heater NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 1 of 5121

MODEL J32 SERIES

© 2008 NISSAN INTERNATIONAL SA

Allrightsreserved.NopartofthisElectronicServiceManualmaybereproducedorstoredinaretrievalsystem,ortransmittedinanyform,or by any means, electronic, mechanical, photocopying, recording or otherwise, without the prior written permission of Nissan InternationalSA, Switzerland.

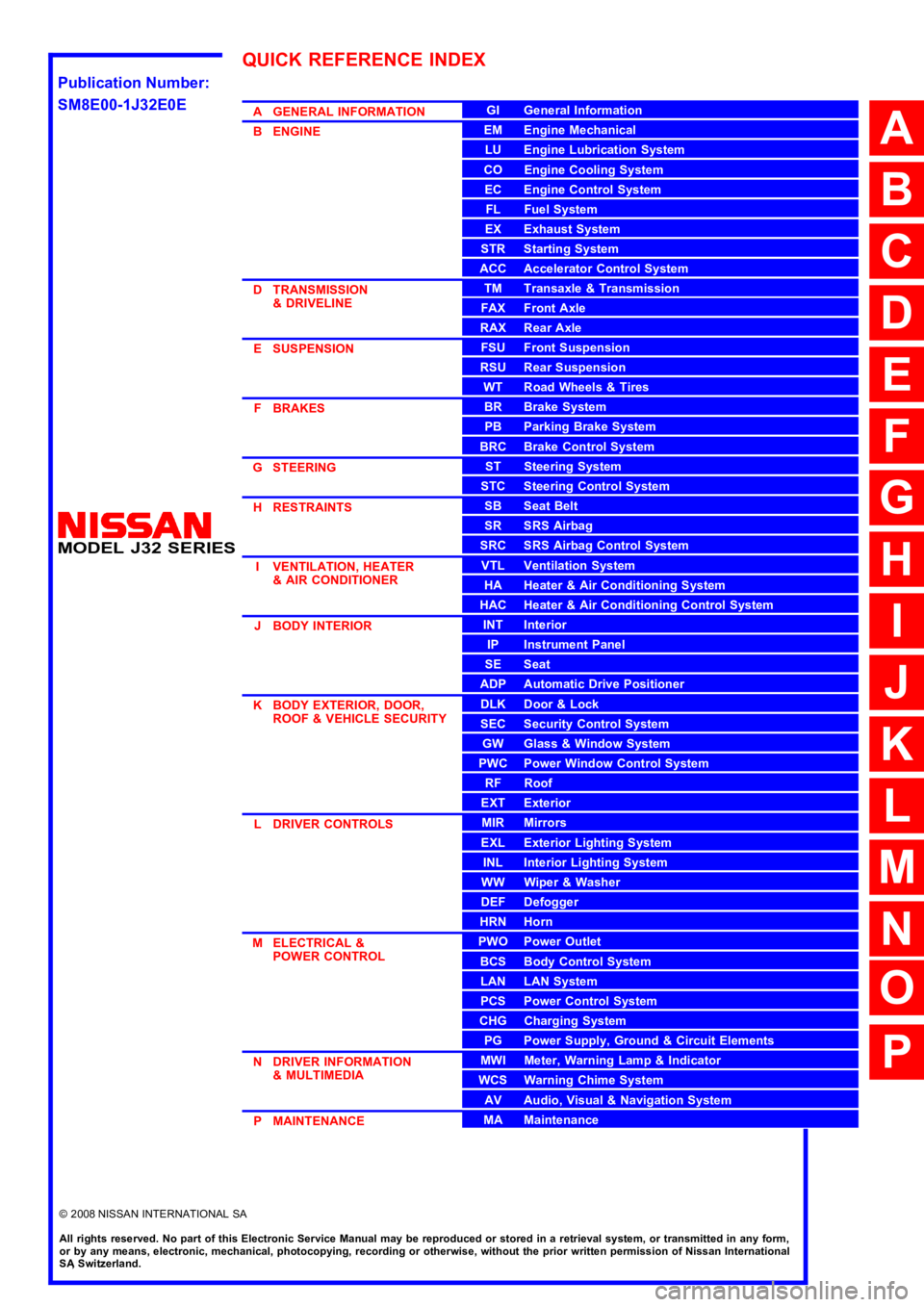

AGENERALINFORMATION

BENGINE

DTRANSMISSION&DRIVELINE

ESUSPENSION

FBRAKES

GSTEERING

HRESTRAINTS

IVENTILATION,HEATER&AIRCONDITIONER

JBODYINTERIOR

KBODYEXTERIOR,DOOR,ROOF&VEHICLESECURITY

LDRIVERCONTROLS

MELECTRICAL&POWERCONTROL

NDRIVERINFORMATION&MULTIMEDIA

PMAINTENANCE

GIGeneralInformation

EMEngineMechanical

LUEngineLubricationSystem

COEngineCoolingSystem

ECEngineControlSystem

FLFuelSystem

EXExhaustSystem

STRStartingSystem

ACCAcceleratorControlSystem

TMTransaxle &Transmission

FAXFrontAxle

RAXRearAxle

FSUFrontSuspension

RSURearSuspension

WTRoadWheels &Tires

BRBrakeSystem

PBParkingBrakeSystem

BRCBrakeControlSystem

STSteeringSystem

STCSteeringControlSystem

SBSeatBelt

SRSRSAirbag

SRCSRSAirbagControlSystem

VTLVentilationSystem

HAHeater &AirConditioningSystem

HACHeater &AirConditioningControlSystem

INTInterior

IPInstrumentPanel

SESeat

ADPAutomaticDrivePositioner

DLKDoor &Lock

SECSecurityControlSystem

GWGlass &WindowSystem

PWCPowerWindowControlSystem

RFRoof

EXTExterior

MIRMirrors

EXLExteriorLightingSystem

INLInteriorLightingSystem

WWWiper &Washer

DEFDefogger

HRNHorn

PWOPowerOutlet

BCSBodyControlSystem

LANLANSystem

PCSPowerControlSystem

CHGChargingSystem

PGPowerSupply,Ground&CircuitElements

MWIMeter,WarningLamp&Indicator

WCSWarningChimeSystem

AVAudio,Visual&NavigationSystem

MAMaintenance

QUICKREFERENCEINDEX

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

M

Publication Number:

SM8E00-1J32E0E

Page 179 of 5121

![NISSAN TEANA 2008 Service Manual AV

NORMAL OPERATING CONDITION

AV-35

< SYMPTOM DIAGNOSIS >[AUDIO SYSTEM]

C

D

E

F

G

H

I

J

K

L

MB A

O

P

NORMAL OPERATING CONDITION

DescriptionINFOID:0000000003765606

NOTE:

Audio operation information, NISSAN TEANA 2008 Service Manual AV

NORMAL OPERATING CONDITION

AV-35

< SYMPTOM DIAGNOSIS >[AUDIO SYSTEM]

C

D

E

F

G

H

I

J

K

L

MB A

O

P

NORMAL OPERATING CONDITION

DescriptionINFOID:0000000003765606

NOTE:

Audio operation information,](/img/5/57391/w960_57391-178.png)

AV

NORMAL OPERATING CONDITION

AV-35

< SYMPTOM DIAGNOSIS >[AUDIO SYSTEM]

C

D

E

F

G

H

I

J

K

L

MB A

O

P

NORMAL OPERATING CONDITION

DescriptionINFOID:0000000003765606

NOTE:

Audio operation information, refer to Owner's Manual.

The majority of the audio concerns are the result of outside causes (bad CD, electromagnetic interference,

etc.).

NOISE

The following noise results from variations in field strength, such as fading noise and multi-path noise, or

external noise from trains and other sources. It is not a malfunction.

Fading noise: This noise occurs because of variations in the field strength in a narrow range due to moun-

tains or buildings blocking the signal.

Multi-path noise: This noise results from the waves sent directly from the broadcast station arriving at the

antenna at a different time from the waves that reflect off mountains or buildings.

The vehicle itself can be a source of noise if noise prevention parts or electrical equipment is malfunctioning.

Check if noise is caused and/or changed by engine speed, ignition switch turned to each position, and opera-

tion of each piece of electrical equipment, and then determine the cause.

NOTE:

The source of the noise can be easily found by listening to the noise while removing the fuses of electrical

components, one by one.

Types of Noise and Possible Causes

Occurrence condition Possible cause

Occurs only when engine is ON.A continuous growling noise occurs. The speed of

the noise varies with changes in the engine speed. Ignition components

The occurrence of the noise is linked with the operation of the fuel pump. Fuel pump condenser

Noise only occurs when various

electrical components are oper-

ating.A cracking or snapping sound occurs with the op-

eration of various switches. Relay malfunction, audio unit malfunction

The noise occurs when various motors are operat-

ing. Motor case ground

Motor

The noise occurs constantly, not just under certain conditions. Rear defogger coil malfunction

Open circuit in printed heater

Poor ground of antenna feeder line

A cracking or snapping sound occurs while the vehicle is being driven, especially when

it is vibrating excessively. Ground wire of body parts

Ground due to improper part installation

Wiring connections or a short circuit

Page 1132 of 5121

ENGINE COOLANT

CO-9

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

MA

CO

N

P O

4. Check drained engine coolant for contaminants such as rust, corrosion or discoloration.

If contaminated, flush the engine cooling system. Refer to CO-10, "

Flushing".

RefillingINFOID:0000000003793168

1. Install reservoir tank if removed, and radiator drain plug.

CAUTION:

Be sure to clean drain plug and install with new O-ring.

If water drain plugs on cylinder block are removed, close and tighten them. Refer to EM-110, "

Dis-

assembly and Assembly".

2. Check that each hose clamp has been firmly tightened.

3. Remove air duct assembly and air cleaner cases (upper and lower) assembly. Refer to EM-26, "

Exploded

View".

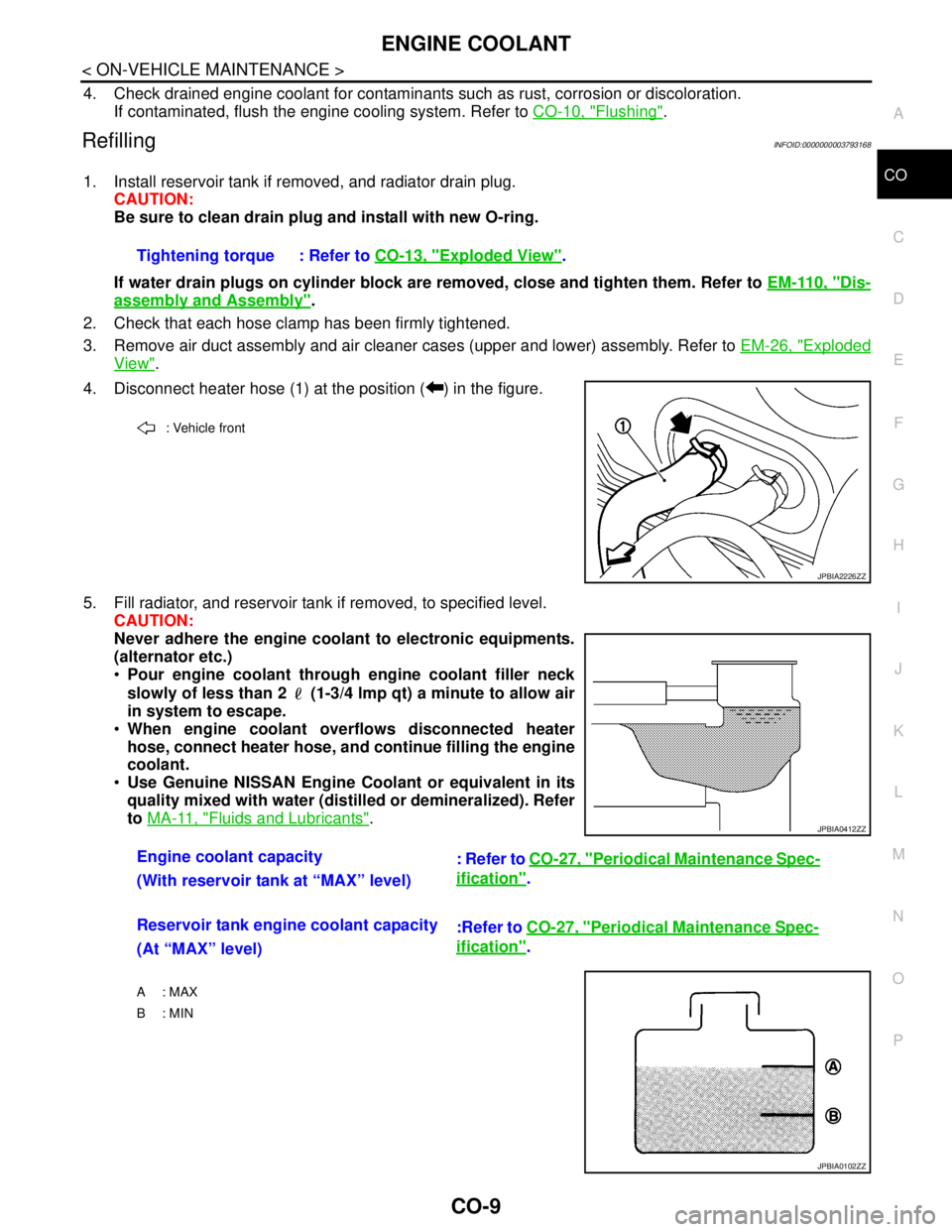

4. Disconnect heater hose (1) at the position ( ) in the figure.

5. Fill radiator, and reservoir tank if removed, to specified level.

CAUTION:

Never adhere the engine coolant to electronic equipments.

(alternator etc.)

Pour engine coolant through engine coolant filler neck

slowly of less than 2 (1-3/4 lmp qt) a minute to allow air

in system to escape.

When engine coolant overflows disconnected heater

hose, connect heater hose, and continue filling the engine

coolant.

Use Genuine NISSAN Engine Coolant or equivalent in its

quality mixed with water (distilled or demineralized). Refer

to MA-11, "

Fluids and Lubricants". Tightening torque : Refer to CO-13, "

Exploded View".

: Vehicle front

JPBIA2226ZZ

Engine coolant capacity

: Refer to CO-27, "Periodical Maintenance Spec-

ification".

(With reservoir tank at “MAX” level)

Reservoir tank engine coolant capacity

:Refer to CO-27, "

Periodical Maintenance Spec-

ification".

(At “MAX” level)

A : MAX

B: MIN

JPBIA0412ZZ

JPBIA0102ZZ

Page 1133 of 5121

CO-10

< ON-VEHICLE MAINTENANCE >

ENGINE COOLANT

6. Install air duct assembly and air cleaner cases (upper and lower) assembly. Refer to EM-26, "Exploded

View".

7. Install radiator cap.

8. Warm up engine until opening thermostat. Standard for warming-up time is approximately 10 minutes at

3,000 rpm.

Check thermostat opening condition by touching radiator hose (lower) to see a flow of warm water.

CAUTION:

Watch water temperature gauge so as not to overheat engine.

9. Stop the engine and cool down to less than approximately 50°C (122°F).

Cool down using fan to reduce the time.

If necessary, refill radiator up to filler neck with engine coolant.

CAUTION:

Never adhere the engine coolant to electronic equipments. (alternator etc.)

10. Refill reservoir tank to “MAX” level line with engine coolant.

11. Repeat steps 7 through 10 two or more times with radiator cap installed until engine coolant level no

longer drops.

12. Check cooling system for leakage with engine running.

13. Warm up the engine, and check for sound of engine coolant flow while running engine from idle up to

3,000 rpm with heater temperature controller set at several position between “COOL” and “WARM”.

Sound may be noticeable at heater unit.

14. Repeat step 13 three times.

15. If sound is heard, bleed air from cooling system by repeating step 5, and steps from 7 to 14 until engine

coolant level no longer drops.

FlushingINFOID:0000000003793169

1. Install reservoir tank if removed, and radiator drain plug.

CAUTION:

Be sure to clean drain plug and install with new O-ring.

If water drain plugs on cylinder block are removed, close and tighten them. Refer to EM-110, "

Dis-

assembly and Assembly".

2. Remove air duct assembly and air cleaner cases (upper and lower) assembly. Refer to EM-26, "

Exploded

View".

3. Disconnect heater hose (1) at the position ( ) in the figure.

4. Fill radiator and reservoir tank with water and reinstall radiator cap.

CAUTION:

Never adhere the water to electronic equipments. (alternator etc.)

When water overflows disconnected heater hose, connect heater hose, and continue filling the

water.

5. Run the engine and warm it up to normal operating temperature.

6. Rev the engine two or three times under no-load.

7. Stop the engine and wait until it cools down.

8. Drain water from the system. Refer to CO-8, "

Draining". Tightening torque : Refer to CO-13, "

Exploded View".

: Vehicle front

JPBIA2226ZZ

Page 1148 of 5121

WATER OUTLET AND WATER PIPING

CO-25

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

K

L

MA

CO

N

P O

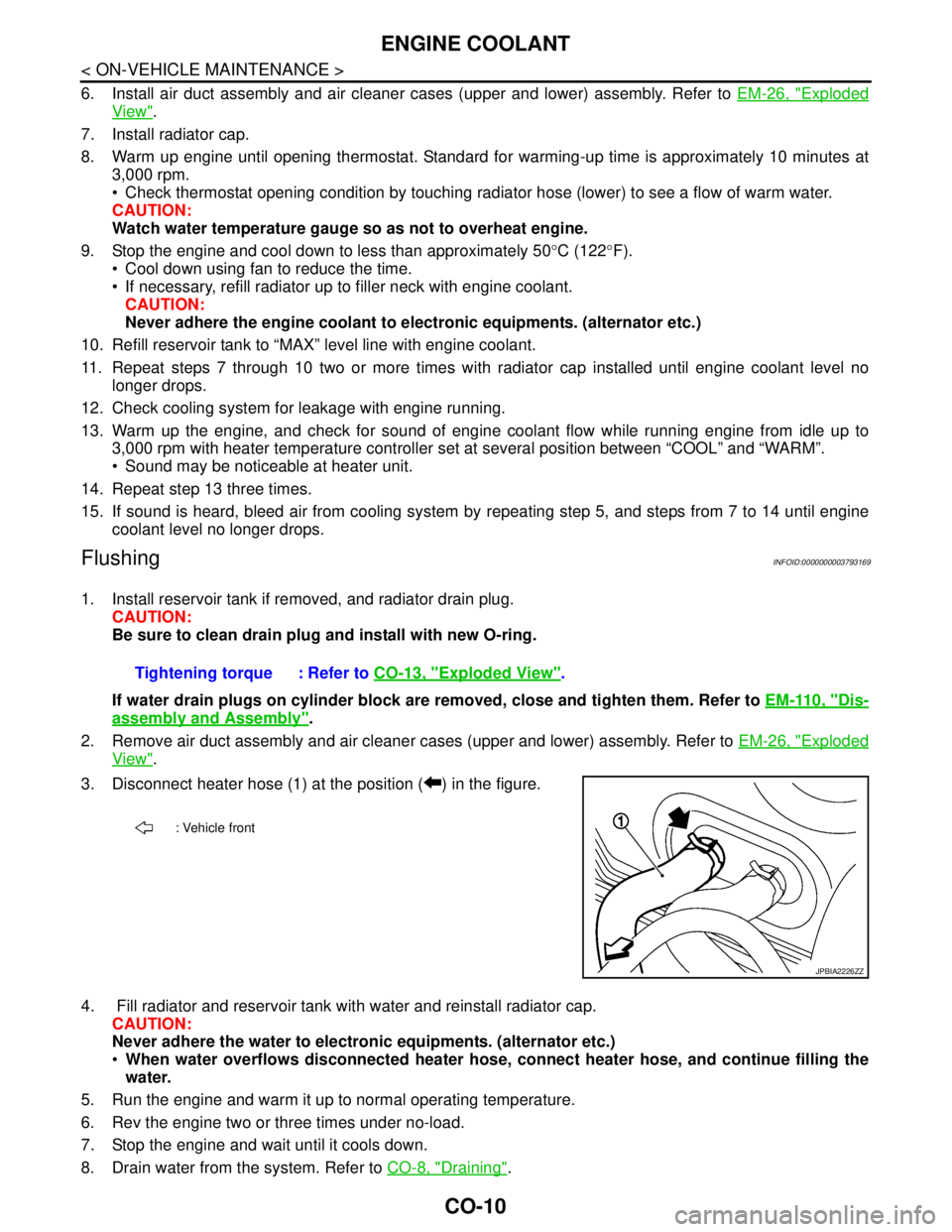

WATER OUTLET AND WATER PIPING

Exploded ViewINFOID:0000000003793185

Removal and InstallationINFOID:0000000003793186

REMOVAL

1. Remove air duct (inlet), air cleaner cases (upper and lower) with mass air flow sensor and air duct assem-

bly. Refer to EM-26, "

Exploded View".

2. Remove engine cover. Refer to EM-24, "

Exploded View".

3. Drain engine coolant from radiator drain plug at the bottom of radiator, and from water drain plug at the

front of cylinder block. Refer to CO-8, "

Draining" and EM-110, "Disassembly and Assembly".

CAUTION:

Perform this step when the engine is cold.

Never spill engine coolant on drive belt.

4. Remove battery and battery tray. Refer to PG-109, "

Removal and Installation".

1. Heater hose 2. Clamp 3. Water hose

4. Clamp 5. Water outlet 6. Gasket

7. Gasket 8. Water connector 9. O-ring

10. Water bypass pipe 11. Clamp 12. Water hose

13. Heater pipe 14. Water hose 15. Heater hose

16. Engine coolant temperature sensor 17. Clamp 18. Radiator hose (upper)

A. To heater core B. To electric throttle control actuator C. To oil cooler

D. To radiator

Refer to GI-4, "

Components" for symbols in the figure.

JPBIA1691GB

Page 1149 of 5121

CO-26

< ON-VEHICLE REPAIR >

WATER OUTLET AND WATER PIPING

5. Remove CVT fluid charging pipe and CVT fluid level gauge. Refer to TM-332, "Exploded View" (VQ25DE)

or TM-168, "

Exploded View" (VQ35DE).

6. Move CVT control cable aside. Refer to TM-319, "

Exploded View" (VQ25DE) or TM-157, "Exploded View"

(VQ35DE).

7. Remove vacuum pipe (front) mounting bolt from water outlet. Refer to EM-67, "

Exploded View".

8. Remove radiator hose (upper) from water outlet.

9. Remove water hoses and heater hoses.

10. Disconnect harness connectors, and move harness to aside.

11. Remove engine coolant temperature sensor as necessary.

CAUTION:

Be careful not to damage engine coolant temperature sensor.

12. Remove water outlet, heater pipe, water bypass pipe and water connector.

INSTALLATION

Note the following, and install in the reverse order of removal.

Securely insert each hose, and install clamp at a position where it does not interfere with the pipe bulge.

When inserting water bypass pipe and heater pipe into water connector, apply neutral detergent to O-ring.

InspectionINFOID:0000000003793187

INSPECTION AFTER INSTALLATION

Check for leakage of engine coolant using the radiator cap tester adapter (commercial service tool) and the

radiator cap tester (commercial service tool). Refer to CO-8, "

Inspection".

Start and warm up the engine. Visually check that there is no leakage of engine coolant.

Page 1463 of 5121

EC-2

Component Parts Location ...................................53

Component Description .........................................58

CAN COMMUNICATION ...................................59

System Description .................................................59

COOLING FAN CONTROL ...............................60

System Diagram .....................................................60

System Description .................................................60

Component Parts Location ...................................62

Component Description ..........................................67

ELECTRONIC CONTROLLED ENGINE

MOUNT ..............................................................

68

System Diagram .....................................................68

System Description .................................................69

Component Parts Location ...................................70

Component Description .........................................75

EVAPORATIVE EMISSION SYSTEM ...............76

System Diagram .....................................................76

System Description .................................................76

Component Parts Location ...................................80

Component Description .........................................85

INTAKE VALVE TIMING CONTROL .................86

System Diagram .....................................................86

System Description .................................................86

Component Parts Location ...................................87

Component Description ..........................................92

VARIABLE INDUCTION AIR SYSTEM .............93

System Diagram .....................................................93

System Description .................................................93

Component Parts Location ...................................96

Component Description ........................................101

ON BOARD DIAGNOSTIC (OBD) SYSTEM ...102

Diagnosis Description ............................................102

CONSULT-III Function ..........................................113

Diagnosis Tool Function ......................................122

COMPONENT DIAGNOSIS .......................124

TROUBLE DIAGNOSIS - SPECIFICATION

VALUE .............................................................

124

Description .............................................................124

Component Function Check ..................................124

Diagnosis Procedure .............................................125

POWER SUPPLY AND GROUND CIRCUIT ...132

Diagnosis Procedure .............................................132

U1000, U1001 CAN COMM CIRCUIT .............135

Description .............................................................135

DTC Logic ..............................................................135

Diagnosis Procedure .............................................135

P0011, P0021 IVT CONTROL .........................136

DTC Logic ..............................................................136

Diagnosis Procedure .............................................137

Component Inspection ..........................................138

P0031, P0032, P0051, P0052 A/F SENSOR 1

HEATER ...........................................................

140

Description ............................................................140

DTC Logic .............................................................140

Diagnosis Procedure .............................................140

Component Inspection ..........................................142

P0037, P0038, P0057, P0058 HO2S2 HEAT-

ER .....................................................................

143

Description ............................................................143

DTC Logic .............................................................143

Diagnosis Procedure .............................................144

Component Inspection ..........................................145

P0075, P0081 IVT CONTROL SOLENOID

VALVE ..............................................................

146

Description ............................................................146

DTC Logic .............................................................146

Diagnosis Procedure .............................................146

Component Inspection ..........................................147

P0102, P0103 MAF SENSOR ..........................149

Description ............................................................149

DTC Logic .............................................................149

Diagnosis Procedure .............................................150

Component Inspection ..........................................151

P0112, P0113 IAT SENSOR ............................154

Description ............................................................154

DTC Logic .............................................................154

Diagnosis Procedure .............................................155

Component Inspection ..........................................155

P0117, P0118 ECT SENSOR ...........................157

Description ............................................................157

DTC Logic .............................................................157

Diagnosis Procedure .............................................158

Component Inspection ..........................................158

P0122, P0123 TP SENSOR ..............................160

Description ............................................................160

DTC Logic .............................................................160

Diagnosis Procedure .............................................160

Component Inspection ..........................................162

Special Repair Requirement .................................162

P0130, P0150 A/F SENSOR 1 .........................163

Description ............................................................163

DTC Logic .............................................................163

Component Function Check .................................165

Diagnosis Procedure .............................................165

P0131, P0151 A/F SENSOR 1 .........................167

Description ............................................................167

DTC Logic .............................................................167

Diagnosis Procedure .............................................168

P0132, P0152 A/F SENSOR 1 .........................170

Description ............................................................170

Page 1486 of 5121

![NISSAN TEANA 2008 Service Manual ENGINE CONTROL SYSTEM

EC-25

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

Component DescriptionINFOID:0000000003856464

1. Fuel level sensor unit and fuel pump

harness connect NISSAN TEANA 2008 Service Manual ENGINE CONTROL SYSTEM

EC-25

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

Component DescriptionINFOID:0000000003856464

1. Fuel level sensor unit and fuel pump

harness connect](/img/5/57391/w960_57391-1485.png)

ENGINE CONTROL SYSTEM

EC-25

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

Component DescriptionINFOID:0000000003856464

1. Fuel level sensor unit and fuel pump

harness connector2. Fuel pressure regulator 3. Fuel level sensor unit and fuel pump

: Vehicle front

JMBIA1385ZZ

Component Reference

A/F sensor 1EC-163, "

Description"

A/F sensor 1 heaterEC-140, "Description"

Accelerator pedal position sensorEC-304, "Description"

ASCD brake switchEC-273, "Description"

ASCD steering switchEC-270, "Description"

Battery current sensorEC-258, "Description"

Camshaft position sensor (PHASE)EC-222, "Description"

Crankshaft position sensor (POS)EC-218, "Description"

Cooling fan motorEC-324, "Description"

Electric throttle control actuatorEC-302, "Description"

Electronic controlled engine mountEC-331, "Description"

Engine coolant temperature sensorEC-157, "Description"

EVAP canister purge volume control solenoid valveEC-231, "Description"

Fuel injectorEC-334, "Description"

Fuel pumpEC-337, "Description"

Heated oxygen sensor 2EC-178, "Description"

Heated oxygen sensor 2 heaterEC-143, "Description"

Ignition coil with power transistorEC-341, "Description"

Intake air temperature sensorEC-154, "Description"

Intake valve timing control solenoid valveEC-146, "Description"

Knock sensorEC-215, "Description"

Mass air flow sensorEC-149, "Description"

PCV valveEC-347, "Description"

Power steering pressure sensorEC-236, "Description"

Power valves 1 and 2EC-351, "Description"

Refrigerant pressure sensorEC-348, "Description"

Stop lamp switchEC-291, "Description"

TCM (VQ35DE engine)

Park/neutral position (PNP) switch (VQ25DE engine)EC-245, "Description"

Throttle control motorEC-300, "Description"

Page 1576 of 5121

![NISSAN TEANA 2008 Service Manual ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-115

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

X: Applicable

*1: This item includes 1st trip DTCs.

*2: This mode includes 1st trip freez NISSAN TEANA 2008 Service Manual ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-115

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

X: Applicable

*1: This item includes 1st trip DTCs.

*2: This mode includes 1st trip freez](/img/5/57391/w960_57391-1575.png)

ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-115

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

X: Applicable

*1: This item includes 1st trip DTCs.

*2: This mode includes 1st trip freeze frame data or freeze frame data. The items appear on CONSULT-III screen in freeze frame data

mode only if a 1st trip DTC or DTC is detected. For details, refer to EC-102, "

Diagnosis Description".

*3: Always “CMPLT” is displayed.

WORK SUPPORT MODE

Work Item

*: This function is not necessary in the usual service procedure.

SELF-DIAG RESULTS MODE

Self Diagnostic Item

Regarding items of DTC and 1st trip DTC, refer to EC-389, "DTCIndex".

ENGINE CONTROL COMPONENT PARTS

OUTPUT

Fuel injector××

Power transistor (Ignition timing)××

Throttle control motor relay××

Throttle control motor×

EVAP canister purge volume control

solenoid valve××××

Air conditioner relay×

Fuel pump relay×××

Cooling fan relay×××

Air fuel ratio (A/F) sensor 1 heater××

×*

3

Heated oxygen sensor 2 heater××

×*3

Intake valve timing control solenoid

valve×××

VIAS control solenoid valve 1×××

VIAS control solenoid valve 2×××

Electronic controlled engine mount××

Alternator××

Calculated load value×× ItemDIAGNOSTIC TEST MODE

WORK

SUPPORTSELF-DIAGNOSTIC

RESULTS

DATA

MONI-

TORACTIVE

TESTDTC & SRT

CONFIRMATION

DTC*

1FREEZE

FRAME

DATA*

2

SRT STA-

TUSDTC

WORK

SUP-

PORT

WORK ITEM CONDITION USAGE

FUEL PRESSURE RELEASE FUEL PUMP WILL STOP BY TOUCHING “START” DUR-

ING IDLING.

CRANK A FEW TIMES AFTER ENGINE STALLS.When releasing fuel pressure from

fuel line

IDLE AIR VOL LEARN THE IDLE AIR VOLUME THAT KEEPS THE ENGINE

WITHIN THE SPECIFIED RANGE IS MEMORIZED IN

ECM.When learning the idle air volume

SELF-LEARNING CONT THE COEFFICIENT OF SELF-LEARNING CONTROL

MIXTURE RATIO RETURNS TO THE ORIGINAL COEF-

FICIENT.When clearing mixture ratio self-

learning value

TARGET IDLE RPM ADJ* IDLE CONDITIONWhen setting target idle speed

TARGET IGN TIM ADJ* IDLE CONDITION When adjusting target ignition tim-

ing

Page 1578 of 5121

![NISSAN TEANA 2008 Service Manual ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-117

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

COOLAN TEMP/S°C or °F The engine coolant temperature (determined by

the signal voltag NISSAN TEANA 2008 Service Manual ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-117

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

COOLAN TEMP/S°C or °F The engine coolant temperature (determined by

the signal voltag](/img/5/57391/w960_57391-1577.png)

ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-117

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

COOLAN TEMP/S°C or °F The engine coolant temperature (determined by

the signal voltage of the engine coolant tempera-

ture sensor) is displayed. When the engine coolant temperature

sensor is open or short-circuited,

ECM enters fail-safe mode. The en-

gine coolant temperature determined

by the ECM is displayed.

A/F SEN1 (B1)

V The A/F signal computed from the input signal of

the air fuel ratio (A/F) sensor 1 is displayed.

A/F SEN1 (B2)

HO2S2 (B1)

V The signal voltage of the heated oxygen sensor 2

is displayed.

HO2S2 (B2)

HO2S2 MNTR(B1)

RICH/LEAN Display of heated oxygen sensor 2 signal:

RICH: means the amount of oxygen after three

way catalyst is relatively small.

LEAN: means the amount of oxygen after three

way catalyst is relatively large. When the engine is stopped, a certain

value is indicated.

HO2S2 MNTR(B2)

VHCL SPEED SE km/h or mph The vehicle speed computed from the vehicle

speed signal sent from combination meter is dis-

played.

BATTERY VOLT V The power supply voltage of ECM is displayed.

ACCEL SEN 1

V The accelerator pedal position sensor signal volt-

age is displayed. ACCEL SEN 2 signal is converted by

ECM internally. Thus, it differs from

ECM terminal voltage signal. ACCEL SEN 2

TP SEN 1-B1

V The throttle position sensor signal voltage is dis-

played. TP SEN 2-B1 signal is converted by

ECM internally. Thus, it differs from

ECM terminal voltage signal. TP SEN 2-B1

INT/A TEMP SE°C or °F The intake air temperature (determined by the

signal voltage of the intake air temperature sen-

sor) is indicated.

START SIGNAL ON/OFF Indicates start signal status [ON/OFF] computed

by the ECM according to the signals of engine

speed and battery voltage. After starting the engine, [OFF] is dis-

played regardless of the starter sig-

nal.

CLSD THL POS ON/OFF Indicates idle position [ON/OFF] computed by

ECM according to the accelerator pedal position

sensor signal.

AIR COND SIG ON/OFF Indicates [ON/OFF] condition of the air condition-

er switch as determined by the air conditioner sig-

nal.

P/N POSI SW ON/OFF Indicates [ON/OFF] condition from the park/neu-

tral position (PNP) signal.

PW/ST SIGNAL ON/OFF [ON/OFF] condition of the power steering system

(determined by the signal voltage of the power

steering pressure sensor) is indicated.

LOAD SIGNAL ON/OFF Indicates [ON/OFF] condition from the electrical

load signal.

ON: Rear window defogger switch is ON and/or

lighting switch is in 2nd position.

OFF: Both rear window defogger switch and light-

ing switch are OFF.

IGNITION SW ON/OFF Indicates [ON/OFF] condition from ignition switch

signal.

HEATER FAN SW ON/OFF Indicates [ON/OFF] condition from the heater fan

switch signal.

BRAKE SW ON/OFF Indicates [ON/OFF] condition from the stop lamp

switch signal.

INJ PULSE-B1

msec Indicates the actual fuel injection pulse width

compensated by ECM according to the input sig-

nals. When the engine is stopped, a certain

computed value is indicated.

INJ PULSE-B2Monitored item Unit Description Remarks