fuel consumption NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 192 of 5121

![NISSAN TEANA 2008 Service Manual AV-48

< FUNCTION DIAGNOSIS >[BASE AUDIO AND DISPLAY SYSTEM]

MULTI AV SYSTEM

FUNCTION DIAGNOSIS

MULTI AV SYSTEM

System DiagramINFOID:0000000003882699

NOTE:

The name MULTIFUNCTION SWITCH indicates the NISSAN TEANA 2008 Service Manual AV-48

< FUNCTION DIAGNOSIS >[BASE AUDIO AND DISPLAY SYSTEM]

MULTI AV SYSTEM

FUNCTION DIAGNOSIS

MULTI AV SYSTEM

System DiagramINFOID:0000000003882699

NOTE:

The name MULTIFUNCTION SWITCH indicates the](/img/5/57391/w960_57391-191.png)

AV-48

< FUNCTION DIAGNOSIS >[BASE AUDIO AND DISPLAY SYSTEM]

MULTI AV SYSTEM

FUNCTION DIAGNOSIS

MULTI AV SYSTEM

System DiagramINFOID:0000000003882699

NOTE:

The name MULTIFUNCTION SWITCH indicates the integration of PRESET SWITCH and MULTIFUNCTION

SWITCH virtually.

A radio antenna base integrated with radio antenna amp. is adopted.

Woofer illustrated in the above figure, integrates two woofers and a woofer amp.

System DescriptionINFOID:0000000003882700

Multi AV system means that the following systems are integrated.

AV control unit controls by transmitting/receiving data one by one with each unit (slave unit) that configures

them completely as a master unit by connecting between units that configure MULTI AV system with two AV

communication lines (H, L).

Two AV communication lines (H, L) adopt a twisted pair line that is resistant to noise.

AV control unit is connected by CAN communication, and it receives data signal from ECM, combination

meter. It computes and displays fuel economy information value with the obtained information. Transmitting/

receiving of data signal is performed by BCM. Also, it transmits the required signal of vehicle setting and

receives the response signal.

JSNIA1431GB

System name System explanation

AUDIO SYSTEMAV- 5 3 , "

System Diagram"

REAR VIEW MONITOR SYSTEMAV- 5 6 , "System Description"

VEHICLE INFORMATION SYSTEM Status of audio, climate control system, fuel economy, mainte-

nance and navigation is displayed.

AV control unit displays the fuel consumption status while re-

ceiving data signal through CAN communication from ECM and

combination meter.

AV control unit is connected to BCM via CAN communication

transmitting/receiving for the vehicle settings function.

AUXILIARY INPUT SYSTEM Refer to “AUXILIARY INPUT SYSTEM” shown below.

Page 332 of 5121

![NISSAN TEANA 2008 Service Manual AV-188

< FUNCTION DIAGNOSIS >[BOSE AUDIO WITHOUT NAVIGATION]

MULTI AV SYSTEM

FUNCTION DIAGNOSIS

MULTI AV SYSTEM

System DiagramINFOID:0000000003765641

NOTE:

The name MULTIFUNCTION SWITCH indicates th NISSAN TEANA 2008 Service Manual AV-188

< FUNCTION DIAGNOSIS >[BOSE AUDIO WITHOUT NAVIGATION]

MULTI AV SYSTEM

FUNCTION DIAGNOSIS

MULTI AV SYSTEM

System DiagramINFOID:0000000003765641

NOTE:

The name MULTIFUNCTION SWITCH indicates th](/img/5/57391/w960_57391-331.png)

AV-188

< FUNCTION DIAGNOSIS >[BOSE AUDIO WITHOUT NAVIGATION]

MULTI AV SYSTEM

FUNCTION DIAGNOSIS

MULTI AV SYSTEM

System DiagramINFOID:0000000003765641

NOTE:

The name MULTIFUNCTION SWITCH indicates the integration of PRESET SWITCH and MULTIFUNCTION

SWITCH virtually.

A radio antenna base integrated with radio antenna amp. is adopted.

Woofer illustrated in the above figure, integrates two woofers and a woofer amp.

System DescriptionINFOID:0000000003791244

Multi AV system means that the following systems are integrated.

AV control unit controls by transmitting/receiving data one by one with each unit (slave unit) that configures

them completely as a master unit by connecting between units that configure MULTI AV system with two AV

communication lines (H, L).

JSNIA1296GB

System name System explanation

AUDIO SYSTEMAV- 1 9 3 , "

System Diagram"

REAR VIEW MONITOR SYSTEMAV- 1 9 6 , "System Description"

VEHICLE INFORMATION SYSTEM Status of audio, climate control system, fuel economy, mainte-

nance and navigation is displayed.

AV control unit displays the fuel consumption status while re-

ceiving data signal through CAN communication from ECM and

combination meter.

AV control unit is connected to BCM via CAN communication

transmitting/receiving for the vehicle settings function.

DVD ENTERTAINMENT SYSTEM Refer to the following “DVD ENTERTAINMENT SYSTEM”.

AUXILIARY INPUT SYSTEM Refer to “AUXILIARY INPUT SYSTEM” shown below.

Page 545 of 5121

![NISSAN TEANA 2008 Service Manual AV

MULTI AV SYSTEM

AV-401

< FUNCTION DIAGNOSIS >[BOSE AUDIO WITH NAVIGATION]

C

D

E

F

G

H

I

J

K

L

MB A

O

P

FUNCTION DIAGNOSIS

MULTI AV SYSTEM

System DiagramINFOID:0000000003765827

NOTE:

The name MULTIF NISSAN TEANA 2008 Service Manual AV

MULTI AV SYSTEM

AV-401

< FUNCTION DIAGNOSIS >[BOSE AUDIO WITH NAVIGATION]

C

D

E

F

G

H

I

J

K

L

MB A

O

P

FUNCTION DIAGNOSIS

MULTI AV SYSTEM

System DiagramINFOID:0000000003765827

NOTE:

The name MULTIF](/img/5/57391/w960_57391-544.png)

AV

MULTI AV SYSTEM

AV-401

< FUNCTION DIAGNOSIS >[BOSE AUDIO WITH NAVIGATION]

C

D

E

F

G

H

I

J

K

L

MB A

O

P

FUNCTION DIAGNOSIS

MULTI AV SYSTEM

System DiagramINFOID:0000000003765827

NOTE:

The name MULTIFUNCTION SWITCH indicates the integration of PRESET SWITCH and MULTIFUNCTION

SWITCH virtually.

System DescriptionINFOID:0000000003765828

Multi AV system means that the following systems are integrated.

AV control unit controls by transmitting/receiving data one by one with each unit (slave unit) that configures

them completely as a master unit by connecting between units that configure MULTI AV system with two AV

communication lines (H, L).

Two AV communication lines (H, L) adopt a twisted pair line that is resistant to noise.

JSNIA1297GB

System name System explanation

NAVIGATION SYSTEMAV- 4 1 0 , "

System Description"

AUDIO SYSTEMAV- 4 0 7 , "System Diagram"

REAR VIEW MONITOR SYSTEMAV- 4 1 5 , "System Description"

VEHICLE INFORMATION SYSTEM Status of audio, climate control system, fuel economy, mainte-

nance and navigation is displayed.

AV control unit displays the fuel consumption status while re-

ceiving data signal through CAN communication from ECM and

combination meter.

AV control unit is connected to BCM via CAN communication

transmitting/receiving for the vehicle settings function.

HANDS-FREE PHONE SYSTEM Refer to the following “HANDS-FREE PHONE SYSTEM”.

DVD ENTERTAINMENT SYSTEM Refer to the following “DVD ENTERTAINMENT SYSTEM”.

AUXILIARY INPUT SYSTEM Refer to “AUXILIARY INPUT SYSTEM” shown below.

TOUCH PANEL SYSTEM Refer to the following “TOUCH PANEL SYSTEM”.

Page 1105 of 5121

CHG

POWER GENERATION VOLTAGE VARIABLE CONTROL SYSTEM

CHG-7

< FUNCTION DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L B A

O

P N

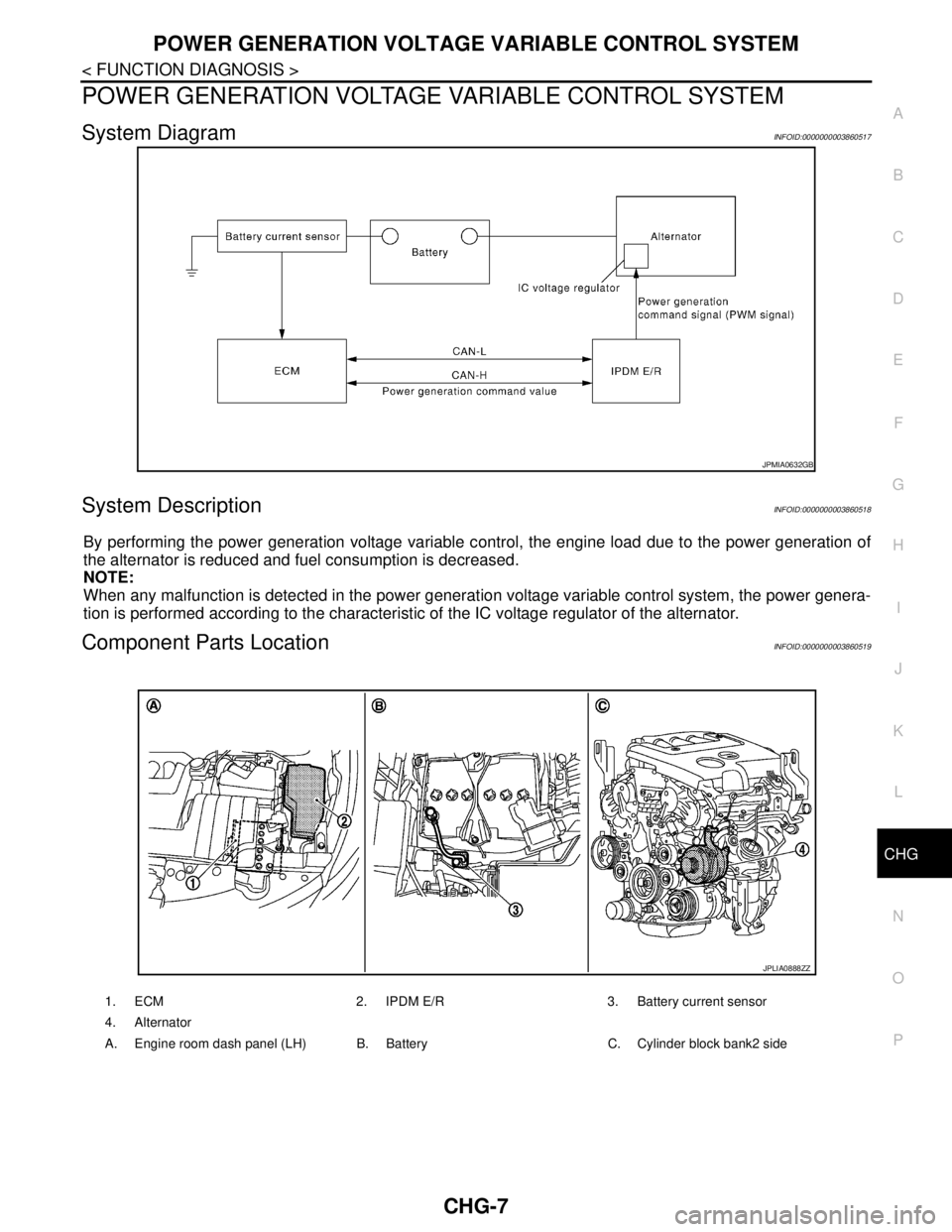

POWER GENERATION VOLTAGE VARIABLE CONTROL SYSTEM

System DiagramINFOID:0000000003860517

System DescriptionINFOID:0000000003860518

By performing the power generation voltage variable control, the engine load due to the power generation of

the alternator is reduced and fuel consumption is decreased.

NOTE:

When any malfunction is detected in the power generation voltage variable control system, the power genera-

tion is performed according to the characteristic of the IC voltage regulator of the alternator.

Component Parts LocationINFOID:0000000003860519

JPMIA0632GB

1. ECM 2. IPDM E/R 3. Battery current sensor

4. Alternator

A. Engine room dash panel (LH) B. Battery C. Cylinder block bank2 side

JPLIA0888ZZ

Page 1719 of 5121

![NISSAN TEANA 2008 Service Manual EC-258

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

P1550 BATTERY CURRENT SENSOR

P1550 BATTERY CURRENT SENSOR

DescriptionINFOID:0000000003856732

The power generation voltage variable control enables fuel c NISSAN TEANA 2008 Service Manual EC-258

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

P1550 BATTERY CURRENT SENSOR

P1550 BATTERY CURRENT SENSOR

DescriptionINFOID:0000000003856732

The power generation voltage variable control enables fuel c](/img/5/57391/w960_57391-1718.png)

EC-258

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

P1550 BATTERY CURRENT SENSOR

P1550 BATTERY CURRENT SENSOR

DescriptionINFOID:0000000003856732

The power generation voltage variable control enables fuel consumption to be decreased by reducing the

engine load which is caused by the power generation of the generator. The battery current sensor is installed

to the battery cable at the negative terminal. The sensor measures the charging/discharging current of the bat-

tery. Based on the sensor signal, ECM judges whether or not the power generation voltage variable control is

performed. When performing the power generation voltage variable control, ECM calculates the target power

generation voltage based on the sensor signal. And ECM sends the calculated value as the power generation

command value to IPDM E/R. For the details of the power generation voltage variable control, refer to CHG-5,

"System Description".

CAUTION:

Never connect the electrical component or the ground wire directly to the battery terminal. The con-

nection causes the malfunction of the power generation voltage variable control, and then the battery

discharge may occur.

DTC LogicINFOID:0000000003856733

DTC DETECTION LOGIC

NOTE:

If DTC P1550 is displayed with DTC P0643, first perform the trouble diagnosis for DTC P0643. Refer to

EC-243, "

DTC Logic".

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and at wait

least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 8 V at idle.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

1. Start engine and wait at least 10 seconds.

2. Check 1st trip DTC.

Is 1st trip DTC detected?

YES >> Go to EC-258, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000003856734

1.CHECK GROUND CONNECTION

1. Turn ignition switch OFF.

2. Check ground connection E38. Refer to Ground Inspection in GI-37, "

Circuit Inspection".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace ground connection.

2.CHECK BATTERY CURRENT SENSOR POWER SUPPLY CIRCUIT

1. Disconnect battery current sensor harness connector.

2. Turn ignition switch ON.

3. Check the voltage between battery current sensor harness connector and ground.

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P1550Battery current sensor circuit

range/performanceThe output voltage of the battery current

sensor remains within the specified

range while engine is running. Harness or connectors

(The sensor circuit is open or shorted.)

Battery current sensor

Page 1722 of 5121

![NISSAN TEANA 2008 Service Manual P1551, P1552 BATTERY CURRENT SENSOR

EC-261

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

P1551, P1552 BATTERY CURRENT SENSOR

DescriptionINFOID:0000000003858133

The power gene NISSAN TEANA 2008 Service Manual P1551, P1552 BATTERY CURRENT SENSOR

EC-261

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

P1551, P1552 BATTERY CURRENT SENSOR

DescriptionINFOID:0000000003858133

The power gene](/img/5/57391/w960_57391-1721.png)

P1551, P1552 BATTERY CURRENT SENSOR

EC-261

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

P1551, P1552 BATTERY CURRENT SENSOR

DescriptionINFOID:0000000003858133

The power generation voltage variable control enables fuel consumption to be decreased by reducing the

engine load which is caused by the power generation of the generator. The battery current sensor is installed

to the battery cable at the negative terminal. The sensor measures the charging/discharging current of the bat-

tery. Based on the sensor signal, ECM judges whether or not the power generation voltage variable control is

performed. When performing the power generation voltage variable control, ECM calculates the target power

generation voltage based on the sensor signal. And ECM sends the calculated value as the power generation

command value to IPDM E/R. For the details of the power generation voltage variable control, refer to CHG-5,

"System Description".

CAUTION:

Never connect the electrical component or the ground wire directly to the battery terminal. The con-

nection causes the malfunction of the power generation voltage variable control, and then the battery

discharge may occur.

DTC LogicINFOID:0000000003856737

DTC DETECTION LOGIC

NOTE:

If DTC P1551 or P1552 is displayed with DTC P0643, first perform the trouble diagnosis for DTC P0643.

Refer to EC-243, "

DTC Logic".

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 8 V with ignition

switch ON

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

1. Turn ignition switch ON and wait at least 10 seconds.

2. Check 1st trip DTC.

Is 1st trip DTC detected?

YES >> Go to EC-261, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000003858135

1.CHECK GROUND CONNECTION

1. Turn ignition switch OFF.

2. Check ground connection E38. Refer to Ground Inspection in GI-37, "

Circuit Inspection".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace ground connection.

2.CHECK BATTERY CURRENT SENSOR POWER SUPPLY CIRCUIT

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P1551Battery current sensor circuit

low inputAn excessively low voltage from the sen-

sor is sent to ECM. Harness or connectors

(The sensor circuit is open or shorted.)

Battery current sensor

P1552Battery current sensor circuit

high inputAn excessively high voltage from the sen-

sor is sent to ECM.

Page 1725 of 5121

![NISSAN TEANA 2008 Service Manual EC-264

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

P1553 BATTERY CURRENT SENSOR

P1553 BATTERY CURRENT SENSOR

DescriptionINFOID:0000000003858136

The power generation voltage variable control enables fuel c NISSAN TEANA 2008 Service Manual EC-264

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

P1553 BATTERY CURRENT SENSOR

P1553 BATTERY CURRENT SENSOR

DescriptionINFOID:0000000003858136

The power generation voltage variable control enables fuel c](/img/5/57391/w960_57391-1724.png)

EC-264

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

P1553 BATTERY CURRENT SENSOR

P1553 BATTERY CURRENT SENSOR

DescriptionINFOID:0000000003858136

The power generation voltage variable control enables fuel consumption to be decreased by reducing the

engine load which is caused by the power generation of the generator. The battery current sensor is installed

to the battery cable at the negative terminal. The sensor measures the charging/discharging current of the bat-

tery. Based on the sensor signal, ECM judges whether or not the power generation voltage variable control is

performed. When performing the power generation voltage variable control, ECM calculates the target power

generation voltage based on the sensor signal. And ECM sends the calculated value as the power generation

command value to IPDM E/R. For the details of the power generation voltage variable control, refer to CHG-5,

"System Description".

CAUTION:

Never connect the electrical component or the ground wire directly to the battery terminal. The con-

nection causes the malfunction of the power generation voltage variable control, and then the battery

discharge may occur.

DTC LogicINFOID:0000000003856741

DTC DETECTION LOGIC

NOTE:

If DTC P1553 is displayed with DTC P0643, first perform the trouble diagnosis for DTC P0643. Refer to

EC-243, "

DTC Logic".

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 8 V at idle.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

1. Start engine and wait at least 10 seconds.

2. Check 1st trip DTC.

Is 1st trip DTC detected?

YES >> Go to EC-264, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000003858137

1.CHECK GROUND CONNECTION

1. Turn ignition switch OFF.

2. Check ground connection E38. Refer to Ground Inspection in GI-37, "

Circuit Inspection".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace ground connection.

2.CHECK BATTERY CURRENT SENSOR POWER SUPPLY CIRCUIT

1. Disconnect battery current sensor harness connector.

2. Turn ignition switch ON.

3. Check the voltage between battery current sensor harness connector and ground.

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P1553Battery current sensor perfor-

manceThe signal voltage transmitted from the

sensor to ECM is higher than the amount

of the maximum power generation. Harness or connectors

(The sensor circuit is open or shorted.)

Battery current sensor

Page 1728 of 5121

![NISSAN TEANA 2008 Service Manual P1554 BATTERY CURRENT SENSOR

EC-267

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

P1554 BATTERY CURRENT SENSOR

DescriptionINFOID:0000000003858139

The power generation voltage NISSAN TEANA 2008 Service Manual P1554 BATTERY CURRENT SENSOR

EC-267

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

P1554 BATTERY CURRENT SENSOR

DescriptionINFOID:0000000003858139

The power generation voltage](/img/5/57391/w960_57391-1727.png)

P1554 BATTERY CURRENT SENSOR

EC-267

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

P1554 BATTERY CURRENT SENSOR

DescriptionINFOID:0000000003858139

The power generation voltage variable control enables fuel consumption to be decreased by reducing the

engine load which is caused by the power generation of the generator. The battery current sensor is installed

to the battery cable at the negative terminal. The sensor measures the charging/discharging current of the bat-

tery. Based on the sensor signal, ECM judges whether or not the power generation voltage variable control is

performed. When performing the power generation voltage variable control, ECM calculates the target power

generation voltage based on the sensor signal. And ECM sends the calculated value as the power generation

command value to IPDM E/R. For the details of the power generation voltage variable control, refer to CHG-5,

"System Description".

CAUTION:

Never connect the electrical component or the ground wire directly to the battery terminal. The con-

nection causes the malfunction of the power generation voltage variable control, and then the battery

discharge may occur.

DTC LogicINFOID:0000000003856745

DTC DETECTION LOGIC

NOTE:

If DTC P1554 is displayed with DTC P0643, first perform the trouble diagnosis for DTC P0643. Refer to

EC-243, "

DTC Logic".

DTC CONFIRMATION PROCEDURE

1.PERFORM COMPONENT FUNCTION CHECK

Perform component function check. Refer to EC-267, "

Component Function Check".

NOTE:

Use component function check to check the overall function of the battery current sensor circuit. During this

check, a 1st trip DTC might not be confirmed.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Go to EC-268, "

Diagnosis Procedure".

Component Function CheckINFOID:0000000003856746

1.PRECONDITIONING

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 12.8 V at idle.

Before performing the following procedure, confirm that all load switches and A/C switch are turned

OFF.

>> GO TO 2.

2.PERFORM COMPONENT FUNCTION CHECK

With CONSULT-III

1. Start engine and let it idle.

2. Select “BAT CUR SEN” in “DATA MONITOR” mode with CONSULT-III.

3. Check “BAT CUR SEN” indication for 10 seconds.

“BAT CUR SEN” should be above 2,300 mV at least once.

Without CONSULT-III

1. Start engine and let it idle.

2. Check voltage between ECM harness connector terminals under the following conditions.

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P1554Battery current sensor perfor-

manceThe output voltage of the battery current

sensor is lower than the specified value

while the battery voltage is high enough. Harness or connectors

(The sensor circuit is open or shorted.)

Battery current sensor

Page 1861 of 5121

![NISSAN TEANA 2008 Service Manual EC-400

< SYMPTOM DIAGNOSIS >[VQ25DE, VQ35DE]

ENGINE CONTROL SYSTEM SYMPTOMS

SYMPTOM DIAGNOSIS

ENGINE CONTROL SYSTEM SYMPTOMS

Symptom TableINFOID:0000000003856875

SYSTEM — BASIC ENGINE CONTROL SYSTEM NISSAN TEANA 2008 Service Manual EC-400

< SYMPTOM DIAGNOSIS >[VQ25DE, VQ35DE]

ENGINE CONTROL SYSTEM SYMPTOMS

SYMPTOM DIAGNOSIS

ENGINE CONTROL SYSTEM SYMPTOMS

Symptom TableINFOID:0000000003856875

SYSTEM — BASIC ENGINE CONTROL SYSTEM](/img/5/57391/w960_57391-1860.png)

EC-400

< SYMPTOM DIAGNOSIS >[VQ25DE, VQ35DE]

ENGINE CONTROL SYSTEM SYMPTOMS

SYMPTOM DIAGNOSIS

ENGINE CONTROL SYSTEM SYMPTOMS

Symptom TableINFOID:0000000003856875

SYSTEM — BASIC ENGINE CONTROL SYSTEM

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Fuel Fuel pump circuit 11232 22 3 2EC-337

Fuel pressure regulator system 334444444 4EC-411

Fuel injector circuit 11232 22 2EC-334

Evaporative emission system 334444444 4EC-76

Air Positive crankcase ventilation sys-

tem

334444444 41EC-347

Incorrect idle speed adjustment 1 1 1 1 1EC-11

Electric throttle control actuator 112332222 2 2EC-296,

EC-302

IgnitionIncorrect ignition timing adjustment33111 11 1EC-11

Ignition circuit 11222 22 2EC-341

Power supply and ground circuit 22333 33 23EC-132

Mass air flow sensor circuit

1

122

222 2EC-149

Engine coolant temperature sensor circuit

333EC-157

Air fuel ratio (A/F) sensor 1 circuitEC-163

,

EC-167

,

EC-170

,

EC-173

,

EC-318

Throttle position sensor circuit

22EC-160

,

EC-206

,

EC-254

,

EC-256

,

EC-311

Accelerator pedal position sensor circuit 3 2 1EC-243

,

EC-304

,

EC-307

,

EC-314

Knock sensor circuit 2 3EC-215

Page 1862 of 5121

![NISSAN TEANA 2008 Service Manual ENGINE CONTROL SYSTEM SYMPTOMS

EC-401

< SYMPTOM DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

1 - 6: The numbers refer to the order of inspection.

(continued on the next figure)

SYSTEM � NISSAN TEANA 2008 Service Manual ENGINE CONTROL SYSTEM SYMPTOMS

EC-401

< SYMPTOM DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

1 - 6: The numbers refer to the order of inspection.

(continued on the next figure)

SYSTEM �](/img/5/57391/w960_57391-1861.png)

ENGINE CONTROL SYSTEM SYMPTOMS

EC-401

< SYMPTOM DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

1 - 6: The numbers refer to the order of inspection.

(continued on the next figure)

SYSTEM — ENGINE MECHANICAL & OTHER

Crankshaft position sensor (POS) circuit 2 2EC-218

Camshaft position sensor (PHASE) circuit 3 2EC-222

Vehicle speed signal circuit 2 3 3 3EC-234

Power steering pressure sensor circuit 2 3 3EC-236

ECM 22333333333EC-238,

EC-240

Intake valve timing control solenoid valve cir-

cuit32 13223 3EC-146

PNP signal circuit 3 3 3 3 3EC-245

VIAS control solenoid valve 1 circuit 1EC-285

VIAS control solenoid valve 2 circuit 1EC-288

Refrigerant pressure sensor circuit 2 3 3 4EC-348

Electrical load signal circuit 3EC-329

Air conditioner circuit 223333333 3 2HAC-159

ABS actuator and electric unit (control unit) 4BRC-80

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA