sensor NISSAN TEANA 2014 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 4705 of 4801

WT-30

< DTC/CIRCUIT DIAGNOSIS >

C1708, C1709, C1710, C1711 TRANSMITTER (NO DATA)

C1708, C1709, C1710, C1711 TRANSMITTER (NO DATA)

DTC LogicINFOID:0000000009464496

NOTE:

The Signal Tech II Tool (J-50190) can be used to perform the following functions. Refer to the Signal Tech II

User Guide for additional information.

• Activate and display TPMS transmitter IDs

• Display tire pressure reported by the TPMS transmitter

• Read TPMS DTCs

• Register TPMS transmitter IDs

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM SELF DIAGNOSTIC RESULT

With CONSULT

1. Perform tire pressure sensor ID registration. Refer to WT-25, "Work Procedure"

.

2. Drive at a speed of 40 km/h (25 MPH) or more fo r 3 minutes, and then drive the vehicle at any speed for

10 minutes.

NOTE:

Avoid driving in areas with radio interference.

3. Perform Self Diagnostic Result.

Is DTC C1708, C1709, C1710, or C1711 detected?

YES >> Proceed to WT-30, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis ProcedureINFOID:0000000009464497

NOTE:

The Signal Tech II Tool (J-50190) can be used to perform the following functions. Refer to the Signal Tech II

User Guide for additional information.

• Activate and display TPMS transmitter IDs

• Display tire pressure reported by the TPMS transmitter

• Read TPMS DTCs

• Register TPMS transmitter IDs

Regarding Wiring Diagram information, refer to WT-14, "Wiring Diagram - With Individual Tire Pressure Dis-

play" or WT-20, "Wiring Diagram - Without Individual Tire Pressure Display".

1.CHECK TIRE PRESSURE SIGNAL

With CONSULT

1. Select Data Monitor from AIR PRESSURE MONITOR of BCM.

2. Check that the air pressures match the specified value.

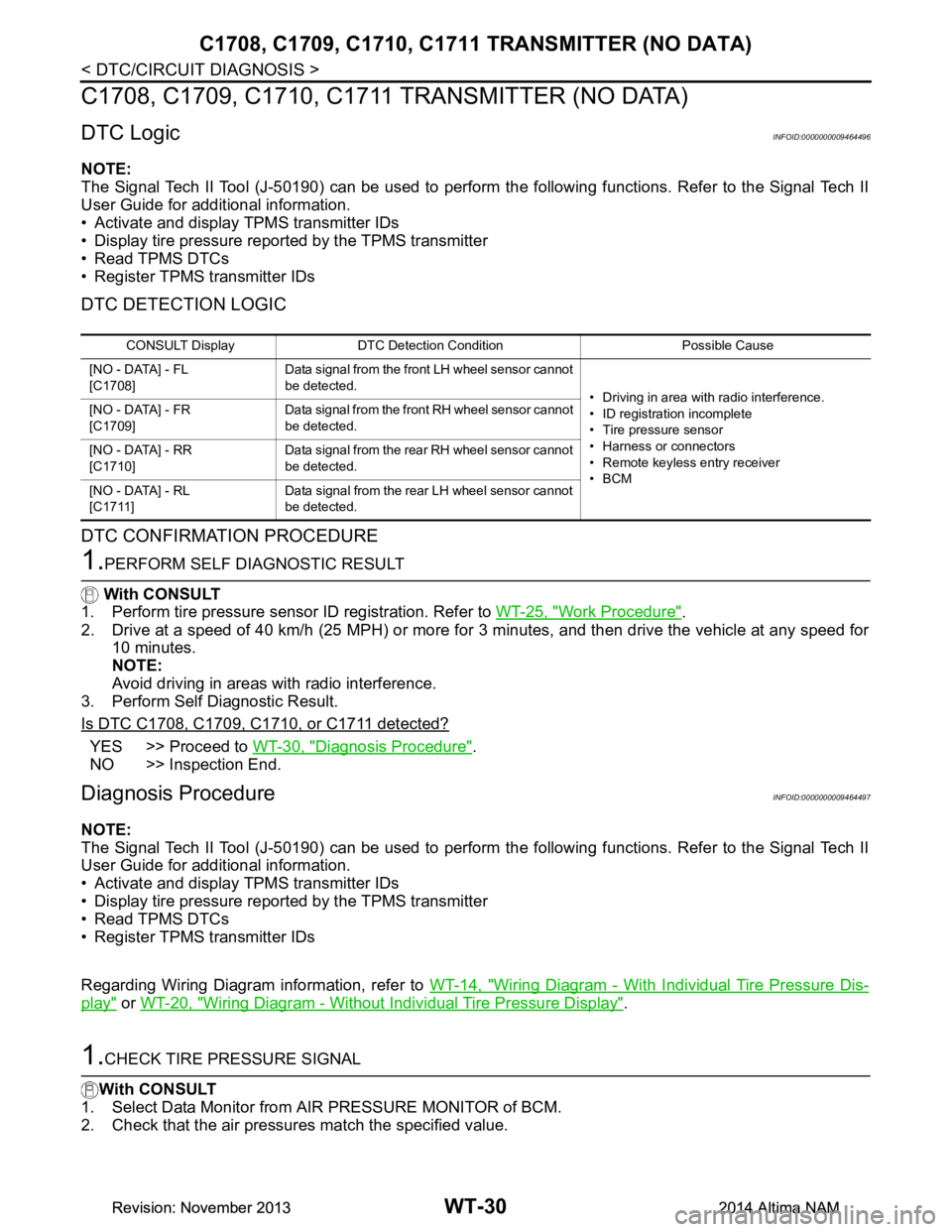

CONSULT Display DTC Detectio n Condition Possible Cause

[NO - DATA] - FL

[C1708] Data signal from the front LH wheel sensor cannot

be detected. • Driving in area with radio interference.

• ID registration incomplete

• Tire pressure sensor

• Harness or connectors

• Remote keyless entry receiver

•BCM

[NO - DATA] - FR

[C1709] Data signal from the front RH wheel sensor cannot

be detected.

[NO - DATA] - RR

[C1710] Data signal from the rear RH wheel sensor cannot

be detected.

[NO - DATA] - RL

[C1711] Data signal from the rear LH wheel sensor cannot

be detected.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4706 of 4801

C1708, C1709, C1710, C1711 TRANSMITTER (NO DATA)

WT-31

< DTC/CIRCUIT DIAGNOSIS >

C

D

F

G H

I

J

K L

M A

B

WT

N

O P

Are all tire pressures displayed 0 kPa (psi)?

YES >> GO TO 2.

NO >> Replace applicable tire pressure sensor. Refer to WT-57, "Removal and Installation"

.

2.CHECK REMOTE KEYLESS ENTRY RECEIVER POWER CIRCUIT

Check voltage between remote keyless entry receiver connector M27 terminal 1 and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace harness or connectors.

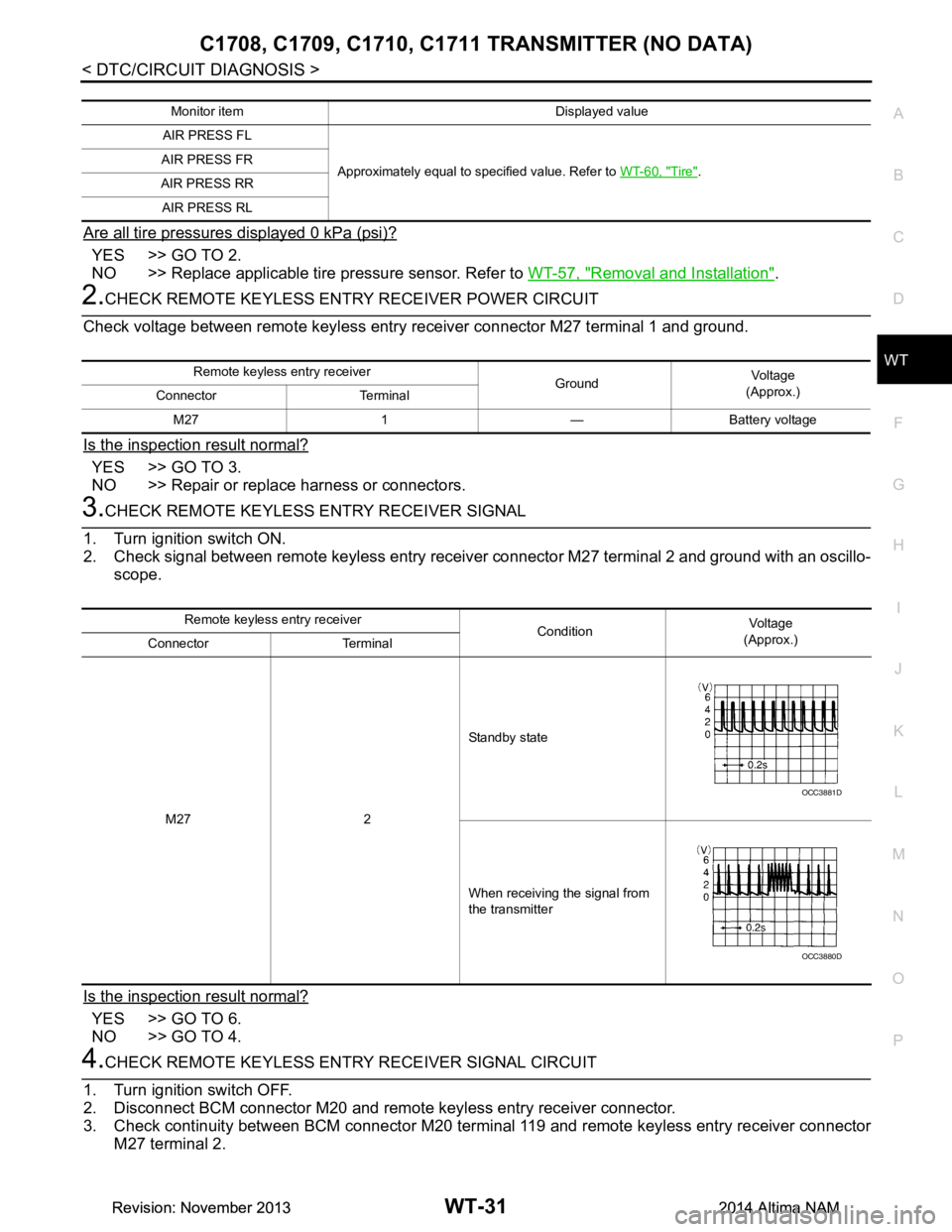

3.CHECK REMOTE KEYLESS ENTRY RECEIVER SIGNAL

1. Turn ignition switch ON.

2. Check signal between remote keyless entry receiver connector M27 terminal 2 and ground with an oscillo-

scope.

Is the inspection result normal?

YES >> GO TO 6.

NO >> GO TO 4.

4.CHECK REMOTE KEYLESS ENTR Y RECEIVER SIGNAL CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connector M20 and remote keyless entry receiver connector.

3. Check continuity between BCM connector M20 terminal 119 and remote keyless entry receiver connector

M27 terminal 2.

Monitor item Displayed value

AIR PRESS FL

Approximately equal to specified value. Refer to WT-60, "Tire"

.

AIR PRESS FR

AIR PRESS RR AIR PRESS RL

Remote keyless entry receiver GroundVo l ta g e

(Approx.)

Connector Terminal

M27 1 — Battery voltage

Remote keyless entry receiver ConditionVo l ta g e

(Approx.)

Connector Terminal

M27 2 Standby state

When receiving the signal from

the transmitter

OCC3881D

OCC3880D

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4707 of 4801

WT-32

< DTC/CIRCUIT DIAGNOSIS >

C1708, C1709, C1710, C1711 TRANSMITTER (NO DATA)

4. Check continuity between BCM connector M20 terminal 119 and ground.

Is the inspection result normal?

YES >> GO TO 5.

NO >> Repair or replace harness or connectors.

5.CHECK REMOTE KEYL ESS ENTRY RECEIVER GROUND CIRCUIT

Check continuity between remote keyless entry receiver connector M27 terminal 3 and ground.

Is the inspection result normal?

YES >> Replace the remote keyless entry receiver. Refer to DLK-224, "Removal and Installation".

NO >> Repair or replace harness or connectors.

6.TIRE PRESSURE SENSOR ID REGISTRATION

Perform tire pressure sensor ID registration. Refer to WT-25, "Work Procedure"

.

Can the tire pressure sensor ID registration be completed?

YES >> GO TO 7.

NO >> Replace applicable tire pressure sensor. Refer to WT-57, "Removal and Installation"

.

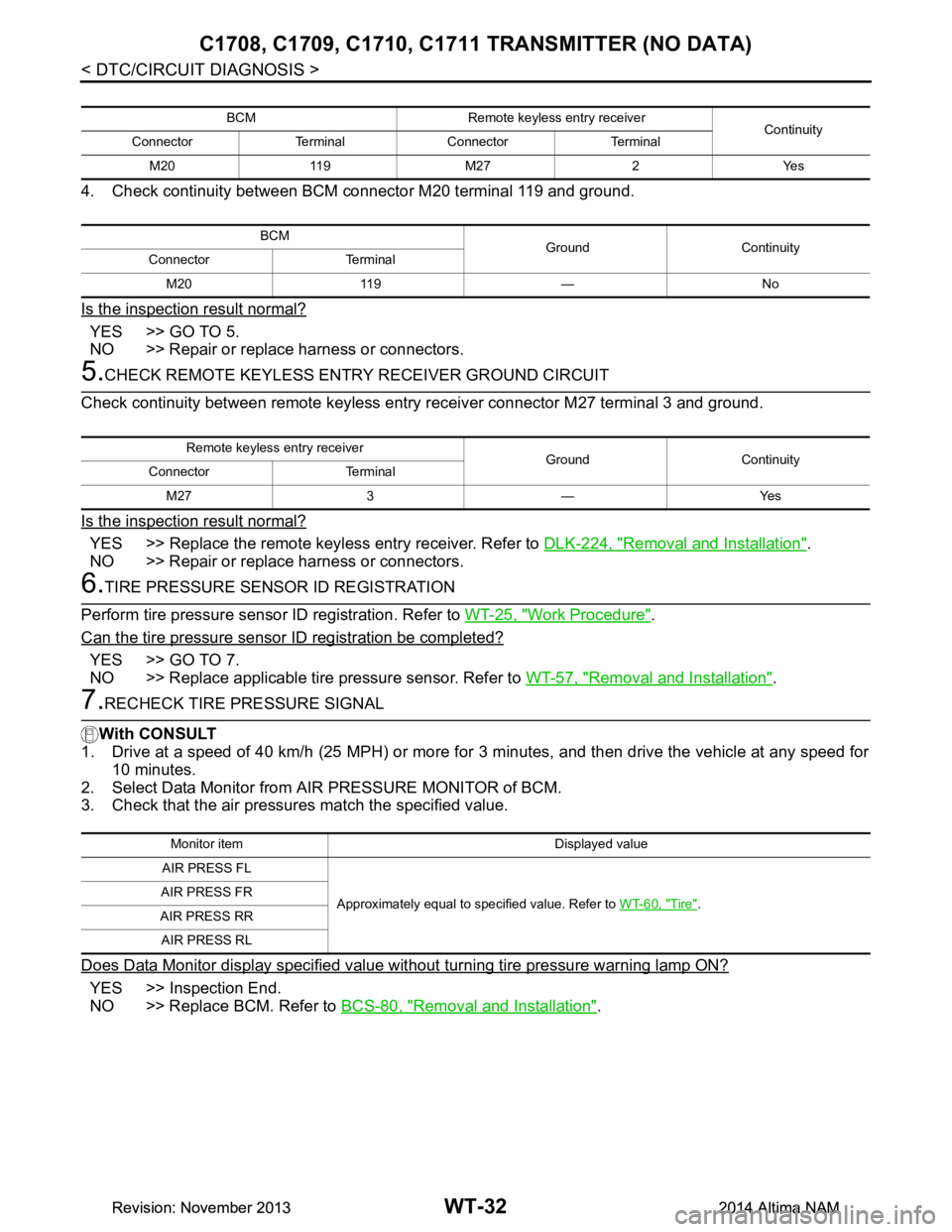

7.RECHECK TIRE PRESSURE SIGNAL

With CONSULT

1. Drive at a speed of 40 km/h (25 MPH) or more fo r 3 minutes, and then drive the vehicle at any speed for

10 minutes.

2. Select Data Monitor from AIR PRESSURE MONITOR of BCM.

3. Check that the air pressures match the specified value.

Does Data Monitor display specified value without turning tire pressure warning lamp ON?

YES >> Inspection End.

NO >> Replace BCM. Refer to BCS-80, "Removal and Installation"

.

BCM Remote keyless entry receiver

Continuity

Connector Terminal Connector Terminal

M20 119 M27 2 Yes

BCM Ground Continuity

Connector Terminal

M20 119 — No

Remote keyless entry receiver Ground Continuity

Connector Terminal

M27 3 — Yes

Monitor item Displayed value

AIR PRESS FL

Approximately equal to specified value. Refer to WT-60, "Tire"

.

AIR PRESS FR

AIR PRESS RR AIR PRESS RL

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4708 of 4801

C1712, C1713, C1714, C1715 TRANSMITTER (CHECKSUM)

WT-33

< DTC/CIRCUIT DIAGNOSIS >

C

D

F

G H

I

J

K L

M A

B

WT

N

O P

C1712, C1713, C1714, C1715 TRANSMITTER (CHECKSUM)

DTC LogicINFOID:0000000009464498

NOTE:

The Signal Tech II Tool (J-50190) can be used to perform the following functions. Refer to the Signal Tech II

User Guide for additional information.

• Activate and display TPMS transmitter IDs

• Display tire pressure repor ted by the TPMS transmitter

• Read TPMS DTCs

• Register TPMS transmitter IDs

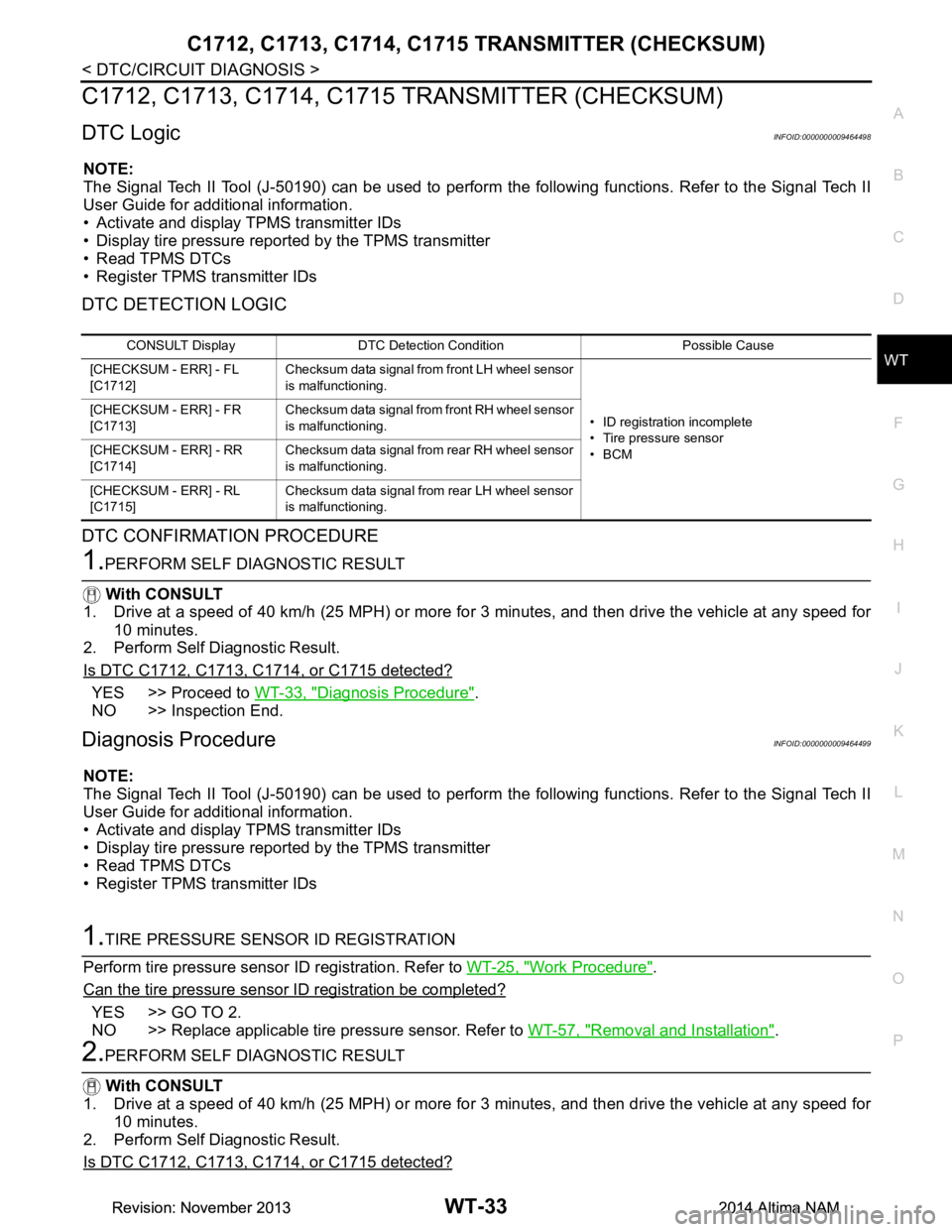

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM SELF DIAGNOSTIC RESULT

With CONSULT

1. Drive at a speed of 40 km/h (25 MPH) or more fo r 3 minutes, and then drive the vehicle at any speed for

10 minutes.

2. Perform Self Diagnostic Result.

Is DTC C1712, C1713, C1714, or C1715 detected?

YES >> Proceed to WT-33, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis ProcedureINFOID:0000000009464499

NOTE:

The Signal Tech II Tool (J-50190) can be used to perform the following functions. Refer to the Signal Tech II

User Guide for additional information.

• Activate and display TPMS transmitter IDs

• Display tire pressure repor ted by the TPMS transmitter

• Read TPMS DTCs

• Register TPMS transmitter IDs

1.TIRE PRESSURE SENS OR ID REGISTRATION

Perform tire pressure sensor ID registration. Refer to WT-25, "Work Procedure"

.

Can the tire pressure sensor ID registration be completed?

YES >> GO TO 2.

NO >> Replace applicable tire pressure sensor. Refer to WT-57, "Removal and Installation"

.

2.PERFORM SELF DIAGNOSTIC RESULT

With CONSULT

1. Drive at a speed of 40 km/h (25 MPH) or more fo r 3 minutes, and then drive the vehicle at any speed for

10 minutes.

2. Perform Self Diagnostic Result.

Is DTC C1712, C1713, C1714, or C1715 detected?

CONSULT Display DTC Detection Condition Possible Cause

[CHECKSUM - ERR] - FL

[C1712] Checksum data signal from front LH wheel sensor

is malfunctioning.

• ID registration incomplete

• Tire pressure sensor

•BCM

[CHECKSUM - ERR] - FR

[C1713] Checksum data signal from front RH wheel sensor

is malfunctioning.

[CHECKSUM - ERR] - RR

[C1714] Checksum data signal from rear RH wheel sensor

is malfunctioning.

[CHECKSUM - ERR] - RL

[C1715] Checksum data signal from rear LH wheel sensor

is malfunctioning.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4710 of 4801

C1716, C1717, C1718, C1719 TRANSMITTER (PRESSURE DATA)

WT-35

< DTC/CIRCUIT DIAGNOSIS >

C

D

F

G H

I

J

K L

M A

B

WT

N

O P

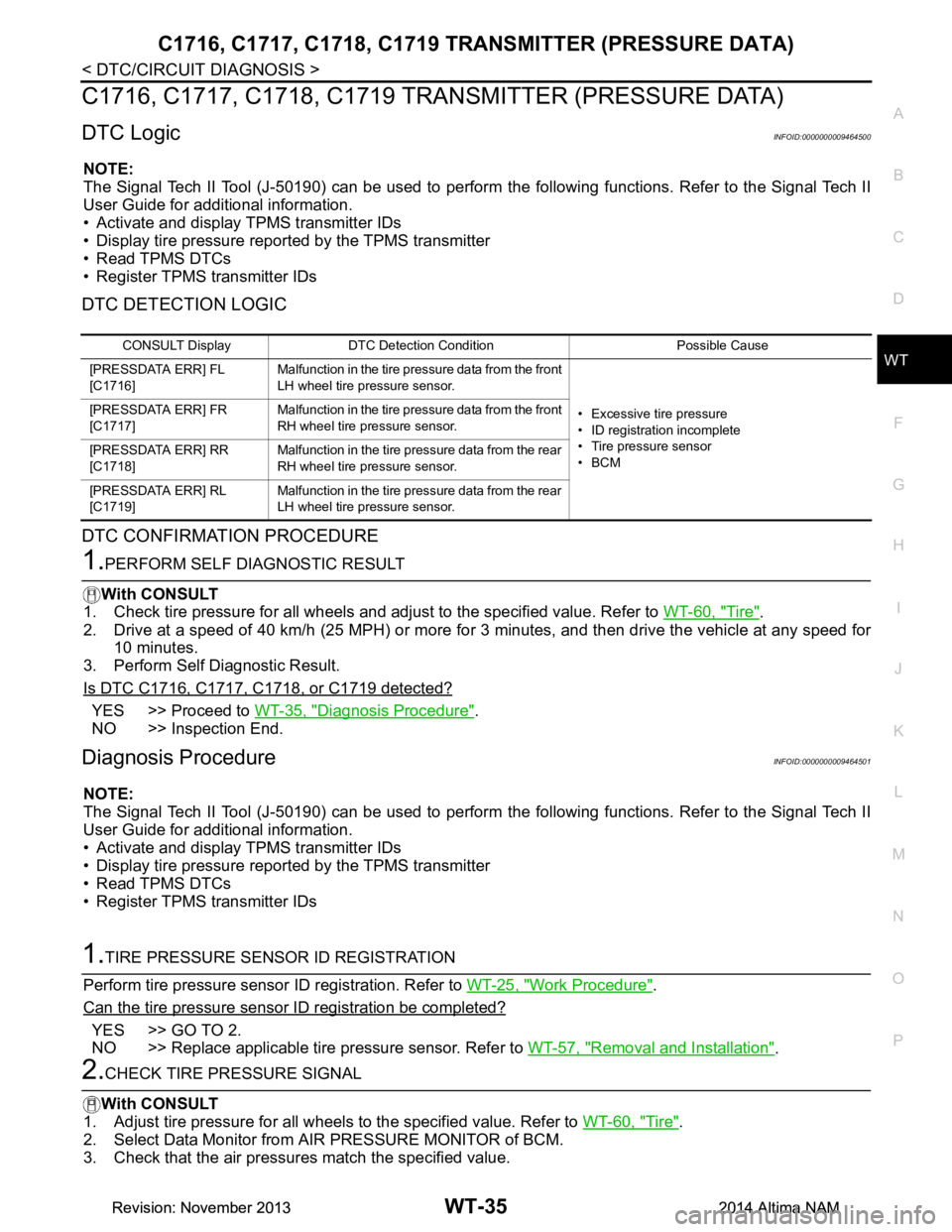

C1716, C1717, C1718, C1719 TRAN SMITTER (PRESSURE DATA)

DTC LogicINFOID:0000000009464500

NOTE:

The Signal Tech II Tool (J-50190) can be used to perform the following functions. Refer to the Signal Tech II

User Guide for additional information.

• Activate and display TPMS transmitter IDs

• Display tire pressure repor ted by the TPMS transmitter

• Read TPMS DTCs

• Register TPMS transmitter IDs

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM SELF DIAGNOSTIC RESULT

With CONSULT

1. Check tire pressure for all wheels and adjust to the specified value. Refer to WT-60, "Tire"

.

2. Drive at a speed of 40 km/h (25 MPH) or more fo r 3 minutes, and then drive the vehicle at any speed for

10 minutes.

3. Perform Self Diagnostic Result.

Is DTC C1716, C1717, C1718, or C1719 detected?

YES >> Proceed to WT-35, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis ProcedureINFOID:0000000009464501

NOTE:

The Signal Tech II Tool (J-50190) can be used to perform the following functions. Refer to the Signal Tech II

User Guide for additional information.

• Activate and display TPMS transmitter IDs

• Display tire pressure repor ted by the TPMS transmitter

• Read TPMS DTCs

• Register TPMS transmitter IDs

1.TIRE PRESSURE SENS OR ID REGISTRATION

Perform tire pressure sensor ID registration. Refer to WT-25, "Work Procedure"

.

Can the tire pressure sensor ID registration be completed?

YES >> GO TO 2.

NO >> Replace applicable tire pressure sensor. Refer to WT-57, "Removal and Installation"

.

2.CHECK TIRE PRESSURE SIGNAL

With CONSULT

1. Adjust tire pressure for all wheels to the specified value. Refer to WT-60, "Tire"

.

2. Select Data Monitor from AIR PRESSURE MONITOR of BCM.

3. Check that the air pressures match the specified value.

CONSULT Display DTC Detectio n Condition Possible Cause

[PRESSDATA ERR] FL

[C1716] Malfunction in the tire pressure data from the front

LH wheel tire pressure sensor.

• Excessive tire pressure

• ID registration incomplete

• Tire pressure sensor

•BCM

[PRESSDATA ERR] FR

[C1717] Malfunction in the tire pressure data from the front

RH wheel tire pressure sensor.

[PRESSDATA ERR] RR

[C1718] Malfunction in the tire pressure data from the rear

RH wheel tire pressure sensor.

[PRESSDATA ERR] RL

[C1719] Malfunction in the tire pressure data from the rear

LH wheel tire pressure sensor.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4712 of 4801

C1720, C1721, C1722, C1723 TRANSMITTER

WT-37

< DTC/CIRCUIT DIAGNOSIS >

C

D

F

G H

I

J

K L

M A

B

WT

N

O P

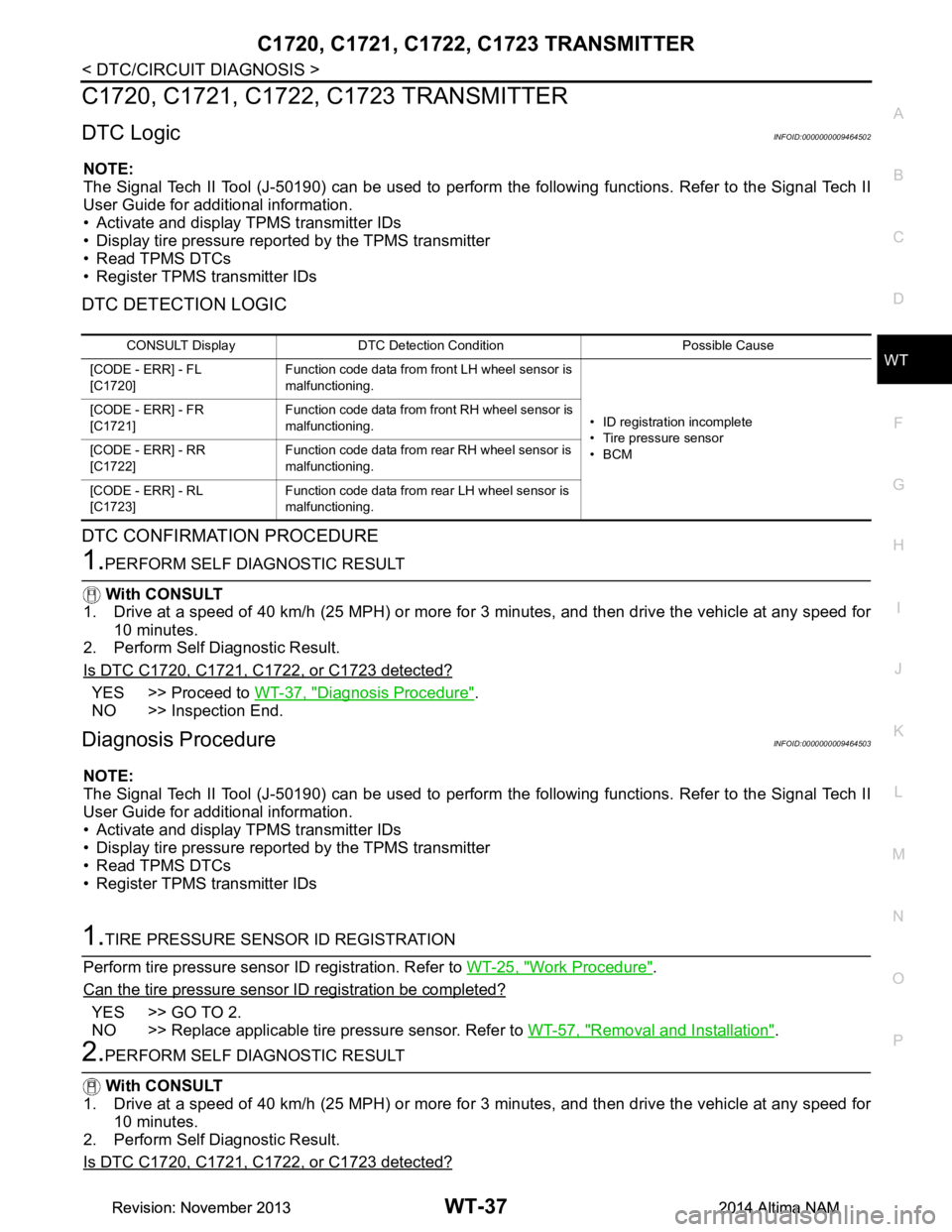

C1720, C1721, C1722, C1723 TRANSMITTER

DTC LogicINFOID:0000000009464502

NOTE:

The Signal Tech II Tool (J-50190) can be used to perform the following functions. Refer to the Signal Tech II

User Guide for additional information.

• Activate and display TPMS transmitter IDs

• Display tire pressure repor ted by the TPMS transmitter

• Read TPMS DTCs

• Register TPMS transmitter IDs

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM SELF DIAGNOSTIC RESULT

With CONSULT

1. Drive at a speed of 40 km/h (25 MPH) or more fo r 3 minutes, and then drive the vehicle at any speed for

10 minutes.

2. Perform Self Diagnostic Result.

Is DTC C1720, C1721, C1722, or C1723 detected?

YES >> Proceed to WT-37, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis ProcedureINFOID:0000000009464503

NOTE:

The Signal Tech II Tool (J-50190) can be used to perform the following functions. Refer to the Signal Tech II

User Guide for additional information.

• Activate and display TPMS transmitter IDs

• Display tire pressure repor ted by the TPMS transmitter

• Read TPMS DTCs

• Register TPMS transmitter IDs

1.TIRE PRESSURE SENS OR ID REGISTRATION

Perform tire pressure sensor ID registration. Refer to WT-25, "Work Procedure"

.

Can the tire pressure sensor ID registration be completed?

YES >> GO TO 2.

NO >> Replace applicable tire pressure sensor. Refer to WT-57, "Removal and Installation"

.

2.PERFORM SELF DIAGNOSTIC RESULT

With CONSULT

1. Drive at a speed of 40 km/h (25 MPH) or more fo r 3 minutes, and then drive the vehicle at any speed for

10 minutes.

2. Perform Self Diagnostic Result.

Is DTC C1720, C1721, C1722, or C1723 detected?

CONSULT Display DTC Detection Condition Possible Cause

[CODE - ERR] - FL

[C1720] Function code data from front LH wheel sensor is

malfunctioning.

• ID registration incomplete

• Tire pressure sensor

•BCM

[CODE - ERR] - FR

[C1721] Function code data from front RH wheel sensor is

malfunctioning.

[CODE - ERR] - RR

[C1722] Function code data from rear RH wheel sensor is

malfunctioning.

[CODE - ERR] - RL

[C1723] Function code data from rear LH wheel sensor is

malfunctioning.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4714 of 4801

C1724, C1725, C1726, C1727 TRANSMI TTER (BATT VOLT)

WT-39

< DTC/CIRCUIT DIAGNOSIS >

C

D

F

G H

I

J

K L

M A

B

WT

N

O P

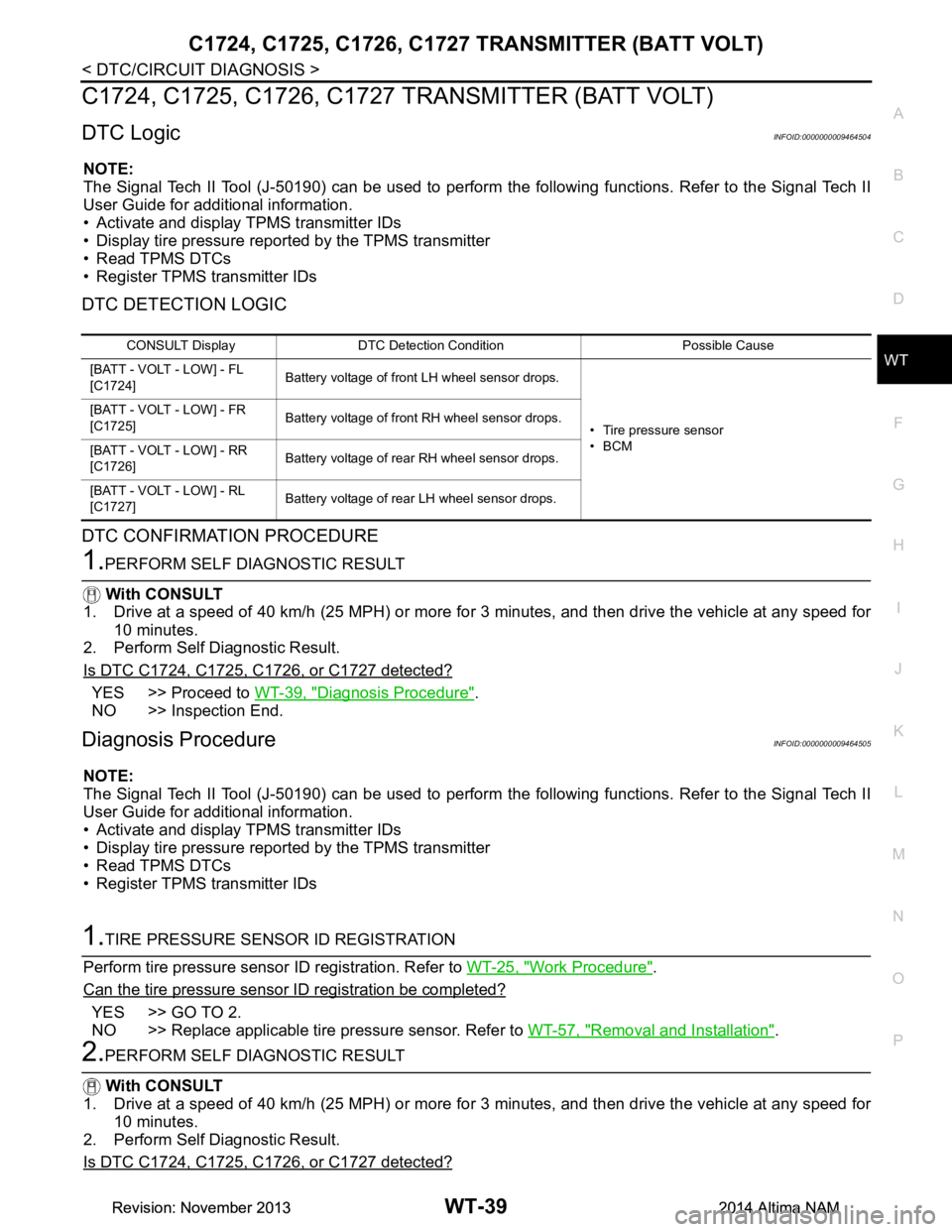

C1724, C1725, C1726, C1727 TR ANSMITTER (BATT VOLT)

DTC LogicINFOID:0000000009464504

NOTE:

The Signal Tech II Tool (J-50190) can be used to perform the following functions. Refer to the Signal Tech II

User Guide for additional information.

• Activate and display TPMS transmitter IDs

• Display tire pressure repor ted by the TPMS transmitter

• Read TPMS DTCs

• Register TPMS transmitter IDs

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM SELF DIAGNOSTIC RESULT

With CONSULT

1. Drive at a speed of 40 km/h (25 MPH) or more fo r 3 minutes, and then drive the vehicle at any speed for

10 minutes.

2. Perform Self Diagnostic Result.

Is DTC C1724, C1725, C1726, or C1727 detected?

YES >> Proceed to WT-39, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis ProcedureINFOID:0000000009464505

NOTE:

The Signal Tech II Tool (J-50190) can be used to perform the following functions. Refer to the Signal Tech II

User Guide for additional information.

• Activate and display TPMS transmitter IDs

• Display tire pressure repor ted by the TPMS transmitter

• Read TPMS DTCs

• Register TPMS transmitter IDs

1.TIRE PRESSURE SENS OR ID REGISTRATION

Perform tire pressure sensor ID registration. Refer to WT-25, "Work Procedure"

.

Can the tire pressure sensor ID registration be completed?

YES >> GO TO 2.

NO >> Replace applicable tire pressure sensor. Refer to WT-57, "Removal and Installation"

.

2.PERFORM SELF DIAGNOSTIC RESULT

With CONSULT

1. Drive at a speed of 40 km/h (25 MPH) or more fo r 3 minutes, and then drive the vehicle at any speed for

10 minutes.

2. Perform Self Diagnostic Result.

Is DTC C1724, C1725, C1726, or C1727 detected?

CONSULT Display DTC Detection Condition Possible Cause

[BATT - VOLT - LOW] - FL

[C1724] Battery voltage of front LH wheel sensor drops.

• Tire pressure sensor

•BCM

[BATT - VOLT - LOW] - FR

[C1725] Battery voltage of front RH wheel sensor drops.

[BATT - VOLT - LOW] - RR

[C1726] Battery voltage of rear RH wheel sensor drops.

[BATT - VOLT - LOW] - RL

[C1727] Battery voltage of rear LH wheel sensor drops.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4717 of 4801

WT-42

< DTC/CIRCUIT DIAGNOSIS >

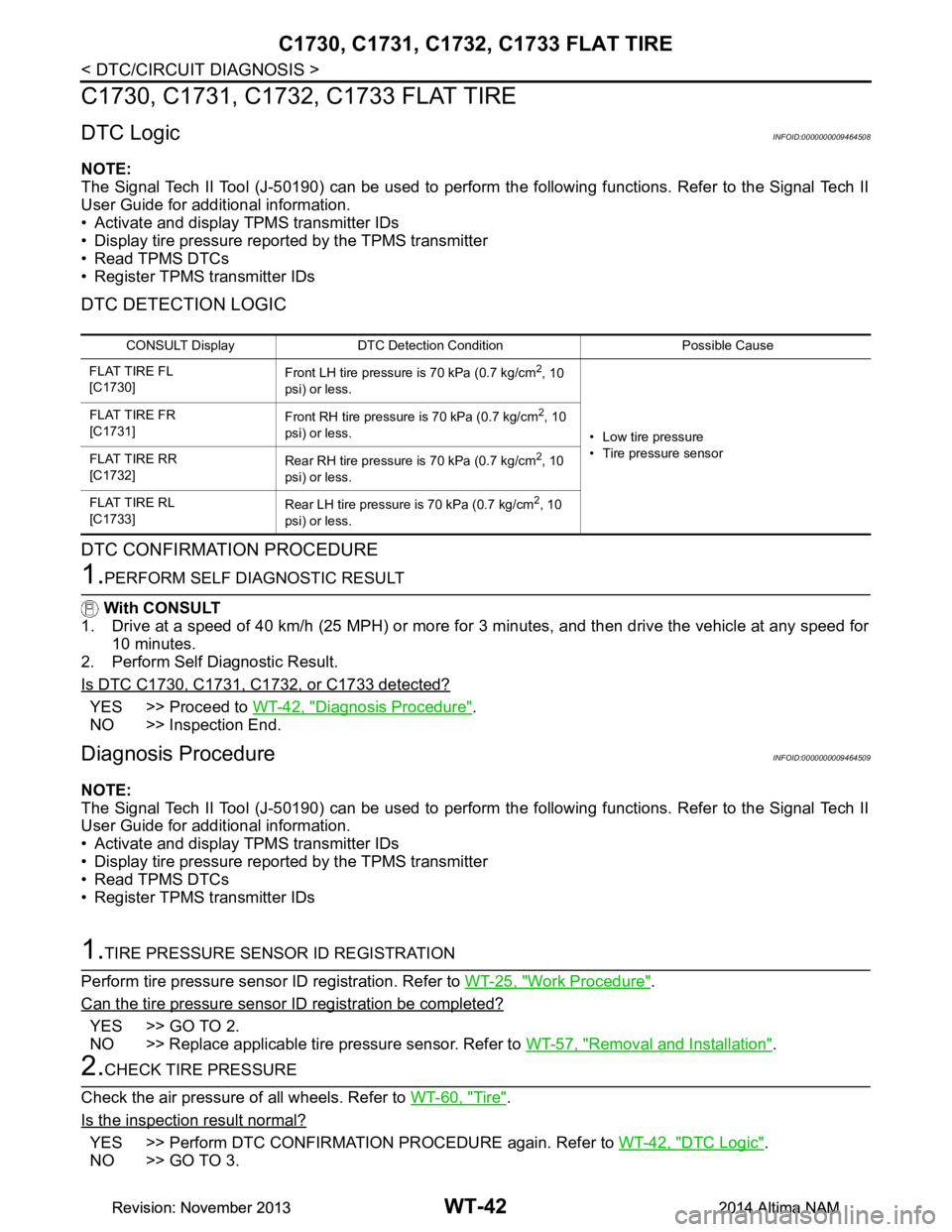

C1730, C1731, C1732, C1733 FLAT TIRE

C1730, C1731, C1732, C1733 FLAT TIRE

DTC LogicINFOID:0000000009464508

NOTE:

The Signal Tech II Tool (J-50190) can be used to perform the following functions. Refer to the Signal Tech II

User Guide for additional information.

• Activate and display TPMS transmitter IDs

• Display tire pressure reported by the TPMS transmitter

• Read TPMS DTCs

• Register TPMS transmitter IDs

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM SELF DIAGNOSTIC RESULT

With CONSULT

1. Drive at a speed of 40 km/h (25 MPH) or more fo r 3 minutes, and then drive the vehicle at any speed for

10 minutes.

2. Perform Self Diagnostic Result.

Is DTC C1730, C1731, C1732, or C1733 detected?

YES >> Proceed to WT-42, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis ProcedureINFOID:0000000009464509

NOTE:

The Signal Tech II Tool (J-50190) can be used to perform the following functions. Refer to the Signal Tech II

User Guide for additional information.

• Activate and display TPMS transmitter IDs

• Display tire pressure reported by the TPMS transmitter

• Read TPMS DTCs

• Register TPMS transmitter IDs

1.TIRE PRESSURE SENSOR ID REGISTRATION

Perform tire pressure sensor ID registration. Refer to WT-25, "Work Procedure"

.

Can the tire pressure sensor ID registration be completed?

YES >> GO TO 2.

NO >> Replace applicable tire pressure sensor. Refer to WT-57, "Removal and Installation"

.

2.CHECK TIRE PRESSURE

Check the air pressure of all wheels. Refer to WT-60, "Tire"

.

Is the inspection result normal?

YES >> Perform DTC CONFIRMATION PROCEDURE again. Refer to WT-42, "DTC Logic".

NO >> GO TO 3.

CONSULT Display DTC Detectio n Condition Possible Cause

FLAT TIRE FL

[C1730] Front LH tire pressure is 70 kPa (0.7 kg/cm

2, 10

psi) or less.

• Low tire pressure

• Tire pressure sensor

FLAT TIRE FR

[C1731] Front RH tire pressure is 70 kPa (0.7 kg/cm

2, 10

psi) or less.

FLAT TIRE RR

[C1732] Rear RH tire pressure is 70 kPa (0.7 kg/cm

2, 10

psi) or less.

FLAT TIRE RL

[C1733] Rear LH tire pressure is 70 kPa (0.7 kg/cm

2, 10

psi) or less.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4732 of 4801

TIRE PRESSURE SENSORWT-57

< UNIT REMOVAL AND INSTALLATION >

C

D

F

G H

I

J

K L

M A

B

WT

N

O P

UNIT REMOVAL AND INSTALLATION

TIRE PRESSURE SENSOR

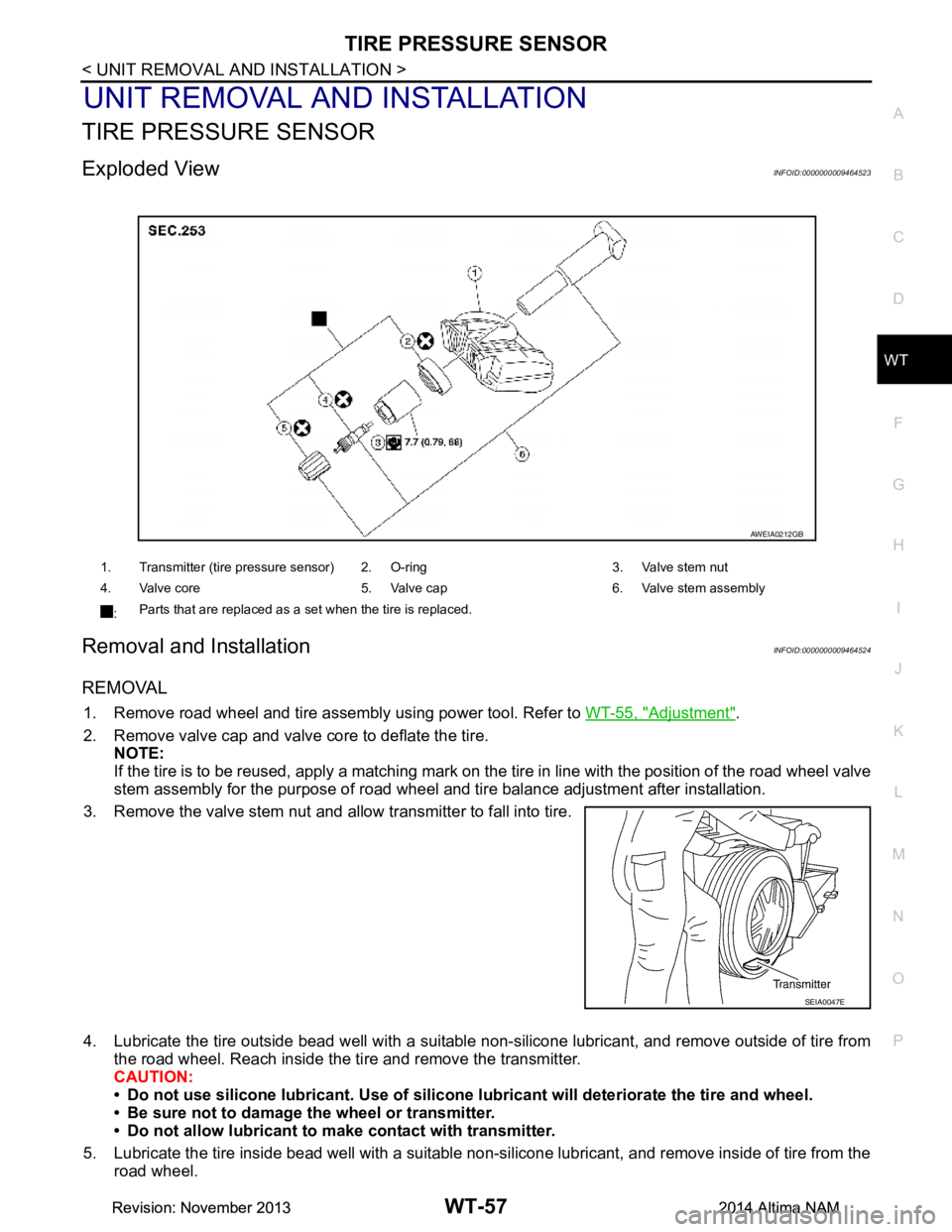

Exploded ViewINFOID:0000000009464523

Removal and InstallationINFOID:0000000009464524

REMOVAL

1. Remove road wheel and tire assembly using power tool. Refer to WT-55, "Adjustment".

2. Remove valve cap and valve core to deflate the tire. NOTE:

If the tire is to be reused, apply a matching mark on t he tire in line with the position of the road wheel valve

stem assembly for the purpose of road wheel and tire balance adjustment after installation.

3. Remove the valve stem nut and allow transmitter to fall into tire.

4. Lubricate the tire outside bead well with a suitable non-silicone lubricant, and remove outside of tire from the road wheel. Reach inside the ti re and remove the transmitter.

CAUTION:

• Do not use silicone lubricant. Use of silicone lubricant will deteriorate the tire and wheel.

• Be sure not to damage the wheel or transmitter.

• Do not allow lubricant to make contact with transmitter.

5. Lubricate the tire inside bead well with a suitable non-silicone lubricant, and remove inside of tire from the road wheel.

1. Transmitter (tire pressure sensor) 2. O-ring 3. Valve stem nut

4. Valve core 5. Valve cap 6. Valve stem assembly

: Parts that are replaced as a set when the tire is replaced.

AWEIA0212GB

SEIA0047E

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4733 of 4801

WT-58

< UNIT REMOVAL AND INSTALLATION >

TIRE PRESSURE SENSOR

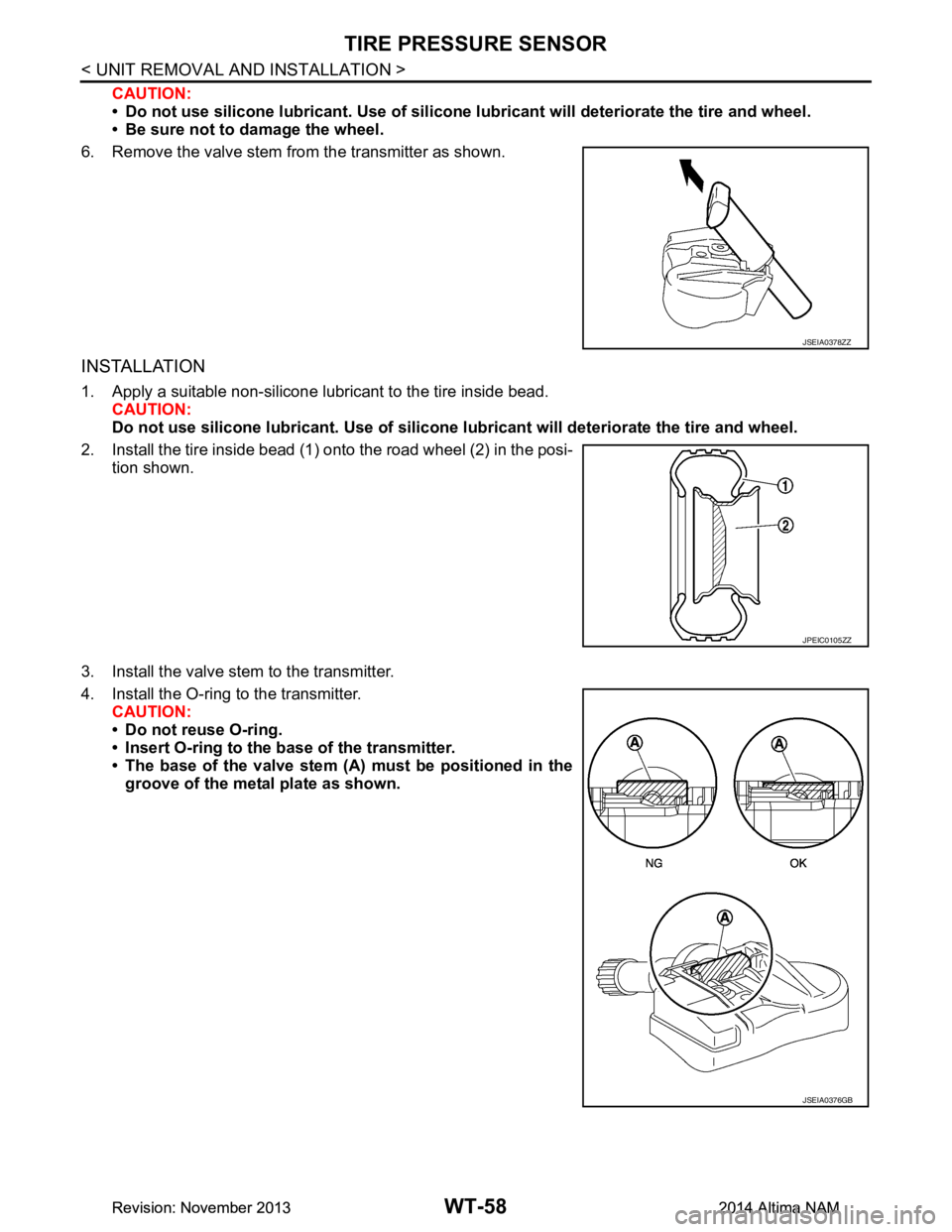

CAUTION:

• Do not use silicone lubricant. Use of silicone lubricant will deteriorate the tire and wheel.

• Be sure not to damage the wheel.

6. Remove the valve stem from the transmitter as shown.

INSTALLATION

1. Apply a suitable non-silicone lubricant to the tire inside bead.

CAUTION:

Do not use silicone lubr icant. Use of silicone lubricant wi ll deteriorate the tire and wheel.

2. Install the tire inside bead (1) onto the road wheel (2) in the posi- tion shown.

3. Install the valve stem to the transmitter.

4. Install the O-ring to the transmitter. CAUTION:

• Do not reuse O-ring.

• Insert O-ring to the base of the transmitter.

• The base of the valve stem (A) must be positioned in the groove of the metal plate as shown.

JSEIA0378ZZ

JPEIC0105ZZ

JSEIA0376GB

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM