brake rotor NISSAN TEANA 2008 Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 2440 of 5121

FAX-12

< ON-VEHICLE REPAIR >

FRONT DRIVE SHAFT BOOT

WHEEL SIDE

WHEEL SIDE : Removal and InstallationINFOID:0000000003811080

REMOVAL

1. Remove tires.

2. Remove wheel sensor and sensor harness. Refer to BRC-57, "

FRONT WHEEL SENSOR : Exploded

View" (without VDC), BRC-151, "FRONT WHEEL SENSOR : Exploded View" (with VDC).

3. Remove lock plate of brake hose from strut assembly. Refer to BR-19, "

FRONT : Exploded View".

4. Remove caliper assembly. Hang caliper assembly not to interfere with work. Refer to BR-34, "

BRAKE

CALIPER ASSEMBLY : Exploded View".

5. Remove disc rotor. Refer to BR-35, "

BRAKE CALIPER ASSEMBLY : Removal and Installation".

6. Remove cotter pin, and then loosen wheel hub lock nut. Refer to FA X - 8 , "

Exploded View".

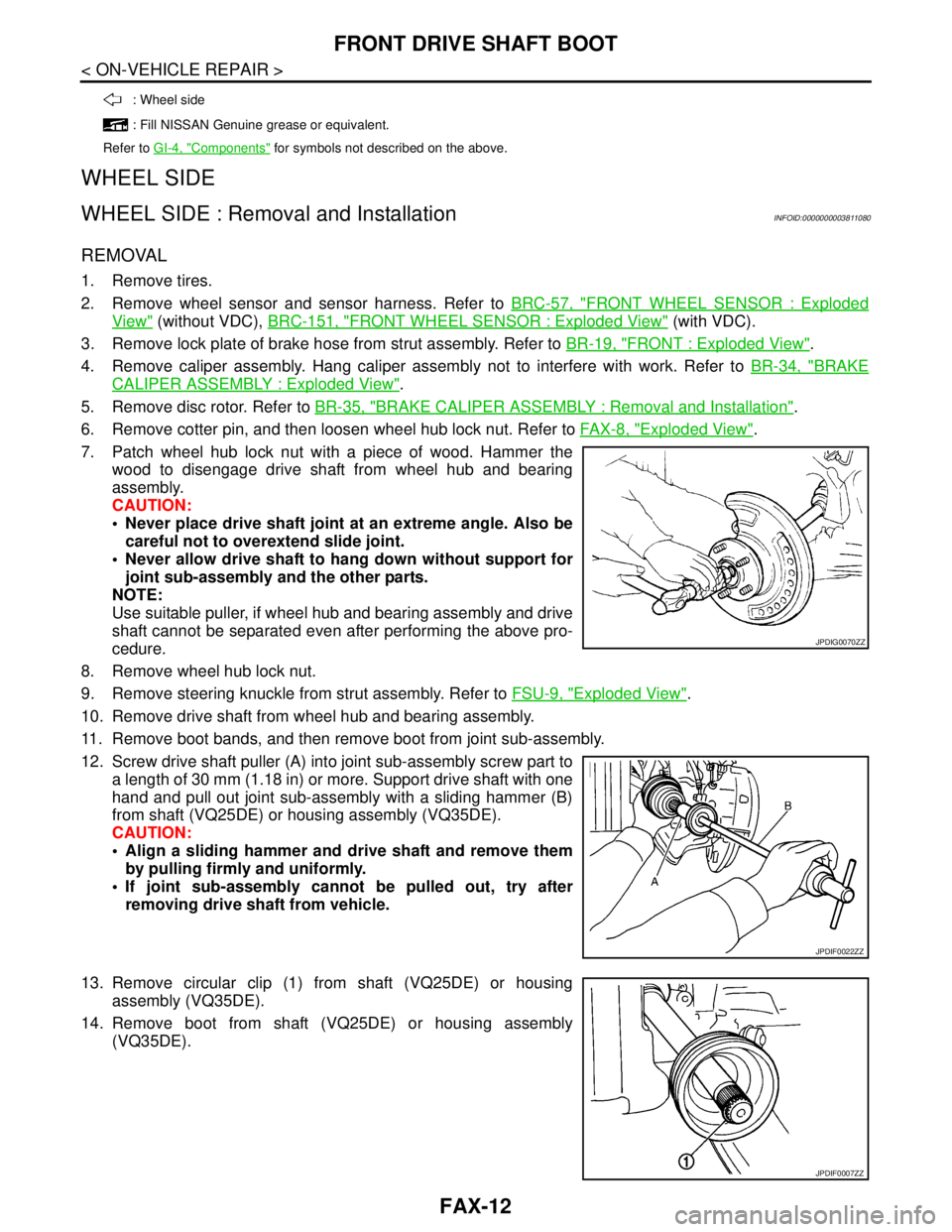

7. Patch wheel hub lock nut with a piece of wood. Hammer the

wood to disengage drive shaft from wheel hub and bearing

assembly.

CAUTION:

Never place drive shaft joint at an extreme angle. Also be

careful not to overextend slide joint.

Never allow drive shaft to hang down without support for

joint sub-assembly and the other parts.

NOTE:

Use suitable puller, if wheel hub and bearing assembly and drive

shaft cannot be separated even after performing the above pro-

cedure.

8. Remove wheel hub lock nut.

9. Remove steering knuckle from strut assembly. Refer to FSU-9, "

Exploded View".

10. Remove drive shaft from wheel hub and bearing assembly.

11. Remove boot bands, and then remove boot from joint sub-assembly.

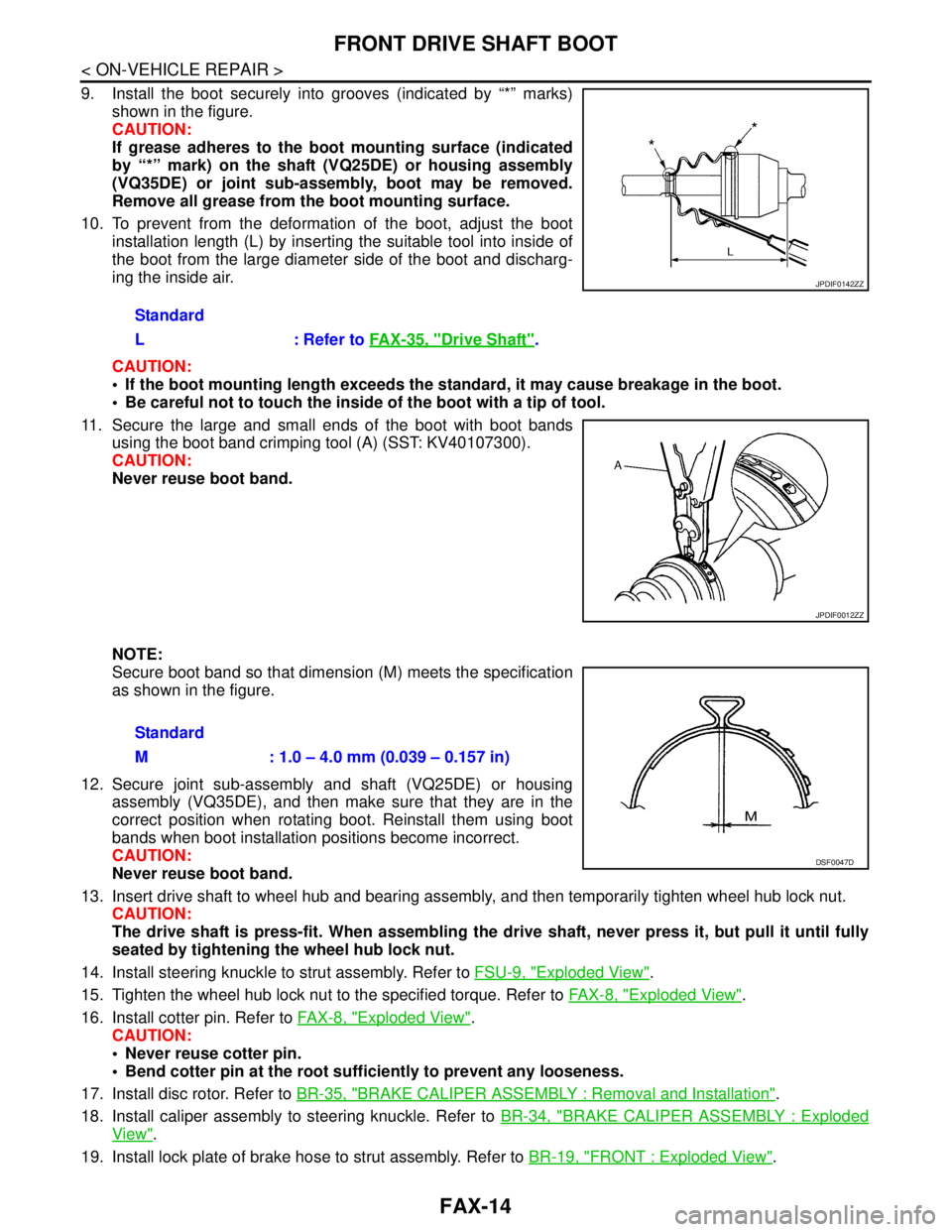

12. Screw drive shaft puller (A) into joint sub-assembly screw part to

a length of 30 mm (1.18 in) or more. Support drive shaft with one

hand and pull out joint sub-assembly with a sliding hammer (B)

from shaft (VQ25DE) or housing assembly (VQ35DE).

CAUTION:

Align a sliding hammer and drive shaft and remove them

by pulling firmly and uniformly.

If joint sub-assembly cannot be pulled out, try after

removing drive shaft from vehicle.

13. Remove circular clip (1) from shaft (VQ25DE) or housing

assembly (VQ35DE).

14. Remove boot from shaft (VQ25DE) or housing assembly

(VQ35DE).

: Wheel side

: Fill NISSAN Genuine grease or equivalent.

Refer to GI-4, "

Components" for symbols not described on the above.

JPDIG0070ZZ

JPDIF0022ZZ

JPDIF0007ZZ

Page 2442 of 5121

FAX-14

< ON-VEHICLE REPAIR >

FRONT DRIVE SHAFT BOOT

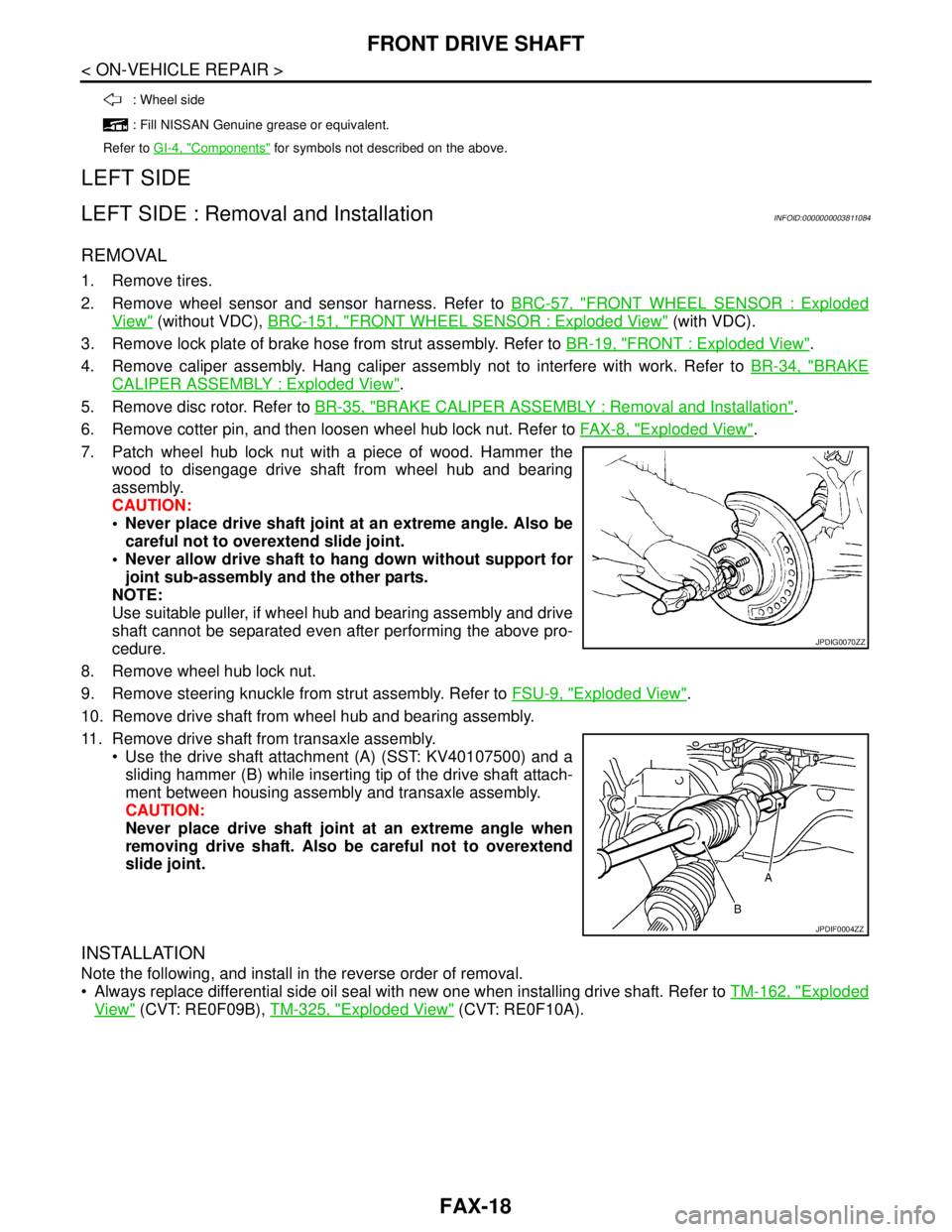

9. Install the boot securely into grooves (indicated by “*” marks)

shown in the figure.

CAUTION:

If grease adheres to the boot mounting surface (indicated

by “*” mark) on the shaft (VQ25DE) or housing assembly

(VQ35DE) or joint sub-assembly, boot may be removed.

Remove all grease from the boot mounting surface.

10. To prevent from the deformation of the boot, adjust the boot

installation length (L) by inserting the suitable tool into inside of

the boot from the large diameter side of the boot and discharg-

ing the inside air.

CAUTION:

If the boot mounting length exceeds the standard, it may cause breakage in the boot.

Be careful not to touch the inside of the boot with a tip of tool.

11. Secure the large and small ends of the boot with boot bands

using the boot band crimping tool (A) (SST: KV40107300).

CAUTION:

Never reuse boot band.

NOTE:

Secure boot band so that dimension (M) meets the specification

as shown in the figure.

12. Secure joint sub-assembly and shaft (VQ25DE) or housing

assembly (VQ35DE), and then make sure that they are in the

correct position when rotating boot. Reinstall them using boot

bands when boot installation positions become incorrect.

CAUTION:

Never reuse boot band.

13. Insert drive shaft to wheel hub and bearing assembly, and then temporarily tighten wheel hub lock nut.

CAUTION:

The drive shaft is press-fit. When assembling the drive shaft, never press it, but pull it until fully

seated by tightening the wheel hub lock nut.

14. Install steering knuckle to strut assembly. Refer to FSU-9, "

Exploded View".

15. Tighten the wheel hub lock nut to the specified torque. Refer to FA X - 8 , "

Exploded View".

16. Install cotter pin. Refer to FA X - 8 , "

Exploded View".

CAUTION:

Never reuse cotter pin.

Bend cotter pin at the root sufficiently to prevent any looseness.

17. Install disc rotor. Refer to BR-35, "

BRAKE CALIPER ASSEMBLY : Removal and Installation".

18. Install caliper assembly to steering knuckle. Refer to BR-34, "

BRAKE CALIPER ASSEMBLY : Exploded

View".

19. Install lock plate of brake hose to strut assembly. Refer to BR-19, "

FRONT : Exploded View". Standard

L : Refer to FAX-35, "

Drive Shaft".

JPDIF0142ZZ

JPDIF0012ZZ

Standard

M : 1.0 – 4.0 mm (0.039 – 0.157 in)

DSF0047D

Page 2446 of 5121

FAX-18

< ON-VEHICLE REPAIR >

FRONT DRIVE SHAFT

LEFT SIDE

LEFT SIDE : Removal and InstallationINFOID:0000000003811084

REMOVAL

1. Remove tires.

2. Remove wheel sensor and sensor harness. Refer to BRC-57, "

FRONT WHEEL SENSOR : Exploded

View" (without VDC), BRC-151, "FRONT WHEEL SENSOR : Exploded View" (with VDC).

3. Remove lock plate of brake hose from strut assembly. Refer to BR-19, "

FRONT : Exploded View".

4. Remove caliper assembly. Hang caliper assembly not to interfere with work. Refer to BR-34, "

BRAKE

CALIPER ASSEMBLY : Exploded View".

5. Remove disc rotor. Refer to BR-35, "

BRAKE CALIPER ASSEMBLY : Removal and Installation".

6. Remove cotter pin, and then loosen wheel hub lock nut. Refer to FA X - 8 , "

Exploded View".

7. Patch wheel hub lock nut with a piece of wood. Hammer the

wood to disengage drive shaft from wheel hub and bearing

assembly.

CAUTION:

Never place drive shaft joint at an extreme angle. Also be

careful not to overextend slide joint.

Never allow drive shaft to hang down without support for

joint sub-assembly and the other parts.

NOTE:

Use suitable puller, if wheel hub and bearing assembly and drive

shaft cannot be separated even after performing the above pro-

cedure.

8. Remove wheel hub lock nut.

9. Remove steering knuckle from strut assembly. Refer to FSU-9, "

Exploded View".

10. Remove drive shaft from wheel hub and bearing assembly.

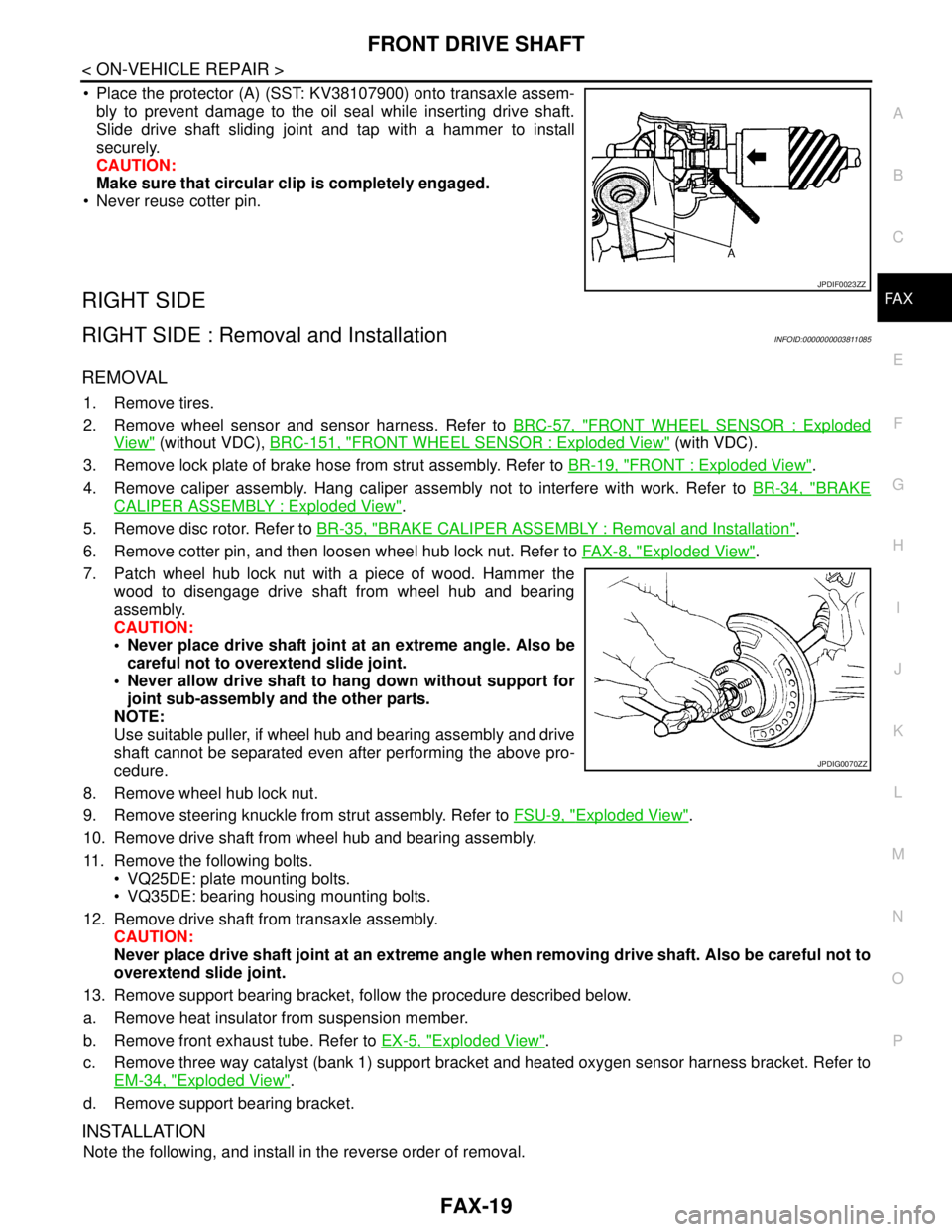

11. Remove drive shaft from transaxle assembly.

Use the drive shaft attachment (A) (SST: KV40107500) and a

sliding hammer (B) while inserting tip of the drive shaft attach-

ment between housing assembly and transaxle assembly.

CAUTION:

Never place drive shaft joint at an extreme angle when

removing drive shaft. Also be careful not to overextend

slide joint.

INSTALLATION

Note the following, and install in the reverse order of removal.

Always replace differential side oil seal with new one when installing drive shaft. Refer to TM-162, "

Exploded

View" (CVT: RE0F09B), TM-325, "Exploded View" (CVT: RE0F10A).

: Wheel side

: Fill NISSAN Genuine grease or equivalent.

Refer to GI-4, "

Components" for symbols not described on the above.

JPDIG0070ZZ

JPDIF0004ZZ

Page 2447 of 5121

FRONT DRIVE SHAFT

FAX-19

< ON-VEHICLE REPAIR >

C

E

F

G

H

I

J

K

L

MA

B

FA X

N

O

P

Place the protector (A) (SST: KV38107900) onto transaxle assem-

bly to prevent damage to the oil seal while inserting drive shaft.

Slide drive shaft sliding joint and tap with a hammer to install

securely.

CAUTION:

Make sure that circular clip is completely engaged.

Never reuse cotter pin.

RIGHT SIDE

RIGHT SIDE : Removal and InstallationINFOID:0000000003811085

REMOVAL

1. Remove tires.

2. Remove wheel sensor and sensor harness. Refer to BRC-57, "

FRONT WHEEL SENSOR : Exploded

View" (without VDC), BRC-151, "FRONT WHEEL SENSOR : Exploded View" (with VDC).

3. Remove lock plate of brake hose from strut assembly. Refer to BR-19, "

FRONT : Exploded View".

4. Remove caliper assembly. Hang caliper assembly not to interfere with work. Refer to BR-34, "

BRAKE

CALIPER ASSEMBLY : Exploded View".

5. Remove disc rotor. Refer to BR-35, "

BRAKE CALIPER ASSEMBLY : Removal and Installation".

6. Remove cotter pin, and then loosen wheel hub lock nut. Refer to FA X - 8 , "

Exploded View".

7. Patch wheel hub lock nut with a piece of wood. Hammer the

wood to disengage drive shaft from wheel hub and bearing

assembly.

CAUTION:

Never place drive shaft joint at an extreme angle. Also be

careful not to overextend slide joint.

Never allow drive shaft to hang down without support for

joint sub-assembly and the other parts.

NOTE:

Use suitable puller, if wheel hub and bearing assembly and drive

shaft cannot be separated even after performing the above pro-

cedure.

8. Remove wheel hub lock nut.

9. Remove steering knuckle from strut assembly. Refer to FSU-9, "

Exploded View".

10. Remove drive shaft from wheel hub and bearing assembly.

11. Remove the following bolts.

VQ25DE: plate mounting bolts.

VQ35DE: bearing housing mounting bolts.

12. Remove drive shaft from transaxle assembly.

CAUTION:

Never place drive shaft joint at an extreme angle when removing drive shaft. Also be careful not to

overextend slide joint.

13. Remove support bearing bracket, follow the procedure described below.

a. Remove heat insulator from suspension member.

b. Remove front exhaust tube. Refer to EX-5, "

Exploded View".

c. Remove three way catalyst (bank 1) support bracket and heated oxygen sensor harness bracket. Refer to

EM-34, "

Exploded View".

d. Remove support bearing bracket.

INSTALLATION

Note the following, and install in the reverse order of removal.

JPDIF0023ZZ

JPDIG0070ZZ

Page 3195 of 5121

PERIODIC MAINTENANCE

MA-7

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

MB

MAN

OA

(5) Replace spark plug when the spark plug gap exceeds 1.4 mm (0.055 in) even if within specified periodic replacement

mileage.

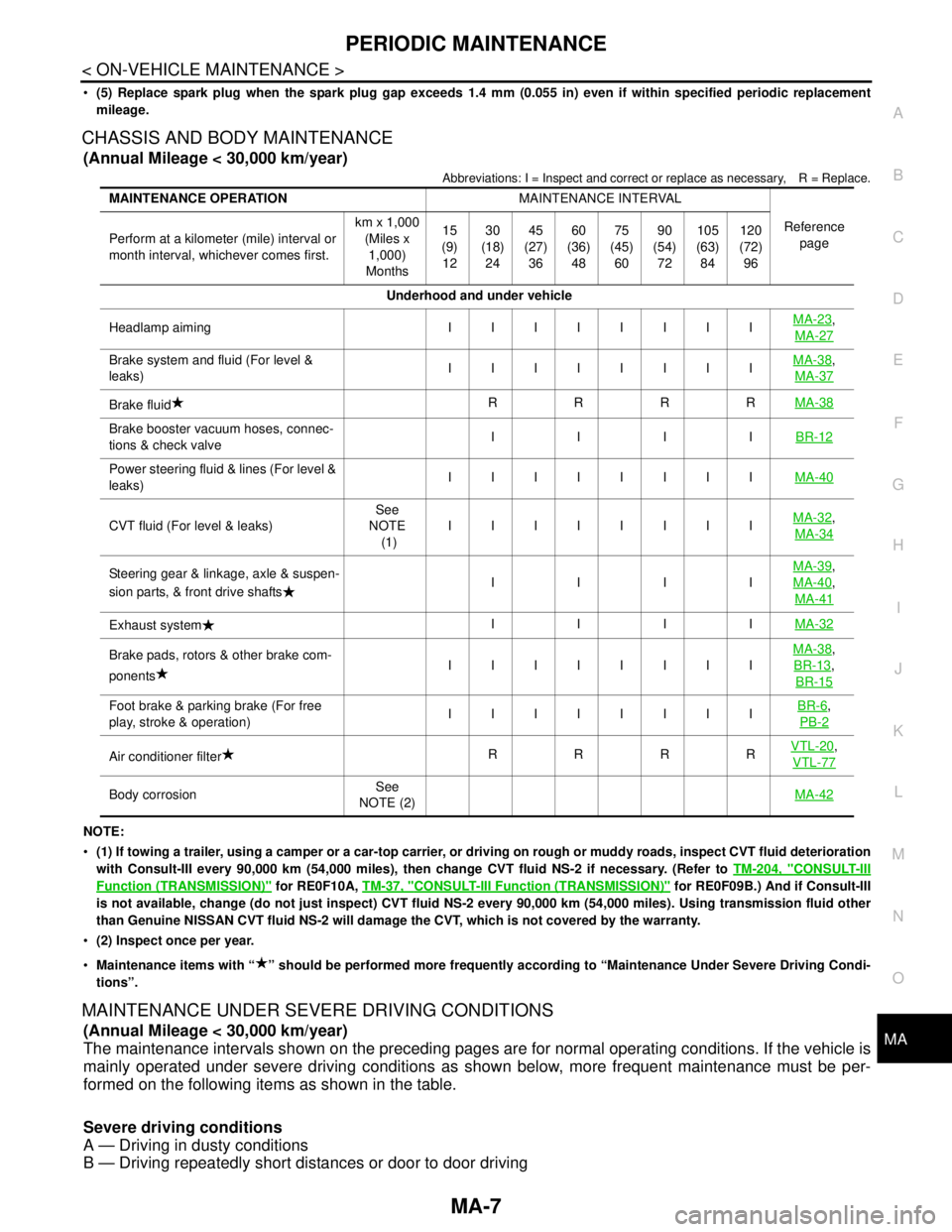

CHASSIS AND BODY MAINTENANCE

(Annual Mileage < 30,000 km/year)

Abbreviations: I = Inspect and correct or replace as necessary, R = Replace.

NOTE:

(1) If towing a trailer, using a camper or a car-top carrier, or driving on rough or muddy roads, inspect CVT fluid deterioration

with Consult-III every 90,000 km (54,000 miles), then change CVT fluid NS-2 if necessary. (Refer to TM-204, "

CONSULT-III

Function (TRANSMISSION)" for RE0F10A, TM-37, "CONSULT-III Function (TRANSMISSION)" for RE0F09B.) And if Consult-III

is not available, change (do not just inspect) CVT fluid NS-2 every 90,000 km (54,000 miles). Using transmission fluid other

than Genuine NISSAN CVT fluid NS-2 will damage the CVT, which is not covered by the warranty.

(2) Inspect once per year.

Maintenance items with “ ” should be performed more frequently according to “Maintenance Under Severe Driving Condi-

tions”.

MAINTENANCE UNDER SEVERE DRIVING CONDITIONS

(Annual Mileage < 30,000 km/year)

The maintenance intervals shown on the preceding pages are for normal operating conditions. If the vehicle is

mainly operated under severe driving conditions as shown below, more frequent maintenance must be per-

formed on the following items as shown in the table.

Severe driving conditions

A — Driving in dusty conditions

B — Driving repeatedly short distances or door to door driving

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference

page Perform at a kilometer (mile) interval or

month interval, whichever comes first.km x 1,000

(Miles x

1,000)

Months15

(9)

1230

(18)

2445

(27)

3660

(36)

4875

(45)

6090

(54)

72105

(63)

84120

(72)

96

Underhood and under vehicle

Headlamp aiming IIIIIIIIMA-23

,

MA-27

Brake system and fluid (For level &

leaks)IIIIIIIIMA-38,

MA-37

Brake fluidRRRRMA-38

Brake booster vacuum hoses, connec-

tions & check valveIIIIBR-12

Power steering fluid & lines (For level &

leaks)IIIIIIIIMA-40

CVT fluid (For level & leaks)See

NOTE

(1)IIIIIIIIMA-32,

MA-34

Steering gear & linkage, axle & suspen-

sion parts, & front drive shaftsIIIIMA-39,

MA-40

,

MA-41

Exhaust systemIIIIMA-32

Brake pads, rotors & other brake com-

ponentsIIIIIIIIMA-38,

BR-13

,

BR-15

Foot brake & parking brake (For free

play, stroke & operation)IIIIIIIIBR-6,

PB-2

Air conditioner filterRRRRVTL-20,

VTL-77

Body corrosionSee

NOTE (2)MA-42

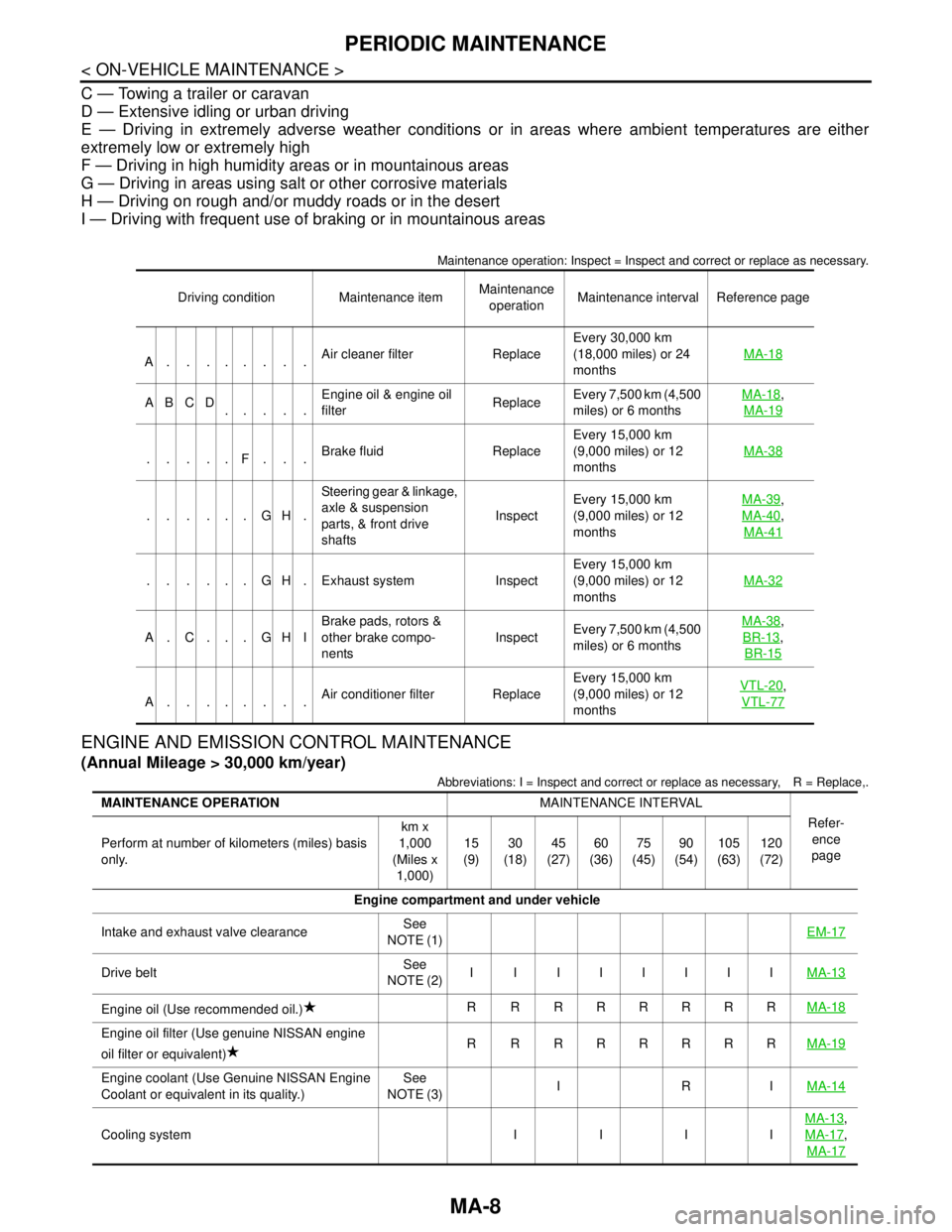

Page 3196 of 5121

MA-8

< ON-VEHICLE MAINTENANCE >

PERIODIC MAINTENANCE

C — Towing a trailer or caravan

D — Extensive idling or urban driving

E — Driving in extremely adverse weather conditions or in areas where ambient temperatures are either

extremely low or extremely high

F — Driving in high humidity areas or in mountainous areas

G — Driving in areas using salt or other corrosive materials

H — Driving on rough and/or muddy roads or in the desert

I — Driving with frequent use of braking or in mountainous areas

Maintenance operation: Inspect = Inspect and correct or replace as necessary.

ENGINE AND EMISSION CONTROL MAINTENANCE

(Annual Mileage > 30,000 km/year)

Abbreviations: I = Inspect and correct or replace as necessary, R = Replace,.

Driving condition Maintenance itemMaintenance

operationMaintenance interval Reference page

A........Air cleaner filter ReplaceEvery 30,000 km

(18,000 miles) or 24

monthsMA-18

ABCD

.....Engine oil & engine oil

filter ReplaceEvery 7,500 km (4,500

miles) or 6 monthsMA-18,

MA-19

.....F...Brake fluid ReplaceEvery 15,000 km

(9,000 miles) or 12

monthsMA-38

......GH.Steering gear & linkage,

axle & suspension

parts, & front drive

shafts InspectEvery 15,000 km

(9,000 miles) or 12

monthsMA-39

,

MA-40

,

MA-41

. . . . . . G H . Exhaust system InspectEvery 15,000 km

(9,000 miles) or 12

monthsMA-32

A. C. . . GHIBrake pads, rotors &

other brake compo-

nentsInspectEvery 7,500 km (4,500

miles) or 6 monthsMA-38

,

BR-13

,

BR-15

A........Air conditioner filter ReplaceEvery 15,000 km

(9,000 miles) or 12

monthsVTL-20

,

VTL-77

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Refer-

ence

page Perform at number of kilometers (miles) basis

only.km x

1,000

(Miles x

1,000)15

(9)30

(18)45

(27)60

(36)75

(45)90

(54)105

(63)120

(72)

Engine compartment and under vehicle

Intake and exhaust valve clearanceSee

NOTE (1)EM-17

Drive beltSee

NOTE (2)I I IIIIIIMA-13

Engine oil (Use recommended oil.)R RRRRRRRMA-18

Engine oil filter (Use genuine NISSAN engine

oil filter or equivalent)R RRRRRRRMA-19

Engine coolant (Use Genuine NISSAN Engine

Coolant or equivalent in its quality.)See

NOTE (3)IRIMA-14

Cooling system I I I IMA-13

,

MA-17

,

MA-17

Page 3197 of 5121

PERIODIC MAINTENANCE

MA-9

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

MB

MAN

OA

NOTE:

Maintenance items with “ ” should be performed more frequently according to “Maintenance Under Severe Driving Condi-

tions”.

(1) Periodic maintenance is not required. However, if valve noise increases, check valve clearance.

(2) Replace the drive belt if found damaged or if the auto belt tensioner reading reaches the maximum limit.

(3) Use Genuine NISSAN Engine Coolant or equivalent in its quality, in order to avoid possible aluminum corrosion within

the engine cooling system caused by the use of non-genuine coolant.

First replace at 90,000 km (54,000 miles), then every 60,000 km (36,000 miles). Perform "I" (Checking the mixture ratio and

correcting the mixture ratio if necessary) at the middle of replacement interval.

(4) Fuel filter is maintenance-free. For service procedures, refer to FL section.

(5) Replace spark plug when the spark plug gap exceeds 1.4 mm (0.055 in) even if within specified periodic replacement

mileage.

CHASSIS AND BODY MAINTENANCE

(Annual Mileage > 30,000 km/year)

Abbreviations: I = Inspect and correct or replace as necessary, R = Replace, L = Lubricate.

Fuel and EVAP vapor lines I IMA-18,

MA-22

Air cleaner filterRRMA-18

Fuel filter (In-tank type)See

NOTE (4)—

Positive crankcase ventilation (PCV) system I I I IMA-21

Spark-plugs (Iridium-tipped type)See

NOTE (5)R R RRRRRRMA-20

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Refer-

ence

page Perform at number of kilometers (miles) basis

only.km x

1,000

(Miles x

1,000)15

(9)30

(18)45

(27)60

(36)75

(45)90

(54)105

(63)120

(72)

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference

page Perform at number of kilometers (miles)

basis only.km x 1,000

(Miles x

1,000)15

(9)30

(18)45

(27)60

(36)75

(45)90

(54)105

(63)120

(72)

Underhood and under vehicle

Headlamp aiming I I I IMA-23

,

MA-27

Brake system and fluid (For level &

leaks)IIIIMA-38,

MA-37

Brake fluidRRMA-38

Brake booster vacuum hoses, connec-

tions & check valveIIBR-12

Power steering fluid & lines (For level &

leaks)IIIIMA-40

CVT fluid (For level & leaks)See

NOTE (1)IIIIMA-32,

MA-34

Steering gear & linkage, axle & suspen-

sion parts, & front drive shafts IIMA-39,

MA-40

,

MA-41

Exhaust systemIIMA-32

Brake pads, rotors & other brake com-

ponentsIIIIMA-38,

BR-13

,

BR-15

Foot brake & parking brake (For free

play, stroke & operation)IIIIBR-6,

PB-2

Page 3198 of 5121

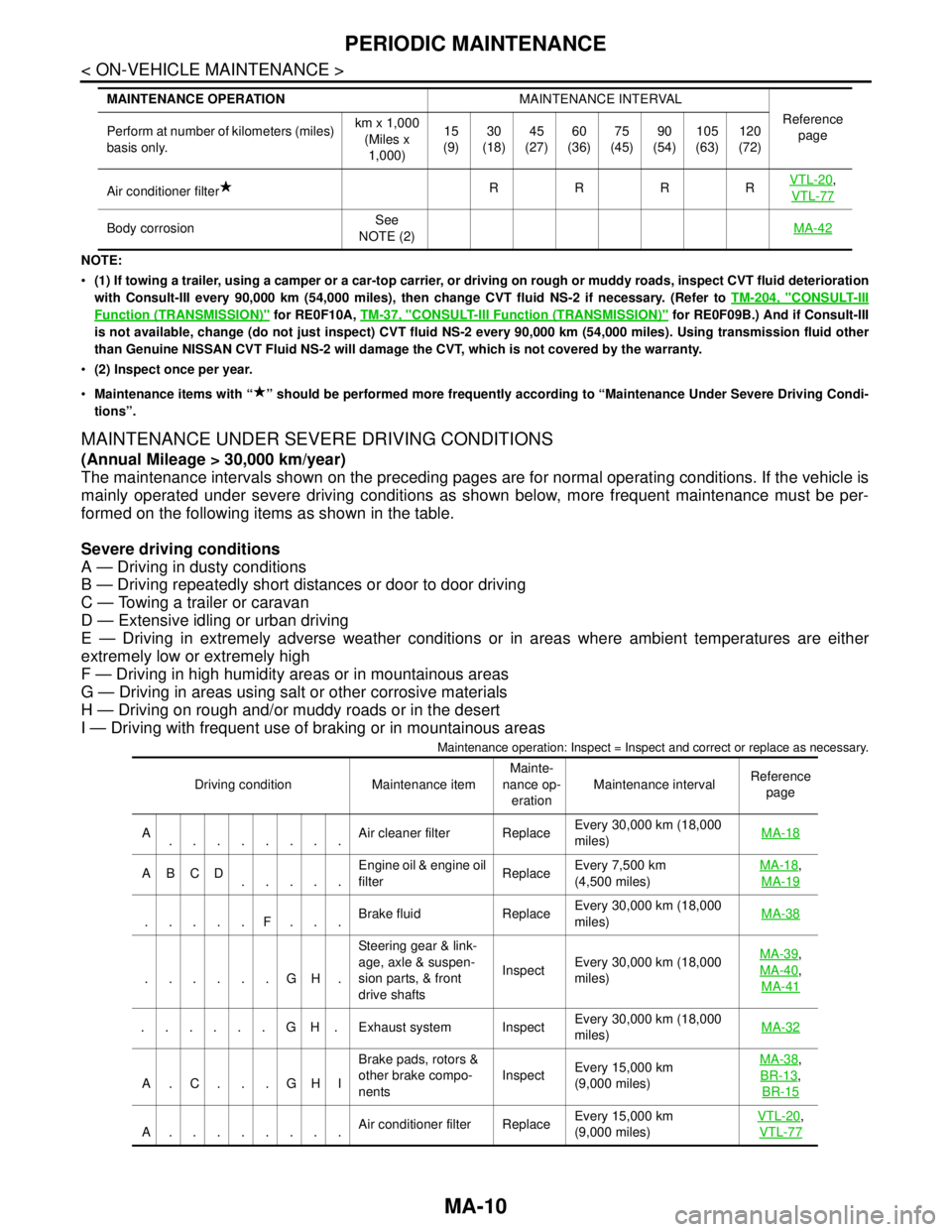

MA-10

< ON-VEHICLE MAINTENANCE >

PERIODIC MAINTENANCE

NOTE:

(1) If towing a trailer, using a camper or a car-top carrier, or driving on rough or muddy roads, inspect CVT fluid deterioration

with Consult-III every 90,000 km (54,000 miles), then change CVT fluid NS-2 if necessary. (Refer to TM-204, "

CONSULT-III

Function (TRANSMISSION)" for RE0F10A, TM-37, "CONSULT-III Function (TRANSMISSION)" for RE0F09B.) And if Consult-III

is not available, change (do not just inspect) CVT fluid NS-2 every 90,000 km (54,000 miles). Using transmission fluid other

than Genuine NISSAN CVT Fluid NS-2 will damage the CVT, which is not covered by the warranty.

(2) Inspect once per year.

Maintenance items with “ ” should be performed more frequently according to “Maintenance Under Severe Driving Condi-

tions”.

MAINTENANCE UNDER SEVERE DRIVING CONDITIONS

(Annual Mileage > 30,000 km/year)

The maintenance intervals shown on the preceding pages are for normal operating conditions. If the vehicle is

mainly operated under severe driving conditions as shown below, more frequent maintenance must be per-

formed on the following items as shown in the table.

Severe driving conditions

A — Driving in dusty conditions

B — Driving repeatedly short distances or door to door driving

C — Towing a trailer or caravan

D — Extensive idling or urban driving

E — Driving in extremely adverse weather conditions or in areas where ambient temperatures are either

extremely low or extremely high

F — Driving in high humidity areas or in mountainous areas

G — Driving in areas using salt or other corrosive materials

H — Driving on rough and/or muddy roads or in the desert

I — Driving with frequent use of braking or in mountainous areas

Maintenance operation: Inspect = Inspect and correct or replace as necessary.

Air conditioner filterRRRRVTL-20,

VTL-77

Body corrosionSee

NOTE (2)MA-42

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference

page Perform at number of kilometers (miles)

basis only.km x 1,000

(Miles x

1,000)15

(9)30

(18)45

(27)60

(36)75

(45)90

(54)105

(63)120

(72)

Driving condition Maintenance itemMainte-

nance op-

erationMaintenance intervalReference

page

A

........Air cleaner filter ReplaceEvery 30,000 km (18,000

miles) MA-18

ABCD

.....Engine oil & engine oil

filter ReplaceEvery 7,500 km

(4,500 miles) MA-18,

MA-19

.....F...Brake fluid ReplaceEvery 30,000 km (18,000

miles) MA-38

......GH.Steering gear & link-

age, axle & suspen-

sion parts, & front

drive shaftsInspectEvery 30,000 km (18,000

miles) MA-39

,

MA-40

,

MA-41

......GH.Exhaust system InspectEvery 30,000 km (18,000

miles)MA-32

A.C. . .GHIBrake pads, rotors &

other brake compo-

nentsInspectEvery 15,000 km

(9,000 miles) MA-38

,

BR-13

,

BR-15

A........Air conditioner filter ReplaceEvery 15,000 km

(9,000 miles) VTL-20

,

VTL-77

Page 3225 of 5121

CHASSIS MAINTENANCE

MA-37

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

MB

MAN

OA

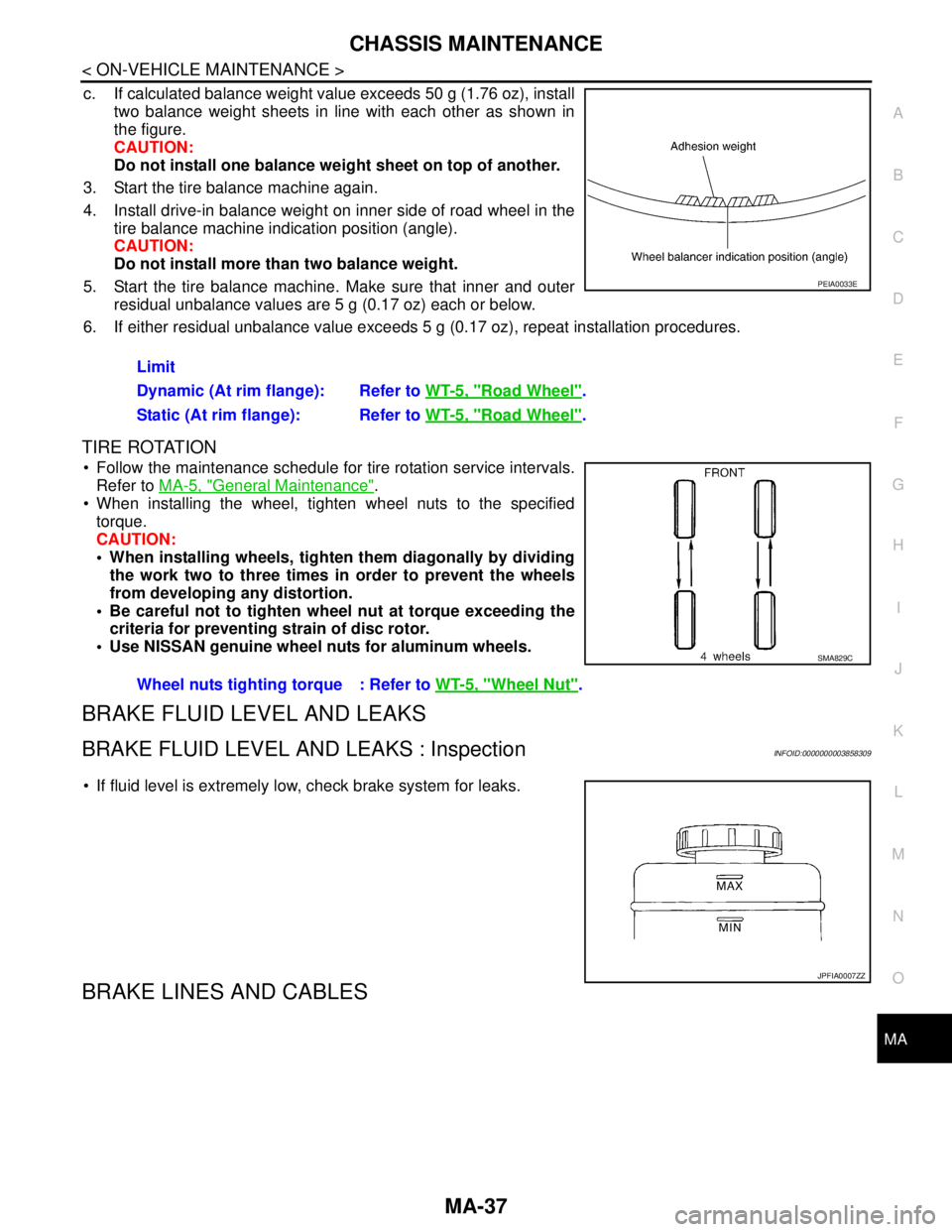

c. If calculated balance weight value exceeds 50 g (1.76 oz), install

two balance weight sheets in line with each other as shown in

the figure.

CAUTION:

Do not install one balance weight sheet on top of another.

3. Start the tire balance machine again.

4. Install drive-in balance weight on inner side of road wheel in the

tire balance machine indication position (angle).

CAUTION:

Do not install more than two balance weight.

5. Start the tire balance machine. Make sure that inner and outer

residual unbalance values are 5 g (0.17 oz) each or below.

6. If either residual unbalance value exceeds 5 g (0.17 oz), repeat installation procedures.

TIRE ROTATION

Follow the maintenance schedule for tire rotation service intervals.

Refer to MA-5, "

General Maintenance".

When installing the wheel, tighten wheel nuts to the specified

torque.

CAUTION:

When installing wheels, tighten them diagonally by dividing

the work two to three times in order to prevent the wheels

from developing any distortion.

Be careful not to tighten wheel nut at torque exceeding the

criteria for preventing strain of disc rotor.

Use NISSAN genuine wheel nuts for aluminum wheels.

BRAKE FLUID LEVEL AND LEAKS

BRAKE FLUID LEVEL AND LEAKS : InspectionINFOID:0000000003858309

If fluid level is extremely low, check brake system for leaks.

BRAKE LINES AND CABLES

Limit

Dynamic (At rim flange): Refer to WT-5, "

Road Wheel".

Static (At rim flange): Refer to WT-5, "

Road Wheel".

PEIA0033E

Wheel nuts tighting torque : Refer to WT-5, "Wheel Nut".

SMA829C

JPFIA0007ZZ

Page 3226 of 5121

MA-38

< ON-VEHICLE MAINTENANCE >

CHASSIS MAINTENANCE

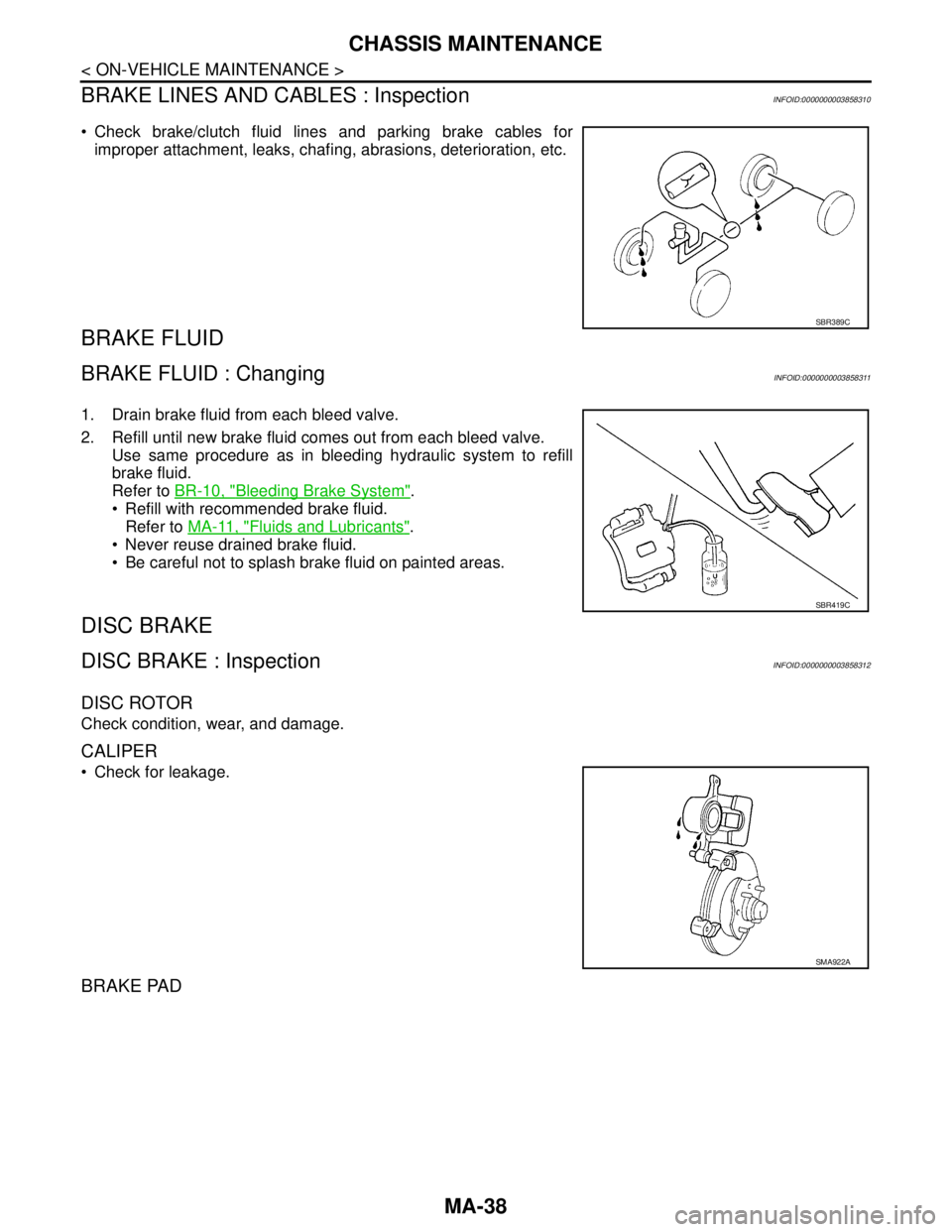

BRAKE LINES AND CABLES : Inspection

INFOID:0000000003858310

Check brake/clutch fluid lines and parking brake cables for

improper attachment, leaks, chafing, abrasions, deterioration, etc.

BRAKE FLUID

BRAKE FLUID : ChangingINFOID:0000000003858311

1. Drain brake fluid from each bleed valve.

2. Refill until new brake fluid comes out from each bleed valve.

Use same procedure as in bleeding hydraulic system to refill

brake fluid.

Refer to BR-10, "

Bleeding Brake System".

Refill with recommended brake fluid.

Refer to MA-11, "

Fluids and Lubricants".

Never reuse drained brake fluid.

Be careful not to splash brake fluid on painted areas.

DISC BRAKE

DISC BRAKE : InspectionINFOID:0000000003858312

DISC ROTOR

Check condition, wear, and damage.

CALIPER

Check for leakage.

BRAKE PAD

SBR389C

SBR419C

SMA922A