ignition NISSAN TEANA 2003 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: TEANA, Model: NISSAN TEANA 2003Pages: 3502, PDF Size: 74.56 MB

Page 1272 of 3502

DI-66

WARNING CHIME

Display Item List

ACTIVE TEST

Operation procedure

1. Touch “BUZZER” on “SELECT TEST ITEM” screen.

2. Touch “ACTIVE TEST” on “SELECT DIAG MODE” screen.

3. Touch the item to be tested, and check the operation.

4. During the operation check, touching “OFF” deactivates the operation.

Display Item LIst

Trouble DiagnosisBKS001T7

HOW TO PROCEED WITH TROUBLE DIAGNOSIS

1. Confirm the malfunction symptom or customer complaint.

2. Understand the outline of system. Refer to DI-56, "

System Description" .

3. Perform preliminary check. Refer to DI-66, "

PRELIMINARY CHECK" .

4. Select “METER A/C AMP” on CONSULT-II, and then perform self-diagnosis of unified meter and A/C

amp. Refer to DI-29, "

CONSULT-II Function (METER A/C AMP)" . When no malfunction detected, go to

next step 5. When malfunction detected, go to DI-17, "

SYMPTOM CHART 2" in “COMBINATION

METER”.

5. Check symptom and repair or replace the cause of malfunction.

6. Does the warning chime operate normally? If so, GO TO 7. If not, GO TO 5.

7. INSPECTION END

PRELIMINARY CHECK

1. CHECK FUSE AND FUSIBLE LINK

Check BCM fuses and fusible link for blown-out.

OK or NG

OK >> GO TO 2.

NG >> If fuse or fusible link is blown, be sure to eliminate cause of malfunction before installing new fuse

or fusible link. Refer to PG-3, "

POWER SUPPLY ROUTING CIRCUIT" .

Monitor item [Unit] ALL SIGNALSSELECTION

FROM MENUDescription

IGN ON SW [ON/OFF] X X Indicates [ON/OFF] condition of ignition switch.

KEY ON SW [ON/OFF] X X Indicates [ON/OFF] condition of key switch.

DOOR SW-DR [ON/OFF] X X Indicates [ON/OFF] condition of front door switch (driver side).

LIGHT SW 1ST [ON/OFF] X X Indicates [ON/OFF] condition of lighting switch.

FR FOG SW [ON/OFF] X X Indicates [ON/OFF] condition of front fog lamp switch.

Test item Malfunction is detected when···

IGN KEY WARN ALMThis test is able to check key warning chime operation. Key warning chime sounds for 2 seconds

after touching “ON” on CONSULT-ll screen.

LIGHT WARN ALMThis test is able to check light warning chime operation. Light warning chime sounds for 2 seconds

after touching “ON” on CONSULT-ll screen.

Unit Power source Fuse and fusible link No.

BCMBatteryM

17

Ignition switch ON or START 1

Page 1273 of 3502

WARNING CHIME

DI-67

C

D

E

F

G

H

I

J

L

MA

B

DI

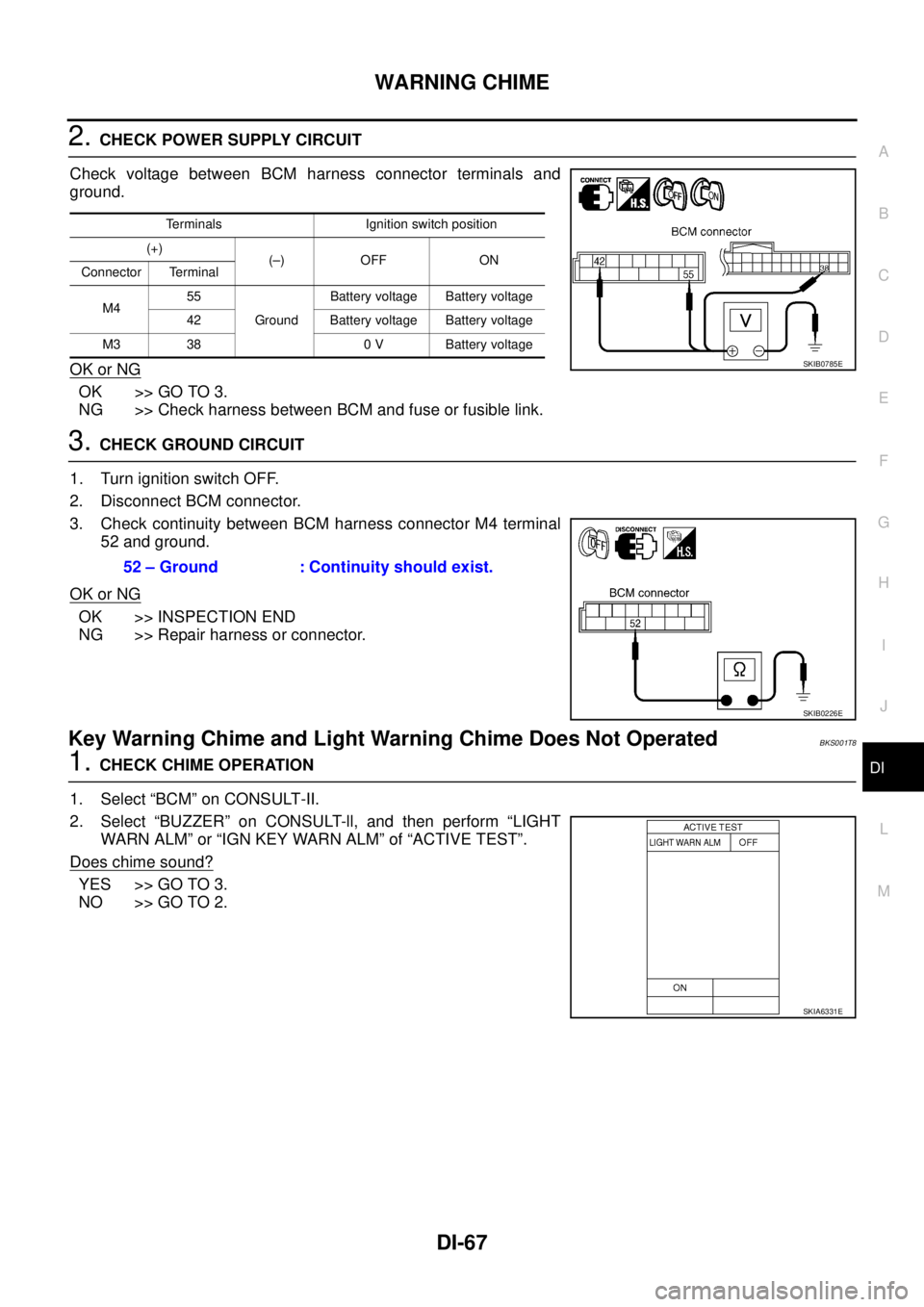

2. CHECK POWER SUPPLY CIRCUIT

Check voltage between BCM harness connector terminals and

ground.

OK or NG

OK >> GO TO 3.

NG >> Check harness between BCM and fuse or fusible link.

3. CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connector.

3. Check continuity between BCM harness connector M4 terminal

52 and ground.

OK or NG

OK >> INSPECTION END

NG >> Repair harness or connector.

Key Warning Chime and Light Warning Chime Does Not OperatedBKS001T8

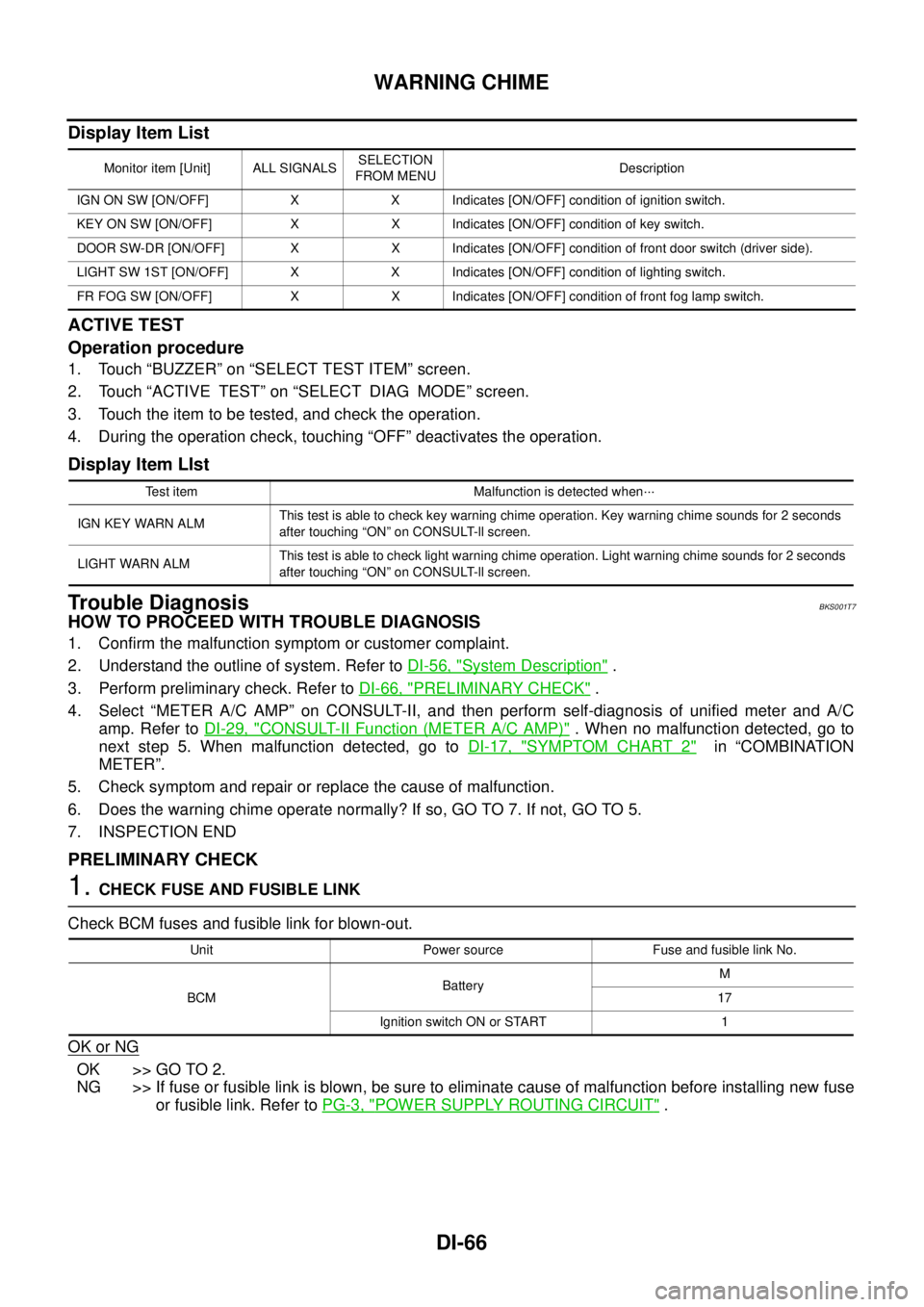

1. CHECK CHIME OPERATION

1. Select “BCM” on CONSULT-II.

2. Select “BUZZER” on CONSULT-ll, and then perform “LIGHT

WARN ALM” or “IGN KEY WARN ALM” of “ACTIVE TEST”.

Does chime sound?

YES >> GO TO 3.

NO >> GO TO 2.

Terminals Ignition switch position

(+)

(–) OFF ON

Connector Terminal

M455

GroundBattery voltage Battery voltage

42 Battery voltage Battery voltage

M3 38 0 V Battery voltage

SKIB0785E

52 – Ground : Continuity should exist.

SKIB0226E

SKIA6331E

Page 1275 of 3502

WARNING CHIME

DI-69

C

D

E

F

G

H

I

J

L

MA

B

DI

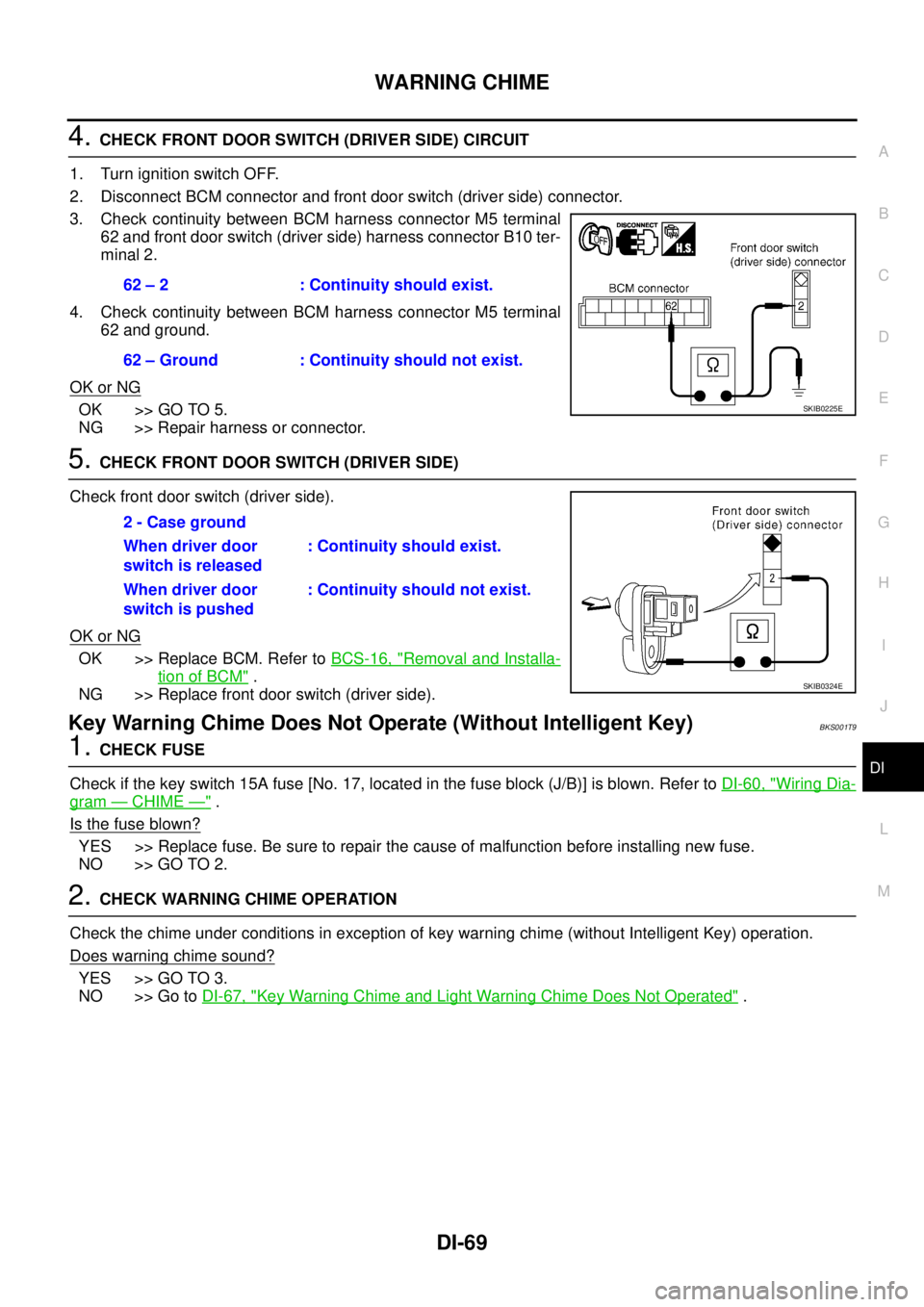

4. CHECK FRONT DOOR SWITCH (DRIVER SIDE) CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connector and front door switch (driver side) connector.

3. Check continuity between BCM harness connector M5 terminal

62 and front door switch (driver side) harness connector B10 ter-

minal 2.

4. Check continuity between BCM harness connector M5 terminal

62 and ground.

OK or NG

OK >> GO TO 5.

NG >> Repair harness or connector.

5. CHECK FRONT DOOR SWITCH (DRIVER SIDE)

Check front door switch (driver side).

OK or NG

OK >> Replace BCM. Refer to BCS-16, "Removal and Installa-

tion of BCM" .

NG >> Replace front door switch (driver side).

Key Warning Chime Does Not Operate (Without Intelligent Key)BKS001T9

1. CHECK FUSE

Check if the key switch 15A fuse [No. 17, located in the fuse block (J/B)] is blown. Refer to DI-60, "

Wiring Dia-

gram — CHIME —" .

Is the fuse blown?

YES >> Replace fuse. Be sure to repair the cause of malfunction before installing new fuse.

NO >> GO TO 2.

2. CHECK WARNING CHIME OPERATION

Check the chime under conditions in exception of key warning chime (without Intelligent Key) operation.

Does warning chime sound?

YES >> GO TO 3.

NO >> Go to DI-67, "

Key Warning Chime and Light Warning Chime Does Not Operated" . 62 – 2 : Continuity should exist.

62 – Ground : Continuity should not exist.

SKIB0225E

2 - Case ground

When driver door

switch is released: Continuity should exist.

When driver door

switch is pushed: Continuity should not exist.

SKIB0324E

Page 1276 of 3502

DI-70

WARNING CHIME

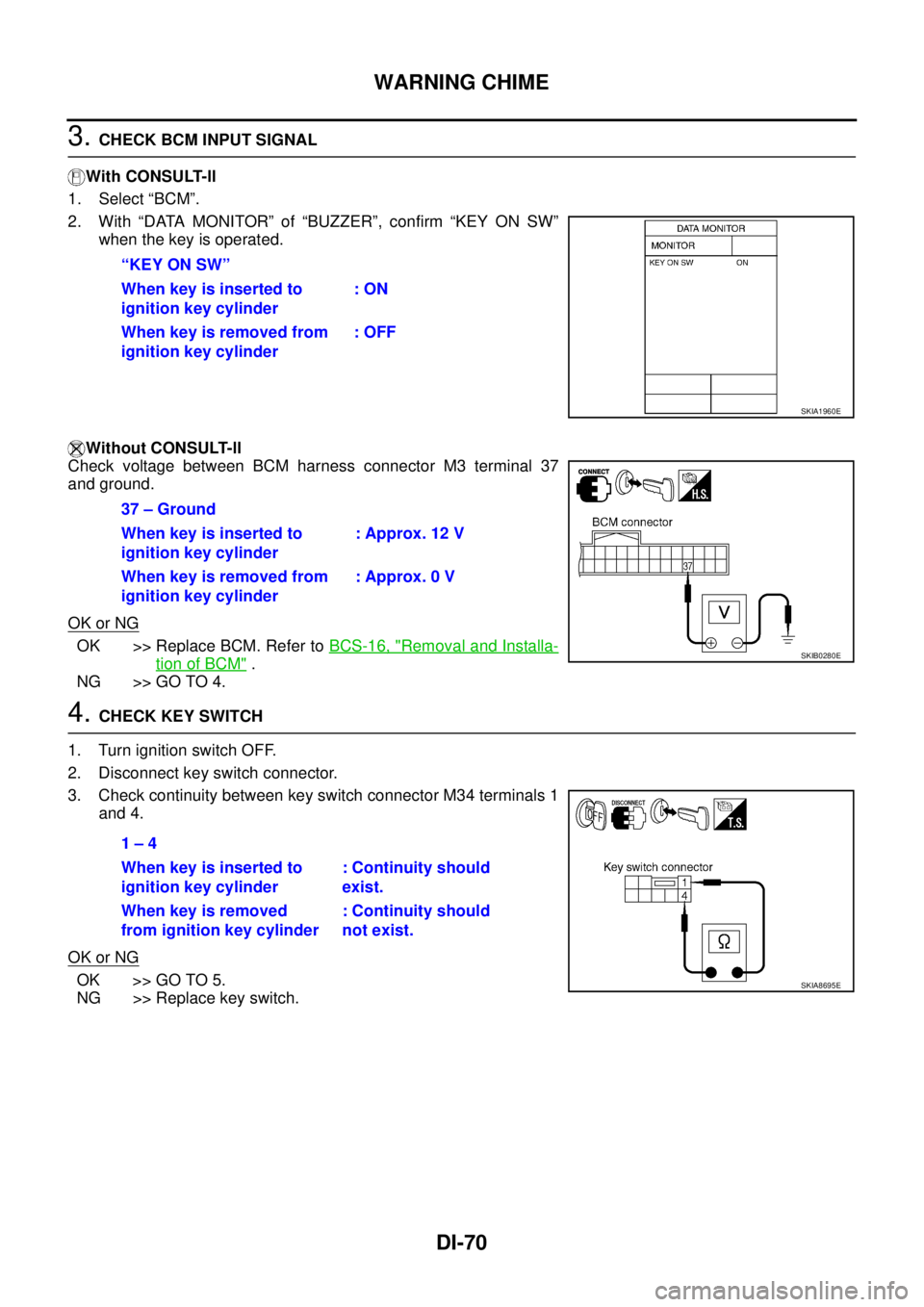

3. CHECK BCM INPUT SIGNAL

With CONSULT-ll

1. Select “BCM”.

2. With “DATA MONITOR” of “BUZZER”, confirm “KEY ON SW”

when the key is operated.

Without CONSULT-ll

Check voltage between BCM harness connector M3 terminal 37

and ground.

OK or NG

OK >> Replace BCM. Refer to BCS-16, "Removal and Installa-

tion of BCM" .

NG >> GO TO 4.

4. CHECK KEY SWITCH

1. Turn ignition switch OFF.

2. Disconnect key switch connector.

3. Check continuity between key switch connector M34 terminals 1

and 4.

OK or NG

OK >> GO TO 5.

NG >> Replace key switch.“KEY ON SW”

When key is inserted to

ignition key cylinder: ON

When key is removed from

ignition key cylinder: OFF

SKIA1960E

37 – Ground

When key is inserted to

ignition key cylinder: Approx. 12 V

When key is removed from

ignition key cylinder: Approx. 0 V

SKIB0280E

1 – 4

When key is inserted to

ignition key cylinder: Continuity should

exist.

When key is removed

from ignition key cylinder: Continuity should

not exist.

SKIA8695E

Page 1278 of 3502

DI-72

WARNING CHIME

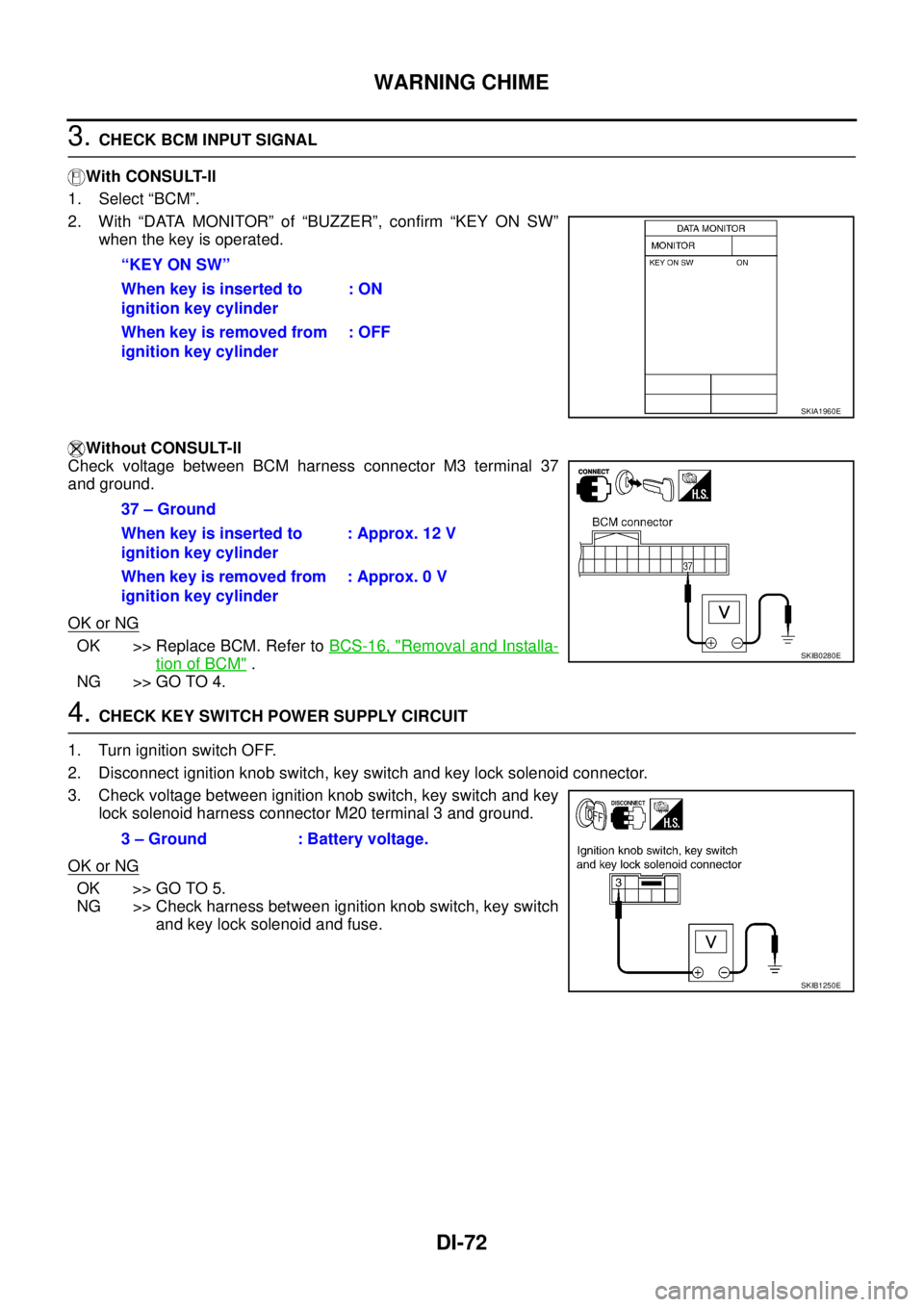

3. CHECK BCM INPUT SIGNAL

With CONSULT-ll

1. Select “BCM”.

2. With “DATA MONITOR” of “BUZZER”, confirm “KEY ON SW”

when the key is operated.

Without CONSULT-ll

Check voltage between BCM harness connector M3 terminal 37

and ground.

OK or NG

OK >> Replace BCM. Refer to BCS-16, "Removal and Installa-

tion of BCM" .

NG >> GO TO 4.

4. CHECK KEY SWITCH POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ignition knob switch, key switch and key lock solenoid connector.

3. Check voltage between ignition knob switch, key switch and key

lock solenoid harness connector M20 terminal 3 and ground.

OK or NG

OK >> GO TO 5.

NG >> Check harness between ignition knob switch, key switch

and key lock solenoid and fuse. “KEY ON SW”

When key is inserted to

ignition key cylinder: ON

When key is removed from

ignition key cylinder: OFF

SKIA1960E

37 – Ground

When key is inserted to

ignition key cylinder: Approx. 12 V

When key is removed from

ignition key cylinder: Approx. 0 V

SKIB0280E

3 – Ground : Battery voltage.

SKIB1250E

Page 1279 of 3502

WARNING CHIME

DI-73

C

D

E

F

G

H

I

J

L

MA

B

DI

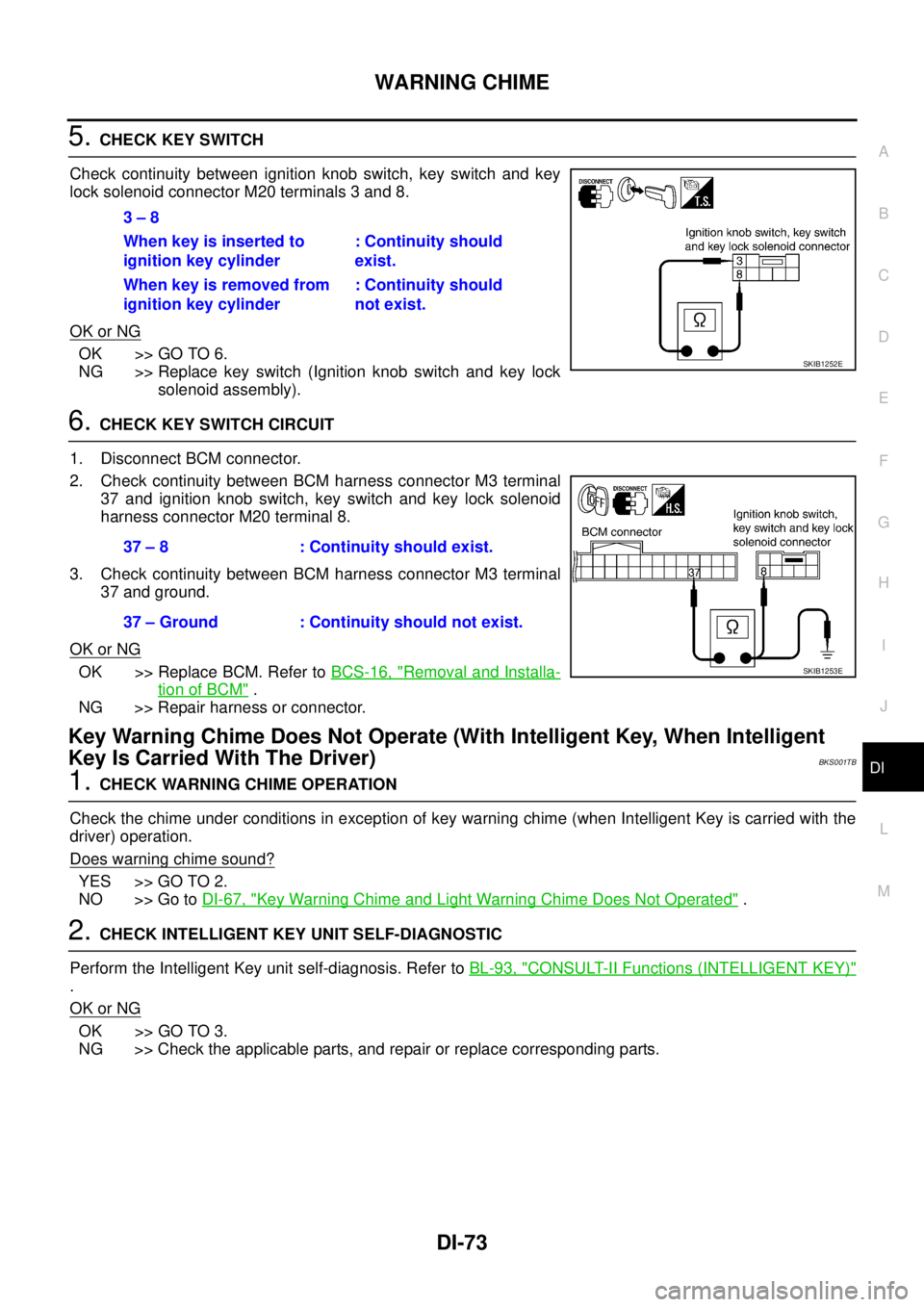

5. CHECK KEY SWITCH

Check continuity between ignition knob switch, key switch and key

lock solenoid connector M20 terminals 3 and 8.

OK or NG

OK >> GO TO 6.

NG >> Replace key switch (Ignition knob switch and key lock

solenoid assembly).

6. CHECK KEY SWITCH CIRCUIT

1. Disconnect BCM connector.

2. Check continuity between BCM harness connector M3 terminal

37 and ignition knob switch, key switch and key lock solenoid

harness connector M20 terminal 8.

3. Check continuity between BCM harness connector M3 terminal

37 and ground.

OK or NG

OK >> Replace BCM. Refer to BCS-16, "Removal and Installa-

tion of BCM" .

NG >> Repair harness or connector.

Key Warning Chime Does Not Operate (With Intelligent Key, When Intelligent

Key Is Carried With The Driver)

BKS001TB

1. CHECK WARNING CHIME OPERATION

Check the chime under conditions in exception of key warning chime (when Intelligent Key is carried with the

driver) operation.

Does warning chime sound?

YES >> GO TO 2.

NO >> Go to DI-67, "

Key Warning Chime and Light Warning Chime Does Not Operated" .

2. CHECK INTELLIGENT KEY UNIT SELF-DIAGNOSTIC

Perform the Intelligent Key unit self-diagnosis. Refer to BL-93, "

CONSULT-II Functions (INTELLIGENT KEY)"

.

OK or NG

OK >> GO TO 3.

NG >> Check the applicable parts, and repair or replace corresponding parts.3 – 8

When key is inserted to

ignition key cylinder: Continuity should

exist.

When key is removed from

ignition key cylinder: Continuity should

not exist.

SKIB1252E

37 – 8 : Continuity should exist.

37 – Ground : Continuity should not exist.

SKIB1253E

Page 1280 of 3502

DI-74

WARNING CHIME

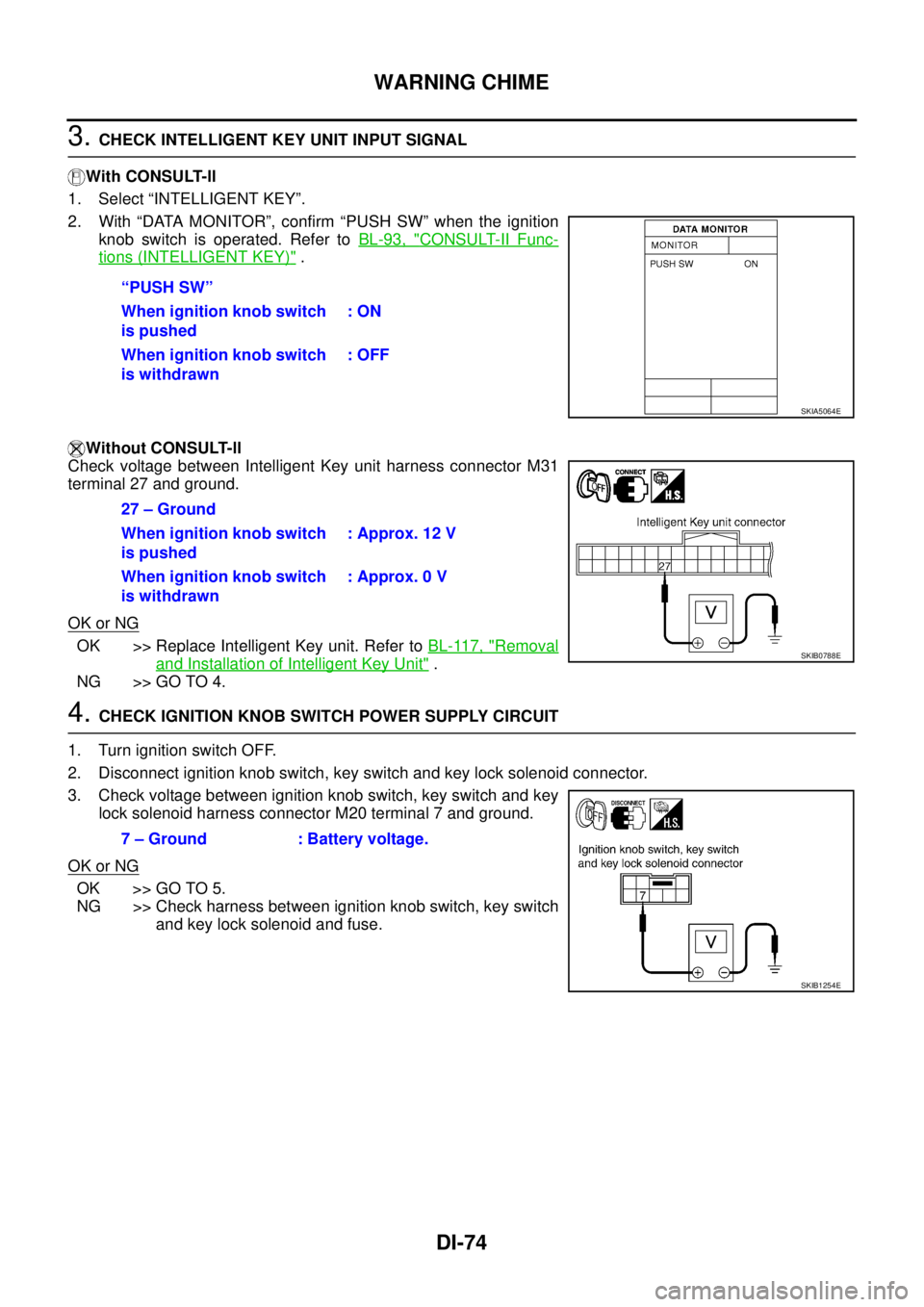

3. CHECK INTELLIGENT KEY UNIT INPUT SIGNAL

With CONSULT-ll

1. Select “INTELLIGENT KEY”.

2. With “DATA MONITOR”, confirm “PUSH SW” when the ignition

knob switch is operated. Refer to BL-93, "

CONSULT-II Func-

tions (INTELLIGENT KEY)" .

Without CONSULT-ll

Check voltage between Intelligent Key unit harness connector M31

terminal 27 and ground.

OK or NG

OK >> Replace Intelligent Key unit. Refer to BL-117, "Removal

and Installation of Intelligent Key Unit" .

NG >> GO TO 4.

4. CHECK IGNITION KNOB SWITCH POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ignition knob switch, key switch and key lock solenoid connector.

3. Check voltage between ignition knob switch, key switch and key

lock solenoid harness connector M20 terminal 7 and ground.

OK or NG

OK >> GO TO 5.

NG >> Check harness between ignition knob switch, key switch

and key lock solenoid and fuse. “PUSH SW”

When ignition knob switch

is pushed: ON

When ignition knob switch

is withdrawn: OFF

SKIA5064E

27 – Ground

When ignition knob switch

is pushed: Approx. 12 V

When ignition knob switch

is withdrawn: Approx. 0 V

SKIB0788E

7 – Ground : Battery voltage.

SKIB1254E

Page 1281 of 3502

WARNING CHIME

DI-75

C

D

E

F

G

H

I

J

L

MA

B

DI

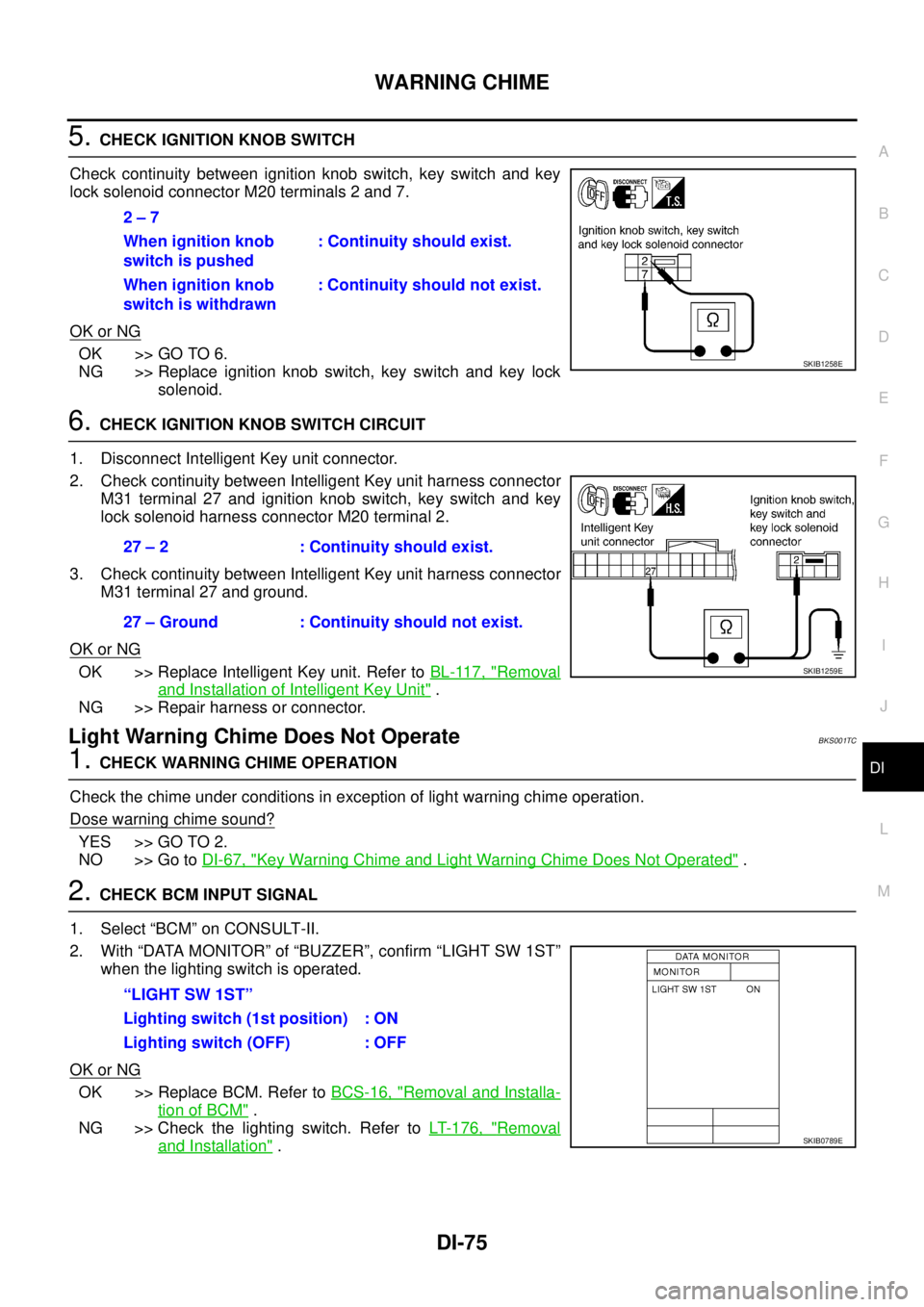

5. CHECK IGNITION KNOB SWITCH

Check continuity between ignition knob switch, key switch and key

lock solenoid connector M20 terminals 2 and 7.

OK or NG

OK >> GO TO 6.

NG >> Replace ignition knob switch, key switch and key lock

solenoid.

6. CHECK IGNITION KNOB SWITCH CIRCUIT

1. Disconnect Intelligent Key unit connector.

2. Check continuity between Intelligent Key unit harness connector

M31 terminal 27 and ignition knob switch, key switch and key

lock solenoid harness connector M20 terminal 2.

3. Check continuity between Intelligent Key unit harness connector

M31 terminal 27 and ground.

OK or NG

OK >> Replace Intelligent Key unit. Refer to BL-117, "Removal

and Installation of Intelligent Key Unit" .

NG >> Repair harness or connector.

Light Warning Chime Does Not OperateBKS001TC

1. CHECK WARNING CHIME OPERATION

Check the chime under conditions in exception of light warning chime operation.

Dose warning chime sound?

YES >> GO TO 2.

NO >> Go to DI-67, "

Key Warning Chime and Light Warning Chime Does Not Operated" .

2. CHECK BCM INPUT SIGNAL

1. Select “BCM” on CONSULT-II.

2. With “DATA MONITOR” of “BUZZER”, confirm “LIGHT SW 1ST”

when the lighting switch is operated.

OK or NG

OK >> Replace BCM. Refer to BCS-16, "Removal and Installa-

tion of BCM" .

NG >> Check the lighting switch. Refer to LT- 1 7 6 , "

Removal

and Installation" . 2 – 7

When ignition knob

switch is pushed: Continuity should exist.

When ignition knob

switch is withdrawn: Continuity should not exist.

SKIB1258E

27 – 2 : Continuity should exist.

27 – Ground : Continuity should not exist.

SKIB1259E

“LIGHT SW 1ST”

Lighting switch (1st position) : ON

Lighting switch (OFF) : OFF

SKIB0789E

Page 1283 of 3502

EC-1

ENGINE CONTROL SYSTEM

B ENGINE

CONTENTS

C

D

E

F

G

H

I

J

K

L

M

SECTION EC

A

EC

ENGINE CONTROL SYSTEM

QR

INDEX FOR DTC ...................................................... 10

DTC No. Index ....................................................... 10

Alphabetical Index .................................................. 12

PRECAUTIONS ........................................................ 14

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” ................................................................ 14

On Board Diagnostic (OBD) System of Engine ...... 14

Precaution .............................................................. 14

PREPARATION ......................................................... 18

Special Service Tools ............................................. 18

Commercial Service Tools ...................................... 19

ENGINE CONTROL SYSTEM .................................. 20

System Diagram ..................................................... 20

Multiport Fuel Injection (MFI) System .................... 21

Electronic Ignition (EI) System ............................... 23

Fuel Cut Control (At No Load and High Engine

Speed) .................................................................... 24

AIR CONDITIONING CUT CONTROL ..................... 25

Input/Output Signal Chart ....................................... 25

CAN COMMUNICATION .......................................... 26

System Description ................................................ 26

EVAPORATIVE EMISSION SYSTEM ....................... 27

Description ............................................................. 27

Component Inspection ........................................... 29

POSITIVE CRANKCASE VENTILATION ................. 30

Description ............................................................. 30

Component Inspection ........................................... 30

NATS (NISSAN ANTI-THEFT SYSTEM) .................. 32

Description ............................................................. 32

ON BOARD DIAGNOSTIC (OBD) SYSTEM ............ 33

Introduction ............................................................ 33

Two Trip Detection Logic ........................................ 33

Emission-related Diagnostic Information ................ 33

Malfunction Indicator (MI) ....................................... 36

BASIC SERVICE PROCEDURE .............................. 40

Basic Inspection ..................................................... 40

Idle Speed and Ignition Timing Check .................... 45

Procedure After Replacing ECM ............................ 47Accelerator Pedal Released Position Learning ...... 47

Throttle Valve Closed Position Learning ................. 47

Idle Air Volume Learning ........................................ 47

Fuel Pressure Check .............................................. 49

TROUBLE DIAGNOSIS ............................................ 52

Trouble Diagnosis Introduction ............................... 52

DTC Inspection Priority Chart ................................. 58

Fail-Safe Chart ....................................................... 59

Symptom Matrix Chart ............................................ 60

Engine Control Component Parts Location ............ 64

Vacuum Hose Drawing ........................................... 69

Circuit Diagram ....................................................... 70

ECM Harness Connector Terminal Layout ............. 72

ECM Terminals and Reference Value ..................... 72

CONSULT-II Function (ENGINE) ............................ 80

CONSULT-II Reference Value in Data Monitor Mode

... 90

Major Sensor Reference Graph in Data Monitor

Mode ....................................................................... 93

TROUBLE DIAGNOSIS - SPECIFICATION VALUE ... 95

Description .............................................................. 95

Testing Condition .................................................... 95

Inspection Procedure .............................................. 95

Diagnostic Procedure ............................................. 96

TROUBLE DIAGNOSIS FOR INTERMITTENT INCI-

DENT .......................................................................105

Description ............................................................105

Diagnostic Procedure ...........................................105

POWER SUPPLY AND GROUND CIRCUIT ...........106

Wiring Diagram .....................................................106

Diagnostic Procedure ...........................................107

Ground Inspection .................................................111

DTC U1000, U1001 CAN COMMUNICATION LINE .113

Description ............................................................113

On Board Diagnosis Logic ....................................113

DTC Confirmation Procedure ...............................113

Wiring Diagram .....................................................114

Diagnostic Procedure ...........................................115

DTC P0011 IVT CONTROL .....................................116

Description ............................................................116

Page 1286 of 3502

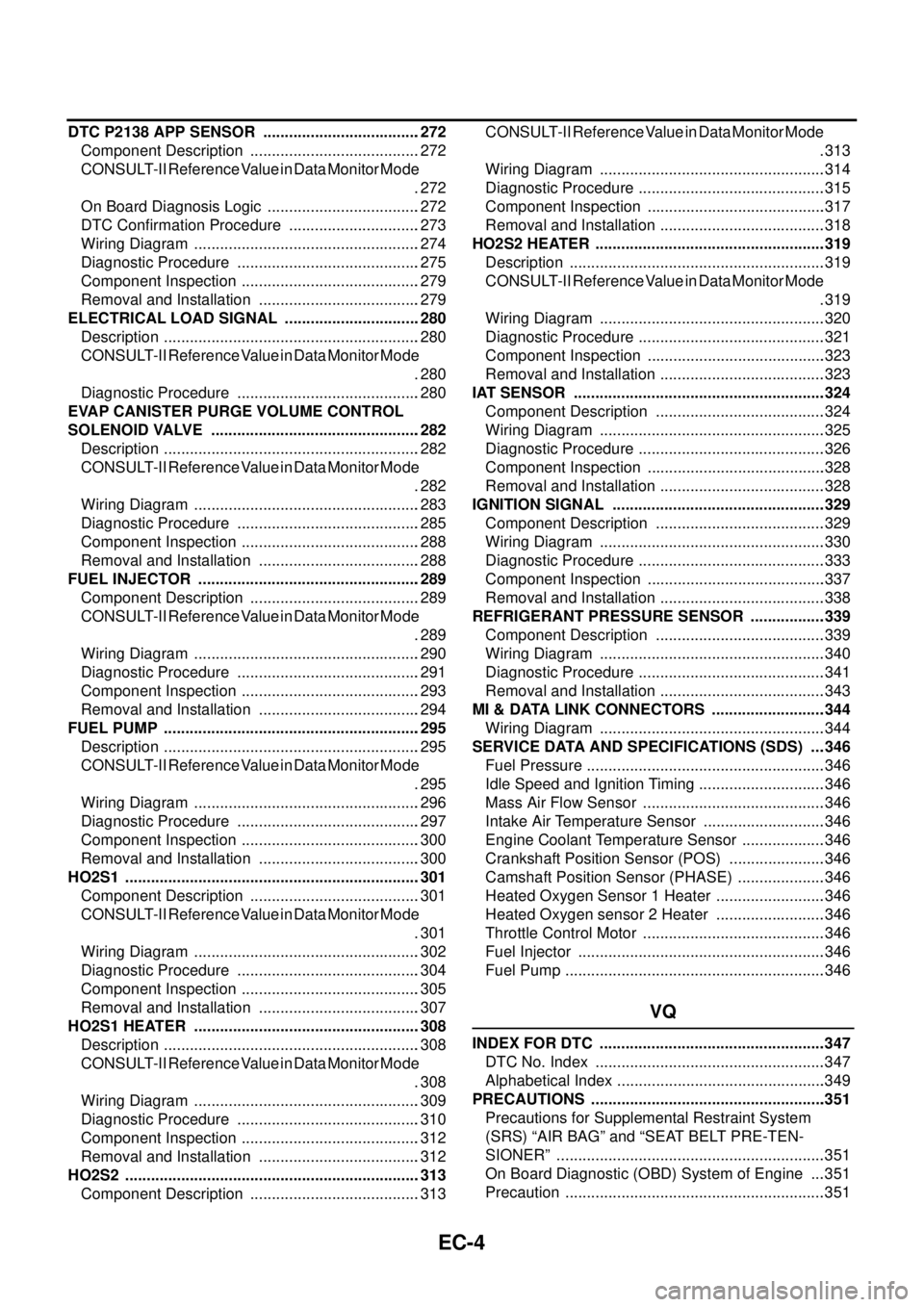

EC-4 DTC P2138 APP SENSOR .....................................272

Component Description ........................................272

CONSULT-II Reference Value in Data Monitor Mode

.272

On Board Diagnosis Logic ....................................272

DTC Confirmation Procedure ...............................273

Wiring Diagram .....................................................274

Diagnostic Procedure ...........................................275

Component Inspection ..........................................279

Removal and Installation ......................................279

ELECTRICAL LOAD SIGNAL ................................280

Description ............................................................280

CONSULT-II Reference Value in Data Monitor Mode

.280

Diagnostic Procedure ...........................................280

EVAP CANISTER PURGE VOLUME CONTROL

SOLENOID VALVE .................................................282

Description ............................................................282

CONSULT-II Reference Value in Data Monitor Mode

.282

Wiring Diagram .....................................................283

Diagnostic Procedure ...........................................285

Component Inspection ..........................................288

Removal and Installation ......................................288

FUEL INJECTOR ....................................................289

Component Description ........................................289

CONSULT-II Reference Value in Data Monitor Mode

.289

Wiring Diagram .....................................................290

Diagnostic Procedure ...........................................291

Component Inspection ..........................................293

Removal and Installation ......................................294

FUEL PUMP ............................................................295

Description ............................................................295

CONSULT-II Reference Value in Data Monitor Mode

.295

Wiring Diagram .....................................................296

Diagnostic Procedure ...........................................297

Component Inspection ..........................................300

Removal and Installation ......................................300

HO2S1 .....................................................................301

Component Description ........................................301

CONSULT-II Reference Value in Data Monitor Mode

.301

Wiring Diagram .....................................................302

Diagnostic Procedure ...........................................304

Component Inspection ..........................................305

Removal and Installation ......................................307

HO2S1 HEATER .....................................................308

Description ............................................................308

CONSULT-II Reference Value in Data Monitor Mode

.308

Wiring Diagram .....................................................309

Diagnostic Procedure ...........................................310

Component Inspection ..........................................312

Removal and Installation ......................................312

HO2S2 .....................................................................313

Component Description ........................................313CONSULT-II Reference Value in Data Monitor Mode

.313

Wiring Diagram .....................................................314

Diagnostic Procedure ............................................315

Component Inspection ..........................................317

Removal and Installation .......................................318

HO2S2 HEATER ......................................................319

Description ............................................................319

CONSULT-II Reference Value in Data Monitor Mode

.319

Wiring Diagram .....................................................320

Diagnostic Procedure ............................................321

Component Inspection ..........................................323

Removal and Installation .......................................323

IAT SENSOR ...........................................................324

Component Description ........................................324

Wiring Diagram .....................................................325

Diagnostic Procedure ............................................326

Component Inspection ..........................................328

Removal and Installation .......................................328

IGNITION SIGNAL ..................................................329

Component Description ........................................329

Wiring Diagram .....................................................330

Diagnostic Procedure ............................................333

Component Inspection ..........................................337

Removal and Installation .......................................338

REFRIGERANT PRESSURE SENSOR ..................339

Component Description ........................................339

Wiring Diagram .....................................................340

Diagnostic Procedure ............................................341

Removal and Installation .......................................343

MI & DATA LINK CONNECTORS ...........................344

Wiring Diagram .....................................................344

SERVICE DATA AND SPECIFICATIONS (SDS) ....346

Fuel Pressure ........................................................346

Idle Speed and Ignition Timing ..............................346

Mass Air Flow Sensor ...........................................346

Intake Air Temperature Sensor .............................346

Engine Coolant Temperature Sensor ....................346

Crankshaft Position Sensor (POS) .......................346

Camshaft Position Sensor (PHASE) .....................346

Heated Oxygen Sensor 1 Heater ..........................346

Heated Oxygen sensor 2 Heater ..........................346

Throttle Control Motor ...........................................346

Fuel Injector ..........................................................346

Fuel Pump .............................................................346

VQ

INDEX FOR DTC .....................................................347

DTC No. Index ......................................................347

Alphabetical Index .................................................349

PRECAUTIONS .......................................................351

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” ...............................................................351

On Board Diagnostic (OBD) System of Engine ....351

Precaution .............................................................351