mileage NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 901 of 5121

PRECAUTIONS

BR-5

< PRECAUTION >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

Precaution for Procedure without Cowl Top CoverINFOID:0000000003890162

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Precaution for Brake SystemINFOID:0000000003811170

WARNING:

Clean any dust from the front brake and rear brake with a vacuum dust collector. Never blow with com-

pressed air.

CAUTION:

Only use “DOT 3 or DOT 4” brake fluid. Refer to MA-11, "

Fluids and Lubricants".

Never reuse drained brake fluid.

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with water if it gets on a painted surface.

Always clean with new brake fluid when cleaning the master cylinder, brake caliper and other com-

ponents.

Never use mineral oils such as gasoline or light oil to clean. They may damage rubber parts and

cause improper operation.

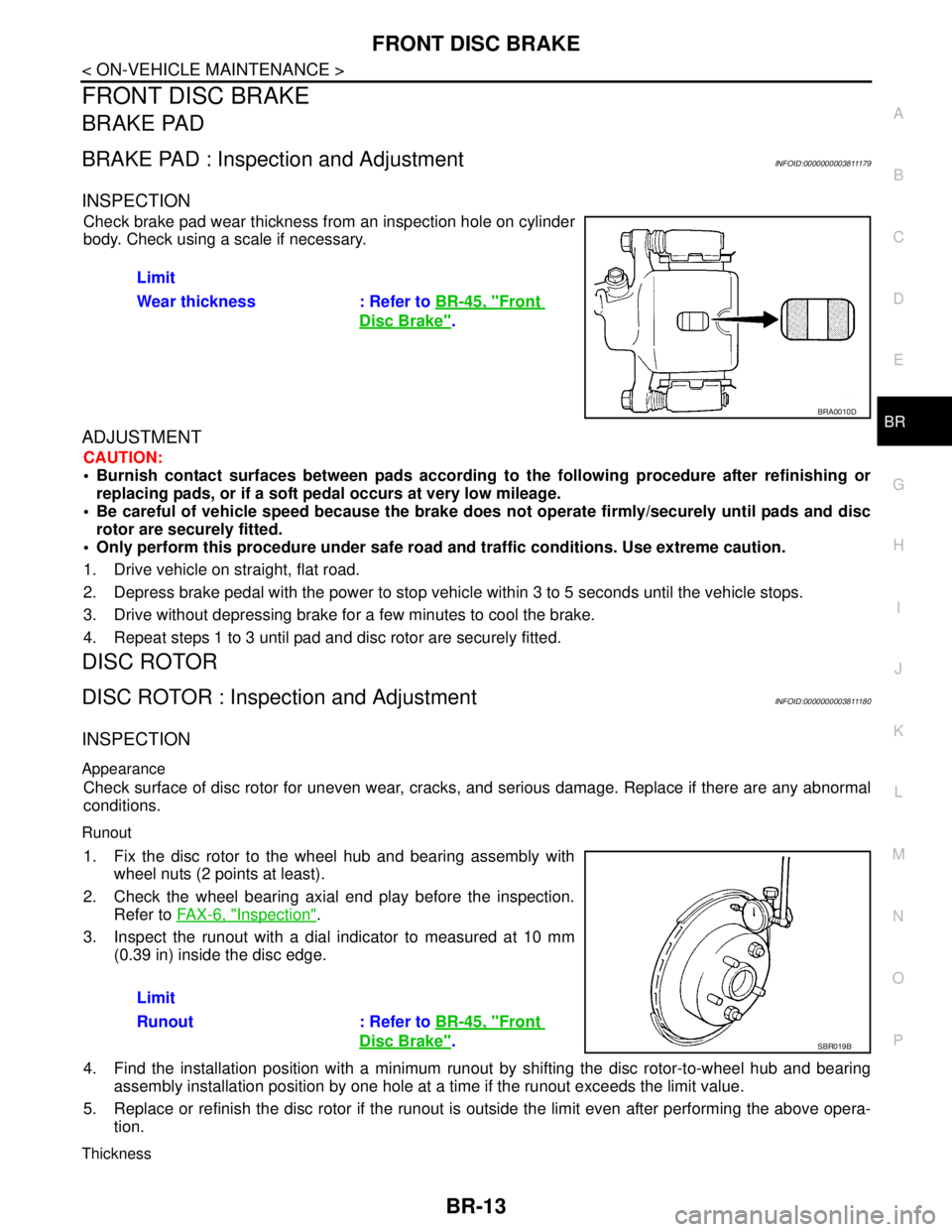

Always loosen the brake tube flare nut with a flare nut wrench.

Tighten the brake tube flare nut to the specified torque with

torque wrench (A).

Always confirm the specified tightening torque when install-

ing the brake pipes.

Turn the ignition switch OFF and disconnect the ABS actuator

and electric unit (control unit) connector or the battery nega-

tive terminal before performing the work.

Check that no brake fluid leakage is present after replacing

the parts.

Burnish the brake contact surfaces after refinishing or replac-

ing rotors, after replacing pads, or if a soft pedal occurs at

very low mileage.

- Front brake pad: refer to BR-13, "

BRAKE PAD : Inspection and Adjustment".

- Front disc rotor: refer to BR-13, "

DISC ROTOR : Inspection and Adjustment".

- Rear brake pad: refer to BR-15, "

BRAKE PAD : Inspection and Adjustment".

- Rear disc rotor: refer to BR-15, "

DISC ROTOR : Inspection and Adjustment".

PIIB3706J

JPFIA0061ZZ

Page 909 of 5121

FRONT DISC BRAKE

BR-13

< ON-VEHICLE MAINTENANCE >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

FRONT DISC BRAKE

BRAKE PAD

BRAKE PAD : Inspection and AdjustmentINFOID:0000000003811179

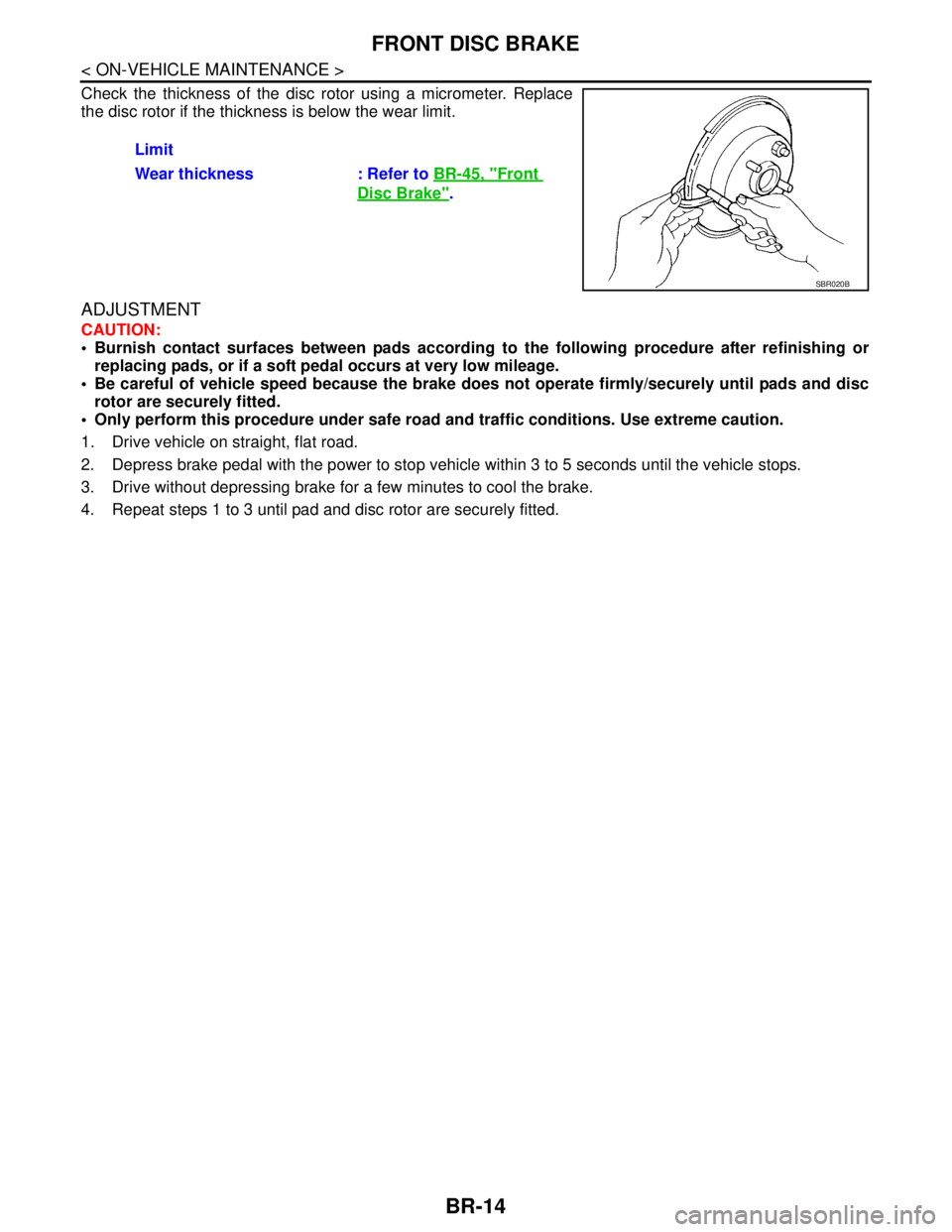

INSPECTION

Check brake pad wear thickness from an inspection hole on cylinder

body. Check using a scale if necessary.

ADJUSTMENT

CAUTION:

Burnish contact surfaces between pads according to the following procedure after refinishing or

replacing pads, or if a soft pedal occurs at very low mileage.

Be careful of vehicle speed because the brake does not operate firmly/securely until pads and disc

rotor are securely fitted.

Only perform this procedure under safe road and traffic conditions. Use extreme caution.

1. Drive vehicle on straight, flat road.

2. Depress brake pedal with the power to stop vehicle within 3 to 5 seconds until the vehicle stops.

3. Drive without depressing brake for a few minutes to cool the brake.

4. Repeat steps 1 to 3 until pad and disc rotor are securely fitted.

DISC ROTOR

DISC ROTOR : Inspection and AdjustmentINFOID:0000000003811180

INSPECTION

Appearance

Check surface of disc rotor for uneven wear, cracks, and serious damage. Replace if there are any abnormal

conditions.

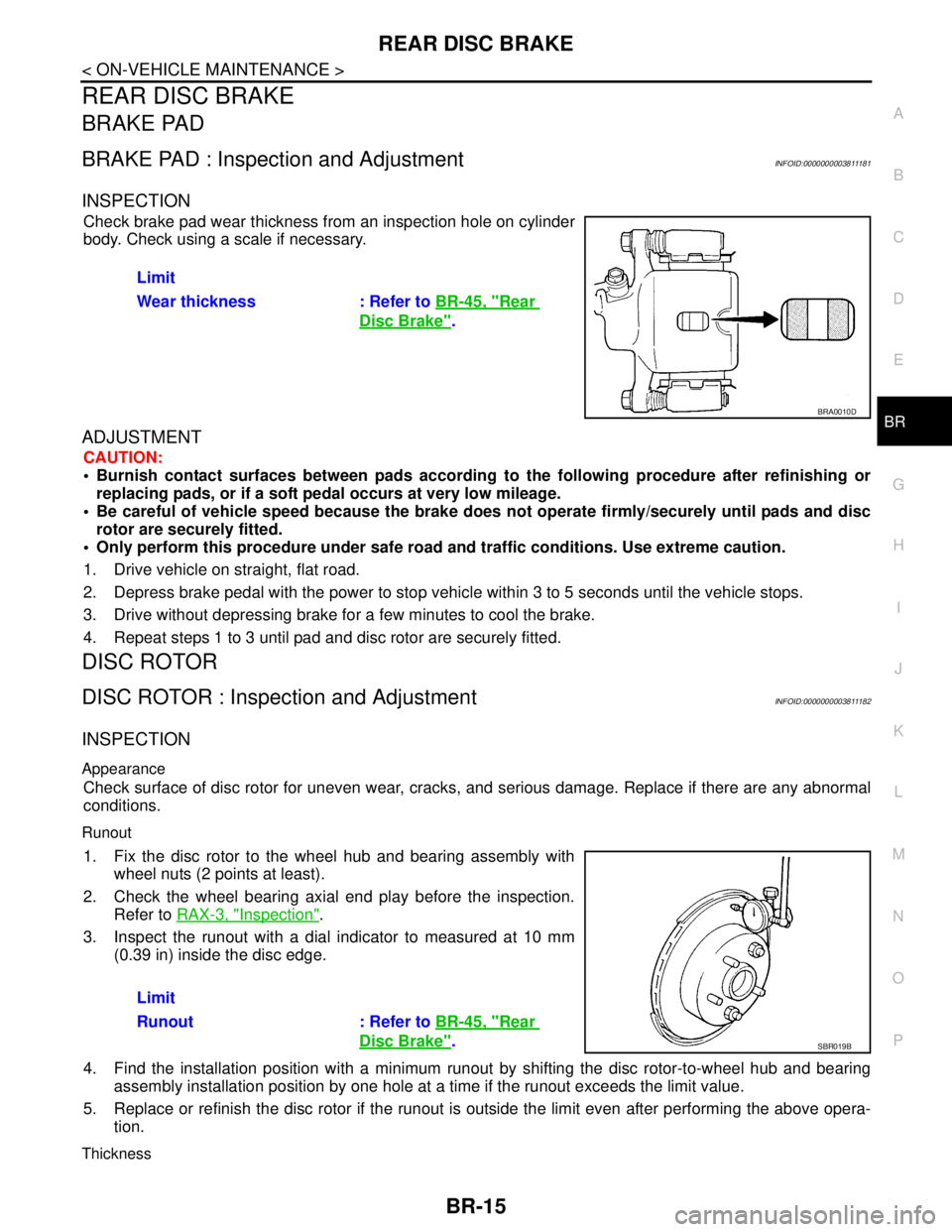

Runout

1. Fix the disc rotor to the wheel hub and bearing assembly with

wheel nuts (2 points at least).

2. Check the wheel bearing axial end play before the inspection.

Refer to FA X - 6 , "

Inspection".

3. Inspect the runout with a dial indicator to measured at 10 mm

(0.39 in) inside the disc edge.

4. Find the installation position with a minimum runout by shifting the disc rotor-to-wheel hub and bearing

assembly installation position by one hole at a time if the runout exceeds the limit value.

5. Replace or refinish the disc rotor if the runout is outside the limit even after performing the above opera-

tion.

Thickness

Limit

Wear thickness : Refer to BR-45, "

Front

Disc Brake".

BRA0010D

Limit

Runout : Refer to BR-45, "

Front

Disc Brake".SBR019B

Page 910 of 5121

BR-14

< ON-VEHICLE MAINTENANCE >

FRONT DISC BRAKE

Check the thickness of the disc rotor using a micrometer. Replace

the disc rotor if the thickness is below the wear limit.

ADJUSTMENT

CAUTION:

Burnish contact surfaces between pads according to the following procedure after refinishing or

replacing pads, or if a soft pedal occurs at very low mileage.

Be careful of vehicle speed because the brake does not operate firmly/securely until pads and disc

rotor are securely fitted.

Only perform this procedure under safe road and traffic conditions. Use extreme caution.

1. Drive vehicle on straight, flat road.

2. Depress brake pedal with the power to stop vehicle within 3 to 5 seconds until the vehicle stops.

3. Drive without depressing brake for a few minutes to cool the brake.

4. Repeat steps 1 to 3 until pad and disc rotor are securely fitted.Limit

Wear thickness : Refer to BR-45, "

Front

Disc Brake".

SBR020B

Page 911 of 5121

REAR DISC BRAKE

BR-15

< ON-VEHICLE MAINTENANCE >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

REAR DISC BRAKE

BRAKE PAD

BRAKE PAD : Inspection and AdjustmentINFOID:0000000003811181

INSPECTION

Check brake pad wear thickness from an inspection hole on cylinder

body. Check using a scale if necessary.

ADJUSTMENT

CAUTION:

Burnish contact surfaces between pads according to the following procedure after refinishing or

replacing pads, or if a soft pedal occurs at very low mileage.

Be careful of vehicle speed because the brake does not operate firmly/securely until pads and disc

rotor are securely fitted.

Only perform this procedure under safe road and traffic conditions. Use extreme caution.

1. Drive vehicle on straight, flat road.

2. Depress brake pedal with the power to stop vehicle within 3 to 5 seconds until the vehicle stops.

3. Drive without depressing brake for a few minutes to cool the brake.

4. Repeat steps 1 to 3 until pad and disc rotor are securely fitted.

DISC ROTOR

DISC ROTOR : Inspection and AdjustmentINFOID:0000000003811182

INSPECTION

Appearance

Check surface of disc rotor for uneven wear, cracks, and serious damage. Replace if there are any abnormal

conditions.

Runout

1. Fix the disc rotor to the wheel hub and bearing assembly with

wheel nuts (2 points at least).

2. Check the wheel bearing axial end play before the inspection.

Refer to RAX-3, "

Inspection".

3. Inspect the runout with a dial indicator to measured at 10 mm

(0.39 in) inside the disc edge.

4. Find the installation position with a minimum runout by shifting the disc rotor-to-wheel hub and bearing

assembly installation position by one hole at a time if the runout exceeds the limit value.

5. Replace or refinish the disc rotor if the runout is outside the limit even after performing the above opera-

tion.

Thickness

Limit

Wear thickness : Refer to BR-45, "

Rear

Disc Brake".

BRA0010D

Limit

Runout : Refer to BR-45, "

Rear

Disc Brake".SBR019B

Page 912 of 5121

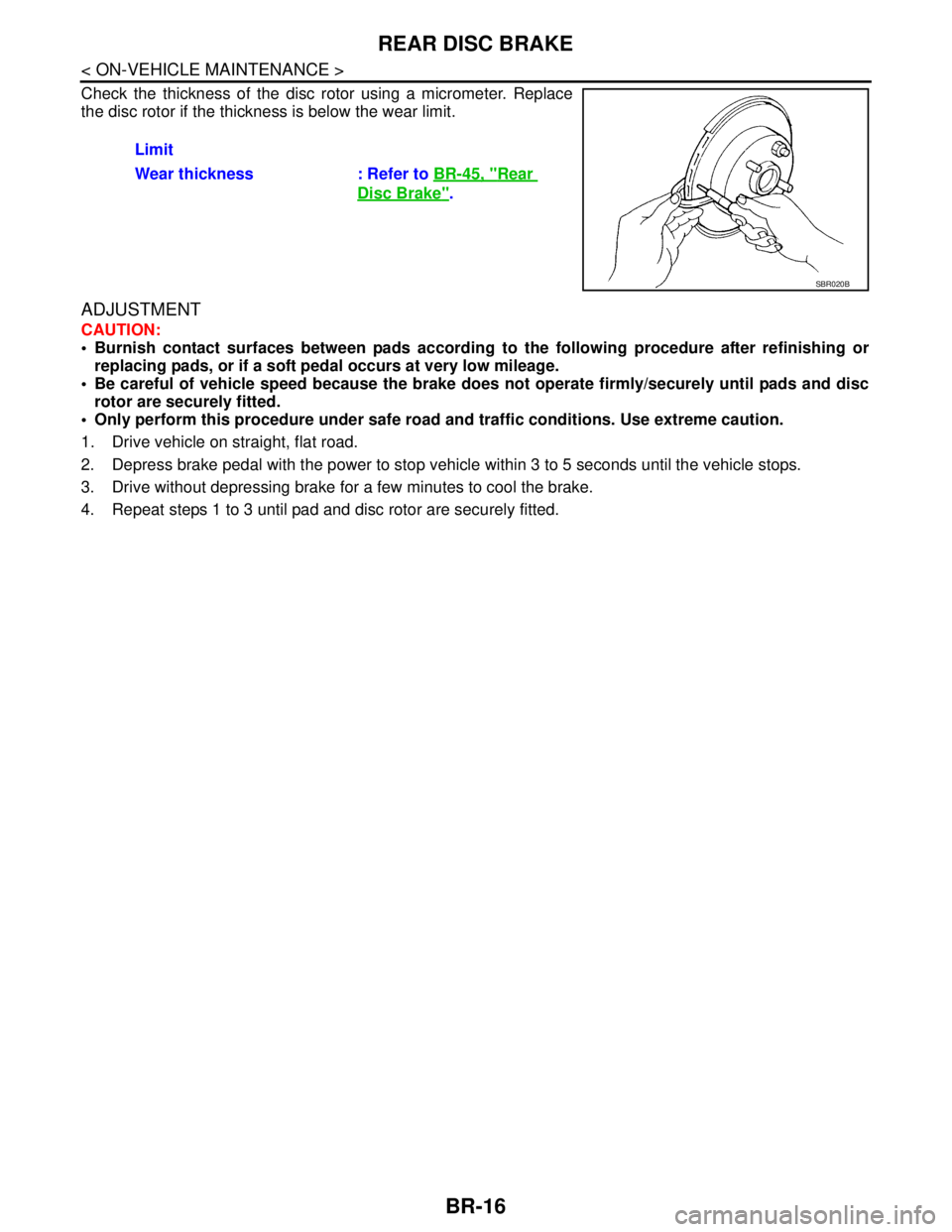

BR-16

< ON-VEHICLE MAINTENANCE >

REAR DISC BRAKE

Check the thickness of the disc rotor using a micrometer. Replace

the disc rotor if the thickness is below the wear limit.

ADJUSTMENT

CAUTION:

Burnish contact surfaces between pads according to the following procedure after refinishing or

replacing pads, or if a soft pedal occurs at very low mileage.

Be careful of vehicle speed because the brake does not operate firmly/securely until pads and disc

rotor are securely fitted.

Only perform this procedure under safe road and traffic conditions. Use extreme caution.

1. Drive vehicle on straight, flat road.

2. Depress brake pedal with the power to stop vehicle within 3 to 5 seconds until the vehicle stops.

3. Drive without depressing brake for a few minutes to cool the brake.

4. Repeat steps 1 to 3 until pad and disc rotor are securely fitted.Limit

Wear thickness : Refer to BR-45, "

Rear

Disc Brake".

SBR020B

Page 930 of 5121

BR-34

< ON-VEHICLE REPAIR >

FRONT DISC BRAKE

1. Install the pad retainer to the torque member if the pad retainers has been removed.

CAUTION:

Securely assemble the pad retainers so that it will not be lifted up from the torque member.

Never deform the pad retainers.

2. Apply copper based brake grease to the mating faces between the brake pads and pad retainers.

3. Apply PBC (Poly Butyl Cuprysil) grease or silicone-based grease to the mating faces between the brake

pads, shims and shim cover, and install them to the brake pad.

CAUTION:

Always replace the shims together with the shim cover when replacing the brake pad.

4. Install the cylinder body and brake pads to the torque member.

CAUTION:

Never damage the piston boot.

When replacing a pad with new one, check a brake fluid level in the reservoir tank because brake

fluid returns to master cylinder reservoir tank when pressing piston in.

NOTE:

Use a disc brake piston tool to easily press piston.

5. Install the lower sliding pin bolt and tighten it to the specified torque.

6. Depress the brake pedal several times to check that no drag feel is present for the front disc brake. Refer

to BR-34, "

BRAKE PAD : Inspection".

BRAKE PAD : InspectionINFOID:0000000003811206

INSPECTION AFTER REMOVAL

Replace the shims and the shim cover if rust is excessively attached.

INSPECTION AFTER INSTALLATION

1. Check a drag of front disc brake. If any drag is found, follow the procedure described below.

2. Remove brake pads.

3. Press the piston.

CAUTION:

Never damage the piston boot.

When replacing a pad with new one, check a brake fluid level in the reservoir tank because brake

fluid returns to master cylinder reservoir tank when pressing piston in.

NOTE:

Use a disc brake piston tool to easily press piston.

4. Install brake pads.

5. Depress the brake pedal several times.

6. Check a drag of front disc brake again. If any drag is found, disassemble the cylinder body. Refer to BR-

36, "BRAKE CALIPER ASSEMBLY : Disassembly and Assembly".

7. Burnish contact surfaces after refinishing or replacing pads, or if a soft pedal occurs at very low mileage.

Refer to BR-13, "

BRAKE PAD : Inspection and Adjustment".

BRAKE CALIPER ASSEMBLY

BRAKE CALIPER ASSEMBLY : Exploded ViewINFOID:0000000003811207

REMOVAL

Page 936 of 5121

BR-40

< ON-VEHICLE REPAIR >

REAR DISC BRAKE

Never depress the brake pedal while removing the brake pads or the cylinder body because the pis-

ton may pop out.

Never spill or splash brake fluid on the disc rotor.

1. Install the pad retainers to the torque member if the pad retainers has been removed.

CAUTION:

Securely assemble the pad retainers not to be lifted up from the torque member.

Never deform the pad retainers.

2. Apply PBC (Poly Butyl Cuprysil) grease or silicone-based grease to the mating faces between the brake

pads, the shims and pawls part of cylinder body, and install them to the brake pad.

CAUTION:

Always replace the shims together when replacing the brake pad.

3. Install cylinder body and brake pads to torque member.

CAUTION:

Never damage the piston boot.

When replacing pads with new one, check a brake fluid level in the reservoir tank because brake

fluid returns to master cylinder reservoir tank when pressing piston in.

NOTE:

Use a disc brake piston tool to easily press piston.

4. Install the upper sliding pin bolt and tighten it to the specified torque.

5. Depress the brake pedal several times to check that no drag feel is present for the rear disc brake. Refer

to BR-40, "

BRAKE PAD : Inspection".

BRAKE PAD : InspectionINFOID:0000000003811213

INSPECTION AFTER REMOVAL

Replace the shims if rust is excessively attached.

INSPECTION AFTER INSTALLATION

1. Check a drag of rear disc brake. If any drag is found, follow the procedure described below.

2. Remove brake pads.

3. Press the piston.

CAUTION:

Never damage the piston boot.

When replacing a pad with new one, check a brake fluid level in the reservoir tank because brake

fluid returns to master cylinder reservoir tank when pressing piston in.

NOTE:

Use a disc brake piston tool to easily press piston.

4. Install brake pads.

5. Depress the brake pedal several times.

6. Check a drag of rear disc brake again. If any drag is found, disassemble the cylinder body. Refer to BR-

42, "BRAKE CALIPER ASSEMBLY : Disassembly and Assembly".

7. Burnish contact surfaces after refinishing or replacing pads, or if a soft pedal occurs at very low mileage.

Refer to BR-15, "

BRAKE PAD : Inspection and Adjustment".

BRAKE CALIPER ASSEMBLY

BRAKE CALIPER ASSEMBLY : Exploded ViewINFOID:0000000003811214

REMOVAL

Page 3194 of 5121

MA-6

< ON-VEHICLE MAINTENANCE >

PERIODIC MAINTENANCE

PERIODIC MAINTENANCE

Periodic MaintenanceINFOID:0000000003858222

The following tables show the normal maintenance schedule. Depending upon weather and atmospheric con-

ditions, varying road surfaces, individual driving habits and vehicle usage, additional or more frequent mainte-

nance may be required.

Periodic maintenance beyond the last period shown on the tables requires similar maintenance.

ENGINE AND EMISSION CONTROL MAINTENANCE

(Annual Mileage < 30,000 km/year)

Abbreviations: I = Inspect and correct or replace as necessary, R = Replace,[ ] = At the specified mileage only.

NOTE:

Maintenance items with “ ” should be performed more frequently according to “Maintenance Under Severe Driving Condi-

tions”.

(1) Periodic maintenance is not required. However, if valve noise increases, check valve clearance.

(2) Replace the drive belt if found damaged or if the auto belt tensioner reading reaches the maximum limit.

(3) Use Genuine NISSAN Engine Coolant or equivalent in its quality, in order to avoid possible aluminum corrosion within

the engine cooling system caused by the use of non-genuine engine coolant.

First replace at 90,000 Km (54,000 miles)/60 months, then every 60,000 km (36,000 miles)/48 months. Perform "I" (Checking

the mixture ratio and correcting the mixture ratio if necessary) at the middle of replacement interval.

(4) Fuel filter is maintenance-free. For service procedures, refer to FL section. MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Refer-

ence

page Perform at a kilometer (mile) interval or

month interval, whichever comes first.km x

1,000

(Miles x

1,000)

Months15

(9)

1230

(18)

2445

(27)

3660

(36)

4875

(45)

6090

(54)

72105

(63)

84120

(72)

96

Engine compartment and under vehicle

Intake and exhaust valve clearanceSee

NOTE

(1)EM-17

Drive beltSee

NOTE

(2)I I IIIIIIMA-13

Engine oil (Use recommended oil.)R R RRRRRRMA-18

Engine oil filter (Use genuine NISSAN

engine oil filter or equivalent)R R RRRRRRMA-19

Engine coolant (Use Genuine NISSAN

Engine Coolant or equivalent in its quali-

ty.)See

NOTE

(3)IMA-14

Cooling system I I IIIIIIMA-13

,

MA-17

,

MA-17

Fuel and EVAP vapor lines I I I IMA-18,

MA-22

Air cleaner filterRRMA-18

Positive crankcase ventilation (PSV)

systemIIIIMA-21

Fuel filter (In-tank type)See

NOTE

(4)—

Spark plugs (Iridium-tipped type)See

NOTE

(5)[R] [R] [R] [R] [R] [R] [R] [R]MA-20

Page 3195 of 5121

PERIODIC MAINTENANCE

MA-7

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

MB

MAN

OA

(5) Replace spark plug when the spark plug gap exceeds 1.4 mm (0.055 in) even if within specified periodic replacement

mileage.

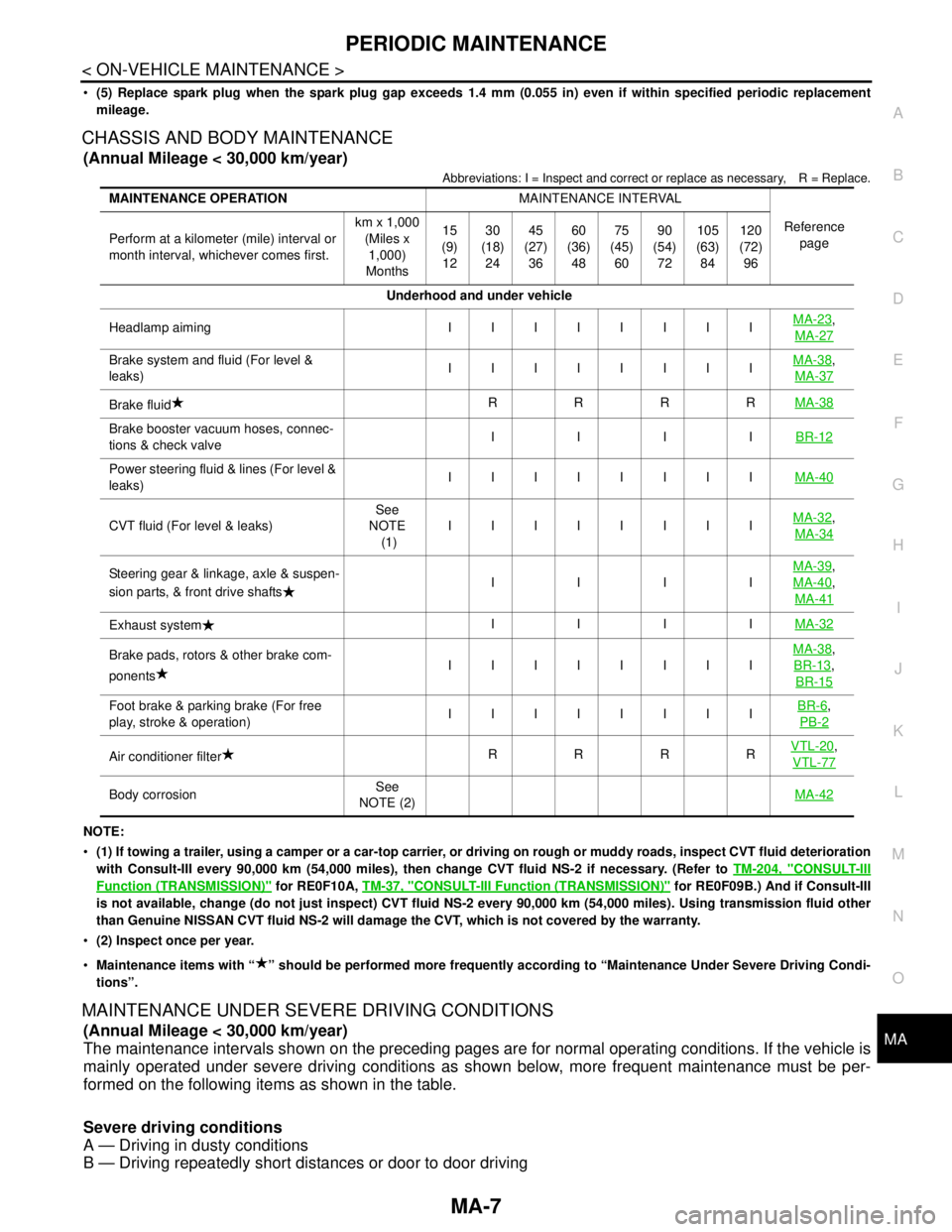

CHASSIS AND BODY MAINTENANCE

(Annual Mileage < 30,000 km/year)

Abbreviations: I = Inspect and correct or replace as necessary, R = Replace.

NOTE:

(1) If towing a trailer, using a camper or a car-top carrier, or driving on rough or muddy roads, inspect CVT fluid deterioration

with Consult-III every 90,000 km (54,000 miles), then change CVT fluid NS-2 if necessary. (Refer to TM-204, "

CONSULT-III

Function (TRANSMISSION)" for RE0F10A, TM-37, "CONSULT-III Function (TRANSMISSION)" for RE0F09B.) And if Consult-III

is not available, change (do not just inspect) CVT fluid NS-2 every 90,000 km (54,000 miles). Using transmission fluid other

than Genuine NISSAN CVT fluid NS-2 will damage the CVT, which is not covered by the warranty.

(2) Inspect once per year.

Maintenance items with “ ” should be performed more frequently according to “Maintenance Under Severe Driving Condi-

tions”.

MAINTENANCE UNDER SEVERE DRIVING CONDITIONS

(Annual Mileage < 30,000 km/year)

The maintenance intervals shown on the preceding pages are for normal operating conditions. If the vehicle is

mainly operated under severe driving conditions as shown below, more frequent maintenance must be per-

formed on the following items as shown in the table.

Severe driving conditions

A — Driving in dusty conditions

B — Driving repeatedly short distances or door to door driving

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference

page Perform at a kilometer (mile) interval or

month interval, whichever comes first.km x 1,000

(Miles x

1,000)

Months15

(9)

1230

(18)

2445

(27)

3660

(36)

4875

(45)

6090

(54)

72105

(63)

84120

(72)

96

Underhood and under vehicle

Headlamp aiming IIIIIIIIMA-23

,

MA-27

Brake system and fluid (For level &

leaks)IIIIIIIIMA-38,

MA-37

Brake fluidRRRRMA-38

Brake booster vacuum hoses, connec-

tions & check valveIIIIBR-12

Power steering fluid & lines (For level &

leaks)IIIIIIIIMA-40

CVT fluid (For level & leaks)See

NOTE

(1)IIIIIIIIMA-32,

MA-34

Steering gear & linkage, axle & suspen-

sion parts, & front drive shaftsIIIIMA-39,

MA-40

,

MA-41

Exhaust systemIIIIMA-32

Brake pads, rotors & other brake com-

ponentsIIIIIIIIMA-38,

BR-13

,

BR-15

Foot brake & parking brake (For free

play, stroke & operation)IIIIIIIIBR-6,

PB-2

Air conditioner filterRRRRVTL-20,

VTL-77

Body corrosionSee

NOTE (2)MA-42

Page 3196 of 5121

MA-8

< ON-VEHICLE MAINTENANCE >

PERIODIC MAINTENANCE

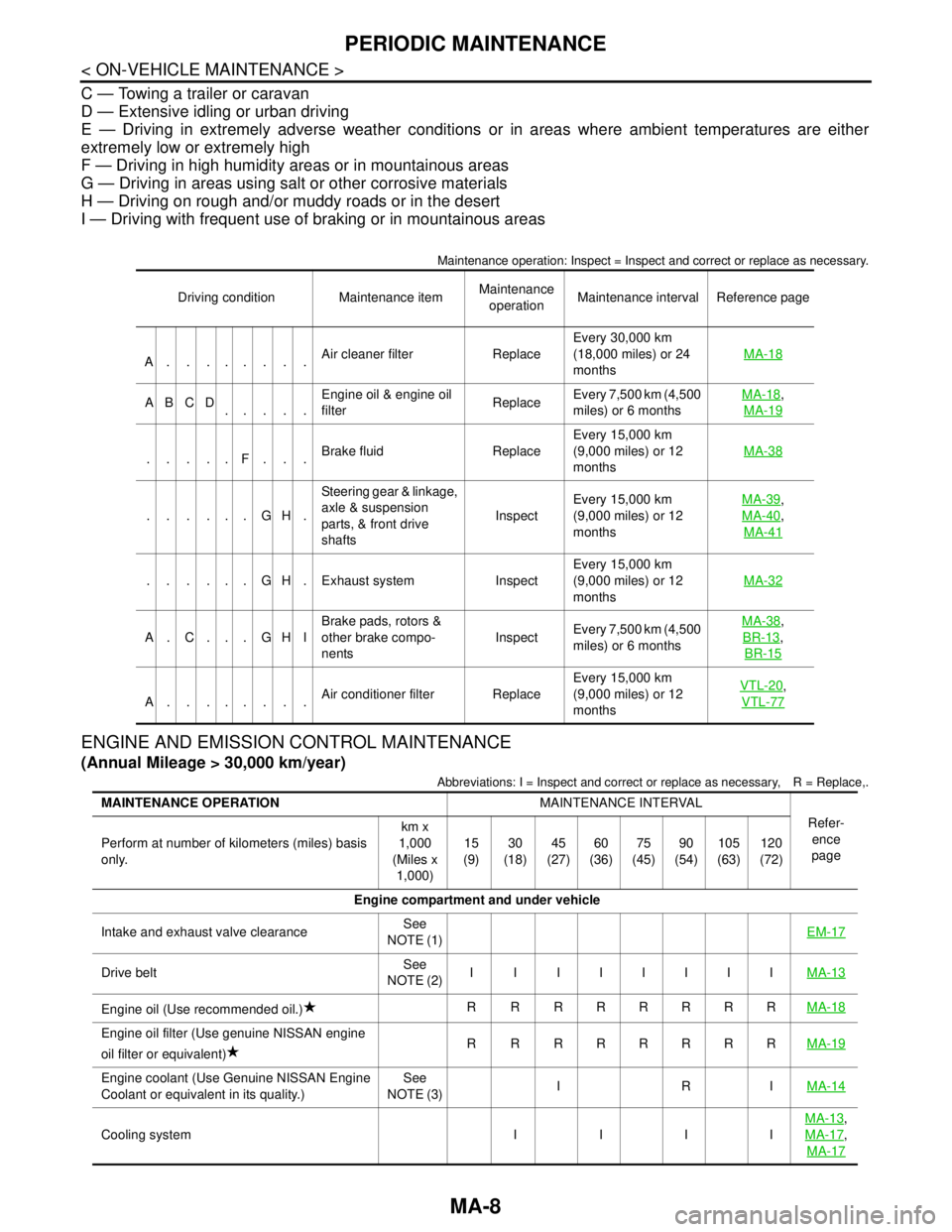

C — Towing a trailer or caravan

D — Extensive idling or urban driving

E — Driving in extremely adverse weather conditions or in areas where ambient temperatures are either

extremely low or extremely high

F — Driving in high humidity areas or in mountainous areas

G — Driving in areas using salt or other corrosive materials

H — Driving on rough and/or muddy roads or in the desert

I — Driving with frequent use of braking or in mountainous areas

Maintenance operation: Inspect = Inspect and correct or replace as necessary.

ENGINE AND EMISSION CONTROL MAINTENANCE

(Annual Mileage > 30,000 km/year)

Abbreviations: I = Inspect and correct or replace as necessary, R = Replace,.

Driving condition Maintenance itemMaintenance

operationMaintenance interval Reference page

A........Air cleaner filter ReplaceEvery 30,000 km

(18,000 miles) or 24

monthsMA-18

ABCD

.....Engine oil & engine oil

filter ReplaceEvery 7,500 km (4,500

miles) or 6 monthsMA-18,

MA-19

.....F...Brake fluid ReplaceEvery 15,000 km

(9,000 miles) or 12

monthsMA-38

......GH.Steering gear & linkage,

axle & suspension

parts, & front drive

shafts InspectEvery 15,000 km

(9,000 miles) or 12

monthsMA-39

,

MA-40

,

MA-41

. . . . . . G H . Exhaust system InspectEvery 15,000 km

(9,000 miles) or 12

monthsMA-32

A. C. . . GHIBrake pads, rotors &

other brake compo-

nentsInspectEvery 7,500 km (4,500

miles) or 6 monthsMA-38

,

BR-13

,

BR-15

A........Air conditioner filter ReplaceEvery 15,000 km

(9,000 miles) or 12

monthsVTL-20

,

VTL-77

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Refer-

ence

page Perform at number of kilometers (miles) basis

only.km x

1,000

(Miles x

1,000)15

(9)30

(18)45

(27)60

(36)75

(45)90

(54)105

(63)120

(72)

Engine compartment and under vehicle

Intake and exhaust valve clearanceSee

NOTE (1)EM-17

Drive beltSee

NOTE (2)I I IIIIIIMA-13

Engine oil (Use recommended oil.)R RRRRRRRMA-18

Engine oil filter (Use genuine NISSAN engine

oil filter or equivalent)R RRRRRRRMA-19

Engine coolant (Use Genuine NISSAN Engine

Coolant or equivalent in its quality.)See

NOTE (3)IRIMA-14

Cooling system I I I IMA-13

,

MA-17

,

MA-17