ignition NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 1108 of 5121

CHG-10

< COMPONENT DIAGNOSIS >

L TERMINAL CIRCUIT (OPEN)

L TERMINAL CIRCUIT (OPEN)

DescriptionINFOID:0000000003860523

The “L” terminal circuit controls the charge warning lamp. The charge warning lamp illuminates when the igni-

tion switch is set to ON or START. When the alternator is providing sufficient voltage with the engine running,

the charge warning lamp will go off. If the charge warning lamp illuminates with the engine running, a malfunc-

tion is indicated.

Diagnosis ProcedureINFOID:0000000003860524

1.CHECK “L” TERMINAL CONNECTION

1. Turn ignition switch OFF.

2. Check if “L” terminal is clean and tight.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair “L” terminal connection. Confirm repair by performing complete Starting/Charging system

test. Refer to Technical Service Bulletin.

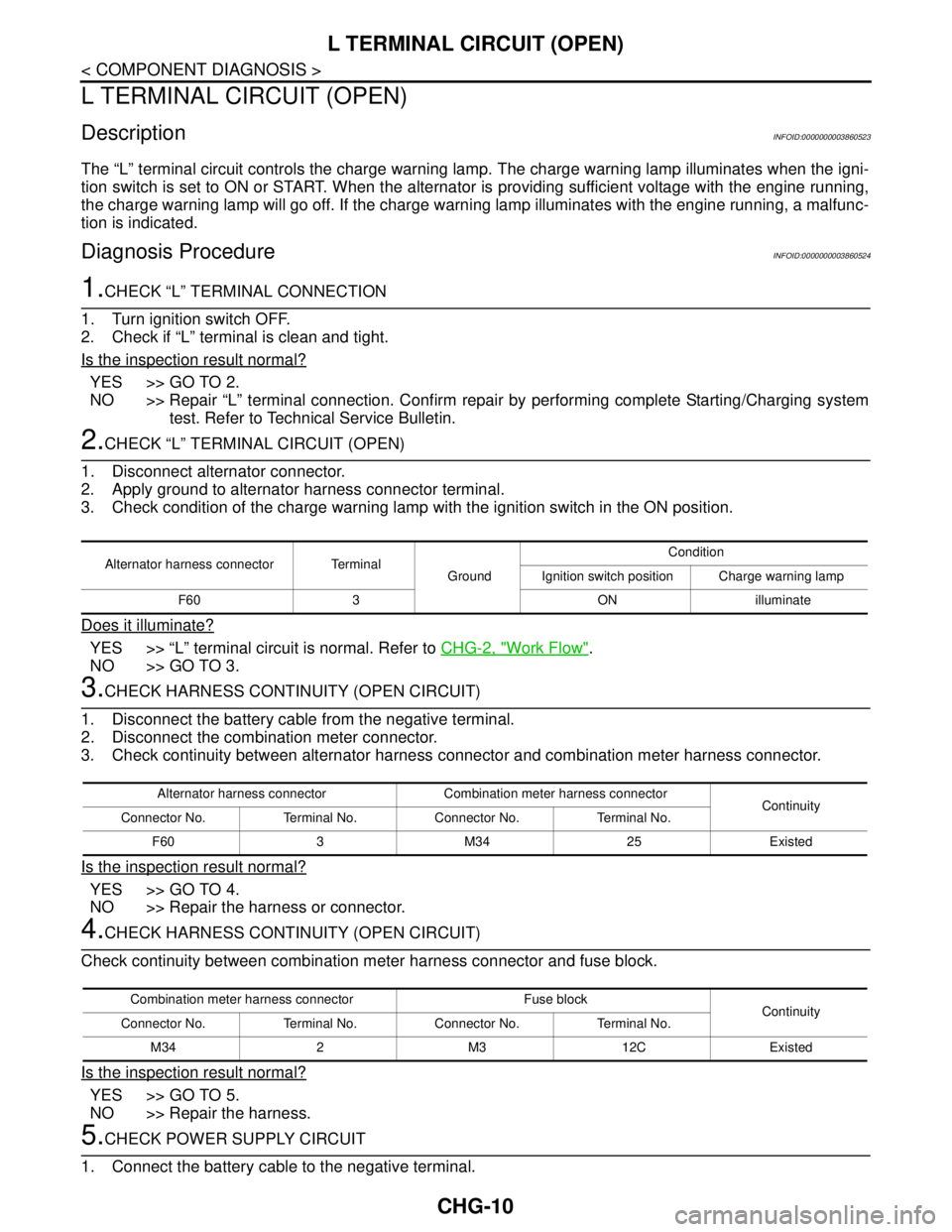

2.CHECK “L” TERMINAL CIRCUIT (OPEN)

1. Disconnect alternator connector.

2. Apply ground to alternator harness connector terminal.

3. Check condition of the charge warning lamp with the ignition switch in the ON position.

Does it illuminate?

YES >> “L” terminal circuit is normal. Refer to CHG-2, "Work Flow".

NO >> GO TO 3.

3.CHECK HARNESS CONTINUITY (OPEN CIRCUIT)

1. Disconnect the battery cable from the negative terminal.

2. Disconnect the combination meter connector.

3. Check continuity between alternator harness connector and combination meter harness connector.

Is the inspection result normal?

YES >> GO TO 4.

NO >> Repair the harness or connector.

4.CHECK HARNESS CONTINUITY (OPEN CIRCUIT)

Check continuity between combination meter harness connector and fuse block.

Is the inspection result normal?

YES >> GO TO 5.

NO >> Repair the harness.

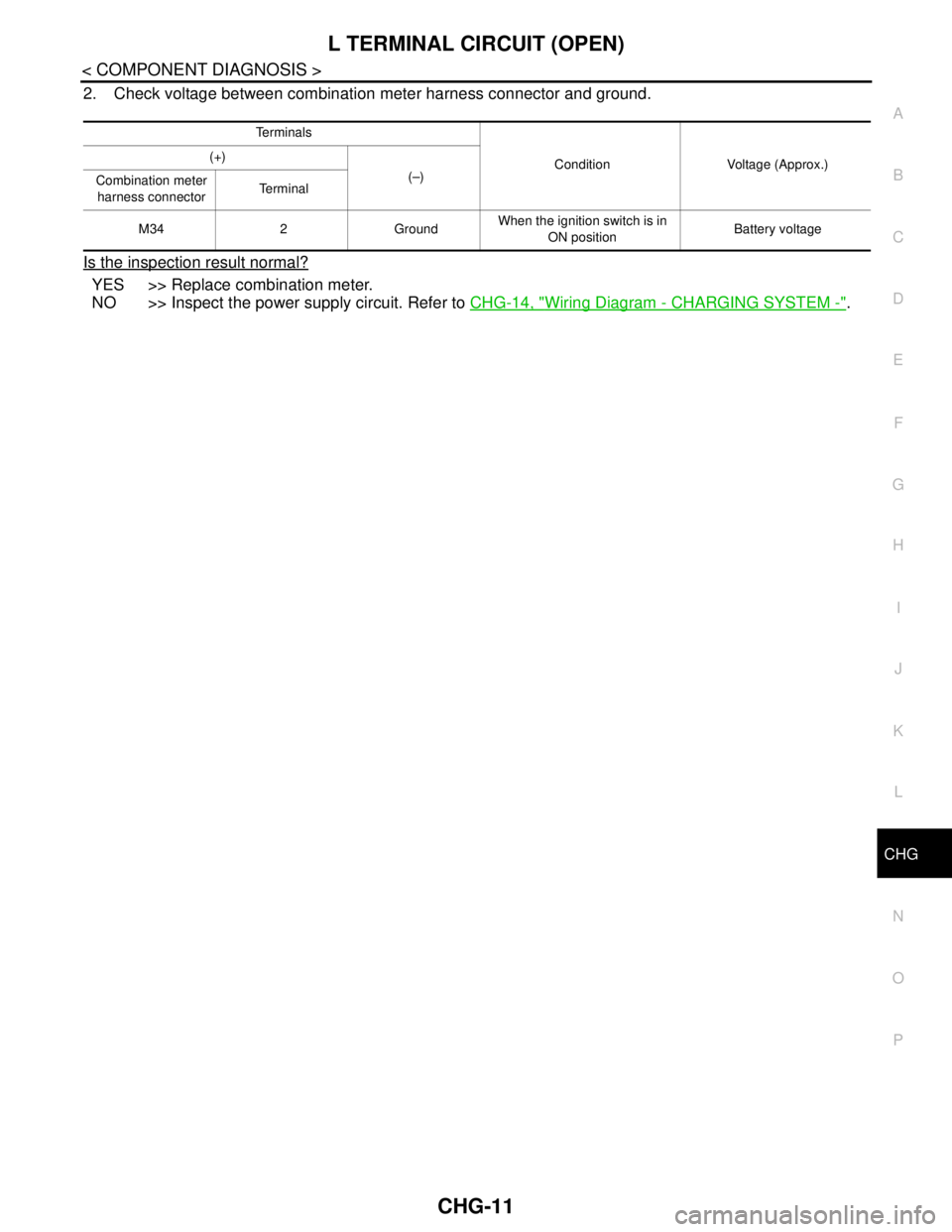

5.CHECK POWER SUPPLY CIRCUIT

1. Connect the battery cable to the negative terminal.

Alternator harness connector Terminal

GroundCondition

Ignition switch position Charge warning lamp

F60 3 ON illuminate

Alternator harness connector Combination meter harness connector

Continuity

Connector No. Terminal No. Connector No. Terminal No.

F60 3 M34 25 Existed

Combination meter harness connector Fuse block

Continuity

Connector No. Terminal No. Connector No. Terminal No.

M34 2 M3 12C Existed

Page 1109 of 5121

CHG

L TERMINAL CIRCUIT (OPEN)

CHG-11

< COMPONENT DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L B A

O

P N

2. Check voltage between combination meter harness connector and ground.

Is the inspection result normal?

YES >> Replace combination meter.

NO >> Inspect the power supply circuit. Refer to CHG-14, "

Wiring Diagram - CHARGING SYSTEM -".

Te r m i n a l s

Condition Voltage (Approx.) (+)

(–)

Combination meter

harness connectorTe r m i n a l

M34 2 GroundWhen the ignition switch is in

ON positionBattery voltage

Page 1110 of 5121

CHG-12

< COMPONENT DIAGNOSIS >

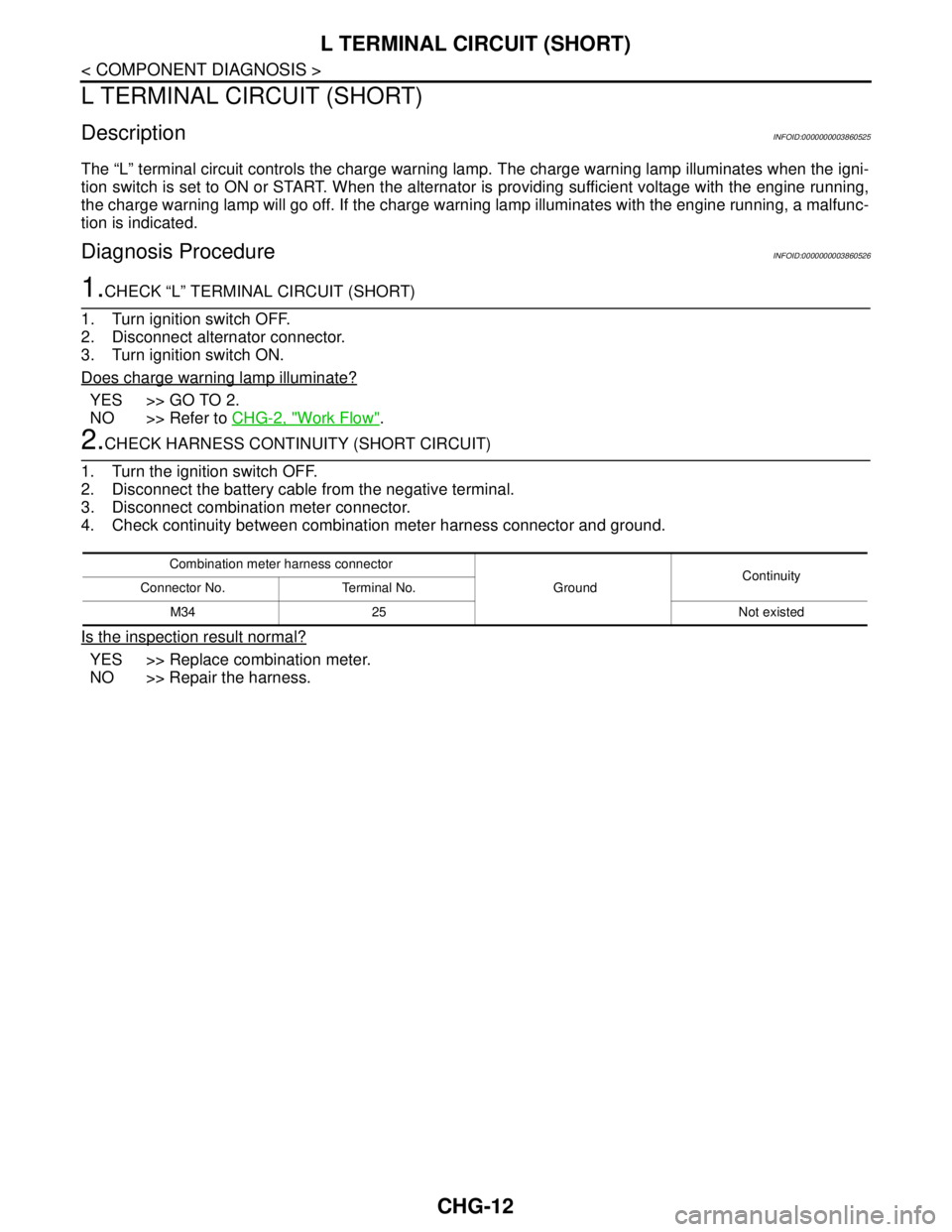

L TERMINAL CIRCUIT (SHORT)

L TERMINAL CIRCUIT (SHORT)

DescriptionINFOID:0000000003860525

The “L” terminal circuit controls the charge warning lamp. The charge warning lamp illuminates when the igni-

tion switch is set to ON or START. When the alternator is providing sufficient voltage with the engine running,

the charge warning lamp will go off. If the charge warning lamp illuminates with the engine running, a malfunc-

tion is indicated.

Diagnosis ProcedureINFOID:0000000003860526

1.CHECK “L” TERMINAL CIRCUIT (SHORT)

1. Turn ignition switch OFF.

2. Disconnect alternator connector.

3. Turn ignition switch ON.

Does charge warning lamp illuminate?

YES >> GO TO 2.

NO >> Refer to CHG-2, "

Work Flow".

2.CHECK HARNESS CONTINUITY (SHORT CIRCUIT)

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Disconnect combination meter connector.

4. Check continuity between combination meter harness connector and ground.

Is the inspection result normal?

YES >> Replace combination meter.

NO >> Repair the harness.

Combination meter harness connector

GroundContinuity

Connector No. Terminal No.

M34 25 Not existed

Page 1111 of 5121

CHG

S TERMINAL CIRCUIT

CHG-13

< COMPONENT DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L B A

O

P N

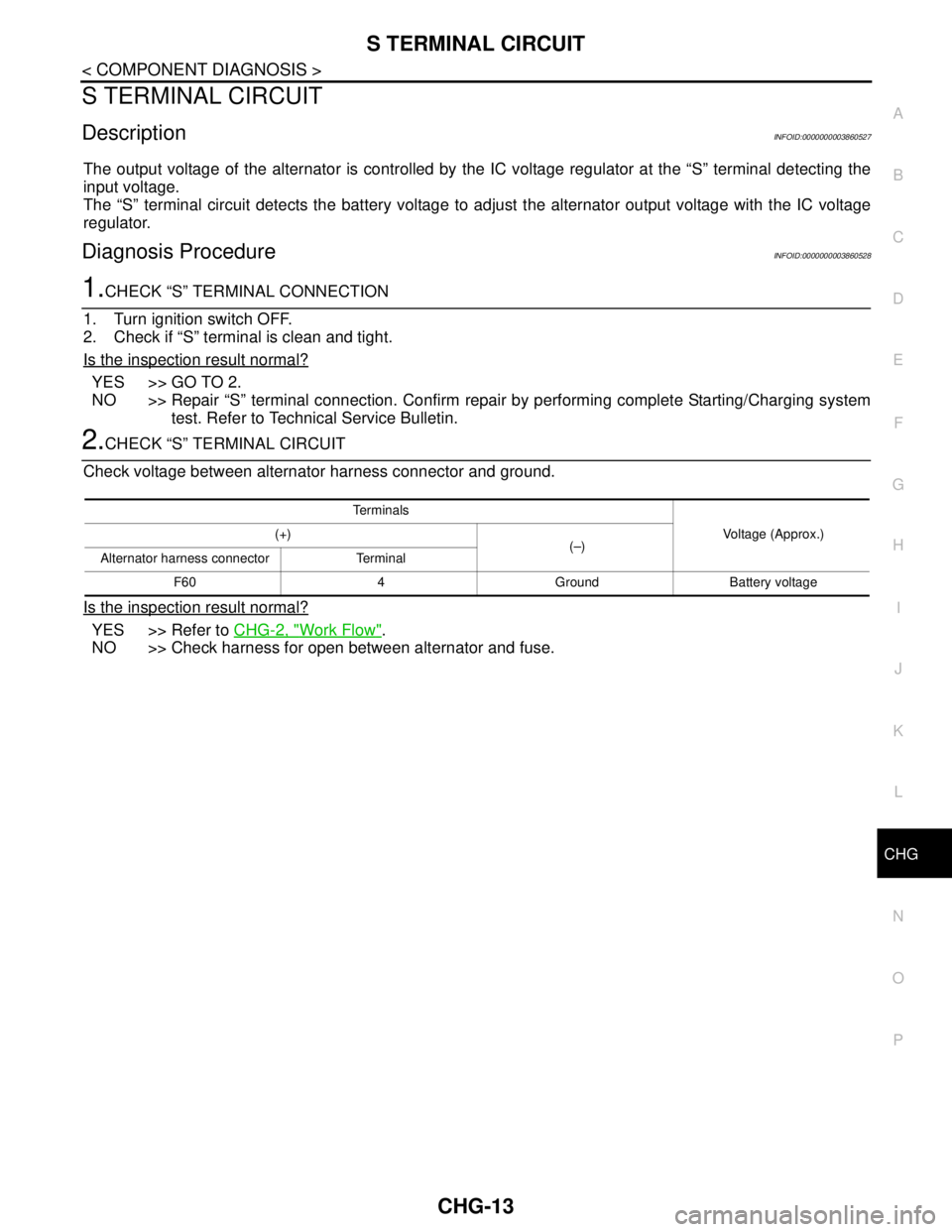

S TERMINAL CIRCUIT

DescriptionINFOID:0000000003860527

The output voltage of the alternator is controlled by the IC voltage regulator at the “S” terminal detecting the

input voltage.

The “S” terminal circuit detects the battery voltage to adjust the alternator output voltage with the IC voltage

regulator.

Diagnosis ProcedureINFOID:0000000003860528

1.CHECK “S” TERMINAL CONNECTION

1. Turn ignition switch OFF.

2. Check if “S” terminal is clean and tight.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair “S” terminal connection. Confirm repair by performing complete Starting/Charging system

test. Refer to Technical Service Bulletin.

2.CHECK “S” TERMINAL CIRCUIT

Check voltage between alternator harness connector and ground.

Is the inspection result normal?

YES >> Refer to CHG-2, "Work Flow".

NO >> Check harness for open between alternator and fuse.

Te r m i n a l s

Voltage (Approx.) (+)

(–)

Alternator harness connector Terminal

F60 4 Ground Battery voltage

Page 1115 of 5121

CHG

CHARGING SYSTEM

CHG-17

< SYMPTOM DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L B A

O

P N

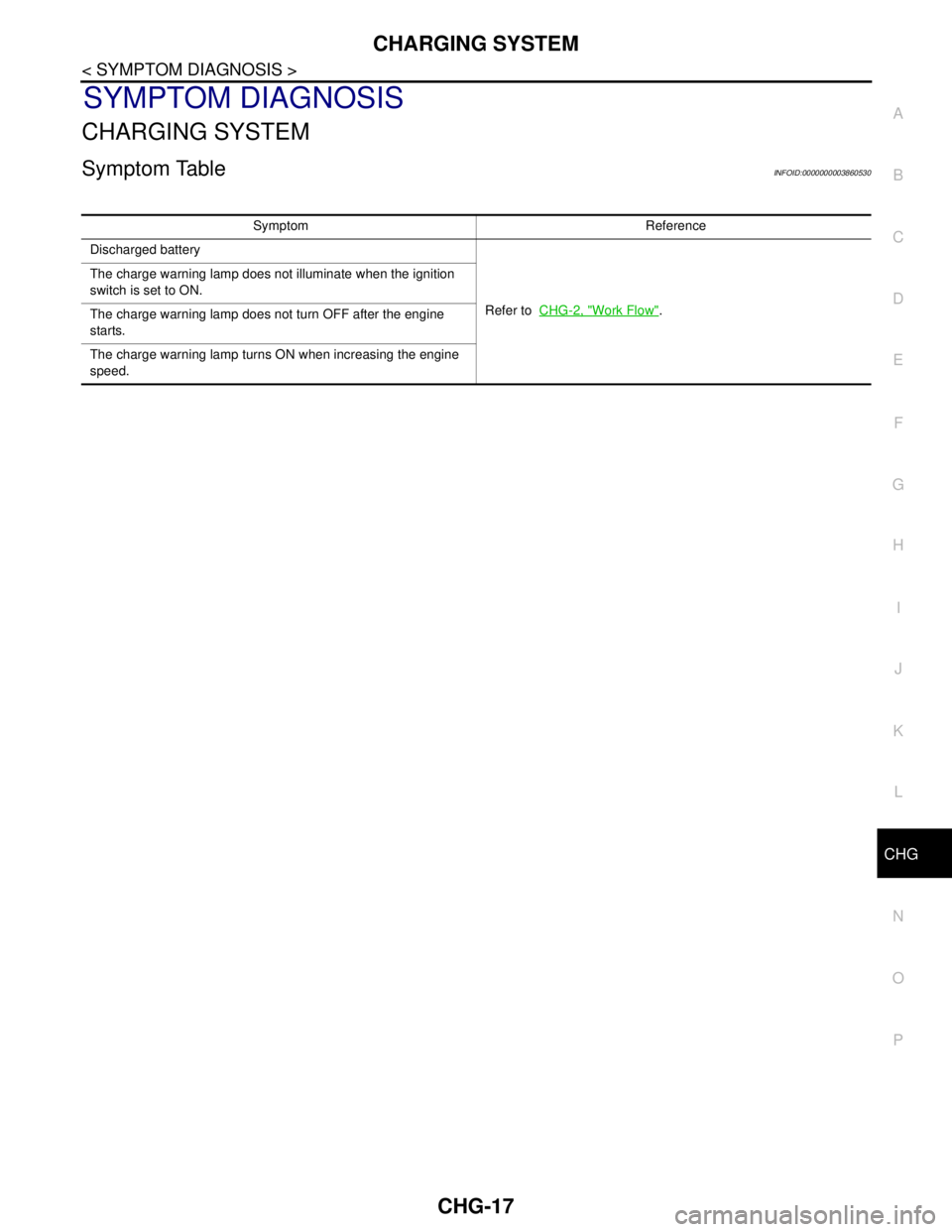

SYMPTOM DIAGNOSIS

CHARGING SYSTEM

Symptom TableINFOID:0000000003860530

Symptom Reference

Discharged battery

Refer to CHG-2, "

Work Flow". The charge warning lamp does not illuminate when the ignition

switch is set to ON.

The charge warning lamp does not turn OFF after the engine

starts.

The charge warning lamp turns ON when increasing the engine

speed.

Page 1118 of 5121

CHG-20

< ON-VEHICLE MAINTENANCE >

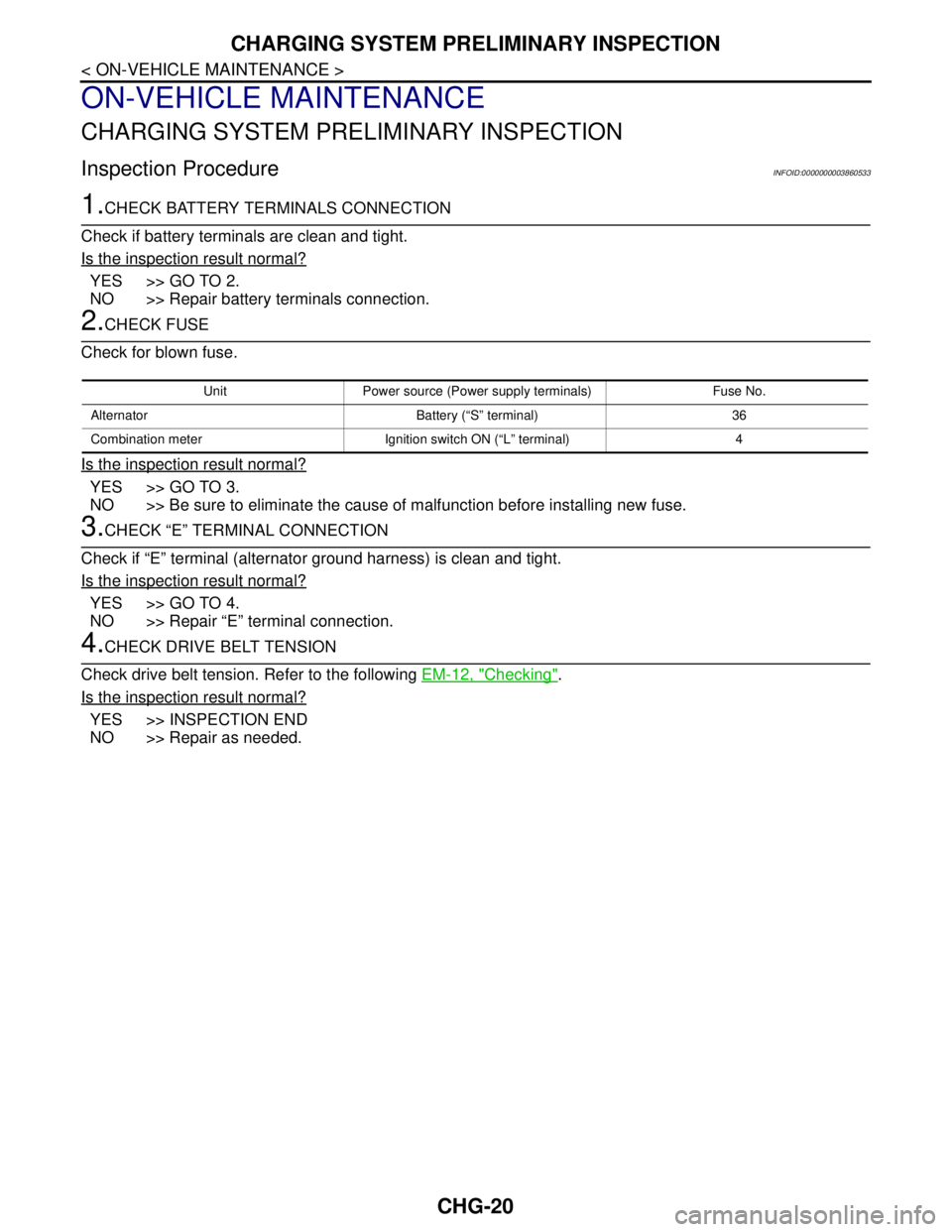

CHARGING SYSTEM PRELIMINARY INSPECTION

ON-VEHICLE MAINTENANCE

CHARGING SYSTEM PRELIMINARY INSPECTION

Inspection ProcedureINFOID:0000000003860533

1.CHECK BATTERY TERMINALS CONNECTION

Check if battery terminals are clean and tight.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair battery terminals connection.

2.CHECK FUSE

Check for blown fuse.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Be sure to eliminate the cause of malfunction before installing new fuse.

3.CHECK “E” TERMINAL CONNECTION

Check if “E” terminal (alternator ground harness) is clean and tight.

Is the inspection result normal?

YES >> GO TO 4.

NO >> Repair “E” terminal connection.

4.CHECK DRIVE BELT TENSION

Check drive belt tension. Refer to the following EM-12, "

Checking".

Is the inspection result normal?

YES >> INSPECTION END

NO >> Repair as needed.

Unit Power source (Power supply terminals) Fuse No.

Alternator Battery (“S” terminal) 36

Combination meter Ignition switch ON (“L” terminal) 4

Page 1127 of 5121

CO-4

< SYMPTOM DIAGNOSIS >

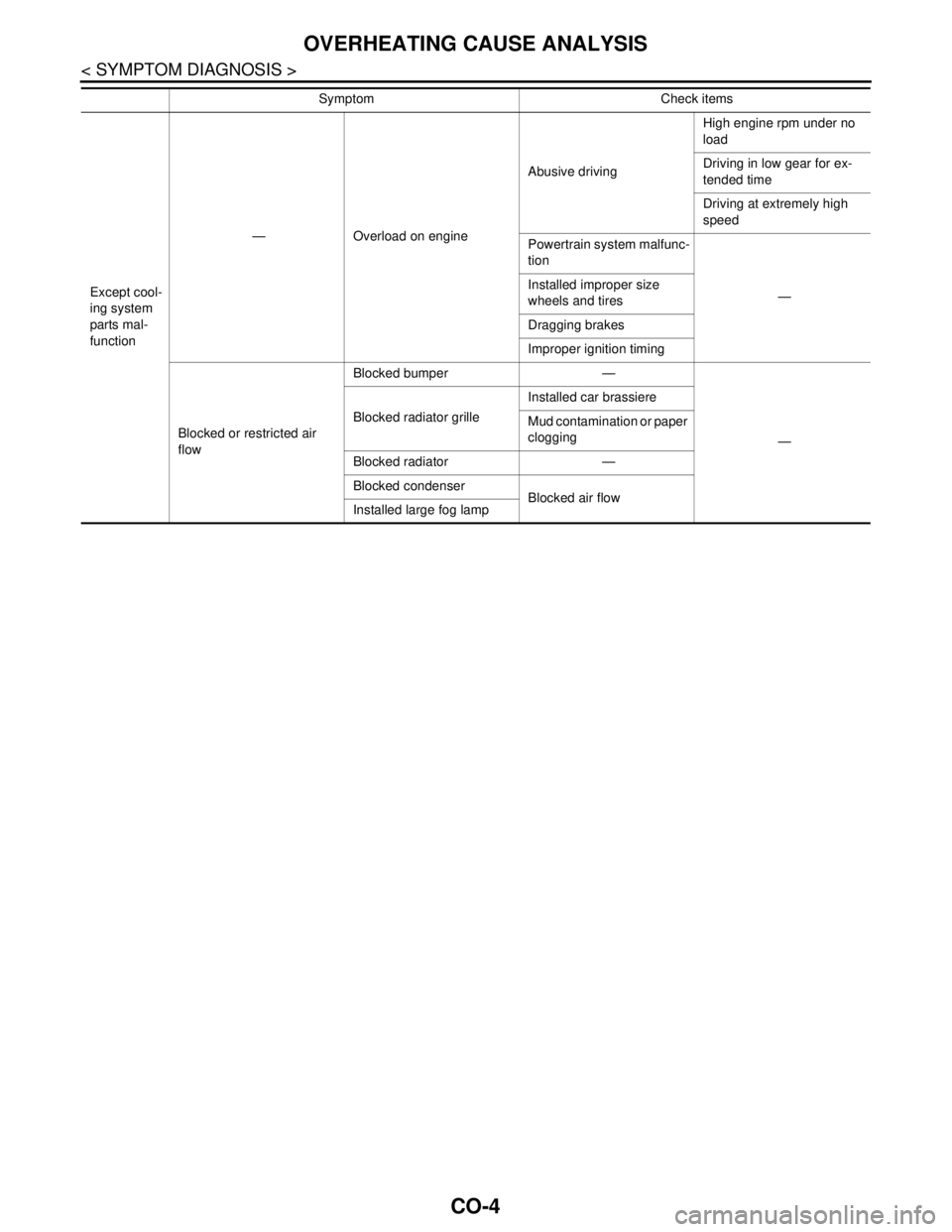

OVERHEATING CAUSE ANALYSIS

Except cool-

ing system

parts mal-

function— Overload on engineAbusive drivingHigh engine rpm under no

load

Driving in low gear for ex-

tended time

Driving at extremely high

speed

Powertrain system malfunc-

tion

— Installed improper size

wheels and tires

Dragging brakes

Improper ignition timing

Blocked or restricted air

flowBlocked bumper —

— Blocked radiator grilleInstalled car brassiere

Mud contamination or paper

clogging

Blocked radiator —

Blocked condenser

Blocked air flow

Installed large fog lamp Symptom Check items

Page 1154 of 5121

DEF-4

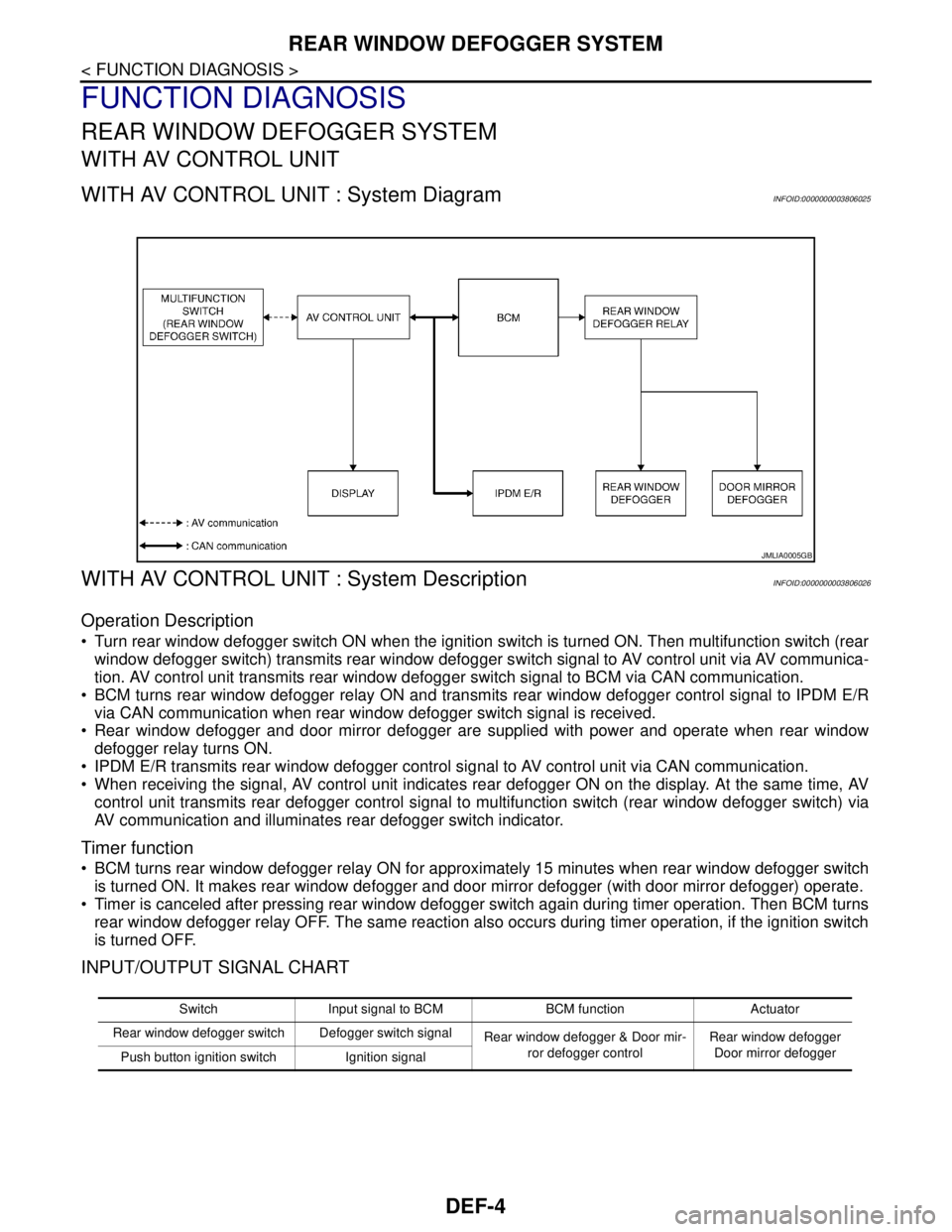

< FUNCTION DIAGNOSIS >

REAR WINDOW DEFOGGER SYSTEM

FUNCTION DIAGNOSIS

REAR WINDOW DEFOGGER SYSTEM

WITH AV CONTROL UNIT

WITH AV CONTROL UNIT : System DiagramINFOID:0000000003806025

WITH AV CONTROL UNIT : System DescriptionINFOID:0000000003806026

Operation Description

Turn rear window defogger switch ON when the ignition switch is turned ON. Then multifunction switch (rear

window defogger switch) transmits rear window defogger switch signal to AV control unit via AV communica-

tion. AV control unit transmits rear window defogger switch signal to BCM via CAN communication.

BCM turns rear window defogger relay ON and transmits rear window defogger control signal to IPDM E/R

via CAN communication when rear window defogger switch signal is received.

Rear window defogger and door mirror defogger are supplied with power and operate when rear window

defogger relay turns ON.

IPDM E/R transmits rear window defogger control signal to AV control unit via CAN communication.

When receiving the signal, AV control unit indicates rear defogger ON on the display. At the same time, AV

control unit transmits rear defogger control signal to multifunction switch (rear window defogger switch) via

AV communication and illuminates rear defogger switch indicator.

Timer function

BCM turns rear window defogger relay ON for approximately 15 minutes when rear window defogger switch

is turned ON. It makes rear window defogger and door mirror defogger (with door mirror defogger) operate.

Timer is canceled after pressing rear window defogger switch again during timer operation. Then BCM turns

rear window defogger relay OFF. The same reaction also occurs during timer operation, if the ignition switch

is turned OFF.

INPUT/OUTPUT SIGNAL CHART

JMLIA0005GB

Switch Input signal to BCM BCM function Actuator

Rear window defogger switch Defogger switch signal

Rear window defogger & Door mir-

ror defogger controlRear window defogger

Door mirror defogger

Push button ignition switch Ignition signal

Page 1156 of 5121

DEF-6

< FUNCTION DIAGNOSIS >

REAR WINDOW DEFOGGER SYSTEM

WITHOUT AV CONTROL UNIT

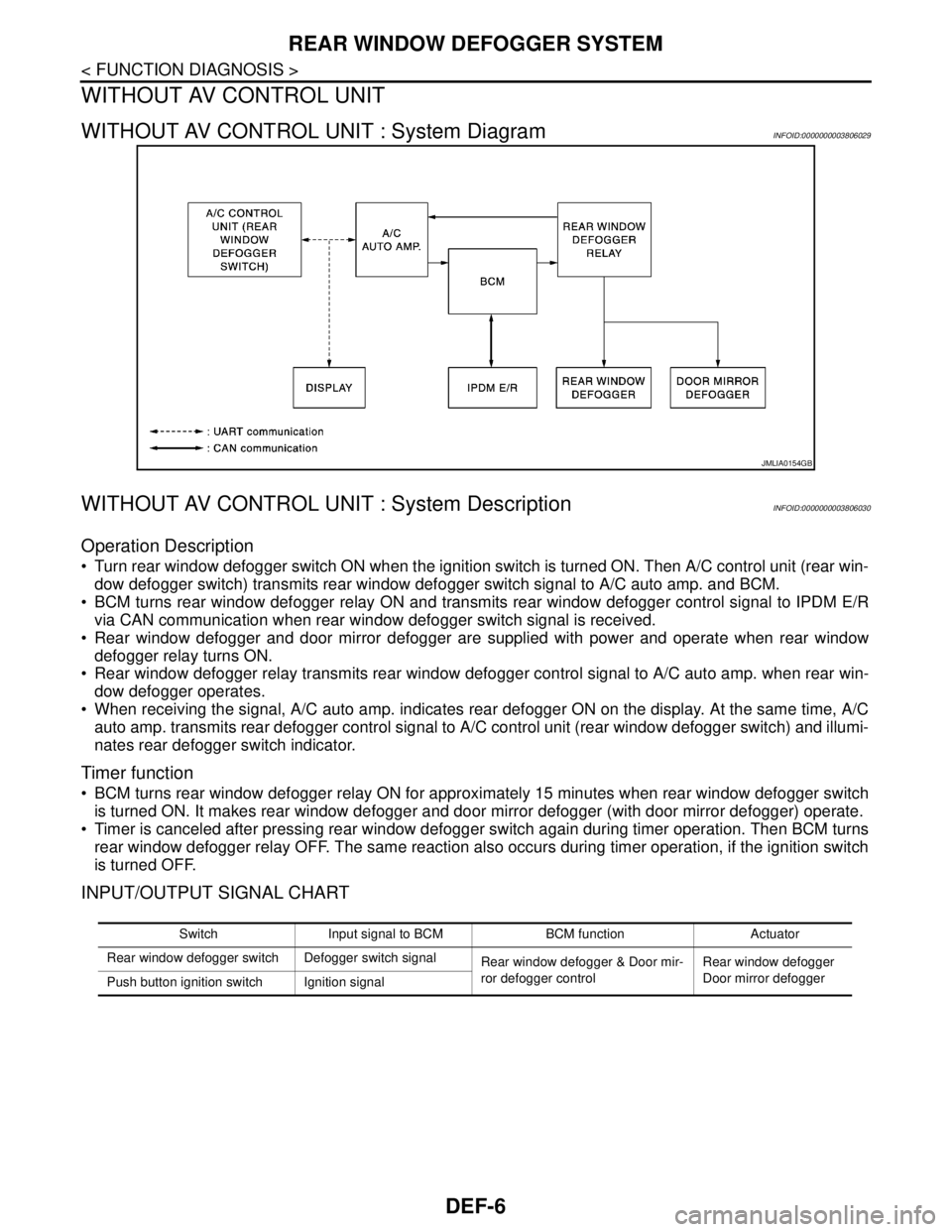

WITHOUT AV CONTROL UNIT : System DiagramINFOID:0000000003806029

WITHOUT AV CONTROL UNIT : System DescriptionINFOID:0000000003806030

Operation Description

Turn rear window defogger switch ON when the ignition switch is turned ON. Then A/C control unit (rear win-

dow defogger switch) transmits rear window defogger switch signal to A/C auto amp. and BCM.

BCM turns rear window defogger relay ON and transmits rear window defogger control signal to IPDM E/R

via CAN communication when rear window defogger switch signal is received.

Rear window defogger and door mirror defogger are supplied with power and operate when rear window

defogger relay turns ON.

Rear window defogger relay transmits rear window defogger control signal to A/C auto amp. when rear win-

dow defogger operates.

When receiving the signal, A/C auto amp. indicates rear defogger ON on the display. At the same time, A/C

auto amp. transmits rear defogger control signal to A/C control unit (rear window defogger switch) and illumi-

nates rear defogger switch indicator.

Timer function

BCM turns rear window defogger relay ON for approximately 15 minutes when rear window defogger switch

is turned ON. It makes rear window defogger and door mirror defogger (with door mirror defogger) operate.

Timer is canceled after pressing rear window defogger switch again during timer operation. Then BCM turns

rear window defogger relay OFF. The same reaction also occurs during timer operation, if the ignition switch

is turned OFF.

INPUT/OUTPUT SIGNAL CHART

JMLIA0154GB

Switch Input signal to BCM BCM function Actuator

Rear window defogger switch Defogger switch signal

Rear window defogger & Door mir-

ror defogger controlRear window defogger

Door mirror defogger

Push button ignition switch Ignition signal

Page 1159 of 5121

DIAGNOSIS SYSTEM (BCM)

DEF-9

< FUNCTION DIAGNOSIS >

C

D

E

F

G

H

I

J

K

MA

B

DEF

N

O

P

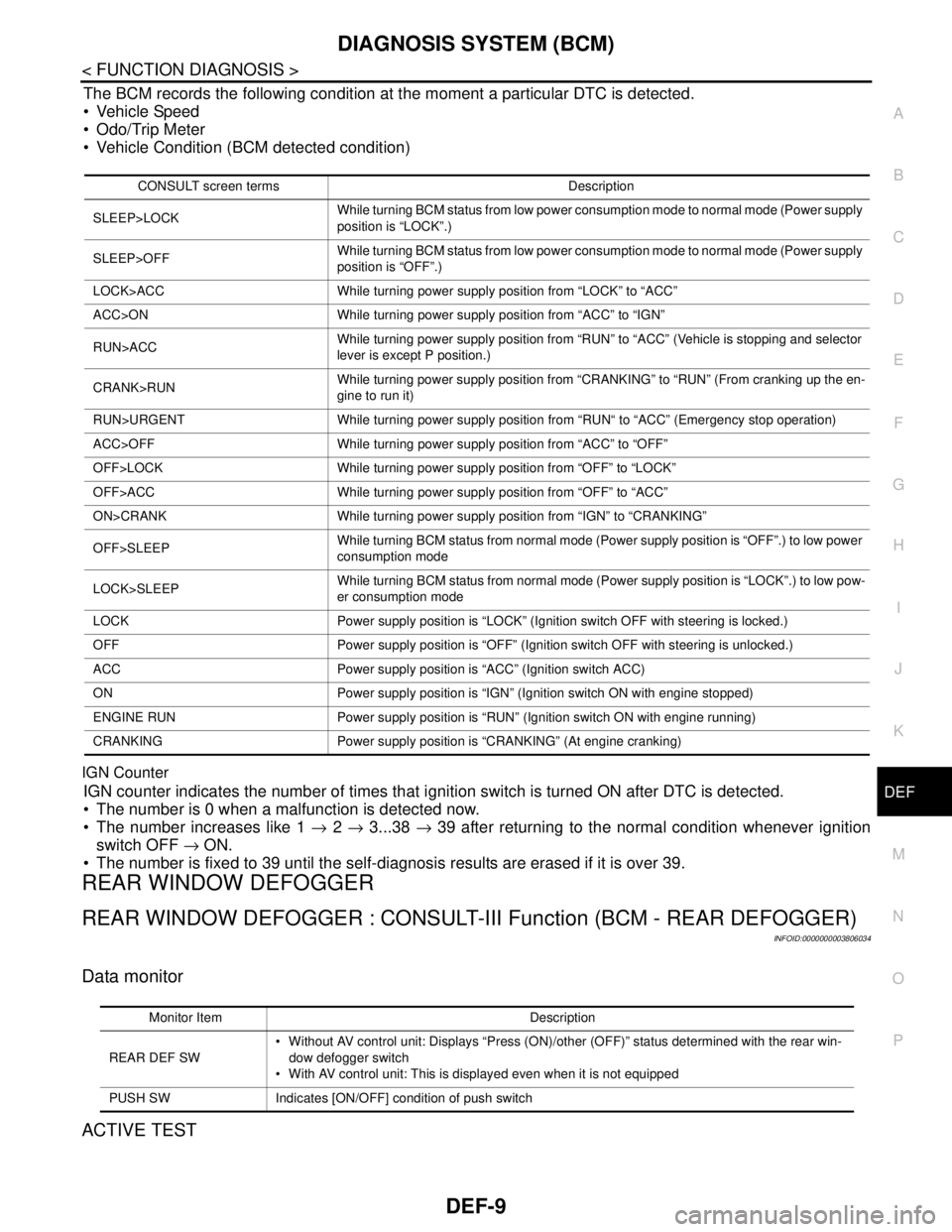

The BCM records the following condition at the moment a particular DTC is detected.

Vehicle Speed

Odo/Trip Meter

Vehicle Condition (BCM detected condition)

IGN Counter

IGN counter indicates the number of times that ignition switch is turned ON after DTC is detected.

The number is 0 when a malfunction is detected now.

The number increases like 1 → 2 → 3...38 → 39 after returning to the normal condition whenever ignition

switch OFF → ON.

The number is fixed to 39 until the self-diagnosis results are erased if it is over 39.

REAR WINDOW DEFOGGER

REAR WINDOW DEFOGGER : CONSULT-III Function (BCM - REAR DEFOGGER)

INFOID:0000000003806034

Data monitor

ACTIVE TEST

CONSULT screen terms Description

SLEEP>LOCKWhile turning BCM status from low power consumption mode to normal mode (Power supply

position is “LOCK”.)

SLEEP>OFFWhile turning BCM status from low power consumption mode to normal mode (Power supply

position is “OFF”.)

LOCK>ACC While turning power supply position from “LOCK” to “ACC”

ACC>ON While turning power supply position from “ACC” to “IGN”

RUN>ACCWhile turning power supply position from “RUN” to “ACC” (Vehicle is stopping and selector

lever is except P position.)

CRANK>RUNWhile turning power supply position from “CRANKING” to “RUN” (From cranking up the en-

gine to run it)

RUN>URGENT While turning power supply position from “RUN“ to “ACC” (Emergency stop operation)

ACC>OFF While turning power supply position from “ACC” to “OFF”

OFF>LOCK While turning power supply position from “OFF” to “LOCK”

OFF>ACC While turning power supply position from “OFF” to “ACC”

ON>CRANK While turning power supply position from “IGN” to “CRANKING”

OFF>SLEEPWhile turning BCM status from normal mode (Power supply position is “OFF”.) to low power

consumption mode

LOCK>SLEEPWhile turning BCM status from normal mode (Power supply position is “LOCK”.) to low pow-

er consumption mode

LOCK Power supply position is “LOCK” (Ignition switch OFF with steering is locked.)

OFF Power supply position is “OFF” (Ignition switch OFF with steering is unlocked.)

ACC Power supply position is “ACC” (Ignition switch ACC)

ON Power supply position is “IGN” (Ignition switch ON with engine stopped)

ENGINE RUN Power supply position is “RUN” (Ignition switch ON with engine running)

CRANKING Power supply position is “CRANKING” (At engine cranking)

Monitor Item Description

REAR DEF SW Without AV control unit: Displays “Press (ON)/other (OFF)” status determined with the rear win-

dow defogger switch

With AV control unit: This is displayed even when it is not equipped

PUSH SW Indicates [ON/OFF] condition of push switch