bulb NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 115 of 5121

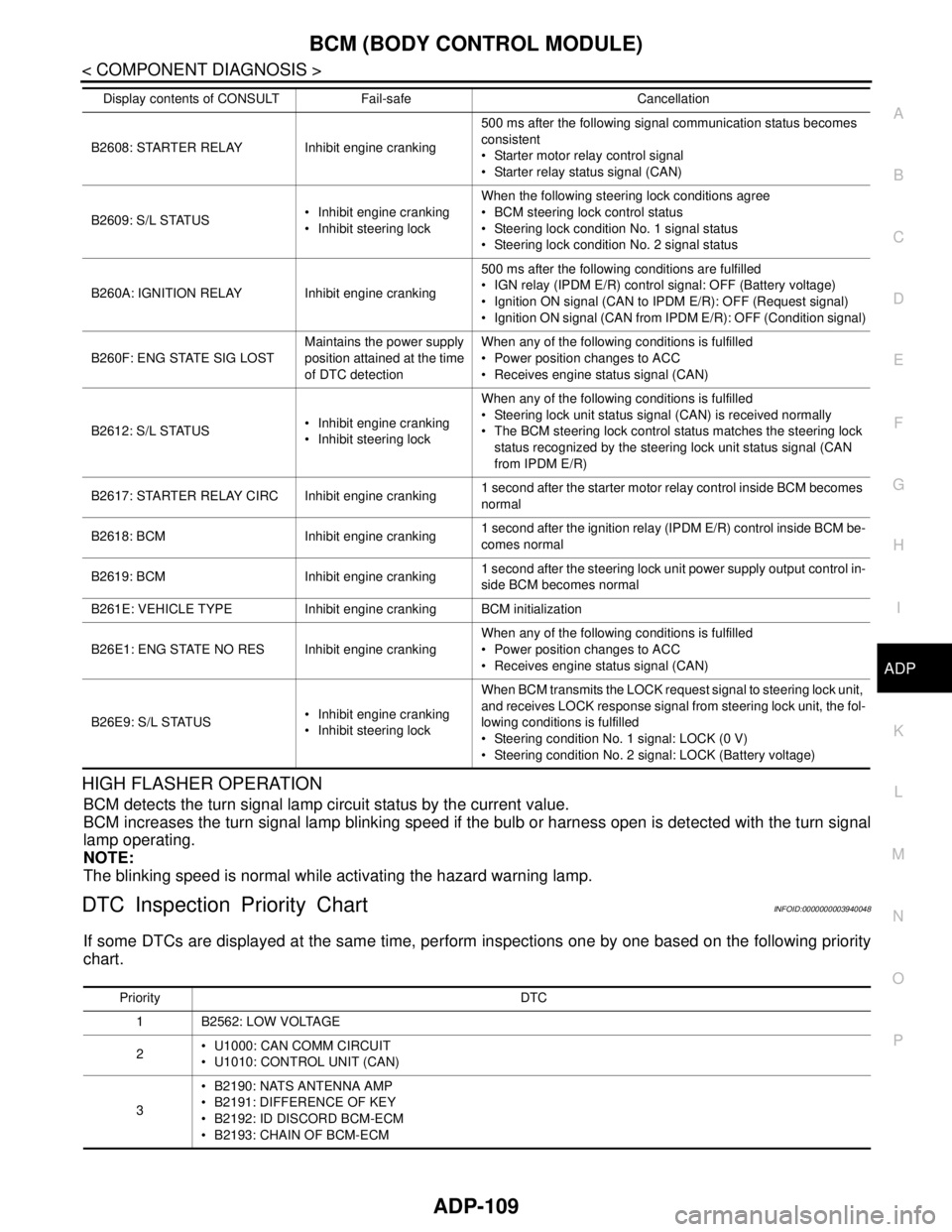

BCM (BODY CONTROL MODULE)

ADP-109

< COMPONENT DIAGNOSIS >

C

D

E

F

G

H

I

K

L

MA

B

ADP

N

O

P

HIGH FLASHER OPERATION

BCM detects the turn signal lamp circuit status by the current value.

BCM increases the turn signal lamp blinking speed if the bulb or harness open is detected with the turn signal

lamp operating.

NOTE:

The blinking speed is normal while activating the hazard warning lamp.

DTC Inspection Priority ChartINFOID:0000000003940048

If some DTCs are displayed at the same time, perform inspections one by one based on the following priority

chart.

B2608: STARTER RELAY Inhibit engine cranking500 ms after the following signal communication status becomes

consistent

Starter motor relay control signal

Starter relay status signal (CAN)

B2609: S/L STATUS Inhibit engine cranking

Inhibit steering lockWhen the following steering lock conditions agree

BCM steering lock control status

Steering lock condition No. 1 signal status

Steering lock condition No. 2 signal status

B260A: IGNITION RELAY Inhibit engine cranking500 ms after the following conditions are fulfilled

IGN relay (IPDM E/R) control signal: OFF (Battery voltage)

Ignition ON signal (CAN to IPDM E/R): OFF (Request signal)

Ignition ON signal (CAN from IPDM E/R): OFF (Condition signal)

B260F: ENG STATE SIG LOSTMaintains the power supply

position attained at the time

of DTC detectionWhen any of the following conditions is fulfilled

Power position changes to ACC

Receives engine status signal (CAN)

B2612: S/L STATUS Inhibit engine cranking

Inhibit steering lockWhen any of the following conditions is fulfilled

Steering lock unit status signal (CAN) is received normally

The BCM steering lock control status matches the steering lock

status recognized by the steering lock unit status signal (CAN

from IPDM E/R)

B2617: STARTER RELAY CIRC Inhibit engine cranking1 second after the starter motor relay control inside BCM becomes

normal

B2618: BCM Inhibit engine cranking1 second after the ignition relay (IPDM E/R) control inside BCM be-

comes normal

B2619: BCM Inhibit engine cranking1 second after the steering lock unit power supply output control in-

side BCM becomes normal

B261E: VEHICLE TYPE Inhibit engine cranking BCM initialization

B26E1: ENG STATE NO RES Inhibit engine crankingWhen any of the following conditions is fulfilled

Power position changes to ACC

Receives engine status signal (CAN)

B26E9: S/L STATUS Inhibit engine cranking

Inhibit steering lockWhen BCM transmits the LOCK request signal to steering lock unit,

and receives LOCK response signal from steering lock unit, the fol-

lowing conditions is fulfilled

Steering condition No. 1 signal: LOCK (0 V)

Steering condition No. 2 signal: LOCK (Battery voltage) Display contents of CONSULT Fail-safe Cancellation

Priority DTC

1 B2562: LOW VOLTAGE

2 U1000: CAN COMM CIRCUIT

U1010: CONTROL UNIT (CAN)

3 B2190: NATS ANTENNA AMP

B2191: DIFFERENCE OF KEY

B2192: ID DISCORD BCM-ECM

B2193: CHAIN OF BCM-ECM

Page 822 of 5121

BCS

INSPECTION AND ADJUSTMENT

BCS-5

< BASIC INSPECTION >

C

D

E

F

G

H

I

J

K

L B A

O

P N

CONFIGURATION (BCM) : Configuration listINFOID:0000000003809648

⇔: Items which confirm vehicle specificationsMANUAL SETTING ITEM

NOTE

Items Setting value

AUTO LIGHT WITH —

RR FOG LAMP WITH —

AV C/U WITH ⇔ WITHOUT WITH: With BOSE audio system

WITHOUT: Without BOSE audio system

THEFT ALM AREA MODE3 —

H/L WASHER TIME 1 WITH —

H/L WASHER TIME 2 WITH —

I-KEY WITH —

Key Fob Type MODE10 —

HANDLE LHD —

AUTO SETTING ITEM

NOTE

Items Setting value

H/L BULB DEFAULT —

FR FOG LAMP WITH —

TRANSMISSION AT with ABS —

TR CANCL SW WITHOUT —

TPMS WITHOUT —

AUTO BACK DOOR WITHOUT —

FOG LAMP BULB SINGLE BULB —

D I L M P VA R I AT M O D E 4 —

LIGHT RECOG MODE4 —

FR FOG LOGIC MODE2 —

PANIC ALM TYPE MODE2 —

HAZARD SW TYPE MODE1 —

BCM AC CONTROL MODE1 —

RAIN SENSOR WITHOUT —

FOG ON WITH AUTO LIGHT WITHOUT —

AUTO LOCK&UNLOCK FUNC WITHOUT —

DROP WIP FUNCTION WITHOUT —

SELECTIVE UNLOCK SETTING WITHOUT —

SEAT BLT WARN WITHOUT —

SPEED SNS WIP WITH —

Page 890 of 5121

BCS

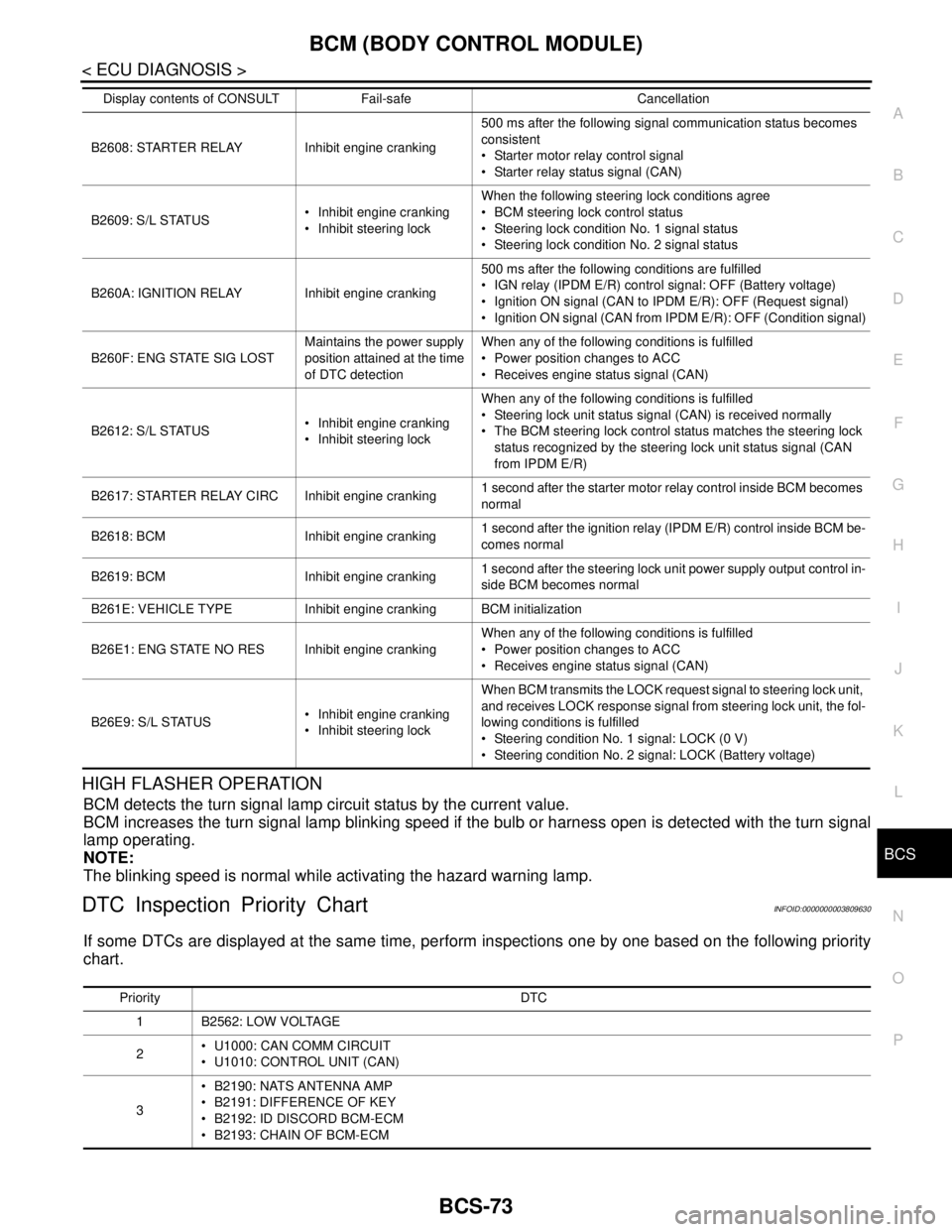

BCM (BODY CONTROL MODULE)

BCS-73

< ECU DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L B A

O

P N

HIGH FLASHER OPERATION

BCM detects the turn signal lamp circuit status by the current value.

BCM increases the turn signal lamp blinking speed if the bulb or harness open is detected with the turn signal

lamp operating.

NOTE:

The blinking speed is normal while activating the hazard warning lamp.

DTC Inspection Priority ChartINFOID:0000000003809630

If some DTCs are displayed at the same time, perform inspections one by one based on the following priority

chart.

B2608: STARTER RELAY Inhibit engine cranking500 ms after the following signal communication status becomes

consistent

Starter motor relay control signal

Starter relay status signal (CAN)

B2609: S/L STATUS Inhibit engine cranking

Inhibit steering lockWhen the following steering lock conditions agree

BCM steering lock control status

Steering lock condition No. 1 signal status

Steering lock condition No. 2 signal status

B260A: IGNITION RELAY Inhibit engine cranking500 ms after the following conditions are fulfilled

IGN relay (IPDM E/R) control signal: OFF (Battery voltage)

Ignition ON signal (CAN to IPDM E/R): OFF (Request signal)

Ignition ON signal (CAN from IPDM E/R): OFF (Condition signal)

B260F: ENG STATE SIG LOSTMaintains the power supply

position attained at the time

of DTC detectionWhen any of the following conditions is fulfilled

Power position changes to ACC

Receives engine status signal (CAN)

B2612: S/L STATUS Inhibit engine cranking

Inhibit steering lockWhen any of the following conditions is fulfilled

Steering lock unit status signal (CAN) is received normally

The BCM steering lock control status matches the steering lock

status recognized by the steering lock unit status signal (CAN

from IPDM E/R)

B2617: STARTER RELAY CIRC Inhibit engine cranking1 second after the starter motor relay control inside BCM becomes

normal

B2618: BCM Inhibit engine cranking1 second after the ignition relay (IPDM E/R) control inside BCM be-

comes normal

B2619: BCM Inhibit engine cranking1 second after the steering lock unit power supply output control in-

side BCM becomes normal

B261E: VEHICLE TYPE Inhibit engine cranking BCM initialization

B26E1: ENG STATE NO RES Inhibit engine crankingWhen any of the following conditions is fulfilled

Power position changes to ACC

Receives engine status signal (CAN)

B26E9: S/L STATUS Inhibit engine cranking

Inhibit steering lockWhen BCM transmits the LOCK request signal to steering lock unit,

and receives LOCK response signal from steering lock unit, the fol-

lowing conditions is fulfilled

Steering condition No. 1 signal: LOCK (0 V)

Steering condition No. 2 signal: LOCK (Battery voltage) Display contents of CONSULT Fail-safe Cancellation

Priority DTC

1 B2562: LOW VOLTAGE

2 U1000: CAN COMM CIRCUIT

U1010: CONTROL UNIT (CAN)

3 B2190: NATS ANTENNA AMP

B2191: DIFFERENCE OF KEY

B2192: ID DISCORD BCM-ECM

B2193: CHAIN OF BCM-ECM

Page 1205 of 5121

BCM (BODY CONTROL MODULE)

DEF-55

< ECU DIAGNOSIS >

C

D

E

F

G

H

I

J

K

MA

B

DEF

N

O

PHIGH FLASHER OPERATION

BCM detects the turn signal lamp circuit status by the current value.

BCM increases the turn signal lamp blinking speed if the bulb or harness open is detected with the turn signal

lamp operating.

NOTE:

The blinking speed is normal while activating the hazard warning lamp.

DTC Inspection Priority ChartINFOID:0000000003940043

If some DTCs are displayed at the same time, perform inspections one by one based on the following priority

chart.

B2608: STARTER RELAY Inhibit engine cranking500 ms after the following signal communication status becomes

consistent

Starter motor relay control signal

Starter relay status signal (CAN)

B2609: S/L STATUS Inhibit engine cranking

Inhibit steering lockWhen the following steering lock conditions agree

BCM steering lock control status

Steering lock condition No. 1 signal status

Steering lock condition No. 2 signal status

B260A: IGNITION RELAY Inhibit engine cranking500 ms after the following conditions are fulfilled

IGN relay (IPDM E/R) control signal: OFF (Battery voltage)

Ignition ON signal (CAN to IPDM E/R): OFF (Request signal)

Ignition ON signal (CAN from IPDM E/R): OFF (Condition signal)

B260F: ENG STATE SIG LOSTMaintains the power supply

position attained at the time

of DTC detectionWhen any of the following conditions is fulfilled

Power position changes to ACC

Receives engine status signal (CAN)

B2612: S/L STATUS Inhibit engine cranking

Inhibit steering lockWhen any of the following conditions is fulfilled

Steering lock unit status signal (CAN) is received normally

The BCM steering lock control status matches the steering lock

status recognized by the steering lock unit status signal (CAN

from IPDM E/R)

B2617: STARTER RELAY CIRC Inhibit engine cranking1 second after the starter motor relay control inside BCM becomes

normal

B2618: BCM Inhibit engine cranking1 second after the ignition relay (IPDM E/R) control inside BCM be-

comes normal

B2619: BCM Inhibit engine cranking1 second after the steering lock unit power supply output control in-

side BCM becomes normal

B261E: VEHICLE TYPE Inhibit engine cranking BCM initialization

B26E1: ENG STATE NO RES Inhibit engine crankingWhen any of the following conditions is fulfilled

Power position changes to ACC

Receives engine status signal (CAN)

B26E9: S/L STATUS Inhibit engine cranking

Inhibit steering lockWhen BCM transmits the LOCK request signal to steering lock unit,

and receives LOCK response signal from steering lock unit, the fol-

lowing conditions is fulfilled

Steering condition No. 1 signal: LOCK (0 V)

Steering condition No. 2 signal: LOCK (Battery voltage) Display contents of CONSULT Fail-safe Cancellation

Priority DTC

1 B2562: LOW VOLTAGE

2 U1000: CAN COMM CIRCUIT

U1010: CONTROL UNIT (CAN)

3 B2190: NATS ANTENNA AMP

B2191: DIFFERENCE OF KEY

B2192: ID DISCORD BCM-ECM

B2193: CHAIN OF BCM-ECM

Page 1368 of 5121

![NISSAN TEANA 2008 Service Manual DLK-152

< ECU DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

BCM (BODY CONTROL MODULE)

HIGH FLASHER OPERATION

BCM detects the turn signal lamp circuit status by the current value.

BCM increases the turn sig NISSAN TEANA 2008 Service Manual DLK-152

< ECU DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

BCM (BODY CONTROL MODULE)

HIGH FLASHER OPERATION

BCM detects the turn signal lamp circuit status by the current value.

BCM increases the turn sig](/img/5/57391/w960_57391-1367.png)

DLK-152

< ECU DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

BCM (BODY CONTROL MODULE)

HIGH FLASHER OPERATION

BCM detects the turn signal lamp circuit status by the current value.

BCM increases the turn signal lamp blinking speed if the bulb or harness open is detected with the turn signal

lamp operating.

NOTE:

The blinking speed is normal while activating the hazard warning lamp.

DTC Inspection Priority ChartINFOID:0000000003904115

If some DTCs are displayed at the same time, perform inspections one by one based on the following priority

chart.

B2608: STARTER RELAY Inhibit engine cranking500 ms after the following signal communication status becomes

consistent

Starter motor relay control signal

Starter relay status signal (CAN)

B2609: S/L STATUS Inhibit engine cranking

Inhibit steering lockWhen the following steering lock conditions agree

BCM steering lock control status

Steering lock condition No. 1 signal status

Steering lock condition No. 2 signal status

B260A: IGNITION RELAY Inhibit engine cranking500 ms after the following conditions are fulfilled

IGN relay (IPDM E/R) control signal: OFF (Battery voltage)

Ignition ON signal (CAN to IPDM E/R): OFF (Request signal)

Ignition ON signal (CAN from IPDM E/R): OFF (Condition signal)

B260F: ENG STATE SIG LOSTMaintains the power supply

position attained at the time

of DTC detectionWhen any of the following conditions is fulfilled

Power position changes to ACC

Receives engine status signal (CAN)

B2612: S/L STATUS Inhibit engine cranking

Inhibit steering lockWhen any of the following conditions is fulfilled

Steering lock unit status signal (CAN) is received normally

The BCM steering lock control status matches the steering lock

status recognized by the steering lock unit status signal (CAN

from IPDM E/R)

B2617: STARTER RELAY CIRC Inhibit engine cranking1 second after the starter motor relay control inside BCM becomes

normal

B2618: BCM Inhibit engine cranking1 second after the ignition relay (IPDM E/R) control inside BCM be-

comes normal

B2619: BCM Inhibit engine cranking1 second after the steering lock unit power supply output control in-

side BCM becomes normal

B261E: VEHICLE TYPE Inhibit engine cranking BCM initialization

B26E1: ENG STATE NO RES Inhibit engine crankingWhen any of the following conditions is fulfilled

Power position changes to ACC

Receives engine status signal (CAN)

B26E9: S/L STATUS Inhibit engine cranking

Inhibit steering lockWhen BCM transmits the LOCK request signal to steering lock unit,

and receives LOCK response signal from steering lock unit, the fol-

lowing conditions is fulfilled

Steering condition No. 1 signal: LOCK (0 V)

Steering condition No. 2 signal: LOCK (Battery voltage) Display contents of CONSULT Fail-safe Cancellation

Priority DTC

1 B2562: LOW VOLTAGE

2 U1000: CAN COMM CIRCUIT

U1010: CONTROL UNIT (CAN)

3 B2190: NATS ANTENNA AMP

B2191: DIFFERENCE OF KEY

B2192: ID DISCORD BCM-ECM

B2193: CHAIN OF BCM-ECM

Page 1568 of 5121

![NISSAN TEANA 2008 Service Manual ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-107

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O How to Display SRT Status

WITH CONSULT-III

Selecting “SRT STATUS” in “DTC CONFIRMAT NISSAN TEANA 2008 Service Manual ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-107

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O How to Display SRT Status

WITH CONSULT-III

Selecting “SRT STATUS” in “DTC CONFIRMAT](/img/5/57391/w960_57391-1567.png)

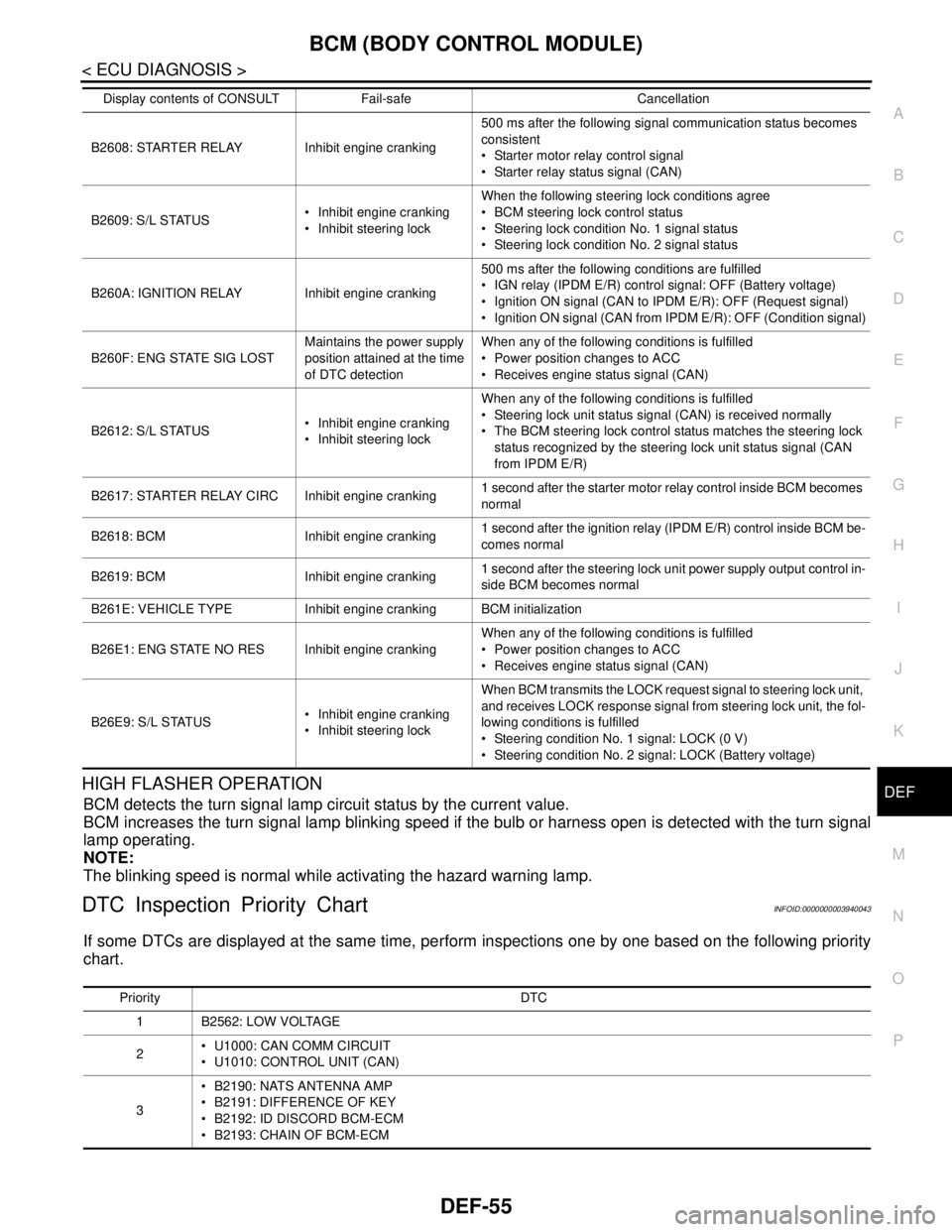

ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-107

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O How to Display SRT Status

WITH CONSULT-III

Selecting “SRT STATUS” in “DTC CONFIRMATION” mode with CONSULT-III.

For items whose SRT codes are set, “CMPLT” is displayed on the CONSULT-III screen; for items whose SRT

codes are not set, “INCMP” is displayed.

NOTE:

Though displayed on the CONSULT-III screen, “HO2S HTR” is not SRT item.

WITH GST

Selecting Service $01 with GST (Generic Scan Tool)

MALFUNCTION INDICATOR (MI)

Description

The MI is located on the instrument panel.

1. The MI will illuminate when the ignition switch is turned ON with-

out the engine running. This is a bulb check.

If the MI does not illuminate, check MI circuit. Refer to EC-346,

"Component Function Check".

2. When the engine is started, the MI should go off.

If the MI remains on, the on board diagnostic system has

detected an engine system malfunction.

On Board Diagnostic System Function

The on board diagnostic system has the following three functions.

Diagnostic Test Mode I — Bulb Check

In this mode, the MI on the instrument panel should stay ON. If it remains OFF, check MI circuit. Refer to EC-

346, "Component Function Check".

Diagnostic Test Mode I — Malfunction Warning

SAT652J

Diagnostic Test

ModeKEY and ENG.

Sta tusFunction Explanation of Function

Mode I Ignition switch in

ON position

Engine stoppedBULB CHECK This function checks the MI bulb for damage (blown, open

circuit, etc.).

If the MI does not come on, check MI circuit.

Engine running MALFUNCTION

WARNINGWhen a malfunction is detected twice in two consecutive

driving cycles (two trip detection logic), the MI will illuminate

to inform the driver that a malfunction has been detected.

The following malfunctions will illuminate or blink the MI in

the 1st trip.

Misfire (Possible three way catalyst damage)

One trip detection diagnoses

Mode II Ignition switch in

ON position

Engine stoppedSELF-DIAGNOSTIC

RESULTSThis function allows DTCs and 1st trip DTCs to be read.

Page 1807 of 5121

![NISSAN TEANA 2008 Service Manual EC-346

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

MALFUNCTION INDICATOR

MALFUNCTION INDICATOR

DescriptionINFOID:0000000003856853

The Malfunction Indicator MI is located on the combination meter.

The MI w NISSAN TEANA 2008 Service Manual EC-346

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

MALFUNCTION INDICATOR

MALFUNCTION INDICATOR

DescriptionINFOID:0000000003856853

The Malfunction Indicator MI is located on the combination meter.

The MI w](/img/5/57391/w960_57391-1806.png)

EC-346

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

MALFUNCTION INDICATOR

MALFUNCTION INDICATOR

DescriptionINFOID:0000000003856853

The Malfunction Indicator MI is located on the combination meter.

The MI will illuminate when the ignition switch is turned ON without

the engine running. This is a bulb check.

When the engine is started, the MI should turn off. If the MI remains

illuminated, the on board diagnostic system has detected an engine

system malfunction.

For details, refer to EC-102, "

Diagnosis Description".

Component Function CheckINFOID:0000000003856854

1.CHECK MI FUNCTION

1. Turn ignition switch ON.

2. Check that MI illuminates.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Go to EC-346, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000003856855

1.CHECK DTC

Check that DTC U1000 or U1001 is not displayed.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Perform trouble diagnosis for DTC U1000, U1001. Refer to EC-135, "

Description".

2.CHECK COMBINATION METER FUNCTION

Refer to MWI-33, "

CONSULT-III Function (METER/M&A)".

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace.

3.CHECK INTERMITTENT INCIDENT

Refer to GI-35, "

Intermittent Incident".

Is the inspection result normal?

YES >> Replace combination meter.

NO >> Repair or replace.

SEF217U

Page 1866 of 5121

![NISSAN TEANA 2008 Service Manual PRECAUTIONS

EC-405

< PRECAUTION >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INF NISSAN TEANA 2008 Service Manual PRECAUTIONS

EC-405

< PRECAUTION >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INF](/img/5/57391/w960_57391-1865.png)

PRECAUTIONS

EC-405

< PRECAUTION >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000003960684

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the “SRS AIRBAG” and

“SEAT BELT” of this Service Manual.

WARNING:

To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SRS AIRBAG”.

Never use electrical test equipment on any circuit related to the SRS unless instructed to in this Ser-

vice Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or harness

connectors.

Precautions For Xenon Headlamp ServiceINFOID:0000000003856878

WARNING:

Comply with the following warnings to prevent any serious accident.

Disconnect the battery cable (negative terminal) or the power supply fuse before installing, remov-

ing, or touching the xenon headlamp (bulb included). The xenon headlamp contains high-voltage

generated parts.

Never work with wet hands.

Check the xenon headlamp ON-OFF status after assembling it to the vehicle. Never turn the xenon

headlamp ON in other conditions. Connect the power supply to the vehicle-side connector.

(Turning it ON outside the lamp case may cause fire or visual impairments.)

Never touch the bulb glass immediately after turning it OFF. It is extremely hot.

CAUTION:

Comply with the following cautions to prevent any error and malfunction.

Install the xenon bulb securely. (Insufficient bulb socket installation may melt the bulb, the connec-

tor, the housing, etc. by high-voltage leakage or corona discharge.)

Never perform HID circuit inspection with a tester.

Never touch the xenon bulb glass with hands. Never put oil and grease on it.

Dispose of the used xenon bulb after packing it in thick vinyl without breaking it.

Never wipe out dirt and contamination with organic solvent (thinner, gasoline, etc.).

Precaution for Procedure without Cowl Top CoverINFOID:0000000003856879

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

On Board Diagnostic (OBD) System of Engine and CVTINFOID:0000000003856880

The ECM has an on board diagnostic system. It will illuminate the malfunction indicator MI to warn the driver of

a malfunction causing emission deterioration.

PIIB3706J

Page 2033 of 5121

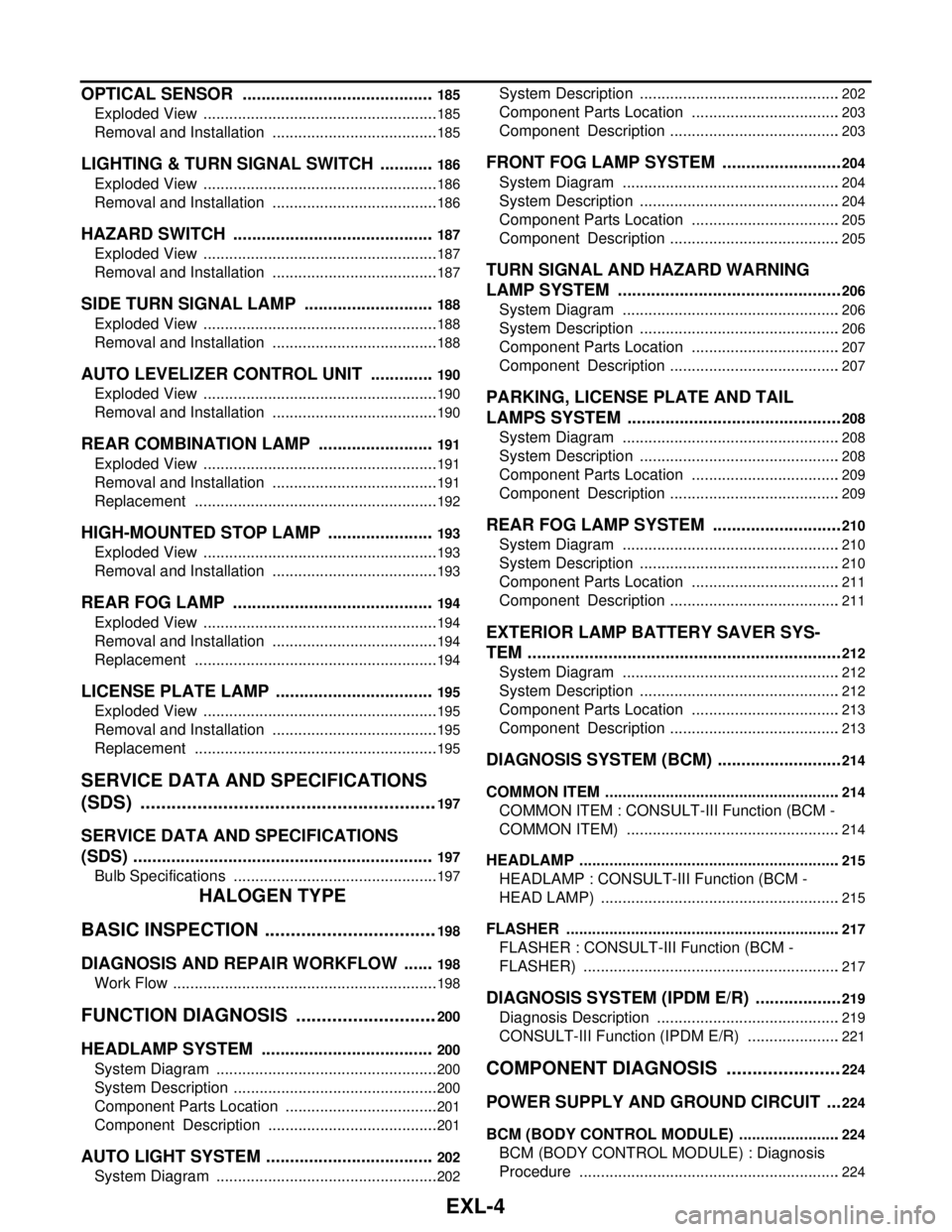

EXL-4

OPTICAL SENSOR .........................................185

Exploded View .......................................................185

Removal and Installation .......................................185

LIGHTING & TURN SIGNAL SWITCH ............186

Exploded View .......................................................186

Removal and Installation .......................................186

HAZARD SWITCH ...........................................187

Exploded View .......................................................187

Removal and Installation .......................................187

SIDE TURN SIGNAL LAMP ............................188

Exploded View .......................................................188

Removal and Installation .......................................188

AUTO LEVELIZER CONTROL UNIT ..............190

Exploded View .......................................................190

Removal and Installation .......................................190

REAR COMBINATION LAMP .........................191

Exploded View .......................................................191

Removal and Installation .......................................191

Replacement .........................................................192

HIGH-MOUNTED STOP LAMP .......................193

Exploded View .......................................................193

Removal and Installation .......................................193

REAR FOG LAMP ...........................................194

Exploded View .......................................................194

Removal and Installation .......................................194

Replacement .........................................................194

LICENSE PLATE LAMP ..................................195

Exploded View .......................................................195

Removal and Installation .......................................195

Replacement .........................................................195

SERVICE DATA AND SPECIFICATIONS

(SDS) ..........................................................

197

SERVICE DATA AND SPECIFICATIONS

(SDS) ................................................................

197

Bulb Specifications ................................................197

HALOGEN TYPE

BASIC INSPECTION ..................................

198

DIAGNOSIS AND REPAIR WORKFLOW .......198

Work Flow ..............................................................198

FUNCTION DIAGNOSIS ............................200

HEADLAMP SYSTEM .....................................200

System Diagram ....................................................200

System Description ................................................200

Component Parts Location ....................................201

Component Description ........................................201

AUTO LIGHT SYSTEM ....................................202

System Diagram ....................................................202

System Description ...............................................202

Component Parts Location ...................................203

Component Description ........................................203

FRONT FOG LAMP SYSTEM ..........................204

System Diagram ...................................................204

System Description ...............................................204

Component Parts Location ...................................205

Component Description ........................................205

TURN SIGNAL AND HAZARD WARNING

LAMP SYSTEM ................................................

206

System Diagram ...................................................206

System Description ...............................................206

Component Parts Location ...................................207

Component Description ........................................207

PARKING, LICENSE PLATE AND TAIL

LAMPS SYSTEM ..............................................

208

System Diagram ...................................................208

System Description ...............................................208

Component Parts Location ...................................209

Component Description ........................................209

REAR FOG LAMP SYSTEM ............................210

System Diagram ...................................................210

System Description ...............................................210

Component Parts Location ...................................211

Component Description ........................................211

EXTERIOR LAMP BATTERY SAVER SYS-

TEM ...................................................................

212

System Diagram ...................................................212

System Description ...............................................212

Component Parts Location ...................................213

Component Description ........................................213

DIAGNOSIS SYSTEM (BCM) ...........................214

COMMON ITEM .......................................................214

COMMON ITEM : CONSULT-III Function (BCM -

COMMON ITEM) ..................................................

214

HEADLAMP .............................................................215

HEADLAMP : CONSULT-III Function (BCM -

HEAD LAMP) ........................................................

215

FLASHER ................................................................217

FLASHER : CONSULT-III Function (BCM -

FLASHER) ............................................................

217

DIAGNOSIS SYSTEM (IPDM E/R) ...................219

Diagnosis Description ...........................................219

CONSULT-III Function (IPDM E/R) ......................221

COMPONENT DIAGNOSIS ......................224

POWER SUPPLY AND GROUND CIRCUIT ....224

BCM (BODY CONTROL MODULE) ........................224

BCM (BODY CONTROL MODULE) : Diagnosis

Procedure .............................................................

224

Page 2035 of 5121

EXL-6

BOTH SIDE FRONT FOG LAMPS ARE NOT

TURNED ON ....................................................

334

Description .............................................................334

Diagnosis Procedure .............................................334

PRECAUTION ............................................335

PRECAUTIONS ...............................................335

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ................................................................

335

ON-VEHICLE MAINTENANCE ..................336

HEADLAMP AIMING ADJUSTMENT .............336

Description .............................................................336

Aiming Adjustment Procedure (Low Beam) ...........337

Aiming Adjustment Procedure (High Beam) ..........338

FRONT FOG LAMP AIMING ADJUSTMENT .341

Description .............................................................341

Aiming Adjustment Procedure ...............................341

ON-VEHICLE REPAIR ...............................343

FRONT COMBINATION LAMP .......................343

Exploded View .......................................................343

Removal and Installation .......................................343

Replacement .........................................................344

Disassembly and Assembly ...................................344

FRONT FOG LAMP .........................................346

Exploded View .......................................................346

Removal and Installation .......................................346

Replacement .........................................................346

OPTICAL SENSOR .........................................348

Exploded View .......................................................348

Removal and Installation .......................................348

LIGHTING & TURN SIGNAL SWITCH ............349

Exploded View ......................................................349

Removal and Installation .......................................349

HEADLAMP AIMING SWITCH .........................350

Exploded View ......................................................350

Removal and Installation .......................................350

HAZARD SWITCH ............................................351

Exploded View ......................................................351

Removal and Installation .......................................351

SIDE TURN SIGNAL LAMP .............................352

Exploded View ......................................................352

Removal and Installation .......................................352

REAR COMBINATION LAMP ..........................354

Exploded View ......................................................354

Removal and Installation .......................................354

Replacement .........................................................355

HIGH-MOUNTED STOP LAMP ........................356

Exploded View ......................................................356

Removal and Installation .......................................356

REAR FOG LAMP ............................................357

Exploded View ......................................................357

Removal and Installation .......................................357

Replacement .........................................................357

LICENSE PLATE LAMP ...................................358

Exploded View ......................................................358

Removal and Installation .......................................358

Replacement .........................................................358

SERVICE DATA AND SPECIFICATIONS

(SDS) .........................................................

360

SERVICE DATA AND SPECIFICATIONS

(SDS) ................................................................

360

Bulb Specifications ................................................360