wiring NISSAN TEANA 2003 Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: TEANA, Model: NISSAN TEANA 2003Pages: 3502, PDF Size: 74.56 MB

Page 135 of 3502

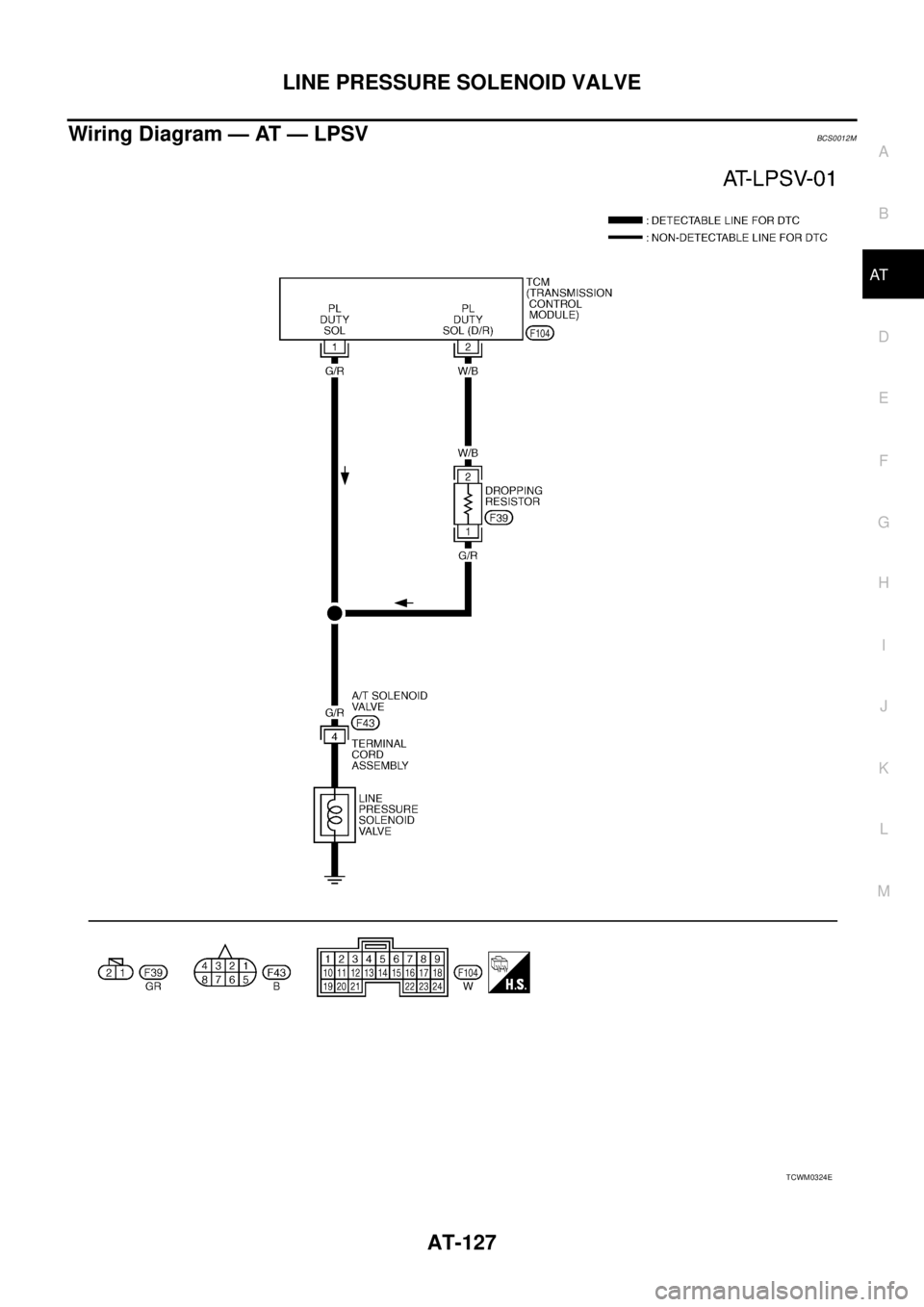

LINE PRESSURE SOLENOID VALVE

AT-127

D

E

F

G

H

I

J

K

L

MA

B

AT

Wiring Diagram — AT — LPSVBCS0012M

TCWM0324E

Page 141 of 3502

CAN COMMUNICATION LINE

AT-133

D

E

F

G

H

I

J

K

L

MA

B

AT

CAN COMMUNICATION LINEPFP:31940

DescriptionBCS0012P

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent malfunction detection ability.

Many electronic control units are equipped onto a vehicle, and each control unit shares information and links

with other control units during operation (not independent). In CAN communication, control units are con-

nected with 2 communication lines (CAN-H line, CAN-L line) allowing a high rate of information transmission

with less wiring. Each control unit transmits/receives data but selectively reads required data only.

On Board Diagnosis LogicBCS0012Q

Diagnostic trouble code “CAN COMM CIRCUIT” with CONSULT-II or 12th judgement flicker without CON-

SULT-II is detected when TCM cannot communicate to other control units.

Possible CauseBCS0012R

Harness or connector

(CAN communication line is open or shorted.)

DTC Confirmation ProcedureBCS0012S

CAUTION:

If performing this “DTC Confirmation Procedure” again, always turn ignition switch OFF and wait at

least 10 seconds before continuing.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-II

1. Turn ignition switch ON. (Do not start engine.)

2. Select “DATA MONITOR” mode for “A/T” with CONSULT-II.

3. Wait at least 6 seconds or start engine and wait for at least 6

seconds.

4. If DTC is detected, go to AT- 1 3 5 , "

Diagnostic Procedure" .

WITHOUT CONSULT-II

1. Turn ignition switch ON.

2. Wait at least 6 seconds or start engine and wait at least 6 seconds.

3. Perform self-diagnosis. Refer to AT- 7 6 , "

Diagnostic Procedure Without CONSULT-II" .

4. If the check result is NG, go to AT- 1 3 5 , "

Diagnostic Procedure" .

BCIA0031E

Page 142 of 3502

AT-134

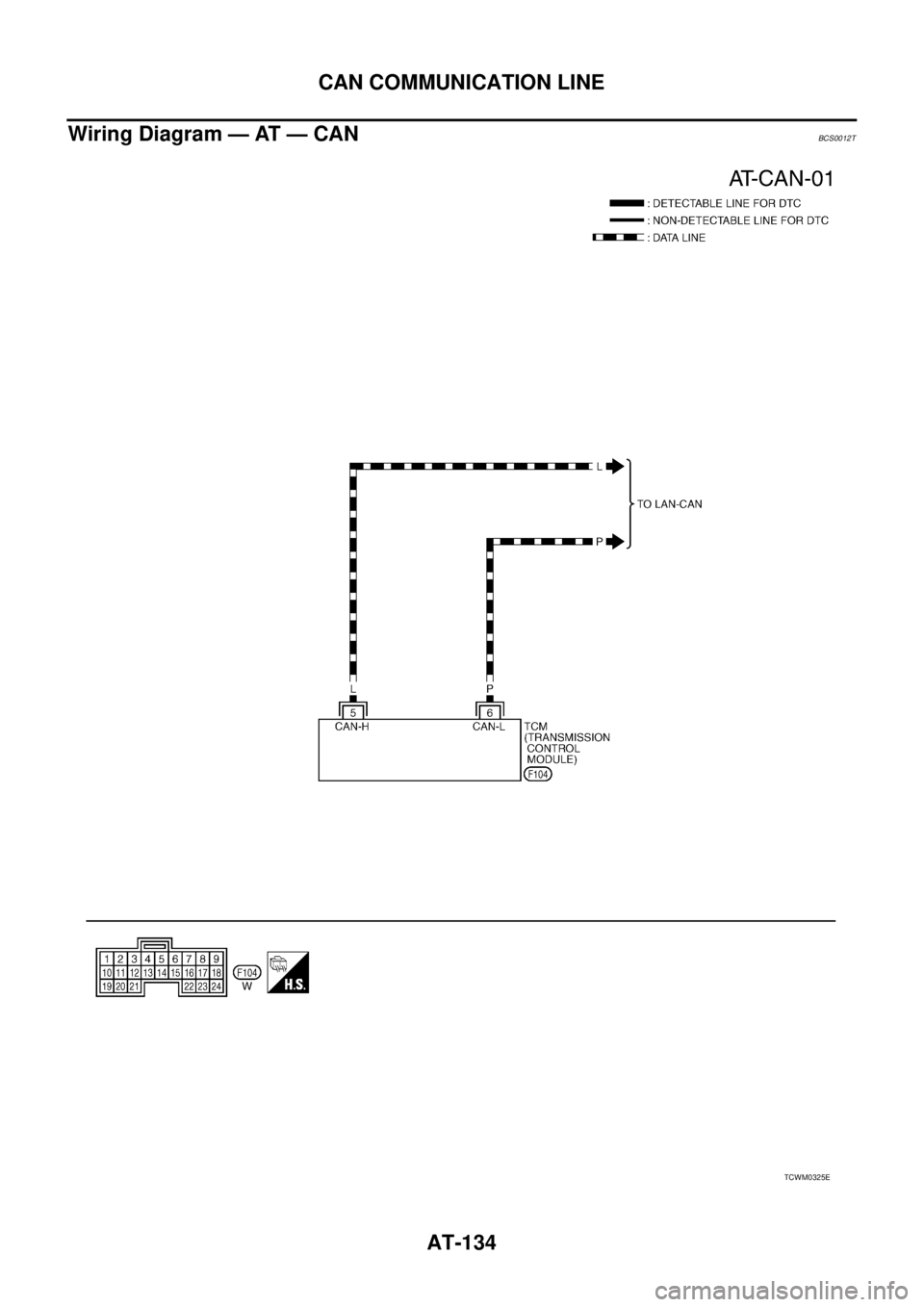

CAN COMMUNICATION LINE

Wiring Diagram — AT — CANBCS0012T

TCWM0325E

Page 146 of 3502

AT-138

A/T 1ST GEAR FUNCTION

Diagnostic ProcedureBCS00135

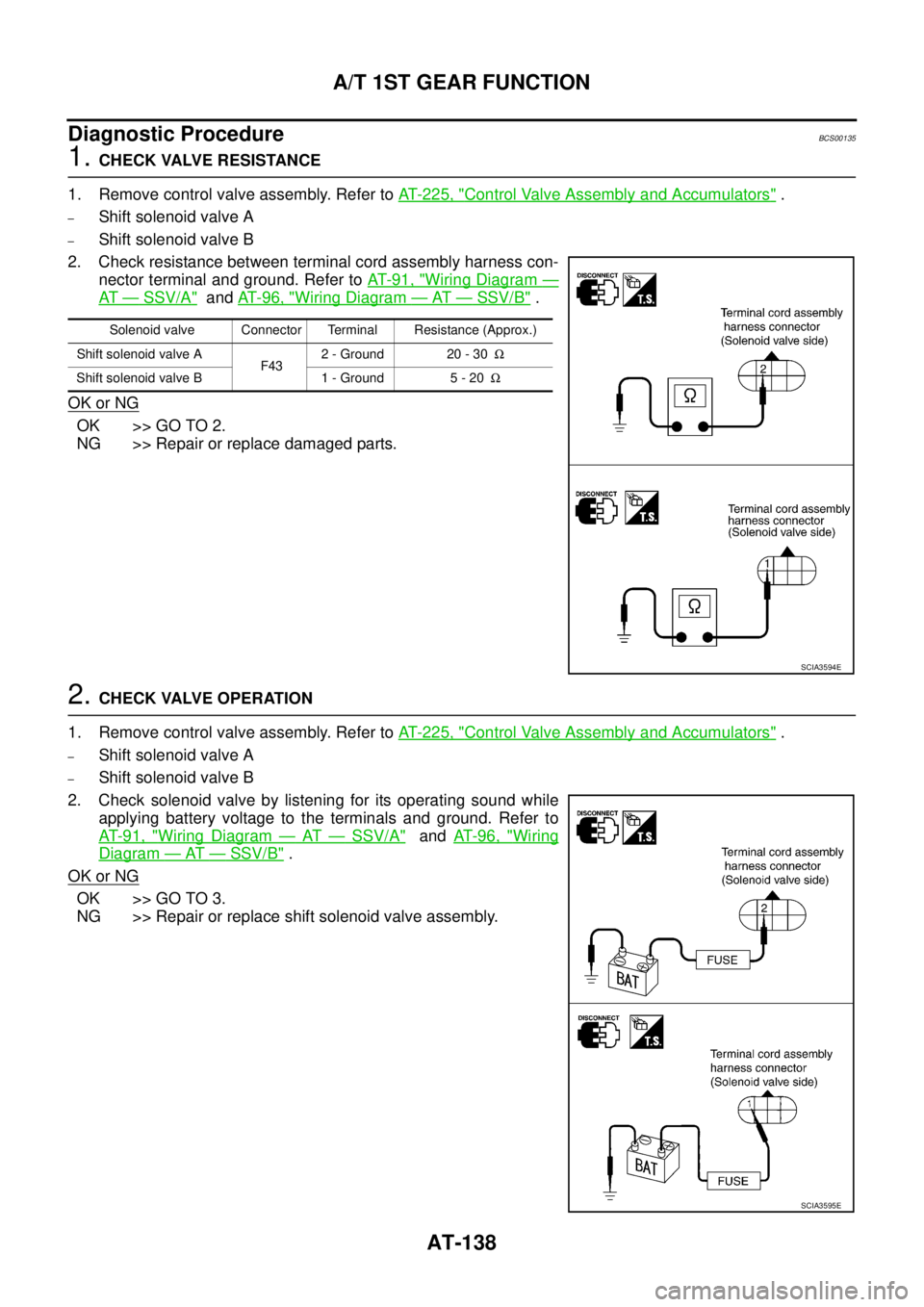

1. CHECK VALVE RESISTANCE

1. Remove control valve assembly. Refer to AT- 2 2 5 , "

Control Valve Assembly and Accumulators" .

–Shift solenoid valve A

–Shift solenoid valve B

2. Check resistance between terminal cord assembly harness con-

nector terminal and ground. Refer to AT- 9 1 , "

Wiring Diagram —

AT — SSV/A" and AT- 9 6 , "Wiring Diagram — AT — SSV/B" .

OK or NG

OK >> GO TO 2.

NG >> Repair or replace damaged parts.

2. CHECK VALVE OPERATION

1. Remove control valve assembly. Refer to AT- 2 2 5 , "

Control Valve Assembly and Accumulators" .

–Shift solenoid valve A

–Shift solenoid valve B

2. Check solenoid valve by listening for its operating sound while

applying battery voltage to the terminals and ground. Refer to

AT- 9 1 , "

Wiring Diagram — AT — SSV/A" and AT- 9 6 , "Wiring

Diagram — AT — SSV/B" .

OK or NG

OK >> GO TO 3.

NG >> Repair or replace shift solenoid valve assembly.

Solenoid valve Connector Terminal Resistance (Approx.)

Shift solenoid valve A

F432 - Ground 20 - 30Ω

Shift solenoid valve B 1 - Ground 5 - 20Ω

SCIA3594E

SCIA3595E

Page 150 of 3502

AT-142

A/T 2ND GEAR FUNCTION

Diagnostic ProcedureBCS0013A

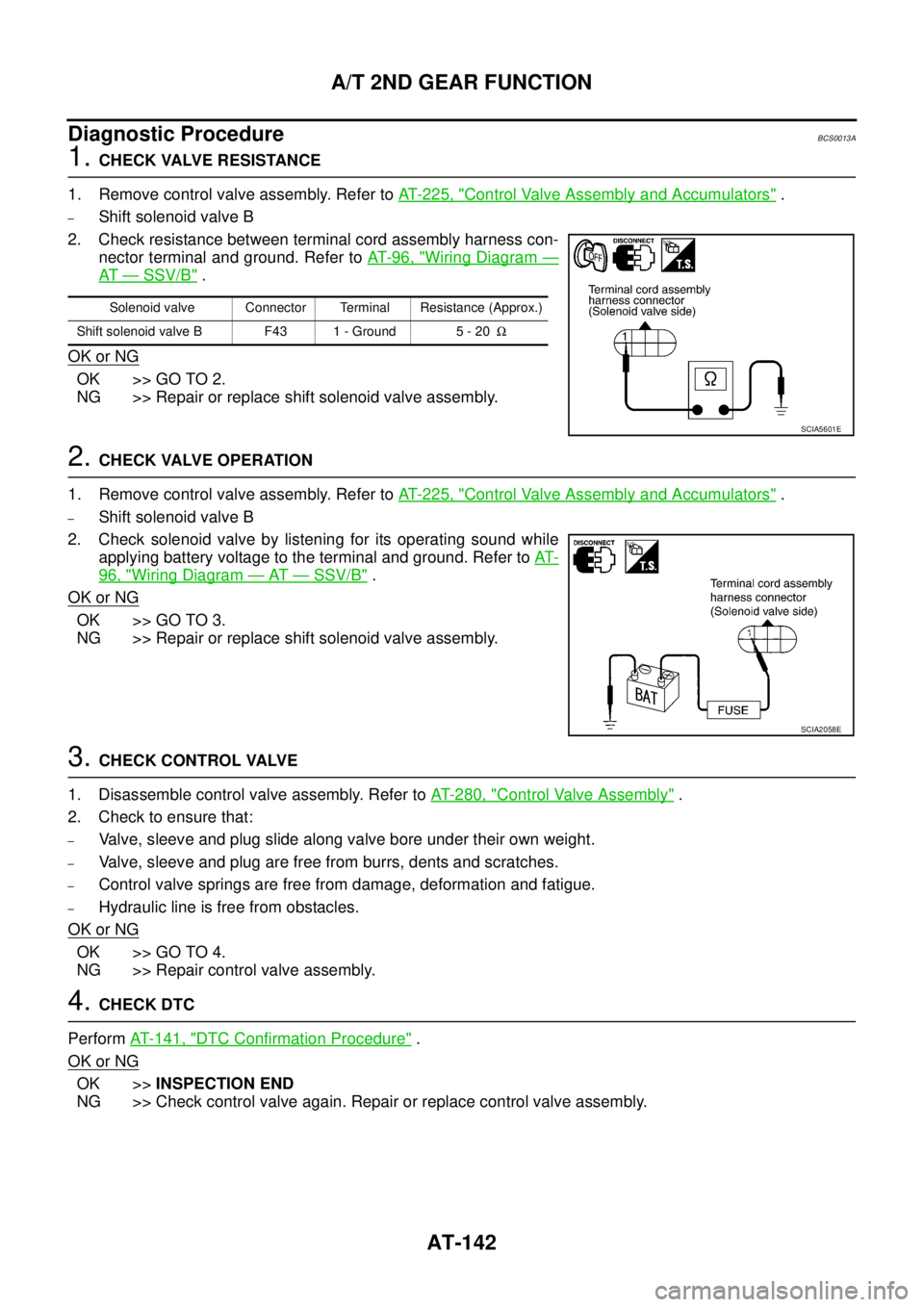

1. CHECK VALVE RESISTANCE

1. Remove control valve assembly. Refer to AT- 2 2 5 , "

Control Valve Assembly and Accumulators" .

–Shift solenoid valve B

2. Check resistance between terminal cord assembly harness con-

nector terminal and ground. Refer to AT- 9 6 , "

Wiring Diagram —

AT — SSV/B" .

OK or NG

OK >> GO TO 2.

NG >> Repair or replace shift solenoid valve assembly.

2. CHECK VALVE OPERATION

1. Remove control valve assembly. Refer to AT- 2 2 5 , "

Control Valve Assembly and Accumulators" .

–Shift solenoid valve B

2. Check solenoid valve by listening for its operating sound while

applying battery voltage to the terminal and ground. Refer to AT-

96, "Wiring Diagram — AT — SSV/B" .

OK or NG

OK >> GO TO 3.

NG >> Repair or replace shift solenoid valve assembly.

3. CHECK CONTROL VALVE

1. Disassemble control valve assembly. Refer to AT- 2 8 0 , "

Control Valve Assembly" .

2. Check to ensure that:

–Valve, sleeve and plug slide along valve bore under their own weight.

–Valve, sleeve and plug are free from burrs, dents and scratches.

–Control valve springs are free from damage, deformation and fatigue.

–Hydraulic line is free from obstacles.

OK or NG

OK >> GO TO 4.

NG >> Repair control valve assembly.

4. CHECK DTC

Perform AT- 1 4 1 , "

DTC Confirmation Procedure" .

OK or NG

OK >>INSPECTION END

NG >> Check control valve again. Repair or replace control valve assembly.

Solenoid valve Connector Terminal Resistance (Approx.)

Shift solenoid valve B F43 1 - Ground 5 - 20Ω

SCIA5601E

SCIA2058E

Page 153 of 3502

A/T 3RD GEAR FUNCTION

AT-145

D

E

F

G

H

I

J

K

L

MA

B

AT

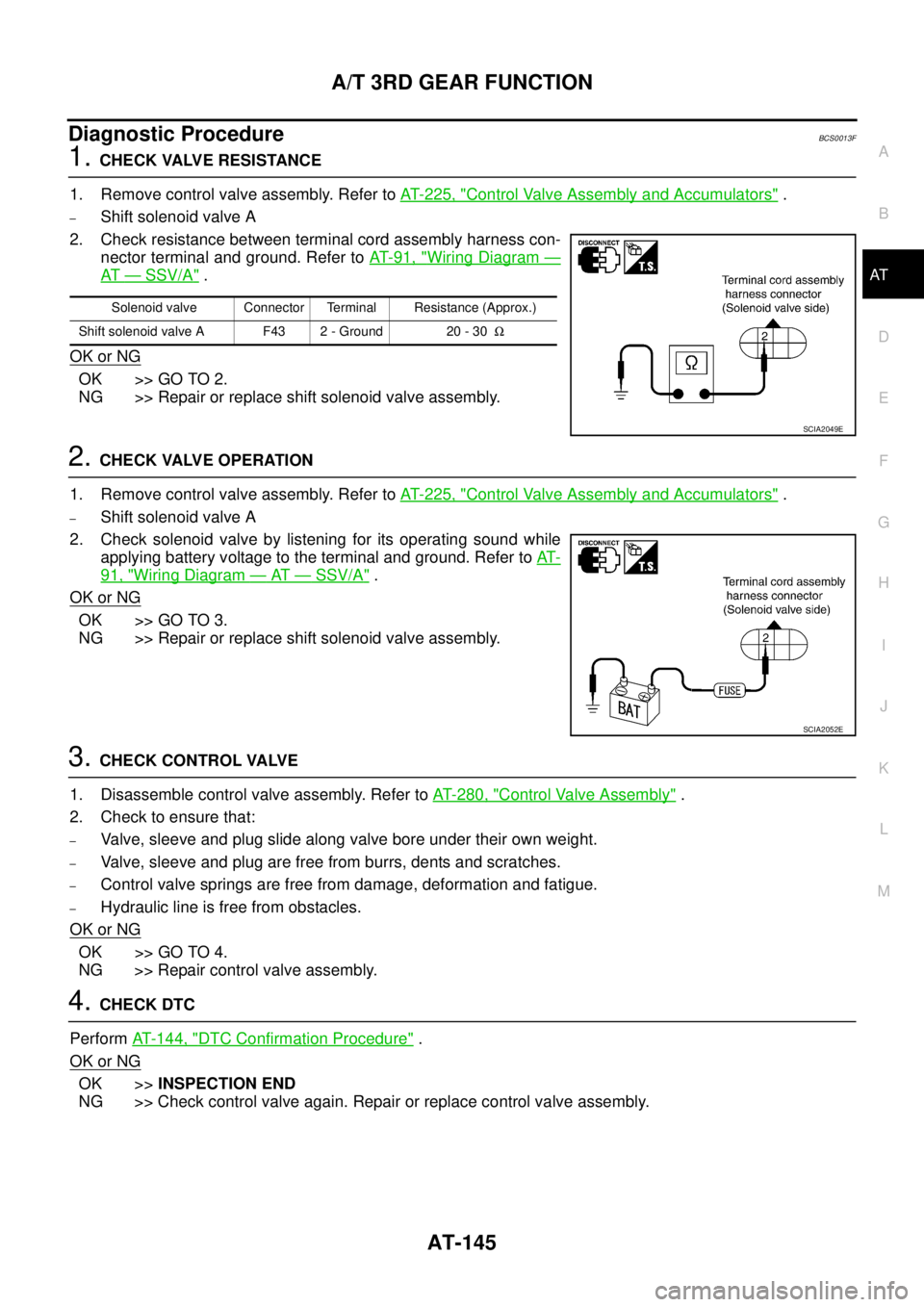

Diagnostic ProcedureBCS0013F

1. CHECK VALVE RESISTANCE

1. Remove control valve assembly. Refer to AT- 2 2 5 , "

Control Valve Assembly and Accumulators" .

–Shift solenoid valve A

2. Check resistance between terminal cord assembly harness con-

nector terminal and ground. Refer to AT- 9 1 , "

Wiring Diagram —

AT — SSV/A" .

OK or NG

OK >> GO TO 2.

NG >> Repair or replace shift solenoid valve assembly.

2. CHECK VALVE OPERATION

1. Remove control valve assembly. Refer to AT- 2 2 5 , "

Control Valve Assembly and Accumulators" .

–Shift solenoid valve A

2. Check solenoid valve by listening for its operating sound while

applying battery voltage to the terminal and ground. Refer to AT-

91, "Wiring Diagram — AT — SSV/A" .

OK or NG

OK >> GO TO 3.

NG >> Repair or replace shift solenoid valve assembly.

3. CHECK CONTROL VALVE

1. Disassemble control valve assembly. Refer to AT- 2 8 0 , "

Control Valve Assembly" .

2. Check to ensure that:

–Valve, sleeve and plug slide along valve bore under their own weight.

–Valve, sleeve and plug are free from burrs, dents and scratches.

–Control valve springs are free from damage, deformation and fatigue.

–Hydraulic line is free from obstacles.

OK or NG

OK >> GO TO 4.

NG >> Repair control valve assembly.

4. CHECK DTC

Perform AT- 1 4 4 , "

DTC Confirmation Procedure" .

OK or NG

OK >>INSPECTION END

NG >> Check control valve again. Repair or replace control valve assembly.

Solenoid valve Connector Terminal Resistance (Approx.)

Shift solenoid valve A F43 2 - Ground 20 - 30Ω

SCIA2049E

SCIA2052E

Page 156 of 3502

AT-148

A/T 4TH GEAR FUNCTION

2. CHECK LINE PRESSURE

Perform line pressure test. Refer to AT- 4 6 , "

LINE PRESSURE TEST" .

OK or NG

OK >> GO TO 3.

NG >> GO TO 7.

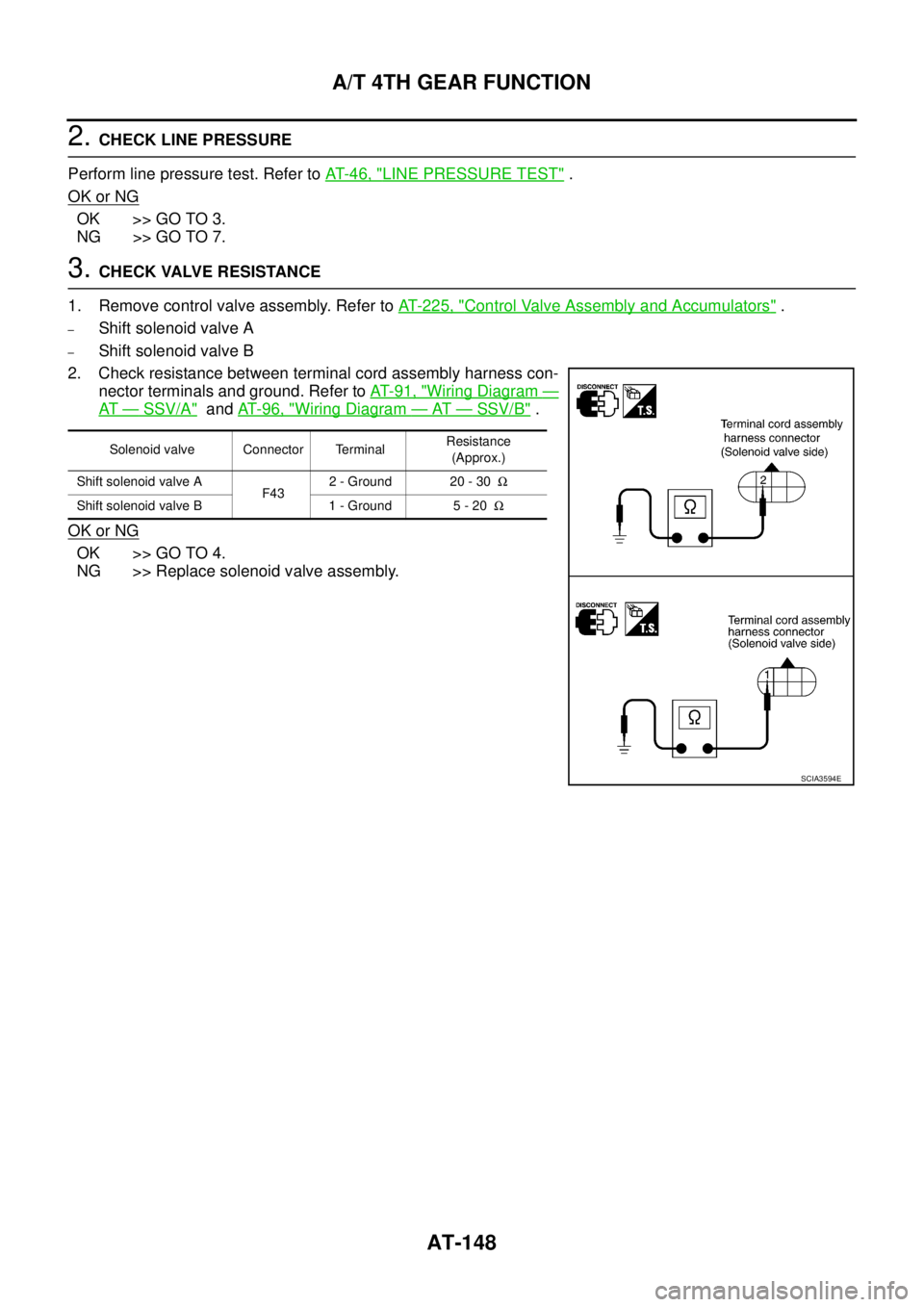

3. CHECK VALVE RESISTANCE

1. Remove control valve assembly. Refer to AT- 2 2 5 , "

Control Valve Assembly and Accumulators" .

–Shift solenoid valve A

–Shift solenoid valve B

2. Check resistance between terminal cord assembly harness con-

nector terminals and ground. Refer to AT- 9 1 , "

Wiring Diagram —

AT — SSV/A" and AT- 9 6 , "Wiring Diagram — AT — SSV/B" .

OK or NG

OK >> GO TO 4.

NG >> Replace solenoid valve assembly.

Solenoid valve Connector TerminalResistance

(Approx.)

Shift solenoid valve A

F432 - Ground 20 - 30Ω

Shift solenoid valve B 1 - Ground 5 - 20Ω

SCIA3594E

Page 157 of 3502

A/T 4TH GEAR FUNCTION

AT-149

D

E

F

G

H

I

J

K

L

MA

B

AT

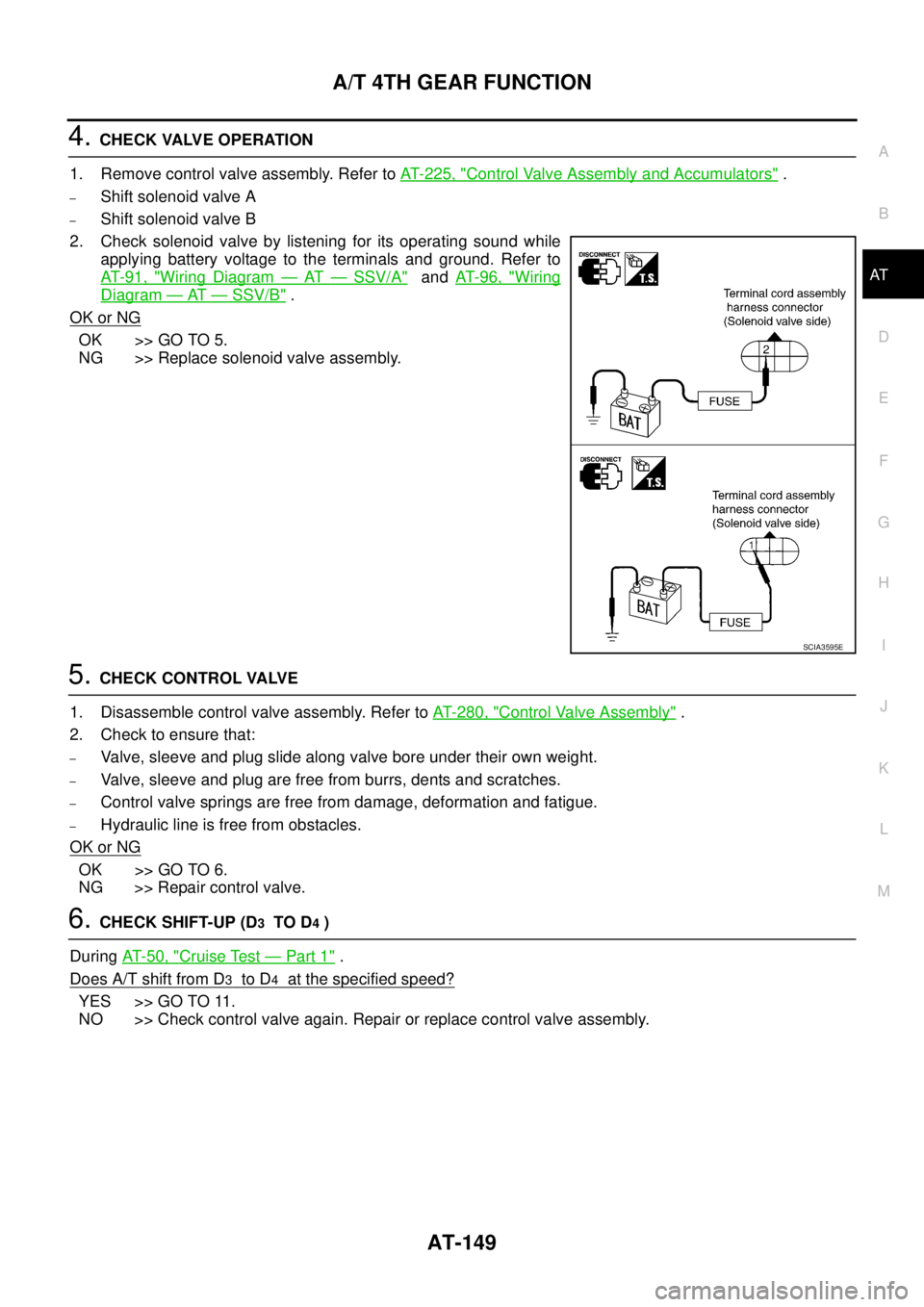

4. CHECK VALVE OPERATION

1. Remove control valve assembly. Refer to AT- 2 2 5 , "

Control Valve Assembly and Accumulators" .

–Shift solenoid valve A

–Shift solenoid valve B

2. Check solenoid valve by listening for its operating sound while

applying battery voltage to the terminals and ground. Refer to

AT- 9 1 , "

Wiring Diagram — AT — SSV/A" and AT- 9 6 , "Wiring

Diagram — AT — SSV/B" .

OK or NG

OK >> GO TO 5.

NG >> Replace solenoid valve assembly.

5. CHECK CONTROL VALVE

1. Disassemble control valve assembly. Refer to AT- 2 8 0 , "

Control Valve Assembly" .

2. Check to ensure that:

–Valve, sleeve and plug slide along valve bore under their own weight.

–Valve, sleeve and plug are free from burrs, dents and scratches.

–Control valve springs are free from damage, deformation and fatigue.

–Hydraulic line is free from obstacles.

OK or NG

OK >> GO TO 6.

NG >> Repair control valve.

6. CHECK SHIFT-UP (D3 TO D4 )

During AT- 5 0 , "

Cruise Test — Part 1" .

Does A/T shift from D

3 to D4 at the specified speed?

YES >> GO TO 11.

NO >> Check control valve again. Repair or replace control valve assembly.

SCIA3595E

Page 158 of 3502

AT-150

A/T 4TH GEAR FUNCTION

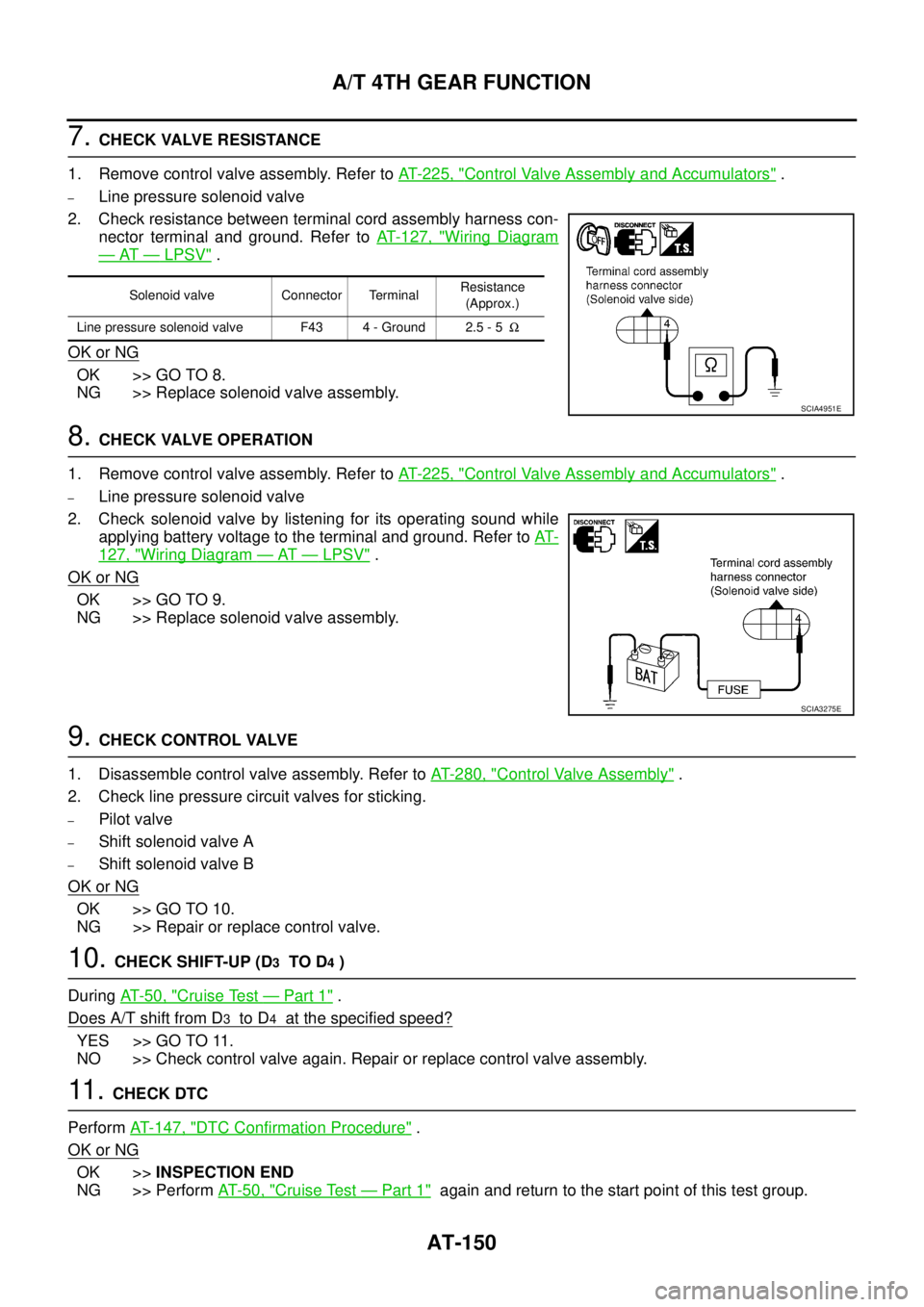

7. CHECK VALVE RESISTANCE

1. Remove control valve assembly. Refer to AT- 2 2 5 , "

Control Valve Assembly and Accumulators" .

–Line pressure solenoid valve

2. Check resistance between terminal cord assembly harness con-

nector terminal and ground. Refer to AT- 1 2 7 , "

Wiring Diagram

— AT — LPSV" .

OK or NG

OK >> GO TO 8.

NG >> Replace solenoid valve assembly.

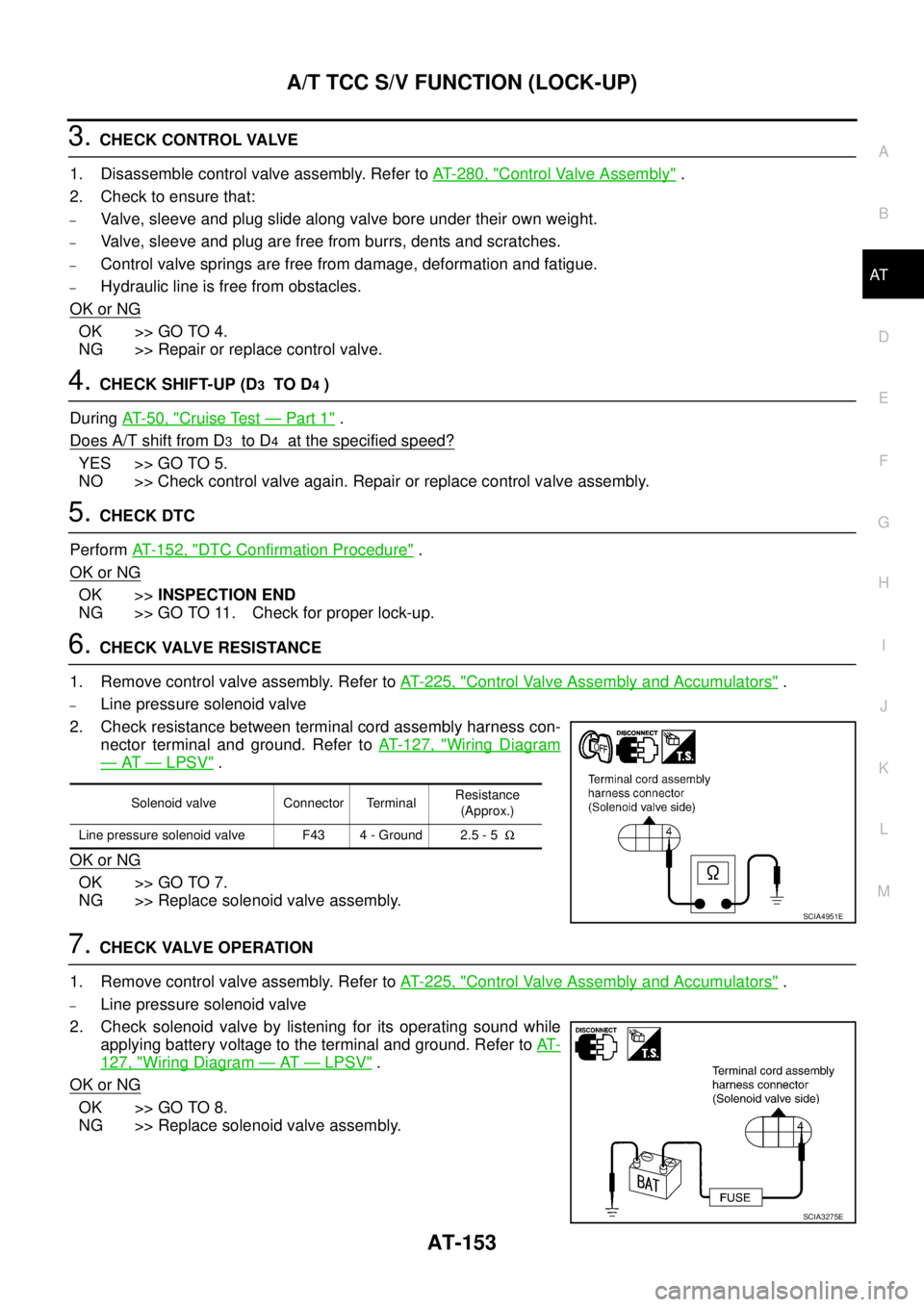

8. CHECK VALVE OPERATION

1. Remove control valve assembly. Refer to AT- 2 2 5 , "

Control Valve Assembly and Accumulators" .

–Line pressure solenoid valve

2. Check solenoid valve by listening for its operating sound while

applying battery voltage to the terminal and ground. Refer to AT-

127, "Wiring Diagram — AT — LPSV" .

OK or NG

OK >> GO TO 9.

NG >> Replace solenoid valve assembly.

9. CHECK CONTROL VALVE

1. Disassemble control valve assembly. Refer to AT- 2 8 0 , "

Control Valve Assembly" .

2. Check line pressure circuit valves for sticking.

–Pilot valve

–Shift solenoid valve A

–Shift solenoid valve B

OK or NG

OK >> GO TO 10.

NG >> Repair or replace control valve.

10. CHECK SHIFT-UP (D3 TO D4 )

During AT- 5 0 , "

Cruise Test — Part 1" .

Does A/T shift from D

3 to D4 at the specified speed?

YES >> GO TO 11.

NO >> Check control valve again. Repair or replace control valve assembly.

11 . CHECK DTC

Perform AT- 1 4 7 , "

DTC Confirmation Procedure" .

OK or NG

OK >>INSPECTION END

NG >> Perform AT- 5 0 , "

Cruise Test — Part 1" again and return to the start point of this test group.

Solenoid valve Connector TerminalResistance

(Approx.)

Line pressure solenoid valve F43 4 - Ground 2.5 - 5Ω

SCIA4951E

SCIA3275E

Page 161 of 3502

A/T TCC S/V FUNCTION (LOCK-UP)

AT-153

D

E

F

G

H

I

J

K

L

MA

B

AT

3. CHECK CONTROL VALVE

1. Disassemble control valve assembly. Refer to AT- 2 8 0 , "

Control Valve Assembly" .

2. Check to ensure that:

–Valve, sleeve and plug slide along valve bore under their own weight.

–Valve, sleeve and plug are free from burrs, dents and scratches.

–Control valve springs are free from damage, deformation and fatigue.

–Hydraulic line is free from obstacles.

OK or NG

OK >> GO TO 4.

NG >> Repair or replace control valve.

4. CHECK SHIFT-UP (D3 TO D4 )

During AT- 5 0 , "

Cruise Test — Part 1" .

Does A/T shift from D

3 to D4 at the specified speed?

YES >> GO TO 5.

NO >> Check control valve again. Repair or replace control valve assembly.

5. CHECK DTC

Perform AT- 1 5 2 , "

DTC Confirmation Procedure" .

OK or NG

OK >>INSPECTION END

NG >> GO TO 11. Check for proper lock-up.

6. CHECK VALVE RESISTANCE

1. Remove control valve assembly. Refer to AT- 2 2 5 , "

Control Valve Assembly and Accumulators" .

–Line pressure solenoid valve

2. Check resistance between terminal cord assembly harness con-

nector terminal and ground. Refer to AT- 1 2 7 , "

Wiring Diagram

— AT — LPSV" .

OK or NG

OK >> GO TO 7.

NG >> Replace solenoid valve assembly.

7. CHECK VALVE OPERATION

1. Remove control valve assembly. Refer to AT- 2 2 5 , "

Control Valve Assembly and Accumulators" .

–Line pressure solenoid valve

2. Check solenoid valve by listening for its operating sound while

applying battery voltage to the terminal and ground. Refer to AT-

127, "Wiring Diagram — AT — LPSV" .

OK or NG

OK >> GO TO 8.

NG >> Replace solenoid valve assembly.

Solenoid valve Connector TerminalResistance

(Approx.)

Line pressure solenoid valve F43 4 - Ground 2.5 - 5Ω

SCIA4951E

SCIA3275E