pri pressure NISSAN TEANA 2014 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 542 of 4801

![NISSAN TEANA 2014 User Guide

DAS

REAR VIEW CAMERA CALIBRATIONDAS-109

< BASIC INSPECTION > [LDW]

C

D E

F

G H

I

J

K L

M B

N P

A

CAUTION:

Make sure that the black/white pattern of the center target is rotated as compared with t NISSAN TEANA 2014 User Guide

DAS

REAR VIEW CAMERA CALIBRATIONDAS-109

< BASIC INSPECTION > [LDW]

C

D E

F

G H

I

J

K L

M B

N P

A

CAUTION:

Make sure that the black/white pattern of the center target is rotated as compared with t](/img/5/57390/w960_57390-541.png)

DAS

REAR VIEW CAMERA CALIBRATIONDAS-109

< BASIC INSPECTION > [LDW]

C

D E

F

G H

I

J

K L

M B

N P

A

CAUTION:

Make sure that the black/white pattern of the center target is rotated as compared with the left and

right targets.

>> Go to DAS-109, "Work Procedure (Rear View Camera Calibration)"

.

Work Procedure (Rear Vi ew Camera Calibration)INFOID:0000000009464744

CAUTION:

Perform the calibration under the sp ecified vehicle condition (fuel full, no-load, specified tire pressure,

etc.). Refer to DAS-107, "Work Procedure (Preparation)"

.

1.CHECK REAR VIEW CAMERA HEIGHT

Measure the rear view camera height “H”.

>> GO TO 2.

2.REAR VIEW CAMERA CALIBRATION

1. Select “Work Support” on “AVM” with CONSULT.

2. Select “REAR CAMERA ITS”.

3. Select "OK". CAUTION:

• Perform the calibration after the ignition or en gine has been kept on for at least 10 minutes to

stabilize camera.

• Operate CONSULT outside the vehicle, and close al l doors to retain appropriate vehicle altitude.

4. Input the rear view camera height "H", and then touch "APPLY".

5. Confirm that the same value is displayed on the center display.

6. Confirm the following items:

- The target should be accurately placed.

- The vehicle should be stopped.

- The vehicle should be under the specified vehicle condition.

7. Select “Start” to perform calibration.

8. Confirm the displayed item.

- “Completed”: Select “Completion”.

- Otherwise, perform the following services:

ALOIA0192GB

ALOIA0188ZZ

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 617 of 4801

![NISSAN TEANA 2014 User Guide

DAS-184

< BASIC INSPECTION >[BSW]

REAR VIEW CAMERA CALIBRATION

CAUTION:

Make sure that the black/white pattern of the center target is rotated as compared with the left and

right targets.

>> Go to NISSAN TEANA 2014 User Guide

DAS-184

< BASIC INSPECTION >[BSW]

REAR VIEW CAMERA CALIBRATION

CAUTION:

Make sure that the black/white pattern of the center target is rotated as compared with the left and

right targets.

>> Go to](/img/5/57390/w960_57390-616.png)

DAS-184

< BASIC INSPECTION >[BSW]

REAR VIEW CAMERA CALIBRATION

CAUTION:

Make sure that the black/white pattern of the center target is rotated as compared with the left and

right targets.

>> Go to DAS-184, "Work Procedure (Rear View Camera Calibration)"

.

Work Procedure (Rear View Camera Calibration)INFOID:0000000009464828

CAUTION:

Perform the calibration under the sp ecified vehicle condition (fuel full, no-load, specified tire pressure,

etc.). Refer to DAS-182, "Work Procedure (Preparation)"

.

1.CHECK REAR VIEW CAMERA HEIGHT

Measure the rear view camera height “H”.

>> GO TO 2.

2.REAR VIEW CAMERA CALIBRATION

1. Select “Work Support” on “AVM” with CONSULT.

2. Select “REAR CAMERA ITS”.

3. Select "OK". CAUTION:

• Perform the calibration after the ignition or engine has been kept on for at least 10 minutes to

stabilize camera.

• Operate CONSULT outside the vehicle, and close al l doors to retain appropriate vehicle altitude.

4. Input the rear view camera height "H", and then touch "APPLY".

5. Confirm that the same value is displayed on the center display.

6. Confirm the following items:

- The target should be accurately placed.

- The vehicle should be stopped.

- The vehicle should be under the specified vehicle condition.

7. Select “Start” to perform calibration.

8. Confirm the displayed item.

- “Completed”: Select “Completion”.

- Otherwise, perform the following services:

ALOIA0192GB

ALOIA0188ZZ

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 691 of 4801

![NISSAN TEANA 2014 User Guide

DAS-258

< BASIC INSPECTION >[MOD]

REAR VIEW CAMERA CALIBRATION

CAUTION:

Make sure that the black/white pattern of the center target is rotated as compared with the left and

right targets.

>> Go to NISSAN TEANA 2014 User Guide

DAS-258

< BASIC INSPECTION >[MOD]

REAR VIEW CAMERA CALIBRATION

CAUTION:

Make sure that the black/white pattern of the center target is rotated as compared with the left and

right targets.

>> Go to](/img/5/57390/w960_57390-690.png)

DAS-258

< BASIC INSPECTION >[MOD]

REAR VIEW CAMERA CALIBRATION

CAUTION:

Make sure that the black/white pattern of the center target is rotated as compared with the left and

right targets.

>> Go to DAS-258, "Work Procedure (Rear View Camera Calibration)"

.

Work Procedure (Rear View Camera Calibration)INFOID:0000000009464909

CAUTION:

Perform the calibration under the sp ecified vehicle condition (fuel full, no-load, specified tire pressure,

etc.). Refer to DAS-256, "Work Procedure (Preparation)"

.

1.CHECK REAR VIEW CAMERA HEIGHT

Measure the rear view camera height “H”.

>> GO TO 2.

2.REAR VIEW CAMERA CALIBRATION

1. Select “Work Support” on “AVM” with CONSULT.

2. Select “REAR CAMERA ITS”.

3. Select "OK". CAUTION:

• Perform the calibration after the ignition or engine has been kept on for at least 10 minutes to

stabilize camera.

• Operate CONSULT outside the vehicle, and close al l doors to retain appropriate vehicle altitude.

4. Input the rear view camera height "H", and then touch "APPLY".

5. Confirm that the same value is displayed on the center display.

6. Confirm the following items:

- The target should be accurately placed.

- The vehicle should be stopped.

- The vehicle should be under the specified vehicle condition.

7. Select “Start” to perform calibration.

8. Confirm the displayed item.

- “Completed”: Select “Completion”.

- Otherwise, perform the following services:

ALOIA0192GB

ALOIA0188ZZ

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1002 of 4801

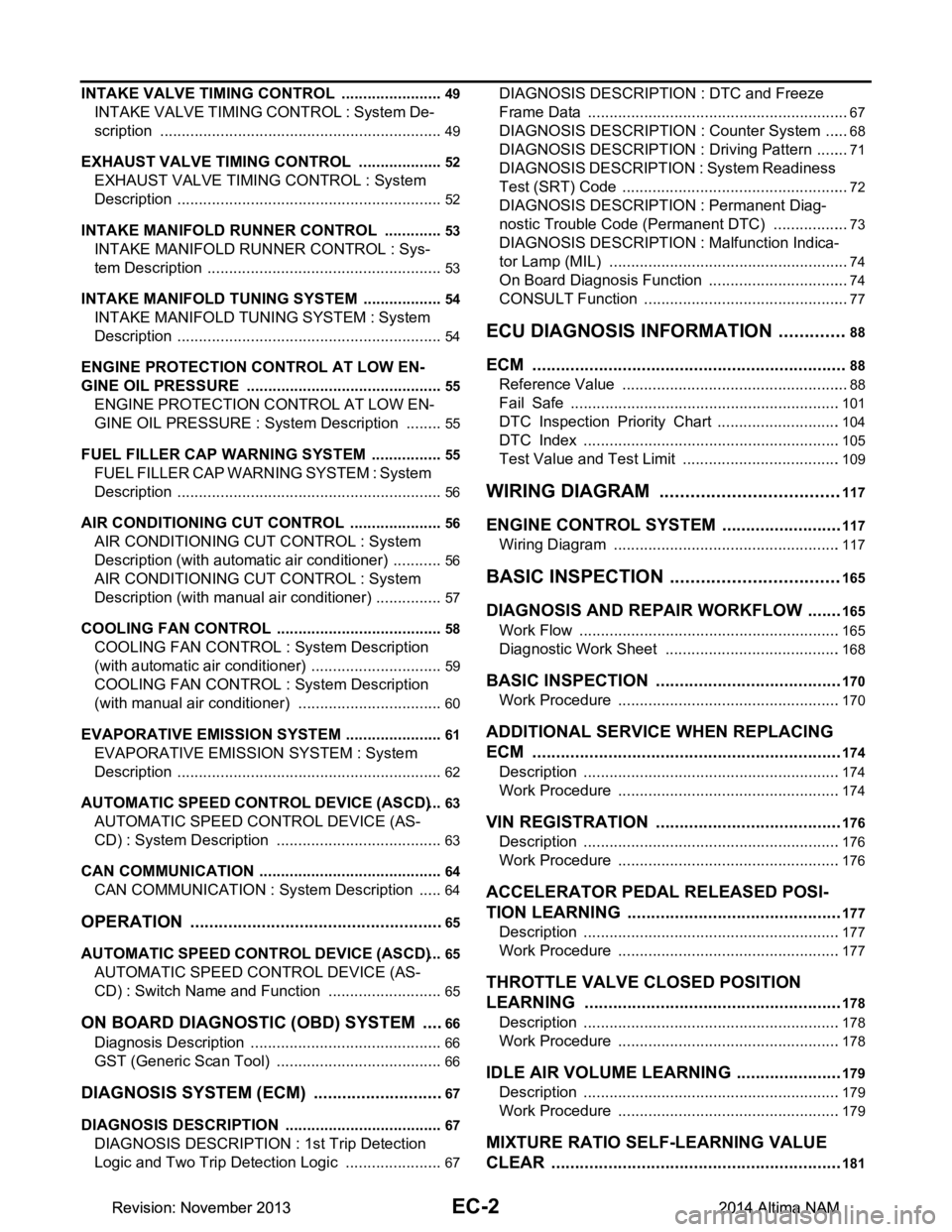

EC-2

INTAKE VALVE TIMING CONTROL ........................49

INTAKE VALVE TIMING CONTROL : System De-

scription ............................................................... ...

49

EXHAUST VALVE TIMING CONTROL ................. ...52

EXHAUST VALVE TIMING CONTROL : System

Description ........................................................... ...

52

INTAKE MANIFOLD RUNNER CONTROL ........... ...53

INTAKE MANIFOLD RUNNER CONTROL : Sys-

tem Description .................................................... ...

53

INTAKE MANIFOLD TUNING SYSTEM ...................54

INTAKE MANIFOLD TUNI NG SYSTEM : System

Description ........................................................... ...

54

ENGINE PROTECTION CONTROL AT LOW EN-

GINE OIL PRESSURE ....... .......................................

55

ENGINE PROTECTION CONTROL AT LOW EN-

GINE OIL PRESSURE : S ystem Description .........

55

FUEL FILLER CAP WARNING SYSTEM .............. ...55

FUEL FILLER CAP WARNING SYSTEM : System

Description ........................................................... ...

56

AIR CONDITIONING CUT CONTROL ................... ...56

AIR CONDITIONING CUT CONTROL : System

Description (with automatic air conditioner) ......... ...

56

AIR CONDITIONING CUT CONTROL : System

Description (with manual air conditioner) ................

57

COOLING FAN CONTROL .................................... ...58

COOLING FAN CONTROL : System Description

(with automatic air condit ioner) ...............................

59

COOLING FAN CONTROL : System Description

(with manual air conditio ner) ..................................

60

EVAPORATIVE EMISSION SYSTEM .................... ...61

EVAPORATIVE EMISSION SYSTEM : System

Description ........................................................... ...

62

AUTOMATIC SPEED CONTROL DEVICE (ASCD) ...63

AUTOMATIC SPEED CONTROL DEVICE (AS-

CD) : System Description .................................... ...

63

CAN COMMUNICATION ........................................ ...64

CAN COMMUNICATION : System Description ......64

OPERATION ................................................... ...65

AUTOMATIC SPEED CONTROL DEVICE (ASCD) ...65

AUTOMATIC SPEED CONTROL DEVICE (AS-

CD) : Switch Name and Function ........................ ...

65

ON BOARD DIAGNOSTIC (OBD) SYSTEM .....66

Diagnosis Description .......................................... ...66

GST (Generic Scan Tool) .......................................66

DIAGNOSIS SYSTEM (ECM) ............................67

DIAGNOSIS DESCRIPTION .................................. ...67

DIAGNOSIS DESCRIPTION : 1st Trip Detection

Logic and Two Trip Detection Logic .................... ...

67

DIAGNOSIS DESCRIPTION : DTC and Freeze

Frame Data .......................................................... ...

67

DIAGNOSIS DESCRIPTION : Counter System ......68

DIAGNOSIS DESCRIPTION : Driving Pattern ........71

DIAGNOSIS DESCRIPTION : System Readiness

Test (SRT) Code .................................................. ...

72

DIAGNOSIS DESCRIPTION : Permanent Diag-

nostic Trouble Code (Permanent DTC) ............... ...

73

DIAGNOSIS DESCRIPTION : Malfunction Indica-

tor Lamp (MIL) ..................................................... ...

74

On Board Diagnosis Function .................................74

CONSULT Function ................................................77

ECU DIAGNOSIS INFORMATION .............88

ECM ...................................................................88

Reference Value .................................................. ...88

Fail Safe ...............................................................101

DTC Inspection Priority Chart .............................104

DTC Index ............................................................105

Test Value and Test Limit .....................................109

WIRING DIAGRAM ...................................117

ENGINE CONTROL SYSTEM ........................ ..117

Wiring Diagram .................................................... .117

BASIC INSPECTION .................................165

DIAGNOSIS AND REPAIR WORKFLOW ...... ..165

Work Flow ............................................................ .165

Diagnostic Work Sheet .........................................168

BASIC INSPECTION ...................................... ..170

Work Procedure ................................................... .170

ADDITIONAL SERVICE WHEN REPLACING

ECM ................................................................ ..

174

Description ........................................................... .174

Work Procedure ....................................................174

VIN REGISTRATION ........................................176

Description ........................................................... .176

Work Procedure ....................................................176

ACCELERATOR PEDAL RELEASED POSI-

TION LEARNING ............................................ ..

177

Description ........................................................... .177

Work Procedure ....................................................177

THROTTLE VALVE CLOSED POSITION

LEARNING ..................................................... ..

178

Description ........................................................... .178

Work Procedure ....................................................178

IDLE AIR VOLUME LEARNING .......................179

Description ........................................................... .179

Work Procedure ....................................................179

MIXTURE RATIO SELF-LEARNING VALUE

CLEAR ............................................................ ..

181

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1009 of 4801

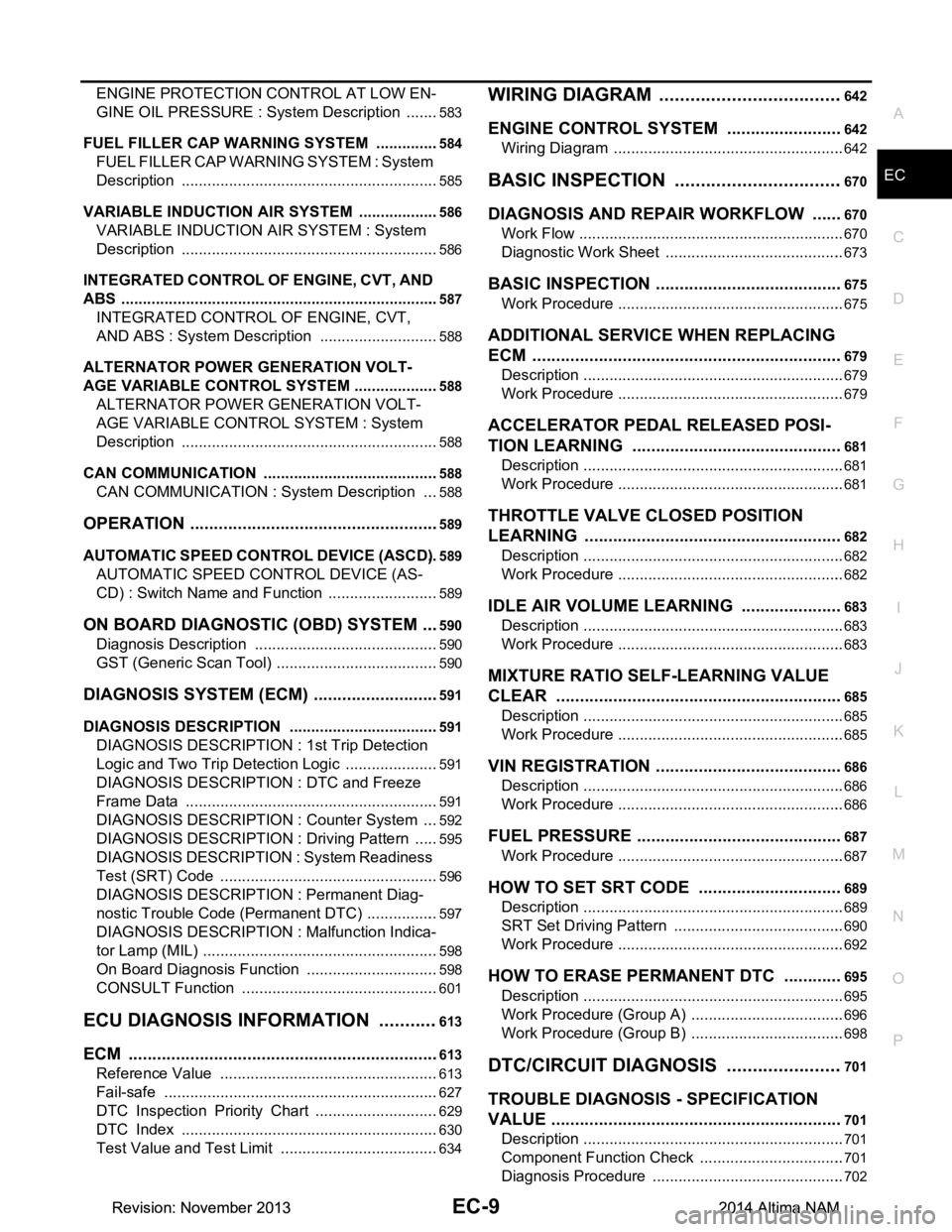

EC-9

C

D E

F

G H

I

J

K L

M

EC A

N

O P

ENGINE PROTECTION CO

NTROL AT LOW EN-

GINE OIL PRESSURE : System Description ...... ..

583

FUEL FILLER CAP WARNING SYSTEM ............. ..584

FUEL FILLER CAP WARNING SYSTEM : System

Description .......................................................... ..

585

VARIABLE INDUCTION AIR SYSTEM ...................586

VARIABLE INDUCTION AIR SYSTEM : System

Description .......................................................... ..

586

INTEGRATED CONTROL OF ENGINE, CVT, AND

ABS ........................................................................ ..

587

INTEGRATED CONTROL OF ENGINE, CVT,

AND ABS : System Descri ption ............................

588

ALTERNATOR POWER GENERATION VOLT-

AGE VARIABLE CONTROL SYSTEM .................. ..

588

ALTERNATOR POWER GENERATION VOLT-

AGE VARIABLE CONTRO L SYSTEM : System

Description .......................................................... ..

588

CAN COMMUNICATION ....................................... ..588

CAN COMMUNICATION : System Description ....588

OPERATION ................................................... ..589

AUTOMATIC SPEED CONTROL DEVICE (ASCD) ..589

AUTOMATIC SPEED CONT ROL DEVICE (AS-

CD) : Switch Name and Function ........................ ..

589

ON BOARD DIAGNOSTIC (OBD) SYSTEM ....590

Diagnosis Description ......................................... ..590

GST (Generic Scan Tool) ......................................590

DIAGNOSIS SYSTEM (ECM) ...........................591

DIAGNOSIS DESCRIPTION ................................. ..591

DIAGNOSIS DESCRIPTION : 1st Trip Detection

Logic and Two Trip Detection Logic .................... ..

591

DIAGNOSIS DESCRIPTION : DTC and Freeze

Frame Data ......................................................... ..

591

DIAGNOSIS DESCRIPTION : Counter System ....592

DIAGNOSIS DESCRIPTION : Driving Pattern ......595

DIAGNOSIS DESCRIPTION : System Readiness

Test (SRT) Code ................................................. ..

596

DIAGNOSIS DESCRIPTION : Permanent Diag-

nostic Trouble Code (Permanent DTC) ............... ..

597

DIAGNOSIS DESCRIPTION : Malfunction Indica-

tor Lamp (MIL) ..................................................... ..

598

On Board Diagnosis Function ...............................598

CONSULT Function ..............................................601

ECU DIAGNOSIS INFORMATION ............613

ECM ................................................................ ..613

Reference Value ................................................. ..613

Fail-safe ................................................................627

DTC Inspection Priority Chart .............................629

DTC Index ............................................................630

Test Value and Test Limit .....................................634

WIRING DIAGRAM ....................................642

ENGINE CONTRO L SYSTEM ........................642

Wiring Diagram .................................................... ..642

BASIC INSPECTION .................................670

DIAGNOSIS AND REPAIR WORKFLOW ......670

Work Flow ............................................................ ..670

Diagnostic Work Sheet ..........................................673

BASIC INSPECTION .......................................675

Work Procedure .....................................................675

ADDITIONAL SERVICE WHEN REPLACING

ECM .................................................................

679

Description ........................................................... ..679

Work Procedure .....................................................679

ACCELERATOR PEDAL RELEASED POSI-

TION LEARNING ............................................

681

Description ........................................................... ..681

Work Procedure .....................................................681

THROTTLE VALVE CLOSED POSITION

LEARNING ....... ...............................................

682

Description ........................................................... ..682

Work Procedure .....................................................682

IDLE AIR VOLUME LEARNING .....................683

Description .............................................................683

Work Procedure .....................................................683

MIXTURE RATIO SELF-LEARNING VALUE

CLEAR ............................................................

685

Description ........................................................... ..685

Work Procedure .....................................................685

VIN REGISTRATION .......................................686

Description .............................................................686

Work Procedure .....................................................686

FUEL PRESSURE ...........................................687

Work Procedure .....................................................687

HOW TO SET SRT CODE ..............................689

Description .............................................................689

SRT Set Driving Pattern ........................................690

Work Procedure .....................................................692

HOW TO ERASE PERMANENT DTC ............695

Description .............................................................695

Work Procedure (Group A) ....................................696

Work Procedure (Group B) ....................................698

DTC/CIRCUIT DIAGNOSIS .......................701

TROUBLE DIAGNOSIS - SPECIFICATION

VALUE .............................................................

701

Description ........................................................... ..701

Component Function Check ..................................701

Diagnosis Procedure .............................................702

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1051 of 4801

![NISSAN TEANA 2014 User Guide

SYSTEMEC-51

< SYSTEM DESCRIPTION > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

The intake valve timing intermediate lock control improv

es the cleaning ability of exhaust gas at cold starting

by fixing NISSAN TEANA 2014 User Guide

SYSTEMEC-51

< SYSTEM DESCRIPTION > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

The intake valve timing intermediate lock control improv

es the cleaning ability of exhaust gas at cold starting

by fixing](/img/5/57390/w960_57390-1050.png)

SYSTEMEC-51

< SYSTEM DESCRIPTION > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

The intake valve timing intermediate lock control improv

es the cleaning ability of exhaust gas at cold starting

by fixing the camshaft sprocket (INT) with two lock keys and bringing the cam phase into intermediate phase.

Cam phase is fixed at the intermediate phase by two lock keys in the camshaft sprocket (INT). Lock key 1 con-

trols retard position and lock key 2 controls advance position.

ECM controls the intermediate phase lock by opening/clos ing the intake valve timing intermediate lock control

solenoid valve to control oil pressure acti ng on the lock key and locking/unlocking the lock key.

Lock/Unlock Activation

When ECM activates the intake valve timing intermediate lock control solenoid valve, oil pressure generated in

the oil pump is drained through the oil pressure path in t he control valve. Since oil pressure is not acted on the

lock key, the lock key position is fixed by the spri ng tension and the cam phase is fixed at the intermediate

phase.

When ECM deactivates the intake valve timing intermediate lock control solenoid valve, unlocking oil pressure

acts on each lock key. Lock key 1 is not released because it is under load due to sprocket rotational force. For

this reason, lock key 2 is released first by being pushed up by unlocking oil pressure. When lock key 2 is

released, some clearance is formed between lock key 1 and the rotor due to sprocket rotational force and

return spring force. Accordingly, lock key 1 is pushed up by unlocking oil pressure and the intermediated

phase lock is released.

When stopping the engine

When the ignition switch is turned from idle state to OFF, ECM receives an ignition switch signal from BCM via

CAN communication and activates the intake valve timing intermediate lock control solenoid valve and drains

oil pressure acting on the lock key before activating the intake valve timing control solenoid valve and operat-

ing the cam phase toward the advance position.

The cam phase is fixed by the lock key when shifting to the intermediated phase and ECM performs Lock

judgment to stop the engine.

When starting the engine

JPBIA6317GB

JPBIA5970GB

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1085 of 4801

![NISSAN TEANA 2014 User Guide

DIAGNOSIS SYSTEM (ECM)EC-85

< SYSTEM DESCRIPTION > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

WORK SUPPORT MODE

Work Item

*: This function is not necessary in the usual service procedure.

ACTIVE TEST NISSAN TEANA 2014 User Guide

DIAGNOSIS SYSTEM (ECM)EC-85

< SYSTEM DESCRIPTION > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

WORK SUPPORT MODE

Work Item

*: This function is not necessary in the usual service procedure.

ACTIVE TEST](/img/5/57390/w960_57390-1084.png)

DIAGNOSIS SYSTEM (ECM)EC-85

< SYSTEM DESCRIPTION > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

WORK SUPPORT MODE

Work Item

*: This function is not necessary in the usual service procedure.

ACTIVE TEST MODE

Test Item

Work item Condition Usage

IDLE AIR VOL LEARN • The idle air volume that keeps the engine within the spec- ified range is memorized in ECM. When learning the idle air volume

EVAP SYSTEM CLOSE Close the EVAP canister vent control valve in order to make

EVAP system close under the following conditions.

• Ignition switch ON

• Engine not running

• Ambient temperature is above 0 °C (32 °F).

• No vacuum and no high pressure in EVAP system

• Fuel tank temp is more than 0 °C (32 °F).

• Within 10 minutes after starting “EVAP SYSTEM CLOSE”

• When trying to execute “EVAP SYSTEM CLOSE” under the condition except above, CONSULT will discontinue it

and display appropriate instruction.

NOTE:

When starting engine, CONSULT may display “BAT-

TERY VOLTAGE IS LOW. CHARGE BATTERY”, even in

when using a charged battery. When detecting EVAP vapor leak

in the EVAP system

FUEL PRESSURE RELEASE • Fuel pump will st op by touching “START” during idling.

Crank a few times after engine stalls. When releasing fuel pressure from

fuel line

TARGET IGN TIM ADJ* • Idle condition When adjusting target ignition tim- ing

TARGET IDLE RPM ADJ* • Idle condition When setting target idle speed

VIN REGISTRATION • In this mode , VIN is registered in ECM. When registering VIN in ECM

SELF-LEARNING CONT • The coefficient of self-learning control mixture ratio returns to the original coefficient. When clearing mixture ratio self-

learning value

CLSD THL POS LEARN • Ignition on and engine stopped. When learning the throttle valve

closed position

SAVING DATA FOR REPLC CPU In th is mode, save data that is in ECM. When ECM is replaced.

WRITING DATA FOR REPLC CPU In this mode, write data stored by “SAVE DATA FOR CPU

REPLC” in work support mode to ECM. When ECM is replaced.

Test item Condition Judgment Check item (Remedy)

FUEL INJECTION • Engine: Return to the original

trouble condition

• Change the amount of fuel injec- tion using CONSULT. If trouble symptom disappears, see

CHECK ITEM. • Harness and connectors

• Fuel injector

• Air fuel ratio (A/F) sensor 1

ENG COOLANT

TEMP • Engine: Return to the original

trouble condition

• Change the engine coolant tem- perature using CONSULT. If trouble symptom disappears, see

CHECK ITEM. • Harness and connectors

• Engine coolant temperature

sensor

• Fuel injector

PURG VOL CONT/V • Engine: After warming up, run en-

gine at 1,500 rpm.

• Change the EVAP canister purge volume control solenoid valve

opening percent using CON-

SULT. Engine speed changes according

to the opening percent. • Harness and connectors

• Solenoid valve

FUEL/T TEMP SEN • Change the fuel tank temperature using CONSULT.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1103 of 4801

![NISSAN TEANA 2014 User Guide

ECM

EC-103

< ECU DIAGNOSIS INFORMATION > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

OP0171

P0172 Fuel injection system

×—— —

P0197

P0198 Engine oil temperature sensor

———Exhaust valve tim NISSAN TEANA 2014 User Guide

ECM

EC-103

< ECU DIAGNOSIS INFORMATION > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

OP0171

P0172 Fuel injection system

×—— —

P0197

P0198 Engine oil temperature sensor

———Exhaust valve tim](/img/5/57390/w960_57390-1102.png)

ECM

EC-103

< ECU DIAGNOSIS INFORMATION > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

OP0171

P0172 Fuel injection system

×—— —

P0197

P0198 Engine oil temperature sensor

———Exhaust valve timing control does not function.

P0300

P0301

P0302

P0303

P0304 Misfire

×—— —

P0500 Vehicle speed sensor ×—— —

P050A Cold start control ×—— —

P0524 Engine oil pressure

———• ECM illuminates oil pressure warning lamp on the combina-

tion meter.

• Engine speed will not rise more than 4,000rpm due to the fuel cut.

• Fail-safe is canceled when ignition switch OFF → ON.

P052A

P052B Intake valve timing intermedi-

ate lock control ——

× —

P0603 ECM power supply circuit — ×——

P0605 ECM — ×——

P0643 Sensor power supply ———ECM stops the electric throttle control actuator control, throttle

valve is maintained at a fixed opening (approx. 5 degrees) by

the return spring.

P1078 Exhaust valve timing control position sensor circuit ×

— × —

P1805 Brake switch

———ECM controls the electric throttle control actuator by regulat-

ing the throttle opening to a small range.

Therefore, acceleration will be poor.

Vehicle condition Driving condition

When engine is idling Normal When accelerating Poor acceleration

P2004 Intake manifold runner control valve —

×× —

P2100

P2103 Throttle contro

l motor relay

——— ECM stops the electric throttle control actuator control, throttle

valve is maintained at a fixed opening (approx. 5 degrees) by

the return spring.

P2101 Electric throttle control func- tion ——— ECM stops the electric throttle control actuator control, throttle

valve is maintained at a fixed opening (approx. 5 degrees) by

the return spring.

P2118 Throttle control motor ———ECM stops the electric throttle control actuator control, throttle

valve is maintained at a fixed opening (approx. 5 degrees) by

the return spring.

P2119 Electric thro ttle control actua-

tor —

×——

P2122

P2123

P2127

P2128

P2138 Accelerator pedal position

sensor

———The ECM controls the electric throttle control actuator in reg-

ulating the throttle opening in order for the idle position to be

within +10 degrees.

The ECM regulates the opening speed of the throttle valve to

be slower than the normal condition.

So, the acceleration will be poor.

DTC

No. Detected items Vehicle behavior

Pattern Others

ABC

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1104 of 4801

![NISSAN TEANA 2014 User Guide

EC-104

< ECU DIAGNOSIS INFORMATION >[QR25DE]

ECM

DTC Inspection Priority Chart

INFOID:0000000009462123

If some DTCs are displayed at the same time, perfo rm inspections one by one based on the follow NISSAN TEANA 2014 User Guide

EC-104

< ECU DIAGNOSIS INFORMATION >[QR25DE]

ECM

DTC Inspection Priority Chart

INFOID:0000000009462123

If some DTCs are displayed at the same time, perfo rm inspections one by one based on the follow](/img/5/57390/w960_57390-1103.png)

EC-104

< ECU DIAGNOSIS INFORMATION >[QR25DE]

ECM

DTC Inspection Priority Chart

INFOID:0000000009462123

If some DTCs are displayed at the same time, perfo rm inspections one by one based on the following priority

chart.

Priority DTC Detected items

1 U0101, U1001 CAN communication line

P0101, P0102, P0103 Mass air flow sensor

P010A Manifold absolute pressure sensor

P0111, P0112, P0113, P0127 Intake air temperature sensor

P0116, P0117, P0118, P0125 Engine coolant temperature sensor

P0122, P0123, P0222, P0223, P1225, P1226, P2135 Throttle position sensor

P0128 Thermostat function

P0181, P0182, P0183 Fuel tank temperature sensor

P0196, P0197, P0198 Engine oil temperature sensor

P0327, P0328 Knock sensor

P0335 Crankshaft position sensor (POS)

P0340 Camshaft position sensor (PHASE)

P0460, P0461, P0462, P0463 Fuel level sensor

P0500 Vehicle speed sensor

P0520 Engine oil pressure sensor

P0603, P0604, P0605, P0606, P0607, P060A, P060B,

P2610 ECM

P0643 Sensor power supply

P0850 Transmission range switch

P1078 Exhaust valve timing control position sensor

P1550, P1551, P1552, P1553, P1554 Battery current sensor

P1556, P1557 Battery temperature sensor

P1610, P1611, P1612, P1615 NATS

P2014, P2016, P2017, P2018 Intake manifold runner control valve position sensor

P2122, P2123, P2127, P2128, P2138 Accelerator pedal position sensor

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1105 of 4801

![NISSAN TEANA 2014 User Guide

ECM

EC-105

< ECU DIAGNOSIS INFORMATION > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

DTC IndexINFOID:0000000009462124

×

:Applicable —: Not applicable

2 P0031, P0032 Air fuel ratio (A/F) sensor 1 hea NISSAN TEANA 2014 User Guide

ECM

EC-105

< ECU DIAGNOSIS INFORMATION > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

DTC IndexINFOID:0000000009462124

×

:Applicable —: Not applicable

2 P0031, P0032 Air fuel ratio (A/F) sensor 1 hea](/img/5/57390/w960_57390-1104.png)

ECM

EC-105

< ECU DIAGNOSIS INFORMATION > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

DTC IndexINFOID:0000000009462124

×

:Applicable —: Not applicable

2 P0031, P0032 Air fuel ratio (A/F) sensor 1 heater

P0037, P0038 Heated oxygen sensor 2 heater

P0075 Intake valve timing control solenoid valve/Intake valve timing

intermediate lock control solenoid valve

P0078 Exhaust valve timing control solenoid valve

P0130, P0131, P0132, P014 C, P014D, P015A, P015B,

P117A, P2096, P2097 Air fuel ratio (A/F) sensor 1

P0137, P0138, P0139 Heated oxygen sensor 2

P0441 EVAP control system purge flow monitoring

P0443, P0444, P0445 EVAP canister purge volume control solenoid valve

P0447, P0448 EVAP canister vent control valve

P0451, P0452, P0453 EVAP control system pressure sensor

P1217 Engine over temperature (OVERHEAT)

P1800 Intake manifold tuning valve

P1805 Brake switch

P2004 Intake manifold runner control valve

P2100, P2103 Throttle control motor relay

P2101 Electric thrott le control function

P2118 Throttle control motor

3 P0011, P052A, P052B Intake valve timing control

P0014 Exhaust valve timing control

P0171, P0172 Fuel injection system function

P0300, P0301, P0302, P0303, P0304 Misfire

P0420 Three way catalyst function

P0456 EVAP control system

P0506, P0507 Idle speed control system

P050A, P050B, P050E Cold start control

P0524 Engine oil pressure

P1148 Closed loop control

P1212 TCS communication line

P1564 ASCD steering switch

P1572 ASCD brake switch

P1574 ASCD vehicle speed sensor

P1715 Input speed sensor

P2119 Electric throttle control actuator

Priority DTC Detected items

DTC*1

Items

(CONSULT screen terms) SRT

code Trip MIL Permanent

DTC group*4Reference page

CONSULT

GST

*2ECM*3

U0101 0101*5CAN COMM CIRCUIT — 1 ×BEC-207

U1001

1001*5CAN COMM CIRCUIT — 2 — — EC-208

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM