ignition NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 3592 of 5121

![NISSAN TEANA 2008 Service Manual PG-74

< COMPONENT DIAGNOSIS >[POWER SUPPLY&GROUND CIRCUIT]

POWER SUPPLY ROUTING CIRCUIT

Wiring Diagram - IGNITION POWER SUPPLY FUSE No. 4 -

INFOID:0000000003792664

JCMWM1758GB NISSAN TEANA 2008 Service Manual PG-74

< COMPONENT DIAGNOSIS >[POWER SUPPLY&GROUND CIRCUIT]

POWER SUPPLY ROUTING CIRCUIT

Wiring Diagram - IGNITION POWER SUPPLY FUSE No. 4 -

INFOID:0000000003792664

JCMWM1758GB](/img/5/57391/w960_57391-3591.png)

PG-74

< COMPONENT DIAGNOSIS >[POWER SUPPLY&GROUND CIRCUIT]

POWER SUPPLY ROUTING CIRCUIT

Wiring Diagram - IGNITION POWER SUPPLY FUSE No. 4 -

INFOID:0000000003792664

JCMWM1758GB

Page 3595 of 5121

![NISSAN TEANA 2008 Service Manual PG

POWER SUPPLY ROUTING CIRCUIT

PG-77

< COMPONENT DIAGNOSIS >[POWER SUPPLY&GROUND CIRCUIT]

C

D

E

F

G

H

I

J

K

L B A

O

P N

Wiring Diagram - IGNITION POWER SUPPLY FUSE No. 43 -INFOID:0000000003858721

JCM NISSAN TEANA 2008 Service Manual PG

POWER SUPPLY ROUTING CIRCUIT

PG-77

< COMPONENT DIAGNOSIS >[POWER SUPPLY&GROUND CIRCUIT]

C

D

E

F

G

H

I

J

K

L B A

O

P N

Wiring Diagram - IGNITION POWER SUPPLY FUSE No. 43 -INFOID:0000000003858721

JCM](/img/5/57391/w960_57391-3594.png)

PG

POWER SUPPLY ROUTING CIRCUIT

PG-77

< COMPONENT DIAGNOSIS >[POWER SUPPLY&GROUND CIRCUIT]

C

D

E

F

G

H

I

J

K

L B A

O

P N

Wiring Diagram - IGNITION POWER SUPPLY FUSE No. 43 -INFOID:0000000003858721

JCMWM1761GB

Page 3597 of 5121

![NISSAN TEANA 2008 Service Manual PG

POWER SUPPLY ROUTING CIRCUIT

PG-79

< COMPONENT DIAGNOSIS >[POWER SUPPLY&GROUND CIRCUIT]

C

D

E

F

G

H

I

J

K

L B A

O

P N

Wiring Diagram - IGNITION POWER SUPPLY FUSE No. 44 -INFOID:0000000003792665

JCM NISSAN TEANA 2008 Service Manual PG

POWER SUPPLY ROUTING CIRCUIT

PG-79

< COMPONENT DIAGNOSIS >[POWER SUPPLY&GROUND CIRCUIT]

C

D

E

F

G

H

I

J

K

L B A

O

P N

Wiring Diagram - IGNITION POWER SUPPLY FUSE No. 44 -INFOID:0000000003792665

JCM](/img/5/57391/w960_57391-3596.png)

PG

POWER SUPPLY ROUTING CIRCUIT

PG-79

< COMPONENT DIAGNOSIS >[POWER SUPPLY&GROUND CIRCUIT]

C

D

E

F

G

H

I

J

K

L B A

O

P N

Wiring Diagram - IGNITION POWER SUPPLY FUSE No. 44 -INFOID:0000000003792665

JCMWM1763GB

Page 3635 of 5121

INSPECTION AND ADJUSTMENT

PWC-5

< BASIC INSPECTION >

C

D

E

F

G

H

I

J

L

MA

B

PWC

N

O

P

INSPECTION AND ADJUSTMENT

ADDITIONAL SERVICE WHEN REMOVING BATTERY NEGATIVE TERMINAL

ADDITIONAL SERVICE WHEN REMOVING BATTERY NEGATIVE TERMINAL : De-

scription

INFOID:0000000003825989

When the negative terminal of battery is disconnected, the initialization is necessary.

If any of the following operations are performed, the initialization is necessary as well as when the negative

terminal of battery is disconnected.

Power supply to the power window main switch or power window motor is cut off by the removal

of battery terminal or if the battery fuse is blown.

Disconnection and connection of power window main switch harness connector.

Removal and installation of motor from regulator assembly.

Operation of regulator assembly as an independent unit.

Removal and installation of glass.

Removal and installation of door glass run.

The following specified operations can not be performed under the non-initialized condition.

Auto-up operation

Anti-pinch function

ADDITIONAL SERVICE WHEN REMOVING BATTERY NEGATIVE TERMINAL : Spe-

cial Repair Requirement

INFOID:0000000003825990

INITIALIZATION PROCEDURE

1. Disconnect battery negative terminal or power window main switch connector. Reconnect it after a minute

or more.

2. Turn ignition switch ON.

3. Operate power window switch to fully open the window. (This operation is unnecessary if the window is

already fully open)

4. Continue pulling the power window switch UP (AUTO-UP operation). Even after glass stops at the fully

closed position, keep pulling the switch for 2 seconds or more.

5. Initializing procedure is completed.

6. Inspect anti-pinch function.

CHECK ANTI-PINCH FUNCTION

1. Fully open the door window.

2. Place a piece of wood near fully closed position.

3. Close door glass completely with AUTO-UP.

Check that glass lowers for approximately 150 mm (5.9 in) or for 2 seconds without pinching piece of wood

and stops.

Check that glass does not rise when operating the power window main switch while lowering.

CAUTION:

• Perform initial setting when auto-up operation or anti-pinch function does not operate normally.

Check that AUTO-UP operates before inspection when system initialization is performed.

Never check with hands or other body parts because they may be pinched. Never get pinched.

It may switch to fail-safe mode if open/close operation is performed continuously without fully clos-

ing. Perform initial setting in that situation. Refer to PWC-72, "

Fail-safe"

Finish initial setting. Otherwise, next operation cannot be done.

1. Auto-up operation

2. Anti-pinch function

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT : Description

INFOID:0000000003825991

When the control unit is replaced, the initialization is necessary.

If any of the following operations are performed, the initialization is necessary as well as when the control unit

is disconnected.

Power supply to the power window main switch or power window motor is cut off by the removal

of battery terminal or if the battery fuse is blown.

Page 3636 of 5121

PWC-6

< BASIC INSPECTION >

INSPECTION AND ADJUSTMENT

Disconnection and connection of power window main switch harness connector.

Removal and installation of motor from regulator assembly.

Disconnection and connection of battery negative terminal.

Removal and installation of glass.

Removal and installation of door glass run.

The following specified operations can not be performed under the non-initialized condition.

Auto-up operation

Anti-pinch function

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT : Special Repair Re-

quirement

INFOID:0000000003825992

INITIALIZATION PROCEDURE

1. Disconnect battery negative terminal or power window main switch connector. Reconnect it after a minute

or more.

2. Turn ignition switch ON.

3. Operate power window switch to fully open the window. (This operation is unnecessary if the window is

already fully open)

4. Continue pulling the power window switch UP (AUTO-UP operation). Even after glass stops at the fully

closed position, keep pulling the switch for 2 seconds or more.

5. Initializing procedure is completed.

6. Inspect anti-pinch function.

CHECK ANTI-PINCH FUNCTION

1. Fully open the door window.

2. Place a piece of wood near fully closed position.

3. Close door glass completely with AUTO-UP.

Check that glass lowers for approximately 150 mm (5.9 in) or for 2 seconds without pinching piece of wood

and stops.

Check that glass does not rise when operating the power window main switch while lowering.

CAUTION:

Perform initial setting when auto-up operation or anti-pinch function does not operate normally.

Check that AUTO-UP operates before inspection when system initialization is performed.

Never check with hands or other body parts because they may be pinched. Never get pinched.

It may switch to fail-safe mode if open/close operation is performed continuously without fully clos-

ing. Perform initial setting in that situation. Refer to PWC-72, "

Fail-safe"

Finish initial setting. Otherwise, next operation cannot be done.

1. Auto-up operation

2. Anti-pinch function

Page 3637 of 5121

POWER WINDOW SYSTEM

PWC-7

< FUNCTION DIAGNOSIS >

C

D

E

F

G

H

I

J

L

MA

B

PWC

N

O

P

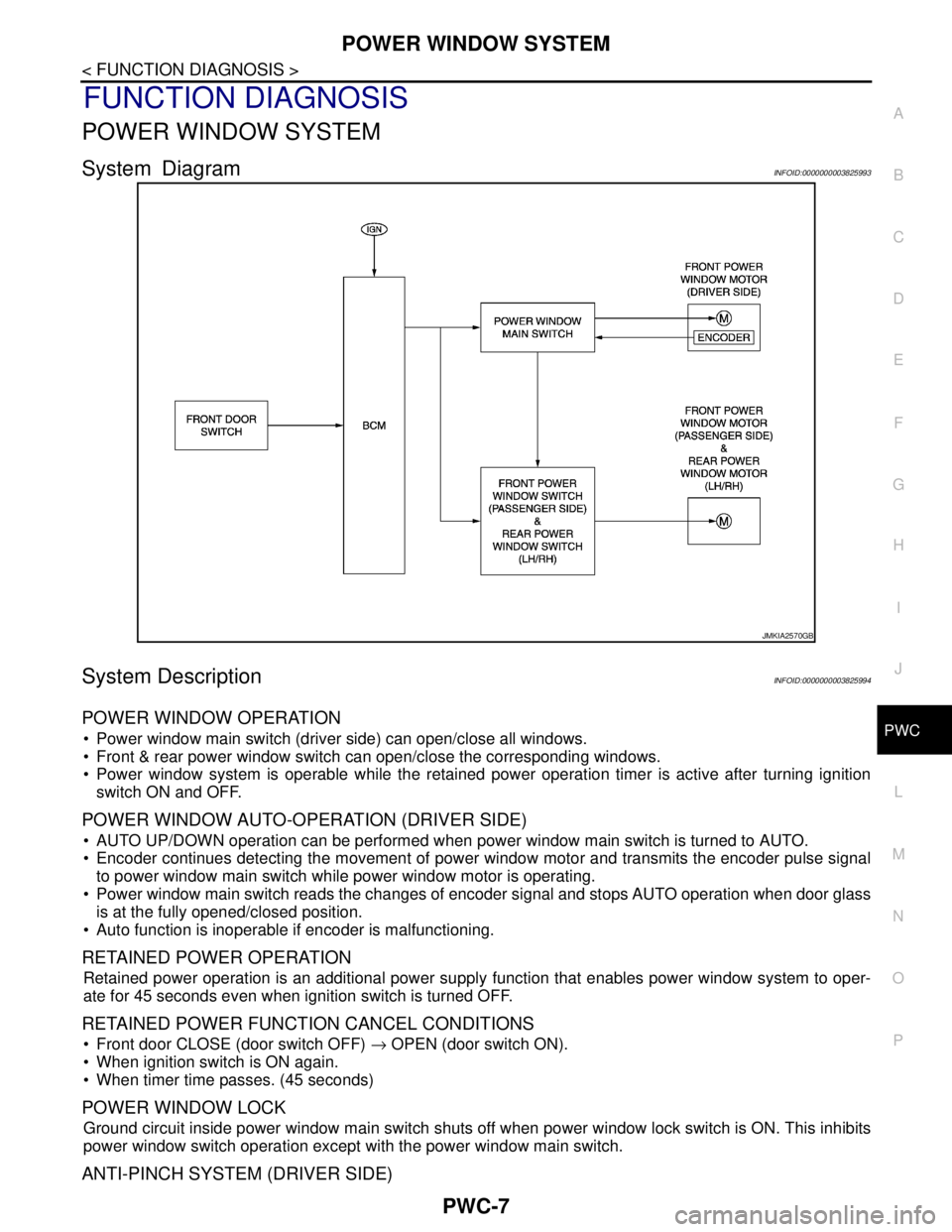

FUNCTION DIAGNOSIS

POWER WINDOW SYSTEM

System DiagramINFOID:0000000003825993

System DescriptionINFOID:0000000003825994

POWER WINDOW OPERATION

Power window main switch (driver side) can open/close all windows.

Front & rear power window switch can open/close the corresponding windows.

Power window system is operable while the retained power operation timer is active after turning ignition

switch ON and OFF.

POWER WINDOW AUTO-OPERATION (DRIVER SIDE)

AUTO UP/DOWN operation can be performed when power window main switch is turned to AUTO.

Encoder continues detecting the movement of power window motor and transmits the encoder pulse signal

to power window main switch while power window motor is operating.

Power window main switch reads the changes of encoder signal and stops AUTO operation when door glass

is at the fully opened/closed position.

Auto function is inoperable if encoder is malfunctioning.

RETAINED POWER OPERATION

Retained power operation is an additional power supply function that enables power window system to oper-

ate for 45 seconds even when ignition switch is turned OFF.

RETAINED POWER FUNCTION CANCEL CONDITIONS

Front door CLOSE (door switch OFF) → OPEN (door switch ON).

When ignition switch is ON again.

When timer time passes. (45 seconds)

POWER WINDOW LOCK

Ground circuit inside power window main switch shuts off when power window lock switch is ON. This inhibits

power window switch operation except with the power window main switch.

ANTI-PINCH SYSTEM (DRIVER SIDE)

JMKIA2570GB

Page 3641 of 5121

DIAGNOSIS SYSTEM (BCM)

PWC-11

< FUNCTION DIAGNOSIS >

C

D

E

F

G

H

I

J

L

MA

B

PWC

N

O

P

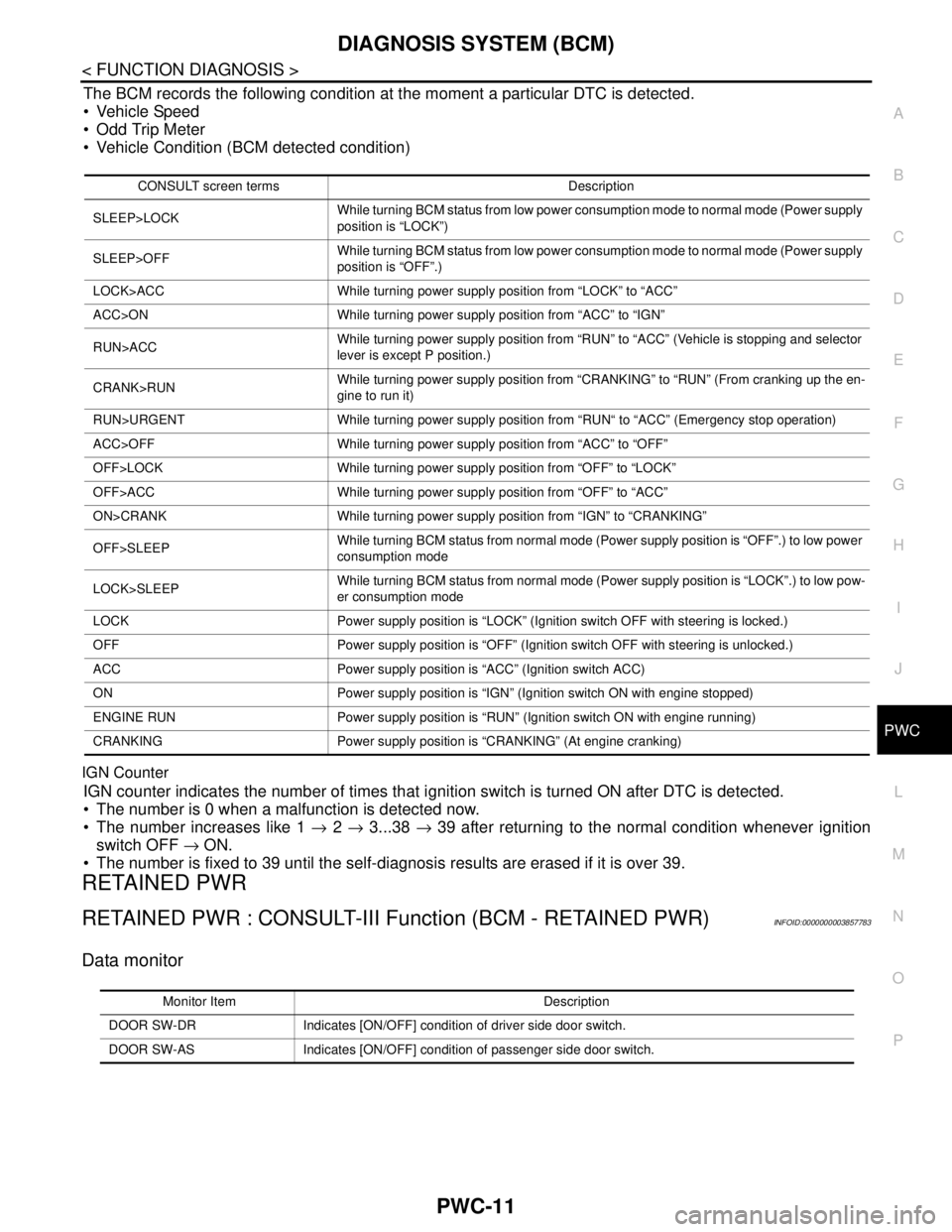

The BCM records the following condition at the moment a particular DTC is detected.

Vehicle Speed

Odd Trip Meter

Vehicle Condition (BCM detected condition)

IGN Counter

IGN counter indicates the number of times that ignition switch is turned ON after DTC is detected.

The number is 0 when a malfunction is detected now.

The number increases like 1 → 2 → 3...38 → 39 after returning to the normal condition whenever ignition

switch OFF → ON.

The number is fixed to 39 until the self-diagnosis results are erased if it is over 39.

RETAINED PWR

RETAINED PWR : CONSULT-III Function (BCM - RETAINED PWR)INFOID:0000000003857783

Data monitor

CONSULT screen terms Description

SLEEP>LOCKWhile turning BCM status from low power consumption mode to normal mode (Power supply

position is “LOCK”)

SLEEP>OFFWhile turning BCM status from low power consumption mode to normal mode (Power supply

position is “OFF”.)

LOCK>ACC While turning power supply position from “LOCK” to “ACC”

ACC>ON While turning power supply position from “ACC” to “IGN”

RUN>ACCWhile turning power supply position from “RUN” to “ACC” (Vehicle is stopping and selector

lever is except P position.)

CRANK>RUNWhile turning power supply position from “CRANKING” to “RUN” (From cranking up the en-

gine to run it)

RUN>URGENT While turning power supply position from “RUN“ to “ACC” (Emergency stop operation)

ACC>OFF While turning power supply position from “ACC” to “OFF”

OFF>LOCK While turning power supply position from “OFF” to “LOCK”

OFF>ACC While turning power supply position from “OFF” to “ACC”

ON>CRANK While turning power supply position from “IGN” to “CRANKING”

OFF>SLEEPWhile turning BCM status from normal mode (Power supply position is “OFF”.) to low power

consumption mode

LOCK>SLEEPWhile turning BCM status from normal mode (Power supply position is “LOCK”.) to low pow-

er consumption mode

LOCK Power supply position is “LOCK” (Ignition switch OFF with steering is locked.)

OFF Power supply position is “OFF” (Ignition switch OFF with steering is unlocked.)

ACC Power supply position is “ACC” (Ignition switch ACC)

ON Power supply position is “IGN” (Ignition switch ON with engine stopped)

ENGINE RUN Power supply position is “RUN” (Ignition switch ON with engine running)

CRANKING Power supply position is “CRANKING” (At engine cranking)

Monitor Item Description

DOOR SW-DR Indicates [ON/OFF] condition of driver side door switch.

DOOR SW-AS Indicates [ON/OFF] condition of passenger side door switch.

Page 3642 of 5121

PWC-12

< COMPONENT DIAGNOSIS >

POWER SUPPLY AND GROUND CIRCUIT

COMPONENT DIAGNOSIS

POWER SUPPLY AND GROUND CIRCUIT

BCM

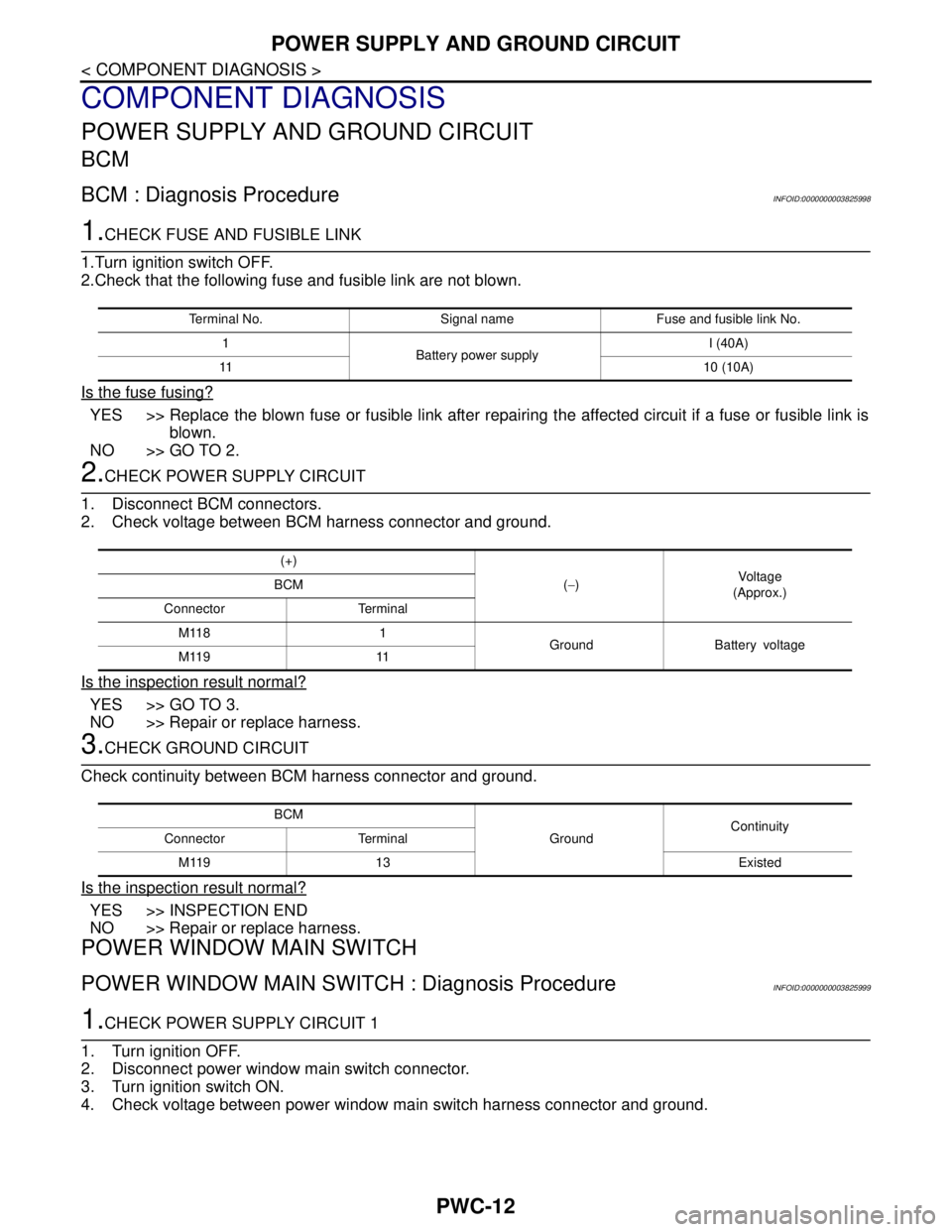

BCM : Diagnosis ProcedureINFOID:0000000003825998

1.CHECK FUSE AND FUSIBLE LINK

1.Turn ignition switch OFF.

2.Check that the following fuse and fusible link are not blown.

Is the fuse fusing?

YES >> Replace the blown fuse or fusible link after repairing the affected circuit if a fuse or fusible link is

blown.

NO >> GO TO 2.

2.CHECK POWER SUPPLY CIRCUIT

1. Disconnect BCM connectors.

2. Check voltage between BCM harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace harness.

3.CHECK GROUND CIRCUIT

Check continuity between BCM harness connector and ground.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Repair or replace harness.

POWER WINDOW MAIN SWITCH

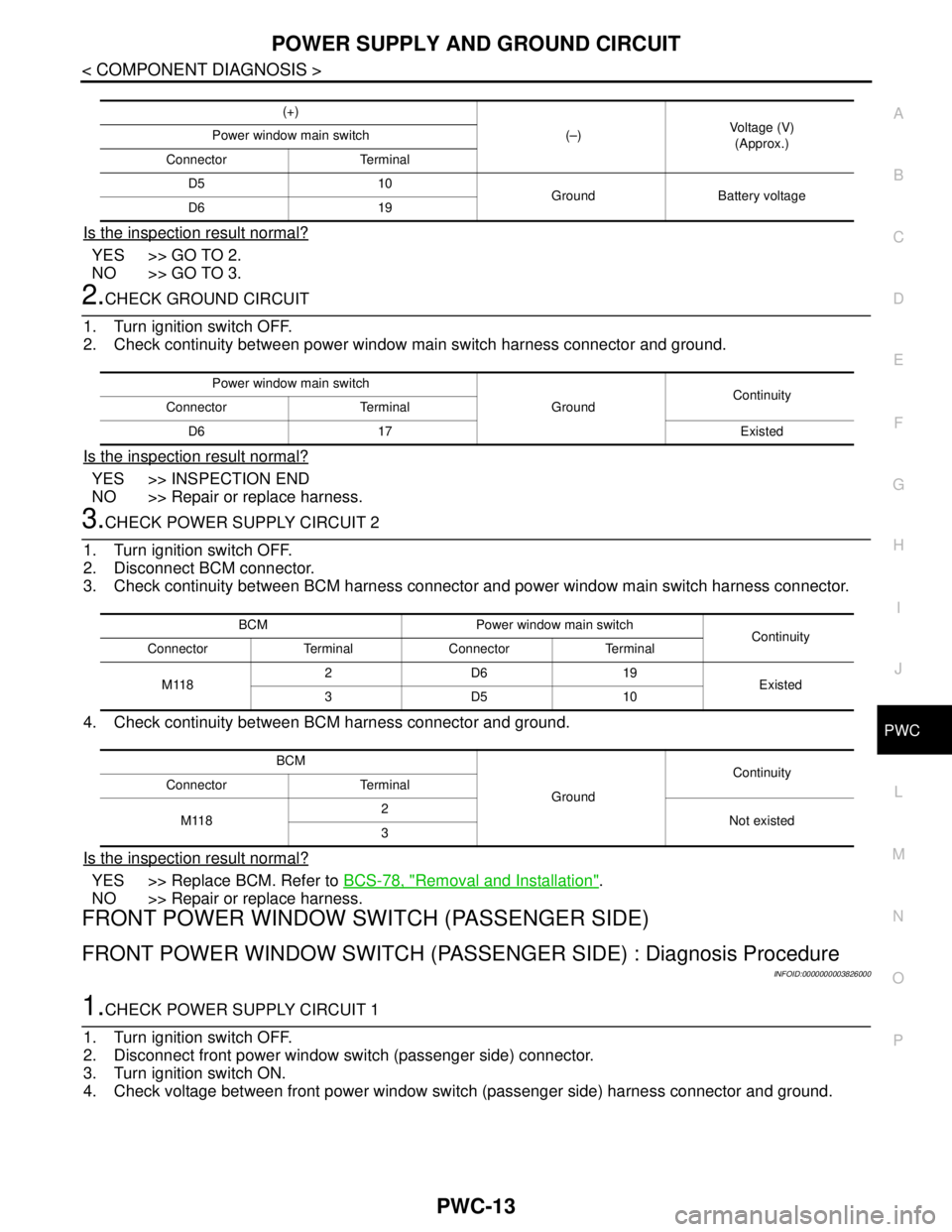

POWER WINDOW MAIN SWITCH : Diagnosis ProcedureINFOID:0000000003825999

1.CHECK POWER SUPPLY CIRCUIT 1

1. Turn ignition OFF.

2. Disconnect power window main switch connector.

3. Turn ignition switch ON.

4. Check voltage between power window main switch harness connector and ground.

Terminal No. Signal name Fuse and fusible link No.

1

Battery power supplyI (40A)

1110 (10A)

(+)

(−)Vo l ta g e

(Approx.) BCM

Connector Terminal

M118 1

Ground Battery voltage

M119 11

BCM

GroundContinuity

Connector Terminal

M119 13 Existed

Page 3643 of 5121

POWER SUPPLY AND GROUND CIRCUIT

PWC-13

< COMPONENT DIAGNOSIS >

C

D

E

F

G

H

I

J

L

MA

B

PWC

N

O

P

Is the inspection result normal?

YES >> GO TO 2.

NO >> GO TO 3.

2.CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between power window main switch harness connector and ground.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Repair or replace harness.

3.CHECK POWER SUPPLY CIRCUIT 2

1. Turn ignition switch OFF.

2. Disconnect BCM connector.

3. Check continuity between BCM harness connector and power window main switch harness connector.

4. Check continuity between BCM harness connector and ground.

Is the inspection result normal?

YES >> Replace BCM. Refer to BCS-78, "Removal and Installation".

NO >> Repair or replace harness.

FRONT POWER WINDOW SWITCH (PASSENGER SIDE)

FRONT POWER WINDOW SWITCH (PASSENGER SIDE) : Diagnosis Procedure

INFOID:0000000003826000

1.CHECK POWER SUPPLY CIRCUIT 1

1. Turn ignition switch OFF.

2. Disconnect front power window switch (passenger side) connector.

3. Turn ignition switch ON.

4. Check voltage between front power window switch (passenger side) harness connector and ground.

(+)

(–)Voltage (V)

(Approx.) Power window main switch

Connector Terminal

D5 10

Ground Battery voltage

D6 19

Power window main switch

GroundContinuity

Connector Terminal

D6 17 Existed

BCM Power window main switch

Continuity

Connector Terminal Connector Terminal

M1182D619

Existed

3D510

BCM

GroundContinuity

Connector Terminal

M1182

Not existed

3

Page 3644 of 5121

PWC-14

< COMPONENT DIAGNOSIS >

POWER SUPPLY AND GROUND CIRCUIT

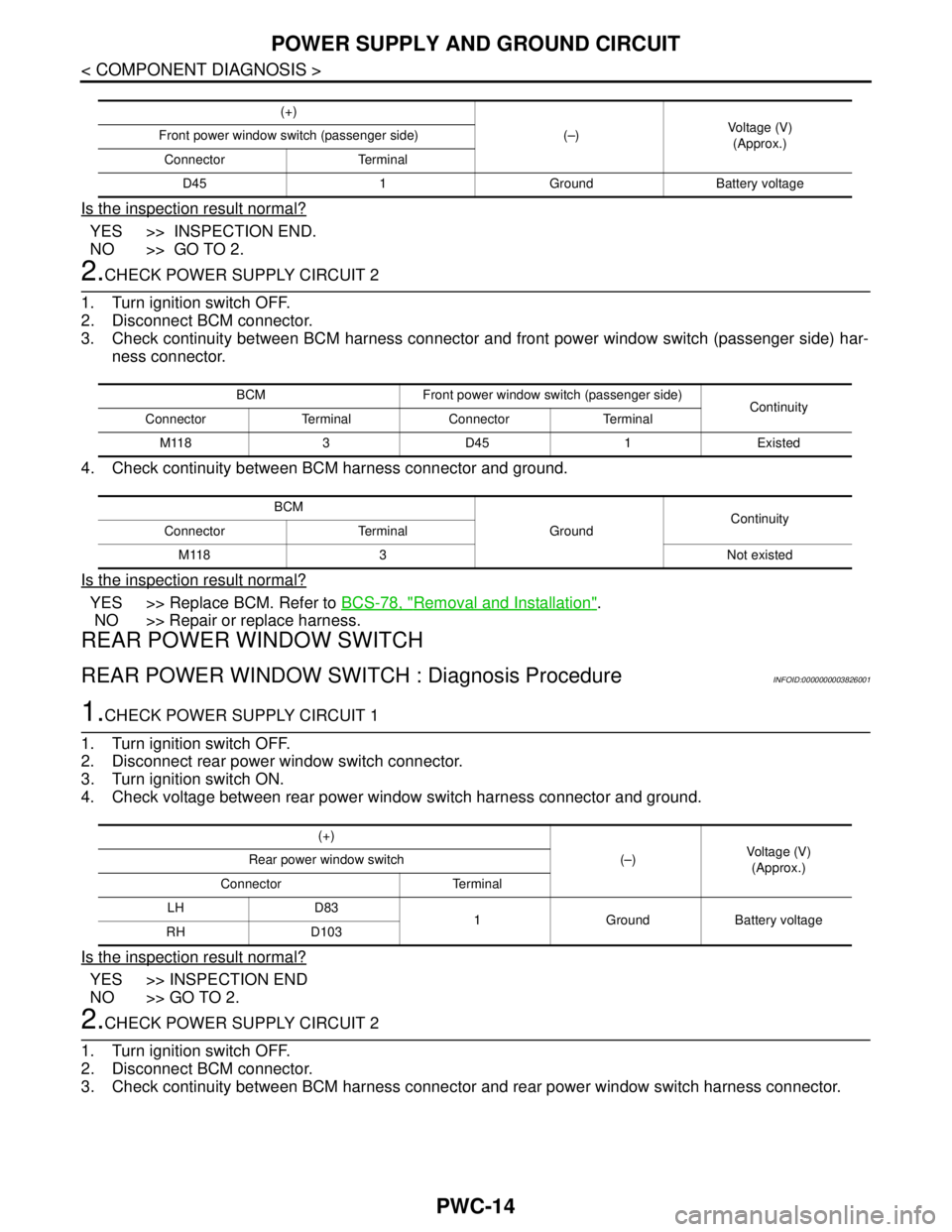

Is the inspection result normal?

YES >> INSPECTION END.

NO >> GO TO 2.

2.CHECK POWER SUPPLY CIRCUIT 2

1. Turn ignition switch OFF.

2. Disconnect BCM connector.

3. Check continuity between BCM harness connector and front power window switch (passenger side) har-

ness connector.

4. Check continuity between BCM harness connector and ground.

Is the inspection result normal?

YES >> Replace BCM. Refer to BCS-78, "Removal and Installation".

NO >> Repair or replace harness.

REAR POWER WINDOW SWITCH

REAR POWER WINDOW SWITCH : Diagnosis ProcedureINFOID:0000000003826001

1.CHECK POWER SUPPLY CIRCUIT 1

1. Turn ignition switch OFF.

2. Disconnect rear power window switch connector.

3. Turn ignition switch ON.

4. Check voltage between rear power window switch harness connector and ground.

Is the inspection result normal?

YES >> INSPECTION END

NO >> GO TO 2.

2.CHECK POWER SUPPLY CIRCUIT 2

1. Turn ignition switch OFF.

2. Disconnect BCM connector.

3. Check continuity between BCM harness connector and rear power window switch harness connector.

(+)

(–)Voltage (V)

(Approx.) Front power window switch (passenger side)

Connector Terminal

D45 1 Ground Battery voltage

BCM Front power window switch (passenger side)

Continuity

Connector Terminal Connector Terminal

M118 3 D45 1 Existed

BCM

GroundContinuity

Connector Terminal

M118 3 Not existed

(+)

(–)Voltage (V)

(Approx.) Rear power window switch

Connector Terminal

LH D83

1 Ground Battery voltage

RH D103