wheel bolt torque NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 917 of 5121

BRAKE PIPINGBR-21

< ON-VEHICLE REPAIR >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

FRONT : Removal and InstallationINFOID:0000000003811188

REMOVAL

CAUTION:

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with wate r if it gets on a painted surface.

1. Remove tires.

2. Drain brake fluid. Refer to BR-9, "

Draining".

3. Loosen the flare nut with a flare nut wrenc h and separate the brake tube from the hose.

CAUTION:

Never scratch the flare nut and the brake tube.

Never bend sharply, twist or strong ly pull out the brake hoses and tubes.

Cover open end of brake tub es and hoses when disconnecting to prevent entrance of dirt.

4. Remove the union bolt and copper washers, and remove the brake hose from the brake caliper assembly.

5. Remove the lock plate and remove the brake hose.

INSTALLATION

CAUTION:

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with wate r if it gets on a painted surface.

1. Assemble the union bolt and the copper washers to the brake hose. CAUTION:

Never reuse the copper washer.

2. Align the brake hose pin to the projection (A) of the brake caliper assembly and tighten the union bolt (1) to the specified torque.

3. Install the brake tube to the brake hose, temporarily tighten the flare nut by hand until it does not rotate further, and fix the brake

hose to the bracket with the lock plate.

CAUTION:

Check that all brake hoses and tubes are not twisted and

bent.

4. Tighten the flare nut to the specified torque with a crowfoot and torque wrench.

CAUTION:

Never scratch the flare nut and the brake tube.

5. Refill with new brake fluid and perform the air bleeding. Refer to BR-10, "

Bleeding Brake System".

CAUTION:

Never reuse drained brake fluid.

FRONT : InspectionINFOID:0000000003811189

INSPECTION AFTER INSTALLATION

1. Check the brake hoses and tubes for the following: no scratches; no twist and deformation; no interfer-

ence with other components when steering the steering wheel; no looseness at connections.

2. Depress the brake pedal with a force of 785N (80 kg, 177 lb) and hold down the pedal for approximately 5

seconds with the engine running. Check for any fluid leakage.

CAUTION:

Retighten the applicable connect ion to the specified torque and repair any abnormal (damaged,

worn or deformed) part if any brake fluid leakage is present.

1. ABS actuator and electric unit (con-

trol unit) 2. Front disc brake 3. Master cylinder assembly

4. Brake booster 5. Connector 6. Rear disc brake

A. Brake tube B. Brake hose : Flare nut

: Union bolt

JPFIA0099ZZ

Page 919 of 5121

BRAKE PIPINGBR-23

< ON-VEHICLE REPAIR >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

REAR : Removal and InstallationINFOID:0000000003811192

REMOVAL

CAUTION:

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with wate r if it gets on a painted surface.

1. Remove tires.

2. Drain brake fluid. Refer to BR-9, "

Draining".

3. Loosen the flare nut with a flare nut wrenc h and separate the brake tube from the hose.

CAUTION:

Never scratch the flare nut and the brake tube.

Never sharply bend, twist or strongly pull the brake hoses and tubes.

Cover the open end of brake tubes and hoses wh en disconnecting to prevent entrance of dirt.

4. Remove the union bolt and copper washers, and remove the brake hose from the brake caliper assembly.

5. Remove the lock plate and remove the brake hose from the vehicle.

INSTALLATION

CAUTION:

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with wate r if it gets on a painted surface.

1. Assemble the union bolt and the copper washers to the brake hose. CAUTION:

Never reuse copper washer.

2. Install the brake hose L-pin by aligning it with the brake caliper assembly positioning hole, and tighten the union bolt (1) to the

specified torque.

3. Connect the hose to the brake tube, temporarily tighten the flare nut by hand until it does not rotate further, and fix the brake hose

to the bracket with the lock plate.

CAUTION:

Check that the brake hoses and tubes are not twisted and

bent.

4. Tighten the flare nut to the specified torque with a crowfoot and torque wrench.

CAUTION:

Never scratch the flare nut and the brake tube.

5. Refill with new brake fluid and perform the air bleeding. Refer to BR-10, "

Bleeding Brake System".

CAUTION:

Never reuse drained brake fluid.

REAR : InspectionINFOID:0000000003811193

INSPECTION AFTER INSTALLATION

1. Check the brake hoses and tubes for the following: no scratches; no twist and deformation; no interfer-

ence with other components when steering the steering wheel; no looseness at connections.

2. Depress the brake pedal with a force of 785N (80

kg, 177 lb) and hold down the pedal for approximately 5

seconds with the engine running. Check for any fluid leakage.

CAUTION:

1. ABS actuator and electric unit (con- trol unit) 2. Front disc brake 3. Master cylinder assembly

4. Brake booster 5. Connector 6. Rear disc brake

A. Brake tube B. Brake hose : Flare nut

: Union bolt

JPFIA0012ZZ

Page 932 of 5121

BR-36

< ON-VEHICLE REPAIR >

FRONT DISC BRAKE

CAUTION:

Never depress the brake pedal. Brake fluid may splash while removing the brake hose.

1. Remove tires.

2. Fix the disc rotor using wheel nuts.

3. Drain brake fluid. Refer to BR-9, "

Draining".

CAUTION:

Never spill or splash brake fluid on the disc rotor.

4. Remove union bolt and copper washers, and then disconnect brake hose from caliper assembly. Refer to

BR-19, "

FRONT : Exploded View".

5. Remove torque member mounting bolts, and remove brake caliper assembly.

CAUTION:

Never drop brake pads and caliper assembly.

6. Remove disc rotor.

CAUTION:

Put matching marks on the wheel hub and bearing assembly and the disc rotor before removing

the disc rotor.

Never drop disc rotor.

INSTALLATION

WARNING:

Clean any dust from the brake caliper and brake pads with a vacuum dust collector. Never blow with

compressed air.

CAUTION:

Never depress the brake pedal. Brake fluid may splash while removing the brake hose.

1. Install disc rotor.

CAUTION:

Align the matching marks put during removal when reusing the disc rotor.

2. Install the brake caliper assembly to the vehicle and tighten the torque member mounting bolts to the

specified torque.

CAUTION:

Never spill or splash any grease and moisture on the brake caliper assembly mounting face,

threads, mounting bolts and washers. Wipe out any grease and moisture.

3. Install brake hose and copper washers to brake caliper assembly, and tighten union bolts to the specified

torque. Refer to BR-19, "

FRONT : Exploded View".

CAUTION:

Never reuse copper washer.

4. Refill with new brake fluid and perform the air bleeding. Refer to BR-10, "

Bleeding Brake System".

CAUTION:

Never reuse drained brake fluid.

Never spill or splash brake fluid on the disc rotor.

5. Check a drag of front disc brake. If any drag is found, refer to BR-38, "

BRAKE CALIPER ASSEMBLY :

Inspection".

BRAKE CALIPER ASSEMBLY : Disassembly and AssemblyINFOID:0000000003811209

DISASSEMBLY

NOTE:

Never remove the torque member and pad retainers when disassembling and assembling the cylinder body.

1. Remove the sliding pin bolts, and remove the cylinder body from the torque member.

CAUTION:

Never drop brake pads, shims, shim cover and pad retainers from torque member.

2. Remove brake pads, shims and shim cover. Refer to BR-33, "

BRAKE PAD : Exploded View".

3. Remove sliding pins and sliding pin boots from torque member.

4. Remove bushing from sliding pin.

Page 938 of 5121

BR-42

< ON-VEHICLE REPAIR >

REAR DISC BRAKE

Clean any dust from the brake caliper and brake pads with a vacuum dust collector. Never blow with

compressed air.

CAUTION:

Never depress the brake pedal. Brake fluid may splash while removing the brake hose.

1. Remove tires.

2. Fix the disc rotor using wheel nuts.

3. Drain brake fluid. Refer to BR-9, "

Draining".

CAUTION:

Never spill or splash brake fluid on the disc rotor.

4. Remove union bolt and copper washers then disconnect brake hose from caliper assembly.

5. Remove torque member mounting bolts, and remove brake caliper assembly.

CAUTION:

Never drop brake pads and caliper assembly.

6. Remove disc rotor.

CAUTION:

Put matching marks on the wheel hub and bearing assembly and the disc rotor before removing

the disc rotor.

Never drop disc rotor.

INSTALLATION

WARNING:

Clean any dust from the brake caliper and brake pads with a vacuum dust collector. Never blow with

compressed air.

CAUTION:

Never depress the brake pedal. Brake fluid may splash while removing the brake hose.

1. Install disc rotor.

CAUTION:

Align the matching marks put during removal when reusing the disc rotor.

2. Install the brake caliper assembly to the vehicle and tighten the torque member mounting bolts to the

specified torque.

CAUTION:

Never spill or splash any grease and moisture on the brake caliper assembly mounting face,

threads, mounting bolts, and washers. Wipe out any grease and moisture.

3. Install brake hose and copper washers to brake caliper assembly, and tighten union bolts to the specified

torque. Refer to BR-22, "

REAR : Exploded View".

CAUTION:

Never reuse copper washer.

4. Refill with new brake fluid and perform the air bleeding. Refer to BR-10, "

Bleeding Brake System".

CAUTION:

Never reuse drained brake fluid.

Never spill or splash brake fluid on the disc rotor.

5. Check that no drag feel is present for the rear disc brake. Refer to BR-44, "

BRAKE CALIPER ASSEMBLY

: Inspection".

BRAKE CALIPER ASSEMBLY : Disassembly and AssemblyINFOID:0000000003811216

DISASSEMBLY

NOTE:

Never remove the torque member and pad retainers when disassembling and assembling the cylinder body.

1. Remove the sliding pin bolts and remove the cylinder body from the torque member.

2. Remove brake pads and shims. Refer to BR-39, "

BRAKE PAD : Exploded View".

3. Remove sliding pin boots from torque member.

4. Remove bushing from sliding pin bolt.

Page 998 of 5121

![NISSAN TEANA 2008 Service Manual WHEEL SENSOR

BRC-57

< ON-VEHICLE REPAIR >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

ON-VEHICLE REPAIR

WHEEL SENSOR

FRONT WHEEL SENSOR

FRONT WHEEL SENSOR : Exploded ViewINFOID:0000000003766865

NOTE:

The ab NISSAN TEANA 2008 Service Manual WHEEL SENSOR

BRC-57

< ON-VEHICLE REPAIR >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

ON-VEHICLE REPAIR

WHEEL SENSOR

FRONT WHEEL SENSOR

FRONT WHEEL SENSOR : Exploded ViewINFOID:0000000003766865

NOTE:

The ab](/img/5/57391/w960_57391-997.png)

WHEEL SENSOR

BRC-57

< ON-VEHICLE REPAIR >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

ON-VEHICLE REPAIR

WHEEL SENSOR

FRONT WHEEL SENSOR

FRONT WHEEL SENSOR : Exploded ViewINFOID:0000000003766865

NOTE:

The above figure shows left side. Right side is the mirror image.

FRONT WHEEL SENSOR : Removal and InstallationINFOID:0000000003766866

REMOVAL

Be careful with the following when removing sensor.

CAUTION:

Do not twist sensor harness as much as possible, when removing it. Pull sensors out without pulling

sensor harness.

Be careful to avoid damaging sensor edges or rotor teeth. Remove wheel sensor first before remov-

ing front or rear wheel hub. This is to avoid damage to sensor wiring and loss of sensor function.

INSTALLATION

Be careful with the following when installing wheel sensor. Tighten installation bolts to the specified torques.

Refer to BRC-57, "

FRONT WHEEL SENSOR : Exploded View".

CAUTION:

When installing, make sure there is no foreign material such as iron chips on and in the mounting

hole of the wheel sensor. Make sure no foreign material has been caught in the sensor rotor. Remove

any foreign material and clean the mount.

1. Front LH wheel sensor 2. Front LH wheel sensor connector

: Vehicle front

Refer to GI section GI-4, "

Components" for symbol marks in the figure.

JSFIA0221GB

Page 999 of 5121

![NISSAN TEANA 2008 Service Manual BRC-58

< ON-VEHICLE REPAIR >[ABS]

WHEEL SENSOR

Completely push in rubber grommets of strut bracket and body bracket until they lock when install-

ing wheel sensor so that the wheel sensor harness wi NISSAN TEANA 2008 Service Manual BRC-58

< ON-VEHICLE REPAIR >[ABS]

WHEEL SENSOR

Completely push in rubber grommets of strut bracket and body bracket until they lock when install-

ing wheel sensor so that the wheel sensor harness wi](/img/5/57391/w960_57391-998.png)

BRC-58

< ON-VEHICLE REPAIR >[ABS]

WHEEL SENSOR

Completely push in rubber grommets of strut bracket and body bracket until they lock when install-

ing wheel sensor so that the wheel sensor harness will not be twisted. Install grommet groove onto

bracket with orange line on the harness facing bracket opening (mounting hole). There should be no

twists in the harness when installed.

REAR WHEEL SENSOR

REAR WHEEL SENSOR : Exploded ViewINFOID:0000000003766867

NOTE:

The above figure shows left side. Right side is the mirror image.

REAR WHEEL SENSOR : Removal and InstallationINFOID:0000000003766868

REMOVAL

Be careful with the following when removing sensor.

CAUTION:

Do not twist sensor harness as much as possible, when removing it. Pull sensors out without pulling

sensor harness.

Be careful to avoid damaging sensor edges or rotor teeth. Remove wheel sensor first before remov-

ing front or rear wheel hub. This is to avoid damage to sensor wiring and loss of sensor function.

INSTALLATION

Be careful with the following when installing wheel sensor. Tighten installation bolts to the specified torques.

Refer to BRC-58, "

REAR WHEEL SENSOR : Exploded View".

CAUTION:

When installing, make sure there is no foreign material such as iron chips on and in the mounting hole

of the wheel sensor. Make sure no foreign material has been caught in the sensor rotor. Remove any

foreign material and clean the mount.

1. Rear LH wheel sensor connector 2. Rear LH wheel sensor

: Vehicle front

Refer to GI section GI-4, "

Components" for symbol marks in the figure.

JSFIA0222GB

Page 1092 of 5121

![NISSAN TEANA 2008 Service Manual WHEEL SENSOR

BRC-151

< ON-VEHICLE REPAIR >[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

ON-VEHICLE REPAIR

WHEEL SENSOR

FRONT WHEEL SENSOR

FRONT WHEEL SENSOR : Exploded ViewINFOID:0000000003767300

NOT NISSAN TEANA 2008 Service Manual WHEEL SENSOR

BRC-151

< ON-VEHICLE REPAIR >[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

ON-VEHICLE REPAIR

WHEEL SENSOR

FRONT WHEEL SENSOR

FRONT WHEEL SENSOR : Exploded ViewINFOID:0000000003767300

NOT](/img/5/57391/w960_57391-1091.png)

WHEEL SENSOR

BRC-151

< ON-VEHICLE REPAIR >[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

ON-VEHICLE REPAIR

WHEEL SENSOR

FRONT WHEEL SENSOR

FRONT WHEEL SENSOR : Exploded ViewINFOID:0000000003767300

NOTE:

The above figure shows left side. Right side is the mirror image.

FRONT WHEEL SENSOR : Removal and InstallationINFOID:0000000003767301

REMOVAL

Be careful with the following when removing sensor.

CAUTION:

Do not twist sensor harness as much as possible, when removing it. Pull sensors out without pulling

sensor harness.

Be careful to avoid damaging sensor edges or rotor teeth. Remove wheel sensor first before remov-

ing front or rear wheel hub. This is to avoid damage to sensor wiring and loss of sensor function.

INSTALLATION

Be careful with the following when installing wheel sensor. Tighten installation bolts to the specified torques.

Refer to BRC-151, "

FRONT WHEEL SENSOR : Exploded View".

CAUTION:

When installing, make sure there is no foreign material such as iron chips on and in the mounting

hole of the wheel sensor. Make sure no foreign material has been caught in the sensor rotor. Remove

any foreign material and clean the mount.

1. Front LH wheel sensor 2. Front LH wheel sensor connector

: Vehicle front

Refer to GI section GI-4, "

Components" for symbol marks in the figure.

JSFIA0221GB

Page 1093 of 5121

![NISSAN TEANA 2008 Service Manual BRC-152

< ON-VEHICLE REPAIR >[VDC/TCS/ABS]

WHEEL SENSOR

Completely push in rubber grommets of strut bracket and body bracket until they lock when install-

ing wheel sensor so that the wheel sensor h NISSAN TEANA 2008 Service Manual BRC-152

< ON-VEHICLE REPAIR >[VDC/TCS/ABS]

WHEEL SENSOR

Completely push in rubber grommets of strut bracket and body bracket until they lock when install-

ing wheel sensor so that the wheel sensor h](/img/5/57391/w960_57391-1092.png)

BRC-152

< ON-VEHICLE REPAIR >[VDC/TCS/ABS]

WHEEL SENSOR

Completely push in rubber grommets of strut bracket and body bracket until they lock when install-

ing wheel sensor so that the wheel sensor harness will not be twisted. Install grommet groove onto

bracket with orange line on the harness facing bracket opening (mounting hole). There should be no

twists in the harness when installed.

REAR WHEEL SENSOR

REAR WHEEL SENSOR : Exploded ViewINFOID:0000000003767302

NOTE:

The above figure shows left side. Right side is the mirror image.

REAR WHEEL SENSOR : Removal and InstallationINFOID:0000000003767303

REMOVAL

Be careful with the following when removing sensor.

CAUTION:

Do not twist sensor harness as much as possible, when removing it. Pull sensors out without pulling

sensor harness.

Be careful to avoid damaging sensor edges or rotor teeth. Remove wheel sensor first before remov-

ing front or rear wheel hub. This is to avoid damage to sensor wiring and loss of sensor function.

INSTALLATION

Be careful with the following when installing wheel sensor. Tighten installation bolts to the specified torques.

Refer to BRC-152, "

REAR WHEEL SENSOR : Exploded View".

CAUTION:

When installing, make sure there is no foreign material such as iron chips on and in the mounting hole

of the wheel sensor. Make sure no foreign material has been caught in the sensor rotor. Remove any

foreign material and clean the mount.

1. Rear LH wheel sensor connector 2. Rear LH wheel sensor

: Vehicle front

Refer to GI section GI-4, "

Components" for symbol marks in the figure.

JSFIA0222GB

Page 1881 of 5121

EM-6

< PRECAUTION >

PRECAUTIONS

3. Disconnect both battery cables. The steering lock will remain released with both battery cables discon-

nected and the steering wheel can be turned.

4. Perform the necessary repair operation.

5. When the repair work is completed, re-connect both battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position to ON position, then to LOCK position. (The steering

wheel will lock when the push-button ignition switch is turned to LOCK position.)

6. Perform self-diagnosis check of all control units using CONSULT-III.

Precaution for Drain Engine Coolant and Engine OilINFOID:0000000003802227

Drain engine coolant and engine oil when the engine is cooled.

Precaution for Disconnecting Fuel PipingINFOID:0000000003802228

Before starting work, check no fire or spark producing items are in the work area.

Release fuel pressure before disconnecting and disassembly.

After disconnecting pipes, plug openings to stop fuel leakage.

Precaution for Removal and DisassemblyINFOID:0000000003802229

When instructed to use SST, use the specified tools. Always be careful to work safely, avoid forceful or unin-

structed operations.

Exercise maximum care to avoid damage to mating or sliding surfaces.

Dowel pins are used for several parts alignment. When replacing and reassembling parts with dowel pins,

check that dowel pins are installed in the original position.

Cover openings of engine system with a tape or the equivalent, if necessary, to seal out foreign materials.

Mark and arrange disassembly parts in an organized way for easy troubleshooting and reassembly.

When loosening nuts and bolts, as a basic rule, start with the one furthest outside, then the one diagonally

opposite, and so on. If the order of loosening is specified, do exactly as specified. Power tools may be used

in the step.

Precaution for Inspection, Repair and ReplacementINFOID:0000000003802230

Before repairing or replacing, thoroughly inspect parts. Inspect new replacement parts in the same way, and

replace if necessary.

Precaution for Assembly and InstallationINFOID:0000000003802231

Use torque wrench to tighten bolts or nuts to specification.

When tightening nuts and bolts, as a basic rule, equally tighten in several different steps starting with the

ones in center, then ones on inside and outside diagonally in this order. If the order of tightening is specified,

do exactly as specified.

Replace with new gasket, packing, oil seal or O-ring.

Dowel pins are used for several parts alignment. When replacing and reassembling parts with dowel pins,

check that dowel pins are installed in the original position.

Thoroughly wash, clean, and air-blow each part. Carefully check engine oil or engine coolant passages for

any restriction and blockage.

Avoid damaging sliding or mating surfaces. Completely remove foreign materials such as cloth lint or dust.

Before assembly, oil sliding surfaces well.

Release air within route when refilling after draining engine coolant.

After repairing, start the engine and increase engine speed to check engine coolant, fuel, engine oil, and

exhaust gases for leakage.

Precaution for Angle TighteningINFOID:0000000003802232

Use the angle wrench [SST: KV10112100 (BT8653-A)] for the final tightening of the following engine parts:

- Cylinder head bolts

- Main bearing cap bolts

- Connecting rod cap bolts

- Crankshaft pulley bolt (No the angle wrench is required as bolt flange is provided with notches for angle

tightening)

Never use a torque value for final tightening.

The torque value for these parts are for a preliminary step.

Page 1944 of 5121

ENGINE ASSEMBLY

EM-69

< REMOVAL AND INSTALLATION >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

10. Remove starter motor. Refer to STR-15, "VQ25DE : Exploded View" (VQ25DE) or STR-20, "VQ35DE :

Exploded View" (VQ35DE).

Vehicle Underbody

1. Remove front drive shafts (RH and LH). Refer to FAX-16, "Exploded View".

2. Remove exhaust front tube. Refer to EX-5, "

Exploded View".

3. Remove heat insulator.

4. Disconnect steering lower joint at power steering gear assembly side, and release steering lower shaft.

Refer to ST-16, "

Exploded View".

5. Disconnect front stabilizer connecting rod. Refer to FSU-14, "

Exploded View".

6. Remove strut assembly and steering knuckle fixing nuts and bolts. Refer to FSU-9, "

Exploded View" and

FA X - 8 , "

Exploded View".

7. Remove front wheel sensor (RH and LH) for ABS from steering knuckle. Refer to BRC-57, "

FRONT

WHEEL SENSOR : Exploded View".

8. Remove front brake caliper assembly with piping connected, and temporarily secure it to aside for vehicle

side. Refer to BR-34, "

BRAKE CALIPER ASSEMBLY : Exploded View".

9. Disconnect power steering piping at a point between vehicle and engine. Refer to ST-34, "

Exploded

View".

Install plug to avoid leakage of power steering fluid.

10. Remove rear plate cover from oil pan (upper). Then remove bolts fixing drive plate to torque converter.

Refer to EM-38, "

Exploded View" and TM-332, "Removal and Installation" (VQ25DE) or TM-168,

"Removal and Installation" (VQ35DE).

11. Remove transaxle joint bolts which pierce at oil pan (upper) lower rear side. Refer to EM-38, "

Exploded

View".

12. Remove crankshaft position sensor (POS). Refer to EM-38, "

Exploded View".

CAUTION:

Handle carefully to avoid dropping and shocks.

Never disassemble.

Never allow metal powder to adhere to magnetic part at sensor tip.

Never place sensors in a location where they are exposed to magnetism.

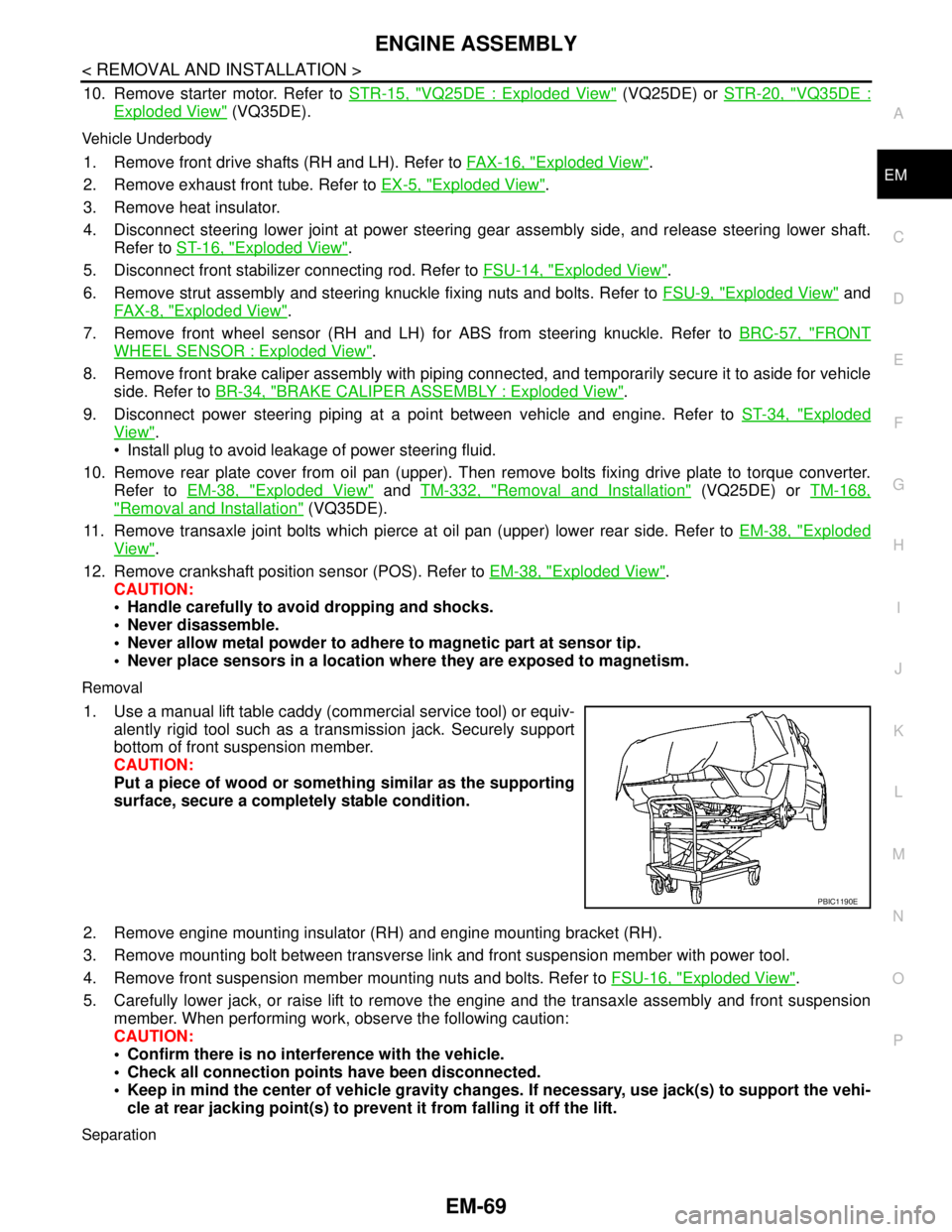

Removal

1. Use a manual lift table caddy (commercial service tool) or equiv-

alently rigid tool such as a transmission jack. Securely support

bottom of front suspension member.

CAUTION:

Put a piece of wood or something similar as the supporting

surface, secure a completely stable condition.

2. Remove engine mounting insulator (RH) and engine mounting bracket (RH).

3. Remove mounting bolt between transverse link and front suspension member with power tool.

4. Remove front suspension member mounting nuts and bolts. Refer to FSU-16, "

Exploded View".

5. Carefully lower jack, or raise lift to remove the engine and the transaxle assembly and front suspension

member. When performing work, observe the following caution:

CAUTION:

Confirm there is no interference with the vehicle.

Check all connection points have been disconnected.

Keep in mind the center of vehicle gravity changes. If necessary, use jack(s) to support the vehi-

cle at rear jacking point(s) to prevent it from falling it off the lift.

Separation

PBIC1190E