heating NISSAN TEANA 2008 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 1670 of 5121

![NISSAN TEANA 2008 User Guide P0300, P0301, P0302, P0303, P0304, P0305, P0306 MISFIRE

EC-209

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

P0300, P0301, P0302, P0303, P0304, P0305, P0306 MISFIRE

DTC Logic NISSAN TEANA 2008 User Guide P0300, P0301, P0302, P0303, P0304, P0305, P0306 MISFIRE

EC-209

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

P0300, P0301, P0302, P0303, P0304, P0305, P0306 MISFIRE

DTC Logic](/img/5/57391/w960_57391-1669.png)

P0300, P0301, P0302, P0303, P0304, P0305, P0306 MISFIRE

EC-209

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

P0300, P0301, P0302, P0303, P0304, P0305, P0306 MISFIRE

DTC LogicINFOID:0000000003856617

DTC DETECTION LOGIC

When a misfire occurs, engine speed will fluctuate. If the engine speed fluctuates enough to cause the crank-

shaft position (CKP) sensor (POS) signal to vary, ECM can determine that a misfire is occurring.

The misfire detection logic consists of the following two conditions.

1. One Trip Detection Logic (Three Way Catalyst Damage)

On the 1st trip that a misfire condition occurs that can damage the three way catalyst (TWC) due to over-

heating, the MI will blink.

When a misfire condition occurs, the ECM monitors the CKP sensor signal every 200 engine revolutions

for a change.

When the misfire condition decreases to a level that will not damage the TWC, the MI will turn off.

If another misfire condition occurs that can damage the TWC on a second trip, the MI will blink.

When the misfire condition decreases to a level that will not damage the TWC, the MI will remain on.

If another misfire condition occurs that can damage the TWC, the MI will begin to blink again.

2. Two Trip Detection Logic (Exhaust quality deterioration)

For misfire conditions that will not damage the TWC (but will affect vehicle emissions), the MI will only light

when the misfire is detected on a second trip. During this condition, the ECM monitors the CKP sensor

signal every 1,000 engine revolutions.

A misfire malfunction can be detected in any one cylinder or in multiple cylinders.

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE-I

1. Start engine and warm it up to normal operating temperature.

2. Turn ignition switch OFF and wait at least 10 seconds.

3. Restart engine and let it idle for about 15 minutes.

4. Check 1st trip DTC.

Is 1st trip DTC detected?

YES >> Go to EC-210, "Diagnosis Procedure".

NO >> GO TO 3.

3.PERFORM DTC CONFIRMATION PROCEDURE-II

1. Turn ignition switch OFF and wait at least 10 seconds.

Sensor Input signal to ECM ECM function

Crankshaft position sensor (POS) Engine speed On board diagnosis of misfire

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0300 Multiple cylinder misfires detected Multiple cylinder misfire. Improper spark plug

Insufficient compression

Incorrect fuel pressure

The fuel injector circuit is open or shorted

Fuel injector

Intake air leak

The ignition signal circuit is open or shorted

Lack of fuel

Signal plate

A/F sensor 1

Incorrect PCV hose connection P0301 No.1 cylinder misfire detected No. 1 cylinder misfires.

P0302 No. 2 cylinder misfire detected No. 2 cylinder misfires.

P0303 No. 3 cylinder misfire detected No. 3 cylinder misfires.

P0304 No. 4 cylinder misfire detected No. 4 cylinder misfires.

P0305 No. 5 cylinder misfire detected No. 5 cylinder misfires.

P0306 No. 6 cylinder misfire detected No. 6 cylinder misfires.

Page 1882 of 5121

PRECAUTIONS

EM-7

< PRECAUTION >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

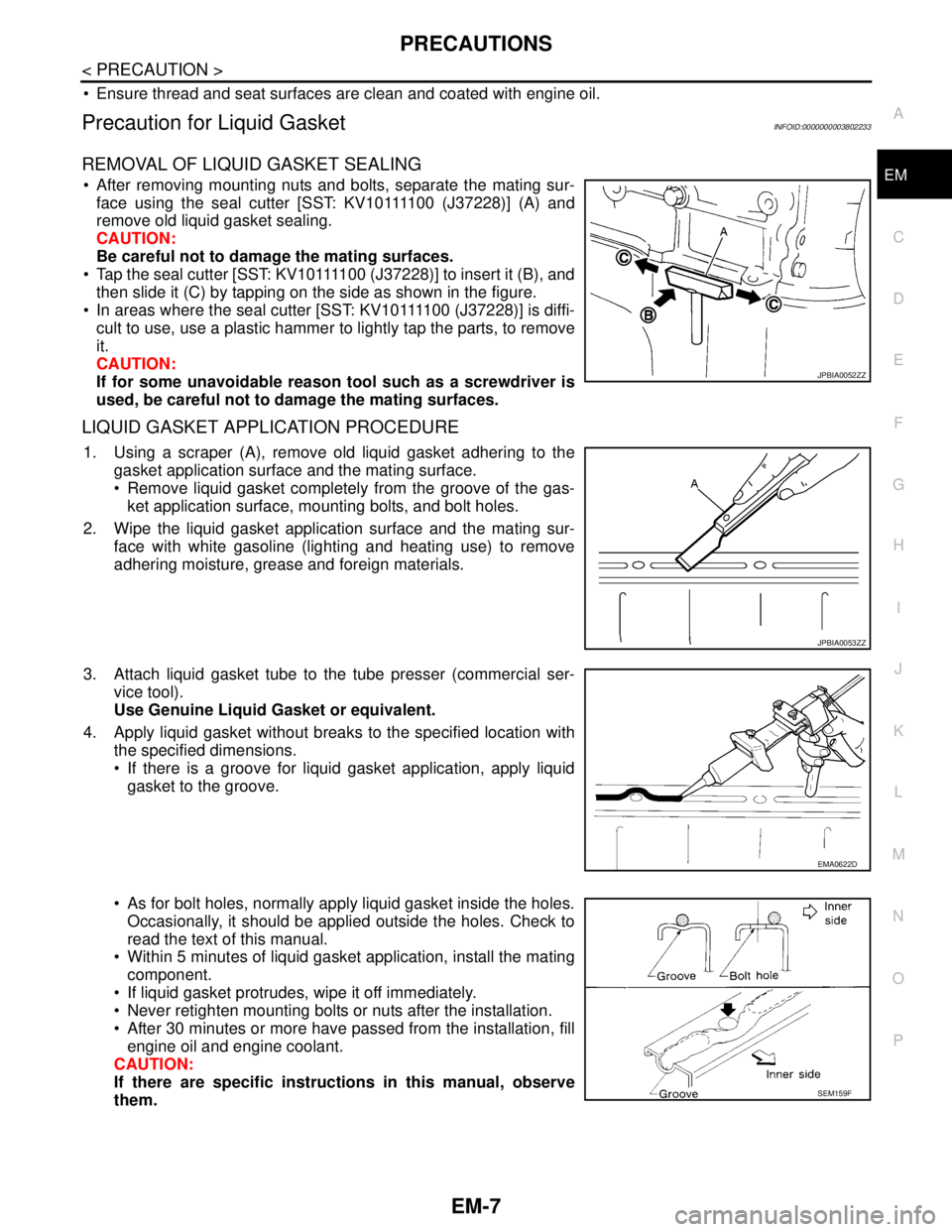

Ensure thread and seat surfaces are clean and coated with engine oil.

Precaution for Liquid GasketINFOID:0000000003802233

REMOVAL OF LIQUID GASKET SEALING

After removing mounting nuts and bolts, separate the mating sur-

f a c e u s i n g t h e s e a l c u t t e r [ S S T: K V 1 0 1111 0 0 ( J37228)] (A) and

remove old liquid gasket sealing.

CAUTION:

Be careful not to damage the mating surfaces.

Tap the seal cutter [SST: KV10111100 (J37228)] to insert it (B), and

then slide it (C) by tapping on the side as shown in the figure.

In areas where the seal cutter [SST: KV10111100 (J37228)] is diffi-

cult to use, use a plastic hammer to lightly tap the parts, to remove

it.

CAUTION:

If for some unavoidable reason tool such as a screwdriver is

used, be careful not to damage the mating surfaces.

LIQUID GASKET APPLICATION PROCEDURE

1. Using a scraper (A), remove old liquid gasket adhering to the

gasket application surface and the mating surface.

Remove liquid gasket completely from the groove of the gas-

ket application surface, mounting bolts, and bolt holes.

2. Wipe the liquid gasket application surface and the mating sur-

face with white gasoline (lighting and heating use) to remove

adhering moisture, grease and foreign materials.

3. Attach liquid gasket tube to the tube presser (commercial ser-

vice tool).

Use Genuine Liquid Gasket or equivalent.

4. Apply liquid gasket without breaks to the specified location with

the specified dimensions.

If there is a groove for liquid gasket application, apply liquid

gasket to the groove.

As for bolt holes, normally apply liquid gasket inside the holes.

Occasionally, it should be applied outside the holes. Check to

read the text of this manual.

Within 5 minutes of liquid gasket application, install the mating

component.

If liquid gasket protrudes, wipe it off immediately.

Never retighten mounting bolts or nuts after the installation.

After 30 minutes or more have passed from the installation, fill

engine oil and engine coolant.

CAUTION:

If there are specific instructions in this manual, observe

them.

JPBIA0052ZZ

JPBIA0053ZZ

EMA0622D

SEM159F

Page 2529 of 5121

GI-36

< BASIC INSPECTION >

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

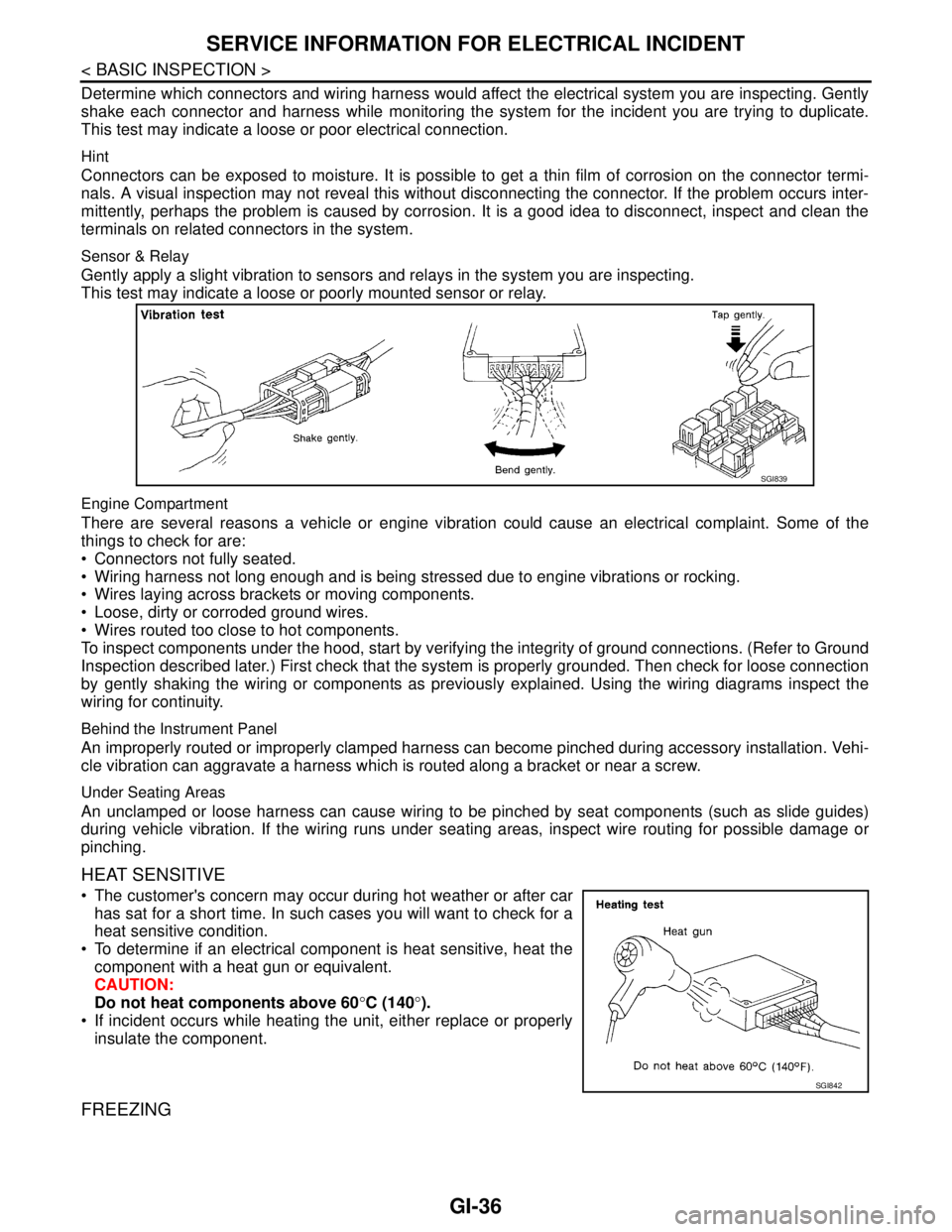

Determine which connectors and wiring harness would affect the electrical system you are inspecting. Gently

shake each connector and harness while monitoring the system for the incident you are trying to duplicate.

This test may indicate a loose or poor electrical connection.

Hint

Connectors can be exposed to moisture. It is possible to get a thin film of corrosion on the connector termi-

nals. A visual inspection may not reveal this without disconnecting the connector. If the problem occurs inter-

mittently, perhaps the problem is caused by corrosion. It is a good idea to disconnect, inspect and clean the

terminals on related connectors in the system.

Sensor & Relay

Gently apply a slight vibration to sensors and relays in the system you are inspecting.

This test may indicate a loose or poorly mounted sensor or relay.

Engine Compartment

There are several reasons a vehicle or engine vibration could cause an electrical complaint. Some of the

things to check for are:

Connectors not fully seated.

Wiring harness not long enough and is being stressed due to engine vibrations or rocking.

Wires laying across brackets or moving components.

Loose, dirty or corroded ground wires.

Wires routed too close to hot components.

To inspect components under the hood, start by verifying the integrity of ground connections. (Refer to Ground

Inspection described later.) First check that the system is properly grounded. Then check for loose connection

by gently shaking the wiring or components as previously explained. Using the wiring diagrams inspect the

wiring for continuity.

Behind the Instrument Panel

An improperly routed or improperly clamped harness can become pinched during accessory installation. Vehi-

cle vibration can aggravate a harness which is routed along a bracket or near a screw.

Under Seating Areas

An unclamped or loose harness can cause wiring to be pinched by seat components (such as slide guides)

during vehicle vibration. If the wiring runs under seating areas, inspect wire routing for possible damage or

pinching.

HEAT SENSITIVE

The customer's concern may occur during hot weather or after car

has sat for a short time. In such cases you will want to check for a

heat sensitive condition.

To determine if an electrical component is heat sensitive, heat the

component with a heat gun or equivalent.

CAUTION:

Do not heat components above 60°C (140°).

If incident occurs while heating the unit, either replace or properly

insulate the component.

FREEZING

SGI839

SGI842

Page 2630 of 5121

HAC-2

DTC Logic ...............................................................53

Diagnosis Procedure ..............................................54

Component Inspection ............................................55

B2632, B2633 AIR MIX DOOR MOTOR

(DRIVER SIDE) ..................................................

56

Description ..............................................................56

DTC Logic ...............................................................56

Diagnosis Procedure ..............................................57

B2634, B2635 AIR MIX DOOR MOTOR (PAS-

SENGER SIDE) ..................................................

58

Description ..............................................................58

DTC Logic ...............................................................58

Diagnosis Procedure ..............................................59

B2636, B2637, B2638, B2639, B2654, B2655

MODE DOOR MOTOR ......................................

60

Description ..............................................................60

DTC Logic ...............................................................60

Diagnosis Procedure ..............................................61

B263D B263E, B263F, B2656 INTAKE DOOR

MOTOR ..............................................................

63

Description ..............................................................63

DTC Logic ...............................................................63

Diagnosis Procedure ..............................................64

POWER SUPPLY AND GROUND CIRCUIT .....65

A/C AUTO AMP. .......................................................65

A/C AUTO AMP. : Diagnosis Procedure ................65

A/C CONTROL ..........................................................65

A/C CONTROL : Diagnosis Procedure ...................65

A/C DISPLAY ............................................................66

A/C DISPLAY : Diagnosis Procedure .....................66

A/C AUTO AMP. ................................................67

Description ..............................................................67

Component Function Check ...................................67

Diagnosis Procedure ..............................................67

BLOWER MOTOR .............................................68

Description ..............................................................68

Component Function Check .................................68

Diagnosis Procedure ..............................................68

Component Inspection ............................................71

MAGNET CLUTCH ............................................72

Description ..............................................................72

Component Function Check ...................................72

Diagnosis Procedure ..............................................72

A/C CONTROL SIGNAL CIRCUIT ....................74

Diagnosis Procedure ..............................................74

ECU DIAGNOSIS ........................................75

A/C AUTO AMP. ................................................75

Reference Value .....................................................75

Wiring Diagram - AIR CONDITIONER CONTROL

SYSTEM - ...............................................................

77

Fail-Safe ..................................................................84

DTC Inspection Priority Chart ...............................85

DTC Index ...............................................................85

SYMPTOM DIAGNOSIS ............................87

AIR CONDITIONER CONTROL ........................87

Diagnosis Chart By Symptom .................................87

INSUFFICIENT COOLING .................................88

Description ..............................................................88

Inspection procedure ..............................................88

INSUFFICIENT HEATING .................................91

Description ..............................................................91

Inspection procedure ..............................................91

NOISE ................................................................94

Description ..............................................................94

Inspection procedure ..............................................94

MEMORY FUNCTION DOES NOT OPERATE ...96

Description ..............................................................96

Inspection procedure ..............................................96

PRECAUTION ............................................97

PRECAUTIONS .................................................97

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .................................................................

97

Precaution Necessary for Steering Wheel Rota-

tion after Battery Disconnect ...................................

97

Precaution for Procedure without Cowl Top Cover ...98

Precautions For Xenon Headlamp Service .............98

Working with HFC-134a (R-134a) ...........................98

General Refrigerant Precaution ..............................99

Refrigerant Connection ...........................................99

Service Equipment ................................................101

COMPRESSOR ................................................104

General Precautions .............................................104

FLUORESCENT LEAK DETECTOR ................105

General Precautions .............................................105

WITH 7 INCH DISPLAY

BASIC INSPECTION .................................

106

DIAGNOSIS AND REPAIR WORKFLOW ........106

Work Flow .............................................................106

INSPECTION AND ADJUSTMENT ..................108

WITHOUT INTELLIGENT AIR CONDITIONER

SYSTEM ..................................................................

108

WITHOUT INTELLIGENT AIR CONDITIONER

SYSTEM : Description & Inspection .....................

108

WITHOUT INTELLIGENT AIR CONDITIONER

SYSTEM : Temperature Setting Trimmer .............

110

Page 2633 of 5121

HAC-5

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P WITH INTELLIGENT AIR CONDITIONER SYS-

TEM : Wiring Diagram - AIR CONDITIONER

CONTROL SYSTEM - ...........................................

215

WITH INTELLIGENT AIR CONDITIONER SYS-

TEM : Fail-Safe .....................................................

223

WITH INTELLIGENT AIR CONDITIONER SYS-

TEM : DTC Inspection Priority Chart ..................

224

WITH INTELLIGENT AIR CONDITIONER SYS-

TEM : DTC Index ..................................................

224

SYMPTOM DIAGNOSIS ............................226

AIR CONDITIONER CONTROL .......................226

Diagnosis Chart By Symptom ...............................226

PLASMACLUSTER SYSTEM DOES NOT OP-

ERATE ..............................................................

227

WITH INTELLIGENT AIR CONDITIONER SYS-

TEM ..........................................................................

227

WITH INTELLIGENT AIR CONDITIONER SYS-

TEM : Description ..................................................

227

WITH INTELLIGENT AIR CONDITIONER SYS-

TEM : Inspection procedure ..................................

227

INSUFFICIENT COOLING ...............................228

Description ............................................................228

Inspection procedure .............................................228

INSUFFICIENT HEATING ................................231

Description ............................................................231

Inspection procedure .............................................231

NOISE ..............................................................234

Description .............................................................234

Inspection procedure .............................................234

MEMORY FUNCTION DOES NOT OPERATE .236

Description .............................................................236

Inspection procedure .............................................236

PRECAUTION ............................................237

PRECAUTIONS ...............................................237

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...............................................................

237

Precaution Necessary for Steering Wheel Rota-

tion after Battery Disconnect .................................

237

Precaution for Procedure without Cowl Top Cover ..238

Precautions For Xenon Headlamp Service ...........238

Working with HFC-134a (R-134a) .........................238

General Refrigerant Precaution .............................239

Refrigerant Connection ..........................................239

Service Equipment ................................................241

COMPRESSOR ...............................................244

General Precautions ..............................................244

FLUORESCENT LEAK DETECTOR ..............245

General Precautions ..............................................245

Page 2637 of 5121

![NISSAN TEANA 2008 User Guide INSPECTION AND ADJUSTMENT

HAC-9

< BASIC INSPECTION >[WITHOUT 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

4.CHECK INTAKE AIR

1. Press the REC switch. REC indicator is turned ON.

2. Press the FRE s NISSAN TEANA 2008 User Guide INSPECTION AND ADJUSTMENT

HAC-9

< BASIC INSPECTION >[WITHOUT 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

4.CHECK INTAKE AIR

1. Press the REC switch. REC indicator is turned ON.

2. Press the FRE s](/img/5/57391/w960_57391-2636.png)

INSPECTION AND ADJUSTMENT

HAC-9

< BASIC INSPECTION >[WITHOUT 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

4.CHECK INTAKE AIR

1. Press the REC switch. REC indicator is turned ON.

2. Press the FRE switch. FRE indicator is turned ON.

3. Listen for the intake door position change. (Slight change of blower sound can be heard.)

NOTE:

Confirm that the compressor clutch is engaged (sound or visual inspection) and the intake door position is at

the FRE when the DEF is selected.

Is the inspection result normal?

YES >> GO TO 5.

NO >> Intake door system malfunction: HAC-64, "

Diagnosis Procedure".

5.CHECK A/C SWITCH

1. Press the A/C switch.

2. The A/C switch indicator is turned ON.

Confirm that the compressor clutch engages (sound or visual inspection).

Is the inspection result normal?

YES >> GO TO 6.

NO >> Magnet clutch system malfunction: HAC-72, "

Diagnosis Procedure".

6.CHECK WITH TEMPERATURE SETTING LOWERED

1. Operate the compressor.

2. Operate the temperature control switch (driver side) and lower the temperature setting to 18°C (60°F).

3. Check that the cool air blows from the outlets.

Is the inspection result normal?

YES >> GO TO 7.

NO >> Insufficient cooling: HAC-88, "

Inspection procedure".

7.CHECK WITH TEMPERATURE SETTING RAISED

1. Operate the temperature control switch (driver side) and raise the temperature setting to 32°C (90°F) after

warming up the engine.

2. Check that the warm air blows from the outlets.

Is the inspection result normal?

YES >> GO TO 8.

NO >> Insufficient heating: HAC-91, "

Inspection procedure".

8.CHECK LEFT AND RIGHT VENTILATION TEMPERATURE SEPARATELY CONTROL SYSTEM FUNC-

TION

1. Press the DUAL switch, and then check that “DUAL” is shown on the display.

2. Operate the temperature control switch (driver side). Check that the discharge air temperature (driver

side) changes.

3. Operate the temperature control switch (passenger side). Check that the discharge air temperature (pas-

senger side) changes.

4. Press the DUAL switch, and then check that the temperature setting (LH/RH) is unified to the driver side

temperature setting.

Is the inspection result normal?

YES >> GO TO 9.

NO >> Refer to HAC-87, "

Diagnosis Chart By Symptom" and perform the appropriate diagnosis.

9.CHECK AUTO MODE

1. Press the AUTO switch, and then check that “AUTO” is shown on the display.

2. Operate the temperature control switch (driver side). Check that the fan speed or outlet changes (the dis-

charge air temperature or fan speed varies depending on the ambient temperature, in-vehicle tempera-

ture, and temperature setting).

Is the inspection result normal?

YES >> GO TO 10.

NO >> Refer to HAC-87, "

Diagnosis Chart By Symptom" and perform the appropriate diagnosis.

Page 2715 of 5121

![NISSAN TEANA 2008 User Guide AIR CONDITIONER CONTROL

HAC-87

< SYMPTOM DIAGNOSIS >[WITHOUT 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

SYMPTOM DIAGNOSIS

AIR CONDITIONER CONTROL

Diagnosis Chart By SymptomINFOID:000000000384638 NISSAN TEANA 2008 User Guide AIR CONDITIONER CONTROL

HAC-87

< SYMPTOM DIAGNOSIS >[WITHOUT 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

SYMPTOM DIAGNOSIS

AIR CONDITIONER CONTROL

Diagnosis Chart By SymptomINFOID:000000000384638](/img/5/57391/w960_57391-2714.png)

AIR CONDITIONER CONTROL

HAC-87

< SYMPTOM DIAGNOSIS >[WITHOUT 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

SYMPTOM DIAGNOSIS

AIR CONDITIONER CONTROL

Diagnosis Chart By SymptomINFOID:0000000003846383

Symptom Reference

A/C system does not activate.Go to Trouble Diagnosis Procedure for A/C Control Signal

Circuit.HAC-74, "

Diagnosis Proce-

dure"

A/C display dose not work. Go to Trouble Diagnosis Procedure for A/C Display.HAC-66, "A/C DISPLAY : Diag-

nosis Procedure"

Air outlet does not change.

Go to Trouble Diagnosis Procedure for Mode Door Motor.

(LAN)HAC-61, "

Diagnosis Proce-

dure"Mode door motor does not operate

normally.

Discharge air temperature does not

change.

Go to Trouble Diagnosis Procedure for Air Mix Door Motor.

(LAN)HAC-57, "

Diagnosis Proce-

dure" (driver side) or HAC-59,

"Diagnosis Procedure" (pas-

senger side) Air mix door motor does not operate

normally.

Intake door does not change.

Go to Trouble Diagnosis Procedure for Intake Door Motor.

(LAN)HAC-64, "

Diagnosis Proce-

dure"Intake door motor does not operate

normally.

Blower motor operation is malfunc-

tioning.Go to Trouble Diagnosis Procedure for Blower Motor.HAC-68, "

Diagnosis Proce-

dure"

Magnet clutch does not engage. Go to Trouble Diagnosis Procedure for Magnet Clutch.HAC-72, "Diagnosis Proce-

dure"

Insufficient cooling

Go to Trouble Diagnosis Procedure for Insufficient Cooling.HAC-88, "Inspection proce-

dure"No cool air comes out.

(Air flow volume is normal.)

Insufficient heating

Go to Trouble Diagnosis Procedure for Insufficient Heating.HAC-91, "

Inspection proce-

dure"No warm air comes out.

(Air flow volume is normal.)

Noise Go to Trouble Diagnosis Procedure for Noise.HAC-94, "

Inspection proce-

dure"

Memory function does not operate. Go to Trouble Diagnosis Procedure for Memory Function.HAC-96, "Inspection proce-

dure"

Page 2719 of 5121

![NISSAN TEANA 2008 User Guide INSUFFICIENT HEATING

HAC-91

< SYMPTOM DIAGNOSIS >[WITHOUT 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

INSUFFICIENT HEATING

DescriptionINFOID:0000000003846388

Symptom

Insufficient heating

No w NISSAN TEANA 2008 User Guide INSUFFICIENT HEATING

HAC-91

< SYMPTOM DIAGNOSIS >[WITHOUT 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

INSUFFICIENT HEATING

DescriptionINFOID:0000000003846388

Symptom

Insufficient heating

No w](/img/5/57391/w960_57391-2718.png)

INSUFFICIENT HEATING

HAC-91

< SYMPTOM DIAGNOSIS >[WITHOUT 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

INSUFFICIENT HEATING

DescriptionINFOID:0000000003846388

Symptom

Insufficient heating

No warm air comes out. (Air flow volume is normal.)

Inspection procedureINFOID:0000000003846389

1.CHECK COOLING SYSTEM

1. Check engine coolant level and check for leakage. Refer to CO-8, "

Inspection".

2. Check radiator cap. Refer to CO-12, "

RADIATOR CAP : Inspection".

3. Check water flow sounds of engine coolant. Refer to CO-9, "

Refilling".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Refill the engine coolant and repair or replace the parts according to the inspection results.

2.CHECK OPERATION

1. Press temperature control switch (driver side) and raise temperature setting to 32°C (90°F) after warming

up the engine.

2. Check that warm air blows from the outlets.

Is the inspection result normal?

YES >> END.

NO >> GO TO 3.

3.CHECK SETTING OF TEMPERATURE SETTING TRIMMER

Using CONSULT-III, check the setting of “TEMP SET CORRECT” on “WORK SUPPORT” of HVAC. Refer to

HAC-10, "

Temperature Setting Trimmer".

1. Check that the temperature setting trimmer is set to “− direction”.

NOTE:

The control temperature can be set by the temperature setting trimmer.

2. Set temperature control switch to “0”.

Are the malfunction solved?

YES >> Perform the setting separately if necessary. END.

NO >> GO TO 4.

4.CHECK WITH SELF-DIAGNOSIS FUNCTION OF CONSULT-III

1. Using CONSULT-III, perform “SELF-DIAGNOSIS RESULTS” of HVAC.

2. Check if any DTC is displayed in the trouble diagnosis results.

NOTE:

If DTC is displayed along with DTC U1000 or U1010, first diagnose the DTC U1000 or U1010. Refer to

HAC-42, "

DTC Logic" or HAC-43, "DTC Logic".

Is any DTC displayed?

YES >> Perform the diagnosis that is applicable to the sensor and the door motor. Refer to HAC-85, "DTC

Index".

NO >> GO TO 5.

5.CHECK WITH ACTIVE TEST OF CONSULT-III

1. Using CONSULT-III, perform “HVAC TEST” in “ACTIVE TEST” of HVAC to check each output device.

Refer to HAC-38, "

CONSULT-III Function".

NOTE:

Perform the ACTIVE TEST after starting the engine because the compressor is operated.

2. Refer to the table and check the outlet, inlet, air flow temperature, blower motor control signal, magnet

clutch operation, and air mix ratio. Visually check each operating condition, by listening for noise, touching

air outlets with a hand, etc.

Page 2720 of 5121

![NISSAN TEANA 2008 User Guide HAC-92

< SYMPTOM DIAGNOSIS >[WITHOUT 7 INCH DISPLAY]

INSUFFICIENT HEATING

NOTE:

Perform the inspection of each output device after starting the engine because the compressor is oper-

ated.

When ch NISSAN TEANA 2008 User Guide HAC-92

< SYMPTOM DIAGNOSIS >[WITHOUT 7 INCH DISPLAY]

INSUFFICIENT HEATING

NOTE:

Perform the inspection of each output device after starting the engine because the compressor is oper-

ated.

When ch](/img/5/57391/w960_57391-2719.png)

HAC-92

< SYMPTOM DIAGNOSIS >[WITHOUT 7 INCH DISPLAY]

INSUFFICIENT HEATING

NOTE:

Perform the inspection of each output device after starting the engine because the compressor is oper-

ated.

When choosing to “MODE 7”, error message is displayed but it is not malfunction.

Does it operate normally?

YES >> GO TO 6.

NO-1 >> Air outlet does not change. Refer to HAC-61, "

Diagnosis Procedure".

NO-2 >> Air inlet does not change. Refer to HAC-64, "

Diagnosis Procedure".

NO-3 >> Discharge air temperature does not change (driver side). Refer to HAC-57, "

Diagnosis Proce-

dure".

NO-4 >> Discharge air temperature does not change (passenger side). Refer to HAC-59, "

Diagnosis Pro-

cedure".

NO-5 >> Blower motor does not operate normally. Refer to HAC-68, "

Diagnosis Procedure".

NO-6 >> Magnet clutch does not operate. Refer to HAC-72, "

Diagnosis Procedure".

6.CHECK AIR LEAKAGE FROM DUCT

Check duct and nozzle, etc, of the A/C system for air leakage.

Is the inspection result normal?

YES >> GO TO 7.

NO >> Repair or replace parts according to the inspection results.

7.CHECK HEATER HOSE INSTALLATION CONDITION

Check the heater hose installation condition visually (for twists, crushes, etc.).

Is the inspection result normal?

YES >> GO TO 8.

NO >> Repair or replace parts according to the inspection results.

8.CHECK TEMPERATURE OF HEATER HOSE

Te s t i t e m

MODE 1 MODE 2 MODE 3 MODE 4 MODE 5 MODE 6 MODE 7

Mode door position VENT B/L1 B/L2 AUTO FOOT D/F DEF -

Intake door position REC REC 20% FRE FRE FRE FRE -

Air mix door position

(driver & passenger

side)FULL COLDFULL

COLDFULL HOT FULL HOT FULL HOT FULL HOT -

Blower motor duty ratio 37% 91% 65% 65% 65% 91% -

Compressor (Magnet

clutch)ON ON OFF OFF ON ON -

JPIIA0877GB

Page 2721 of 5121

![NISSAN TEANA 2008 User Guide INSUFFICIENT HEATING

HAC-93

< SYMPTOM DIAGNOSIS >[WITHOUT 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

1. Check the temperature of inlet hose and outlet hose of heater core.

2. Check that the inle NISSAN TEANA 2008 User Guide INSUFFICIENT HEATING

HAC-93

< SYMPTOM DIAGNOSIS >[WITHOUT 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

1. Check the temperature of inlet hose and outlet hose of heater core.

2. Check that the inle](/img/5/57391/w960_57391-2720.png)

INSUFFICIENT HEATING

HAC-93

< SYMPTOM DIAGNOSIS >[WITHOUT 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

1. Check the temperature of inlet hose and outlet hose of heater core.

2. Check that the inlet side of heater core is hot and the outlet side is slightly lower than/almost equal to the

inlet side.

CAUTION:

Always perform the temperature inspection in a short period of time because the engine coolant

temperature is very hot.

Is the inspection result normal?

YES >> GO TO 9.

NO >> Replace the heater core after performing the procedures after the cooling system inspection. GO

TO 1.

9.REPLACE HEATER CORE

Replace the heater core. Refer to heater core. Refer to VTL-43, "

Exploded View".

Are the malfunction solved?

YES >> END.

NO >> Perform the procedures again after the cooling system inspection. GO TO 1.