ad blue NISSAN TEANA 2014 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 2118 of 4801

![NISSAN TEANA 2014 User Guide

EM-120

< SERVICE DATA AND SPECIFICATIONS (SDS) [QR25DE]

SERVICE DATA AND SPECIFICATIONS (SDS)

*: Total indicator reading

MAIN BEARING

Unit: mm (in)

Main journal dia. (Dm) grade Grade No. A

Grade No. NISSAN TEANA 2014 User Guide

EM-120

< SERVICE DATA AND SPECIFICATIONS (SDS) [QR25DE]

SERVICE DATA AND SPECIFICATIONS (SDS)

*: Total indicator reading

MAIN BEARING

Unit: mm (in)

Main journal dia. (Dm) grade Grade No. A

Grade No.](/img/5/57390/w960_57390-2117.png)

EM-120

< SERVICE DATA AND SPECIFICATIONS (SDS) [QR25DE]

SERVICE DATA AND SPECIFICATIONS (SDS)

*: Total indicator reading

MAIN BEARING

Unit: mm (in)

Main journal dia. (Dm) grade Grade No. A

Grade No. B

Grade No. C

Grade No. D

Grade No. E

Grade No. F

Grade No. G

Grade No. H

Grade No. J

Grade No. K

Grade No. L

Grade No. M

Grade No. N

Grade No. P

Grade No. R

Grade No. S

Grade No. T

Grade No. U

Grade No. V

Grade No. W

Grade No. X

Grade No. Y

Grade No. 4

Grade No. 7 54.979 - 54.978 (2.1645 - 2.1645)

54.978 - 54.977 (2.1645 - 2.1644)

54.977 - 54.976 (2.1644 - 2.1644)

54.976 - 54.975 (2.1644 - 2.1644)

54.975 - 54.974 (2.1644 - 2.1643)

54.974 - 54.973 (2.1643 - 2.1643)

54.973 - 54.972 (2.1643 - 2.1642)

54.972 - 54.971 (2.1642 - 2.1642)

54.971 - 54.970 (2.1642 - 2.1642)

54.970 - 54.969 (2.1642 - 2.1641)

54.969 - 54.968 (2.1641 - 2.1641)

54.968 - 54.967 (2.1641 - 2.1641)

54.967 - 54.966 (2.1641 - 2.1640)

54.966 - 54.965 (2.1640 - 2.1640)

54.965 - 54.964 (2.1640 - 2.1639)

54.964 - 54.963 (2.1639 - 2.1639)

54.963 - 54.962 (2.1639 - 2.1639)

54.962 - 54.961 (2.1639 - 2.1638)

54.961 - 54.960 (2.1638 - 2.1638)

54.960 - 54.959 (2.1638 - 2.1637)

54.959 - 54.958 (2.1637 - 2.1637)

54.958 - 54.957 (2.1637 - 2.1637)

54.957 - 54.956 (2.1637 - 2.1636)

54.956 - 54.955 (2.1636 - 2.1636)

Center distance (r) 49.60 - 50.04 (1.9528 - 1.9701)

Out-of-round (X − Y) Standard Less than 0.005 (0.0002)

Taper (A − B) Standard Less than 0.005 (0.0002)

Runout [TIR*] Limit Less than 0.05 (0.002)

Free end play Standard 0.10 - 0.26 (0.0039 - 0.0102)

Limit 0.30 (0.0118)

Grade number* Thickness Identification color Remarks 0 1.973 - 1.976 (0.0777 - 0.0778) Black

Grade and color are the same

for upper and lower bearings.

1 1.976 - 1.979 (0.0778 - 0.0779) Brown

2 1.979 - 1.982 (0.0779 - 0.0780) Green

3 1.982 - 1.985 (0.0780 - 0.0781) Yellow

4 1.985 - 1.988 (0.0781 - 0.0783) Blue

5 1.988 - 1.991 (0.0783 - 0.0784) Pink

6 1.991 - 1.994 (0.0784 - 0.0785) Purple

7 1.994 - 1.997 (0.0785 - 0.0786) White

SEM685D

Revision: November 20132014 Altima NAM

Page 2119 of 4801

![NISSAN TEANA 2014 User Guide

SERVICE DATA AND SPECIFICATIONS (SDS)EM-121

< SERVICE DATA AND SPECIFICATIONS (SDS) [QR25DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

*: Always check with the Parts Department for the latest parts informati NISSAN TEANA 2014 User Guide

SERVICE DATA AND SPECIFICATIONS (SDS)EM-121

< SERVICE DATA AND SPECIFICATIONS (SDS) [QR25DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

*: Always check with the Parts Department for the latest parts informati](/img/5/57390/w960_57390-2118.png)

SERVICE DATA AND SPECIFICATIONS (SDS)EM-121

< SERVICE DATA AND SPECIFICATIONS (SDS) [QR25DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

*: Always check with the Parts Department for the latest parts information.

Undersize

Unit: mm (in)

Bearing Clearance

Unit: mm (in)

CONNECTING ROD BEARING

01

UPR 1.973 - 1.976 (0.0777 - 0.0778) Black

Grade and color are different

for upper and lower bearings.

LWR 1.976 - 1.979 (0.0778 - 0.0779) Brown

12 UPR 1.976 - 1.979 (0.0778 - 0.0779) Brown

LWR 1.979 - 1.982 (0.0779 - 0.0780) Green

23 UPR 1.979 - 1.982 (0.0779 - 0.0780) Green

LWR 1.982 - 1.985 (0.0780 - 0.0781) Yellow

34 UPR 1.982 - 1.985 (0.0780 - 0.0781) Yellow

LWR 1.985 - 1.988 (0.0781 - 0.0783) Blue

45 UPR 1.985 - 1.988 (0.0781 - 0.0783) Blue

LWR 1.988 - 1.991 (0.0783 - 0.0784) Pink

56 UPR 1.988 - 1.991 (0.0783 - 0.0784) Pink

LWR 1.991 - 1.994 (0.0784 - 0.0785) Purple

67 UPR 1.991 - 1.994 (0.0784 - 0.0785) Purple

LWR 1.994 - 1.997 (0.0785 - 0.0786) White

Size U.S. Thickness Main journal diameter

0.25 (0.0098) 2.106 - 2.114 (0.0829 - 0.0832) Grind so that bearing clearance is the spec-

ified value.

Main bearing oil clearance StandardNo.1, 3, and 5 0.012 - 0.022 (0.0005 - 0.0009)

No.2 and 4 0.018 - 0.028 (0.0007 - 0.0011)

Limit 0.1 (0.004)

Grade number* Thickness mm (in) Identification color (mark) 0 (upper) 1.496 - 1.493 (0.0589 - 0.0588) Black-Black0 (lower) 1.496 - 1.493 (0.0589 - 0.0588) Black-Black

01 (upper) 1.496 - 1.493 (0.0589 - 0.0588) Black-Black 01 (lower) 1.499 - 1.496 (0.0590 - 0.0589) Brown-Brown 1 (upper) 1.499 - 1.496 (0 .0590 - 0.0589) Brown-Brown

1 (lower) 1.499 - 1.496 (0 .0590 - 0.0589) Brown-Brown

12 (upper) 1.499 - 1.496 (0.0590 - 0.0589) Brown-Brown 12 (lower) 1.502 - 1.499 (0.0591 - 0.0590) Green-Green 2 (upper) 1.502 - 1.499 (0.0591 - 0.0590) Green-Green2 (lower) 1.502 - 1.499 (0.0591 - 0.0590) Green-Green

23 (upper) 1.502 - 1.499 (0.0591 - 0.0590) Green-Green 23 (lower) 1.505 - 1.502 (0.0593 - 0.0591) Yellow-Yellow 3 (upper) 1.505 - 1.502 (0.0593 - 0.0591) Yellow-Yellow3 (lower) 1.505 - 1.502 (0.0593 - 0.0591) Yellow-Yellow

34 (upper) 1.505 - 1.502 (0.0593 - 0.0591) Yellow-Yellow 34 (lower) 1.508 - 1.505 (0.0594 - 0.0593) Blue-Blue 4 (upper) 1.508 - 1.505 (0.0594 - 0.0593) Blue-Blue4 (lower) 1.508 - 1.505 (0.0594 - 0.0593) Blue-Blue

Revision: November 20132014 Altima NAM

Page 2195 of 4801

![NISSAN TEANA 2014 User Guide

CAMSHAFTEM-197

< REMOVAL AND INSTALLATION > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

6. Install exhaust and intake camshafts and camshaft brackets.

• Intake camshaft has a drill mark on camshaft s NISSAN TEANA 2014 User Guide

CAMSHAFTEM-197

< REMOVAL AND INSTALLATION > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

6. Install exhaust and intake camshafts and camshaft brackets.

• Intake camshaft has a drill mark on camshaft s](/img/5/57390/w960_57390-2194.png)

CAMSHAFTEM-197

< REMOVAL AND INSTALLATION > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

6. Install exhaust and intake camshafts and camshaft brackets.

• Intake camshaft has a drill mark on camshaft sprocket mount-ing flange.

• Follow your identification marks made during removal, or fol- low the identification marks t hat are present on the new cam-

shafts components for proper placement and direction of the

components.

• Position the camshaft dowel pins (A) as shown.

SEM652F

:Engine front

Bank INT/EXH ID mark

(A) Drill mark

Paint marks

M1 (E) M2 (F) M3 (D)

RH (B) INT 1A Yes Pink No Light blue

EXH 1C No No Light blue Light blue

LH (C) INT 1B Yes Pink No Light blue

EXH 1D No No Light blue Light blue

(1) :Crankshaft key

AWBIA1352ZZ

AWBIA1221GB

Revision: November 20132014 Altima NAM

Page 2213 of 4801

![NISSAN TEANA 2014 User Guide

CYLINDER HEADEM-215

< REMOVAL AND INSTALLATION > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

5. Using a valve guide reamer, apply a reamer finish to the valve

guide.

VALVE SEAT CONTACT

• After confir NISSAN TEANA 2014 User Guide

CYLINDER HEADEM-215

< REMOVAL AND INSTALLATION > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

5. Using a valve guide reamer, apply a reamer finish to the valve

guide.

VALVE SEAT CONTACT

• After confir](/img/5/57390/w960_57390-2212.png)

CYLINDER HEADEM-215

< REMOVAL AND INSTALLATION > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

5. Using a valve guide reamer, apply a reamer finish to the valve

guide.

VALVE SEAT CONTACT

• After confirming that the dimensions of valve guides and valves are

within specifications, perform this procedure.

• Apply prussian blue onto contacting surface of valve seat to check the condition of the valve contact on the surface.

• Check if the contact area band is continuous all around the circum- ference.

• If not, grind to adjust valve fitti ng and check again. If the contacting

surface still has NG conditions even after the re-check, replace

valve seat.

VALVE SEAT REPLACEMENT

1. Bore out old seat until it collapses. Boring should not continue beyond the bottom face of the seat recess in cylinder head. Set

the machine depth stop to ensure this.

2. Ream cylinder head recess for service valve seat.

Be sure to ream in circles co ncentric to the valve guide cen-

ter.

This will enable valve seat to fit correctly.

3. Heat cylinder head to 110 ° to 130 °C (230 ° to 266 °F) by soaking

in heated oil.

WARNING:

Cylinder head contains heat . When working, wear protec-

tive equipment to avo id getting burned.

4. Press fit valve seat until it seats on the bottom.

5. Cut or grind valve seat using suitable t ool to the specified dimensions. Refer to EM-249, "Cylinder Head"

.

6. After cutting, lap valve seat with abrasive compound.

7. Check valve seating condition. Intake and exhaust

finished size : 6.000 - 6.018 mm

(0.2362 - 0.2369 in)

SEM932C

SBIA0322E

Oversize : 0.5 mm (0.020 in)

Intake : 38.500 - 38.516 mm (1.5157 - 1.5164 in)

Exhaust : 32.100 - 32.116 mm (1.2638 - 1.2644 in)

SEM795A

SEM008A

Revision: November 20132014 Altima NAM

Page 2254 of 4801

![NISSAN TEANA 2014 User Guide

EM-256

< SERVICE DATA AND SPECIFICATIONS (SDS) [VQ35DE]

SERVICE DATA AND SPECIFICATIONS (SDS)

*: Always check with the Parts Department for the latest parts information.

UNDERSIZE

Unit: mm (in)

MAIN NISSAN TEANA 2014 User Guide

EM-256

< SERVICE DATA AND SPECIFICATIONS (SDS) [VQ35DE]

SERVICE DATA AND SPECIFICATIONS (SDS)

*: Always check with the Parts Department for the latest parts information.

UNDERSIZE

Unit: mm (in)

MAIN](/img/5/57390/w960_57390-2253.png)

EM-256

< SERVICE DATA AND SPECIFICATIONS (SDS) [VQ35DE]

SERVICE DATA AND SPECIFICATIONS (SDS)

*: Always check with the Parts Department for the latest parts information.

UNDERSIZE

Unit: mm (in)

MAIN BEARING OIL CLEARANCE

Unit: mm (in)

*: Actual clearance

Connecting Rod BearingINFOID:0000000009460593

CONNECTING ROD BEARING

Unit: mm (in)

*: Always check with the Parts Department for the latest parts information.

UNDERSIZE

Unit: mm (in)

0 2.000 - 2.003 (0.0787 - 0.0789)

19.9 - 20.1

(0.783 - 0.791) Black

Grade is the same

for upper and lower

bearings.

1 2.003 - 2.006 (0.0789 - 0.0790) Brown

2 2.006 - 2.009 (0.0790 - 0.0791) Green

3 2.009 - 2.012 (0.0791 - 0.0792) Yellow

4 2.012 - 2.015 (0.0792 - 0.0793) Blue

5 2.015 - 2.018 (0.0793 - 0.0794) Pink

6 2.018 - 2.021 (0.0794 - 0.0796) Purple

7 2.021 - 2.024 (0.0796 - 0.0797) White

01 UPR 2.003 - 2.006 (0.0789 - 0.0790) Brown

Grade and color are

different for upper

and lower bearings.

LWR 2.000 - 2.003 (0.0787 - 0.0789) Black

12 UPR 2.006 - 2.009 (0.0790 - 0.0791) Green

LWR 2.003 - 2.006 (0.0789 - 0.0790) Brown

23 UPR 2.009 - 2.012 (0.0791 - 0.0792) Yellow

LWR 2.006 - 2.009 (0.0790 - 0.0791) Green

34 UPR 2.012 - 2.015 (0.0792 - 0.0793) Blue

LWR 2.009 - 2.012 (0.0791 - 0.0792) Yellow

45 UPR 2.015 - 2.018 (0.0793 - 0.0794) Pink

LWR 2.012 - 2.015 (0.0792 - 0.0793) Blue

56 UPR 2.018 - 2.021 (0.0794 - 0.0796) Purple

LWR 2.015 - 2.018 (0.0793 - 0.0794) Pink

67 UPR 2.021 - 2.024 (0.0796 - 0.0797) White

LWR 2.018 - 2.021 (0.0794 - 0.0796) Purple

Items Thickness Main journal diameter

0.25 (0.0098) 2.132 - 2.140 (0.0839 - 0.0843) Grind so that bearing clearance is the specified value.

Items Standard Limit

Main bearing oil clearance 0.012 - 0.022 (0.0005 - 0.0009)* 0.065 (0.0026)

Grade number* Thickness Identification color (mark) 0 1.500 - 1.503 (0.0591 - 0.0592) Black

1 1.503 - 1.506 (0.0592 - 0.0593) Brown

2 1.506 - 1.509 (0.0593 - 0.0594) Green

Items Thickness Crank pin journal diameter (Dp)

0.25 (0.0098) 1.626 - 1.634 (0.0640 - 0.0643) Grind so that bearing clearance is the specified value.

Revision: November 20132014 Altima NAM

Page 2539 of 4801

HOW TO READ WIRING DIAGRAMSGI-11

< HOW TO USE THIS MANUAL >

C

D E

F

G H

I

J

K L

M B

GI

N

O P

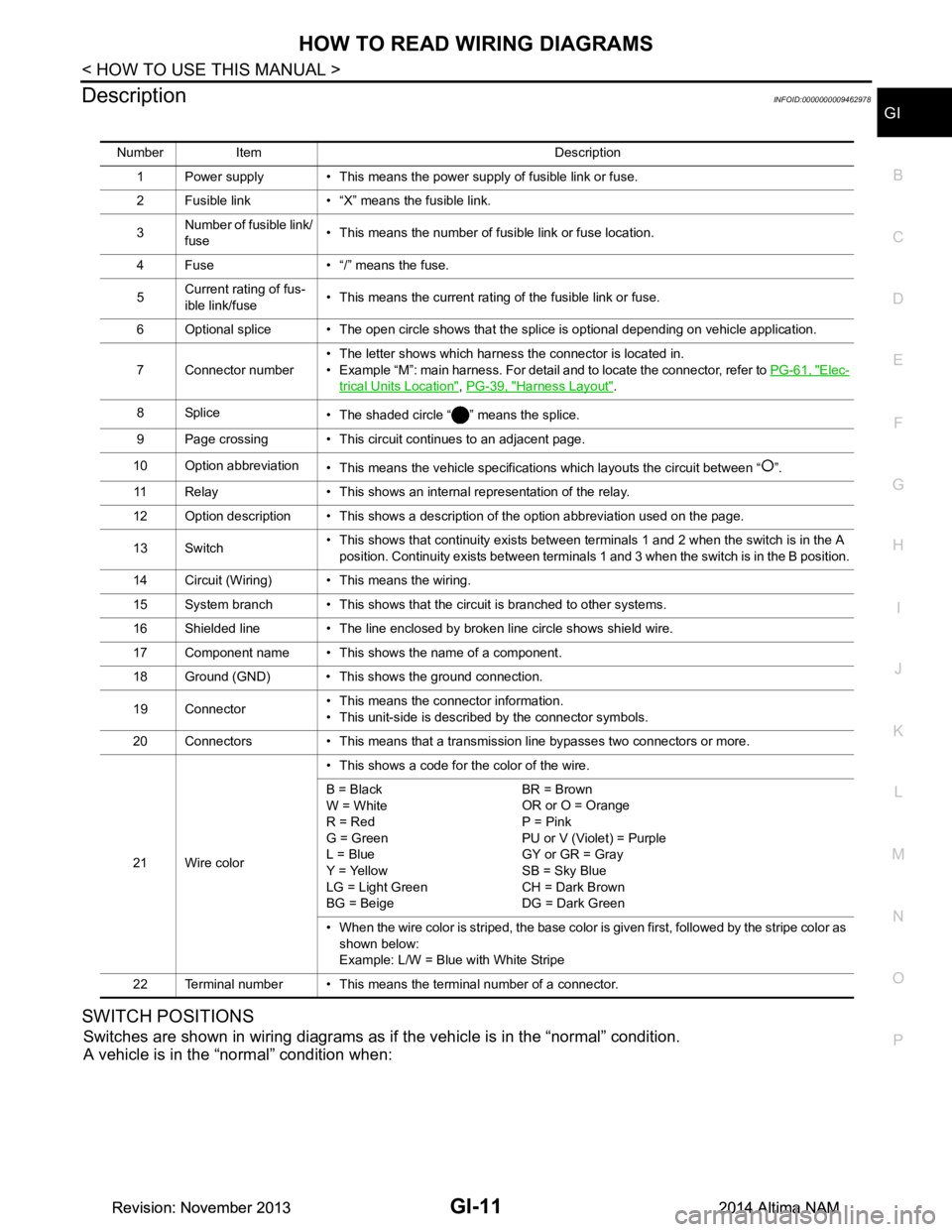

DescriptionINFOID:0000000009462978

SWITCH POSITIONS

Switches are shown in wiring diagrams as if the vehicle is in the “normal” condition.

A vehicle is in the “normal” condition when:

Number Item Description

1 Power supply • This means the power supply of fusible link or fuse.

2 Fusible link • “X” means the fusible link.

3 Number of fusible link/

fuse • This means the number of fusible link or fuse location.

4 Fuse • “/” means the fuse.

5 Current rating of fus-

ible link/fuse • This means the current rating of the fusible link or fuse.

6 Optional splice • The open circle shows that the splice is optional depending on vehicle application.

7 Connector number • The letter shows which harness the connector is located in.

• Example “M”: main harness. For detail and to locate the connector, refer to PG-61, "Elec-

trical Units Location", PG-39, "Harness Layout".

8Splice • The shaded circle “ ” means the splice.

9 Page crossing • This circuit continues to an adjacent page.

10 Option abbreviation • This means the vehicle specifications which layouts the circuit between “ ”.

11 Relay • This shows an internal representation of the relay.

12 Option description • This shows a description of the option abbreviation used on the page.

13 Switch • This shows that continuity exists between terminals 1 and 2 when the switch is in the A

position. Continuity exists between terminals 1 and 3 when the switch is in the B position.

14 Circuit (Wiring) • This means the wiring.

15 System branch • This shows that the circuit is branched to other systems.

16 Shielded line • The line enclosed by broken line circle shows shield wire.

17 Component name • This shows the name of a component.

18 Ground (GND) • This shows the ground connection.

19 Connector • This means the connector information.

• This unit-side is described by the connector symbols.

20 Connectors • This means that a transmission line bypasses two connectors or more.

21 Wire color • This shows a code for the color of the wire.

B = Black

W = White

R = Red

G = Green

L = Blue

Y = Yellow

LG = Light Green

BG = Beige BR = Brown

OR or O = Orange

P = Pink

PU or V (Violet) = Purple

GY or GR = Gray

SB = Sky Blue

CH = Dark Brown

DG = Dark Green

• When the wire color is striped, the base color is given first, followed by the stripe color as shown below:

Example: L/W = Blue with White Stripe

22 Terminal number • This means the terminal number of a connector.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2549 of 4801

RECOMMENDED CHEMICAL PRODUCTS AND SEALANTS

GI-21

< HOW TO USE THIS MANUAL >

C

D E

F

G H

I

J

K L

M B

GI

N

O PRECOMMENDED CHEMICAL PRODUCTS AND SEALANTS

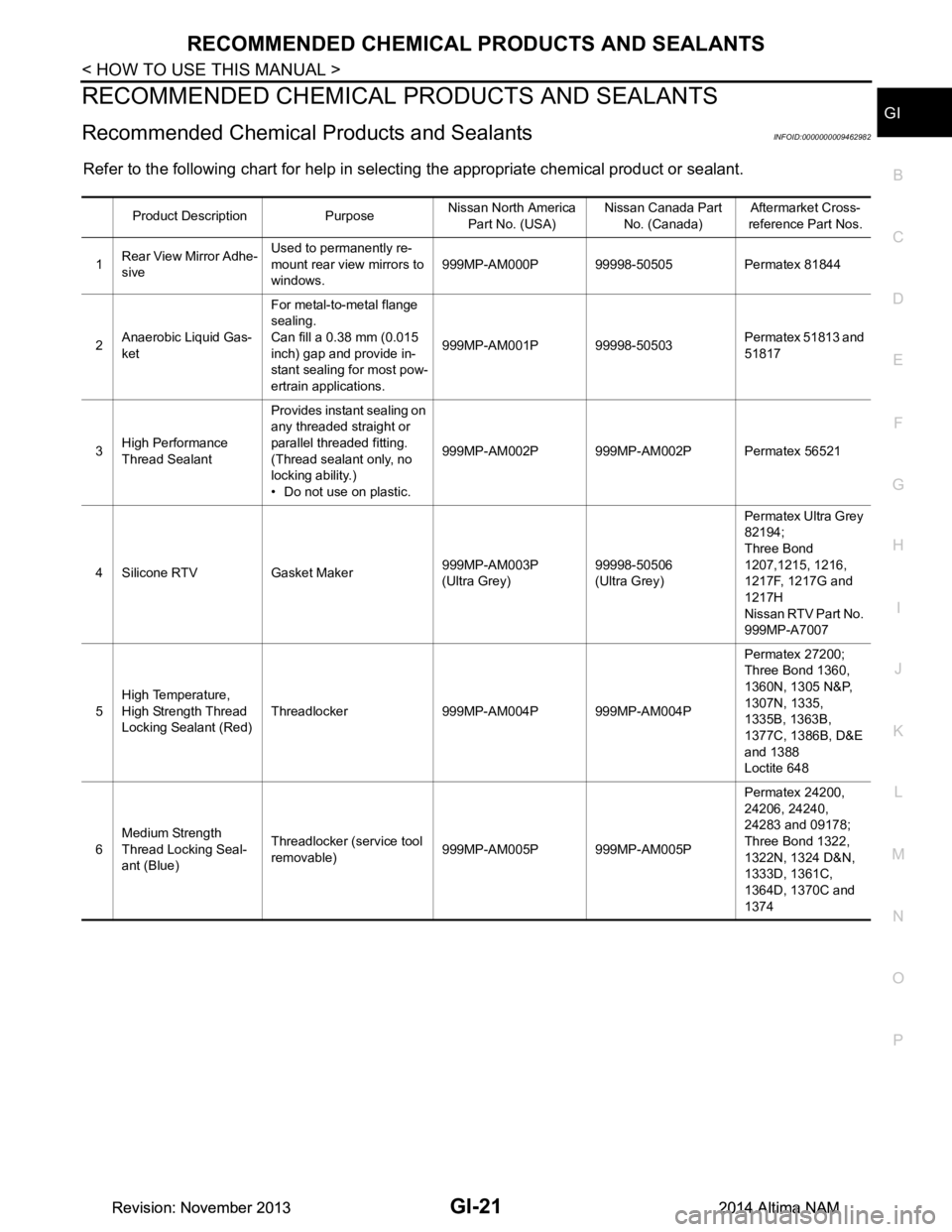

Recommended Chemical Products and SealantsINFOID:0000000009462982

Refer to the following chart for help in selecting the appropriate chemical product or sealant.

Product Description Purpose Nissan North America

Part No. (USA) Nissan Canada Part

No. (Canada) Aftermarket Cross-

reference Part Nos.

1 Rear View Mirror Adhe-

sive Used to permanently re-

mount rear view mirrors to

windows. 999MP-AM000P 99998-50505 Permatex 81844

2 Anaerobic Liquid Gas-

ket For metal-to-metal flange

sealing.

Can fill a 0.38 mm (0.015

inch) gap and provide in-

stant sealing for most pow-

ertrain applications. 999MP-AM001P 99998-50503

Permatex 51813 and

51817

3 High Performance

Thread Sealant Provides instant sealing on

any threaded straight or

parallel threaded fitting.

(Thread sealant only, no

locking ability.)

• Do not use on plastic. 999MP-AM002P 999MP-AM002P Permatex 56521

4 Silicone RTV Gasket Maker 999MP-AM003P

(Ultra Grey) 99998-50506

(Ultra Grey) Permatex Ultra Grey

82194;

Three Bond

1207,1215, 1216,

1217F, 1217G and

1217H

Nissan RTV Part No.

999MP-A7007

5 High Temperature,

High Strength Thread

Locking Sealant (Red) Threadlocker 999MP-AM004P 999MP-AM004P Permatex 27200;

Three Bond 1360,

1360N, 1305 N&P,

1307N, 1335,

1335B, 1363B,

1377C, 1386B, D&E

and 1388

Loctite 648

6 Medium Strength

Thread Locking Seal-

ant (Blue) Threadlocker (service tool

removable) 999MP-AM005P 999MP-AM005P Permatex 24200,

24206, 24240,

24283 and 09178;

Three Bond 1322,

1322N, 1324 D&N,

1333D, 1361C,

1364D, 1370C and

1374

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2616 of 4801

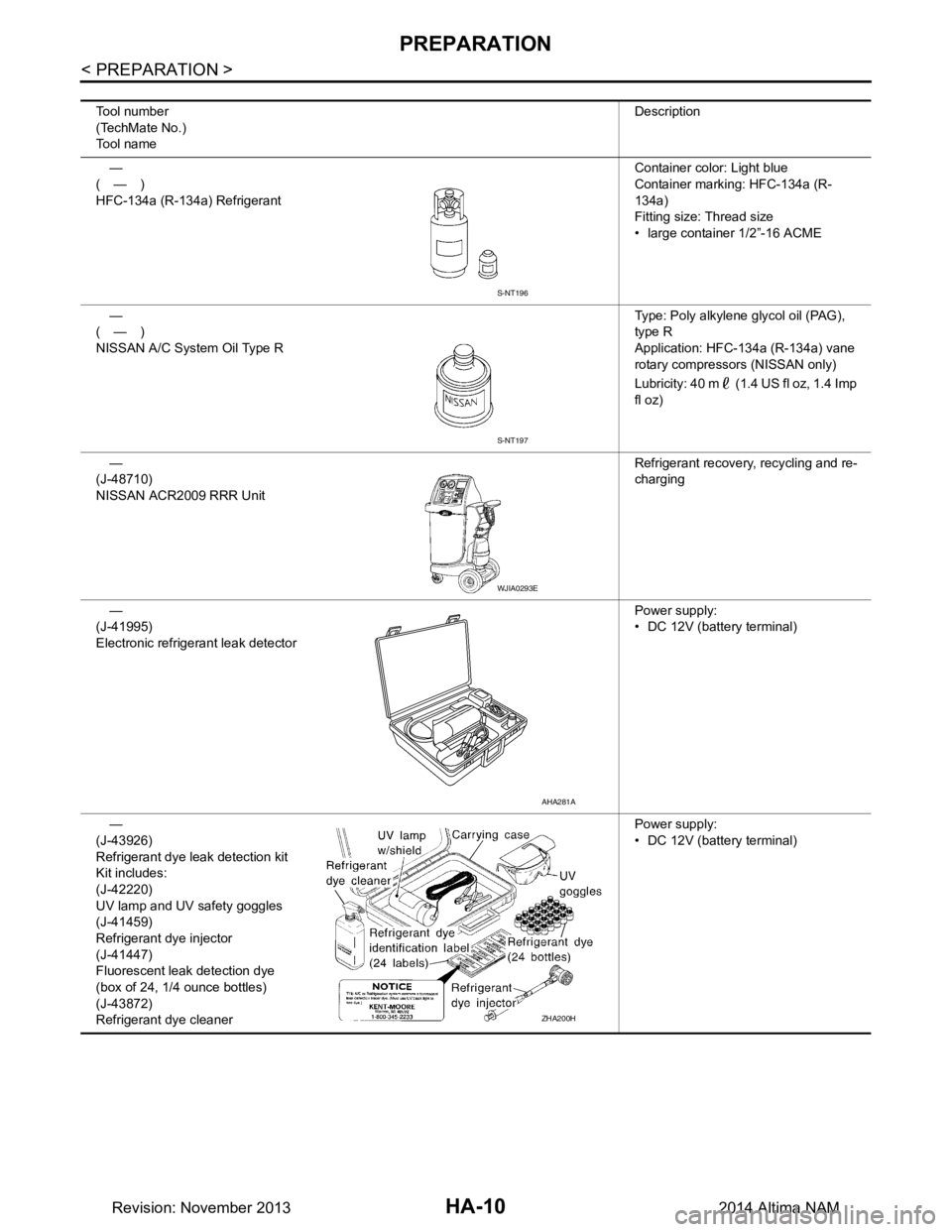

HA-10

< PREPARATION >

PREPARATION

Tool number

(TechMate No.)

Tool name Description

—

(—)

HFC-134a (R-134a) Refrigerant Container color: Light blue

Container marking: HFC-134a (R-

134a)

Fitting size: Thread size

• large container 1/2”-16 ACME

—

(—)

NISSAN A/C System Oil Type R Type: Poly alkylene glycol oil (PAG),

type R

Application: HFC-134a (R-134a) vane

rotary compressors (NISSAN only)

Lubricity: 40 m (1.4 US fl oz, 1.4 Imp

fl oz)

—

(J-48710)

NISSAN ACR2009 RRR Unit Refrigerant recovery, recycling and re-

charging

—

(J-41995)

Electronic refrigerant leak detector Power supply:

• DC 12V (batte ry terminal)

—

(J-43926)

Refrigerant dye leak detection kit

Kit includes:

(J-42220)

UV lamp and UV safety goggles

(J-41459)

Refrigerant dye injector

(J-41447)

Fluorescent leak detection dye

(box of 24, 1/4 ounce bottles)

(J-43872)

Refrigerant dye cleaner Power supply:

• DC 12V (batte ry terminal)

S-NT196

S-NT197

WJIA0293E

AHA281A

ZHA200H

Revision: November 20132014 Altima NAM

Page 2617 of 4801

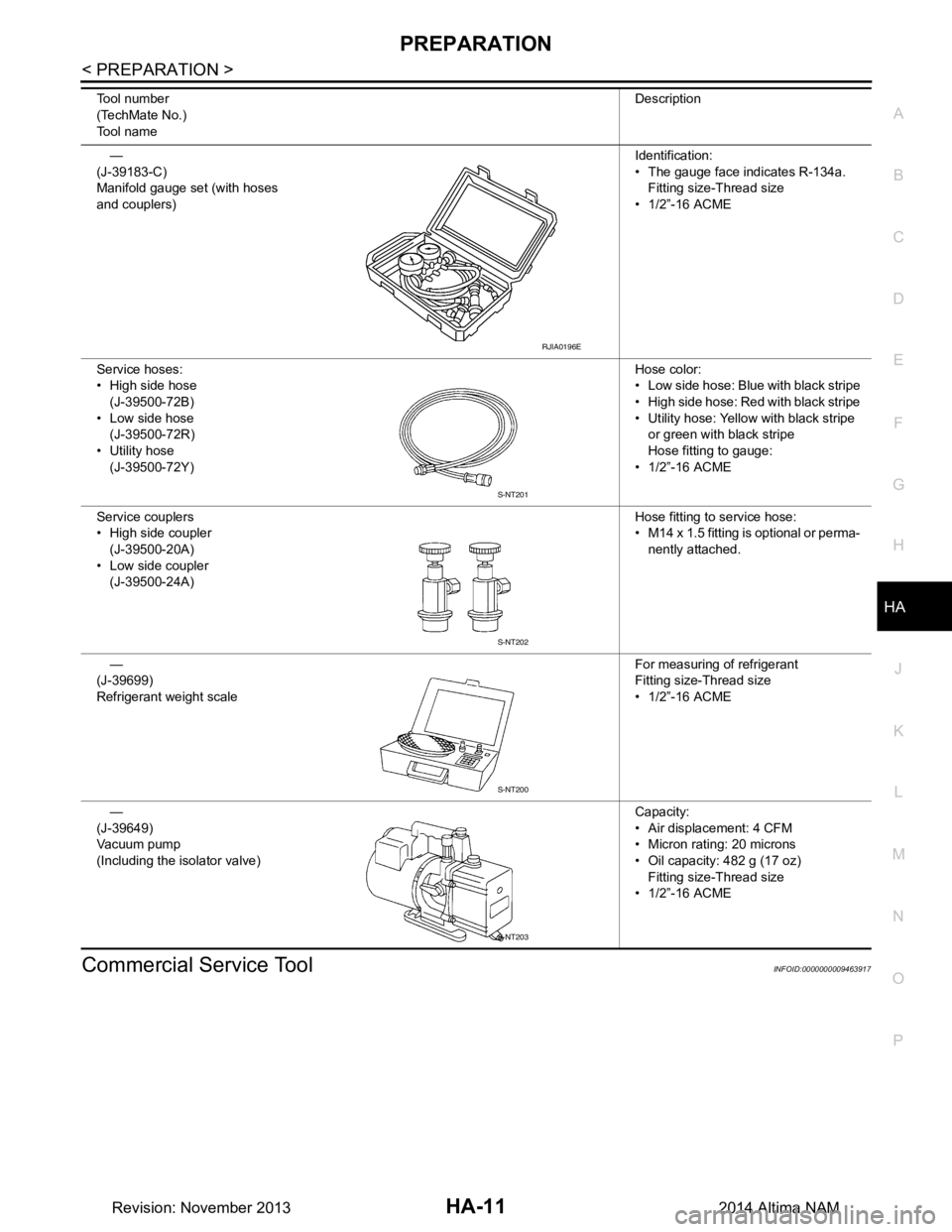

PREPARATIONHA-11

< PREPARATION >

C

D E

F

G H

J

K L

M A

B

HA

N

O P

Commercial Service ToolINFOID:0000000009463917

—

(J-39183-C)

Manifold gauge set (with hoses

and couplers) Identification:

• The gauge face indicates R-134a. Fitting size-Thread size

• 1/2”-16 ACME

Service hoses:

• High side hose (J-39500-72B)

• Low side hose (J-39500-72R)

• Utility hose

(J-39500-72Y) Hose color:

• Low side hose: Blue with black stripe

• High side hose: Red with black stripe

• Utility hose: Yellow with black stripe or green with black stripe

Hose fitting to gauge:

• 1/2”-16 ACME

Service couplers

• High side coupler (J-39500-20A)

• Low side coupler

(J-39500-24A) Hose fitting to service hose:

• M14 x 1.5 fitting is optional or perma- nently attached.

—

(J-39699)

Refrigerant weight scale For measuring of refrigerant

Fitting size-Thread size

• 1/2”-16 ACME

—

(J-39649)

Va c u u m p u m p

(Including the isolator valve) Capacity:

• Air displacement: 4 CFM

• Micron rating: 20 microns

• Oil capacity: 482 g (17 oz)

Fitting size-Thread size

• 1/2”-16 ACME

Tool number

(TechMate No.)

Tool name Description

RJIA0196E

S-NT201

S-NT202

S-NT200

S-NT203

Revision: November 20132014 Altima NAM

Page 3192 of 4801

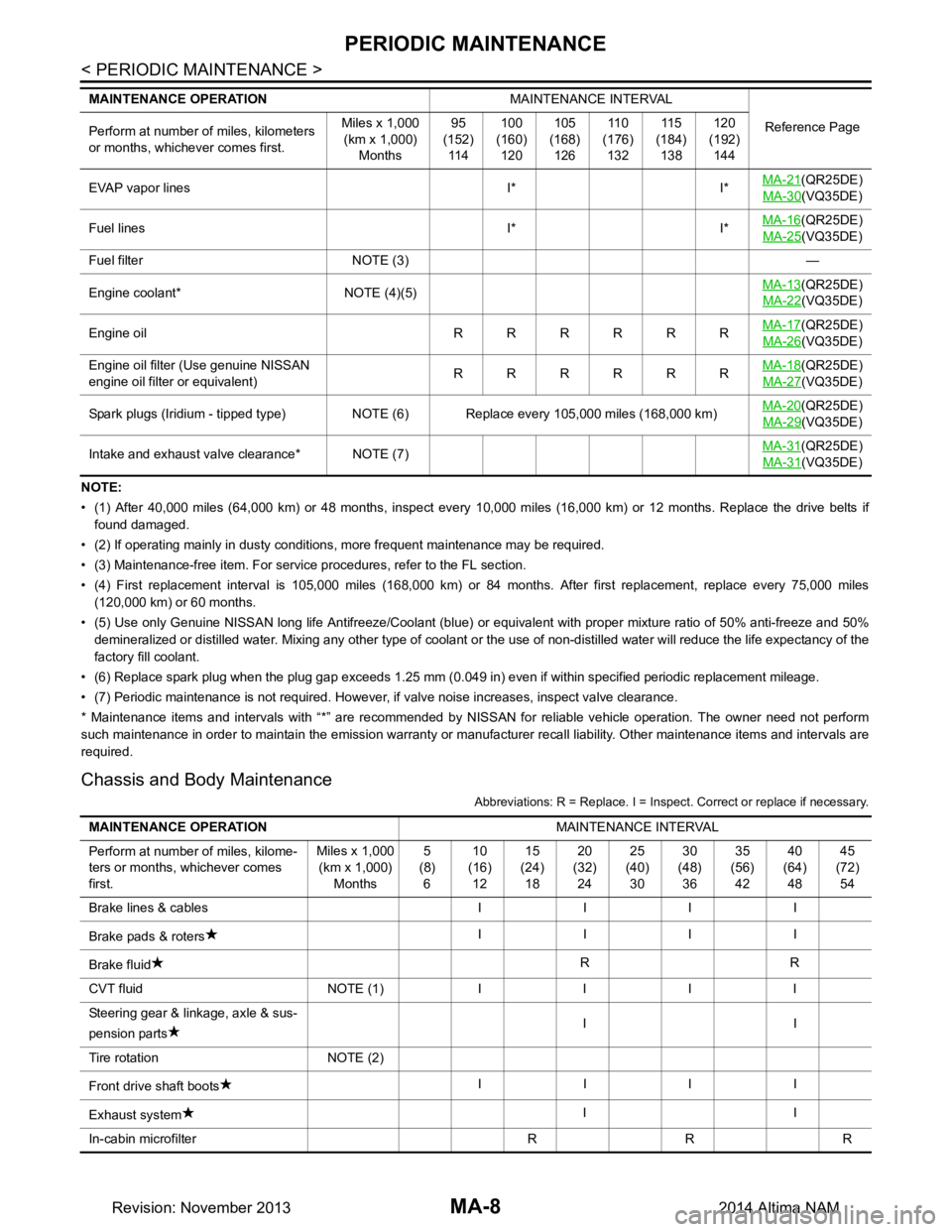

MA-8

< PERIODIC MAINTENANCE >

PERIODIC MAINTENANCE

NOTE:

• (1) After 40,000 miles (64,000 km) or 48 months, inspect every 10,000 miles (16,000 km) or 12 months. Replace the drive belts if

found damaged.

• (2) If operating mainly in dusty conditions, more frequent maintenance may be required.

• (3) Maintenance-free item. For service procedures, refer to the FL section.

• (4) First replacement interval is 105,000 miles (168,000 km) or 84 months. After first replacement, replace every 75,000 miles (120,000 km) or 60 months.

• (5) Use only Genuine NISSAN long life Antifreeze/Coolant (blue) or equivalent with proper mixture ratio of 50% anti-freeze and 50%

demineralized or distilled water. Mixing any other type of coolant or the use of non-distilled water will reduce the life expec tancy of the

factory fill coolant.

• (6) Replace spark plug when the plug gap exceeds 1.25 mm (0.049 in) even if within specified periodic replacement mileage.

• (7) Periodic maintenance is not required. However, if valve noise increases, inspect valve clearance.

* Maintenance items and intervals with “*” are recommended by NISSAN for reliable vehicle operation. The owner need not perform

such maintenance in order to maintain the emission warranty or manufacturer recall liability. Other maintenance items and inter vals are

required.

Chassis and Body Maintenance

Abbreviations: R = Replace. I = Inspec t. Correct or replace if necessary.

EVAP vapor lines I* I* MA-21(QR25DE)

MA-30

(VQ35DE)

Fuel lines I* I* MA-16

(QR25DE)

MA-25

(VQ35DE)

Fuel filter NOTE (3) —

Engine coolant* NOTE (4)(5) MA-13

(QR25DE)

MA-22

(VQ35DE)

Engine oil RRRRRR MA-17

(QR25DE)

MA-26

(VQ35DE)

Engine oil filter (Use genuine NISSAN

engine oil filter or equivalent) RRRRRRMA-18

(QR25DE)

MA-27

(VQ35DE)

Spark plugs (Iridium - tipped type) NOTE (6) Replace every 105,000 miles (168,000 km) MA-20

(QR25DE)

MA-29

(VQ35DE)

Intake and exhaust valve clearance* NOTE (7) MA-31

(QR25DE)

MA-31

(VQ35DE)

MAINTENANCE OPERATION

MAINTENANCE INTERVAL

Reference Page

Perform at number of miles, kilometers

or months, whichever comes first. Miles x 1,000

(km x 1,000)

Months 95

(152)

11 4 100

(160)

120 105

(168)

126 11 0

(176)

132 11 5

(184)

138 120

(192)

144

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Perform at number of miles, kilome-

ters or months, whichever comes

first. Miles x 1,000

(km x 1,000) Months 5

(8) 6 10

(16) 12 15

(24) 18 20

(32) 24 25

(40) 30 30

(48) 36 35

(56) 42 40

(64) 48 45

(72) 54

Brake lines & cables I I I I

Brake pads & roters IIII

Brake fluid RR

CVT fluid NOTE (1)IIII

Steering gear & linkage, axle & sus-

pension parts II

Tire rotation NOTE (2)

Front drive shaft boots IIII

Exhaust system II

In-cabin microfilter R R R

Revision: November 20132014 Altima NAM