check engine NISSAN TEANA 2014 Owners Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 814 of 4801

![NISSAN TEANA 2014 Owners Manual

DLK-46

< SYSTEM DESCRIPTION >

DIAGNOSIS SYSTEM (BCM)

WORK SUPPORT

PUSH SWITCH INDICATOR This test is able to check push-button ignition switch indicator operation [On/Off].

ACC CONT This test is abl NISSAN TEANA 2014 Owners Manual

DLK-46

< SYSTEM DESCRIPTION >

DIAGNOSIS SYSTEM (BCM)

WORK SUPPORT

PUSH SWITCH INDICATOR This test is able to check push-button ignition switch indicator operation [On/Off].

ACC CONT This test is abl](/img/5/57390/w960_57390-813.png)

DLK-46

< SYSTEM DESCRIPTION >

DIAGNOSIS SYSTEM (BCM)

WORK SUPPORT

PUSH SWITCH INDICATOR This test is able to check push-button ignition switch indicator operation [On/Off].

ACC CONT This test is able to check accessory relay control operation [On/Off].

IGN CONT1 This test is able to check ignition relay-1 control operation [On/Off].

ST CONT LOW This test is able to check starter control relay operation [On/Off].

IGNITION RELAY This test is able to ignition relay operation [On/Off].

REVERSE LAMP TEST This test is able to check reverse lamp illumination operation [On/Off].

TRUNK/LUGGAGE LAMP TEST This test is able to check cargo lamp illumination operation [On/Off].

KEYFOB PW TEST This test is able to check power wind ow operation using the Intelligent Key [Off/DOWN/UP].

SHIFTLOCK SOLENOID TEST This test is able to check shift lock solenoid operation [On/Off]. Test Item Description

Support Item Setting Description

IGN/ACC BATTERY SAVER On* Battery saver function ON.

Off Battery saver function OFF.

REMOTE ENGINE STARTER On* Remote engine start function ON.

Off Remote engine start function OFF.

ANSWERBACK I-KEY LOCK UNLOCK BUZZER Buzzer reminder function by door lock/unlock request switch ON.

HORN Horn chirp reminder function by door lock request switch ON.

Off* No reminder function by door lock/unlock request switch.

INVALID This mode is not used.

ANSWERBACK KEYLESS LOCK UN-

LOCK On

Buzzer or horn chirp reminder when doors are locked/unlocked with

Intelligent Key.

Off* No buzzer or horn chirp reminder when doors are locked/unlocked

with Intelligent Key.

ANSWER BACK On* Horn chirp reminder when doors are locked with Intelligent Key.

Off No horn chirp reminder when doors are locked with Intelligent Key.

RETRACTABLE MIRROR SET On Retractable mirror set ON.

Off* Retractable mirror set OFF.

CONFIRM KEY FOB ID — Intelligent Key ID code can check.

LOCK/UNLOCK BY I-KEY On* Door lock/unlock function from Intelligent Key ON.

Off Door lock/unlock function from Intelligent Key OFF.

ENGINE START BY I-KEY On* Engine start function from Intelligent Key ON.

Off Engine start function from Intelligent Key OFF.

TRUNK/GLASS HATCH OPEN On* Buzzer reminder function by trunk opener request switch ON.

Off Buzzer reminder function by trunk opener request switch OFF.

INTELLIGENT KEY LINK SET On Intelligent Key link set ON.

Off* Intelligent Key link set OFF.

SHORT CRANKING OUTPUT Start70 msec

Starter motor operation duration times.

100 msec

200 msec

End —

INSIDE ANT DIAGNOSIS — This function allows inside key antenna self-diagnosis.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 855 of 4801

B261B REMOTE ENGINE STARTDLK-87

< DTC/CIRCUIT DIAGNOSIS >

C

D E

F

G H

I

J

L

M A

B

DLK

N

O P

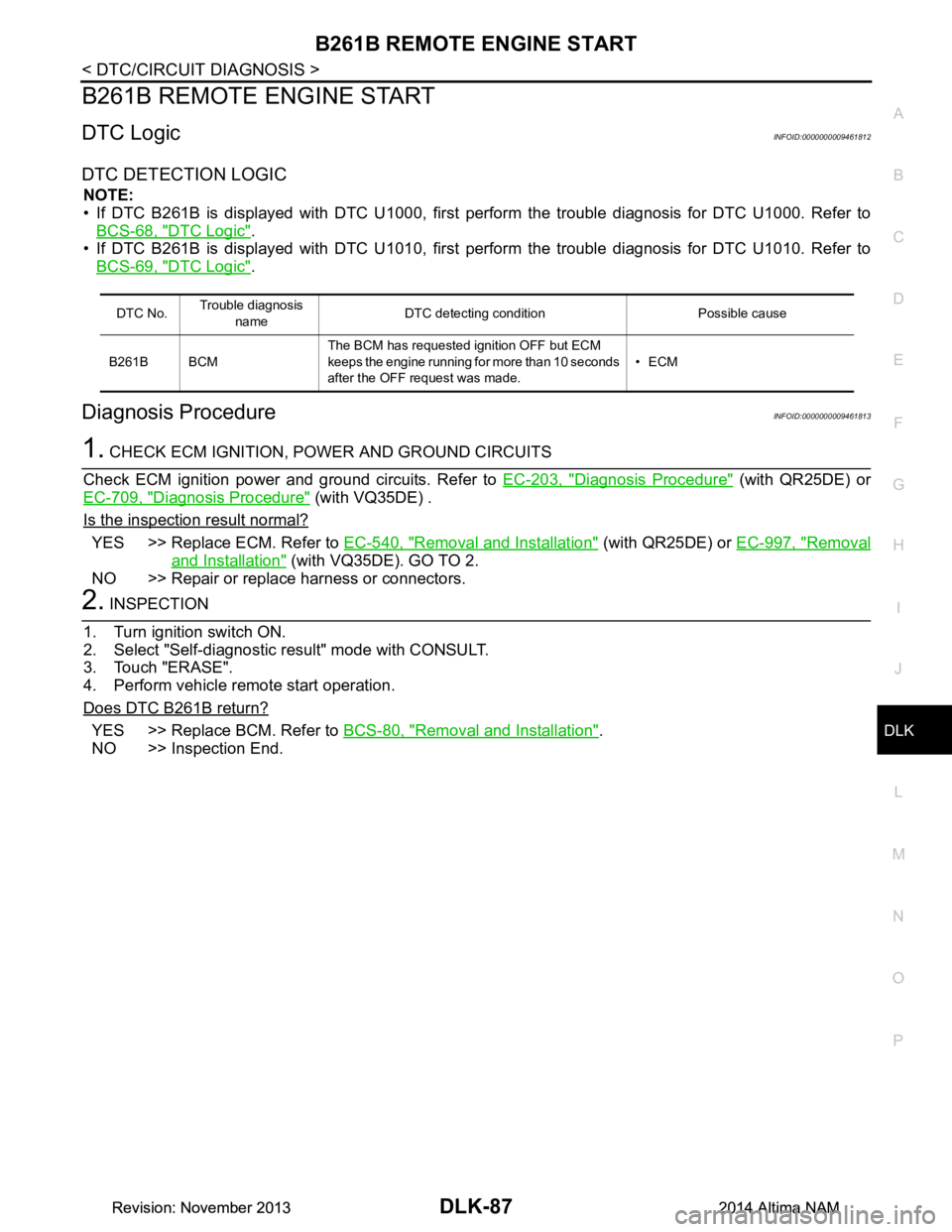

B261B REMOTE ENGINE START

DTC LogicINFOID:0000000009461812

DTC DETECTION LOGIC

NOTE:

• If DTC B261B is displayed with DTC U1000, first perform the trouble diagnosis for DTC U1000. Refer to

BCS-68, "DTC Logic"

.

• If DTC B261B is displayed with DTC U1010, first perform the trouble diagnosis for DTC U1010. Refer to

BCS-69, "DTC Logic"

.

Diagnosis ProcedureINFOID:0000000009461813

1. CHECK ECM IGNITION, POWER AND GROUND CIRCUITS

Check ECM ignition power and ground circuits. Refer to EC-203, "Diagnosis Procedure"

(with QR25DE) or

EC-709, "Diagnosis Procedure"

(with VQ35DE) .

Is the inspection result normal?

YES >> Replace ECM. Refer to EC-540, "Removal and Installation" (with QR25DE) or EC-997, "Removal

and Installation" (with VQ35DE). GO TO 2.

NO >> Repair or replace harness or connectors.

2. INSPECTION

1. Turn ignition switch ON.

2. Select "Self-diagnostic result" mode with CONSULT.

3. Touch "ERASE".

4. Perform vehicle remote start operation.

Does DTC B261B return?

YES >> Replace BCM. Refer to BCS-80, "Removal and Installation".

NO >> Inspection End.

DTC No. Trouble diagnosis

name DTC detecting condition Possible cause

B261B BCM The BCM has requested ignition OFF but ECM

keeps the engine running for more than 10 seconds

after the OFF request was made. •ECM

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 910 of 4801

DLK-142

< DTC/CIRCUIT DIAGNOSIS >

INTELLIGENT KEY WARNING BUZZER

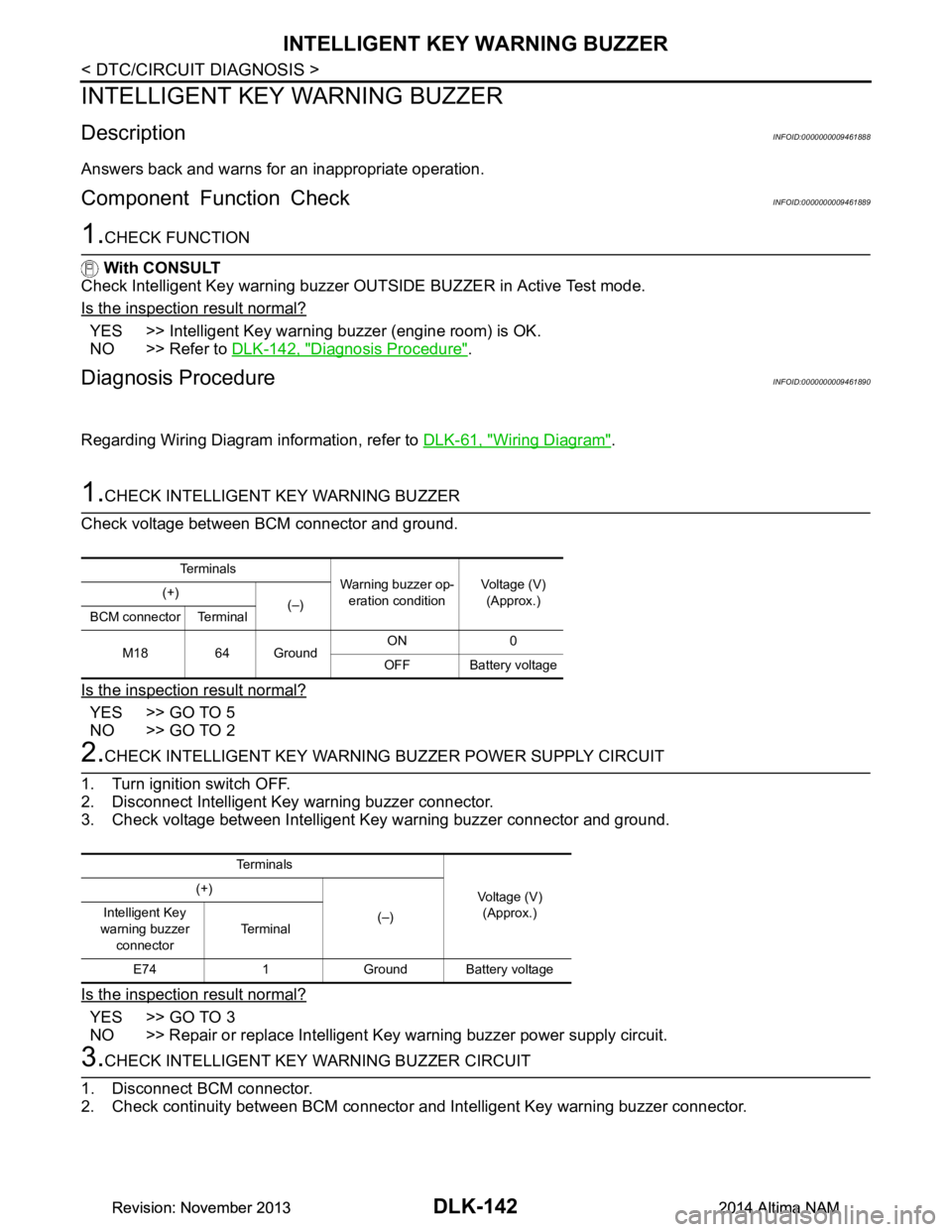

INTELLIGENT KEY WARNING BUZZER

DescriptionINFOID:0000000009461888

Answers back and warns for an inappropriate operation.

Component Function CheckINFOID:0000000009461889

1.CHECK FUNCTION

With CONSULT

Check Intelligent Key warning buzzer OUTSIDE BUZZER in Active Test mode.

Is the inspection result normal?

YES >> Intelligent Key warning buzzer (engine room) is OK.

NO >> Refer to DLK-142, "Diagnosis Procedure"

.

Diagnosis ProcedureINFOID:0000000009461890

Regarding Wiring Diagram information, refer to DLK-61, "Wiring Diagram".

1.CHECK INTELLIGENT KEY WARNING BUZZER

Check voltage between BCM connector and ground.

Is the inspection result normal?

YES >> GO TO 5

NO >> GO TO 2

2.CHECK INTELLIGENT KEY WARNING BUZZER POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect Intelligent Key warning buzzer connector.

3. Check voltage between Intelligent Key warning buzzer connector and ground.

Is the inspection result normal?

YES >> GO TO 3

NO >> Repair or replace Intelligent Key warning buzzer power supply circuit.

3.CHECK INTELLIGENT KEY WARNING BUZZER CIRCUIT

1. Disconnect BCM connector.

2. Check continuity between BCM connector and Intelligent Key warning buzzer connector.

Te r m i n a l s

Warning buzzer op-

eration condition Voltage (V)

(Approx.)

(+)

(–)

BCM connector Terminal

M18 64 Ground ON 0

OFF Battery voltage

Te r m i n a l s

Voltage (V)(Approx.)

(+)

(–)

Intelligent Key

warning buzzer connector Te r m i n a l

E74 1 Ground Battery voltage

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 920 of 4801

DLK-152

< SYMPTOM DIAGNOSIS >

INTELLIGENT KEY SYSTEM SYMPTOMS

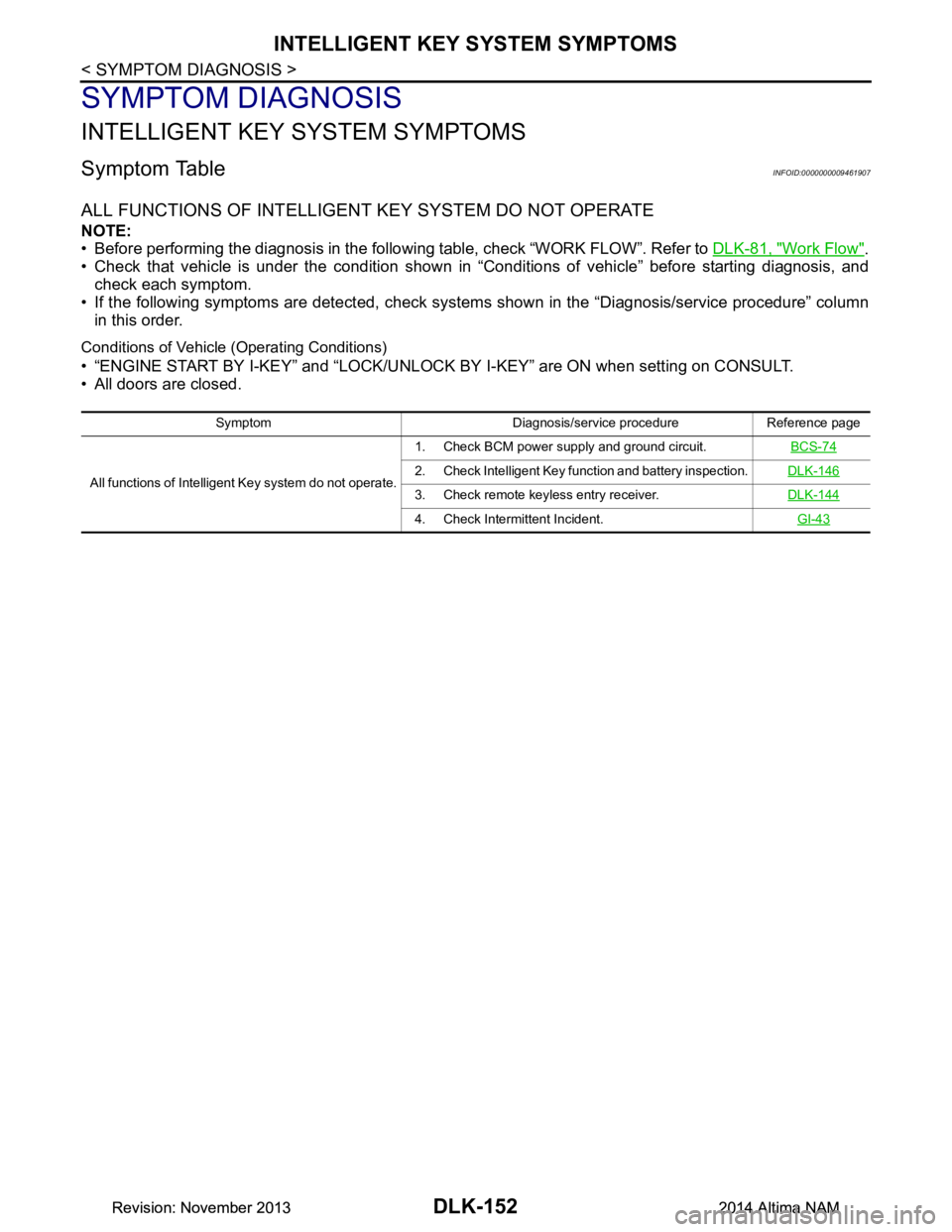

SYMPTOM DIAGNOSIS

INTELLIGENT KEY SYSTEM SYMPTOMS

Symptom TableINFOID:0000000009461907

ALL FUNCTIONS OF INTELLIGENT KEY SYSTEM DO NOT OPERATE

NOTE:

• Before performing the diagnosis in the following table, check “WORK FLOW”. Refer to DLK-81, "Work Flow"

.

• Check that vehicle is under the condition shown in “Conditions of vehicle” before starting diagnosis, and

check each symptom.

• If the following symptoms are detected, check syst ems shown in the “Diagnosis/service procedure” column

in this order.

Conditions of Vehicle (Operating Conditions)

• “ENGINE START BY I-KEY” and “LOCK/UNLOCK BY I-KEY” are ON when setting on CONSULT.

• All doors are closed.

Symptom Diagnosis/service procedure Reference page

All functions of Intelligent Key system do not operate. 1. Check BCM power supply and ground circuit.

BCS-74

2. Check Intelligent Key function and battery inspection.DLK-146

3. Check remote keyless entry receiver.DLK-144

4. Check Intermittent Incident. GI-43

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 933 of 4801

SQUEAK AND RATTLE TROUBLE DIAGNOSESDLK-165

< SYMPTOM DIAGNOSIS >

C

D E

F

G H

I

J

L

M A

B

DLK

N

O P

If the noise can be duplicated easily during the test drive, to help identify the source of the noise, try to dupli-

cate the noise with the vehicle stopped by doing one or all of the following:

1) Close a door.

2) Tap or push/pull around the area where the noise appears to be coming from.

3) Rev the engine.

4) Use a floor jack to recreate vehicle “twist”.

5) At idle, apply engine load (electrical load, half-clutch on M/T model, drive position on CVT and A/T models).

6) Raise the vehicle on a hoist and hit a tire with a rubber hammer.

• Drive the vehicle and attempt to duplicate the conditions the customer states exist when the noise occurs.

• If it is difficult to duplicate the noise, drive the vehicle slowly on an undulating or rough road to stress the vehicle body.

CHECK RELATED SERVICE BULLETINS

After verifying the customer concern or symptom, che ck ASIST for Technical Service Bulletins (TSBs) related

to that concern or symptom.

If a TSB relates to the symptom, follow the procedure to repair the noise.

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

1. Narrow down the noise to a general area. To help pi npoint the source of the noise, use a listening tool

(Chassis Ear: J-39570, Engine Ear: J-39565 and mechanic's stethoscope).

2. Narrow down the noise to a more specific area and identify the cause of the noise by: • removing the components in the area that you suspect the noise is coming from.

Do not use too much force when removing clips and fasteners, otherwise clips and fasteners can be

broken or lost during the repair, resulting in the creation of new noise.

• tapping or pushing/pulling the component that you suspect is causing the noise.

Do not tap or push/pull the component with excessive force, otherwise the noise will be eliminated only

temporarily.

• feeling for a vibration with your hand by touching the component(s) that you suspect is (are) causing the

noise.

• placing a piece of paper between components that you suspect are causing the noise.

• looking for loose components and contact marks. Refer to DLK-165, "Generic Squeak and Rattle Troubleshooting"

.

REPAIR THE CAUSE

• If the cause is a loose component, tighten the component securely.

• If the cause is insufficient clearance between components:

- separate components by repositioning or loos ening and retightening the component, if possible.

- insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape or urethane tape. A NISSAN Squeak and Rattle Kit (J-50397) is av ailable through your authorized NISSAN Parts Depart-

ment.

CAUTION:

Do not use excessive force as many components are constructed of plastic and may be damaged.

NOTE:

• Always check with the Parts Department for the latest parts information.

• The materials contained in the NISSAN Squeak and Rattle Kit (J-50397) are listed on the inside cover of the

kit; and can each be ordered seperately as needed.

• The following materials not found in the kit can also be used to repair squeaks and rattles.

- SILICONE GREASE: Use instead of UHMW tape that will be visible or does not fit. The silicone grease will

only last a few months.

- SILICONE SPRAY: Use when grease cannot be applied.

- DUCT TAPE: Use to eliminate movement.

CONFIRM THE REPAIR

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Generic Squeak and Rattle TroubleshootingINFOID:0000000009889730

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1005 of 4801

EC-5

C

D E

F

G H

I

J

K L

M

EC A

N

O P

P0447 EVAP CANISTER VENT CONTROL

VALVE ............................................................ ..

350

DTC Logic ........................................................... ..350

Diagnosis Procedure .............................................350

Component Inspection ..........................................352

P0448 EVAP CANISTER VENT CONTROL

VALVE ............................................................ ..

354

DTC Logic ........................................................... ..354

Diagnosis Procedure .............................................355

Component Inspection ..........................................356

P0451 EVAP CONTROL SYSTEM PRES-

SURE SENSOR .............................................. ..

358

DTC Logic ........................................................... ..358

Diagnosis Procedure .............................................359

Component Inspection ..........................................361

P0452 EVAP CONTROL SYSTEM PRES-

SURE SENSOR .............................................. ..

362

DTC Logic ........................................................... ..362

Diagnosis Procedure .............................................363

Component Inspection ..........................................364

P0453 EVAP CONTROL SYSTEM PRES-

SURE SENSOR .............................................. ..

366

DTC Logic ........................................................... ..366

Diagnosis Procedure .............................................367

Component Inspection ..........................................369

P0456 EVAP CONTROL SYSTEM ..................370

DTC Logic ........................................................... ..370

Diagnosis Procedure .............................................371

Component Inspection ..........................................375

P0460 FUEL LEVEL SENSOR ........................376

DTC Logic ........................................................... ..376

Diagnosis Procedure .............................................376

P0461 FUEL LEVEL SENSOR ........................377

DTC Logic ........................................................... ..377

Component Function Check ..................................377

Diagnosis Procedure .............................................378

P0462, P0463 FUEL LEVEL SENSOR ............379

DTC Logic ........................................................... ..379

Diagnosis Procedure .............................................379

P0500 VSS .......................................................380

Description .......................................................... ..380

DTC Logic .............................................................380

Diagnosis Procedure .............................................380

P0506 ISC SYSTEM .........................................382

Description .......................................................... ..382

DTC Logic .............................................................382

Diagnosis Procedure .............................................382

P0507 ISC SYSTEM .........................................384

Description .......................................................... ..384

DTC Logic .............................................................384

Diagnosis Procedure ........................................... ..384

P050A, P050B, P050E COLD START CON-

TROL ...............................................................

386

Description ........................................................... ..386

DTC Logic ..............................................................386

Diagnosis Procedure .............................................387

P0520 EOP SENSOR ......................................388

DTC Logic ..............................................................388

Diagnosis Procedure .............................................388

Component Inspection ...........................................390

P0524 ENGINE OIL PRESSURE ....................391

DTC Logic ..............................................................391

Diagnosis Procedure .............................................392

Component Inspection ...........................................393

P052A, P052B INTAKE VALVE TIMING CON-

TROL ...............................................................

394

DTC Logic ............................................................ ..394

Diagnosis Procedure .............................................394

Component Inspection (Intake Valve Timing Con-

trol Solenoid Valve) ............................................. ..

396

Component Inspection (Intake Valve Timing Inter-

mediate Lock Control Solenoid Valve) ................ ..

397

Component Inspection (Crankshaft Position sen-

sor) ...................................................................... ..

397

Component Inspection (Camshaft position sen-

sor) ...................................................................... ..

398

P0603 ECM .....................................................400

DTC Logic ..............................................................400

Diagnosis Procedure .............................................400

P0604 ECM .....................................................401

DTC Logic ..............................................................401

Diagnosis Procedure .............................................401

P0605 ECM .....................................................402

DTC Logic ..............................................................402

Diagnosis Procedure .............................................402

P0606 ECM .....................................................403

DTC Logic ..............................................................403

Diagnosis Procedure .............................................403

P0607 ECM .....................................................404

DTC Logic ..............................................................404

Diagnosis Procedure .............................................404

P060A ECM .....................................................405

DTC Logic ..............................................................405

Diagnosis Procedure .............................................405

P060B ECM .....................................................406

DTC Logic ..............................................................406

Diagnosis Procedure .............................................406

P0643 SENSOR POWER SUPPLY ................407

Description .............................................................407

DTC Logic ..............................................................407

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1006 of 4801

EC-6

Diagnosis Procedure .............................................408

P0850 PNP SWITCH .......................................410

Description ........................................................... ..410

DTC Logic ..............................................................410

Component Function Check ..................................411

Diagnosis Procedure .............................................411

P1078 EVT CONTROL POSITION SENSOR ..413

DTC Logic ............................................................ ..413

Diagnosis Procedure .............................................413

Component Inspection ...........................................415

P1148 CLOSED LOOP CONTROL .................416

DTC Logic ............................................................ ..416

Diagnosis Procedure .............................................416

P117A AIR FUEL RATIO .................................417

DTC Logic ............................................................ ..417

Diagnosis Procedure .............................................418

P1212 TCS COMMUNICATION LINE .............422

Description ........................................................... ..422

DTC Logic ..............................................................422

Diagnosis Procedure .............................................422

P1217 ENGINE OVER TEMPERATURE .........423

DTC Logic ............................................................ ..423

Component Function Check ..................................423

Diagnosis Procedure .............................................424

P1225 TP SENSOR .........................................426

DTC Logic ............................................................ ..426

Diagnosis Procedure .............................................426

P1226 TP SENSOR .........................................427

DTC Logic ............................................................ ..427

Diagnosis Procedure .............................................427

P1550 BATTERY CURRENT SENSOR ..........428

DTC Logic ............................................................ ..428

Diagnosis Procedure .............................................428

Component Inspection ...........................................429

P1551, P1552 BATTERY CURRENT SEN-

SOR ................................................................. .

431

DTC Logic ............................................................ ..431

Diagnosis Procedure .............................................431

Component Inspection ...........................................432

P1553 BATTERY CURRENT SENSOR ..........434

DTC Logic ............................................................ ..434

Diagnosis Procedure .............................................434

Component Inspection ...........................................435

P1554 BATTERY CURRENT SENSOR ..........437

DTC Logic ............................................................ ..437

Component Function Check ..................................437

Diagnosis Procedure .............................................438

Component Inspection ...........................................439

P1556, P1557 BATTERY TEMPERATURE

SENSOR ......................................................... ..

440

DTC Logic ............................................................ .440

Diagnosis Procedure .............................................440

Component Inspection ..........................................441

P1564 ASCD STEERING SWITCH ..................442

DTC Logic ............................................................ .442

Diagnosis Procedure .............................................442

Component Inspection ..........................................444

P1572 ASCD BRAKE SWITCH ........................445

DTC Logic ............................................................ .445

Diagnosis Procedure .............................................446

Component Inspection (Brake Pedal Position

Switch) ................................................................. .

449

Component Inspection (Stop Lamp Switch) ..........450

Component Inspection (Stop Lamp Relay) ...........450

P1574 ASCD VEHICLE SPEED SENSOR ..... ..452

Description ........................................................... .452

DTC Logic .............................................................452

Diagnosis Procedure .............................................452

P1715 INPUT SPEED SENSOR .......................454

Description ........................................................... .454

DTC Logic .............................................................454

Diagnosis Procedure .............................................454

P1800 INTAKE MANIFOLD TUNING VALVE ..456

DTC Logic .............................................................456

Diagnosis Procedure .............................................456

Component Inspection ..........................................457

P1805 BRAKE SWITCH ................................. ..459

DTC Logic ............................................................ .459

Diagnosis Procedure .............................................459

Component Inspection (Stop Lamp Switch) ..........461

Component Inspection (Stop Lamp Relay) ...........461

P2004 INTAKE MANIFOLD RUNNER CON-

TROL VALVE ................................................. ..

462

DTC Logic ............................................................ .462

Diagnosis Procedure .............................................462

Component Inspection ..........................................463

P2014, P2016, P2017, P2018 INTAKE MANI-

FOLD RUNNER CONTROL VALVE POSI-

TION SENSOR ............................................... ..

465

DTC Logic ............................................................ .465

Diagnosis Procedure .............................................465

P2096, P2097 A/F SENSOR 1 .........................468

DTC Logic ............................................................ .468

Diagnosis Procedure .............................................468

P2100, P2103 THROTTLE CONTROL MO-

TOR RELAY ................................................... ..

472

DTC Logic ............................................................ .472

Diagnosis Procedure .............................................472

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1007 of 4801

EC-7

C

D E

F

G H

I

J

K L

M

EC A

N

O P

P2101 ELECTRIC THROTTLE CONTROL

FUNCTION ..................................................... ..

475

DTC Logic ........................................................... ..475

Diagnosis Procedure .............................................475

Component Inspection ..........................................477

P2118 THROTTLE CONTROL MOTOR ..........478

DTC Logic ........................................................... ..478

Diagnosis Procedure .............................................478

Component Inspection ..........................................479

P2119 ELECTRIC THROTTLE CONTROL

ACTUATOR .................................................... ..

480

DTC Logic ........................................................... ..480

Diagnosis Procedure .............................................480

P2122, P2123 APP SENSOR ...........................482

DTC Logic ........................................................... ..482

Diagnosis Procedure .............................................482

Component Inspection ..........................................484

P2127, P2128 APP SENSOR ...........................485

DTC Logic ........................................................... ..485

Diagnosis Procedure .............................................485

Component Inspection ..........................................486

P2135 TP SENSOR ..........................................488

DTC Logic ........................................................... ..488

Diagnosis Procedure .............................................488

Component Inspection ..........................................490

P2138 APP SENSOR .......................................491

DTC Logic ........................................................... ..491

Diagnosis Procedure .............................................491

Component Inspection ..........................................493

P2610 ECM INTERNAL TIMER .......................494

Description .......................................................... ..494

DTC Logic .............................................................494

Diagnosis Procedure .............................................495

BRAKE PEDAL POSITION SWITCH ...............496

Component Function Check ................................ ..496

Diagnosis Procedure .............................................496

Component Inspection (Brake Pedal Position

Switch) ................................................................ ..

497

COOLING FAN .................................................499

Component Function Check ................................ ..499

Diagnosis Procedure .............................................499

Component Inspection (Cooling Fan Motor) .........501

Component Inspection (C ooling Fan Relay) .........502

ELECTRICAL LOAD SIGNAL ....................... ..503

Description .......................................................... ..503

Component Function Check ..................................503

Diagnosis Procedure .............................................503

FUEL INJECTOR .............................................505

Component Function Check ................................ ..505

Diagnosis Procedure .............................................505

Component Inspection ......................................... ..506

FUEL PUMP ....................................................508

Description .............................................................508

Component Function Check ..................................508

Diagnosis Procedure .............................................508

Component Inspection ...........................................510

IGNITION SIGNAL ..........................................511

Component Function Check ..................................511

Diagnosis Procedure .............................................511

Component Inspection (Ignition Coil with Power

Transistor) ........................................................... ..

514

Component Inspection (Condenser) ......................515

INFORMATION DISPLAY (ASCD) .................516

Component Function Check ..................................516

Diagnosis Procedure .............................................516

MALFUNCTION INDICATOR LAMP ..............517

Component Function Check ..................................517

Diagnosis Procedure .............................................517

ON BOARD REFUELING VAPOR RECOV-

ERY (ORVR) ....................................................

518

Component Function Check ................................ ..518

Diagnosis Procedure .............................................518

Component Inspection ...........................................520

REFRIGERANT PRESSURE SENSOR ..........523

Component Function Check ..................................523

Diagnosis Procedure .............................................523

SENSOR POWER SUPPLY 2 CIRCUIT .........525

Description .............................................................525

Diagnosis Procedure .............................................525

SYMPTOM DIAGNOSIS ............................527

ENGINE CONTRO L SYSTEM ........................527

Symptom Table ................................................... ..527

INFORMATION DISPLAY IS MALFUNCTION-

ING ..................................................................

532

Diagnosis Procedure ........................................... ..532

NORMAL OPERATING CONDITION .............533

Description .............................................................533

PERIODIC MAINTENANCE ......................534

IDLE SPEED .... ...............................................534

Inspection ............................................................ ..534

IGNITION TIMING ...........................................535

Inspection ..............................................................535

EVAPORATIVE EMISSION SYSTEM .............536

Inspection ..............................................................536

EVAP LEAK CHECK ......................................537

Inspection ..............................................................537

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1009 of 4801

EC-9

C

D E

F

G H

I

J

K L

M

EC A

N

O P

ENGINE PROTECTION CO

NTROL AT LOW EN-

GINE OIL PRESSURE : System Description ...... ..

583

FUEL FILLER CAP WARNING SYSTEM ............. ..584

FUEL FILLER CAP WARNING SYSTEM : System

Description .......................................................... ..

585

VARIABLE INDUCTION AIR SYSTEM ...................586

VARIABLE INDUCTION AIR SYSTEM : System

Description .......................................................... ..

586

INTEGRATED CONTROL OF ENGINE, CVT, AND

ABS ........................................................................ ..

587

INTEGRATED CONTROL OF ENGINE, CVT,

AND ABS : System Descri ption ............................

588

ALTERNATOR POWER GENERATION VOLT-

AGE VARIABLE CONTROL SYSTEM .................. ..

588

ALTERNATOR POWER GENERATION VOLT-

AGE VARIABLE CONTRO L SYSTEM : System

Description .......................................................... ..

588

CAN COMMUNICATION ....................................... ..588

CAN COMMUNICATION : System Description ....588

OPERATION ................................................... ..589

AUTOMATIC SPEED CONTROL DEVICE (ASCD) ..589

AUTOMATIC SPEED CONT ROL DEVICE (AS-

CD) : Switch Name and Function ........................ ..

589

ON BOARD DIAGNOSTIC (OBD) SYSTEM ....590

Diagnosis Description ......................................... ..590

GST (Generic Scan Tool) ......................................590

DIAGNOSIS SYSTEM (ECM) ...........................591

DIAGNOSIS DESCRIPTION ................................. ..591

DIAGNOSIS DESCRIPTION : 1st Trip Detection

Logic and Two Trip Detection Logic .................... ..

591

DIAGNOSIS DESCRIPTION : DTC and Freeze

Frame Data ......................................................... ..

591

DIAGNOSIS DESCRIPTION : Counter System ....592

DIAGNOSIS DESCRIPTION : Driving Pattern ......595

DIAGNOSIS DESCRIPTION : System Readiness

Test (SRT) Code ................................................. ..

596

DIAGNOSIS DESCRIPTION : Permanent Diag-

nostic Trouble Code (Permanent DTC) ............... ..

597

DIAGNOSIS DESCRIPTION : Malfunction Indica-

tor Lamp (MIL) ..................................................... ..

598

On Board Diagnosis Function ...............................598

CONSULT Function ..............................................601

ECU DIAGNOSIS INFORMATION ............613

ECM ................................................................ ..613

Reference Value ................................................. ..613

Fail-safe ................................................................627

DTC Inspection Priority Chart .............................629

DTC Index ............................................................630

Test Value and Test Limit .....................................634

WIRING DIAGRAM ....................................642

ENGINE CONTRO L SYSTEM ........................642

Wiring Diagram .................................................... ..642

BASIC INSPECTION .................................670

DIAGNOSIS AND REPAIR WORKFLOW ......670

Work Flow ............................................................ ..670

Diagnostic Work Sheet ..........................................673

BASIC INSPECTION .......................................675

Work Procedure .....................................................675

ADDITIONAL SERVICE WHEN REPLACING

ECM .................................................................

679

Description ........................................................... ..679

Work Procedure .....................................................679

ACCELERATOR PEDAL RELEASED POSI-

TION LEARNING ............................................

681

Description ........................................................... ..681

Work Procedure .....................................................681

THROTTLE VALVE CLOSED POSITION

LEARNING ....... ...............................................

682

Description ........................................................... ..682

Work Procedure .....................................................682

IDLE AIR VOLUME LEARNING .....................683

Description .............................................................683

Work Procedure .....................................................683

MIXTURE RATIO SELF-LEARNING VALUE

CLEAR ............................................................

685

Description ........................................................... ..685

Work Procedure .....................................................685

VIN REGISTRATION .......................................686

Description .............................................................686

Work Procedure .....................................................686

FUEL PRESSURE ...........................................687

Work Procedure .....................................................687

HOW TO SET SRT CODE ..............................689

Description .............................................................689

SRT Set Driving Pattern ........................................690

Work Procedure .....................................................692

HOW TO ERASE PERMANENT DTC ............695

Description .............................................................695

Work Procedure (Group A) ....................................696

Work Procedure (Group B) ....................................698

DTC/CIRCUIT DIAGNOSIS .......................701

TROUBLE DIAGNOSIS - SPECIFICATION

VALUE .............................................................

701

Description ........................................................... ..701

Component Function Check ..................................701

Diagnosis Procedure .............................................702

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1012 of 4801

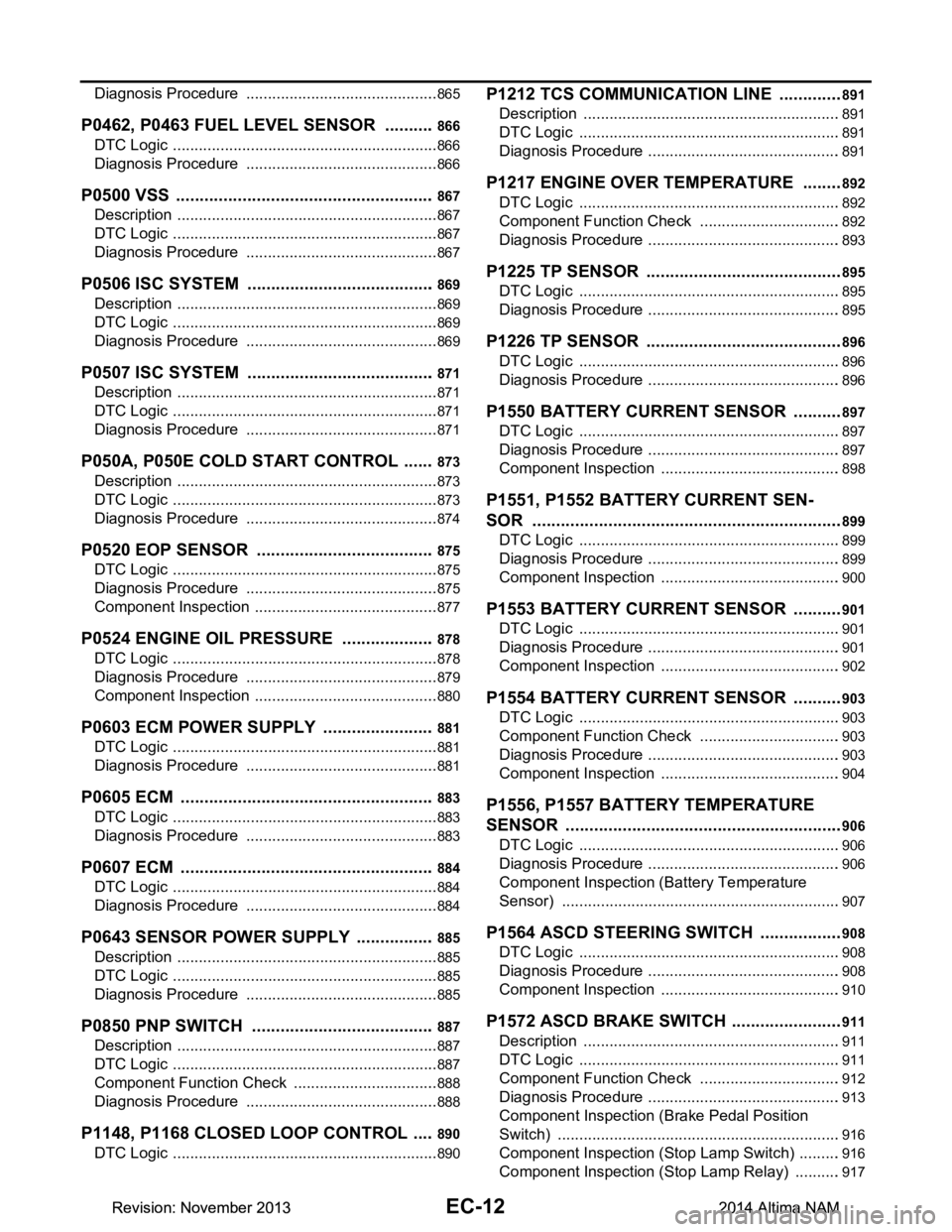

EC-12

Diagnosis Procedure .............................................865

P0462, P0463 FUEL LEVEL SENSOR ...........866

DTC Logic ............................................................ ..866

Diagnosis Procedure .............................................866

P0500 VSS .......................................................867

Description ........................................................... ..867

DTC Logic ..............................................................867

Diagnosis Procedure .............................................867

P0506 ISC SYSTEM ........................................869

Description ........................................................... ..869

DTC Logic ..............................................................869

Diagnosis Procedure .............................................869

P0507 ISC SYSTEM ........................................871

Description ........................................................... ..871

DTC Logic ..............................................................871

Diagnosis Procedure .............................................871

P050A, P050E COLD START CONTROL .......873

Description ........................................................... ..873

DTC Logic ..............................................................873

Diagnosis Procedure .............................................874

P0520 EOP SENSOR ......................................875

DTC Logic ............................................................ ..875

Diagnosis Procedure .............................................875

Component Inspection ...........................................877

P0524 ENGINE OIL PRESSURE ....................878

DTC Logic ............................................................ ..878

Diagnosis Procedure .............................................879

Component Inspection ...........................................880

P0603 ECM POWER SUPPLY ........................881

DTC Logic ............................................................ ..881

Diagnosis Procedure .............................................881

P0605 ECM ......................................................883

DTC Logic ............................................................ ..883

Diagnosis Procedure .............................................883

P0607 ECM ......................................................884

DTC Logic ............................................................ ..884

Diagnosis Procedure .............................................884

P0643 SENSOR POWER SUPPLY .................885

Description ........................................................... ..885

DTC Logic ..............................................................885

Diagnosis Procedure .............................................885

P0850 PNP SWITCH .......................................887

Description ........................................................... ..887

DTC Logic ..............................................................887

Component Function Check ..................................888

Diagnosis Procedure .............................................888

P1148, P1168 CLOSED LOOP CONTROL .....890

DTC Logic ............................................................ ..890

P1212 TCS COMMUNICATION LINE ..............891

Description ........................................................... .891

DTC Logic .............................................................891

Diagnosis Procedure .............................................891

P1217 ENGINE OVER TEMPERATURE .........892

DTC Logic ............................................................ .892

Component Function Check .................................892

Diagnosis Procedure .............................................893

P1225 TP SENSOR ..........................................895

DTC Logic ............................................................ .895

Diagnosis Procedure .............................................895

P1226 TP SENSOR ..........................................896

DTC Logic ............................................................ .896

Diagnosis Procedure .............................................896

P1550 BATTERY CURRENT SENSOR ...........897

DTC Logic ............................................................ .897

Diagnosis Procedure .............................................897

Component Inspection ..........................................898

P1551, P1552 BATTERY CURRENT SEN-

SOR ................................................................ ..

899

DTC Logic ............................................................ .899

Diagnosis Procedure .............................................899

Component Inspection ..........................................900

P1553 BATTERY CURRENT SENSOR ...........901

DTC Logic ............................................................ .901

Diagnosis Procedure .............................................901

Component Inspection ..........................................902

P1554 BATTERY CURRENT SENSOR ...........903

DTC Logic ............................................................ .903

Component Function Check .................................903

Diagnosis Procedure .............................................903

Component Inspection ..........................................904

P1556, P1557 BATTERY TEMPERATURE

SENSOR ......................................................... ..

906

DTC Logic ............................................................ .906

Diagnosis Procedure .............................................906

Component Inspection (Battery Temperature

Sensor) ................................................................ .

907

P1564 ASCD STEERING SWITCH ..................908

DTC Logic ............................................................ .908

Diagnosis Procedure .............................................908

Component Inspection ..........................................910

P1572 ASCD BRAKE SWITCH ........................911

Description ........................................................... .911

DTC Logic .............................................................911

Component Function Check .................................912

Diagnosis Procedure .............................................913

Component Inspection (Brake Pedal Position

Switch) ................................................................. .

916

Component Inspection (Stop Lamp Switch) ..........916

Component Inspection (Stop Lamp Relay) ...........917

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM