wheel torque NISSAN TEANA 2014 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 2492 of 4801

FL-12

< REMOVAL AND INSTALLATION >

FUEL TANK

8. Remove rear wheel and tire using power tool. Refer to WT-55, "Adjustment".

9. Remove rear brake pads. Refer to BR-38, "BRAKE PAD : Removal and Installation"

.

10. Remove rear torque members and rear disc brake rotor.

11. Disconnect rear parking brake shoe, and remove rear cables from toggle lever. Refer to PB-9, "Removal

and Installation".

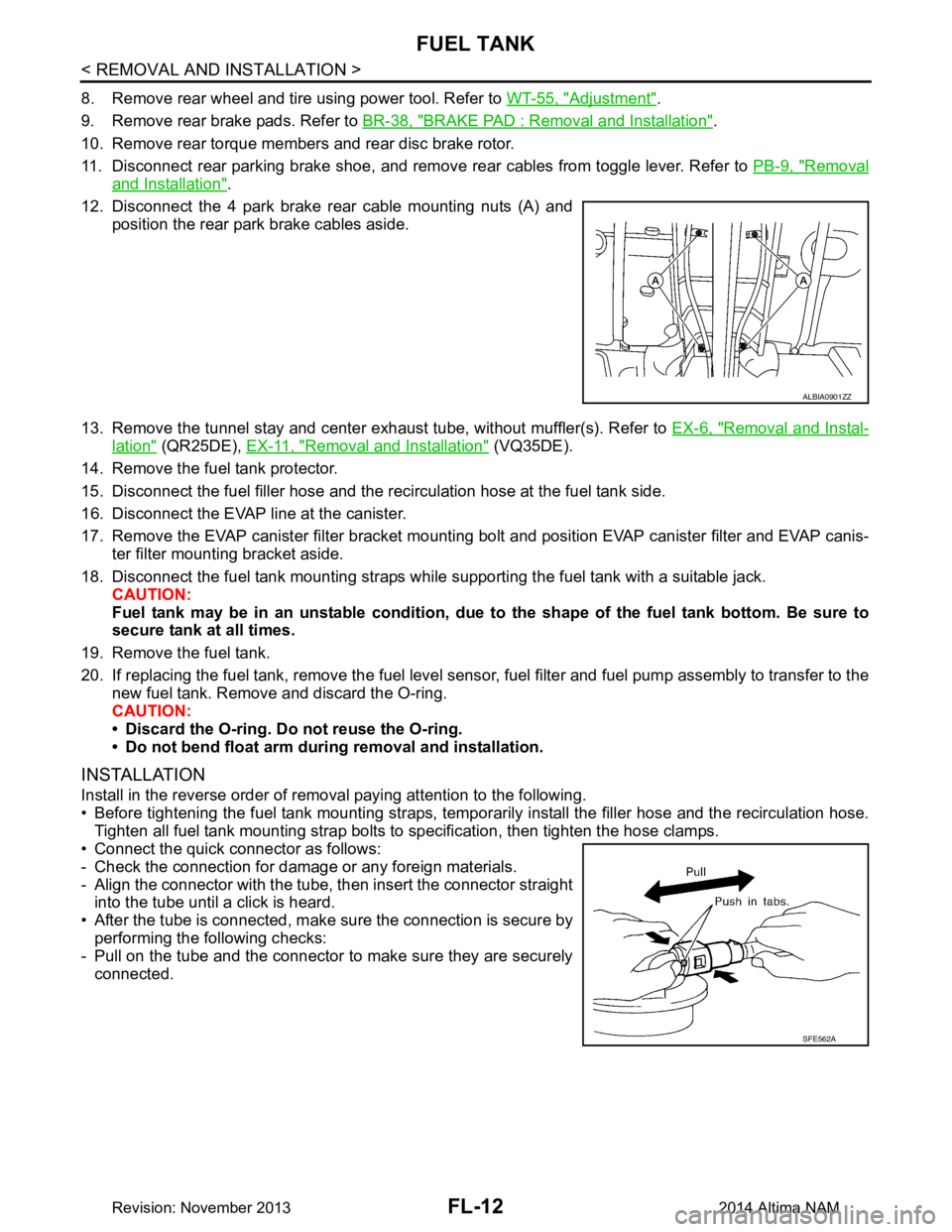

12. Disconnect the 4 park brake rear cable mounting nuts (A) and position the rear park brake cables aside.

13. Remove the tunnel stay and center exhaust tube, without muffler(s). Refer to EX-6, "Removal and Instal-

lation" (QR25DE), EX-11, "Removal and Installation" (VQ35DE).

14. Remove the fuel tank protector.

15. Disconnect the fuel filler hose and the recirculation hose at the fuel tank side.

16. Disconnect the EVAP line at the canister.

17. Remove the EVAP canister filter bracket mounti ng bolt and position EVAP canister filter and EVAP canis-

ter filter mounting bracket aside.

18. Disconnect the fuel tank mounting straps while supporting the fuel tank with a suitable jack. CAUTION:

Fuel tank may be in an unstable condition, due to the shape of the fuel tank bottom. Be sure to

secure tank at all times.

19. Remove the fuel tank.

20. If replacing the fuel tank, remove the fuel level sens or, fuel filter and fuel pump assembly to transfer to the

new fuel tank. Remove and discard the O-ring.

CAUTION:

• Discard the O-ring. Do not reuse the O-ring.

• Do not bend float arm during removal and installation.

INSTALLATION

Install in the reverse order of removal paying attention to the following.

• Before tightening the fuel tank mounting straps, tempor arily install the filler hose and the recirculation hose.

Tighten all fuel tank mounting strap bolts to specification, then tighten the hose clamps.

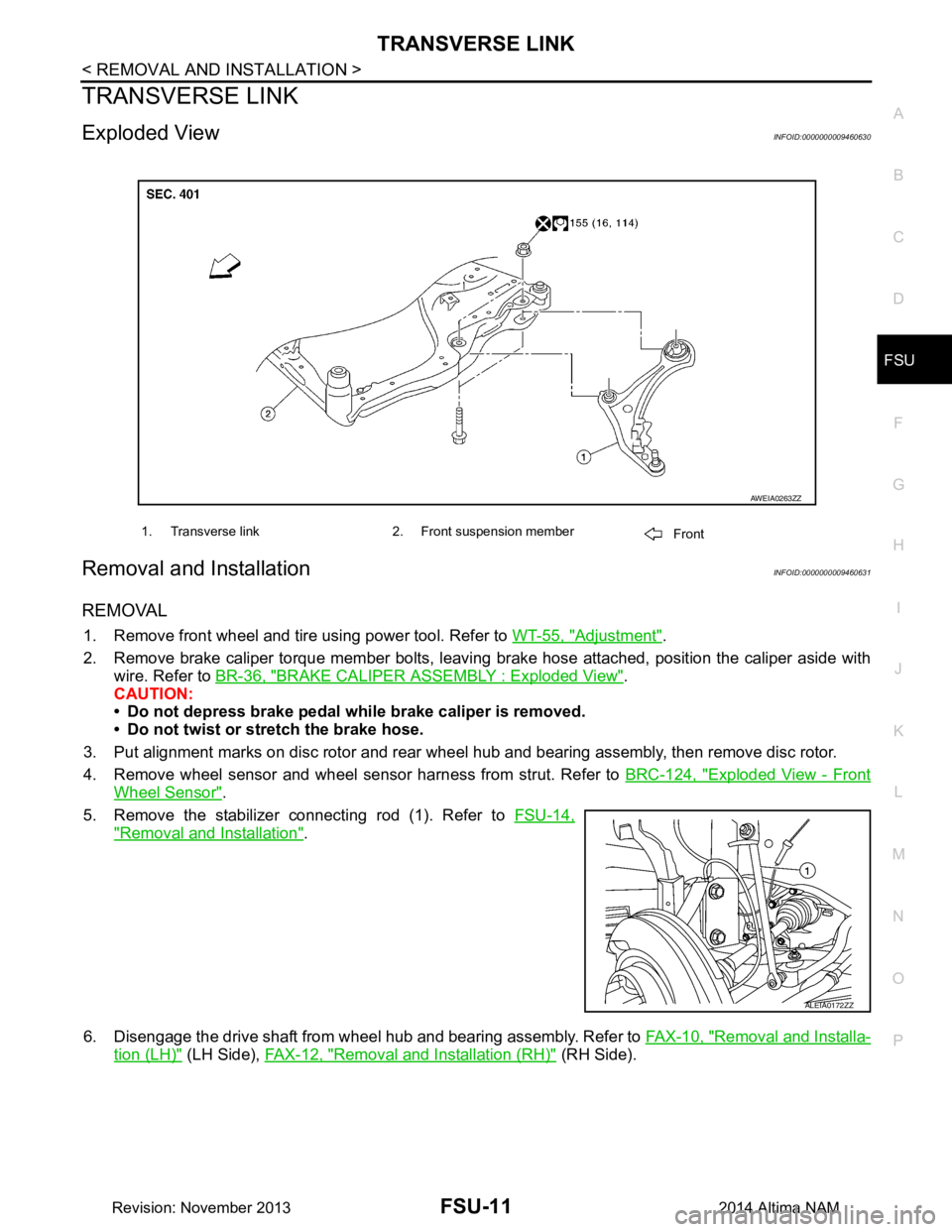

• Connect the quick connector as follows:

- Check the connection for damage or any foreign materials.

- Align the connector with the tube, then insert the connector straight into the tube until a click is heard.

• After the tube is connected, make sure the connection is secure by performing the following checks:

- Pull on the tube and the connector to make sure they are securely

connected.

ALBIA0901ZZ

SFE562A

Revision: November 20132014 Altima NAM

Page 2512 of 4801

TRANSVERSE LINKFSU-11

< REMOVAL AND INSTALLATION >

C

D

F

G H

I

J

K L

M A

B

FSU

N

O P

TRANSVERSE LINK

Exploded ViewINFOID:0000000009460630

Removal and InstallationINFOID:0000000009460631

REMOVAL

1. Remove front wheel and tire using power tool. Refer to WT-55, "Adjustment".

2. Remove brake caliper torque member bolts, leaving brake hose attached, position the caliper aside with

wire. Refer to BR-36, "BRAKE CALIPER ASSEMBLY : Exploded View"

.

CAUTION:

• Do not depress brake pedal while brake caliper is removed.

• Do not twist or stretch the brake hose.

3. Put alignment marks on disc rotor and rear wheel hub and bearing assembly, then remove disc rotor.

4. Remove wheel sensor and wheel sensor harness from strut. Refer to BRC-124, "Exploded View - Front

Wheel Sensor".

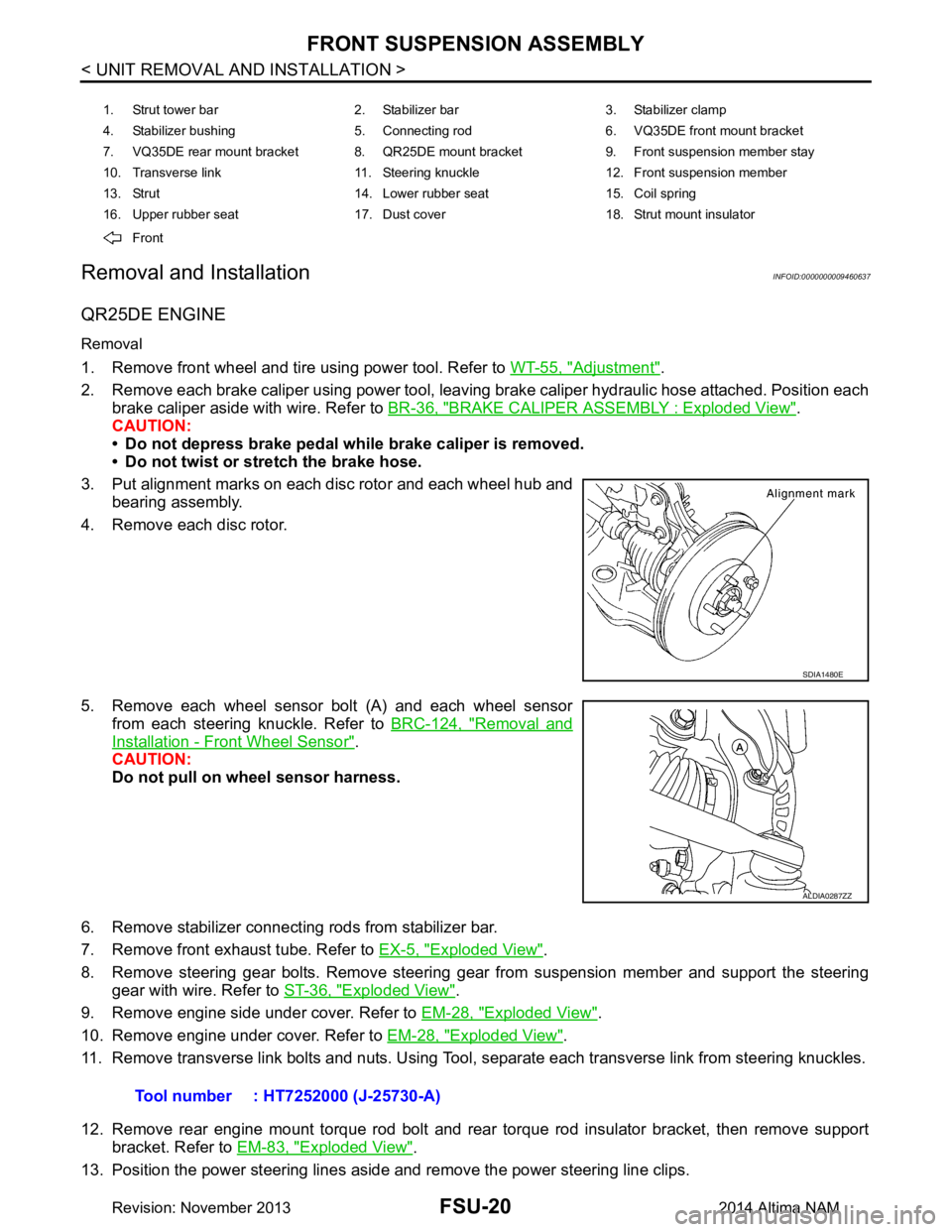

5. Remove the stabilizer connecting rod (1). Refer to FSU-14,

"Removal and Installation".

6. Disengage the drive shaft from wheel hub and bearing assembly. Refer to FAX-10, "Removal and Installa-

tion (LH)" (LH Side), FAX-12, "Removal and Installation (RH)" (RH Side).

1. Transverse link 2. Front suspension member

Front

AWEIA0263ZZ

ALEIA0172ZZ

Revision: November 20132014 Altima NAM

Page 2521 of 4801

FSU-20

< UNIT REMOVAL AND INSTALLATION >

FRONT SUSPENSION ASSEMBLY

Removal and Installation

INFOID:0000000009460637

QR25DE ENGINE

Removal

1. Remove front wheel and tire using power tool. Refer to WT-55, "Adjustment".

2. Remove each brake caliper using power tool, leaving brake caliper hydraulic hose attached. Position each brake caliper aside with wire. Refer to BR-36, "BRAKE CALIPER ASSEMBLY : Exploded View"

.

CAUTION:

• Do not depress brake pedal while brake caliper is removed.

• Do not twist or stretch the brake hose.

3. Put alignment marks on each disc rotor and each wheel hub and bearing assembly.

4. Remove each disc rotor.

5. Remove each wheel sensor bolt (A) and each wheel sensor from each steering knuckle. Refer to BRC-124, "Removal and

Installation - Front Wheel Sensor".

CAUTION:

Do not pull on wheel sensor harness.

6. Remove stabilizer connecting rods from stabilizer bar.

7. Remove front exhaust tube. Refer to EX-5, "Exploded View"

.

8. Remove steering gear bolts. Remove steering gear from suspension member and support the steering gear with wire. Refer to ST-36, "Exploded View"

.

9. Remove engine side under cover. Refer to EM-28, "Exploded View"

.

10. Remove engine under cover. Refer to EM-28, "Exploded View"

.

11. Remove transverse link bolts and nuts. Using Tool, separate each transverse link from steering knuckles.

12. Remove rear engine mount torque rod bolt and rear torque rod insulator bracket, then remove support bracket. Refer to EM-83, "Exploded View"

.

13. Position the power steering lines aside and remove the power steering line clips.

1. Strut tower bar 2. Stabilizer bar 3. Stabilizer clamp

4. Stabilizer bushing 5. Connecting rod 6. VQ35DE front mount bracket

7. VQ35DE rear mount bracket 8. QR25DE mount bracket 9. Front suspension member stay

10. Transverse link 11. Steering knuckle 12. Front suspension member

13. Strut 14. Lower rubber seat 15. Coil spring

16. Upper rubber seat 17. Dust cover 18. Strut mount insulator

Front

SDIA1480E

ALDIA0287ZZ

Tool number : HT7252000 (J-25730-A)

Revision: November 20132014 Altima NAM

Page 2527 of 4801

FSU-26

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

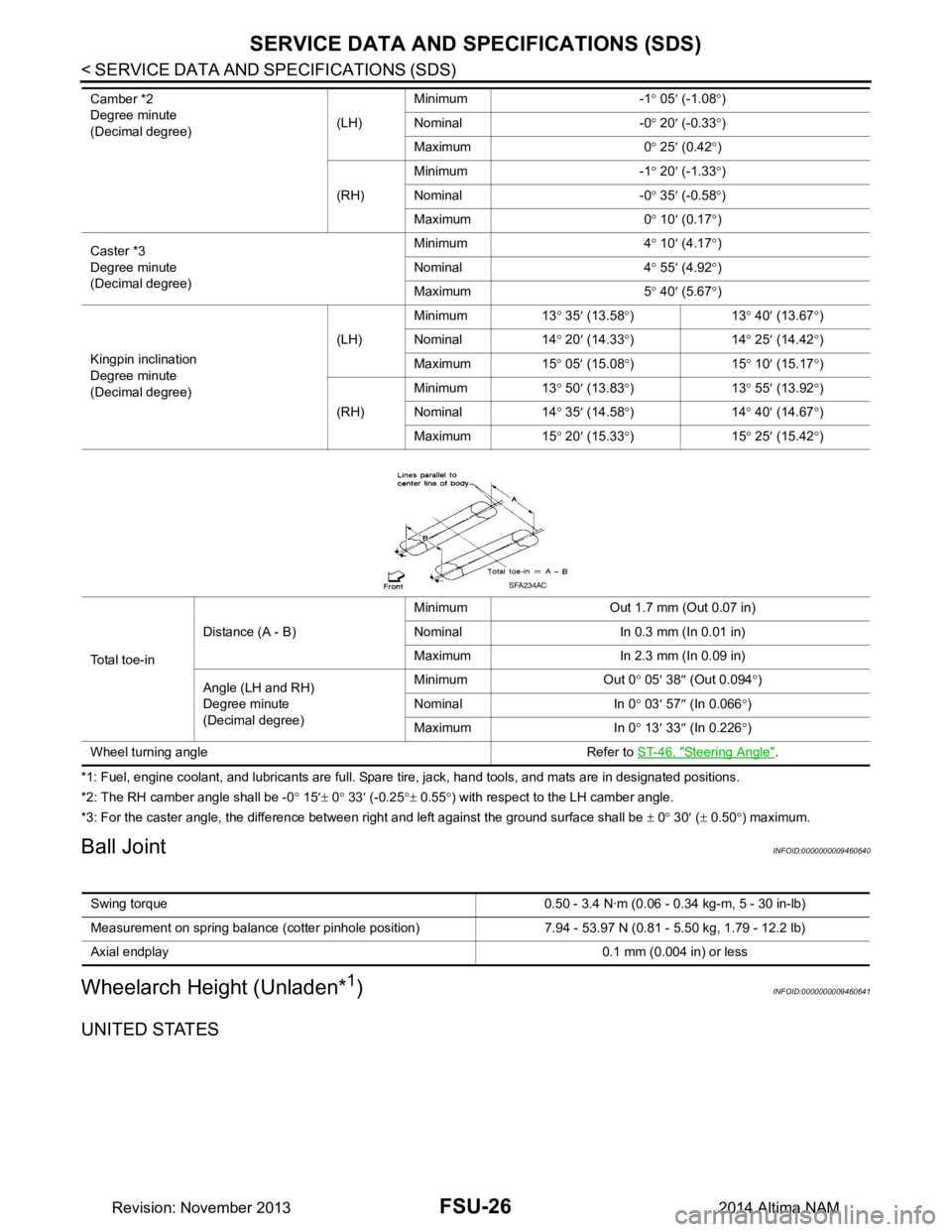

*1: Fuel, engine coolant, and lubricants are full. Spare tire, jack, hand tools, and mats are in designated positions.

*2: The RH camber angle shall be -0 ° 15 ′± 0 ° 33 ′ (-0.25 °± 0.55 °) with respect to the LH camber angle.

*3: For the caster angle, the difference between right and left against the ground surface shall be ± 0 ° 30 ′ ( ± 0.50 °) maximum.

Ball JointINFOID:0000000009460640

Wheelarch Height (Unladen*1)INFOID:0000000009460641

UNITED STATES

Camber *2

Degree minute

(Decimal degree) (LH)Minimum -1

° 05 ′ (-1.08 °)

Nominal -0 ° 20 ′ (-0.33 °)

Maximum 0 ° 25 ′ (0.42 °)

(RH) Minimum -1

° 20 ′ (-1.33 °)

Nominal -0 ° 35 ′ (-0.58 °)

Maximum 0 ° 10 ′ (0.17 °)

Caster *3

Degree minute

(Decimal degree) Minimum 4

° 10 ′ (4.17 °)

Nominal 4 ° 55 ′ (4.92 °)

Maximum 5 ° 40 ′ (5.67 °)

Kingpin inclination

Degree minute

(Decimal degree) (LH)

Minimum 13

° 35 ′ (13.58 °)13 ° 40 ′ (13.67 °)

Nominal 14 ° 20 ′ (14.33 °)14 ° 25 ′ (14.42 °)

Maximum 15 ° 05 ′ (15.08 °)15 ° 10 ′ (15.17 °)

(RH) Minimum 13

° 50 ′ (13.83 °)13 ° 55 ′ (13.92 °)

Nominal 14 ° 35 ′ (14.58 °)14 ° 40 ′ (14.67 °)

Maximum 15 ° 20 ′ (15.33 °)15 ° 25 ′ (15.42 °)

Total toe-in Distance (A - B)

Minimum Out 1.7 mm (Out 0.07 in)

Nominal In 0.3 mm (In 0.01 in)

Maximum In 2.3 mm (In 0.09 in)

Angle (LH and RH)

Degree minute

(Decimal degree) Minimum Out 0

° 05 ′ 38 ″ (Out 0.094 °)

Nominal In 0 ° 03 ′ 57 ″ (In 0.066 °)

Maximum In 0 ° 13 ′ 33 ″ (In 0.226 °)

Wheel turning angle Refer to ST-46, "Steering Angle"

.

SFA234AC

Swing torque 0.50 - 3.4 N·m (0 .06 - 0.34 kg-m, 5 - 30 in-lb)

Measurement on spring balance (cotter pinhole position) 7.94 - 53.97 N (0.81 - 5.50 kg, 1.79 - 12.2 lb)

Axial endplay 0.1 mm (0.004 in) or less

Revision: November 20132014 Altima NAM

Page 2529 of 4801

GI-1

GENERAL INFORMATION

C

D E

F

G H

I

J

K L

M B

GI

SECTION GI

N

O P

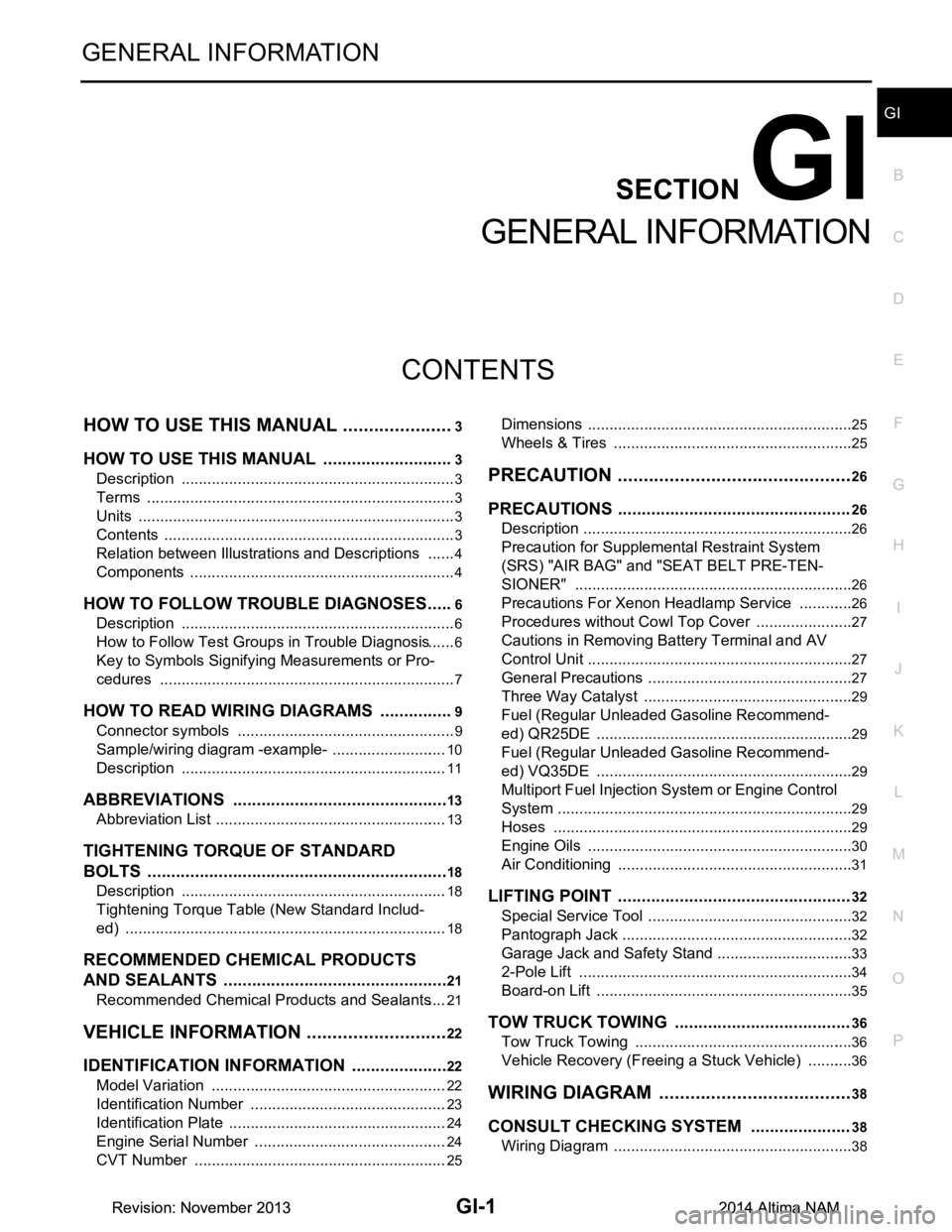

CONTENTS

GENERAL INFORMATION

HOW TO USE THIS MANU AL ......................3

HOW TO USE THIS MANUAL ....................... .....3

Description .......................................................... ......3

Terms ........................................................................3

Units ..........................................................................3

Contents ....................................................................3

Relation between Illustrations and Descriptions .......4

Components ..............................................................4

HOW TO FOLLOW TROUBLE DIAGNOSES .....6

Description ................................................................6

How to Follow Test Groups in Trouble Diagnosis ......6

Key to Symbols Signifying Measurements or Pro-

cedures ............................................................... ......

7

HOW TO READ WIRING DIAGRAMS ................9

Connector symbols ............................................. ......9

Sample/wiring diagram -example- ...........................10

Description ..............................................................11

ABBREVIATIONS .......................................... ....13

Abbreviation List .................................................. ....13

TIGHTENING TORQUE OF STANDARD

BOLTS ............................................................ ....

18

Description .......................................................... ....18

Tightening Torque Table (New Standard Includ-

ed) ....................................................................... ....

18

RECOMMENDED CHEMICAL PRODUCTS

AND SEALANTS ............................................ ....

21

Recommended Chemical Products and Sealants ....21

VEHICLE INFORMATION ............................22

IDENTIFICATION INFORMATION ................. ....22

Model Variation ................................................... ....22

Identification Number ..............................................23

Identification Plate ...................................................24

Engine Serial Number .............................................24

CVT Number ...........................................................25

Dimensions .......................................................... ....25

Wheels & Tires ........................................................25

PRECAUTION ..............................................26

PRECAUTIONS .................................................26

Description ........................................................... ....26

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ....

26

Precautions For Xenon Headlamp Service .............26

Procedures without Cowl Top Cover .......................27

Cautions in Removing Battery Terminal and AV

Control Unit .......................................................... ....

27

General Precautions ................................................27

Three Way Catalyst .................................................29

Fuel (Regular Unleaded Gasoline Recommend-

ed) QR25DE ........................................................ ....

29

Fuel (Regular Unleaded Gasoline Recommend-

ed) VQ35DE ........................................................ ....

29

Multiport Fuel Injection System or Engine Control

System ................................................................. ....

29

Hoses ......................................................................29

Engine Oils ..............................................................30

Air Conditioning .......................................................31

LIFTING POINT .................................................32

Special Service Tool ................................................32

Pantograph Jack ......................................................32

Garage Jack and Safety Stand ................................33

2-Pole Lift ................................................................34

Board-on Lift ............................................................35

TOW TRUCK TOWING .....................................36

Tow Truck Towing ...................................................36

Vehicle Recovery (Freeing a Stuck Vehicle) ...........36

WIRING DIAGRAM ......................................38

CONSULT CHECKING SYSTEM .....................38

Wiring Diagram .................................................... ....38

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3224 of 4801

MA-40

< PERIODIC MAINTENANCE >

CHASSIS AND BODY MAINTENANCE

4. If calculated balance weight value exceeds 50 g (1.76 oz), installtwo balance weight sheets in line with each other as shown.

CAUTION:

Do not install one balance weight sheet on top another.

5. Start balancer machine again.

6. Install balance weight on inner side of road wheel in the bal- ancer machine indication position (angle).

CAUTION:

Do not install more than two balance weights.

7. Start balancer machine. Make sure that inner and outer residual imbalance values are 5 g (0.17 oz) each or below.

8. If either residual imbalance value exceeds 5 g (0.17 oz), repeat installation procedures.

TIRE ROTATION

• Follow the maintenance schedule for tire rotation service intervals.

Refer to MA-7, "FOR USA AND CANADA : Introduction of Periodic

Maintenance".

• When installing the wheel, tighten wheel nuts to the specified torque.

CAUTION:

• Do not include the T-type spare tire when rotating the tires.

• When installing wheels, tighten them diagonally by dividing

the work two to three times in order to prevent the wheels

from developing any distortion.

• Be careful not to tighten wheel nut at torque exceeding the criteria for preventing strain of disc rotor.

• Use NISSAN genuine wheel nuts for aluminum wheels.

• Perform the ID registration, after tire rotation. Refer to WT-25, "Work Procedure"

.

BRAKE FLUID LEVEL AND LEAKS

BRAKE FLUID LEVEL AND LEAKS : InspectionINFOID:0000000009464576

BRAKE FLUID LEVEL

• Make sure that the brake fluid level in the reservoir tank is between

the MAX and MIN lines.

• Visually check around the reservoir tank for brake fluid leakage.

• If the brake fluid level is excessively low, check the brake system for leakage.

• If brake warning lamp remains illuminated after parking brake

pedal is released, check the brake system for brake fluid leakage.

BRAKE LINE

1. Check brake line (tubes and hoses) for cracks, deterioration or other damage. Replace any damaged

parts.

Wheel balance Dynamic (At flange) Static (At flange)

Maximum allowable im-

balance Refer to

WT-55, "Adjustment"

.

PEIA0033E

Wheel nut tightening

torque : 113 N·m (12 kg-m, 83 ft-lb)

SMA829C

ALFIA0273ZZ

Revision: November 20132014 Altima NAM

Page 3663 of 4801

RAX-6

< REMOVAL AND INSTALLATION >

WHEEL HUB

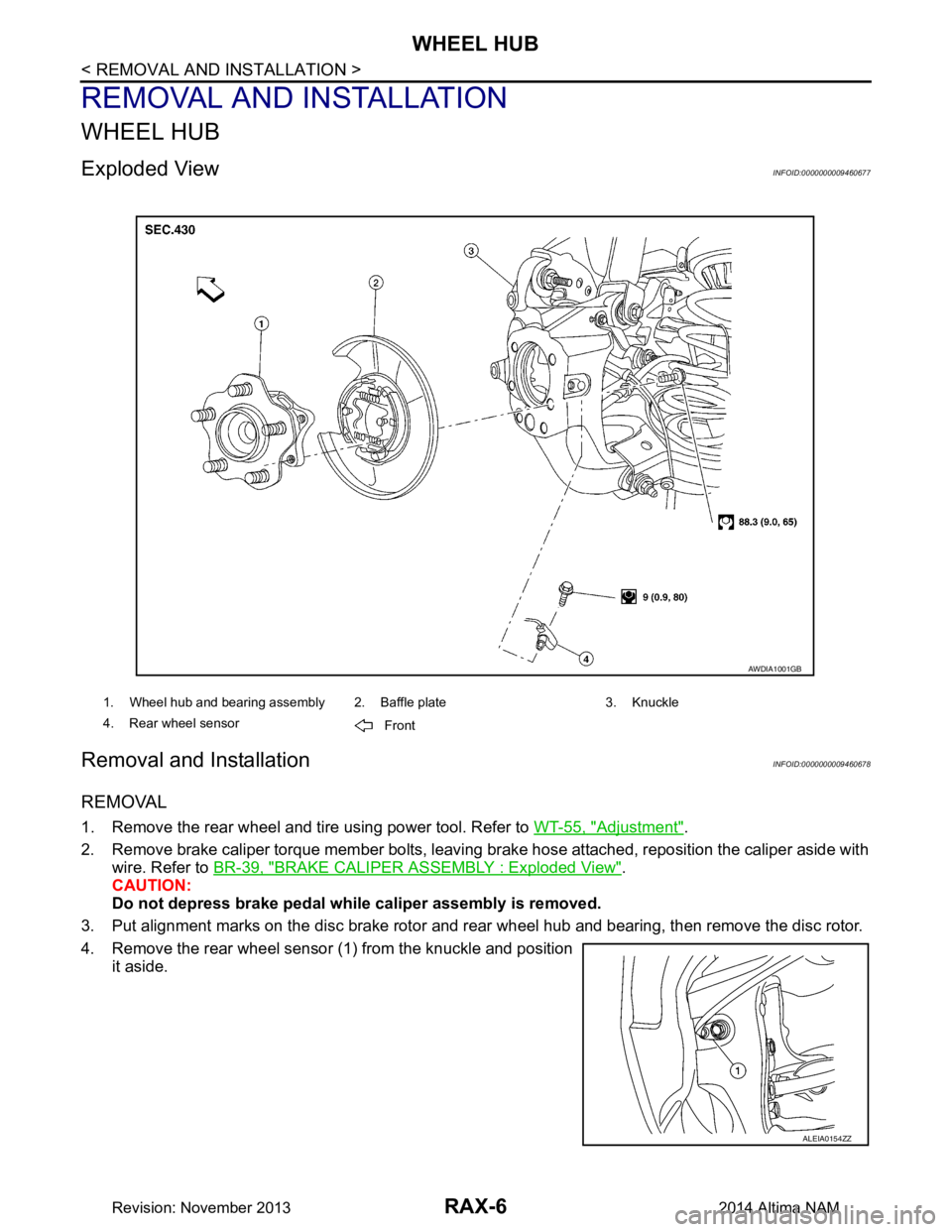

REMOVAL AND INSTALLATION

WHEEL HUB

Exploded ViewINFOID:0000000009460677

Removal and InstallationINFOID:0000000009460678

REMOVAL

1. Remove the rear wheel and tire using power tool. Refer to WT-55, "Adjustment".

2. Remove brake caliper torque member bolts, leaving brake hose attached, reposition the caliper aside with

wire. Refer to BR-39, "BRAKE CALIPER AS SEMBLY : Exploded View"

.

CAUTION:

Do not depress brake pedal while caliper assembly is removed.

3. Put alignment marks on the disc brake rotor and rear wheel hub and bearing, then remove the disc rotor.

4. Remove the rear wheel sensor (1) from the knuckle and position

it aside.

1. Wheel hub and bearing assembly 2. Baffle plate 3. Knuckle

4. Rear wheel sensor Front

AWDIA1001GB

ALEIA0154ZZ

Revision: November 20132014 Altima NAM

Page 3722 of 4801

REAR SUSPENSION ASSEMBLYRSU-5

< PERIODIC MAINTENANCE >

C

D

F

G H

I

J

K L

M A

B

RSU

N

O P

PERIODIC MAINTENANCE

REAR SUSPENSION ASSEMBLY

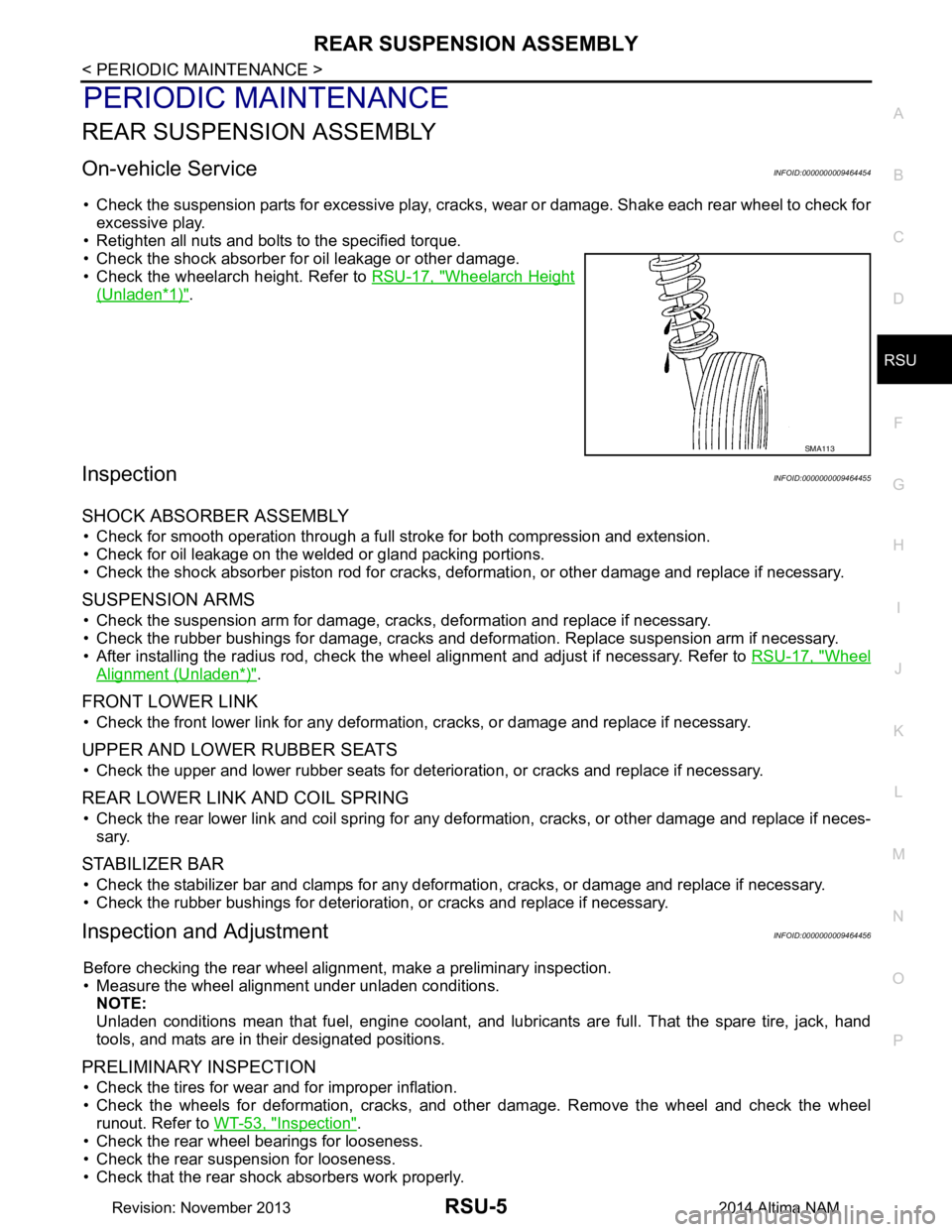

On-vehicle ServiceINFOID:0000000009464454

• Check the suspension parts for excessive play, cracks, wear or damage. Shake each rear wheel to check for

excessive play.

• Retighten all nuts and bolts to the specified torque.

• Check the shock absorber for oil leakage or other damage.

• Check the wheelarch height. Refer to RSU-17, "Wheelarch Height

(Unladen*1)".

InspectionINFOID:0000000009464455

SHOCK ABSORBER ASSEMBLY

• Check for smooth operation through a full stroke for both compression and extension.

• Check for oil leakage on the welded or gland packing portions.

• Check the shock absorber piston r od for cracks, deformation, or other damage and replace if necessary.

SUSPENSION ARMS

• Check the suspension arm for damage, cracks, deformation and replace if necessary.

• Check the rubber bushings for damage, cracks and defo rmation. Replace suspension arm if necessary.

• After installing the radius rod, check the wheel alignment and adjust if necessary. Refer to RSU-17, "Wheel

Alignment (Unladen*)".

FRONT LOWER LINK

• Check the front lower link for any deformation, cracks, or damage and replace if necessary.

UPPER AND LOWER RUBBER SEATS

• Check the upper and lower rubber seats for deterioration, or cracks and replace if necessary.

REAR LOWER LINK AND COIL SPRING

• Check the rear lower link and coil spring for any def ormation, cracks, or other damage and replace if neces-

sary.

STABILIZER BAR

• Check the stabilizer bar and clamps for any deformation, cracks, or damage and replace if necessary.

• Check the rubber bushings for deterioration, or cracks and replace if necessary.

Inspection and AdjustmentINFOID:0000000009464456

Before checking the rear wheel ali gnment, make a preliminary inspection.

• Measure the wheel alignment under unladen conditions. NOTE:

Unladen conditions mean that fuel, engine coolant, and l ubricants are full. That the spare tire, jack, hand

tools, and mats are in their designated positions.

PRELIMINARY INSPECTION

• Check the tires for wear and for improper inflation.

• Check the wheels for deformation, cracks, and ot her damage. Remove the wheel and check the wheel

runout. Refer to WT-53, "Inspection"

.

• Check the rear wheel bearings for looseness.

• Check the rear suspension for looseness.

• Check that the rear shock absorbers work properly.

SMA113

Revision: November 20132014 Altima NAM

Page 3724 of 4801

REAR SUSPENSION ASSEMBLYRSU-7

< PERIODIC MAINTENANCE >

C

D

F

G H

I

J

K L

M A

B

RSU

N

O P

NOTE:

• Camber changes about 0 ° 5’ (0.08 °) with each graduation of the adjusting bolt.

• Turn the adjusting bolts in the same direction to calibrate camber.

• Toe changes about 1.5 mm (0.059 in) [one side] with each graduation of the adjusting bolt.

• Turn the adjusting bolts in the opposite direction to calibrate toe.

4. Tighten the adjusting bolt nuts to the specified torque. Camber : Refer to

RSU-17, "Wheel Alignment (Unlad-

en*)".

Total toe-in : Refer to RSU-17, "Wheel Alignment (Unlad-

en*)".

Adjusting bolt nuts : Refer to RSU-8, "Exploded View"

.

Revision: November 20132014 Altima NAM

Page 3964 of 4801

SR-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000009951759

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISS AN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

ServiceINFOID:0000000009463063

• Do not use electrical test equipment to check SRS ci rcuits unless instructed to in this Service Manual.

• Before servicing the SRS, turn ignition switch OFF, disconnect both battery cables and wait at least three

minutes.

For approximately three minutes after the cables are remo ved, it is still possible for the air bag and seat belt

pre-tensioner to deploy. Therefore, do not work on any SRS connectors or wires until at least three minutes

have passed.

• Diagnosis sensor unit must always be installed with their arrow marks “ ⇐” pointing towards the front of the

vehicle for proper operation. Also chec k diagnosis sensor unit for cracks, deformities or rust before installa-

tion and replace as required.

• The spiral cable must be aligned with the neutral position since its rotations are limited. Do not turn steering

wheel and column after removal of steering gear.

• Handle air bag module carefully. Always place driver and front passenger air bag modules with the pad side facing upward and seat mounted front side air bag m odule standing with the stud bolt side facing down.

• Conduct self-diagnosis to check entire SRS for proper function after replacing any components.

• After air bag inflates, the instrument panel assembly should be replaced if damaged.

• Always replace instrument panel pad following front passenger air bag deployment.

Precaution for WorkINFOID:0000000009463065

• When removing or disassembling each component, be careful not to damage or deform it. If a component may be subject to interference, be sure to protect it with a shop cloth.

• When removing (disengaging) components with a screwdriver or similar tool, be sure to wrap the component with a shop cloth or vinyl tape to protect it.

• Protect the removed parts with a s hop cloth and prevent them from being dropped.

• Replace a deformed or damaged clip.

• If a part is specified as a non-reusable part, always replace it with a new one.

• Be sure to tighten bolts and nuts securely to the specified torque.

• After installation is complete, be sure to check that each part works properly.

Revision: November 20132014 Altima NAM