air filter NISSAN TEANA 2014 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 1793 of 4801

![NISSAN TEANA 2014 User Guide

P0172, P0175 FUEL INJECTION SYSTEM FUNCTION

EC-793

< DTC/CIRCUIT DIAGNOSIS > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

6. Also check harness for short to power.

Is the inspection result normal?

YES NISSAN TEANA 2014 User Guide

P0172, P0175 FUEL INJECTION SYSTEM FUNCTION

EC-793

< DTC/CIRCUIT DIAGNOSIS > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

6. Also check harness for short to power.

Is the inspection result normal?

YES](/img/5/57390/w960_57390-1792.png)

P0172, P0175 FUEL INJECTION SYSTEM FUNCTION

EC-793

< DTC/CIRCUIT DIAGNOSIS > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

6. Also check harness for short to power.

Is the inspection result normal?

YES >> GO TO 4.

NO >> Repair open circuit, short to ground or short to power in harness or connectors.

4.CHECK FUEL PRESSURE

1. Release fuel pressure to zero. Refer to EC-687, "Work Procedure"

.

2. Install fuel pressure gauge kit [SST: — (J-44321)] and check fuel pressure. Refer to EC-687, "Work Proce-

dure".

Is the inspection result normal?

YES >> GO TO 5.

NO >> Replace “fuel filter and fuel pump assembly”. Refer to FL-6, "Removal and Installation"

.

5.CHECK MASS AIR FLOW SENSOR

With CONSULT

1. Install all removed parts.

2. Check “MASS AIR FLOW” in “DATA MONITOR” mode with CONSULT. For specification, refer to EC-998, "Mass Air Flow Sensor"

.

With GST

1. Install all removed parts.

2. Check mass air flow sensor signal in “Service $01” with GST. For specification, refer to EC-998, "Mass Air Flow Sensor"

.

Is the measurement value within the specification?

YES >> GO TO 6.

NO >> Check connectors for rusted terminals or loose c onnections in the mass air flow sensor circuit or

ground. Refer to EC-732, "Diagnosis Procedure"

.

6.CHECK FUNCTION OF FUEL INJECTOR

With CONSULT

1. Start engine.

2. Perform “POWER BALANCE” in “ACTIVE TEST” mode with CONSULT.

3. Check that each circuit produces a momentary engine speed drop.

With GST

1. Let engine idle.

DTC A/F sensor 1

Ground Continuity

Bank Connector Terminal

P0172 1 F12 1

Ground Not existed

2

P0175 2 F61 1

2

DTC ECM

Ground Continuity

Connector Terminal

P0172 F79 69

Ground Not existed

73

P0175 77

81

At idling: Approximately 350 kPa (3.57 kg/cm2, 51 psi)

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1812 of 4801

![NISSAN TEANA 2014 User Guide

EC-812

< DTC/CIRCUIT DIAGNOSIS >[VQ35DE]

P0300, P0301, P030

2, P0303, P0304, P03 05, P0306 MISFIRE

3. Crank engine for approximately 3 seconds, and rec heck whether spark is generated between the spa NISSAN TEANA 2014 User Guide

EC-812

< DTC/CIRCUIT DIAGNOSIS >[VQ35DE]

P0300, P0301, P030

2, P0303, P0304, P03 05, P0306 MISFIRE

3. Crank engine for approximately 3 seconds, and rec heck whether spark is generated between the spa](/img/5/57390/w960_57390-1811.png)

EC-812

< DTC/CIRCUIT DIAGNOSIS >[VQ35DE]

P0300, P0301, P030

2, P0303, P0304, P03 05, P0306 MISFIRE

3. Crank engine for approximately 3 seconds, and rec heck whether spark is generated between the spark

plug and the grounded metal portion.

Is the inspection result normal?

YES >> GO TO 7.

NO >> Check ignition coil, power transistor and their circuits. Refer to EC-967, "Diagnosis Procedure"

.

7.CHECK SPARK PLUG

Check the initial spark plug for fouling, etc.

Is the inspection result normal?

YES >> Replace spark plug(s) with standard type one(s). For spark plug type, refer to EM-247, "Spark Plug"

.

NO >> Repair or clean spark plug. Then GO TO 8.

8.CHECK FUNCTION OF IGNITION COIL-III

1. Reconnect the initial spark plugs.

2. Crank engine for approximately 3 seconds, and rec heck whether spark is generated between the spark

plug and the grounded portion.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace spark plug(s) with standard type one(s). For spark plug type, refer to EM-247, "Spark

Plug".

9.CHECK COMPRESSION PRESSURE

Check compression pressure. Refer to EM-142, "On-Vehicle Service"

.

Is the inspection result normal?

YES >> GO TO 10.

NO >> Check pistons, piston rings, valves, valve seats and cylinder head gaskets.

10.CHECK FUEL PRESSURE

1. Install all removed parts.

2. Release fuel pressure to zero. Refer to EC-687, "Work Procedure"

.

3. Install fuel pressure gauge kit [SST: — (J-44321)] and check fuel pressure. Refer to EC-687, "Work Proce-

dure".

Is the inspection result normal?

YES >> GO TO 12.

NO >> GO TO 11.

11 .DETECT MALFUNCTIONING PART

Check fuel hoses and fuel tubes for clogging.

Is the inspection result normal?

YES >> Replace “fuel filter and fuel pump assembly”. Refer to FL-6, "Removal and Installation".

NO >> Repair or replace malfunctioning part.

12.CHECK IGNITION TIMING

Check idle speed and ignition timing. Spark should be generated.

SEF156I

Spark should be generated.

At idle: Approximately 350 kPa (3.57 kg/cm

2, 51 psi)

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1966 of 4801

![NISSAN TEANA 2014 User Guide

EC-966

< DTC/CIRCUIT DIAGNOSIS >[VQ35DE]

FUEL PUMP

NO >> Repair or replace error-detected parts.

4.CHECK FUEL PUMP POWER SUPPLY CIRCUIT

1. Disconnect “fuel level sensor uni t and fuel pump” harne NISSAN TEANA 2014 User Guide

EC-966

< DTC/CIRCUIT DIAGNOSIS >[VQ35DE]

FUEL PUMP

NO >> Repair or replace error-detected parts.

4.CHECK FUEL PUMP POWER SUPPLY CIRCUIT

1. Disconnect “fuel level sensor uni t and fuel pump” harne](/img/5/57390/w960_57390-1965.png)

EC-966

< DTC/CIRCUIT DIAGNOSIS >[VQ35DE]

FUEL PUMP

NO >> Repair or replace error-detected parts.

4.CHECK FUEL PUMP POWER SUPPLY CIRCUIT

1. Disconnect “fuel level sensor uni t and fuel pump” harness connector.

2. Check harness continuity between IPDM E/R har ness connector and “fuel level sensor unit and fuel

pump” harness connector.

Is the inspection result normal?

YES >> GO TO 5.

NO >> Repair open circuit or short to power in harness or connectors.

5.CHECK FUEL PUMP GROUND CIRCUIT

1. Disconnect “fuel level sensor uni t and fuel pump” harness connector.

2. Check the continuity between “fuel level s ensor unit and fuel pump” harness connector and ground.

Is the inspection result normal?

YES >> GO TO 6.

NO >> Repair open circuit or short to power in harness or connectors.

6.CHECK FUEL PUMP

Check fuel pump. Refer to EC-966, "Component Inspection"

.

Is the inspection result normal?

YES >> GO TO 7.

NO >> Replace fuel pump. Refer to FL-6, "Exploded View"

.

7.CHECK INTERMITTENT INCIDENT

Check intermittent incident. Refer to GI-43, "Intermittent Incident"

.

Is the inspection result normal?

YES >> Replace IPDM E/R. Refer to PCS-32, "Removal and Installation".

NO >> Repair or replace error-detected parts.

Component InspectionINFOID:0000000009462847

1.CHECK FUEL PUMP

1. Turn ignition switch OFF.

2. Disconnect “fuel level sensor unit (fuel pump)” harness connector.

3. Check resistance between “fuel level sensor unit (fuel pump)” terminals as follows.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace fuel level sensor unit, fuel filter and fuel pump assembly. Refer to FL-6, "Removal and

Installation".

IPDM E/RFuel level sensor unit and fuel

pump Continuity

Connector Terminal Connector Terminal

E1815B42 6 Existed

Fuel level sensor unit and fuel pump Ground Continuity

Connector Terminal

B42 4 Ground Existed

Terminals Resistance [at 25 °C (77 °F)]

4 and 6 0.2 - 5.0 Ω

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1999 of 4801

EM-1

ENGINE

C

D E

F

G H

I

J

K L

M

SECTION EM

A

EM

N

O P

CONTENTS

ENGINE MECHANICAL

QR25DE

PRECAUTION ................ ...............................

4

PRECAUTIONS .............................................. .....4

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

4

Precaution for Draining Coolant ................................4

Precaution for Disconnecting Fuel Piping .................4

Precaution for Removal and Disassembly ................4

Precaution for Inspection, Repair and Replace-

ment .................................................................... ......

4

Special Cautions to Ensure the Safe Disposal of

Sodium-filled Exhaust Valves .............................. ......

5

Precaution for Assembly and Installation ..................6

Parts Requiring Angular Tightening ..........................6

Precaution for Liquid Gasket ............................... ......6

PREPARATION ............................................8

PREPARATION .............................................. .....8

Special Service Tool ........................................... ......8

Commercial Service Tool ........................................10

SYMPTOM DIAGNOSIS ..............................13

NOISE, VIBRATION, AND HARSHNESS

(NVH) TROUBLESHOOTING ........................ ....

13

NVH Troubleshooting - Engine Noise ................. ....13

Use the Chart Below to Help You Find the Cause

of the Symptom ................................................... ....

14

PERIODIC MAINTENANCE .........................16

SPARK PLUG .. .............................................. ....16

Exploded View .................................................... ....16

Removal and Installation .........................................16

DRIVE BELTS ................................................ ....19

Exploded View .................................................... ....19

Checking Drive Belts ...............................................19

Tension Adjustment ............................................. ....19

Removal and Installation .........................................19

Removal and Installation of Drive Belt Auto-ten-

sioner ................................................................... ....

20

AIR CLEANER FILTER .....................................22

Exploded View .........................................................22

Removal and Installation .........................................22

CAMSHAFT VALVE CLEARANCE ..................23

Camshaft valve clearance .......................................23

COMPRESSION PRESSURE ...........................26

Compression pressure ............................................26

REMOVAL AND INSTALLATION ...............28

ENGINE ROOM COVER ...................................28

Exploded View ..................................................... ....28

Removal and Installation .........................................28

AIR CLEANER AND AIR DUCT .......................29

Exploded View .........................................................29

Removal and Installation .........................................29

INTAKE MANIFOLD .........................................30

Exploded View .........................................................30

Removal and Installation .........................................30

EXHAUST MANIFOLD AND THREE WAY

CATALYST ........................................................

33

Exploded View ..................................................... ....33

Removal and Installation .........................................33

OIL PAN AND OIL STRAINER .........................36

Exploded View .........................................................36

Removal and Installation .........................................36

IGNITION COIL .................................................40

Exploded View .........................................................40

Removal and Installation .........................................40

FUEL INJECTOR AND FUEL TUBE ................41

Revision: November 20132014 Altima NAM

Page 2000 of 4801

EM-2

Exploded View ........................................................41

Removal and Installation ........................................41

ROCKER COVER ..............................................45

Exploded View ..................................................... ...45

Removal and Installation ........................................45

CAMSHAFT .......................................................47

Exploded View ..................................................... ...47

Removal and Installation ........................................47

Inspection After Installation ................................. ...56

VALVE TIMING CONTROL ............................ ...58

Exploded View ..................................................... ...58

Intake Valve Timing Intermediate Lock Control

Solenoid Valve, Intake Va lve Timing Control Sole-

noid Valve, and Exhaust Valve Timing Control So-

lenoid Valve ......................................................... ...

58

Valve Timing Control Cover ....................................59

TIMING CHAIN ............................................... ...61

Exploded View ..................................................... ...61

Removal and Installation ........................................62

OIL SEAL ...........................................................70

Removal and Installation of Valve Oil Seal .......... ...70

Removal and Installation of Front Oil Seal .............71

Removal and Installation of Rear Oil Seal ..............72

CYLINDER HEAD ..............................................74

Exploded View ..................................................... ...74

Removal and Installation ........................................74

Disassembly and Assembly ....................................76

Inspection After Disassembly .................................78

UNIT REMOVAL AND INSTALLATION .. ...83

ENGINE ASSEMBLY ...................................... ...83

Exploded View ..................................................... ...83

Removal and Installation ........................................84

UNIT DISASSEMBLY AND ASSEMBLY ....87

CYLINDER BLOCK ........................................ ...87

Exploded View ..................................................... ...87

Disassembly and Assembly ....................................88

Inspection After Disassembly .................................96

HOW TO SELECT PISTON AND BEARING .. .105

How to Select Piston and Bearing ....................... ..105

SERVICE DATA AND SPECIFICATIONS

(SDS) .............. ............................................

111

SERVICE DATA AND SPECIFICATIONS

(SDS) ............................................................... .

111

Standard and Limit .............................................. ..111

VQ35DE

PRECAUTION .............. ..............................

123

PRECAUTIONS .............................................. .123

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .............................................................. .

123

Precaution for Draining Coolant ............................123

Precaution for Disconnecting Fuel Piping .............123

Precaution for Removal and Disassembly ............123

Precaution for Inspection, Repair and Replace-

ment ..................................................................... .

123

Precaution for Assembly and Installation ..............123

Parts Requiring Angular Tightening ..................... .124

Precaution for Liquid Gasket .................................124

PREPARATION .........................................126

PREPARATION .............................................. ..126

Special Service Tool ............................................ .126

Commercial Service Tool ......................................127

SYSTEM DESCRIPTION ..........................130

NOISE, VIBRATION, AND HARSHNESS

(NVH) TROUBLESHOOTING ......................... ..

130

NVH Troubleshooting - Engine Noise .................. .130

Use the Chart Below to Help You Find the Cause

of the Symptom .................................................... .

131

PERIODIC MAINTENANCE ......................132

SPARK PLUG ... .............................................. ..132

Exploded View ..................................................... .132

Removal and Installation .......................................132

DRIVE BELTS ................................................ ..134

Exploded View ..................................................... .134

Checking Drive Belts .............................................134

Tension Adjustment ..............................................134

Removal and Installation .......................................134

Removal and Installation of Drive Belt Auto-ten-

sioner ................................................................... .

135

AIR CLEANER FILTER ....................................137

Exploded View ..................................................... .137

Removal and Installation .......................................137

CAMSHAFT VALVE CLEARANCE ............... ..138

Valve Clearance ................................................... .138

COMPRESSION PRESSURE ..........................142

On-Vehicle Service .............................................. .142

REMOVAL AND INSTALLATION .............143

ENGINE ROOM COVER ................................ ..143

Exploded View ..................................................... .143

Removal and Installation .......................................143

AIR CLEANER AND AIR DUCT ..................... ..144

Exploded View ..................................................... .144

Removal and Installation .......................................144

INTAKE MANIFOLD COLLECTOR ............... ..146

Exploded View ..................................................... .146

Revision: November 20132014 Altima NAM

Page 2020 of 4801

![NISSAN TEANA 2014 User Guide

EM-22

< PERIODIC MAINTENANCE >[QR25DE]

AIR CLEANER FILTER

AIR CLEANER FILTER

Exploded ViewINFOID:0000000009460472

Removal and InstallationINFOID:0000000009460473

CHANGING THE AIR CLEANER FILTER

1. Re NISSAN TEANA 2014 User Guide

EM-22

< PERIODIC MAINTENANCE >[QR25DE]

AIR CLEANER FILTER

AIR CLEANER FILTER

Exploded ViewINFOID:0000000009460472

Removal and InstallationINFOID:0000000009460473

CHANGING THE AIR CLEANER FILTER

1. Re](/img/5/57390/w960_57390-2019.png)

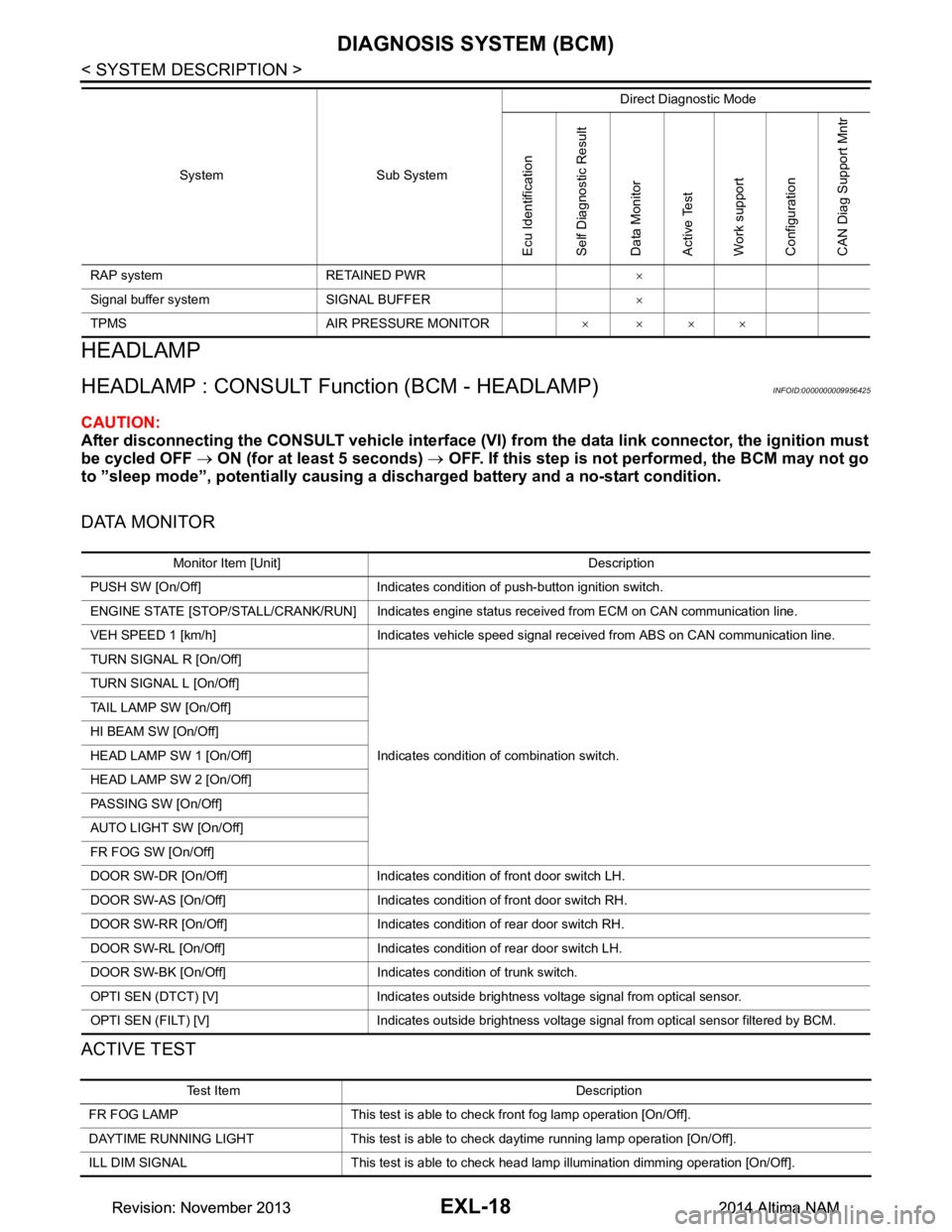

EM-22

< PERIODIC MAINTENANCE >[QR25DE]

AIR CLEANER FILTER

AIR CLEANER FILTER

Exploded ViewINFOID:0000000009460472

Removal and InstallationINFOID:0000000009460473

CHANGING THE AIR CLEANER FILTER

1. Release the air cleaner case clips.

2. Open the air cleaner case (top).

3. Remove the air cleaner filter.

4. Install a new air cleaner filter.

5. Close the air cleaner case (top).

6. Secure the air cleaner case clips.

INSPECTION AFTER REMOVAL

Examine the air cleaner filter for stains, clogging, or damage.

• Remove dirt and foreign objects (such as dead leaves) on air cleaner filter surface and inside cleaner case.

• If clogging or damage is observed, replace the air cleaner filter.

CAUTION:

Do not clean the viscous paper type air cleaner filter by blowing as there is a risk of deterioration of its

performance.

MAINTENANCE INTERVAL

Refer to MA-7, "FOR USA AND CANADA : In troduction of Periodic Maintenance".

1. Air duct hose and resonator 2. Front air duct 3. Air cleaner case (bottom)

4. Grommets 5. Air cleaner mounting bracket 6. Air cleaner mounting bracket

7. Air cleaner filter 8. Air cleaner case (top) 9. Air cleaner case clips

AWBIA1294GB

Revision: November 20132014 Altima NAM

Page 2135 of 4801

![NISSAN TEANA 2014 User Guide

AIR CLEANER FILTEREM-137

< PERIODIC MAINTENANCE > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

AIR CLEANER FILTER

Exploded ViewINFOID:0000000009460533

Removal and InstallationINFOID:0000000009460534

REM NISSAN TEANA 2014 User Guide

AIR CLEANER FILTEREM-137

< PERIODIC MAINTENANCE > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

AIR CLEANER FILTER

Exploded ViewINFOID:0000000009460533

Removal and InstallationINFOID:0000000009460534

REM](/img/5/57390/w960_57390-2134.png)

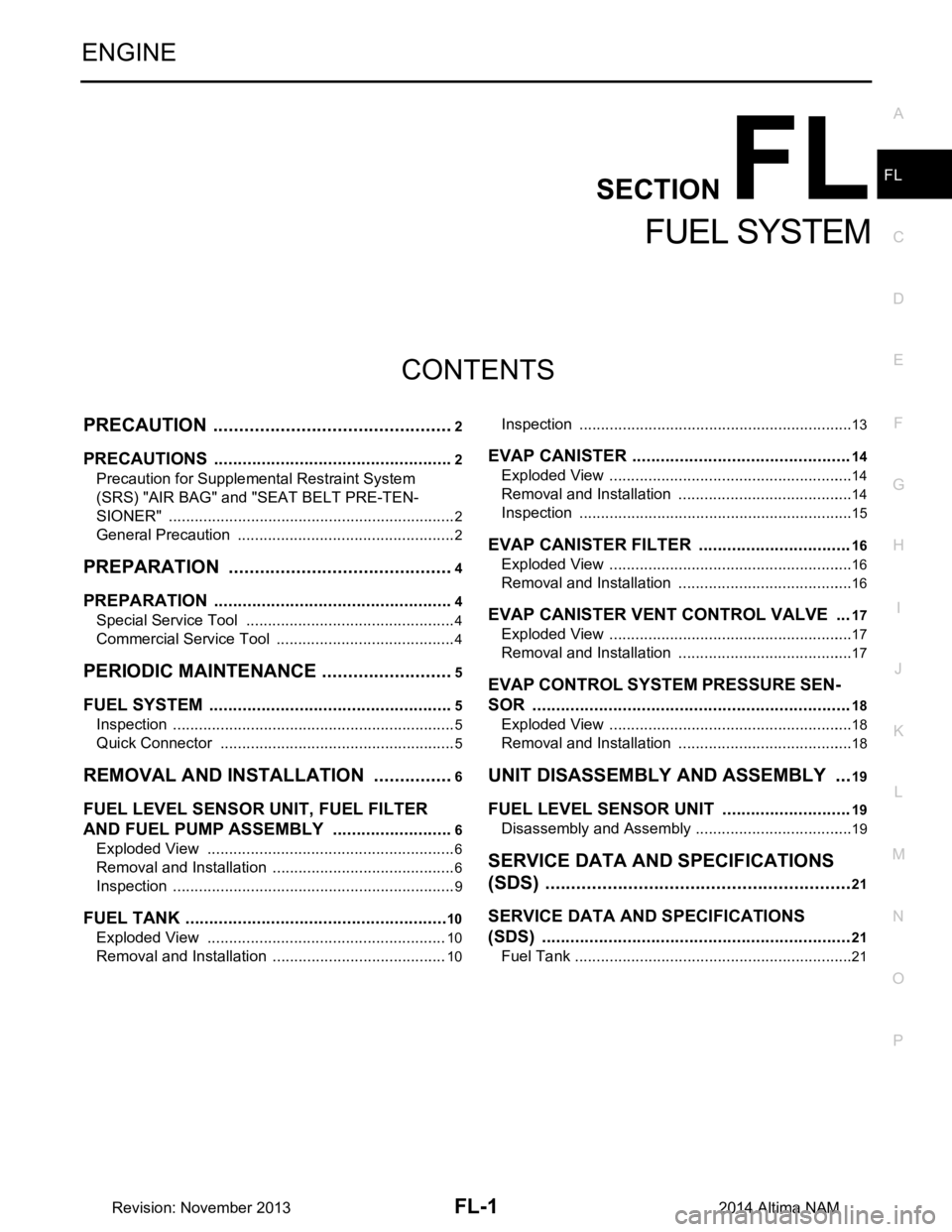

AIR CLEANER FILTEREM-137

< PERIODIC MAINTENANCE > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EM

NP

O

AIR CLEANER FILTER

Exploded ViewINFOID:0000000009460533

Removal and InstallationINFOID:0000000009460534

REMOVAL

CAUTION:

It is not necessary to remove the front ai r duct to replace the air cleaner filter.

NOTE:

Replace the air cleaner filter per the periodic maintenance schedule or as necessary. Refer to MA-7, "FOR

USA AND CANADA : Introduction of Periodic Maintenance".

1. Unhook air cleaner case side clips and lift air cleaner case (upper).

2. Remove the air cleaner filter.

INSTALLATION

Installation is in the reverse order of removal.

1. Air duct hose and resonator assembly 2. Duct sub-cover 3. Front air duct

4. Air cleaner case (lower) 5. Grommets 6. Air cleaner case mounting bracket

7. Bracket 8. Air cleaner filter 9. Air cleaner case (upper)

10. Mass air flow sensor A. To electric throttle control actuator B. Air cleaner case side clips

AWBIA0569ZZ

Revision: November 20132014 Altima NAM

Page 2284 of 4801

EXL-18

< SYSTEM DESCRIPTION >

DIAGNOSIS SYSTEM (BCM)

HEADLAMP

HEADLAMP : CONSULT Function (BCM - HEADLAMP)INFOID:0000000009956425

CAUTION:

After disconnecting the CONSULT vehicle interface (VI) from the data link connector, the ignition must

be cycled OFF → ON (for at least 5 seconds) → OFF. If this step is not performed, the BCM may not go

to ”sleep mode”, potentially causing a di scharged battery and a no-start condition.

DATA MONITOR

ACTIVE TEST

RAP system RETAINED PWR ×

Signal buffer system SIGNAL BUFFER ×

TPMS AIR PRESSURE MONITOR ××××

System Sub System

Direct Diagnostic Mode

Ecu Identification

Self Diagnostic Result

Data Monitor

Active Test

Work support

Configuration

CAN Diag Support Mntr

Monitor Item [Unit] Description

PUSH SW [On/Off] Indicates condition of push-button ignition switch.

ENGINE STATE [STOP/STALL/CRANK/RUN] Indicates engine st atus received from ECM on CAN communication line.

VEH SPEED 1 [km/h] Indicates vehicle speed signal received from ABS on CAN communication line.

TURN SIGNAL R [On/Off]

Indicates condition of combination switch.

TURN SIGNAL L [On/Off]

TAIL LAMP SW [On/Off]

HI BEAM SW [On/Off]

HEAD LAMP SW 1 [On/Off]

HEAD LAMP SW 2 [On/Off]

PASSING SW [On/Off]

AUTO LIGHT SW [On/Off]

FR FOG SW [On/Off]

DOOR SW-DR [On/Off] Indicates condition of front door switch LH.

DOOR SW-AS [On/Off] Indicates condition of front door switch RH.

DOOR SW-RR [On/Off] Indicates condition of rear door switch RH.

DOOR SW-RL [On/Off] Indicates condition of rear door switch LH.

DOOR SW-BK [On/Off] Indicates condition of trunk switch.

OPTI SEN (DTCT) [V] Indicates outside brightness voltage signal from optical sensor.

OPTI SEN (FILT) [V] Indicates outside brightness voltage signal from optical sensor filtered by BCM.

Test Item Description

FR FOG LAMP This test is able to check front fog lamp operation [On/Off].

DAYTIME RUNNING LIGHT This test is able to check daytime running la mp operation [On/Off].

ILL DIM SIGNAL This test is able to check head lamp illumination dimming operation [On/Off].

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 2481 of 4801

FL-1

ENGINE

C

D E

F

G H

I

J

K L

M

SECTION FL

A

FL

N

O P

CONTENTS

FUEL SYSTEM

PRECAUTION ................ ...............................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

General Precaution ...................................................2

PREPARATION ............................................4

PREPARATION .............................................. .....4

Special Service Tool ........................................... ......4

Commercial Service Tool ..........................................4

PERIODIC MAINTENANCE ..........................5

FUEL SYSTEM ............................................... .....5

Inspection ............................................................ ......5

Quick Connector .......................................................5

REMOVAL AND INSTALLATION ................6

FUEL LEVEL SENSOR UNIT, FUEL FILTER

AND FUEL PUMP ASSEMBLY ..................... .....

6

Exploded View .................................................... ......6

Removal and Installation ...........................................6

Inspection ............................................................ ......9

FUEL TANK ........................................................10

Exploded View .................................................... ....10

Removal and Installation .........................................10

Inspection ............................................................ ....13

EVAP CANISTER ..............................................14

Exploded View .........................................................14

Removal and Installation .........................................14

Inspection ................................................................15

EVAP CANISTER FILTER ................................16

Exploded View .........................................................16

Removal and Installation .........................................16

EVAP CANISTER VENT CONTROL VALVE ...17

Exploded View .........................................................17

Removal and Installation .........................................17

EVAP CONTROL SYSTEM PRESSURE SEN-

SOR ...................................................................

18

Exploded View ..................................................... ....18

Removal and Installation .........................................18

UNIT DISASSEMBLY AND ASSEMBLY ....19

FUEL LEVEL SENSOR UNIT ...........................19

Disassembly and Assembly ................................. ....19

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .............................................

21

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

21

Fuel Tank ............................................................. ....21

Revision: November 20132014 Altima NAM

Page 2559 of 4801

PRECAUTIONSGI-31

< PRECAUTION >

C

D E

F

G H

I

J

K L

M B

GI

N

O P

• Heavily soiled clothing and oil-impregnated footwear should not be worn. Overalls must be cleaned regu- larly.

• First aid treatment should be obtained immediately for open cuts and wounds.

• Use barrier creams, applying them before each work period, to help the removal of oil from the skin.

• Wash with soap and water to ensure all oil is removed (skin cleansers and nail brushes will help). Prepara- tions containing lanolin replace the natural skin oils which have been removed.

• Do not use gasoline, kerosene, diesel fuel, gas oil, thinners or solvents for cleaning skin.

• If skin disorders develop, obtain medical advice without delay.

• Where practical, degrease components prior to handling.

• Where there is a risk of eye contact, eye protecti on should be worn, for example, chemical goggles or face

shields; in addition an eye wash facility should be provided.

ENVIRONMENTAL PROTECTION PRECAUTIONS

Dispose of used oil and used oil filters through authorized waste disposal contractors to licensed waste dis-

posal sites, or to the waste oil reclamation trade. If in doubt, contact the local authority for advice on disposal

facilities.

It is illegal to pour used oil on to the ground, down sewers or drains, or into water sources.

The regulations concerning po llution vary between regions.

Air ConditioningINFOID:0000000009463002

Use an approved refrigerant recovery unit any time t he air conditioning system must be discharged. Refer to

HA-21, "Description"

.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM