSULT-II)

With CONSULT-II

1. Turn ignition switch ON. (Do not start engine.)

2. Select “TCM INPUT SIGNALS” in “DATA MONITOR” mode for

“A/T” with CONSULT-II.

3. Read out “P·N”, “R”, “D”, “3”, “2” and “1” position switches mov-

ing selector lever to each position.

OK or NG

OK >> GO TO 3.

NG >> Check PNP switch. Refer to AT- 1 6 6 , "

PNP SWITCH" .

Item name Condition Display value

PN POSI SWWhen setting selector lever to

“N” or “P” position.ON

When setting selector lever to

other positions.OFF

R POSITION SWWhen setting selector lever to

“R” position.ON

When setting selector lever to

other positions.OFF

D POSITION SWWhen setting selector lever to

“D” and “3” positions.ON

When setting selector lever to

other positions.OFF

2 POSITION SWWhen setting selector lever to

“2” position.ON

When setting selector lever to

other positions.OFF

1 POSITION SWWhen setting selector lever to

“1” position.ON

When setting selector lever to

other positions.OFF

SAT701J

Page 209 of 3502

TROUBLE DIAGNOSIS FOR SYMPTOMS

AT-201

D

E

F

G

H

I

J

K

L

MA

B

AT

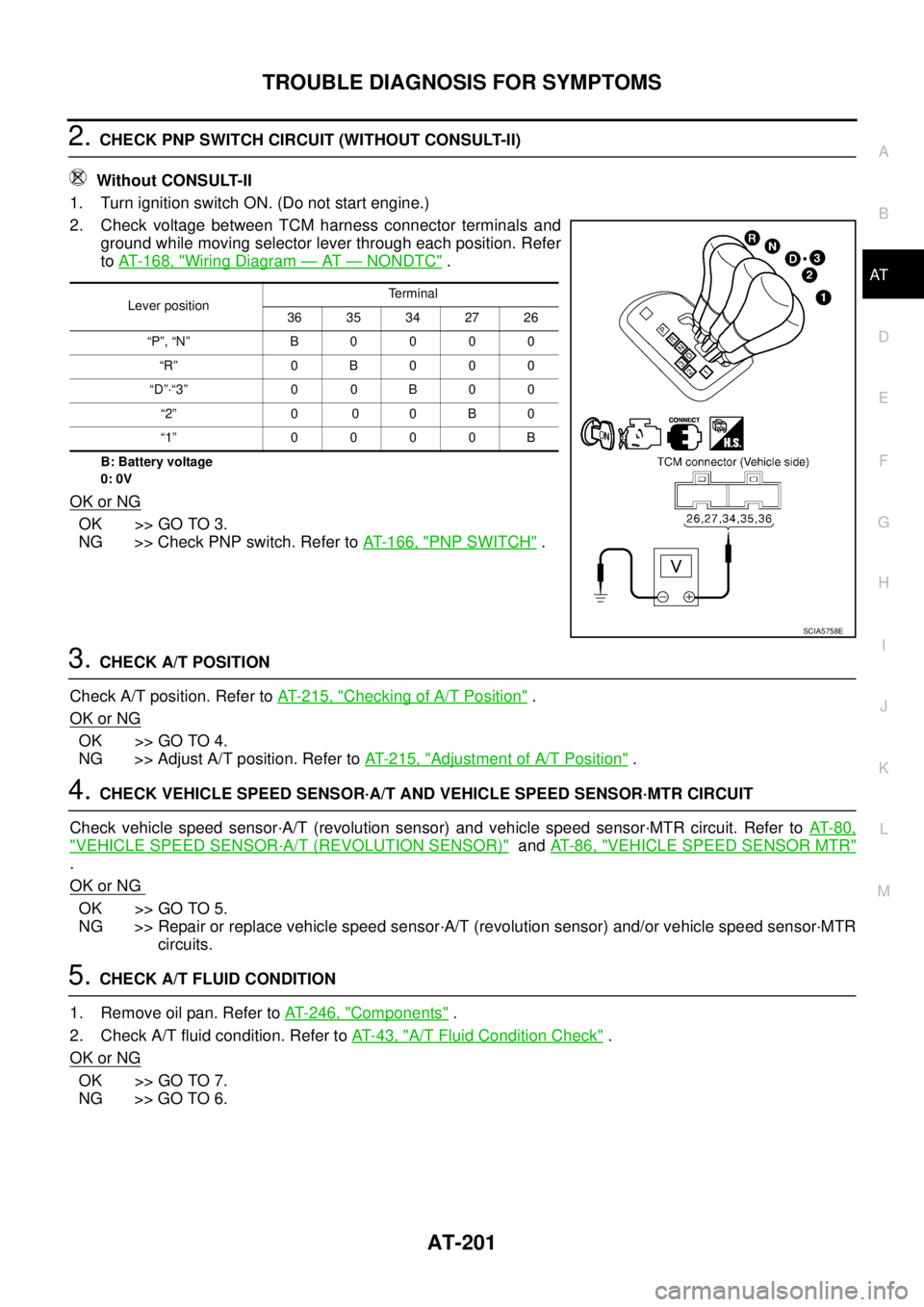

2. CHECK PNP SWITCH CIRCUIT (WITHOUT CONSULT-II)

Without CONSULT-II

1. Turn ignition switch ON. (Do not start engine.)

2. Check voltage between TCM harness connector terminals and

ground while moving selector lever through each position. Refer

to AT- 1 6 8 , "

Wiring Diagram — AT — NONDTC" .

B: Battery voltage

0: 0V

OK or NG

OK >> GO TO 3.

NG >> Check PNP switch. Refer to AT- 1 6 6 , "

PNP SWITCH" .

3. CHECK A/T POSITION

Check A/T position. Refer to AT- 2 1 5 , "

Checking of A/T Position" .

OK or NG

OK >> GO TO 4.

NG >> Adjust A/T position. Refer to AT- 2 1 5 , "

Adjustment of A/T Position" .

4. CHECK VEHICLE SPEED SENSOR·A/T AND VEHICLE SPEED SENSOR·MTR CIRCUIT

Check vehicle speed sensor·A/T (revolution sensor) and vehicle speed sensor·MTR circuit. Refer to AT- 8 0 ,

"VEHICLE SPEED SENSOR·A/T (REVOLUTION SENSOR)" and AT- 8 6 , "VEHICLE SPEED SENSOR MTR"

.

OK or NG

OK >> GO TO 5.

NG >> Repair or replace vehicle speed sensor·A/T (revolution sensor) and/or vehicle speed sensor·MTR

circuits.

5. CHECK A/T FLUID CONDITION

1. Remove oil pan. Refer to AT- 2 4 6 , "

Components" .

2. Check A/T fluid condition. Refer to AT- 4 3 , "

A/T Fluid Condition Check" .

OK or NG

OK >> GO TO 7.

NG >> GO TO 6.

Lever positionTerminal

36 35 34 27 26

“P”, “N” B 0 0 0 0

“R” 0 B 0 0 0

“D”·“3” 0 0 B 0 0

“2” 0 0 0 B 0

“1” 0 0 0 0 B

SCIA5758E

Page 210 of 3502

AT-202

TROUBLE DIAGNOSIS FOR SYMPTOMS

6. DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT- 2 2 5 , "

Control Valve Assembly and Accumulators" .

2. Check the following items:

–Shift valve A

–Shift solenoid valve A

–Overrun clutch control valve

–Overrun clutch solenoid valve

3. Disassemble A/T. Refer to AT- 2 5 5 , "

Disassembly" .

4. Check the following items:

–Servo piston assembly

–Brake band

OK or NG

OK >> GO TO 7.

NG >> Repair or replace damaged parts.

7. SYMPTOM CHECK

Check again. Refer to AT- 5 2 , "

Cruise Test — Part 3" .

OK or NG

OK >>INSPECTION END

NG >> GO TO 8.

8. CHECK TCM

1. Check TCM input/output signals. Refer to AT- 6 4 , "

TCM Terminals and Reference Value" .

2. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

OK or NG

OK >>INSPECTION END

NG >> Repair or replace damaged parts.