ignition NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 4388 of 5121

SRS AIR BAG WARNING LAMP DOES NOT TURN OFF

SRC-145

< SYMPTOM DIAGNOSIS >

C

D

E

F

G

I

J

K

L

MA

B

SRC

N

O

P

SYMPTOM DIAGNOSIS

SRS AIR BAG WARNING LAMP DOES NOT TURN OFF

Diagnosis ProcedureINFOID:0000000003814106

1.CHECK FRONT AIR BAG MODULE

Check the deployment of front air bag module.

Is air bag module deployed?

YES >> Refer to SR-6, "Exploded View" or SR-12, "Exploded View".

NO >> GO TO 2.

2.CHECK AIR BAG FUSE

Check the air bag fuse. Refer to PG-82, "

Fuse".

Is 10A fuse [No.2, located in fuse block (J/B)] normal?

YES >> GO TO 4.

NO >> Replace the air bag fuse and GO TO 3.

3.CHECK AIR BAG FUSE AGAIN

Turn ignition switch ON.

Check the air bag fuse. Refer to PG-82, "

Fuse".

Did the air bag fuse blow again?

YES >> Repair or replace related harness.

NO >> GO TO 4.

4.CHECK SELF DIAGNOSIS RESULT

Perform “AIR BAG” Self Diagnostic result.

Is DTC detected?

YES >> Repair or replace the malfunctioning parts.

NO >> Check the intermittent incident. Refer to GI-35, "

Intermittent Incident".

Page 4389 of 5121

SRC-146

< SYMPTOM DIAGNOSIS >

SRS AIR BAG WARNING LAMP DOES NOT TURN ON

SRS AIR BAG WARNING LAMP DOES NOT TURN ON

Diagnosis ProcedureINFOID:0000000003814107

1.CHECK METER FUSE

Check the meter fuse. Refer to PG-82, "

Fuse".

Is 10A fuse [No.4, located in fuse block (J/B)] normal?

YES >> GO TO 3.

NO >> Replace the fuse GO TO 2.

2.CHECK METER FUSE AGAIN

Turn ignition switch ON.

Check the meter fuse. Refer to PG-82, "

Fuse".

Did the meter fuse blow again?

YES >> Repair or replace the related harness.

NO >> INSPECTION END

3.CHECK HARNESS CONNECTION

1. Check harness connection between air bag diagnosis sensor unit and combination meter.

2. Disconnect air bag diagnosis sensor unit connector and turn ignition switch ON.

Did air bag warning lamp turn ON?

YES >> Replace air bag diagnosis sensor unit. Refer to SR-22, "Exploded View".

NO >> Replace combination meter assembly. Refer to MWI-127, "

Exploded View".

Page 4390 of 5121

PRECAUTIONS

SRC-147

< PRECAUTION >

C

D

E

F

G

I

J

K

L

MA

B

SRC

N

O

P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000003814141

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the “SRS AIRBAG” and

“SEAT BELT” of this Service Manual.

WARNING:

To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SRS AIRBAG”.

Never use electrical test equipment on any circuit related to the SRS unless instructed to in this Ser-

vice Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or harness

connectors.

ServiceINFOID:0000000003814109

Do not use electrical test equipment to check SRS circuits unless instructed to in this Service Manual.

Before servicing the SRS, turn ignition switch OFF, disconnect battery negative terminal and wait at least 3

minutes.

For approximately 3 minutes after the battery negative terminal is removed, it is still possible for the air bag

and seat belt pre-tensioner to deploy. Therefore, do not work on any SRS connectors or wires until at least 3

minutes have elapsed.

Diagnosis sensor unit must always be installed with their arrow marks “⇐” pointing towards the front of the

vehicle for proper operation. Also check diagnosis sensor unit for cracks, deformities or rust before installa-

tion and replace as required.

The spiral cable must be aligned in the neutral position since its rotations are limited. Do not turn steering

wheel and column after removal of steering gear.

Handle air bag module carefully. Always place driver and front passenger air bag modules with the pad side

facing upward and seat mounted front side air bag module standing with the stud bolt side facing down.

Conduct self-diagnosis to check entire SRS for proper function after replacing any components.

After air bag inflates, the front instrument panel assembly should be replaced if damaged.

Always replace instrument panel pad following front passenger air bag deployment.

Page 4393 of 5121

PRECAUTIONS

ST-3

< PRECAUTION >

C

D

E

F

H

I

J

K

L

MA

B

ST

N

O

P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000003971958

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the “SRS AIRBAG” and

“SEAT BELT” of this Service Manual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SRS AIRBAG”.

Never use electrical test equipment on any circuit related to the SRS unless instructed to in this Ser-

vice Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or harness

connectors.

Precaution Necessary for Steering Wheel Rotation after Battery Disconnect

INFOID:0000000003806307

NOTE:

Before removing and installing any control units, first turn the push-button ignition switch to the LOCK posi-

tion, then disconnect both battery cables.

After finishing work, confirm that all control unit connectors are connected properly, then re-connect both

battery cables.

Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If a DTC is detected, perform trouble diagnosis according to self-diagnosis results.

This vehicle is equipped with a push-button ignition switch and a steering lock unit.

If the battery is disconnected or discharged, the steering wheel will lock and cannot be turned.

If turning the steering wheel is required with the battery disconnected or discharged, follow the procedure

below before starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables.

NOTE:

Supply power using jumper cables if battery is discharged.

2. Carry the Intelligent Key or insert it to the key slot and turn the push-button ignition switch to ACC position.

(At this time, the steering lock will be released.)

3. Disconnect both battery cables. The steering lock will remain released with both battery cables discon-

nected and the steering wheel can be turned.

4. Perform the necessary repair operation.

5. When the repair work is completed, re-connect both battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position to ON position, then to LOCK position. (The steering

wheel will lock when the push-button ignition switch is turned to LOCK position.)

6. Perform self-diagnosis check of all control units using CONSULT-III.

Service Notice or Precautions for Steering SystemINFOID:0000000003806308

CAUTION:

In case of removing steering gear assembly, make the final tightening with grounded and unloaded

vehicle condition, and then check wheel alignment.

Observe the following precautions when disassembling.

- Before disassembly, thoroughly clean the outside of the unit.

- Disassembly should be done in a clean work area. It is important to prevent the internal parts from

becoming contaminated by dirt or other foreign matter.

Page 4434 of 5121

STC-6

< COMPONENT DIAGNOSIS >

POWER SUPPLY AND GROUND CIRCUIT

COMPONENT DIAGNOSIS

POWER SUPPLY AND GROUND CIRCUIT

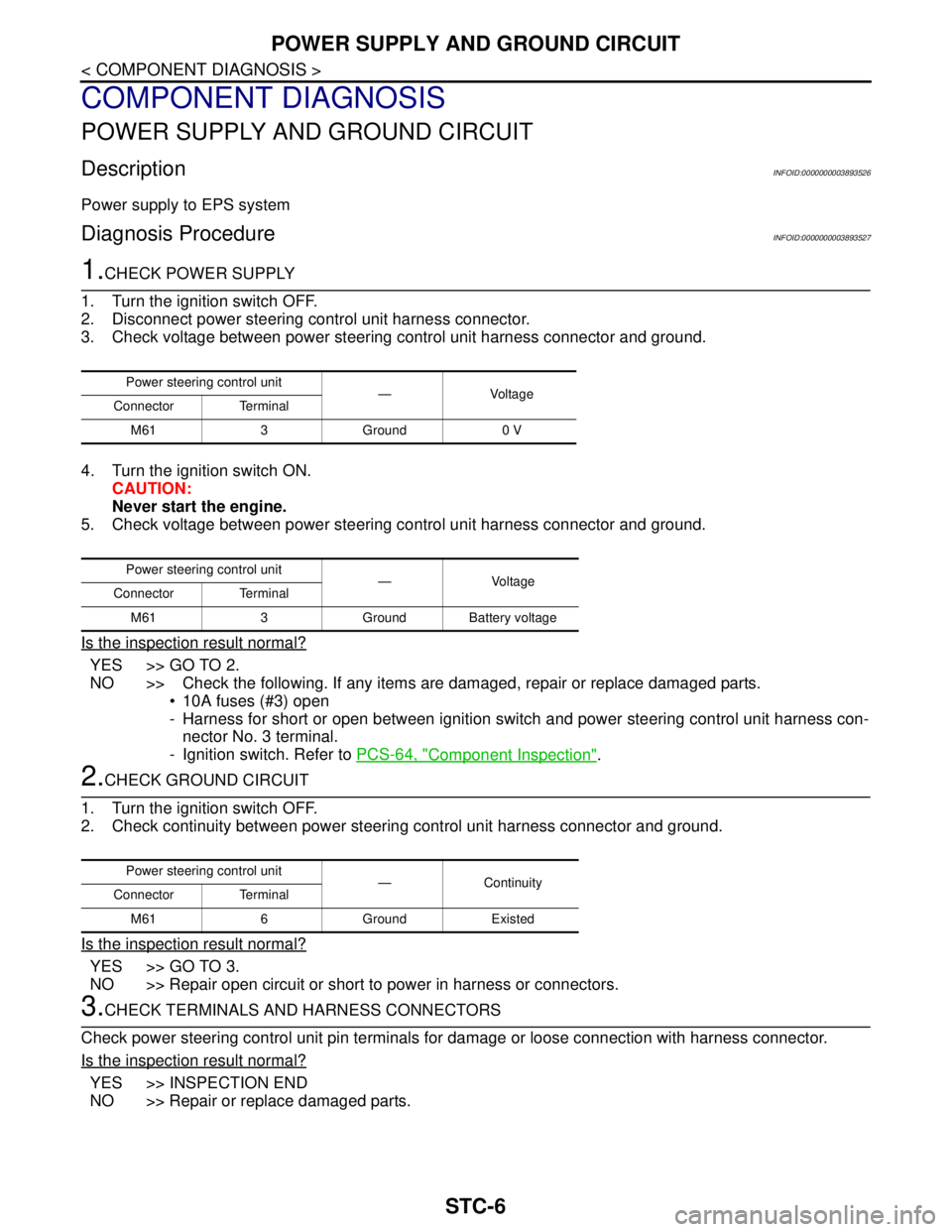

DescriptionINFOID:0000000003893526

Power supply to EPS system

Diagnosis ProcedureINFOID:0000000003893527

1.CHECK POWER SUPPLY

1. Turn the ignition switch OFF.

2. Disconnect power steering control unit harness connector.

3. Check voltage between power steering control unit harness connector and ground.

4. Turn the ignition switch ON.

CAUTION:

Never start the engine.

5. Check voltage between power steering control unit harness connector and ground.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Check the following. If any items are damaged, repair or replace damaged parts.

10A fuses (#3) open

- Harness for short or open between ignition switch and power steering control unit harness con-

nector No. 3 terminal.

- Ignition switch. Refer to PCS-64, "

Component Inspection".

2.CHECK GROUND CIRCUIT

1. Turn the ignition switch OFF.

2. Check continuity between power steering control unit harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair open circuit or short to power in harness or connectors.

3.CHECK TERMINALS AND HARNESS CONNECTORS

Check power steering control unit pin terminals for damage or loose connection with harness connector.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Repair or replace damaged parts.

Power steering control unit

—Voltage

Connector Terminal

M61 3 Ground 0 V

Power steering control unit

— Voltage

Connector Terminal

M61 3 Ground Battery voltage

Power steering control unit

—Continuity

Connector Terminal

M61 6 Ground Existed

Page 4435 of 5121

POWER STEERING SOLENOID VALVE

STC-7

< COMPONENT DIAGNOSIS >

C

D

E

F

H

I

J

K

L

MA

B

STC

N

O

P

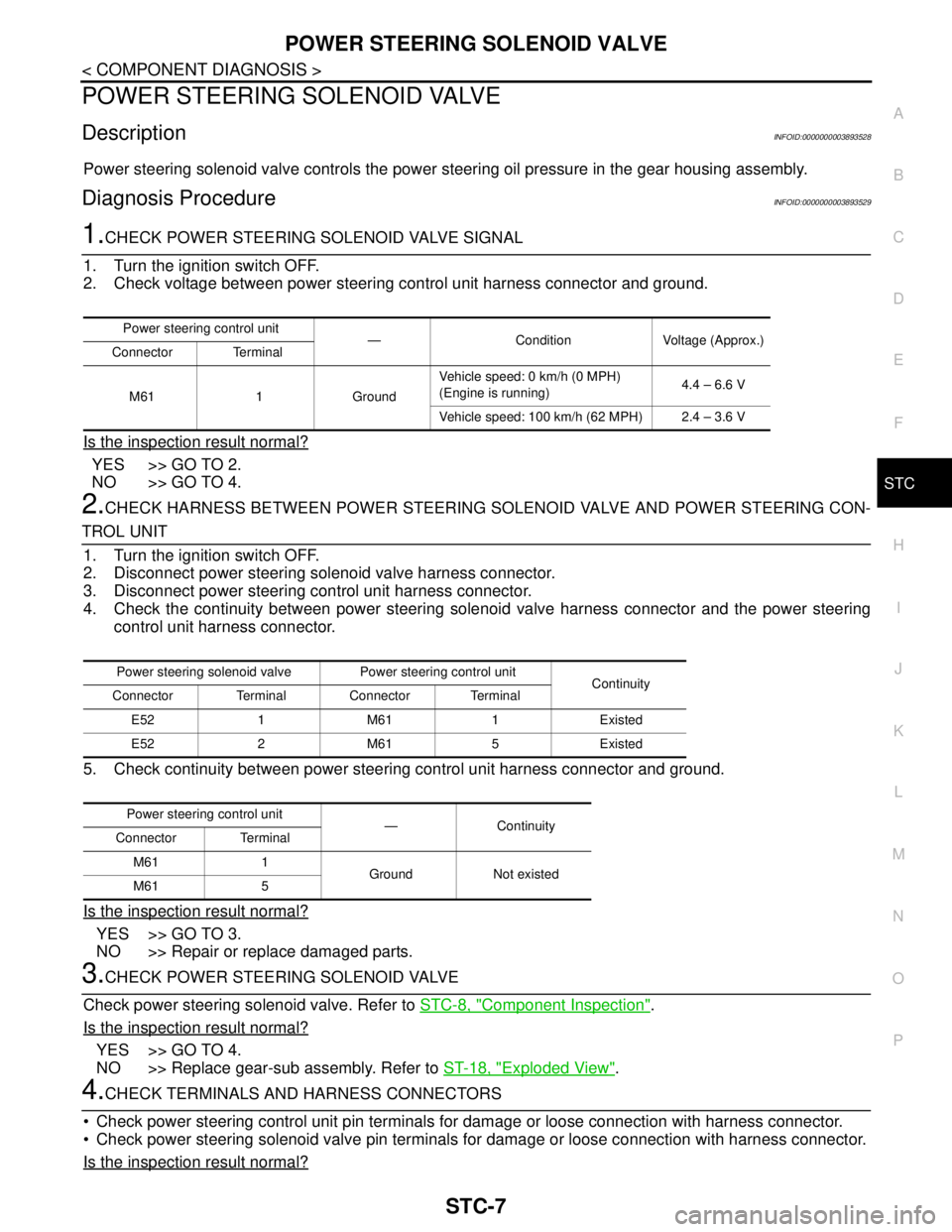

POWER STEERING SOLENOID VALVE

DescriptionINFOID:0000000003893528

Power steering solenoid valve controls the power steering oil pressure in the gear housing assembly.

Diagnosis ProcedureINFOID:0000000003893529

1.CHECK POWER STEERING SOLENOID VALVE SIGNAL

1. Turn the ignition switch OFF.

2. Check voltage between power steering control unit harness connector and ground.

Is the inspection result normal?

YES >> GO TO 2.

NO >> GO TO 4.

2.CHECK HARNESS BETWEEN POWER STEERING SOLENOID VALVE AND POWER STEERING CON-

TROL UNIT

1. Turn the ignition switch OFF.

2. Disconnect power steering solenoid valve harness connector.

3. Disconnect power steering control unit harness connector.

4. Check the continuity between power steering solenoid valve harness connector and the power steering

control unit harness connector.

5. Check continuity between power steering control unit harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace damaged parts.

3.CHECK POWER STEERING SOLENOID VALVE

Check power steering solenoid valve. Refer to STC-8, "

Component Inspection".

Is the inspection result normal?

YES >> GO TO 4.

NO >> Replace gear-sub assembly. Refer to ST-18, "

Exploded View".

4.CHECK TERMINALS AND HARNESS CONNECTORS

Check power steering control unit pin terminals for damage or loose connection with harness connector.

Check power steering solenoid valve pin terminals for damage or loose connection with harness connector.

Is the inspection result normal?

Power steering control unit

— Condition Voltage (Approx.)

Connector Terminal

M61 1 GroundVehicle speed: 0 km/h (0 MPH)

(Engine is running)4.4 – 6.6 V

Vehicle speed: 100 km/h (62 MPH) 2.4 – 3.6 V

Power steering solenoid valve Power steering control unit

Continuity

Connector Terminal Connector Terminal

E52 1 M61 1 Existed

E52 2 M61 5 Existed

Power steering control unit

—Continuity

Connector Terminal

M61 1

Ground Not existed

M61 5

Page 4436 of 5121

STC-8

< COMPONENT DIAGNOSIS >

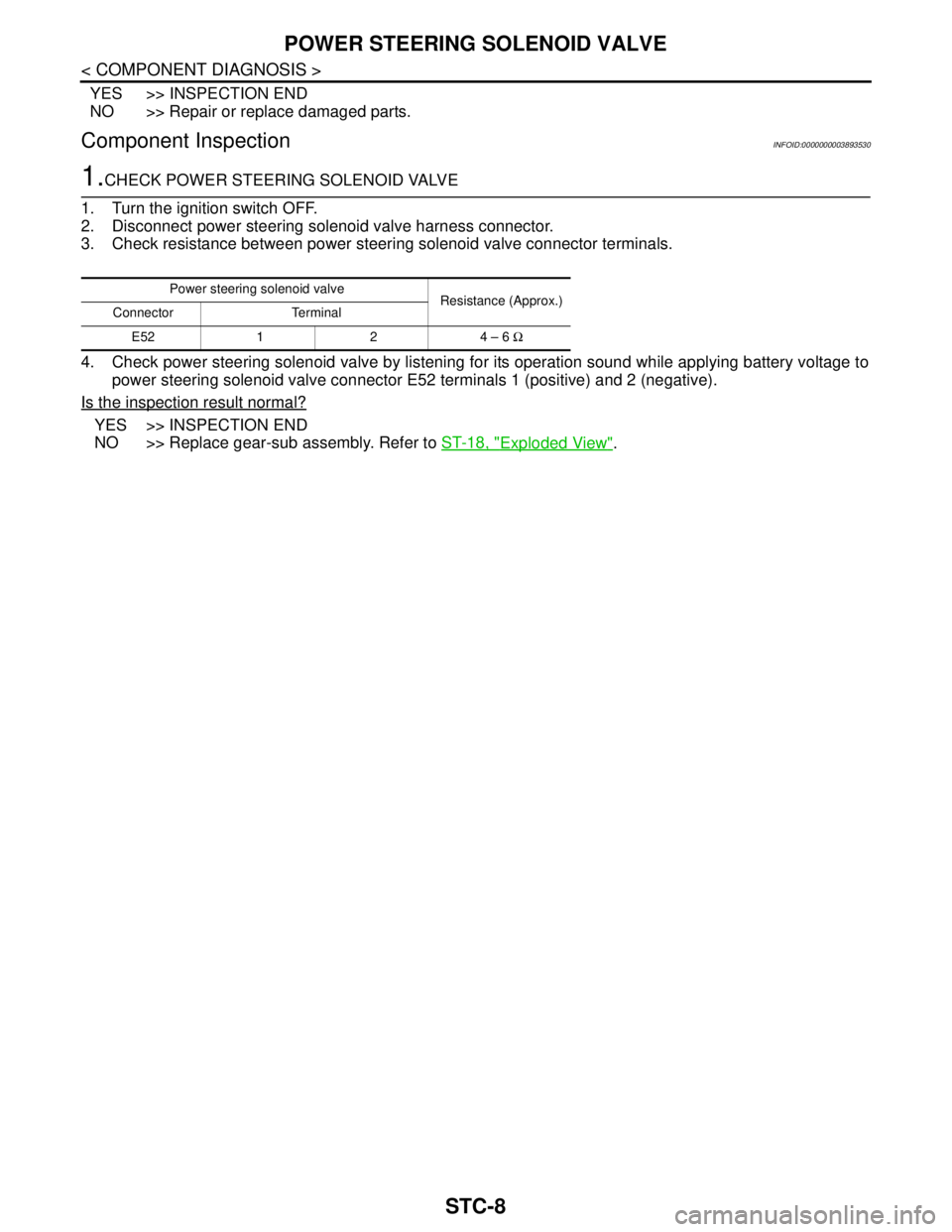

POWER STEERING SOLENOID VALVE

YES >> INSPECTION END

NO >> Repair or replace damaged parts.

Component InspectionINFOID:0000000003893530

1.CHECK POWER STEERING SOLENOID VALVE

1. Turn the ignition switch OFF.

2. Disconnect power steering solenoid valve harness connector.

3. Check resistance between power steering solenoid valve connector terminals.

4. Check power steering solenoid valve by listening for its operation sound while applying battery voltage to

power steering solenoid valve connector E52 terminals 1 (positive) and 2 (negative).

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace gear-sub assembly. Refer to ST-18, "

Exploded View".

Power steering solenoid valve

Resistance (Approx.)

Connector Terminal

E52 1 2 4 – 6 Ω

Page 4437 of 5121

ENGINE SPEED SIGNAL CIRCUIT

STC-9

< COMPONENT DIAGNOSIS >

C

D

E

F

H

I

J

K

L

MA

B

STC

N

O

P

ENGINE SPEED SIGNAL CIRCUIT

DescriptionINFOID:0000000003893531

ECM sends engine speed signal to power steering control unit.

Diagnosis ProcedureINFOID:0000000003893532

1.PERFORM ECM SELF-DIAGNOSIS

With CONSULT-III

1. Turn the ignition switch ON.

Perform ECM self-diagnosis. Refer to EC-113, "

CONSULT-III Function".

Is any DTC detected?

YES >> Check the DTC.

NO >> GO TO 2.

2.CHECK HARNESS BETWEEN ECM AND POWER STEERING CONTROL UNIT

1. Turn the ignition switch OFF.

2. Disconnect ECM harness connectors.

3. Disconnect power steering control unit harness connector.

4. Check continuity between ECM harness connector and power steering control unit harness connector.

5. Check continuity between power steering control unit harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace damaged parts.

3.CHECK ENGINE SPEED SIGNAL (1)

1. Connect ECM harness connectors.

2. Check signal between ECM harness connector and ground with oscilloscope.

ECM Power steering control unit

Continuity

Connector Terminal Connector Terminal

E16 94 M61 10 Existed

Power steering control unit

— Continuity

Connector Terminal

M61 10 Ground Not existed

Page 4439 of 5121

VEHICLE SPEED SIGNAL CIRCUIT

STC-11

< COMPONENT DIAGNOSIS >

C

D

E

F

H

I

J

K

L

MA

B

STC

N

O

P

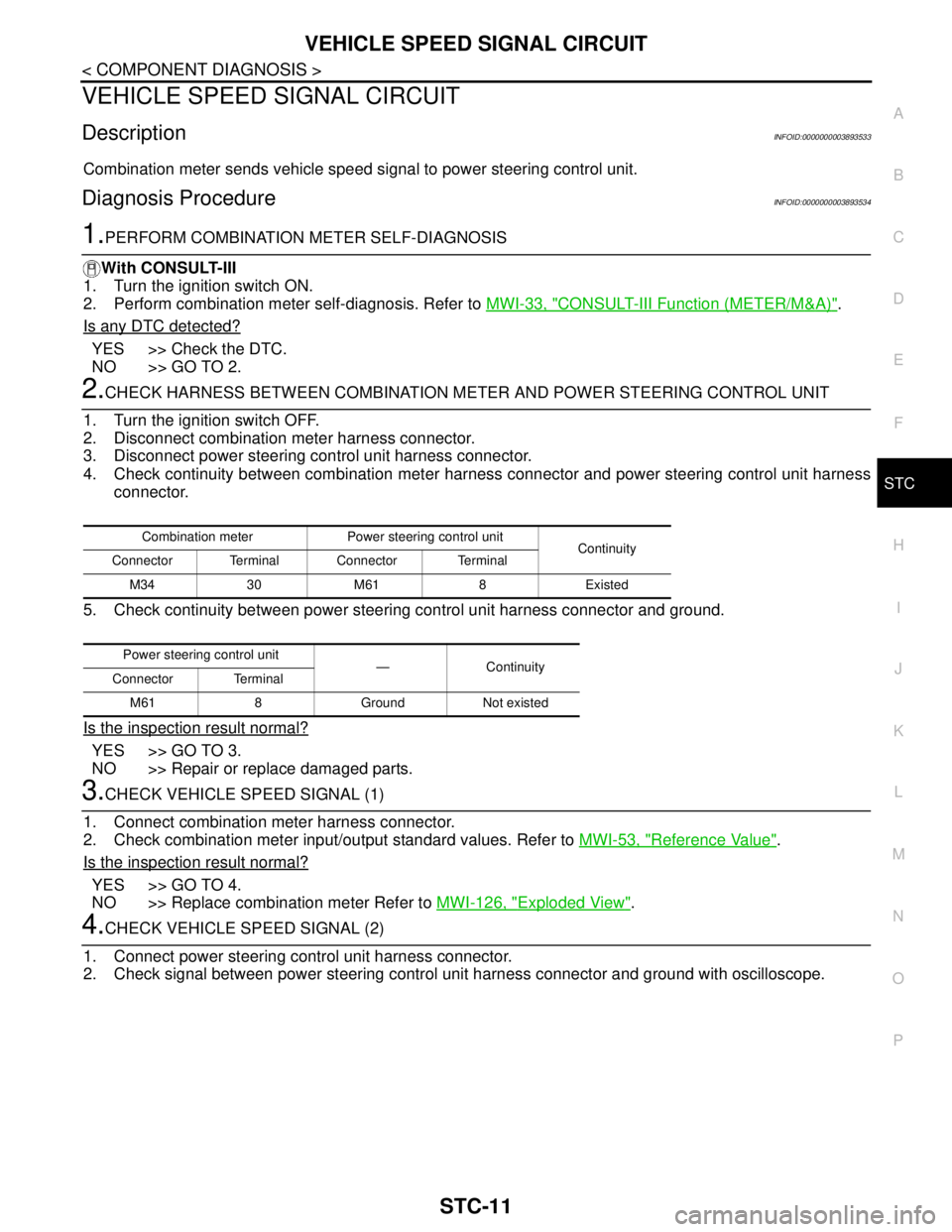

VEHICLE SPEED SIGNAL CIRCUIT

DescriptionINFOID:0000000003893533

Combination meter sends vehicle speed signal to power steering control unit.

Diagnosis ProcedureINFOID:0000000003893534

1.PERFORM COMBINATION METER SELF-DIAGNOSIS

With CONSULT-III

1. Turn the ignition switch ON.

2. Perform combination meter self-diagnosis. Refer to MWI-33, "

CONSULT-III Function (METER/M&A)".

Is any DTC detected?

YES >> Check the DTC.

NO >> GO TO 2.

2.CHECK HARNESS BETWEEN COMBINATION METER AND POWER STEERING CONTROL UNIT

1. Turn the ignition switch OFF.

2. Disconnect combination meter harness connector.

3. Disconnect power steering control unit harness connector.

4. Check continuity between combination meter harness connector and power steering control unit harness

connector.

5. Check continuity between power steering control unit harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace damaged parts.

3.CHECK VEHICLE SPEED SIGNAL (1)

1. Connect combination meter harness connector.

2. Check combination meter input/output standard values. Refer to MWI-53, "

Reference Value".

Is the inspection result normal?

YES >> GO TO 4.

NO >> Replace combination meter Refer to MWI-126, "

Exploded View".

4.CHECK VEHICLE SPEED SIGNAL (2)

1. Connect power steering control unit harness connector.

2. Check signal between power steering control unit harness connector and ground with oscilloscope.

Combination meter Power steering control unit

Continuity

Connector Terminal Connector Terminal

M3430M618Existed

Power steering control unit

—Continuity

Connector Terminal

M61 8 Ground Not existed

Page 4441 of 5121

POWER STEERING CONTROL UNIT

STC-13

< ECU DIAGNOSIS >

C

D

E

F

H

I

J

K

L

MA

B

STC

N

O

P

ECU DIAGNOSIS

POWER STEERING CONTROL UNIT

Reference ValueINFOID:0000000003893535

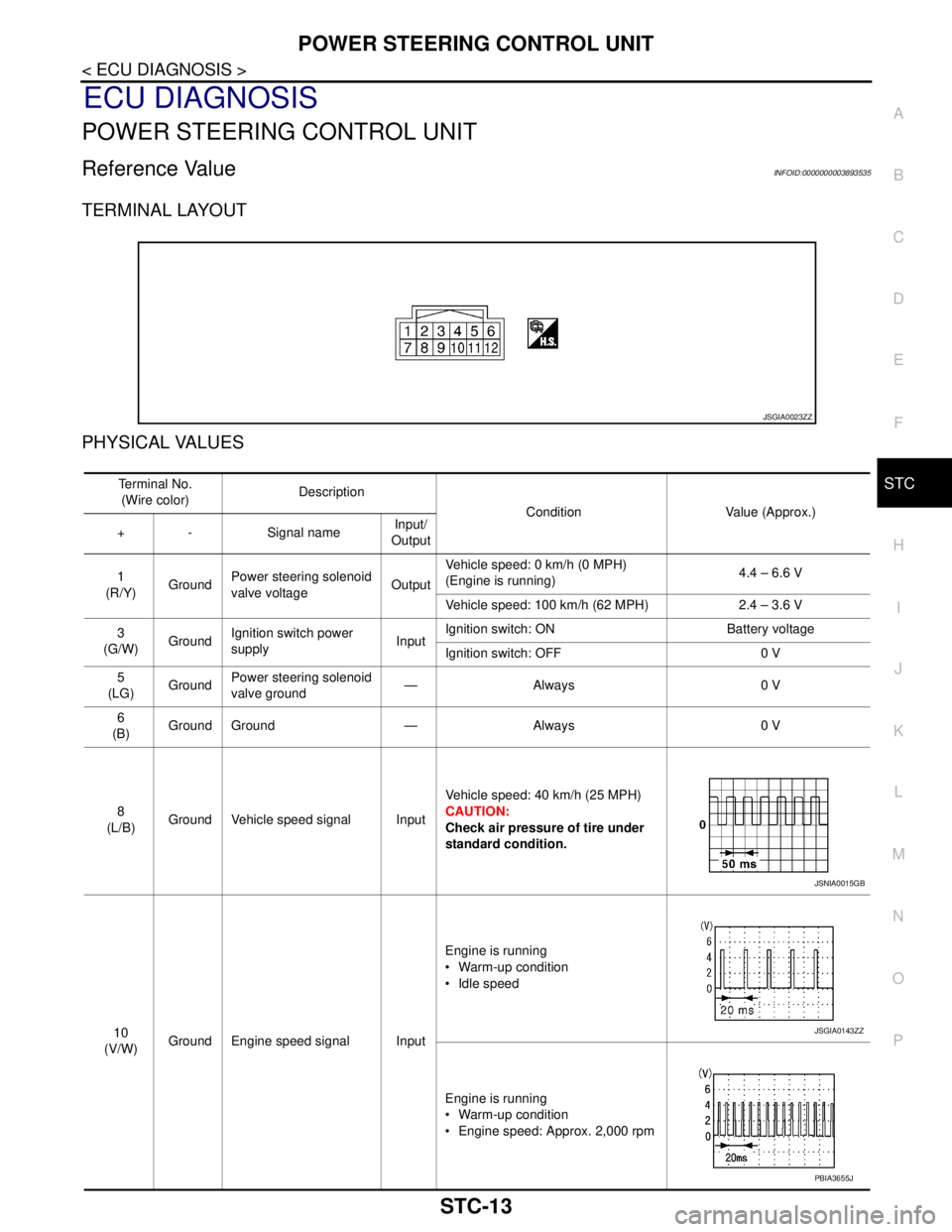

TERMINAL LAYOUT

PHYSICAL VALUES

JSGIA0023ZZ

Te r m i n a l N o .

(Wire color)Description

Condition Value (Approx.)

+ - Signal nameInput/

Output

1

(R/Y)GroundPower steering solenoid

valve voltageOutputVehicle speed: 0 km/h (0 MPH)

(Engine is running)4.4 – 6.6 V

Vehicle speed: 100 km/h (62 MPH) 2.4 – 3.6 V

3

(G/W)GroundIgnition switch power

supplyInputIgnition switch: ON Battery voltage

Ignition switch: OFF 0 V

5

(LG)GroundPower steering solenoid

valve ground—Always 0 V

6

(B)Ground Ground — Always 0 V

8

(L/B)Ground Vehicle speed signal InputVehicle speed: 40 km/h (25 MPH)

CAUTION:

Check air pressure of tire under

standard condition.

10

(V/W)Ground Engine speed signal InputEngine is running

Warm-up condition

Idle speed

Engine is running

Warm-up condition

Engine speed: Approx. 2,000 rpm

JSNIA0015GB

JSGIA0143ZZ

PBIA3655J