warning NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 5024 of 5121

WW-12

< FUNCTION DIAGNOSIS >

DIAGNOSIS SYSTEM (BCM)

DIAGNOSIS SYSTEM (BCM)

COMMON ITEM

COMMON ITEM : CONSULT-III Function (BCM - COMMON ITEM)INFOID:0000000003941291

APPLICATION ITEM

CONSULT-III performs the following functions via CAN communication with BCM.

SYSTEM APPLICATION

BCM can perform the following functions for each system.

NOTE:

It can perform the diagnosis modes except the following for all sub system selection items.

×: Applicable item

NOTE:

*: This item is displayed, but is not used.

FREEZE FRAME DATA (FFD) AND IGN COUNTER

Freeze Frame Data

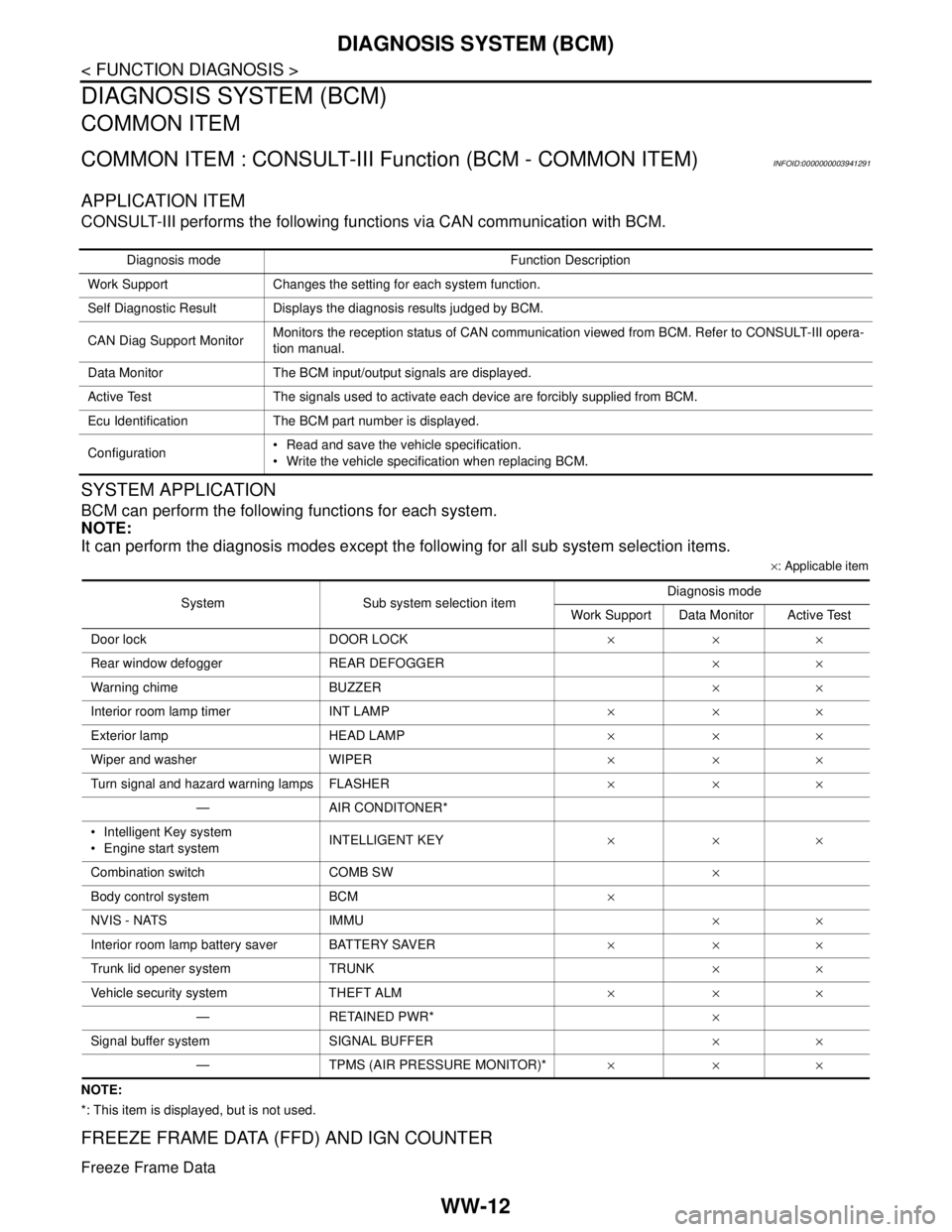

Diagnosis mode Function Description

Work Support Changes the setting for each system function.

Self Diagnostic Result Displays the diagnosis results judged by BCM.

CAN Diag Support MonitorMonitors the reception status of CAN communication viewed from BCM. Refer to CONSULT-III opera-

tion manual.

Data Monitor The BCM input/output signals are displayed.

Active Test The signals used to activate each device are forcibly supplied from BCM.

Ecu Identification The BCM part number is displayed.

Configuration Read and save the vehicle specification.

Write the vehicle specification when replacing BCM.

System Sub system selection itemDiagnosis mode

Work Support Data Monitor Active Test

Door lock DOOR LOCK×××

Rear window defogger REAR DEFOGGER××

Warning chime BUZZER××

Interior room lamp timer INT LAMP×××

Exterior lamp HEAD LAMP×××

Wiper and washer WIPER×××

Turn signal and hazard warning lamps FLASHER×××

— AIR CONDITONER*

Intelligent Key system

Engine start systemINTELLIGENT KEY×××

Combination switch COMB SW×

Body control system BCM×

NVIS - NATS IMMU××

Interior room lamp battery saver BATTERY SAVER×××

Trunk lid opener system TRUNK××

Vehicle security system THEFT ALM×××

— RETAINED PWR*×

Signal buffer system SIGNAL BUFFER××

— TPMS (AIR PRESSURE MONITOR)*×××

Page 5027 of 5121

DIAGNOSIS SYSTEM (IPDM E/R)

WW-15

< FUNCTION DIAGNOSIS >

C

D

E

F

G

H

I

J

K

MA

B

WW

N

O

P

DIAGNOSIS SYSTEM (IPDM E/R)

Diagnosis DescriptionINFOID:0000000003941292

AUTO ACTIVE TEST

Description

In auto active test mode, the IPDM E/R sends a drive signal to the following systems to check their operation.

Oil pressure warning lamp

Front wiper (LO, HI)

Parking lamps

License plate lamps

Tail lamps

Front fog lamps

Headlamps (LO, HI)

A/C compressor (magnet clutch)

Cooling fan

Operation Procedure

1. Close the hood and lift the wiper arms from the windshield. (Prevent windshield damage due to wiper

operation)

NOTE:

When auto active test is performed with hood opened, sprinkle water on windshield beforehand.

2. Turn ignition switch OFF.

3. Turn the ignition switch ON, and within 20 seconds, press the driver door switch 10 times. Then turn the

ignition switch OFF.

CAUTION:

Close passenger door.

4. Turn the ignition switch ON within 10 seconds. After that the horn sounds once and the auto active test

starts.

5. The oil pressure warning lamp starts blinking when the auto active test starts.

6. After a series of the following operations is repeated 3 times, auto active test is completed.

NOTE:

When auto active test mode has to be cancelled halfway through test, turn ignition switch OFF.

CAUTION:

• If auto active test mode cannot be actuated, check door switch system. Refer to DLK-57,

"ComponentFunctionCheck".

Do not start the engine.

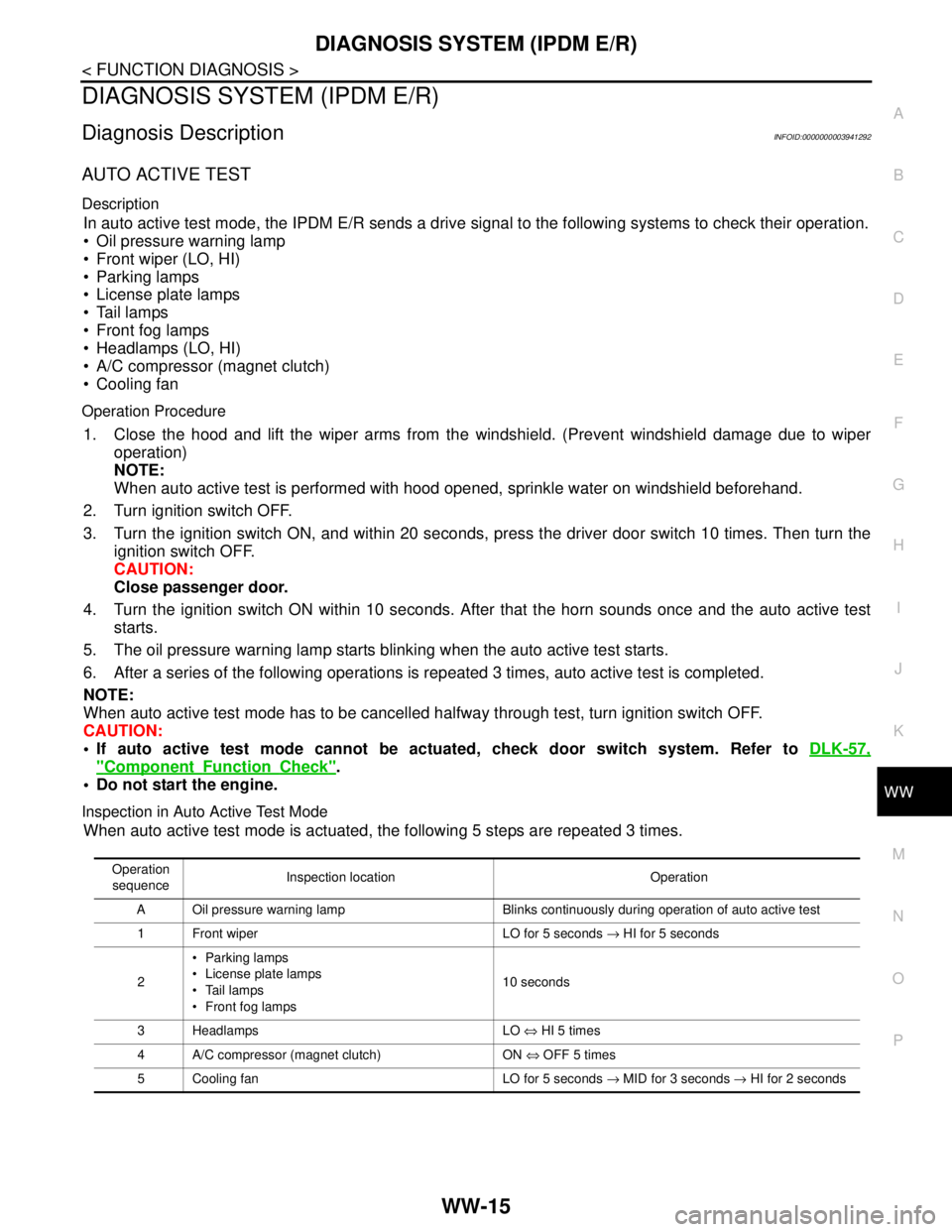

Inspection in Auto Active Test Mode

When auto active test mode is actuated, the following 5 steps are repeated 3 times.

Operation

sequenceInspection location Operation

A Oil pressure warning lamp Blinks continuously during operation of auto active test

1 Front wiper LO for 5 seconds → HI for 5 seconds

2Parking lamps

License plate lamps

Tail lamps

Front fog lamps10 seconds

3 Headlamps LO ⇔ HI 5 times

4 A/C compressor (magnet clutch) ON ⇔ OFF 5 times

5 Cooling fan LO for 5 seconds → MID for 3 seconds → HI for 2 seconds

Page 5028 of 5121

WW-16

< FUNCTION DIAGNOSIS >

DIAGNOSIS SYSTEM (IPDM E/R)

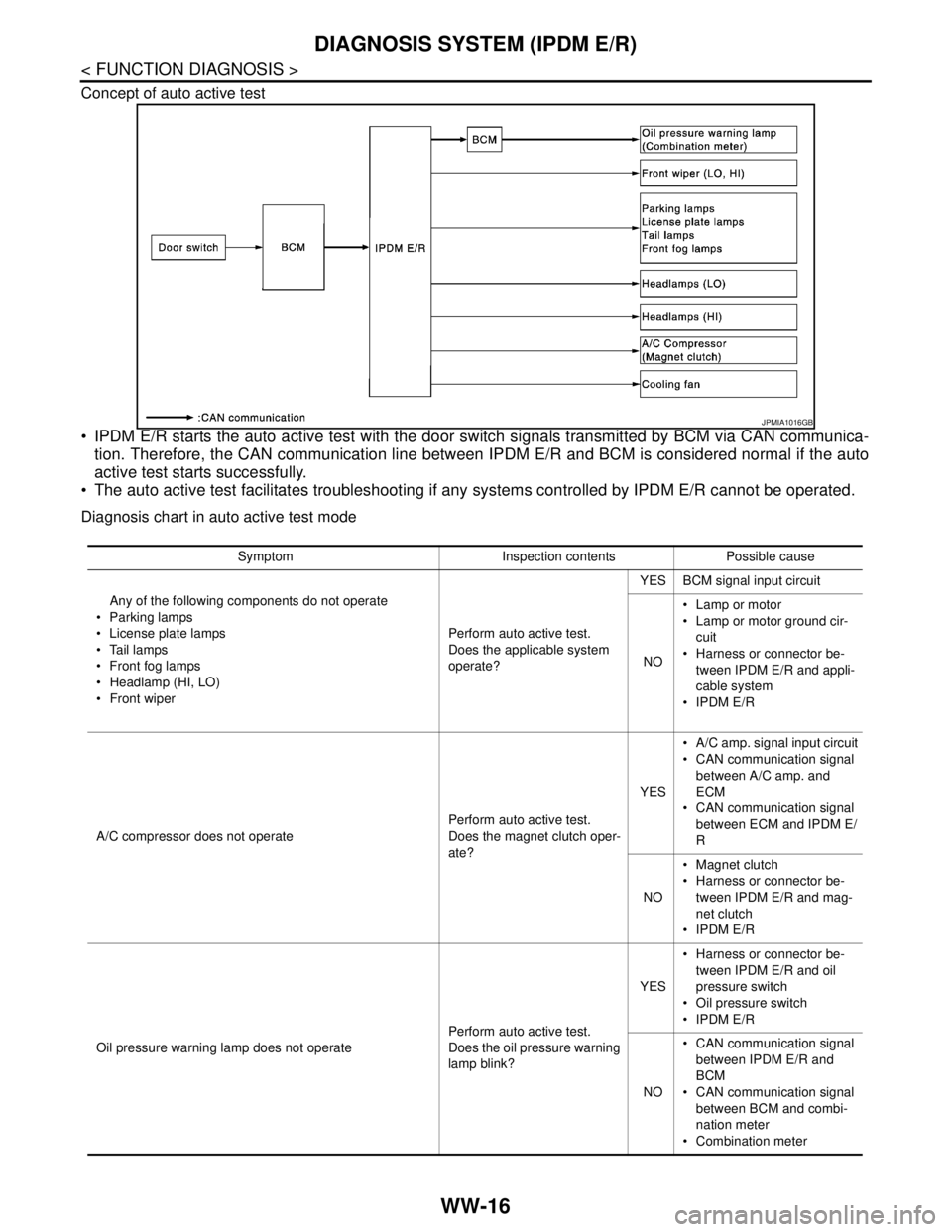

Concept of auto active test

IPDM E/R starts the auto active test with the door switch signals transmitted by BCM via CAN communica-

tion. Therefore, the CAN communication line between IPDM E/R and BCM is considered normal if the auto

active test starts successfully.

The auto active test facilitates troubleshooting if any systems controlled by IPDM E/R cannot be operated.

Diagnosis chart in auto active test mode

JPMIA1016GB

Symptom Inspection contents Possible cause

Any of the following components do not operate

Parking lamps

License plate lamps

Tail lamps

Front fog lamps

Headlamp (HI, LO)

Front wiperPerform auto active test.

Does the applicable system

operate?YES BCM signal input circuit

NO Lamp or motor

Lamp or motor ground cir-

cuit

Harness or connector be-

tween IPDM E/R and appli-

cable system

IPDM E/R

A/C compressor does not operatePerform auto active test.

Does the magnet clutch oper-

ate?YES A/C amp. signal input circuit

CAN communication signal

between A/C amp. and

ECM

CAN communication signal

between ECM and IPDM E/

R

NO Magnet clutch

Harness or connector be-

tween IPDM E/R and mag-

net clutch

IPDM E/R

Oil pressure warning lamp does not operatePerform auto active test.

Does the oil pressure warning

lamp blink?YES Harness or connector be-

tween IPDM E/R and oil

pressure switch

Oil pressure switch

IPDM E/R

NO CAN communication signal

between IPDM E/R and

BCM

CAN communication signal

between BCM and combi-

nation meter

Combination meter

Page 5030 of 5121

![NISSAN TEANA 2008 Service Manual WW-18

< FUNCTION DIAGNOSIS >

DIAGNOSIS SYSTEM (IPDM E/R)

ACTIVE TEST

Te s t i t e m

IGN RLY

[Off/On]×Displays the status of the ignition relay judged by IPDM E/R.

PUSH SW

[Off/On]Displays the status NISSAN TEANA 2008 Service Manual WW-18

< FUNCTION DIAGNOSIS >

DIAGNOSIS SYSTEM (IPDM E/R)

ACTIVE TEST

Te s t i t e m

IGN RLY

[Off/On]×Displays the status of the ignition relay judged by IPDM E/R.

PUSH SW

[Off/On]Displays the status](/img/5/57391/w960_57391-5029.png)

WW-18

< FUNCTION DIAGNOSIS >

DIAGNOSIS SYSTEM (IPDM E/R)

ACTIVE TEST

Te s t i t e m

IGN RLY

[Off/On]×Displays the status of the ignition relay judged by IPDM E/R.

PUSH SW

[Off/On]Displays the status of the push-button ignition switch judged by IPDM E/R.

INTER/NP SW

[Off/On]Displays the status of the shift position judged by IPDM E/R.

ST RLY CONT

[Off/On]Displays the status of the starter relay status signal received from BCM via CAN

communication.

IHBT RLY -REQ

[Off/On]Displays the status of the starter control relay signal received from BCM via CAN

communication.

ST/INHI RLY

[Off/ ST /INHI/UNKWN]Displays the status of the starter relay and starter control relay judged by IPDM

E/R.

DETENT SW

[Off/On]Displays the status of the control device (detention switch) judged by IPDM E/R.

S/L RLY -REQ

[Off/On]Displays the status of the steering lock relay signal received from BCM via CAN

communication.

S/L STATE

[LOCK/UNLOCK/UNKWN]Displays the status of the steering lock judged by IPDM E/R.

DTRL REQ

[Off]NOTE:

The item is indicated, but not monitored.

OIL P SW

[Open/Close]Displays the status of the oil pressure switch judged by IPDM E/R.

HOOD SW

[Off/On]Displays the status of the hood switch judged by IPDM E/R.

HL WASHER REQ

[Off]Display the status of the headlamp washer request signal received from BCM via

CAN communication.

THFT HRN REQ

[Off/On]Displays the status of the theft warning horn request signal received from BCM

via CAN communication.

HORN CHIRP

[Off/On]Displays the status of the horn reminder signal received from BCM via CAN com-

munication.

CRNRNG LMP REQ

[Off]NOTE:

The item is indicated, but not monitored. Monitor Item

[Unit]MAIN SIG-

NALSDescription

Test item Operation Description

CORNERING LAMPOff

NOTE:

The item is indicated, but cannot be tested. LH

RH

HORN On Operates horn relay for 20 ms.

FRONT WIPEROff OFF

Lo Operates the front wiper relay.

Hi Operates the front wiper relay and front wiper high relay.

MOTOR FAN1OFF

2 Operates the cooling fan relay-1.

3 Operates the cooling fan relay-2.

4 Operates the cooling fan relay-2 and cooling fan relay-3.

HEAD LAMP WASHER On Operates the headlamp washer relay for 1 s.

Page 5085 of 5121

BCM (BODY CONTROL MODULE)

WW-73

< ECU DIAGNOSIS >

C

D

E

F

G

H

I

J

K

MA

B

WW

N

O

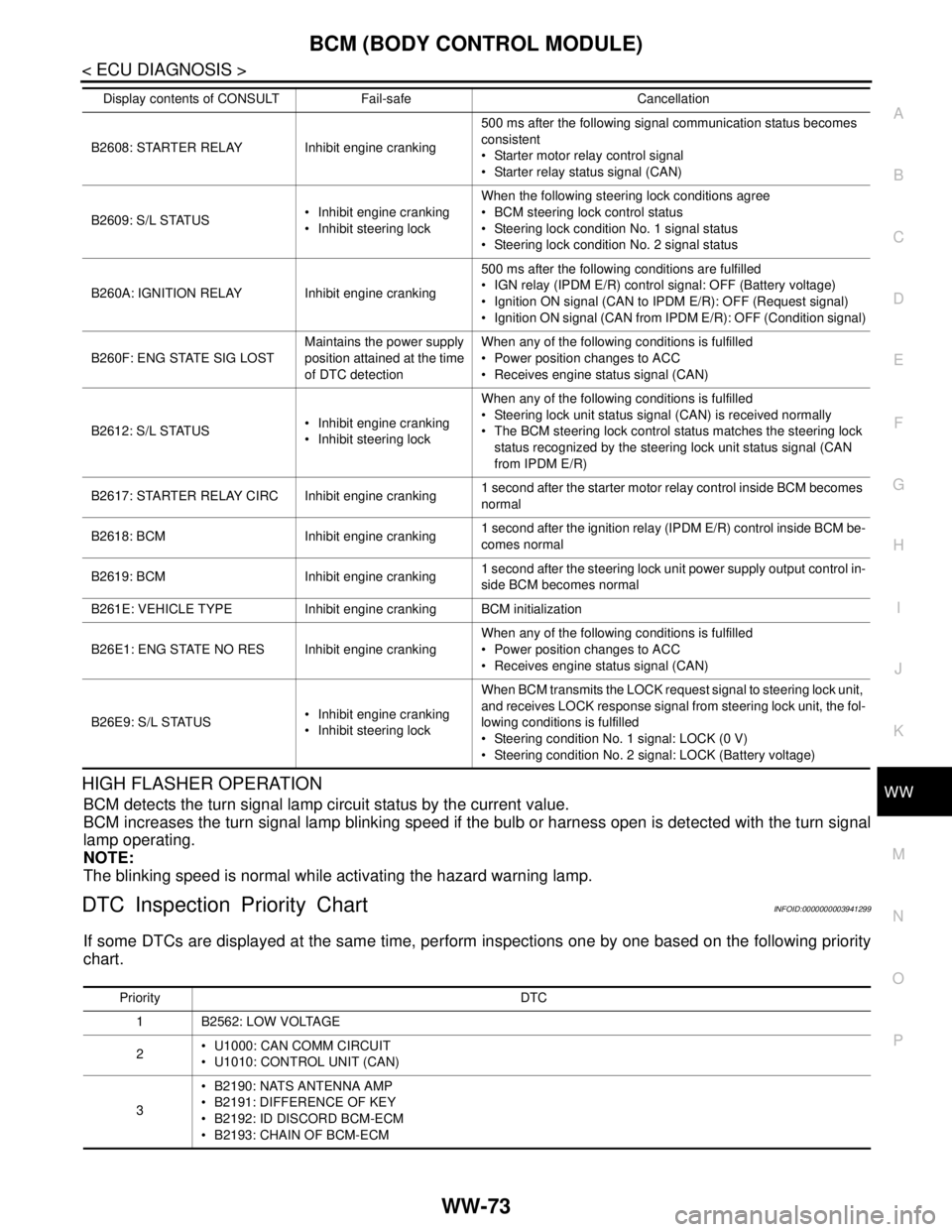

PHIGH FLASHER OPERATION

BCM detects the turn signal lamp circuit status by the current value.

BCM increases the turn signal lamp blinking speed if the bulb or harness open is detected with the turn signal

lamp operating.

NOTE:

The blinking speed is normal while activating the hazard warning lamp.

DTC Inspection Priority ChartINFOID:0000000003941299

If some DTCs are displayed at the same time, perform inspections one by one based on the following priority

chart.

B2608: STARTER RELAY Inhibit engine cranking500 ms after the following signal communication status becomes

consistent

Starter motor relay control signal

Starter relay status signal (CAN)

B2609: S/L STATUS Inhibit engine cranking

Inhibit steering lockWhen the following steering lock conditions agree

BCM steering lock control status

Steering lock condition No. 1 signal status

Steering lock condition No. 2 signal status

B260A: IGNITION RELAY Inhibit engine cranking500 ms after the following conditions are fulfilled

IGN relay (IPDM E/R) control signal: OFF (Battery voltage)

Ignition ON signal (CAN to IPDM E/R): OFF (Request signal)

Ignition ON signal (CAN from IPDM E/R): OFF (Condition signal)

B260F: ENG STATE SIG LOSTMaintains the power supply

position attained at the time

of DTC detectionWhen any of the following conditions is fulfilled

Power position changes to ACC

Receives engine status signal (CAN)

B2612: S/L STATUS Inhibit engine cranking

Inhibit steering lockWhen any of the following conditions is fulfilled

Steering lock unit status signal (CAN) is received normally

The BCM steering lock control status matches the steering lock

status recognized by the steering lock unit status signal (CAN

from IPDM E/R)

B2617: STARTER RELAY CIRC Inhibit engine cranking1 second after the starter motor relay control inside BCM becomes

normal

B2618: BCM Inhibit engine cranking1 second after the ignition relay (IPDM E/R) control inside BCM be-

comes normal

B2619: BCM Inhibit engine cranking1 second after the steering lock unit power supply output control in-

side BCM becomes normal

B261E: VEHICLE TYPE Inhibit engine cranking BCM initialization

B26E1: ENG STATE NO RES Inhibit engine crankingWhen any of the following conditions is fulfilled

Power position changes to ACC

Receives engine status signal (CAN)

B26E9: S/L STATUS Inhibit engine cranking

Inhibit steering lockWhen BCM transmits the LOCK request signal to steering lock unit,

and receives LOCK response signal from steering lock unit, the fol-

lowing conditions is fulfilled

Steering condition No. 1 signal: LOCK (0 V)

Steering condition No. 2 signal: LOCK (Battery voltage) Display contents of CONSULT Fail-safe Cancellation

Priority DTC

1 B2562: LOW VOLTAGE

2 U1000: CAN COMM CIRCUIT

U1010: CONTROL UNIT (CAN)

3 B2190: NATS ANTENNA AMP

B2191: DIFFERENCE OF KEY

B2192: ID DISCORD BCM-ECM

B2193: CHAIN OF BCM-ECM

Page 5089 of 5121

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

WW-77

< ECU DIAGNOSIS >

C

D

E

F

G

H

I

J

K

MA

B

WW

N

O

P

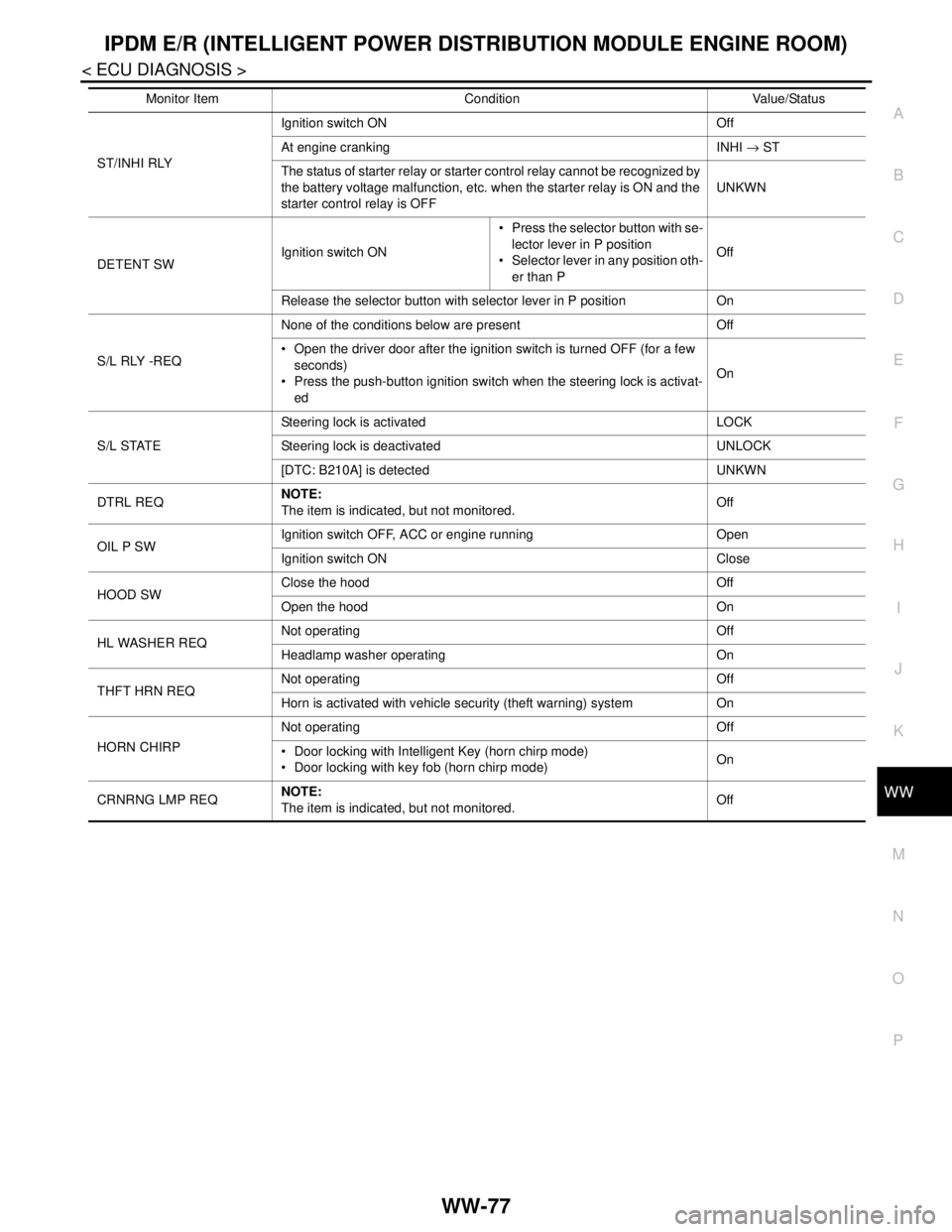

ST/INHI RLYIgnition switch ON Off

At engine cranking INHI → ST

The status of starter relay or starter control relay cannot be recognized by

the battery voltage malfunction, etc. when the starter relay is ON and the

starter control relay is OFFUNKWN

DETENT SWIgnition switch ON Press the selector button with se-

lector lever in P position

Selector lever in any position oth-

er than POff

Release the selector button with selector lever in P position On

S/L RLY -REQNone of the conditions below are present Off

Open the driver door after the ignition switch is turned OFF (for a few

seconds)

Press the push-button ignition switch when the steering lock is activat-

edOn

S/L STATESteering lock is activated LOCK

Steering lock is deactivated UNLOCK

[DTC: B210A] is detected UNKWN

DTRL REQNOTE:

The item is indicated, but not monitored.Off

OIL P SWIgnition switch OFF, ACC or engine running Open

Ignition switch ON Close

HOOD SWClose the hood Off

Open the hood On

HL WASHER REQNot operating Off

Headlamp washer operating On

THFT HRN REQNot operating Off

Horn is activated with vehicle security (theft warning) system On

HORN CHIRPNot operating Off

Door locking with Intelligent Key (horn chirp mode)

Door locking with key fob (horn chirp mode)On

CRNRNG LMP REQNOTE:

The item is indicated, but not monitored.Off Monitor Item Condition Value/Status

Page 5108 of 5121

WW-96

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000003761618

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SRS AIRBAG” and “SEAT BELT” of this

Service Manual.

WARNING:

To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SRS AIRBAG”.

Never use electrical test equipment on any circuit related to the SRS unless instructed to in this Ser-

vice Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or harness

connectors.

Precaution for Procedure without Cowl Top CoverINFOID:0000000003761619

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

PIIB3706J