NISSAN TEANA 2003 Manual Online

TEANA 2003

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57392/w960_57392-0.png

NISSAN TEANA 2003 Manual Online

Page 1037 of 3502

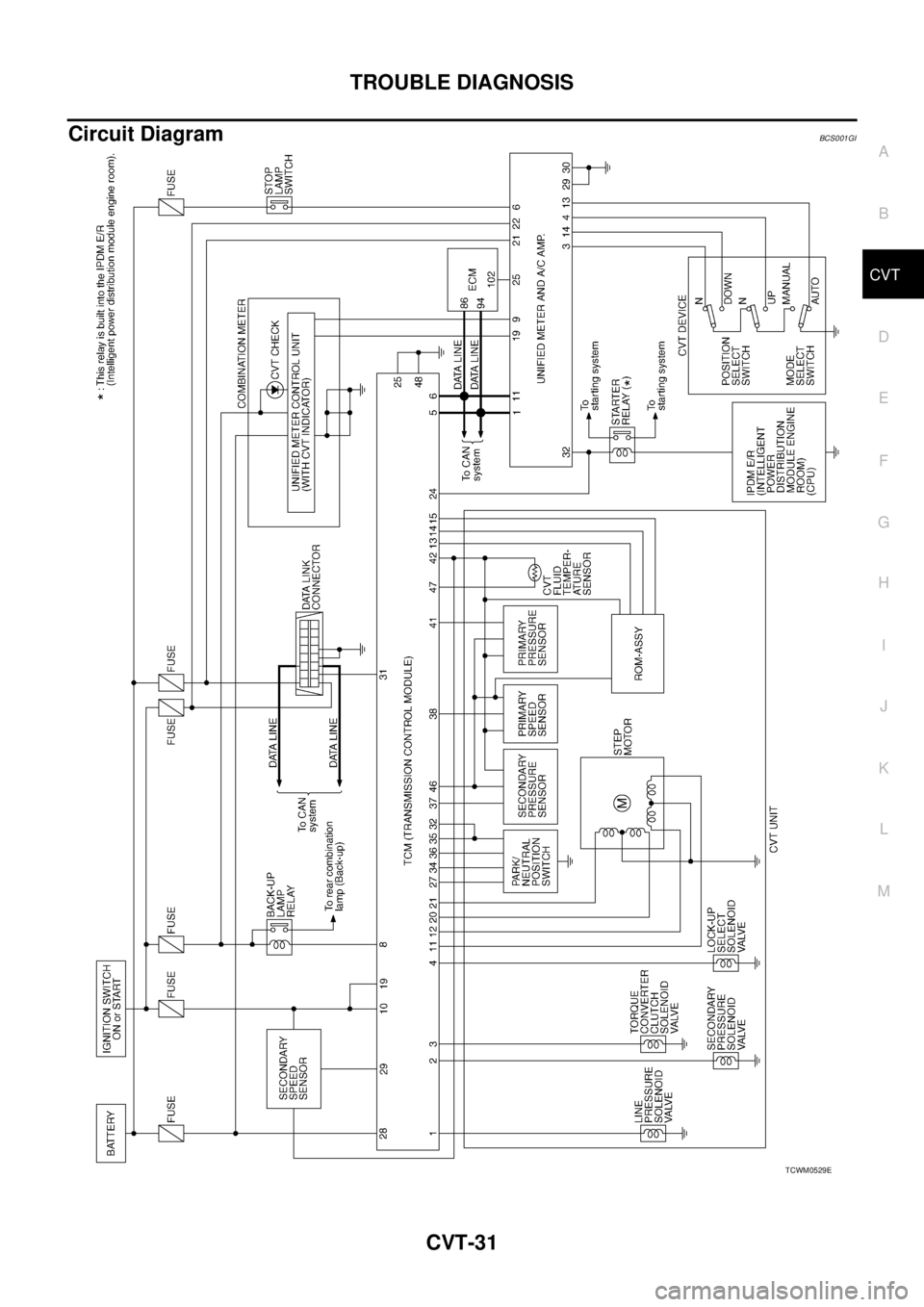

TROUBLE DIAGNOSIS

CVT-31

D

E

F

G

H

I

J

K

L

MA

B

CVT

Circuit DiagramBCS001GI

TCWM0529E

Page 1060 of 3502

CVT-54

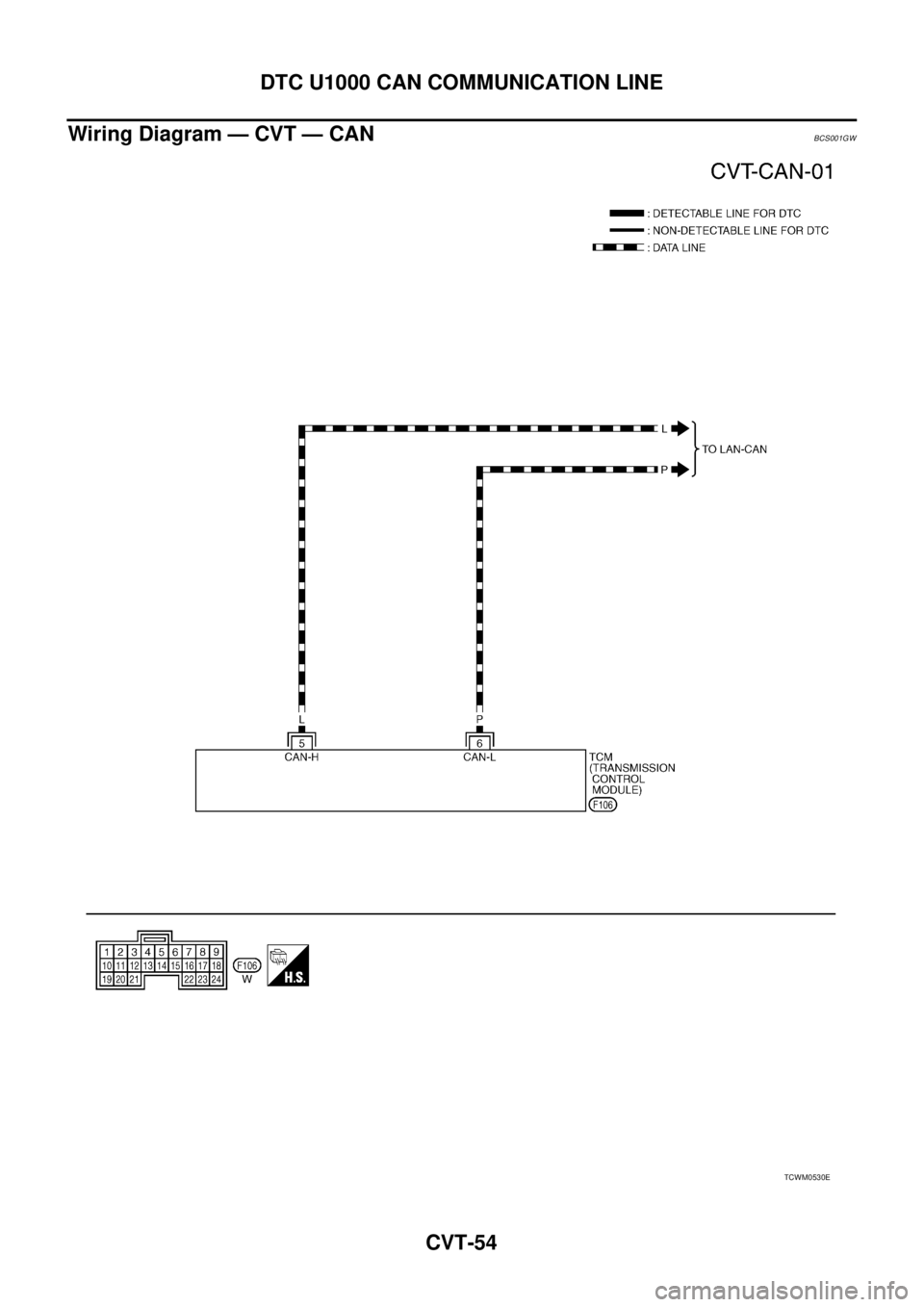

DTC U1000 CAN COMMUNICATION LINE

Wiring Diagram — CVT — CANBCS001GW

TCWM0530E

Page 1063 of 3502

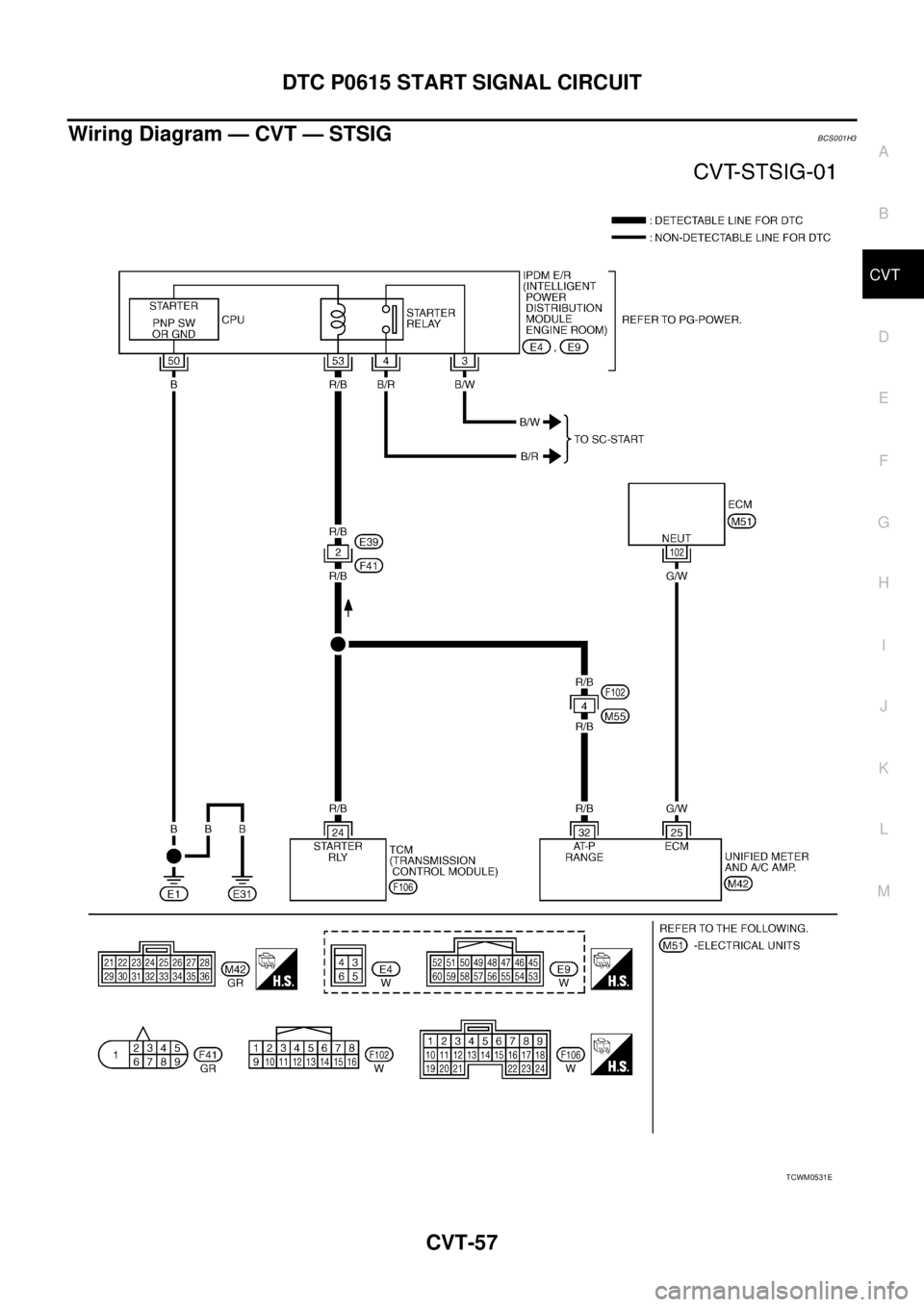

DTC P0615 START SIGNAL CIRCUIT

CVT-57

D

E

F

G

H

I

J

K

L

MA

B

CVT

Wiring Diagram — CVT — STSIGBCS001H3

TCWM0531E

Page 1064 of 3502

CVT-58

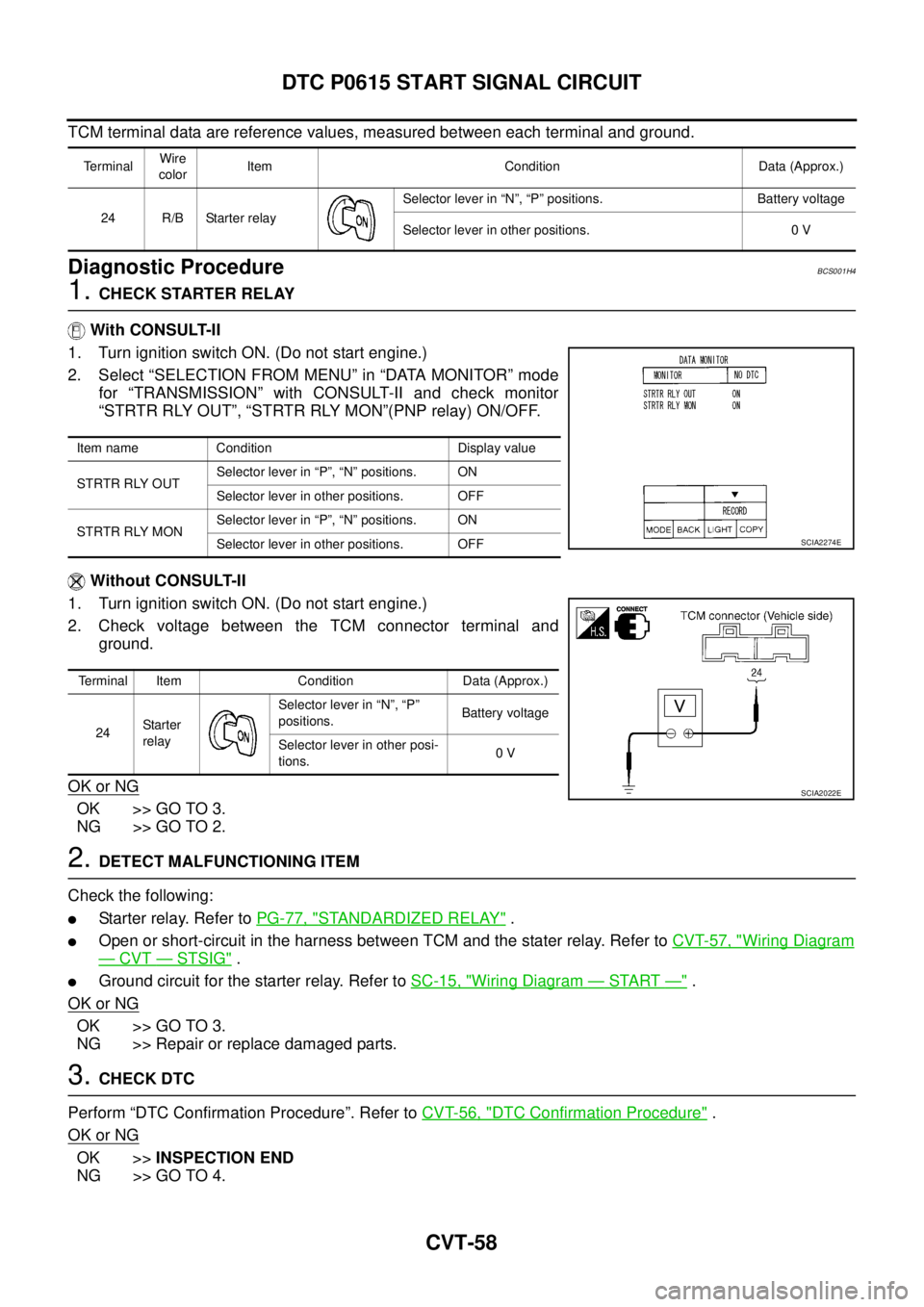

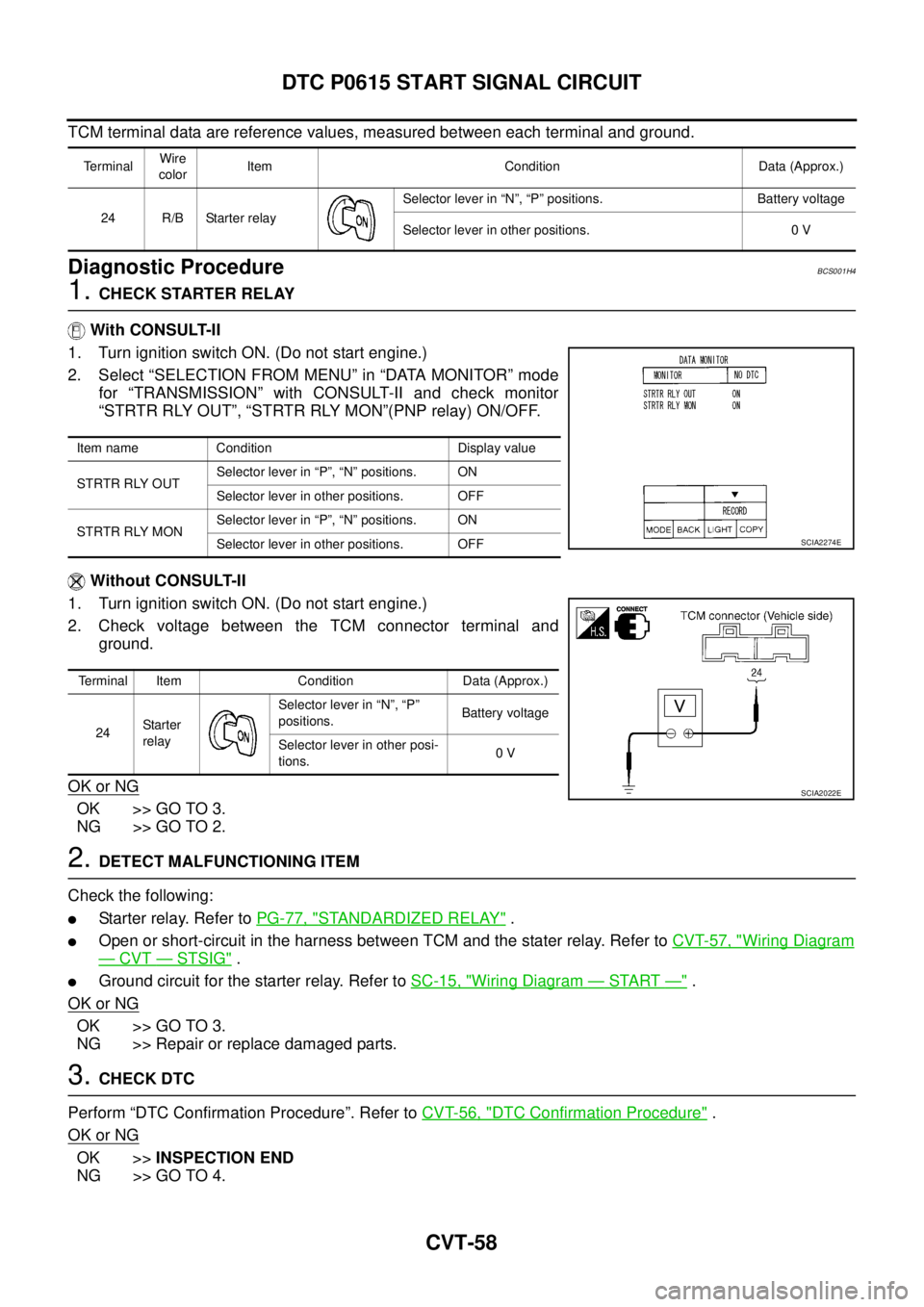

DTC P0615 START SIGNAL CIRCUIT

TCM terminal data are reference values, measured between each terminal and ground.

Diagnostic ProcedureBCS001H4

1. CHECK STARTER RELAY

With CONSULT-II

1. Turn ignition switch ON. (Do not start engine.)

2. Select “SELECTION FROM MENU” in “DATA MONITOR” mode

for “TRANSMISSION” with CONSULT-II and check monitor

“STRTR RLY OUT”, “STRTR RLY MON”(PNP relay) ON/OFF.

Without CONSULT-II

1. Turn ignition switch ON. (Do not start engine.)

2. Check voltage between the TCM connector terminal and

ground.

OK or NG

OK >> GO TO 3.

NG >> GO TO 2.

2. DETECT MALFUNCTIONING ITEM

Check the following:

�Starter relay. Refer to PG-77, "STANDARDIZED RELAY" .

�Open or short-circuit in the harness between TCM and the stater relay. Refer to CVT-57, "Wiring Diagram

— CVT — STSIG" .

�Ground circuit for the starter relay. Refer to SC-15, "Wiring Diagram — START —" .

OK or NG

OK >> GO TO 3.

NG >> Repair or replace damaged parts.

3. CHECK DTC

Perform “DTC Confirmation Procedure”. Refer to CVT-56, "

DTC Confirmation Procedure" .

OK or NG

OK >>INSPECTION END

NG >> GO TO 4.

TerminalWire

colorItem Condition Data (Approx.)

24 R/B Starter relaySelector lever in “N”, “P” positions. Battery voltage

Selector lever in other positions. 0 V

Item name Condition Display value

STRTR RLY OUTSelector lever in “P”, “N” positions. ON

Selector lever in other positions. OFF

STRTR RLY MONSelector lever in “P”, “N” positions. ON

Selector lever in other positions. OFF

Terminal Item Condition Data (Approx.)

24Starter

relaySelector lever in “N”, “P”

positions.Battery voltage

Selector lever in other posi-

tions.0 V

SCIA2274E

SCIA2022E

Page 1067 of 3502

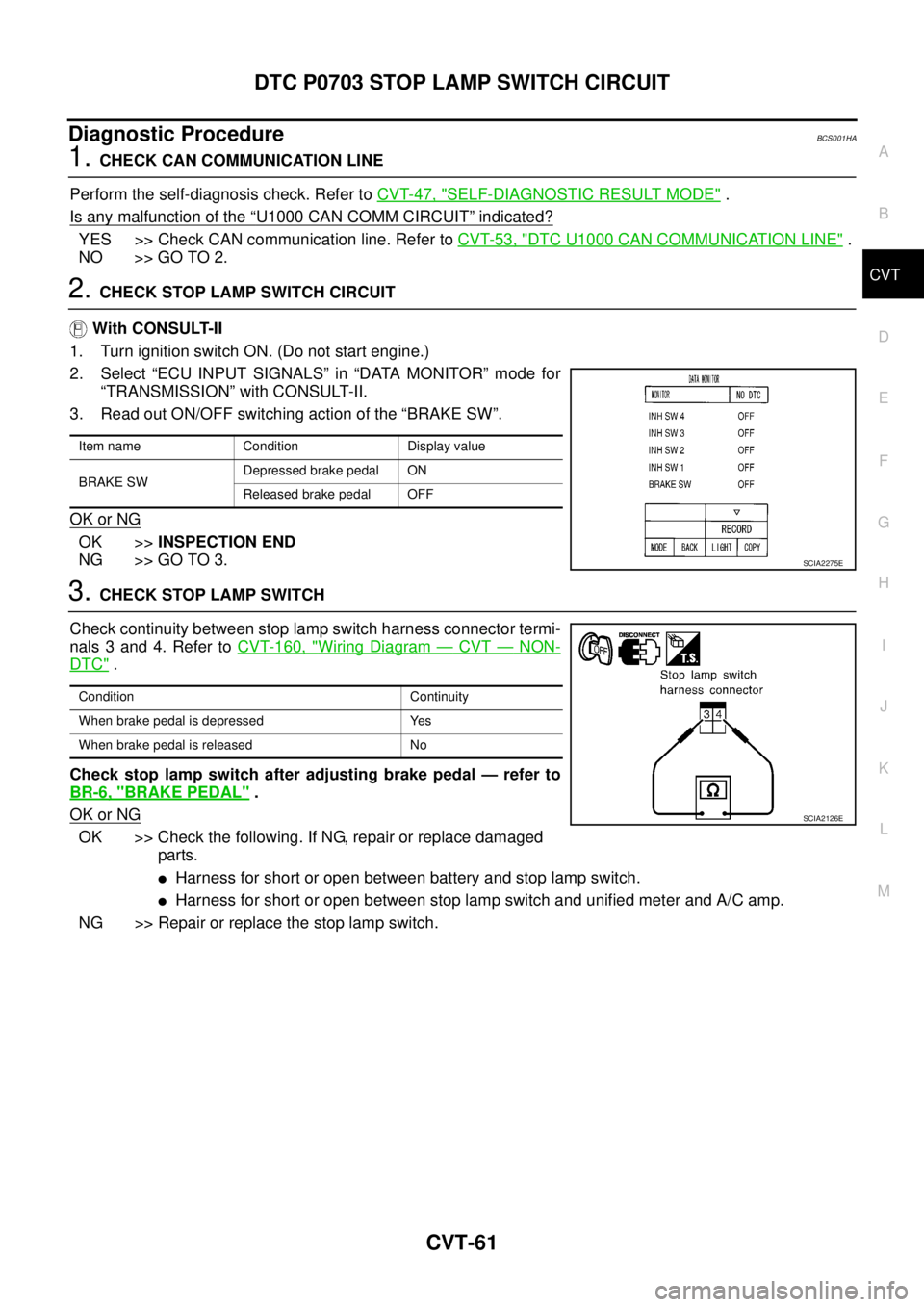

DTC P0703 STOP LAMP SWITCH CIRCUIT

CVT-61

D

E

F

G

H

I

J

K

L

MA

B

CVT

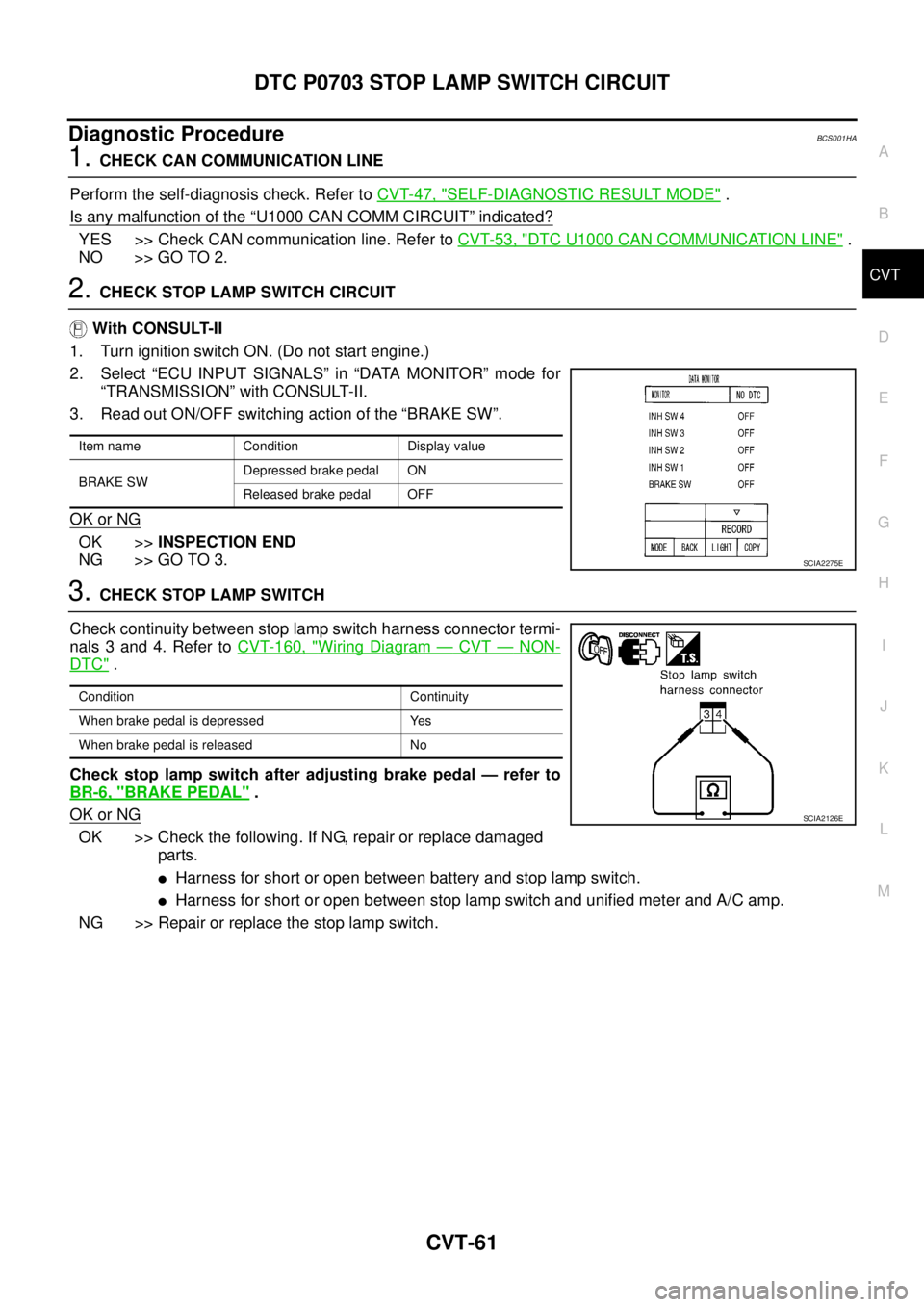

Diagnostic ProcedureBCS001HA

1. CHECK CAN COMMUNICATION LINE

Perform the self-diagnosis check. Refer to CVT-47, "

SELF-DIAGNOSTIC RESULT MODE" .

Is any malfunction of the

“U1000 CAN COMM CIRCUIT” indicated?

YES >> Check CAN communication line. Refer to CVT-53, "DTC U1000 CAN COMMUNICATION LINE" .

NO >> GO TO 2.

2. CHECK STOP LAMP SWITCH CIRCUIT

With CONSULT-II

1. Turn ignition switch ON. (Do not start engine.)

2. Select “ECU INPUT SIGNALS” in “DATA MONITOR” mode for

“TRANSMISSION” with CONSULT-II.

3. Read out ON/OFF switching action of the “BRAKE SW”.

OK or NG

OK >>INSPECTION END

NG >> GO TO 3.

3. CHECK STOP LAMP SWITCH

Check continuity between stop lamp switch harness connector termi-

nals 3 and 4. Refer to CVT-160, "

Wiring Diagram — CVT — NON-

DTC" .

Check stop lamp switch after adjusting brake pedal — refer to

BR-6, "

BRAKE PEDAL" .

OK or NG

OK >> Check the following. If NG, repair or replace damaged

parts.

�Harness for short or open between battery and stop lamp switch.

�Harness for short or open between stop lamp switch and unified meter and A/C amp.

NG >> Repair or replace the stop lamp switch.

Item name Condition Display value

BRAKE SWDepressed brake pedal ON

Released brake pedal OFF

SCIA2275E

Condition Continuity

When brake pedal is depressed Yes

When brake pedal is released No

SCIA2126E

Page 1070 of 3502

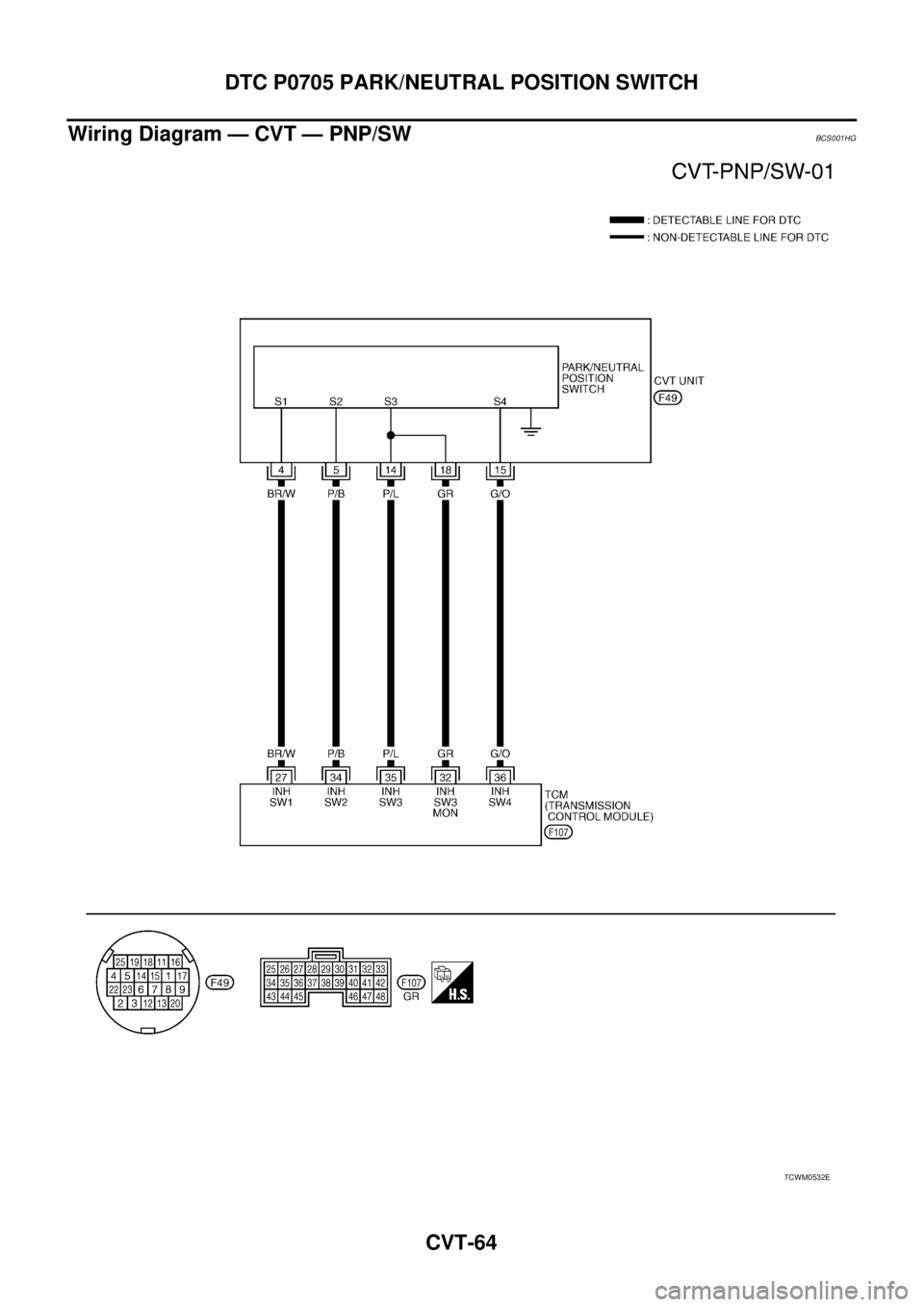

CVT-64

DTC P0705 PARK/NEUTRAL POSITION SWITCH

Wiring Diagram — CVT — PNP/SWBCS001HG

TCWM0532E

Page 1076 of 3502

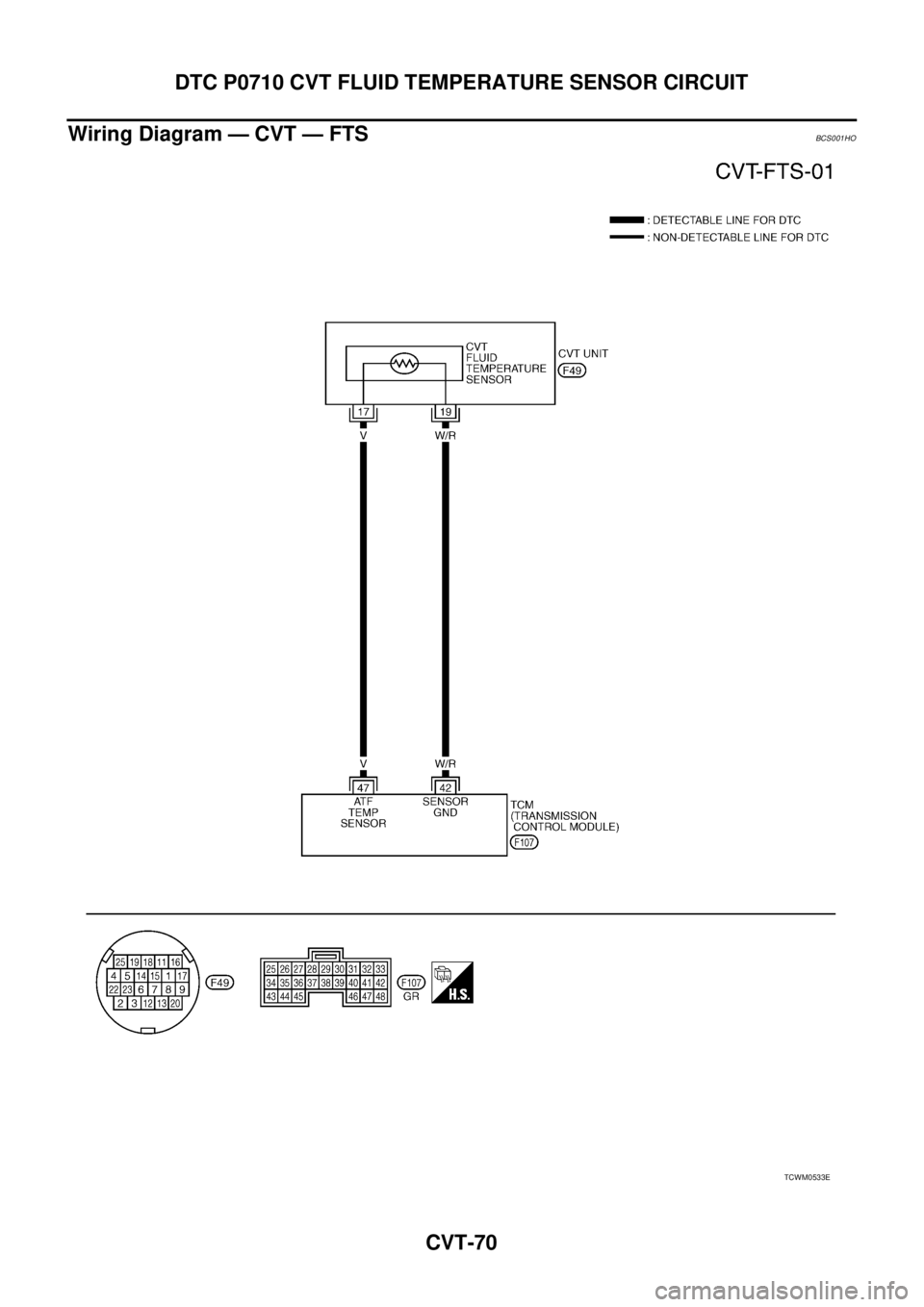

CVT-70

DTC P0710 CVT FLUID TEMPERATURE SENSOR CIRCUIT

Wiring Diagram — CVT — FTSBCS001HO

TCWM0533E

Page 1081 of 3502

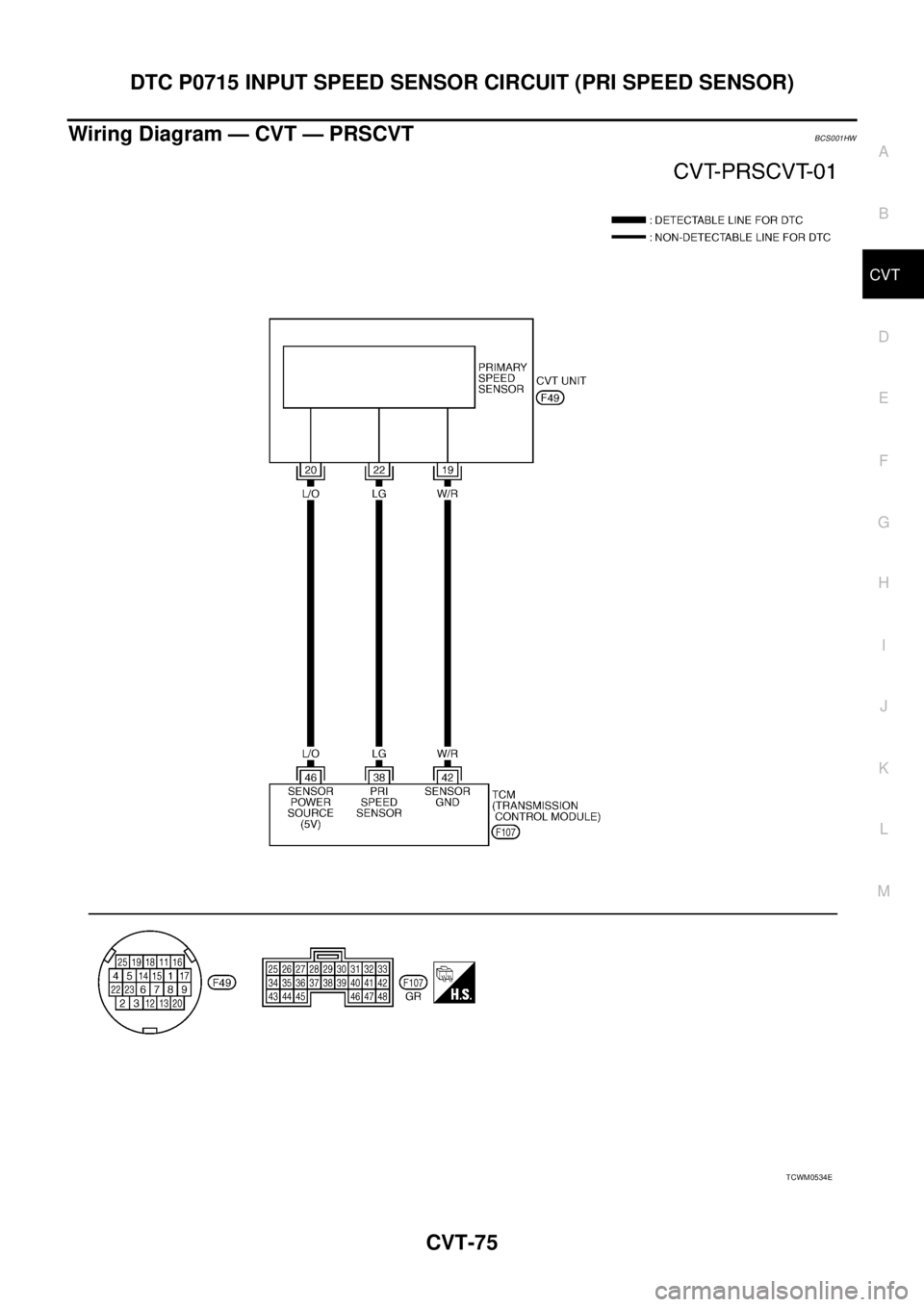

DTC P0715 INPUT SPEED SENSOR CIRCUIT (PRI SPEED SENSOR)

CVT-75

D

E

F

G

H

I

J

K

L

MA

B

CVT

Wiring Diagram — CVT — PRSCVTBCS001HW

TCWM0534E

Page 1086 of 3502

CVT-80

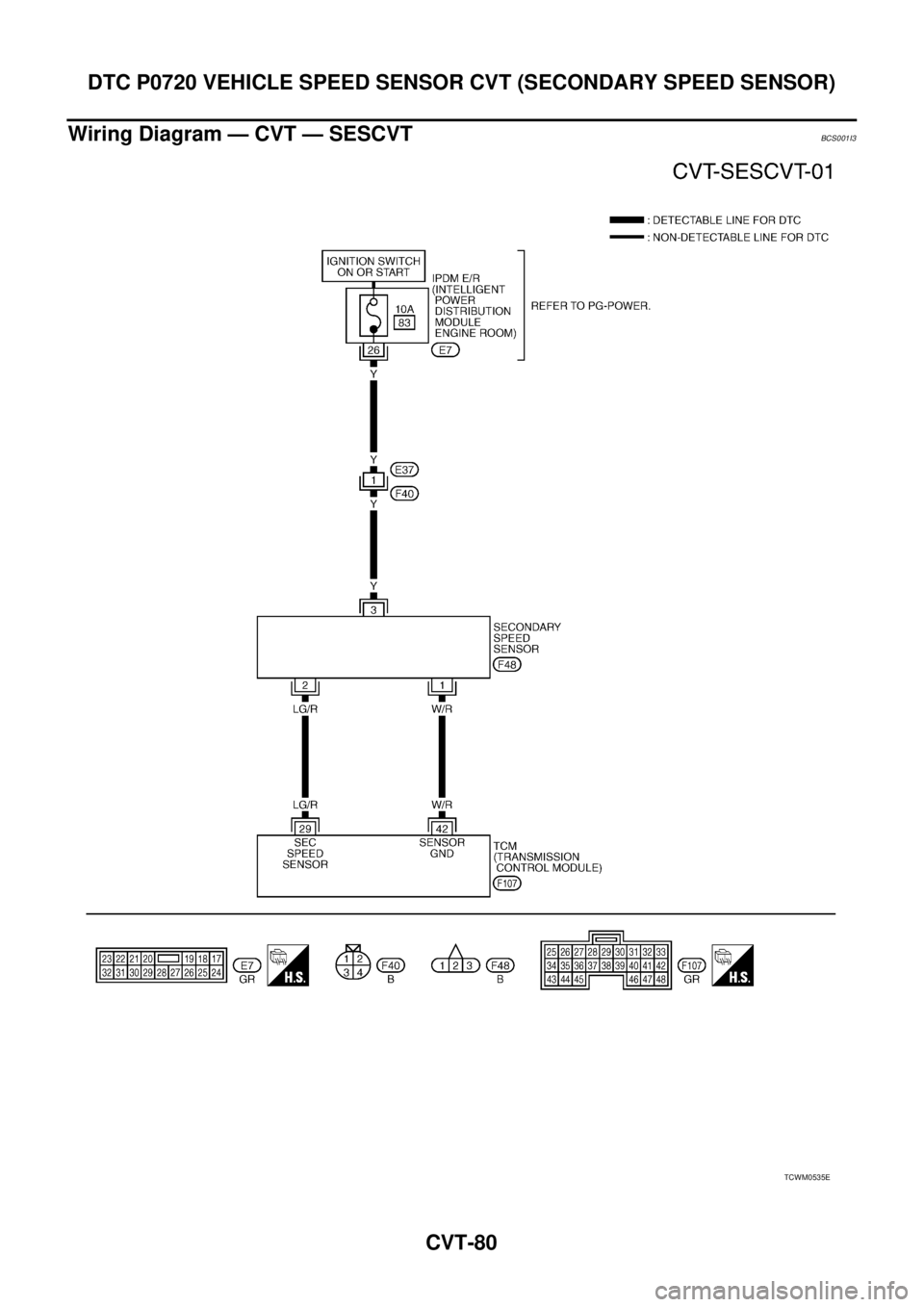

DTC P0720 VEHICLE SPEED SENSOR CVT (SECONDARY SPEED SENSOR)

Wiring Diagram — CVT — SESCVTBCS001I3

TCWM0535E

Page 1087 of 3502

DTC P0720 VEHICLE SPEED SENSOR CVT (SECONDARY SPEED SENSOR)

CVT-81

D

E

F

G

H

I

J

K

L

MA

B

CVT

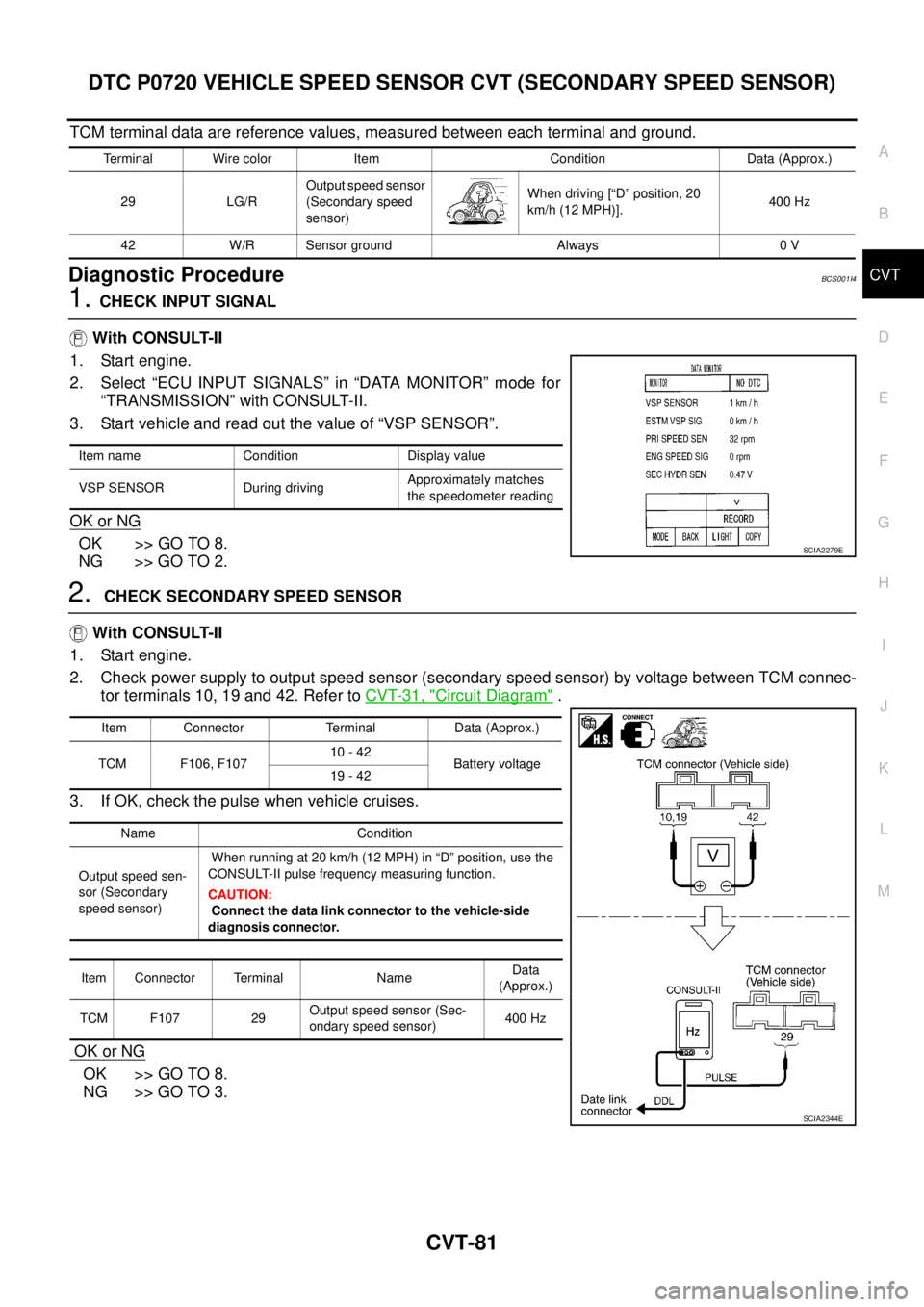

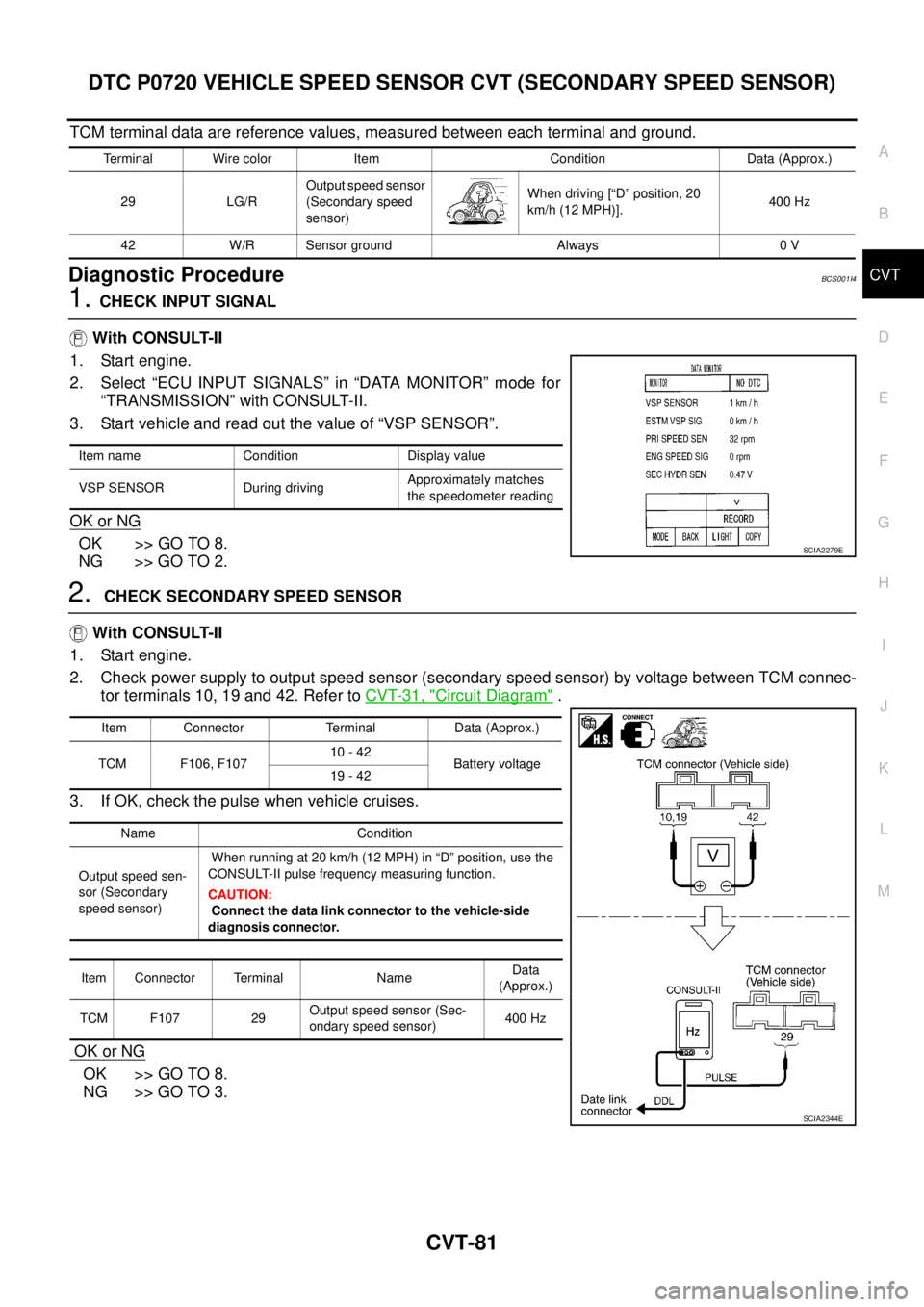

TCM terminal data are reference values, measured between each terminal and ground.

Diagnostic ProcedureBCS001I4

1. CHECK INPUT SIGNAL

With CONSULT-II

1. Start engine.

2. Select “ECU INPUT SIGNALS” in “DATA MONITOR” mode for

“TRANSMISSION” with CONSULT-II.

3. Start vehicle and read out the value of “VSP SENSOR”.

OK or NG

OK >> GO TO 8.

NG >> GO TO 2.

2. CHECK SECONDARY SPEED SENSOR

With CONSULT-II

1. Start engine.

2. Check power supply to output speed sensor (secondary speed sensor) by voltage between TCM connec-

tor terminals 10, 19 and 42. Refer to CVT-31, "

Circuit Diagram" .

3. If OK, check the pulse when vehicle cruises.

OK or NG

OK >> GO TO 8.

NG >> GO TO 3.

Terminal Wire color Item Condition Data (Approx.)

29 LG/ROutput speed sensor

(Secondary speed

sensor)When driving [“D” position, 20

km/h (12 MPH)].400 Hz

42 W/R Sensor ground Always 0 V

Item name Condition Display value

VSP SENSOR During drivingApproximately matches

the speedometer reading

SCIA2279E

Item Connector Terminal Data (Approx.)

TCM F106, F10710 - 42

Battery voltage

19 - 42

Name Condition

Output speed sen-

sor (Secondary

speed sensor) When running at 20 km/h (12 MPH) in “D” position, use the

CONSULT-II pulse frequency measuring function.

CAUTION:

Connect the data link connector to the vehicle-side

diagnosis connector.

Item Connector Terminal NameData

(Approx.)

TCM F107 29Output speed sensor (Sec-

ondary speed sensor)400 Hz

SCIA2344E