boot NISSAN TEANA 2008 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 939 of 5121

REAR DISC BRAKE

BR-43

< ON-VEHICLE REPAIR >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

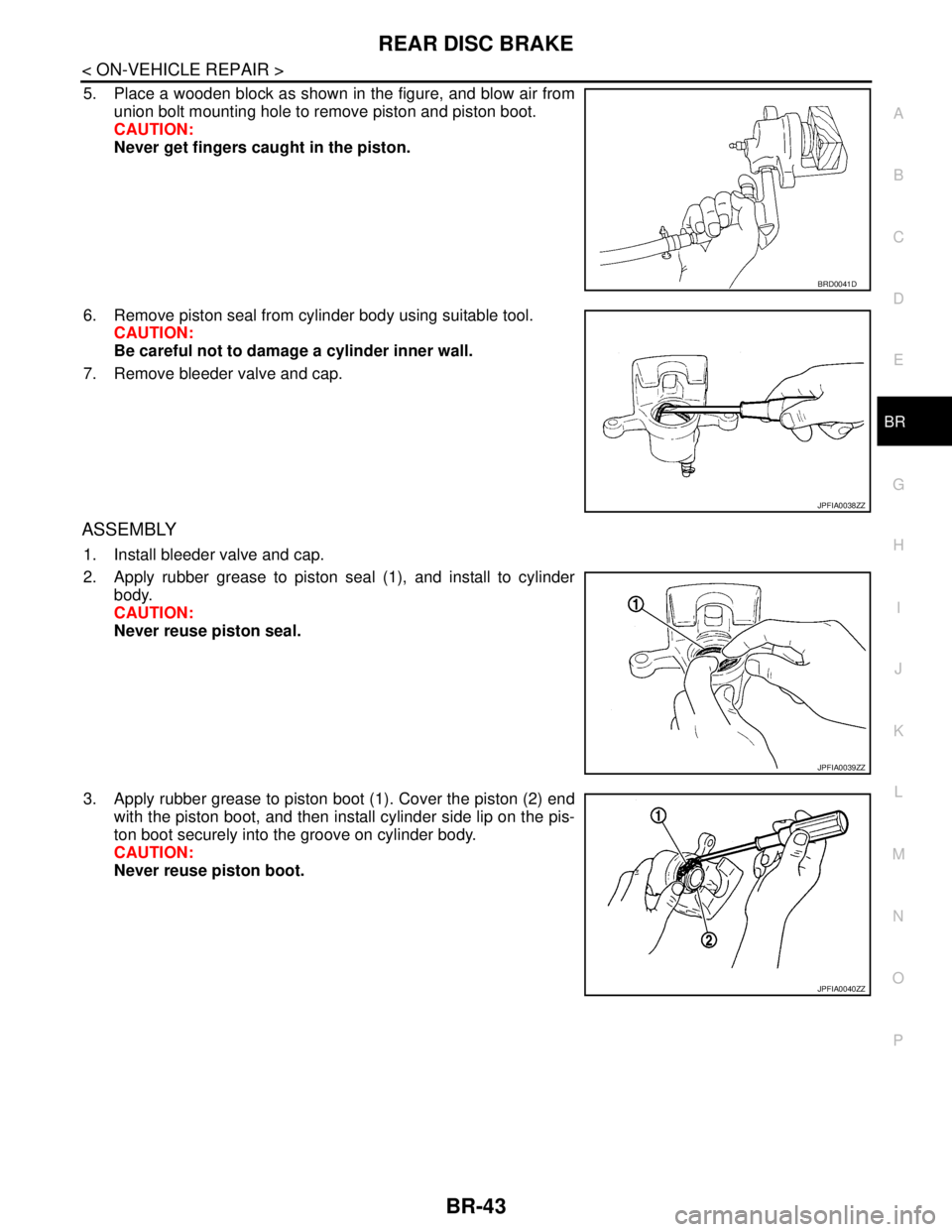

5. Place a wooden block as shown in the figure, and blow air from

union bolt mounting hole to remove piston and piston boot.

CAUTION:

Never get fingers caught in the piston.

6. Remove piston seal from cylinder body using suitable tool.

CAUTION:

Be careful not to damage a cylinder inner wall.

7. Remove bleeder valve and cap.

ASSEMBLY

1. Install bleeder valve and cap.

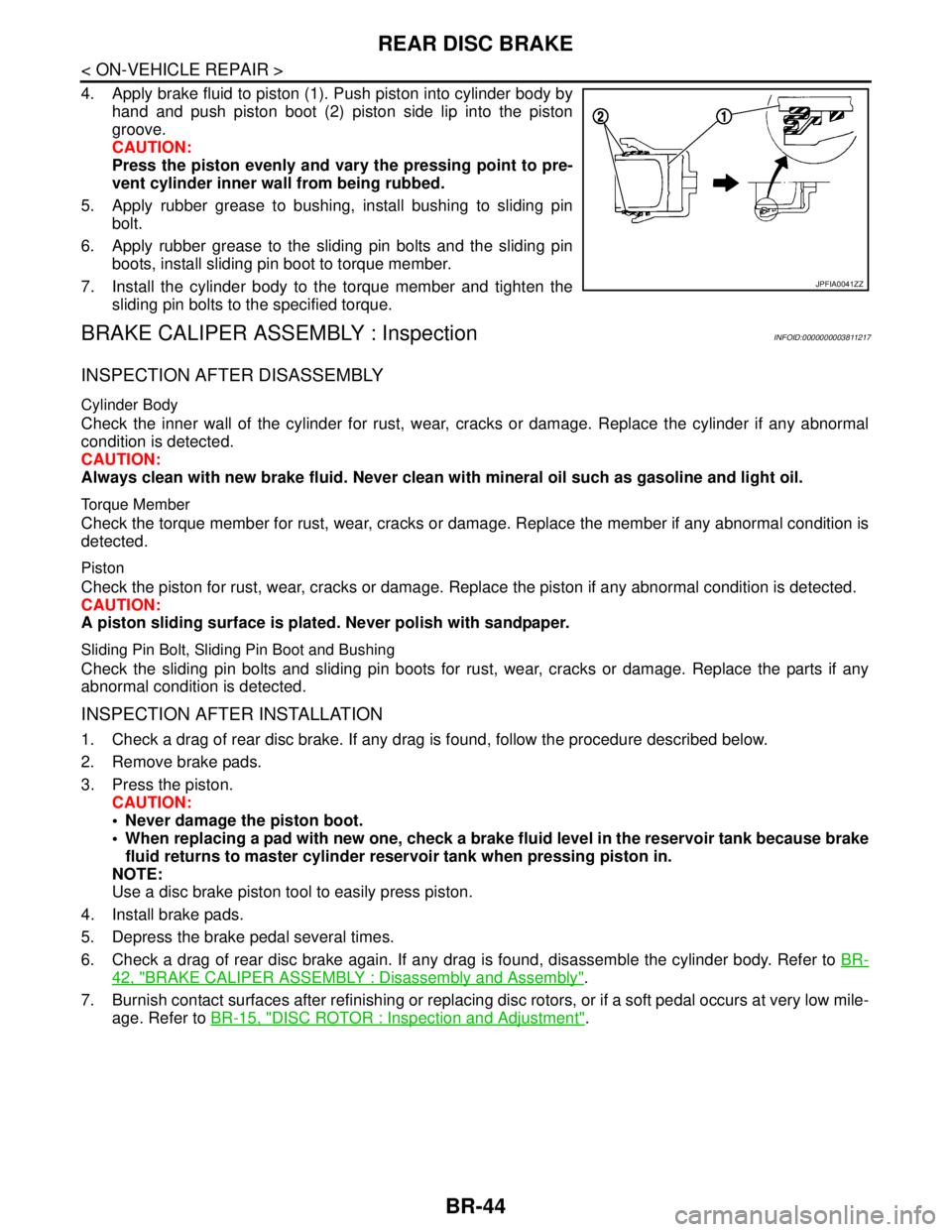

2. Apply rubber grease to piston seal (1), and install to cylinder

body.

CAUTION:

Never reuse piston seal.

3. Apply rubber grease to piston boot (1). Cover the piston (2) end

with the piston boot, and then install cylinder side lip on the pis-

ton boot securely into the groove on cylinder body.

CAUTION:

Never reuse piston boot.

BRD0041D

JPFIA0038ZZ

JPFIA0039ZZ

JPFIA0040ZZ

Page 940 of 5121

BR-44

< ON-VEHICLE REPAIR >

REAR DISC BRAKE

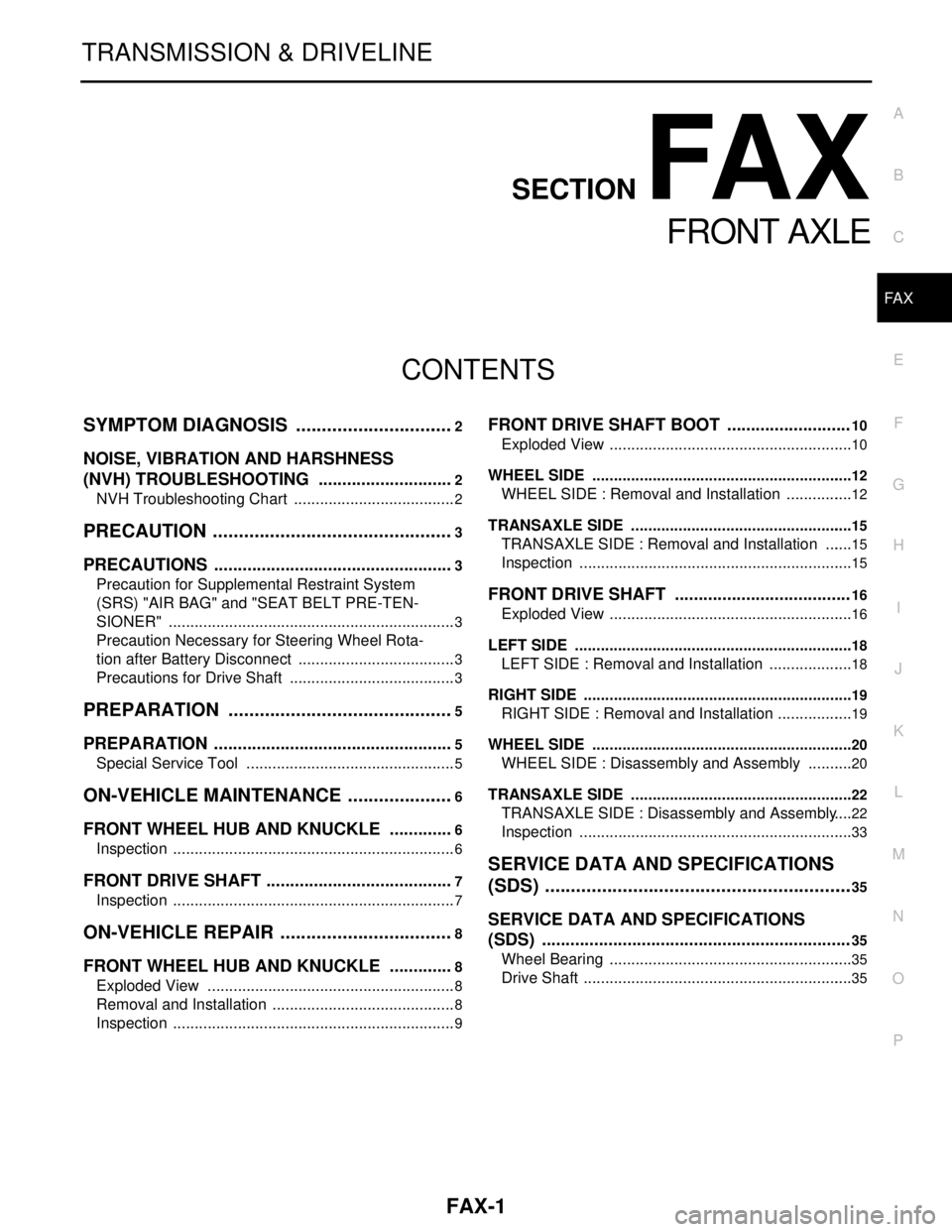

4. Apply brake fluid to piston (1). Push piston into cylinder body by

hand and push piston boot (2) piston side lip into the piston

groove.

CAUTION:

Press the piston evenly and vary the pressing point to pre-

vent cylinder inner wall from being rubbed.

5. Apply rubber grease to bushing, install bushing to sliding pin

bolt.

6. Apply rubber grease to the sliding pin bolts and the sliding pin

boots, install sliding pin boot to torque member.

7. Install the cylinder body to the torque member and tighten the

sliding pin bolts to the specified torque.

BRAKE CALIPER ASSEMBLY : InspectionINFOID:0000000003811217

INSPECTION AFTER DISASSEMBLY

Cylinder Body

Check the inner wall of the cylinder for rust, wear, cracks or damage. Replace the cylinder if any abnormal

condition is detected.

CAUTION:

Always clean with new brake fluid. Never clean with mineral oil such as gasoline and light oil.

Torque Member

Check the torque member for rust, wear, cracks or damage. Replace the member if any abnormal condition is

detected.

Piston

Check the piston for rust, wear, cracks or damage. Replace the piston if any abnormal condition is detected.

CAUTION:

A piston sliding surface is plated. Never polish with sandpaper.

Sliding Pin Bolt, Sliding Pin Boot and Bushing

Check the sliding pin bolts and sliding pin boots for rust, wear, cracks or damage. Replace the parts if any

abnormal condition is detected.

INSPECTION AFTER INSTALLATION

1. Check a drag of rear disc brake. If any drag is found, follow the procedure described below.

2. Remove brake pads.

3. Press the piston.

CAUTION:

Never damage the piston boot.

When replacing a pad with new one, check a brake fluid level in the reservoir tank because brake

fluid returns to master cylinder reservoir tank when pressing piston in.

NOTE:

Use a disc brake piston tool to easily press piston.

4. Install brake pads.

5. Depress the brake pedal several times.

6. Check a drag of rear disc brake again. If any drag is found, disassemble the cylinder body. Refer to BR-

42, "BRAKE CALIPER ASSEMBLY : Disassembly and Assembly".

7. Burnish contact surfaces after refinishing or replacing disc rotors, or if a soft pedal occurs at very low mile-

age. Refer to BR-15, "

DISC ROTOR : Inspection and Adjustment".

JPFIA0041ZZ

Page 2429 of 5121

FAX-1

TRANSMISSION & DRIVELINE

CEF

G H

I

J

K L

M

SECTION FA X

A

B

FA X

N

O P

CONTENTS

FRONT AXLE

SYMPTOM DIAGNOSIS ..... ..........................2

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ........................ .....

2

NVH Troubleshooting Chart ................................ ......2

PRECAUTION ...............................................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution Necessary for Steering Wheel Rota-

tion after Battery Disconnect .....................................

3

Precautions for Drive Shaft .......................................3

PREPARATION ............................................5

PREPARATION .............................................. .....5

Special Service Tool ........................................... ......5

ON-VEHICLE MAINTENANCE .....................6

FRONT WHEEL HUB AND KNUCKLE ......... .....6

Inspection ............................................................ ......6

FRONT DRIVE SHAFT ........................................7

Inspection ............................................................ ......7

ON-VEHICLE REPAIR ..................................8

FRONT WHEEL HUB AND KNUCKLE ......... .....8

Exploded View .................................................... ......8

Removal and Installation ...........................................8

Inspection ..................................................................9

FRONT DRIVE SHAFT BOOT ..........................10

Exploded View ..................................................... ....10

WHEEL SIDE ......................................................... ....12

WHEEL SIDE : Removal and Installation ................12

TRANSAXLE SIDE ................................................ ....15

TRANSAXLE SIDE : Removal and Installation .......15

Inspection ............................................................ ....15

FRONT DRIVE SHAFT .....................................16

Exploded View .........................................................16

LEFT SIDE ............................................................. ....18

LEFT SIDE : Removal and Installation ....................18

RIGHT SIDE ........................................................... ....19

RIGHT SIDE : Removal and Installation ..................19

WHEEL SIDE ......................................................... ....20

WHEEL SIDE : Disassembly and Assembly ...........20

TRANSAXLE SIDE ................................................ ....22

TRANSAXLE SIDE : Disassembly and Assembly ....22

Inspection ............................................................ ....33

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .............................................

35

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

35

Wheel Bearing ..................................................... ....35

Drive Shaft ...............................................................35

Page 2433 of 5121

PREPARATION

FAX-5

< PREPARATION >

C

E

F

G

H

I

J

K

L

MA

B

FA X

N

O

P

PREPARATION

PREPARATION

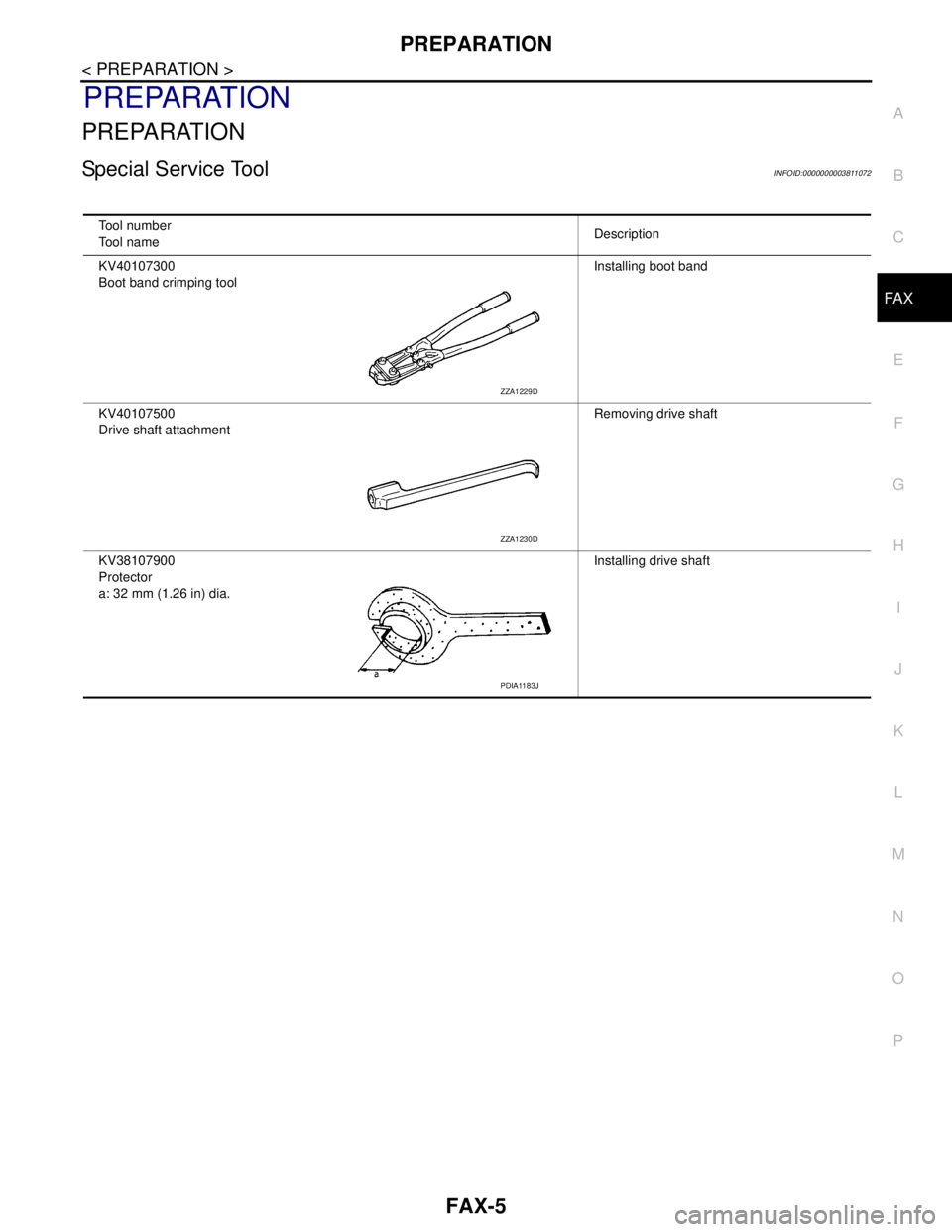

Special Service ToolINFOID:0000000003811072

Tool number

Tool nameDescription

KV40107300

Boot band crimping toolInstalling boot band

KV40107500

Drive shaft attachmentRemoving drive shaft

KV38107900

Protector

a: 32 mm (1.26 in) dia.Installing drive shaft

ZZA1229D

ZZA1230D

PDIA1183J

Page 2435 of 5121

FRONT DRIVE SHAFT

FAX-7

< ON-VEHICLE MAINTENANCE >

C

E

F

G

H

I

J

K

L

MA

B

FA X

N

O

P

FRONT DRIVE SHAFT

InspectionINFOID:0000000003811075

Check drive shaft mounting point and joint for looseness and other damage.

Check boot for cracks and other damage.

CAUTION:

Replace drive shaft assembly when noise or vibration occur from drive shaft.

Page 2437 of 5121

FRONT WHEEL HUB AND KNUCKLE

FAX-9

< ON-VEHICLE REPAIR >

C

E

F

G

H

I

J

K

L

MA

B

FA X

N

O

P

11. Temporarily tighten strut assembly and steering knuckle.

12. Remove wheel hub and bearing assembly, and then remove splash guard.

13. Remove steering outer socket from steering knuckle. Refer to ST-18, "

Exploded View".

14. Remove steering knuckle from transverse link and strut assembly.

INSTALLATION

Note the following, and install in the reverse order of the removal.

Install removed wheel hub and bearing assembly and steering knuckle and perform the final tightening of

each part under unladen conditions on the level surface.

Never reuse cotter pin.

InspectionINFOID:0000000003811078

INSPECTION AFTER REMOVAL

Check components for deformation, cracks, and other damage. Replace if necessary.

Ball Joint Inspection

Check boots of transverse link and steering outer socket ball joint for breakage, axial play, and torque. Refer to

FSU-12, "

Inspection" and ST-26, "Inspection".

INSPECTION AFTER INSTALLATION

1. Check wheel sensor harness for proper connection. Refer to BRC-57, "FRONT WHEEL SENSOR :

Exploded View" (without VDC), BRC-151, "FRONT WHEEL SENSOR : Exploded View". (with VDC).

2. Check the wheel alignment. Refer to FSU-7, "

Wheel Alignment Inspection".

3. Adjust neutral position of steering angle sensor (with VDC). Refer to BRC-66, "

ADJUSTMENT OF

STEERING ANGLE SENSOR NEUTRAL POSITION : Special Repair Requirement".

Page 2438 of 5121

FAX-10

< ON-VEHICLE REPAIR >

FRONT DRIVE SHAFT BOOT

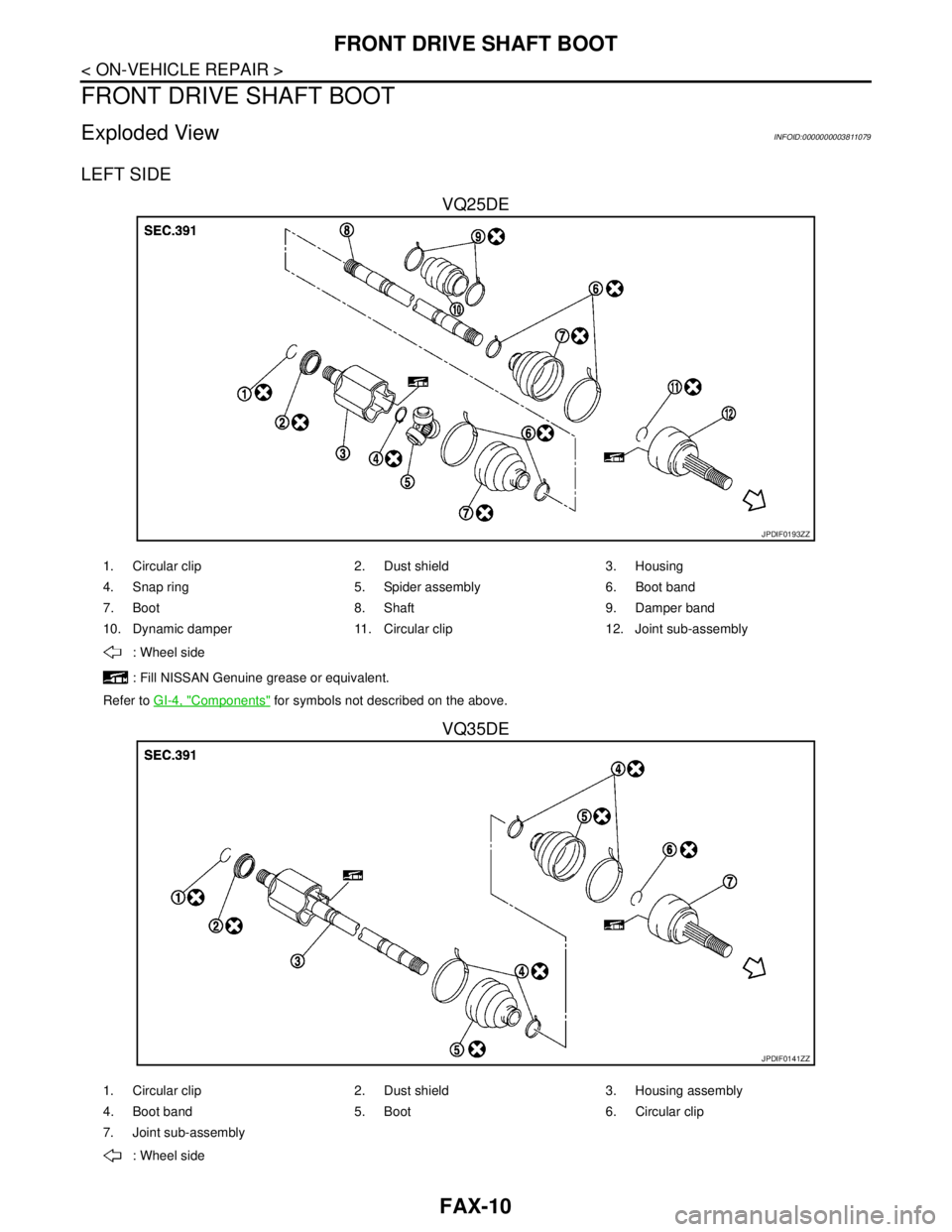

FRONT DRIVE SHAFT BOOT

Exploded ViewINFOID:0000000003811079

LEFT SIDE

VQ25DE

VQ35DE

JPDIF0193ZZ

1. Circular clip 2. Dust shield 3. Housing

4. Snap ring 5. Spider assembly 6. Boot band

7. Boot 8. Shaft 9. Damper band

10. Dynamic damper 11. Circular clip 12. Joint sub-assembly

: Wheel side

: Fill NISSAN Genuine grease or equivalent.

Refer to GI-4, "

Components" for symbols not described on the above.

JPDIF0141ZZ

1. Circular clip 2. Dust shield 3. Housing assembly

4. Boot band 5. Boot 6. Circular clip

7. Joint sub-assembly

: Wheel side

Page 2439 of 5121

FRONT DRIVE SHAFT BOOT

FAX-11

< ON-VEHICLE REPAIR >

C

E

F

G

H

I

J

K

L

MA

B

FA X

N

O

P

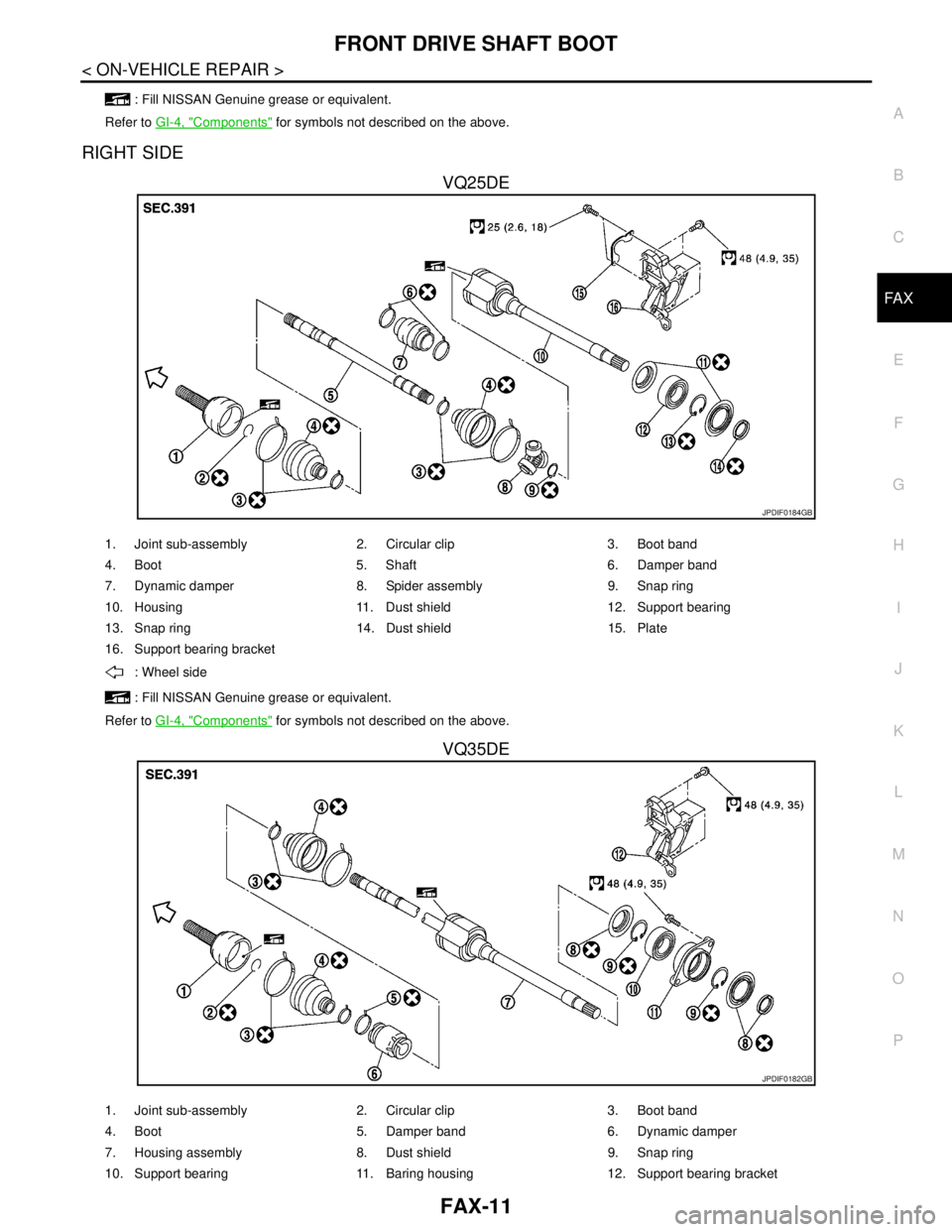

RIGHT SIDE

VQ25DE

VQ35DE

: Fill NISSAN Genuine grease or equivalent.

Refer to GI-4, "

Components" for symbols not described on the above.

JPDIF0184GB

1. Joint sub-assembly 2. Circular clip 3. Boot band

4. Boot 5. Shaft 6. Damper band

7. Dynamic damper 8. Spider assembly 9. Snap ring

10. Housing 11. Dust shield 12. Support bearing

13. Snap ring 14. Dust shield 15. Plate

16. Support bearing bracket

: Wheel side

: Fill NISSAN Genuine grease or equivalent.

Refer to GI-4, "

Components" for symbols not described on the above.

JPDIF0182GB

1. Joint sub-assembly 2. Circular clip 3. Boot band

4. Boot 5. Damper band 6. Dynamic damper

7. Housing assembly 8. Dust shield 9. Snap ring

10. Support bearing 11. Baring housing 12. Support bearing bracket

Page 2440 of 5121

FAX-12

< ON-VEHICLE REPAIR >

FRONT DRIVE SHAFT BOOT

WHEEL SIDE

WHEEL SIDE : Removal and InstallationINFOID:0000000003811080

REMOVAL

1. Remove tires.

2. Remove wheel sensor and sensor harness. Refer to BRC-57, "

FRONT WHEEL SENSOR : Exploded

View" (without VDC), BRC-151, "FRONT WHEEL SENSOR : Exploded View" (with VDC).

3. Remove lock plate of brake hose from strut assembly. Refer to BR-19, "

FRONT : Exploded View".

4. Remove caliper assembly. Hang caliper assembly not to interfere with work. Refer to BR-34, "

BRAKE

CALIPER ASSEMBLY : Exploded View".

5. Remove disc rotor. Refer to BR-35, "

BRAKE CALIPER ASSEMBLY : Removal and Installation".

6. Remove cotter pin, and then loosen wheel hub lock nut. Refer to FA X - 8 , "

Exploded View".

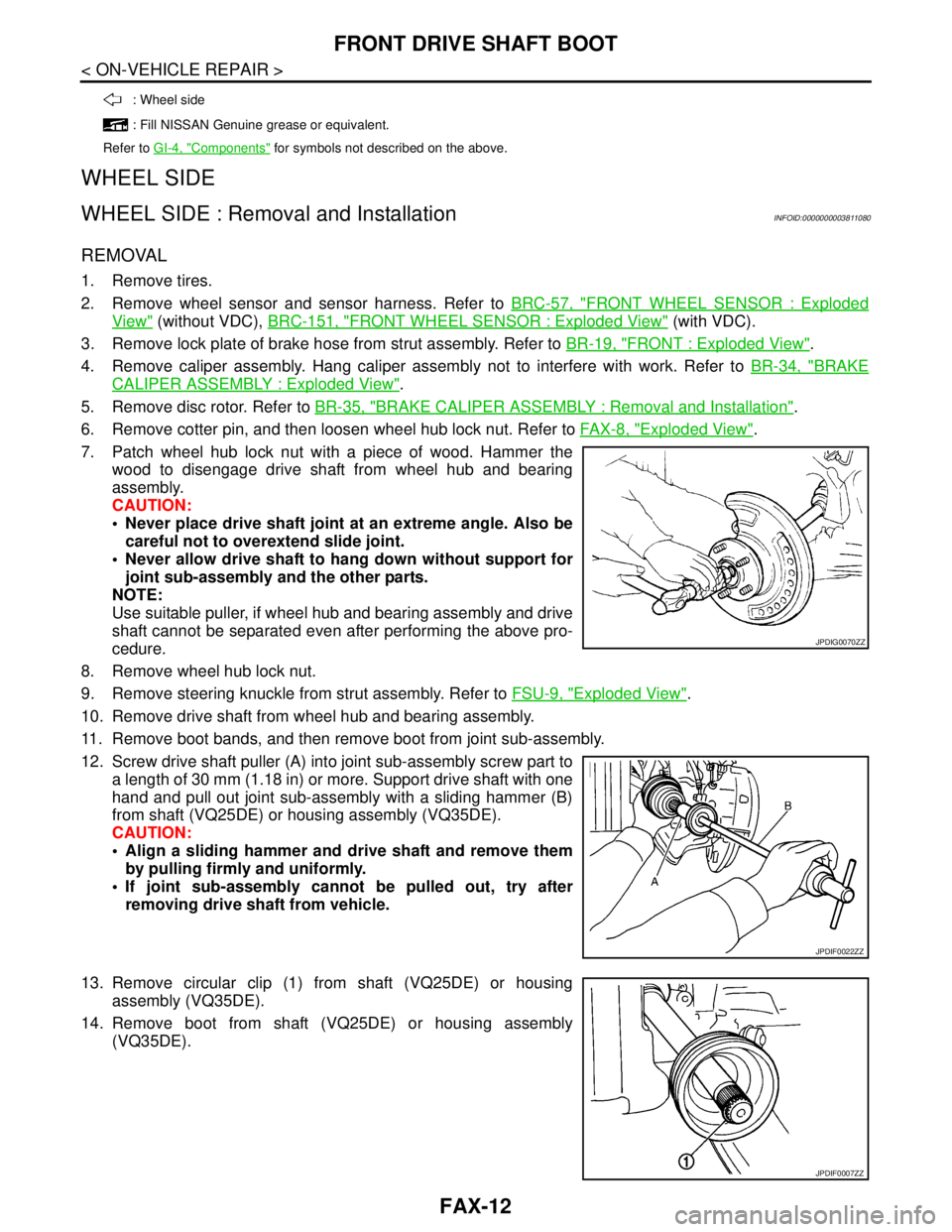

7. Patch wheel hub lock nut with a piece of wood. Hammer the

wood to disengage drive shaft from wheel hub and bearing

assembly.

CAUTION:

Never place drive shaft joint at an extreme angle. Also be

careful not to overextend slide joint.

Never allow drive shaft to hang down without support for

joint sub-assembly and the other parts.

NOTE:

Use suitable puller, if wheel hub and bearing assembly and drive

shaft cannot be separated even after performing the above pro-

cedure.

8. Remove wheel hub lock nut.

9. Remove steering knuckle from strut assembly. Refer to FSU-9, "

Exploded View".

10. Remove drive shaft from wheel hub and bearing assembly.

11. Remove boot bands, and then remove boot from joint sub-assembly.

12. Screw drive shaft puller (A) into joint sub-assembly screw part to

a length of 30 mm (1.18 in) or more. Support drive shaft with one

hand and pull out joint sub-assembly with a sliding hammer (B)

from shaft (VQ25DE) or housing assembly (VQ35DE).

CAUTION:

Align a sliding hammer and drive shaft and remove them

by pulling firmly and uniformly.

If joint sub-assembly cannot be pulled out, try after

removing drive shaft from vehicle.

13. Remove circular clip (1) from shaft (VQ25DE) or housing

assembly (VQ35DE).

14. Remove boot from shaft (VQ25DE) or housing assembly

(VQ35DE).

: Wheel side

: Fill NISSAN Genuine grease or equivalent.

Refer to GI-4, "

Components" for symbols not described on the above.

JPDIG0070ZZ

JPDIF0022ZZ

JPDIF0007ZZ

Page 2441 of 5121

FRONT DRIVE SHAFT BOOT

FAX-13

< ON-VEHICLE REPAIR >

C

E

F

G

H

I

J

K

L

MA

B

FA X

N

O

P

INSTALLATION

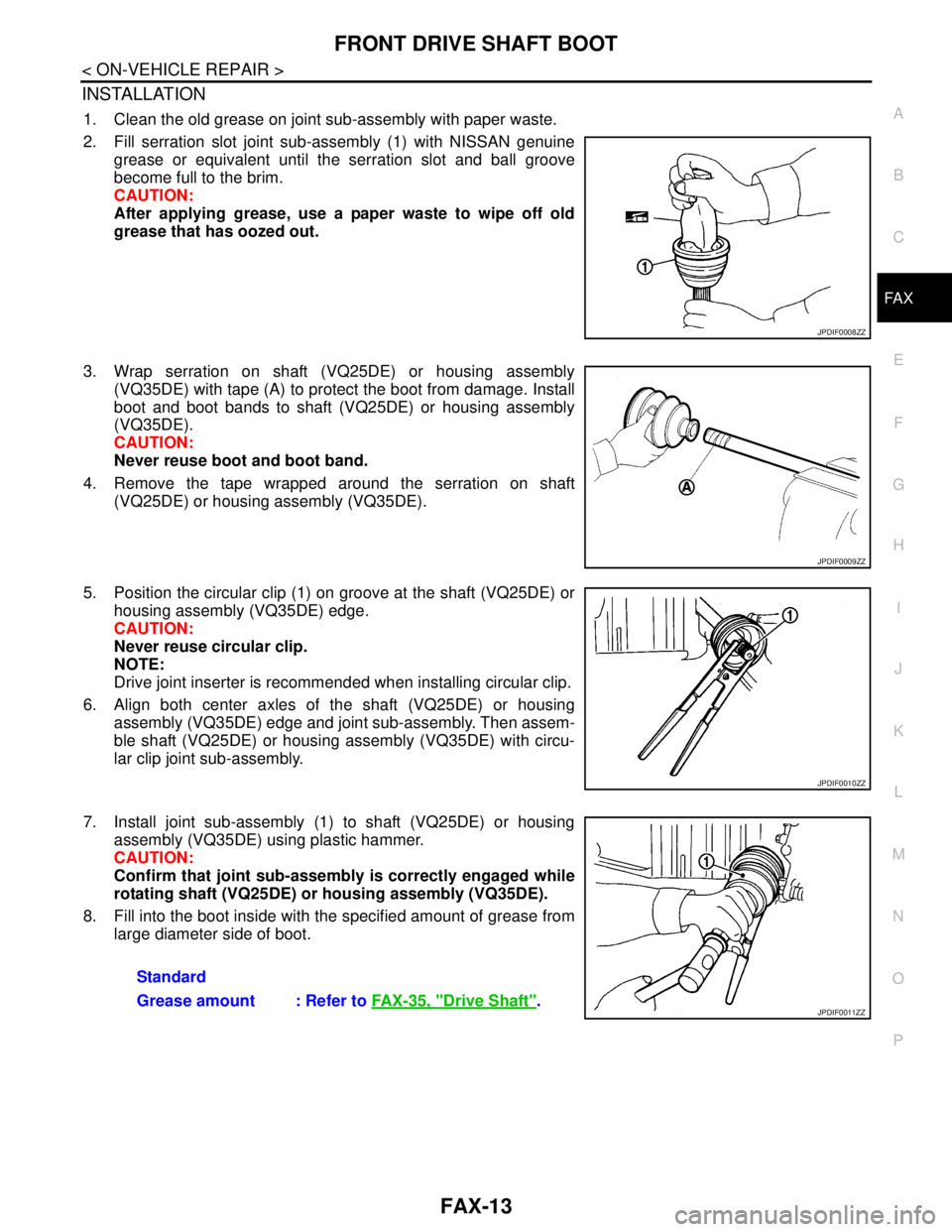

1. Clean the old grease on joint sub-assembly with paper waste.

2. Fill serration slot joint sub-assembly (1) with NISSAN genuine

grease or equivalent until the serration slot and ball groove

become full to the brim.

CAUTION:

After applying grease, use a paper waste to wipe off old

grease that has oozed out.

3. Wrap serration on shaft (VQ25DE) or housing assembly

(VQ35DE) with tape (A) to protect the boot from damage. Install

boot and boot bands to shaft (VQ25DE) or housing assembly

(VQ35DE).

CAUTION:

Never reuse boot and boot band.

4. Remove the tape wrapped around the serration on shaft

(VQ25DE) or housing assembly (VQ35DE).

5. Position the circular clip (1) on groove at the shaft (VQ25DE) or

housing assembly (VQ35DE) edge.

CAUTION:

Never reuse circular clip.

NOTE:

Drive joint inserter is recommended when installing circular clip.

6. Align both center axles of the shaft (VQ25DE) or housing

assembly (VQ35DE) edge and joint sub-assembly. Then assem-

ble shaft (VQ25DE) or housing assembly (VQ35DE) with circu-

lar clip joint sub-assembly.

7. Install joint sub-assembly (1) to shaft (VQ25DE) or housing

assembly (VQ35DE) using plastic hammer.

CAUTION:

Confirm that joint sub-assembly is correctly engaged while

rotating shaft (VQ25DE) or housing assembly (VQ35DE).

8. Fill into the boot inside with the specified amount of grease from

large diameter side of boot.

JPDIF0008ZZ

JPDIF0009ZZ

JPDIF0010ZZ

Standard

Grease amount : Refer to FAX-35, "

Drive Shaft".JPDIF0011ZZ