headrest NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 1401 of 5121

![NISSAN TEANA 2008 Service Manual SQUEAK AND RATTLE TROUBLE DIAGNOSES

DLK-185

< SYMPTOM DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

DLK

N

O

P

SEATS

When isolating seat noise it is important to note the position the NISSAN TEANA 2008 Service Manual SQUEAK AND RATTLE TROUBLE DIAGNOSES

DLK-185

< SYMPTOM DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

DLK

N

O

P

SEATS

When isolating seat noise it is important to note the position the](/img/5/57391/w960_57391-1400.png)

SQUEAK AND RATTLE TROUBLE DIAGNOSES

DLK-185

< SYMPTOM DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

DLK

N

O

P

SEATS

When isolating seat noise it is important to note the position the seat is in and the load placed on the seat

when the noise occurs. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. Rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of these incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component mounted to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Page 2394 of 5121

SQUEAK AND RATTLE TROUBLE DIAGNOSES

EXT-5

< SYMPTOM DIAGNOSIS >

C

D

E

F

G

H

I

J

L

MA

B

EXT

N

O

P

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

SEATS

When isolating seat noise it is important to note the position the seat is in and the load placed on the seat

when the noise occurs. These conditions must duplicated when verifying and isolating the cause of the noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. Rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of these incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component mounted to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Page 2548 of 5121

SQUEAK AND RATTLE TROUBLE DIAGNOSES

GW-5

< SYMPTOM DIAGNOSIS >

C

D

E

F

G

H

I

J

L

MA

B

GW

N

O

P

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

SEATS

When isolating seat noise it is important to note the position the seat is in and the load placed on the seat

when the noise occurs. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. Rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of these incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component mounted to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Page 3001 of 5121

INT-24

< SYMPTOM DIAGNOSIS >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

SEATS

When isolating seat noise it is important to note the position the seat is in and the load placed on the seat

when the noise occurs. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. Rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of these incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component mounted to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Page 3045 of 5121

SQUEAK AND RATTLE TROUBLE DIAGNOSES

IP-5

< SYMPTOM DIAGNOSIS >

C

D

E

F

G

H

I

K

L

MA

B

IP

N

O

P

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

SEATS

When isolating seat noise it is important to note the position the seat is in and the load placed on the seat

when the noise occurs. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. Rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of these incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component mounted to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Page 3242 of 5121

SQUEAK AND RATTLE TROUBLE DIAGNOSES

MIR-9

< SYMPTOM DIAGNOSIS >

C

D

E

F

G

H

I

J

K

MA

B

MIR

N

O

P

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

SEATS

When isolating seat noise it is important to note the position the seat is in and the load placed on the seat

when the noise occurs. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. Rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of these incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component mounted to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Page 3805 of 5121

RF-74

< SYMPTOM DIAGNOSIS >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

SEATS

When isolating seat noise it is important to note the position the seat is in and the load placed on the seat

when the noise occurs. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. Rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of these incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component mounted to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Page 3947 of 5121

![NISSAN TEANA 2008 Service Manual SQUEAK AND RATTLE TROUBLE DIAGNOSES

SE-83

< SYMPTOM DIAGNOSIS >[WITH VENTILATION SEAT]

C

D

E

F

G

H

I

K

L

MA

B

SE

N

O

P

SEATS

When isolating seat noise it is important to note the position the seat is NISSAN TEANA 2008 Service Manual SQUEAK AND RATTLE TROUBLE DIAGNOSES

SE-83

< SYMPTOM DIAGNOSIS >[WITH VENTILATION SEAT]

C

D

E

F

G

H

I

K

L

MA

B

SE

N

O

P

SEATS

When isolating seat noise it is important to note the position the seat is](/img/5/57391/w960_57391-3946.png)

SQUEAK AND RATTLE TROUBLE DIAGNOSES

SE-83

< SYMPTOM DIAGNOSIS >[WITH VENTILATION SEAT]

C

D

E

F

G

H

I

K

L

MA

B

SE

N

O

P

SEATS

When isolating seat noise it is important to note the position the seat is in and the load placed on the seat

when the noise occurs. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. Rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of these incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component mounted to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Page 3954 of 5121

![NISSAN TEANA 2008 Service Manual SE-90

< ON-VEHICLE REPAIR >[WITH VENTILATION SEAT]

FRONT SEAT

PASSENGERS POWER SEAT

1. Headrest 2. Seatback trim 3. Seatback pad

4. Lumbar support lever knob 5. Snap pin 6. Seat cushion trim

7. Seat NISSAN TEANA 2008 Service Manual SE-90

< ON-VEHICLE REPAIR >[WITH VENTILATION SEAT]

FRONT SEAT

PASSENGERS POWER SEAT

1. Headrest 2. Seatback trim 3. Seatback pad

4. Lumbar support lever knob 5. Snap pin 6. Seat cushion trim

7. Seat](/img/5/57391/w960_57391-3953.png)

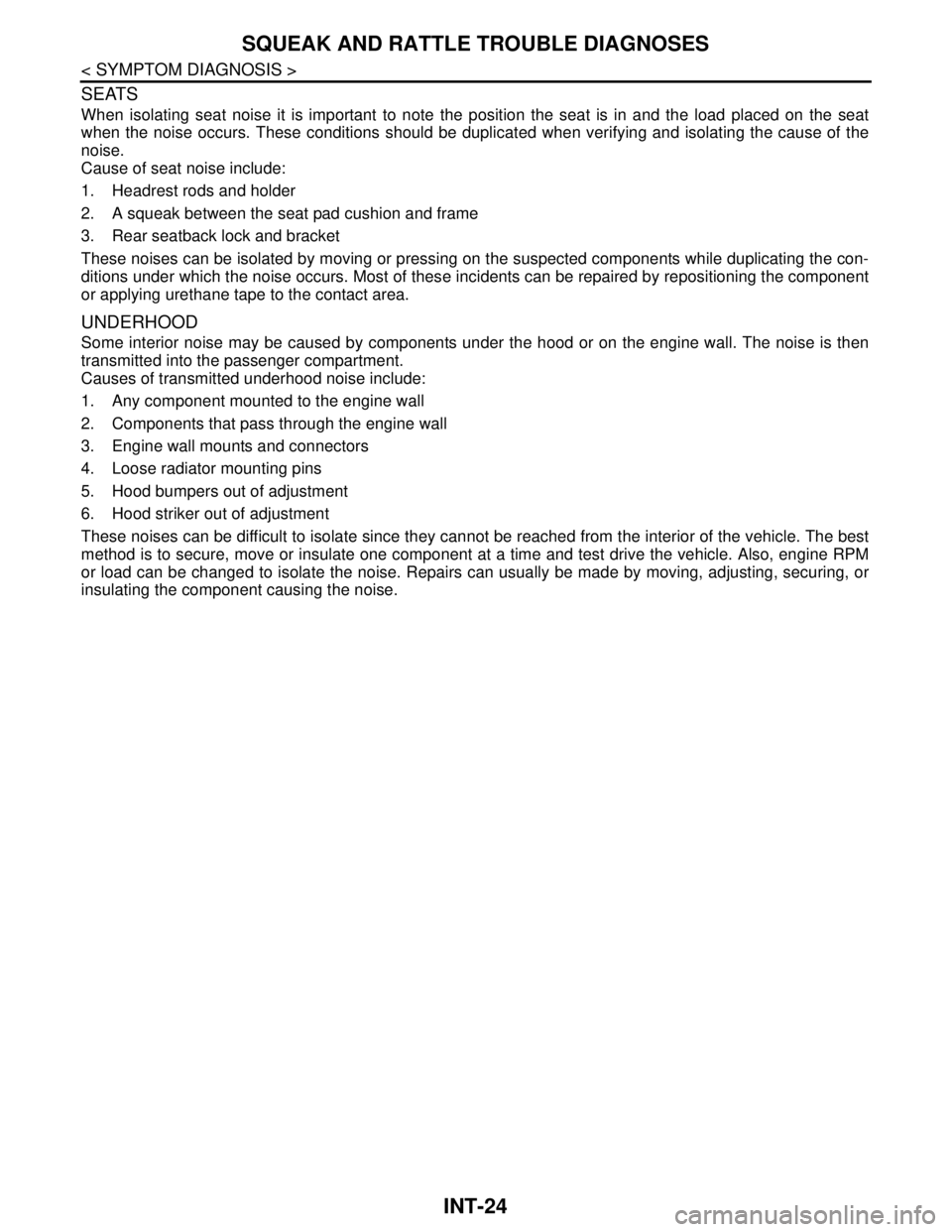

SE-90

< ON-VEHICLE REPAIR >[WITH VENTILATION SEAT]

FRONT SEAT

PASSENGER'S POWER SEAT

1. Headrest 2. Seatback trim 3. Seatback pad

4. Lumbar support lever knob 5. Snap pin 6. Seat cushion trim

7. Seat cushion pad 8. Seat belt buckle 9. Seat control unit

10. Seat cushion frame bracket 11. Front slide cover 12. Clip

13. Seat cushion duct B 14. Seat cushion duct A 15. Blower filter

16. Ventilation seat control unit 17. Ventilation motor 18. Seatback duct A

19. Seatback duct B 20. Seatback duct C 21. Clip

22. Seat slide and lifter switch knob 23. Reclining switch knob 24. Seat cushion outer finisher

25. Seat control switch 26. Seat cushion outer finisher inside 27. Seat harness clamp

28. Seat harness 29. Side air bag module 30. Seatback finisher

31. Side air bag module bracket 32. Seat cushion rear finisher 33. Seatback board

34. Seatback silencer 35. Seatback heater unit 36. Seat cushion heater unit

37. Seat slide inner cover 38. Lumbar support unit 39. Seat cushion inner finisher

40. Seat cushion inner finisher inside 41. TORX bolt 42. Seat frame assembly

43. TORX bolt 44. Seat slide outer cover 45. Rear slide cover

46. End cap 47. Reclining device outer cover 48. Reclining device inner cover

49. Headrest holder (locked) 50. Headrest holder (free)

Refer to GI-4, "

Components" for symbols in the figure.

Page 3956 of 5121

![NISSAN TEANA 2008 Service Manual SE-92

< ON-VEHICLE REPAIR >[WITH VENTILATION SEAT]

FRONT SEAT

Removal and Installation

INFOID:0000000003812466

REMOVAL

CAUTION:

When removing and installing, use shop cloths to protect parts from da NISSAN TEANA 2008 Service Manual SE-92

< ON-VEHICLE REPAIR >[WITH VENTILATION SEAT]

FRONT SEAT

Removal and Installation

INFOID:0000000003812466

REMOVAL

CAUTION:

When removing and installing, use shop cloths to protect parts from da](/img/5/57391/w960_57391-3955.png)

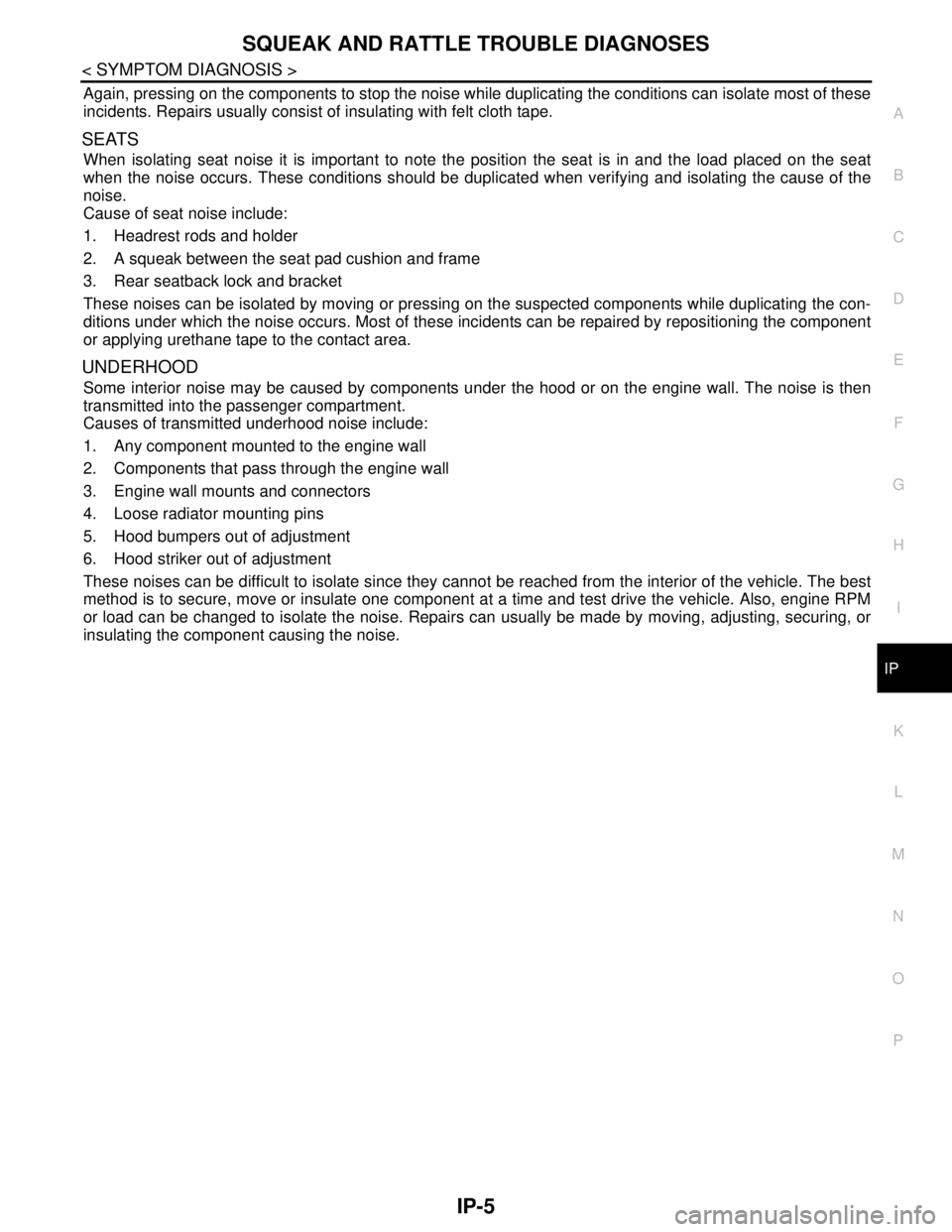

SE-92

< ON-VEHICLE REPAIR >[WITH VENTILATION SEAT]

FRONT SEAT

Removal and Installation

INFOID:0000000003812466

REMOVAL

CAUTION:

When removing and installing, use shop cloths to protect parts from damage.

Before removal, turn ignition switch OFF, disconnect battery negative terminal and then wait for at

least 3 minutes.

NOTE:

Confirm the position of connector before starting work.

1. Remove the headrest.

2. Slide the seat to the frontmost position.

3. Remove the rear outer mounting TORX bolt.

4. Remove the rear inner mounting TORX bolt.

5. Slide the seat to the rearmost position.

6. Remove the front slide cover.

Open the front end of the front slide cover to release the

pawls.

Slide the front slide cover forward to release the pawls.

7. Remove the front outer mounting TORX bolt.

8. Remove the front inner mounting TORX bolt.

9. Set seatback in a standing position.

10. Lift the seat to the uppermost position.

11. Lift the ottoman to the uppermost position. (With ottoman model)

12. Disconnect harness connector under the seat and remove harness clamps.

13. Remove seat from the vehicle.

INSTALLATION

Install in the reverse order of removal.

CAUTION:

Before installation, turn ignition switch OFF, disconnect battery negative terminal, and then wait for

at least 3 minutes.

Clamp the harness in position.

19. Clip 20. Seatback duct C 21. Front slide cover

22. Ottoman trim and pad 23. Front outer link cover 24. Rear outer link cover

25. Ottoman unit assembly 26. Front inner link cover 27. Rear inner link cover

28. Ottoman protector 29. Seat cushion inner finisher inside 30. Seat cushion inner finisher

31. Seat belt buckle 32. Seat cushion heater unit 33. Seat cushion pad

34. Seat cushion trim 35. Seatback pad 36. Seatback trim

37. Headrest 38. Seatback heater unit 39. Seatback silencer

40. Reclining device inner cover 41. Reclining device outer cover 42. Rear slide cover

43. End cap 44. Seat cushion outer finisher inside 45. Seat control switch

46. TORX bolt 47. TORX bolt 48. Seat frame assembly

49. Seat slide inner cover 50. Headrest holder (locked) 51. Headrest holder (free)

Refer to GI-4, "

Components" for symbols in the figure.

: Pawl

JMJIA1863ZZ