ignition NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 4444 of 5121

STC-16

< ECU DIAGNOSIS >

POWER STEERING CONTROL UNIT

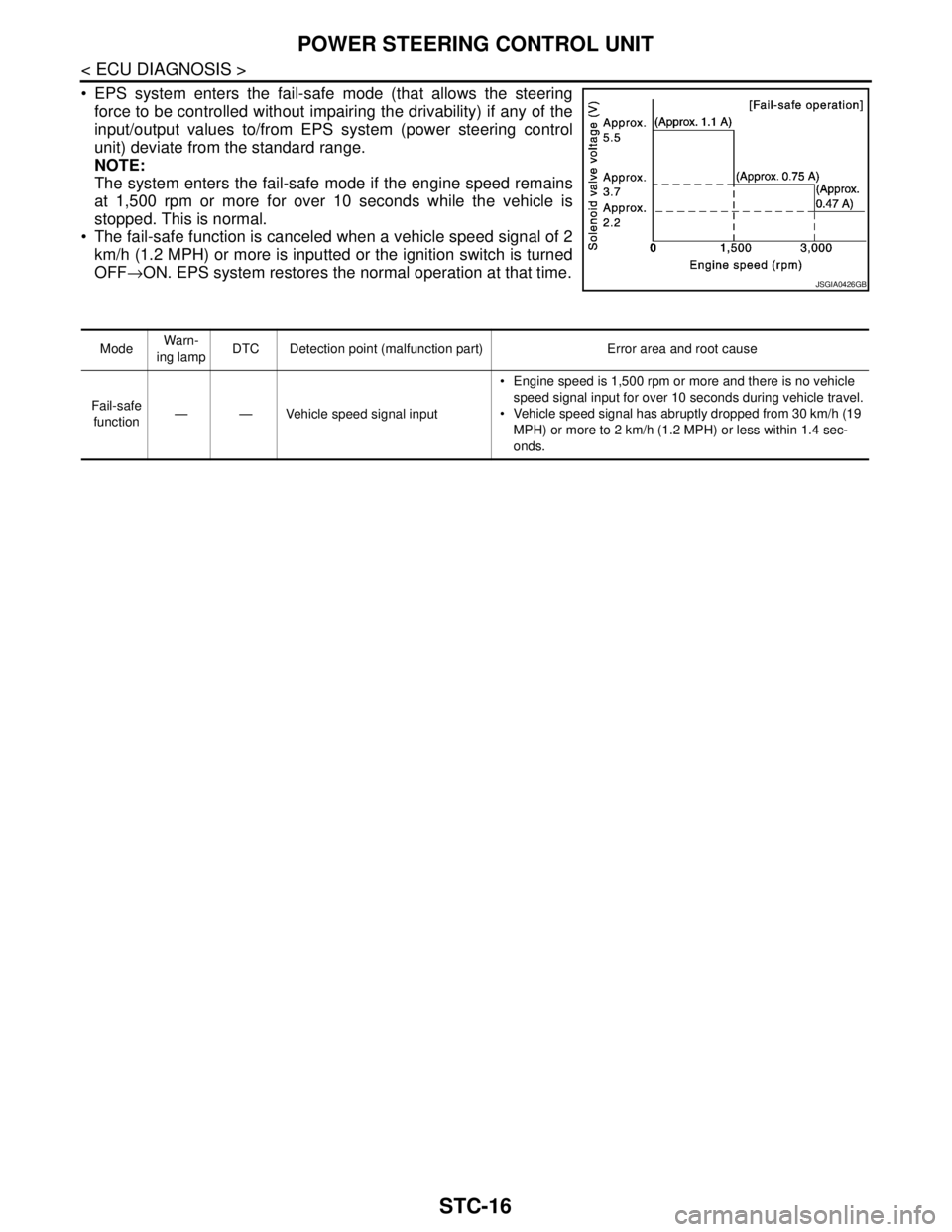

EPS system enters the fail-safe mode (that allows the steering

force to be controlled without impairing the drivability) if any of the

input/output values to/from EPS system (power steering control

unit) deviate from the standard range.

NOTE:

The system enters the fail-safe mode if the engine speed remains

at 1,500 rpm or more for over 10 seconds while the vehicle is

stopped. This is normal.

The fail-safe function is canceled when a vehicle speed signal of 2

km/h (1.2 MPH) or more is inputted or the ignition switch is turned

OFF→ON. EPS system restores the normal operation at that time.

JSGIA0426GB

ModeWarn-

ing lampDTC Detection point (malfunction part) Error area and root cause

Fail-safe

function— — Vehicle speed signal input Engine speed is 1,500 rpm or more and there is no vehicle

speed signal input for over 10 seconds during vehicle travel.

Vehicle speed signal has abruptly dropped from 30 km/h (19

MPH) or more to 2 km/h (1.2 MPH) or less within 1.4 sec-

onds.

Page 4446 of 5121

STC-18

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000003971959

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the “SRS AIRBAG” and

“SEAT BELT” of this Service Manual.

WARNING:

To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SRS AIRBAG”.

Never use electrical test equipment on any circuit related to the SRS unless instructed to in this Ser-

vice Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or harness

connectors.

Precaution Necessary for Steering Wheel Rotation after Battery Disconnect

INFOID:0000000003893541

NOTE:

Before removing and installing any control units, first turn the push-button ignition switch to the LOCK posi-

tion, then disconnect both battery cables.

After finishing work, confirm that all control unit connectors are connected properly, then re-connect both

battery cables.

Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If a DTC is detected, perform trouble diagnosis according to self-diagnosis results.

This vehicle is equipped with a push-button ignition switch and a steering lock unit.

If the battery is disconnected or discharged, the steering wheel will lock and cannot be turned.

If turning the steering wheel is required with the battery disconnected or discharged, follow the procedure

below before starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables.

NOTE:

Supply power using jumper cables if battery is discharged.

2. Carry the Intelligent Key or insert it to the key slot and turn the push-button ignition switch to ACC position.

(At this time, the steering lock will be released.)

3. Disconnect both battery cables. The steering lock will remain released with both battery cables discon-

nected and the steering wheel can be turned.

4. Perform the necessary repair operation.

5. When the repair work is completed, re-connect both battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position to ON position, then to LOCK position. (The steering

wheel will lock when the push-button ignition switch is turned to LOCK position.)

6. Perform self-diagnosis check of all control units using CONSULT-III.

Page 4450 of 5121

DIAGNOSIS AND REPAIR WORKFLOW

STR-3

< BASIC INSPECTION >

C

D

E

F

G

H

I

J

K

L

MA

STR

N

P O

NOTE:

If any malfunction is found, immediately disconnect the battery cable from the negative terminal.

1.CHECK ENGINE START

Crank the engine and check that the engine starts.

Does the engine start?

YES >> GO TO 2.

NO >> GO TO 3.

2.CHECK THAT THE STARTER MOTOR STOPS

Check that the starter motor stops after starting the engine.

Does the starter motor stop?

YES >> INSPECTION END

NO >> Replace magnetic switch.

3.CHECK THE ENGINE SPEED WITH CRANKING

Check that the engine turns at cranking.

Does engine turn by cranking?

YES >> GO TO 4.

NO >> GO TO 5.

4.CHECK THE ENGINE SPEED WITH CRANKING

Check that the engine speed is not low at cranking.

Does engine turn normally?

YES >> Check ignition/fuel system.

NO >> Check charge condition, corrosion and connection condition of the battery. Refer to STR-2, "

Work

Flow".

5.CHECK STARTER MOTOR ACTIVATION

Check that the starter motor turns at cranking.

Does starter motor turn?

YES >> GO TO 6.

NO >> GO TO 7.

6.CHECK STARTER MOTOR UNIT

1. Remove starter motor.

2. Check that the gear shaft of starter motor rotates.

Does gear shaft turn?

YES >> Check pinion clutch. Refer to the following.

• VQ25DE models: STR-16, "

VQ25DE : Inspection"

VQ35DE models: STR-22, "VQ35DE : Inspection"

NO >> Check reduction gear, armature and gear shaft.

7.CHECK POWER SUPPLY CIRCUIT

Check the following conditions.

Fuse and fusible link

Charge condition, corrosion and connection condition of the battery. Refer to STR-2, "

Work Flow".

Are these inspection results normal?

YES >> GO TO 8.

NO >> Repair as needed.

8.CHECK STARTING SYSTEM WIRING

Check the following.

“B” terminal circuit. Refer to STR-8, "

Diagnosis Procedure".

“S” terminal circuit. Refer to STR-9, "

Diagnosis Procedure".

Are these inspection results normal?

YES >> GO TO 9.

Page 4451 of 5121

STR-4

< BASIC INSPECTION >

DIAGNOSIS AND REPAIR WORKFLOW

NO >> Repair as needed.

9.CHECK MAGNETIC SWITCH OPERATION SOUND

Check that a magnetic switch operation sound can be heard when the ignition switch is set at the starting posi-

tion.

Does magnetic switch operation sound occur?

YES >> GO TO 10.

NO >> Replace magnetic switch.

10.PINION AND RING GEAR ENGAGEMENT CHECK

Check condition of pinion and ring gear mesh.

Is the inspection result normal?

YES >> GO TO 12.

NO >> GO TO 11.

11 .CHECK STARTER MOTOR UNIT

Check the following.

Adjust pinion movement. Refer to the following.

- VQ25DE models: STR-16, "

VQ25DE : Inspection"

- VQ35DE models: STR-22, "VQ35DE : Inspection"

Check pinion moving mechanism.

Check ring gear.

Are these inspection results normal?

YES >> INSPECTION END

NO >> Repair or replace, if necessary.

12.CHECK STARTER MOTOR UNIT

Check that the starter motor turns when connecting the positive ter-

minal (12 V) to starter motor terminal M and the negative terminal

(ground) to starter motor body.

Does the starter motor run?

YES >> Replace magnetic switch.

NO >> Repair starter motor.

SEL009Z

Page 4453 of 5121

STR-6

< FUNCTION DIAGNOSIS >

STARTING SYSTEM

VQ25DE : Component Description

INFOID:0000000003860420

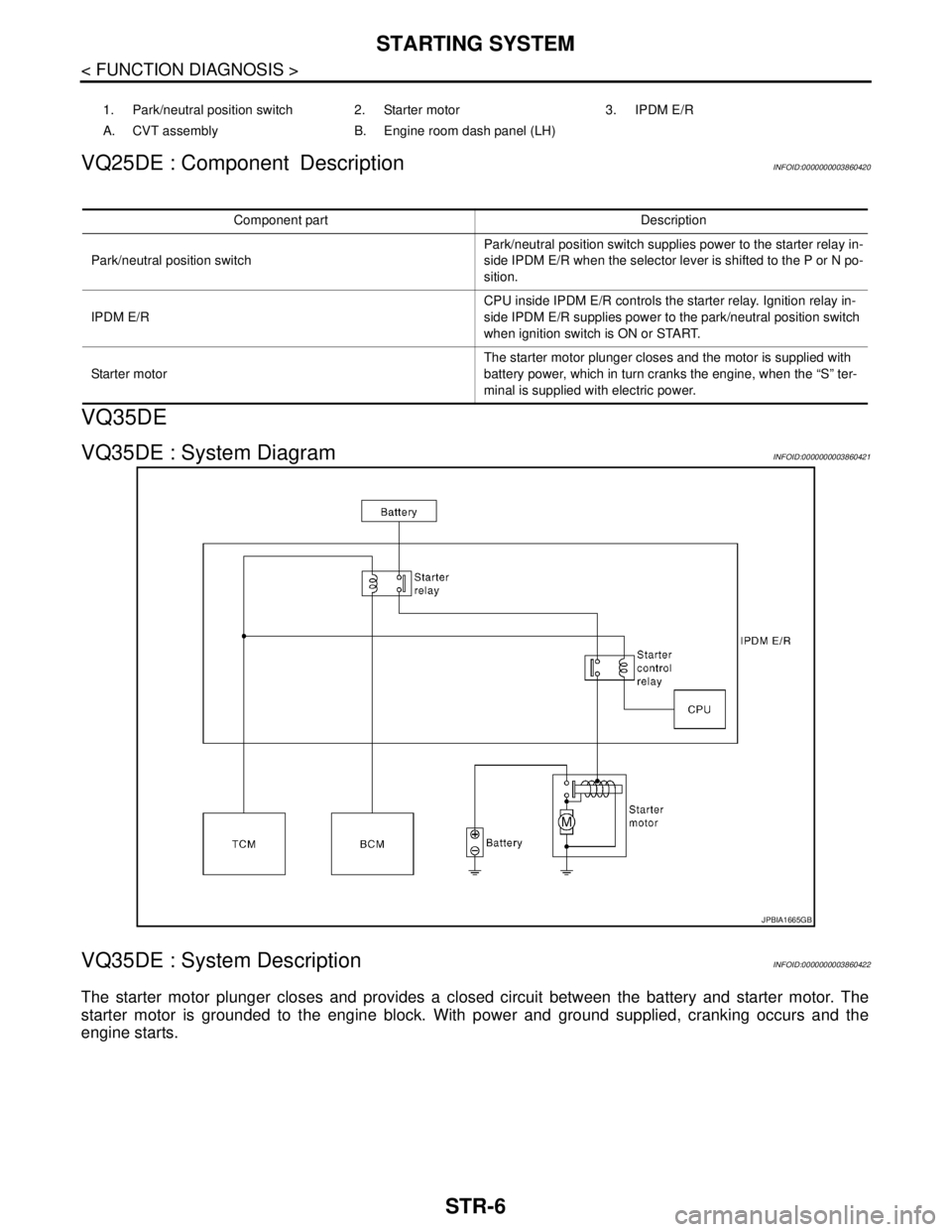

VQ35DE

VQ35DE : System DiagramINFOID:0000000003860421

VQ35DE : System DescriptionINFOID:0000000003860422

The starter motor plunger closes and provides a closed circuit between the battery and starter motor. The

starter motor is grounded to the engine block. With power and ground supplied, cranking occurs and the

engine starts.

1. Park/neutral position switch 2. Starter motor 3. IPDM E/R

A. CVT assembly B. Engine room dash panel (LH)

Component part Description

Park/neutral position switchPark/neutral position switch supplies power to the starter relay in-

side IPDM E/R when the selector lever is shifted to the P or N po-

sition.

IPDM E/RCPU inside IPDM E/R controls the starter relay. Ignition relay in-

side IPDM E/R supplies power to the park/neutral position switch

when ignition switch is ON or START.

Starter motorThe starter motor plunger closes and the motor is supplied with

battery power, which in turn cranks the engine, when the “S” ter-

minal is supplied with electric power.

JPBIA1665GB

Page 4455 of 5121

STR-8

< COMPONENT DIAGNOSIS >

B TERMINAL CIRCUIT

COMPONENT DIAGNOSIS

B TERMINAL CIRCUIT

DescriptionINFOID:0000000003860425

The “B” terminal is constantly supplied with battery power.

Diagnosis ProcedureINFOID:0000000003860426

CAUTION:

Perform diagnosis under the condition that engine cannot start by the following procedure.

1. Remove fuel pump fuse.

2. Crank or start the engine (where possible) until the fuel pressure is released.

1.CHECK “B” TERMINAL CIRCUIT

1. Turn ignition switch OFF.

2. Check that starter motor “B” terminal connection is clean and tight.

3. Check voltage between starter motor “B” terminal and ground.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Check harness between battery and starter motor for open circuit.

2.CHECK BATTERY CABLE CONNECTION STATUS (VOLTAGE DROP TEST)

1. Shift the selector lever to “P” or “N” position.

2. Check voltage between battery positive terminal and starter motor “B” terminal.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Check harness between the battery and the starter motor for poor continuity.

3.CHECK GROUND CIRCUIT STATUS (VOLTAGE DROP TEST)

1. Shift the selector lever to “P” or “N” position.

2. Check voltage between starter motor case and battery negative terminal.

Is the inspection result normal?

YES >> “B” terminal circuit is OK. Further inspection is necessary. Refer to STR-2, "Work Flow".

NO >> Check the starter motor case and ground for poor continuity.

Te r m i n a l s

Voltage (Approx.) (+)

(–)

Starter motor “B” terminal Terminal

F49 (VQ25DE)

F10 (VQ35DE)2 Ground Battery voltage

Te r m i n a l s

Condition Voltage (Approx.)

(+)(–)

Starter motor

“B” terminalTerminal

Battery positive terminalF49 (VQ25DE)

F10 (VQ35DE)2 When the ignition switch is

in START positionLess than

0.5 V

Te r m i n a l s

Condition Voltage (Approx.)

(+) (–)

Starter motor case Battery negative terminalWhen the ignition switch is in

START positionLess than 0.2 V

Page 4456 of 5121

S TERMINAL CIRCUIT

STR-9

< COMPONENT DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

MA

STR

N

P O

S TERMINAL CIRCUIT

DescriptionINFOID:0000000003860427

The starter motor magnetic switch is supplied with power when the ignition switch is turned to START with the

selector lever “P” or “N”.

Diagnosis ProcedureINFOID:0000000003860428

CAUTION:

Perform diagnosis under the condition that engine cannot start by the following procedure.

1. Remove fuel pump fuse.

2. Crank or start the engine (where possible) until the fuel pressure is released.

1.CHECK “S” CONNECTOR CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect “S” terminal.

3. Shift the selector lever to “P” or “N” position.

4. Check voltage between starter motor harness connector and ground.

Is the inspection result normal?

YES >> “S” terminal circuit is OK. Further inspection is necessary. Refer to STR-2, "Work Flow".

NO >> GO TO 2.

2.CHECK HARNESS CONTINUITY (OPEN CIRCUIT)

1. Disconnect IPDM E/R connector.

2. Check continuity between starter motor “S” terminal and IPDM E/R harness connector.

Is the inspection result normal?

YES >> Inspect IPDM E/R and power supply circuit. Refer to STR-2, "Work Flow".

NO >> Repair the harness.

Te r m i n a l s

Condition Voltage (Approx.) (+)

(–)

Starter motor harness

connectorTe r m i n a l

F50 (VQ25DE)

F47 (VQ35DE)1 GroundWhen the ignition switch

is in START positionBattery voltage

Starter motor “S” terminal IPDM E/R harness connector

Continuity

Connector No. Terminal No. Connector No. Terminal No.

F50 (VQ25DE)

F47 (VQ35DE)1E1080Existed

Page 4485 of 5121

![NISSAN TEANA 2008 Service Manual TM-12

< BASIC INSPECTION >[CVT: RE0F09B]

INSPECTION AND ADJUSTMENT

INSPECTION AND ADJUSTMENT

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT : Precaution NISSAN TEANA 2008 Service Manual TM-12

< BASIC INSPECTION >[CVT: RE0F09B]

INSPECTION AND ADJUSTMENT

INSPECTION AND ADJUSTMENT

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT : Precaution](/img/5/57391/w960_57391-4484.png)

TM-12

< BASIC INSPECTION >[CVT: RE0F09B]

INSPECTION AND ADJUSTMENT

INSPECTION AND ADJUSTMENT

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT : Precaution for TCM

and CVT Assembly Replacement

INFOID:0000000003848916

CAUTION:

• Check if new data (Unit ID) are entered correctly after replacing CVT assembly and erasing data in

TCM. (Connect CONSULT-III, and then turn ignition switch OFF.)

When replacing CVT assembly or TCM, refer to the pattern table below and erase the EEPROM in the

TCM if necessary.

EEPROM ERASING PATTERNS

METHOD FOR ERASING THE EEPROM IN THE TCM

1. Turn ignition switch ON.

2. Move selector lever to “R” position.

3. Perform “Self-Diagnostic Results” mode for “TRANSMISSION”.

4. Press the brake pedal and turn the brake switch ON.

5. Press the accelerator pedal (0.5/8 - 4/8 throttle) not to exceed the half, and hold it in the half or less open

position. (This will set the closed throttle position signal to OFF and the wide open throttle position signal

to OFF.)

6. Perform “ERASE”.

7. Wait 3 seconds and then release the accelerator pedal.

8. Turn ignition switch OFF.

METHOD FOR WRITING DATA FROM THE ROM ASSEMBLY IN THE TRANSAXLE

In the following procedure, the TCM reads data from the ROM assembly and writes it to the EEPROM in the

TCM.

1. Erase the EEPROM in the TCM.

2. Move selector lever to “P” position.

3. Turn ignition switch ON.

CHECK METHOD

Standard: About 2 seconds after the ignition switch ON, the CVT indicator lamp lights up for 2 seconds.

Non-standard: Even after the ignition switch ON, the CVT indicator lamp does not light up after 2 seconds or

illuminates immediately.

CAUTION:

Perform in the “P” or “N” position.

Action for Non-standard

Replace the CVT assembly.

Replace the TCM.

CVT assembly TCM Erasing EEPROM in TCM Remarks

Replaced Replaced Not requiredNot required because the EEPROM in the TCM is in

the default state. (CVT assembly must be replaced

first.)

Not replaced Replaced Not requiredNot required because the EEPROM in the TCM is in

the default state.

Replaced Not replaced RequiredRequired because data has been written in the EE-

PROM in the TCM and because the TCM cannot write

data from the ROM assembly in the transmission.

Page 4506 of 5121

![NISSAN TEANA 2008 Service Manual SHIFT LOCK SYSTEM

TM-33

< FUNCTION DIAGNOSIS >[CVT: RE0F09B]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

SHIFT LOCK SYSTEM

System DescriptionINFOID:0000000003848940

The shift lever cannot be shifted from the “P NISSAN TEANA 2008 Service Manual SHIFT LOCK SYSTEM

TM-33

< FUNCTION DIAGNOSIS >[CVT: RE0F09B]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

SHIFT LOCK SYSTEM

System DescriptionINFOID:0000000003848940

The shift lever cannot be shifted from the “P](/img/5/57391/w960_57391-4505.png)

SHIFT LOCK SYSTEM

TM-33

< FUNCTION DIAGNOSIS >[CVT: RE0F09B]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

SHIFT LOCK SYSTEM

System DescriptionINFOID:0000000003848940

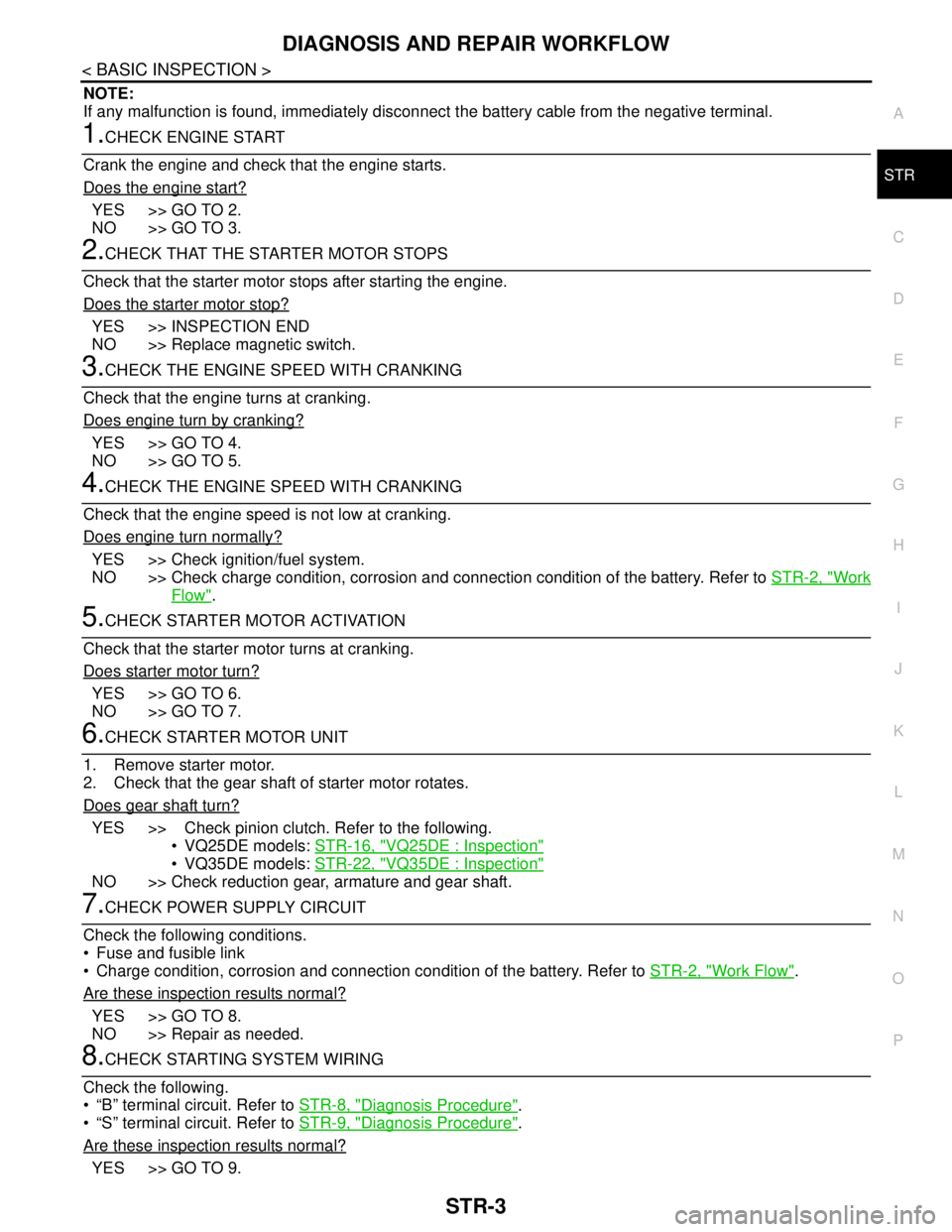

The shift lever cannot be shifted from the “P” position unless the

brake pedal is depressed while the ignition switch is set to ON. The

shift lock is unlocked by turning the shift lock solenoid ON when the

ignition switch is set to ON, the park position switch is turned ON

(selector lever is in “P” position), and the stop lamp switch is turned

ON (brake pedal is depressed) as shown in the operation chart in the

figure. Therefore, the shift lock solenoid receives no ON signal and

the shift lock remains locked if all of the above conditions are not ful-

filled. (However, selector operation is allowed if the shift lock release

button is pressed.)

SHIFT LOCK OPERATION at “P” POSITION

When Brake Pedal Is Not Depressed (No Selector Operation Allowed)

The shift lock solenoid (A) is turned OFF (not energized) and the

solenoid rod (B) is extended with the spring when the brake pedal is

not depressed (no selector operation allowed) with the ignition

switch ON.

The connecting lock lever (C) is located at the position shown in the

figure when the solenoid rod is extended. It prevents the movement

of the detent rod (D). The selector lever cannot be shifted from the

“P” position for this reason.

When Brake Pedal Is Depressed (Shift Operation Allowed)

The shift lock solenoid (A) is turned ON (energized) when the brake

pedal is depressed with the ignition switch ON. The solenoid rod (B)

is compressed by the electromagnetic force. The connecting lock

lever (C) rotates when the solenoid is activated. Therefore, the

detent rod (D) can be moved. The selector lever can be shifted to

other positions for this reason.

“P” POSITION HOLD MECHANISM (IGNITION SWITCH LOCK)

JPDIA0624GB

JPDIA0612ZZ

JPDIA0613ZZ

Page 4507 of 5121

![NISSAN TEANA 2008 Service Manual TM-34

< FUNCTION DIAGNOSIS >[CVT: RE0F09B]

SHIFT LOCK SYSTEM

The shift lock solenoid (A) is not energized when the ignition switch

is in any position other than ON. In this condition, the shift mecha- NISSAN TEANA 2008 Service Manual TM-34

< FUNCTION DIAGNOSIS >[CVT: RE0F09B]

SHIFT LOCK SYSTEM

The shift lock solenoid (A) is not energized when the ignition switch

is in any position other than ON. In this condition, the shift mecha-](/img/5/57391/w960_57391-4506.png)

TM-34

< FUNCTION DIAGNOSIS >[CVT: RE0F09B]

SHIFT LOCK SYSTEM

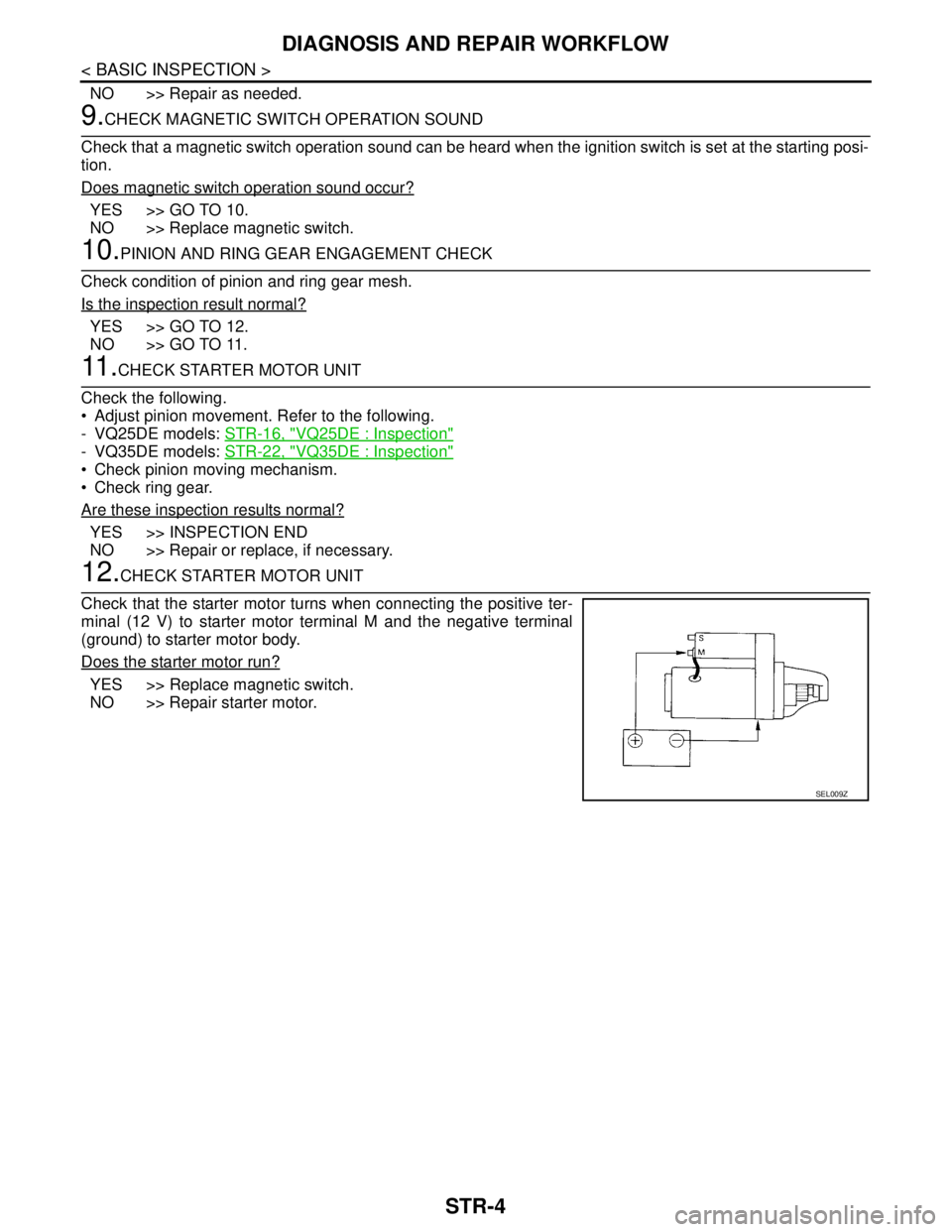

The shift lock solenoid (A) is not energized when the ignition switch

is in any position other than ON. In this condition, the shift mecha-

nism is locked and “P” position is held. The operation cannot be per-

formed from “P” position if the brake pedal is depressed with the

ignition switch ON when the operation system of shift lock solenoid is

malfunctioning. However, the lock lever (B) is forcibly rotated and the

shift lock is released when the shift lock release button (C) is

pressed from above. Then the selector operation from “P” position

can be performed.

CAUTION:

Use the shift lock release button only when the selector lever cannot be operated even if the brake

pedal is depressed with the ignition switch ON.

Component Parts LocationINFOID:0000000003848941

Component DescriptionINFOID:0000000003848942

SHIFT LOCK

D : Detent rodJPDIA0614ZZ

1. Stop lamp switch

A. Shift lock release button B. Shift lock solenoid C. Park position switch

JPDIA0753ZZ

Component Function

Shift lock solenoid

TM-103

Lock lever

Detent rod

Park position switch

Shift lock release button