remove seats NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 212 of 5121

![NISSAN TEANA 2008 Service Manual AV-68

< FUNCTION DIAGNOSIS >[BASE AUDIO AND DISPLAY SYSTEM]

DIAGNOSIS SYSTEM (AV CONTROL UNIT)

Displays the communication status between AV control unit (mas-

ter unit) and each unit.

The error co NISSAN TEANA 2008 Service Manual AV-68

< FUNCTION DIAGNOSIS >[BASE AUDIO AND DISPLAY SYSTEM]

DIAGNOSIS SYSTEM (AV CONTROL UNIT)

Displays the communication status between AV control unit (mas-

ter unit) and each unit.

The error co](/img/5/57391/w960_57391-211.png)

AV-68

< FUNCTION DIAGNOSIS >[BASE AUDIO AND DISPLAY SYSTEM]

DIAGNOSIS SYSTEM (AV CONTROL UNIT)

Displays the communication status between AV control unit (mas-

ter unit) and each unit.

The error counter displays “OK” if any malfunction was not

detected in the past and displays “0” if a malfunction is detected. It

increases by 1 if the condition is normal at the next ignition switch

ON cycle. The upper limit of the counter is 39.

If it resets, the error counter is erased.

Delete Unit Connection Log

Deletes any unit connection records and error records from the AV

control unit memory. (Clear the records of the unit that has been

removed)

CONSULT-III Function (MULTI AV)INFOID:0000000003882712

CONSULT-III FUNCTIONS

CONSULT-III performs the following functions via the communication with the AV control unit.

AV COMMUNICATION

When “AV communication” of “CAN Diag Support Monitor” is selected, the following function will be performed.

SELF-DIAGNOSIS RESULTS

In CONSULT-III self-diagnosis, self-diagnosis results and error history are displayed collectively.

The timing is displayed as “0” if any of the error codes [U1000], [U1010], [U1300] and [U1310] is detected.

The counter increases by 1 if the condition is normal at the next ignition switch ON cycle.

Self-diagnosis Results Display Item

ItemsStatus

(Current)Counter

(Past)

C Tx(ITM–SW) OK / UNKWN OK / 0 – 39

C Rx(PrimarySW–ITM) OK / UNKWN OK / 0 – 39

C Rx(RrSeatSW–ITM) OK / UNKWN OK / 0 – 39

C Rx(RearCamera–ITM) OK / UNKWN OK / 0 – 39

JSNIA1439GB

JSNIA0154GB

Diagnosis mode Description

Ecu Identification The part number of AV control unit can be checked.

Self Diagnostic ResultPerforms a diagnosis on the AV control unit and a connection diagnosis for the communication

circuit of the Multi AV system, and displays the current and past malfunctions collectively.

Data Monitor The diagnosis of vehicle signal that is input to the AV control unit can be performed.

AV communicationAV&NAVI C/UDisplays the communication status from AV control unit to each unit as well as the error

counter.

AUDIO Displays the AV control unit communication status and the error counter.

Error item Detection logic Possible malfunction factor/Action to take

CAN COMM CIRCUIT [U1000]CAN communication malfunction is detect-

ed.Refer to AV- 7 2 , "

DiagnosisProcedure".

Page 355 of 5121

![NISSAN TEANA 2008 Service Manual AV

DIAGNOSIS SYSTEM (AV CONTROL UNIT)

AV-211

< FUNCTION DIAGNOSIS >[BOSE AUDIO WITHOUT NAVIGATION]

C

D

E

F

G

H

I

J

K

L

MB A

O

P Delete Unit Connection Log

Deletes any unit connection records and error NISSAN TEANA 2008 Service Manual AV

DIAGNOSIS SYSTEM (AV CONTROL UNIT)

AV-211

< FUNCTION DIAGNOSIS >[BOSE AUDIO WITHOUT NAVIGATION]

C

D

E

F

G

H

I

J

K

L

MB A

O

P Delete Unit Connection Log

Deletes any unit connection records and error](/img/5/57391/w960_57391-354.png)

AV

DIAGNOSIS SYSTEM (AV CONTROL UNIT)

AV-211

< FUNCTION DIAGNOSIS >[BOSE AUDIO WITHOUT NAVIGATION]

C

D

E

F

G

H

I

J

K

L

MB A

O

P Delete Unit Connection Log

Deletes any unit connection records and error records from the AV

control unit memory. (Clear the records of the unit that has been

removed)

CONSULT-III Function (MULTI AV)INFOID:0000000003765658

CONSULT-III FUNCTIONS

CONSULT-III performs the following functions via the communication with the AV control unit.

AV COMMUNICATION

When “AV communication” of “CAN Diag Support Monitor” is selected, the following function will be performed.

SELF-DIAGNOSIS RESULTS

In CONSULT-III self-diagnosis, self-diagnosis results and error history are displayed collectively.

The timing is displayed as “0” if any of the error codes [U1000], [U1010], [U1300] and [U1310] is detected.

The counter increases by 1 if the condition is normal at the next ignition switch ON cycle.

Self-diagnosis Results Display Item

C Rx(RrSeatSW–ITM) OK / UNKWN OK / 0 – 39

C Rx(Amp–ITM) OK / UNKWN OK / 0 – 39

C Rx(RearCamera–ITM) OK / UNKWN OK / 0 – 39

C Rx(DVD–ITM) OK / UNKWN OK / 0 – 39

C Rx(AmpAudio–ITM) OK / UNKWN OK / 0 – 39

C Rx(DVDAudio–ITM) OK / UNKWN OK / 0 – 39ItemsStatu s

(Current)Counter

(Past)

JSNIA0154GB

Diagnosis mode Description

Ecu Identification The part number of AV control unit can be checked.

Self Diagnostic ResultPerforms a diagnosis on the AV control unit and a connection diagnosis for the communication

circuit of the Multi AV system, and displays the current and past malfunctions collectively.

Data Monitor The diagnosis of vehicle signal that is input to the AV control unit can be performed.

AV communicationAV&NAVI C/UDisplays the communication status from AV control unit to each unit as well as the error

counter.

AUDIO Displays the AV control unit communication status and the error counter.

Error item Detection logic Possible malfunction factor/Action to take

CAN COMM CIRCUIT [U1000]CAN communication malfunction is detect-

ed.Refer to AV- 2 1 6 , "

DiagnosisProcedure".

CONTROL UNIT (CAN) [U1010]CAN initial diagnosis malfunction is detect-

ed.

Replace the AV control unit.

Refer toAV- 3 7 8 , "

Removal and Installation"

AV- 3 7 8 , "

Removal and Installation". CONTROL UNIT (AV) [U1310]AV communication circuit initial diagnosis

malfunction is detected.

Control Unit FLASH-ROM [U1200]

AV control unit malfunction is detected.

CAN CONT [U1216]

Page 577 of 5121

![NISSAN TEANA 2008 Service Manual AV

DIAGNOSIS SYSTEM (AV CONTROL UNIT)

AV-433

< FUNCTION DIAGNOSIS >[BOSE AUDIO WITH NAVIGATION]

C

D

E

F

G

H

I

J

K

L

MB A

O

P Vehicle CAN Diagnosis

CAN communication status and error counter is displ NISSAN TEANA 2008 Service Manual AV

DIAGNOSIS SYSTEM (AV CONTROL UNIT)

AV-433

< FUNCTION DIAGNOSIS >[BOSE AUDIO WITH NAVIGATION]

C

D

E

F

G

H

I

J

K

L

MB A

O

P Vehicle CAN Diagnosis

CAN communication status and error counter is displ](/img/5/57391/w960_57391-576.png)

AV

DIAGNOSIS SYSTEM (AV CONTROL UNIT)

AV-433

< FUNCTION DIAGNOSIS >[BOSE AUDIO WITH NAVIGATION]

C

D

E

F

G

H

I

J

K

L

MB A

O

P Vehicle CAN Diagnosis

CAN communication status and error counter is displayed.

The error counter displays “OK” if any malfunction was not

detected in the past and displays “0” if a malfunction is detected. It

increases by 1 if the condition is normal at the next ignition switch

ON cycle. The upper limit of the counter is 39.

The error counter is erased if reset.

AV COMM Diagnosis

Displays the communication status between AV control unit (mas-

ter unit) and each unit.

The error counter displays “OK” if any malfunction was not

detected in the past and displays “0” if a malfunction is detected. It

increases by 1 if the condition is normal at the next ignition switch

ON cycle. The upper limit of the counter is 39.

If it resets, the error counter is erased.

Delete Unit Connection Log

Deletes any unit connection records and error records from the AV

control unit memory. (Clear the records of the unit that has been

removed)

Initialize Settings

Items Display (Current)Malfunction counter

(Past)

Tx (HVAC) OK / UNKWN OK / 0 – 39

Rx (ECM) OK / UNKWN OK / 0 – 39

Rx (Cluster) OK / UNKWN OK / 0 – 39

Rx (BCM) OK / UNKWN OK / 0 – 39

Rx (HVAC) OK / UNKWN OK / 0 – 39

Rx (USM) OK / UNKWN OK / 0 – 39

JSNIA1287GB

ItemsStatu s

(Current)Counter

(Past)

C Tx(ITM–SW) OK / UNKWN OK / 0 – 39

C Rx(PrimarySW–ITM) OK / UNKWN OK / 0 – 39

C Rx(RrSeatSW–ITM) OK / UNKWN OK / 0 – 39

C Rx(Amp–ITM) OK / UNKWN OK / 0 – 39

C Rx(RearCamera–ITM) OK / UNKWN OK / 0 – 39

C Rx(DVD–ITM) OK / UNKWN OK / 0 – 39

C Rx(DVDNavi–ITM) OK / UNKWN OK / 0 – 39

C Rx(AmpAudio–ITM) OK / UNKWN OK / 0 – 39

C Rx(DVDAudio–ITM) OK / UNKWN OK / 0 – 39

JSNIA1292GB

JSNIA0522GB

Page 1673 of 5121

![NISSAN TEANA 2008 Service Manual EC-212

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

P0300, P0301, P0302, P0303, P0304, P0305, P0306 MISFIRE

7.CHECK SPARK PLUG

Check the initial spark plug for fouling, etc.

Is the inspection result normal NISSAN TEANA 2008 Service Manual EC-212

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

P0300, P0301, P0302, P0303, P0304, P0305, P0306 MISFIRE

7.CHECK SPARK PLUG

Check the initial spark plug for fouling, etc.

Is the inspection result normal](/img/5/57391/w960_57391-1672.png)

EC-212

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

P0300, P0301, P0302, P0303, P0304, P0305, P0306 MISFIRE

7.CHECK SPARK PLUG

Check the initial spark plug for fouling, etc.

Is the inspection result normal?

YES >> Replace spark plug(s) with standard type one(s). For

spark plug type, refer to EM-136, "

Spark Plug".

NO >> Repair or clean spark plug. Then GO TO 8.

8.CHECK FUNCTION OF IGNITION COIL-III

1. Reconnect the initial spark plugs.

2. Crank engine for about 3 seconds, and recheck whether spark is generated between the spark plug and

the grounded portion.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace spark plug(s) with standard type one(s). For spark plug type, refer to EM-136, "

Spark

Plug".

9.CHECK COMPRESSION PRESSURE

Check compression pressure. Refer to EM-22, "

Inspection".

Is the inspection result normal?

YES >> GO TO 10.

NO >> Check pistons, piston rings, valves, valve seats and cylinder head gaskets.

10.CHECK FUEL PRESSURE

1. Install all removed parts.

2. Release fuel pressure to zero. Refer to EC-411, "

Inspection".

3. Install fuel pressure gauge and check fuel pressure. Refer to EC-411, "

Inspection".

Is the inspection result normal?

YES >> GO TO 12.

NO >> GO TO 11.

11 .DETECT MALFUNCTIONING PART

Check fuel hoses and fuel tubes for clogging.

Is the inspection result normal?

YES >> Replace “fuel filter and fuel pump assembly”.

NO >> Repair or replace malfunctioning part.

12.CHECK IGNITION TIMING

Check idle speed and ignition timing.

For procedure, refer to EC-11, "

BASIC INSPECTION : Special Repair Requirement".

For specification, refer to EC-414, "

Idle Speed" and EC-414, "Ignition Timing".

Is the inspection result normal?

YES >> GO TO 13.

NO >> Follow the EC-11, "

BASIC INSPECTION : Special Repair Requirement".

13.CHECK A/F SENSOR 1 INPUT SIGNAL CIRCUIT

1. Turn ignition switch OFF.

SEF156I

Spark should be generated.

At idle: Approximately 350 kPa (3.50 bar, 3.57 kg/cm

2, 51 psi)

Page 1977 of 5121

EM-102

< DISASSEMBLY AND ASSEMBLY >

CYLINDER HEAD

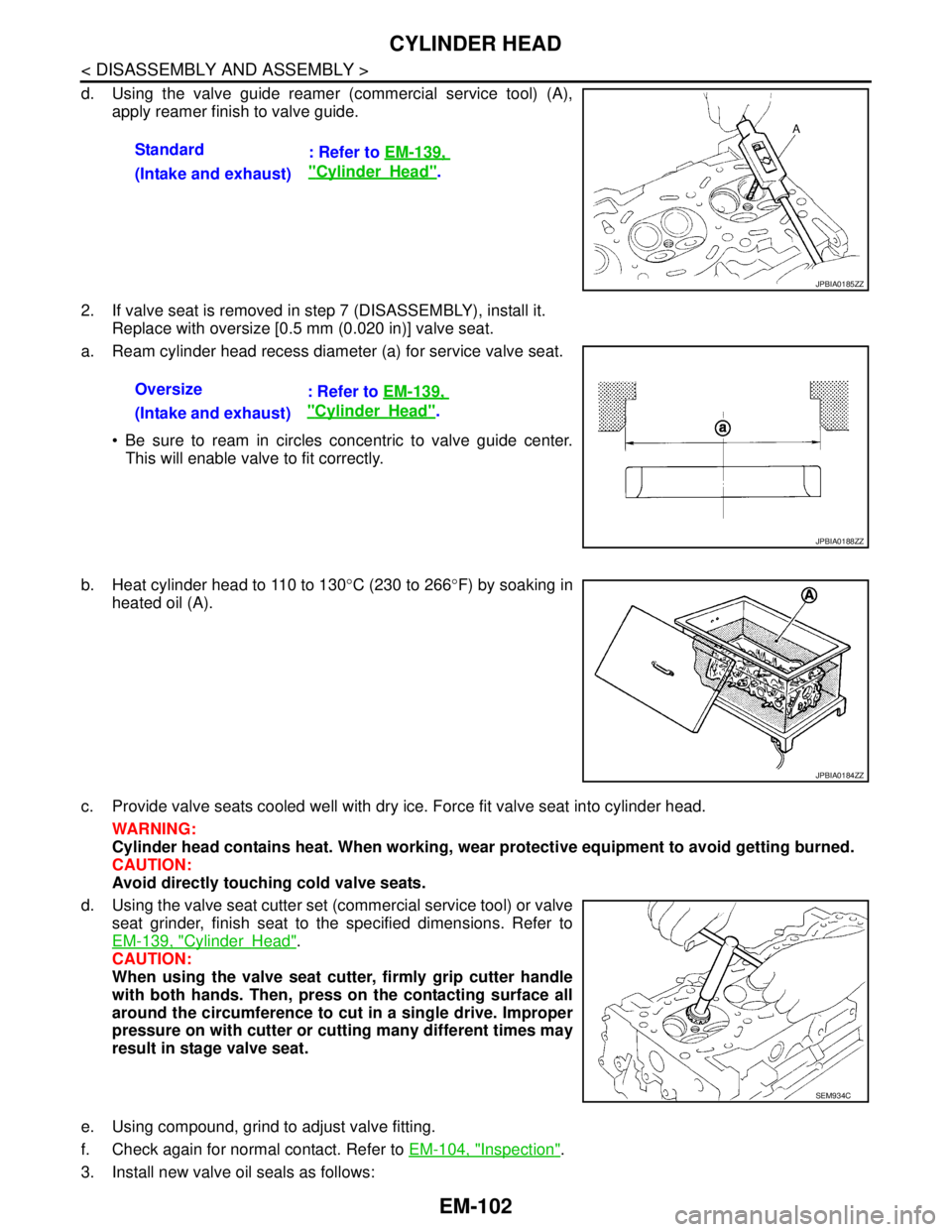

d. Using the valve guide reamer (commercial service tool) (A),

apply reamer finish to valve guide.

2. If valve seat is removed in step 7 (DISASSEMBLY), install it.

Replace with oversize [0.5 mm (0.020 in)] valve seat.

a. Ream cylinder head recess diameter (a) for service valve seat.

Be sure to ream in circles concentric to valve guide center.

This will enable valve to fit correctly.

b. Heat cylinder head to 110 to 130°C (230 to 266°F) by soaking in

heated oil (A).

c. Provide valve seats cooled well with dry ice. Force fit valve seat into cylinder head.

WARNING:

Cylinder head contains heat. When working, wear protective equipment to avoid getting burned.

CAUTION:

Avoid directly touching cold valve seats.

d. Using the valve seat cutter set (commercial service tool) or valve

seat grinder, finish seat to the specified dimensions. Refer to

EM-139, "

CylinderHead".

CAUTION:

When using the valve seat cutter, firmly grip cutter handle

with both hands. Then, press on the contacting surface all

around the circumference to cut in a single drive. Improper

pressure on with cutter or cutting many different times may

result in stage valve seat.

e. Using compound, grind to adjust valve fitting.

f. Check again for normal contact. Refer to EM-104, "

Inspection".

3. Install new valve oil seals as follows:Standard

: Refer to EM-139,

"CylinderHead".

(Intake and exhaust)

JPBIA0185ZZ

Oversize

: Refer to EM-139,

"CylinderHead".

(Intake and exhaust)

JPBIA0188ZZ

JPBIA0184ZZ

SEM934C

Page 3808 of 5121

PRECAUTIONS

RF-77

< PRECAUTION >

C

D

E

F

G

H

I

J

L

MA

B

RF

N

O

P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000003940151

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the “SRS AIRBAG” and

“SEAT BELT” of this Service Manual.

WARNING:

To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SRS AIRBAG”.

Never use electrical test equipment on any circuit related to the SRS unless instructed to in this Ser-

vice Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or harness

connectors.

Service NoticeINFOID:0000000003812880

When removing or installing various parts, place a cloth or padding onto the vehicle body to prevent

scratches.

Handle trim, molding, instruments, grille, etc. carefully during removing or installing. Be careful not to oil or

damage them.

Apply sealing compound where necessary when installing parts.

When applying sealing compound, be careful that the sealing compound does not protrude from parts.

When replacing any metal parts (for example body outer panel, members, etc.), be sure to take rust preven-

tion measures.

Precaution for WorkINFOID:0000000003812881

When removing or disassembling each component, be careful not to damage or deform it. If a component

may be subject to interference, be sure to protect it with a shop cloth.

When removing (disengaging) components with a screwdriver or similar tool, be sure to wrap the component

with a shop cloth or vinyl tape to protect it.

Protect the removed parts with a shop cloth and keep them.

Replace a deformed or damaged clip.

If a part is specified as a non-reusable part, always replace it with new one.

Be sure to tighten bolts and nuts securely to the specified torque.

After re-installation is completed, be sure to check that each part works normally.

Follow the steps below to clean components.

- Water soluble foul: Dip a soft cloth into lukewarm water, and wring the water out of the cloth to wipe the

fouled area.

Then rub with a soft and dry cloth.

- Oily foul: Dip a soft cloth into lukewarm water with mild detergent (concentration: within 2 to 3%), and wipe

the fouled area.

Then dip a cloth into fresh water, and wring the water out of the cloth to wipe the detergent off. Then rub with

a soft and dry cloth.

Do not use organic solvent such as thinner, benzene, alcohol, and gasoline.

For genuine leather seats, use a genuine leather seat cleaner.

Page 3855 of 5121

FRONT SEAT BELT

SB-3

< ON-VEHICLE REPAIR >

C

D

E

F

G

I

J

K

L

MA

B

SB

N

O

P

ON-VEHICLE REPAIR

FRONT SEAT BELT

SEAT BELT RETRACTOR

SEAT BELT RETRACTOR : InspectionINFOID:0000000003848852

AFTER A COLLISION

WARNING:

Inspect all seat belt assemblies including retractors and attached hardware after any collision.

NISSAN/INFINITI recommends that all seat belt assemblies in use during a collision be replaced

unless the collision is minor and the belts show no damage and continue to operate properly. Not

doing so could result in serious personal injury in an accident. Seat belt assemblies not in use during

a collision must also be replaced if either damage or improper operation is noted. Seat belt pre-ten-

sioners must be replaced even if the seat belts are not in use during a frontal collision in which the air

bags are deployed.

Replace any seat belt assembly (including anchor bolts) if:

The seat belt was in use at the time of a collision (except for minor collisions and the belts, retractors and

buckles show no damage and continue to operate properly).

The seat belt was damaged in an accident (i.e. torn webbing, bent retractor or guide, etc.).

The seat belt attaching point was damaged in an accident. Inspect the seat belt attaching area for damage

or distortion and repair as necessary before installing a new seat belt assembly.

Anchor bolts are deformed or worn out.

The seat belt pre-tensioners should be replaced even if the seat belts are not in use during the collision in

which the air bags are deployed.

PRELIMINARY CHECKS

1. Check the seat belt warning lamp/chime for proper operation as follows:

a. Turn ignition switch ON. The seat belt warning lamp should illuminate. Also, the seat belt warning chime

should sound for about six seconds.

b. Fasten driver seat belt. The seat belt warning lamp should turn off and the chime (if sounding) should

stop.

2. If the air bag warning lamp is blinking, conduct self-diagnosis with CONSULT-III and air bag warning lamp.

Refer to SRC-10, "

Diagnosis Description".

3. Check that the seat belt retractor, seat belt anchor and buckle bolts are securely attached.

4. Check the shoulder seat belt guide and shoulder belt height adjuster for front seats. Ensure guide swivels

freely and that webbing lays flat and does not bind in guide. Ensure height adjuster operates properly and

holds securely.

5. Check retractor operation:

a. Fully extend the seat belt webbing and check for twists, tears or other damage.

b. Allow the seat belt to retract. Ensure that webbing returns smoothly and completely into the retractor. If

the seat belt does not return smoothly, wipe the inside of the loops with a clean paper cloth. Because dirt

build-up in the loops of the upper anchors can cause the seat belts to retract slowly.

c. Fasten the seat belt. Check that seat belt returns smoothly and completely to the retractor. If the webbing

does not return smoothly, the cause may be an accumulation of dust or dirt. Use the “SEAT BELT TAPE

SET” and perform the following steps.

Inspect the front seat belt through-anchor

1. Pull the seat belt out to a length of 500 mm (19.69 in) or more.

2. Fix the seat belt at the center pillar webbing opening with a clip or other device.

3. Pass a thin wire through the through-anchor webbing opening. Hold both ends of the wire and pull it

tauntly while moving it up and down several times along the webbing opening surface to remove dirt

stuck there.

4. Any dirt that cannot be removed with the wire can be removed by cleaning the opening with a clean

cloth.

5. Apply tape at the point where the webbing contacts the through-anchor webbing opening.

NOTE:

Apply the tape so that there is no looseness or wrinkling.

Page 3856 of 5121

SB-4

< ON-VEHICLE REPAIR >

FRONT SEAT BELT

6. Remove the clip fixing the seat belt and check that the webbing returns smoothly.

6. Repeat steps above as necessary to check the other seat belts.

SEAT BELT RETRACTOR ON-VEHICLE CHECK

Emergency Locking Retractors (ELR) and Automatic Locking Retractors (ALR)

NOTE:

All seat belt retractors are Emergency Locking Retractors (ELR) type. In an emergency (sudden stop) the

retractor will lock and prevent the webbing from extending any further. All 3-point type seat belt retractors

except the driver seat belt also have an Automatic Locking Retractors (ALR) mode. The ALR mode (also

called child restraint mode) is used when installing child seats. The ALR mode is activated when the seat belt

is fully extended. When the webbing is then retracted partially, the ALR mode automatically locks the seat belt

in a specific position so the webbing cannot be extended any further. To cancel the ALR mode, allow the seat

belt to fully wind back into the retractor.

Check the seat belt retractors with the following test(s) to determine if a retractor assembly is operating prop-

erly.

ELR Function Stationary Check

Grasp the shoulder webbing and pull forward quickly. The retractor should lock and prevent the belt from

extending further.

ALR Function Stationary Check

1. Pull out the entire length of seat belt from retractor until a click is heard.

2. Retract the webbing partially. A clicking noise should be heard as the webbing retracts indicating that the

retractor is in the Automatic Locking Retractors (ALR) mode.

3. Grasp the seat belt and try to pull out the retractor. The webbing must lock and not extend any further. If

NG, replace the retractor assembly.

4. Allow the entire length of the webbing to retract to cancel the automatic locking mode.

ELR Function Moving Check

WARNING:

Perform the following test in a safe, open area clear of other vehicles and obstructions (for example, a

large, empty parking lot). Road surface must be paved and dry. Never perform the following test on

wet or gravel roads or on public streets and highways. This could result in an accident and serious

personal injury. The driver and passenger must be prepared to brace themselves in the event that the

retractor does not lock.

1. Fasten driver seat belt. Buckle a passenger into the seat for the belt that is to be tested.

2. Proceed to the designated safe area.

3. Drive the vehicle at approximately 16 km/h (10 MPH). Notify any passengers of a pending sudden stop

and the driver and passenger must be prepared to brace themselves in the event that the retractor does

not lock, apply brakes firmly and make a very hard stop.

During stopping, seat belts should lock and not be extended. If the seat belt retractor assembly does not lock,

perform the retractor off-vehicle check.

SEAT BELT RETRACTOR OFF-VEHICLE CHECK

1. Remove the seat belt retractor.

Remove the front seat belt assembly, refer to SB-5, "

SEAT BELT RETRACTOR : Removal and Installa-

tion".

2. Slowly pull out webbing while tilting the retractor assembly forward from the mounted position without

twisting the retractor assembly as shown in the illustration.

Page 3951 of 5121

![NISSAN TEANA 2008 Service Manual PRECAUTIONS

SE-87

< PRECAUTION >[WITH VENTILATION SEAT]

C

D

E

F

G

H

I

K

L

MA

B

SE

N

O

P

When replacing any metal parts (for example body outer panel, members, etc.), be sure to take rust preven-

tio NISSAN TEANA 2008 Service Manual PRECAUTIONS

SE-87

< PRECAUTION >[WITH VENTILATION SEAT]

C

D

E

F

G

H

I

K

L

MA

B

SE

N

O

P

When replacing any metal parts (for example body outer panel, members, etc.), be sure to take rust preven-

tio](/img/5/57391/w960_57391-3950.png)

PRECAUTIONS

SE-87

< PRECAUTION >[WITH VENTILATION SEAT]

C

D

E

F

G

H

I

K

L

MA

B

SE

N

O

P

When replacing any metal parts (for example body outer panel, members, etc.), be sure to take rust preven-

tion measures.

Precaution for WorkINFOID:0000000003809272

When removing or disassembling each component, be careful not to damage or deform it. If a component

may be subject to interference, be sure to protect it with a shop cloth.

When removing (disengaging) components with a screwdriver or similar tool, be sure to wrap the component

with a shop cloth or vinyl tape to protect it.

Protect the removed parts with a shop cloth and keep them.

Replace a deformed or damaged clip.

If a part is specified as a non-reusable part, always replace it with new one.

Be sure to tighten bolts and nuts securely to the specified torque.

After re-installation is completed, be sure to check that each part works normally.

Follow the steps below to clean components.

- Water soluble foul: Dip a soft cloth into lukewarm water, and wring the water out of the cloth to wipe the

fouled area.

Then rub with a soft and dry cloth.

- Oily foul: Dip a soft cloth into lukewarm water with mild detergent (concentration: within 2 to 3%), and wipe

the fouled area.

Then dip a cloth into fresh water, and wring the water out of the cloth to wipe the detergent off. Then rub with

a soft and dry cloth.

Never use organic solvent such as thinner, benzene, alcohol, and gasoline.

For genuine leather seats, use a genuine leather seat cleaner.

Page 3992 of 5121

![NISSAN TEANA 2008 Service Manual SE-128

< PRECAUTION >[WITHOUT VENTILATION SEAT]

PRECAUTIONS

When replacing any metal parts (for example body outer panel, members, etc.), be sure to take rust preven-

tion measures.

Precaution for W NISSAN TEANA 2008 Service Manual SE-128

< PRECAUTION >[WITHOUT VENTILATION SEAT]

PRECAUTIONS

When replacing any metal parts (for example body outer panel, members, etc.), be sure to take rust preven-

tion measures.

Precaution for W](/img/5/57391/w960_57391-3991.png)

SE-128

< PRECAUTION >[WITHOUT VENTILATION SEAT]

PRECAUTIONS

When replacing any metal parts (for example body outer panel, members, etc.), be sure to take rust preven-

tion measures.

Precaution for WorkINFOID:0000000003840020

When removing or disassembling each component, be careful not to damage or deform it. If a component

may be subject to interference, be sure to protect it with a shop cloth.

When removing (disengaging) components with a screwdriver or similar tool, be sure to wrap the component

with a shop cloth or vinyl tape to protect it.

Protect the removed parts with a shop cloth and keep them.

Replace a deformed or damaged clip.

If a part is specified as a non-reusable part, always replace it with new one.

Be sure to tighten bolts and nuts securely to the specified torque.

After re-installation is completed, be sure to check that each part works normally.

Follow the steps below to clean components.

- Water soluble foul: Dip a soft cloth into lukewarm water, and wring the water out of the cloth to wipe the

fouled area.

Then rub with a soft and dry cloth.

- Oily foul: Dip a soft cloth into lukewarm water with mild detergent (concentration: within 2 to 3%), and wipe

the fouled area.

Then dip a cloth into fresh water, and wring the water out of the cloth to wipe the detergent off. Then rub with

a soft and dry cloth.

Never use organic solvent such as thinner, benzene, alcohol, and gasoline.

For genuine leather seats, use a genuine leather seat cleaner.