DISPLAY UNIT NISSAN TEANA 2014 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 4179 of 4801

STC-28

< DTC/CIRCUIT DIAGNOSIS >

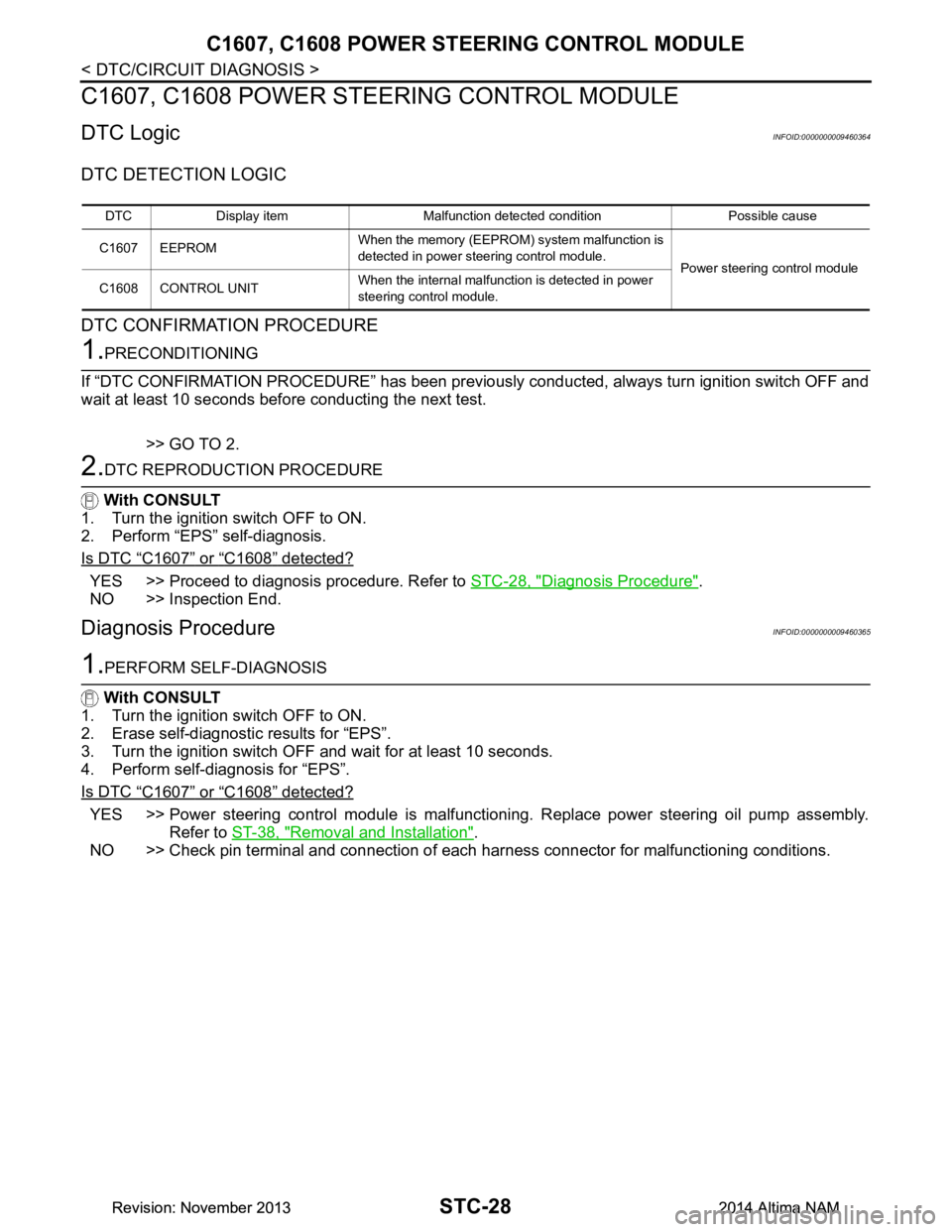

C1607, C1608 POWER STEERING CONTROL MODULE

C1607, C1608 POWER STEERING CONTROL MODULE

DTC LogicINFOID:0000000009460364

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn ignition switch OFF and

wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.DTC REPRODUCTION PROCEDURE

With CONSULT

1. Turn the ignition switch OFF to ON.

2. Perform “EPS” self-diagnosis.

Is DTC

“C1607” or “C1608” detected?

YES >> Proceed to diagnosis procedure. Refer to STC-28, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis ProcedureINFOID:0000000009460365

1.PERFORM SELF-DIAGNOSIS

With CONSULT

1. Turn the ignition switch OFF to ON.

2. Erase self-diagnostic results for “EPS”.

3. Turn the ignition switch OFF and wait for at least 10 seconds.

4. Perform self-diagnosis for “EPS”.

Is DTC

“C1607” or “C1608” detected?

YES >> Power steering control module is malfunctioni ng. Replace power steering oil pump assembly.

Refer to ST-38, "Removal and Installation"

.

NO >> Check pin terminal and connection of each harness connector for malfunctioning conditions.

DTC Display item Malfunction detected condition Possible cause

C1607 EEPROM When the memo

ry (EEPROM) system malfunction is

detected in power steering control module. Power steering control module

C1608 CONTROL UNIT When the internal malfunction is detected in power

steering control module.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4181 of 4801

STC-30

< DTC/CIRCUIT DIAGNOSIS >

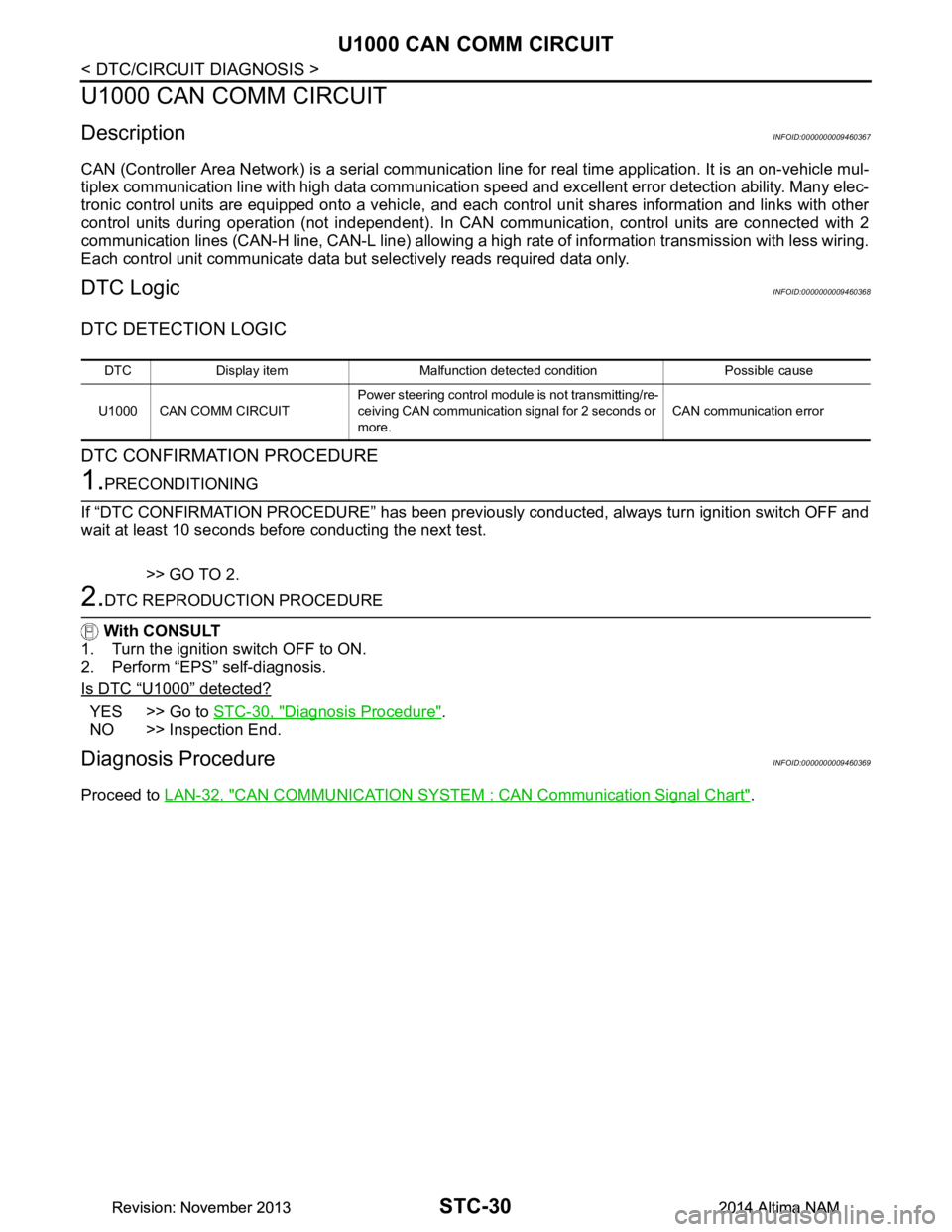

U1000 CAN COMM CIRCUIT

U1000 CAN COMM CIRCUIT

DescriptionINFOID:0000000009460367

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication s peed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CA N communication, control units are connected with 2

communication lines (CAN-H line, CAN-L line) allowing a high rate of information transmission with less wiring.

Each control unit communicate data but selectively reads required data only.

DTC LogicINFOID:0000000009460368

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn ignition switch OFF and

wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.DTC REPRODUCTION PROCEDURE

With CONSULT

1. Turn the ignition switch OFF to ON.

2. Perform “EPS” self-diagnosis.

Is DTC

“U1000” detected?

YES >> Go to STC-30, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis ProcedureINFOID:0000000009460369

Proceed to LAN-32, "CAN COMMUNICATION SYSTEM : CAN Communication Signal Chart".

DTC Display item Malfunction detected condition Possible cause

U1000 CAN COMM CIRCUIT Power steering control module is not transmitting/re-

ceiving CAN communication signal for 2 seconds or

more. CAN communication error

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4185 of 4801

STC-34

< SYMPTOM DIAGNOSIS >

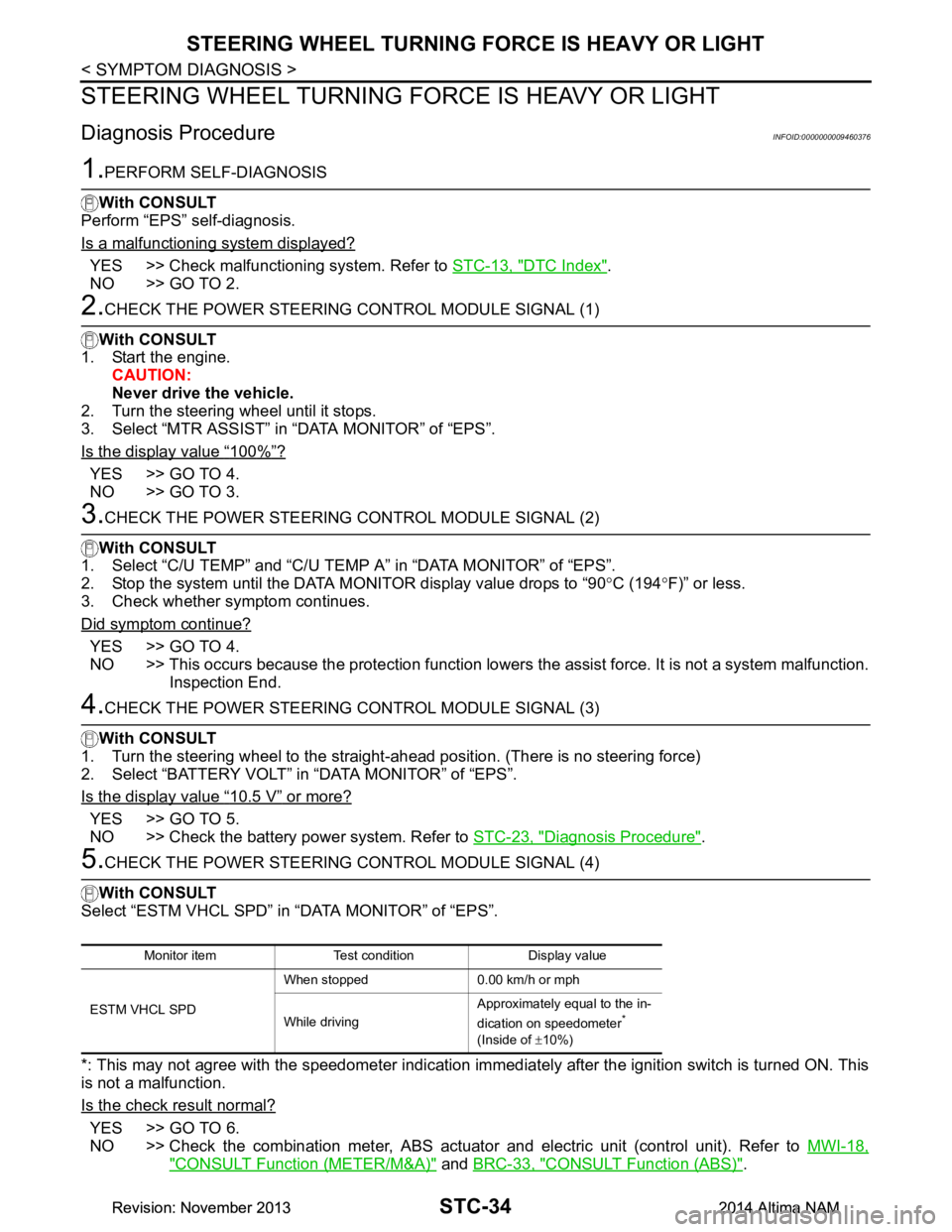

STEERING WHEEL TURNING FORCE IS HEAVY OR LIGHT

STEERING WHEEL TURNING FORCE IS HEAVY OR LIGHT

Diagnosis ProcedureINFOID:0000000009460376

1.PERFORM SELF-DIAGNOSIS

With CONSULT

Perform “EPS” self-diagnosis.

Is a malfunctioning system displayed?

YES >> Check malfunctioning system. Refer to STC-13, "DTC Index".

NO >> GO TO 2.

2.CHECK THE POWER STEERING CONTROL MODULE SIGNAL (1)

With CONSULT

1. Start the engine. CAUTION:

Never drive the vehicle.

2. Turn the steering wheel until it stops.

3. Select “MTR ASSIST” in “DATA MONITOR” of “EPS”.

Is the display value

“100%”?

YES >> GO TO 4.

NO >> GO TO 3.

3.CHECK THE POWER STEERING CONTROL MODULE SIGNAL (2)

With CONSULT

1. Select “C/U TEMP” and “C/U TEMP A” in “DATA MONITOR” of “EPS”.

2. Stop the system until the DATA MONITOR display value drops to “90 °C (194 °F)” or less.

3. Check whether symptom continues.

Did symptom continue?

YES >> GO TO 4.

NO >> This occurs because the protection function lowers the assist force. It is not a system malfunction.

Inspection End.

4.CHECK THE POWER STEERING CONTROL MODULE SIGNAL (3)

With CONSULT

1. Turn the steering wheel to the straight -ahead position. (There is no steering force)

2. Select “BATTERY VOLT” in “DATA MONITOR” of “EPS”.

Is the display value

“10.5 V” or more?

YES >> GO TO 5.

NO >> Check the battery power system. Refer to STC-23, "Diagnosis Procedure"

.

5.CHECK THE POWER STEERING CONTROL MODULE SIGNAL (4)

With CONSULT

Select “ESTM VHCL SPD” in “DATA MONITOR” of “EPS”.

*: This may not agree with the speedometer indication imm ediately after the ignition switch is turned ON. This

is not a malfunction.

Is the check result normal?

YES >> GO TO 6.

NO >> Check the combination meter, ABS actuator and electric unit (control unit). Refer to MWI-18,

"CONSULT Function (METER/M&A)" and BRC-33, "CONSULT Function (ABS)".

Monitor item Test condition Display value

ESTM VHCL SPD When stopped 0.00 km/h or mph

While driving Approximately equal to the in-

dication on speedometer

*

(Inside of ±10%)

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4189 of 4801

STC-38

< SYMPTOM DIAGNOSIS >

UNBALANCE STEERING WHEEL TURNING FORCE (TORQUE VARIATION)

NO >> Check the combination meter, ABS actuator and electric unit (control unit). Refer to MWI-18,

"CONSULT Function (METER/M&A)" and BRC-33, "CONSULT Function (ABS)".

6.CHECK THE POWER STEERING CONTROL MODULE SIGNAL (5)

With CONSULT

Select “STR ANG SPD” in “DATA MONITOR” of “EPS”.

Is the check result normal?

YES >> GO TO 7.

NO >> Check the steering angle sensor. Refer to STC-22, "Diagnosis Procedure"

.

7.CHECK THE POWER STEERING CONTROL MODULE SIGNAL (6)

With CONSULT

Select “ENGINE STATUS” in “DATA MONITOR” of “EPS”.

Is the display value

“RUN”?

YES >> GO TO 8.

NO >> Check the ECM. Refer to EC-77, "CONSULT Function"

.

8.CHECK STEERING COLUMN AND STEERING GEAR

Check the steering column assembly and steering gear assembly.

• Steering column assembly. Refer to ST-46, "Steering Column"

.

• Steering gear assembly. Refer to ST-47, "Power Steering Gear"

.

Is the inspection result normal?

YES >> GO TO 9.

NO >> Repair or replace malfunctioning component.

9.CHECK STEERING WHEEL TURNING FORCE

Check the steering wheel turning force. Refer to STC-34, "Diagnosis Procedure"

.

Is the inspection result normal?

YES >> Inspection End.

NO >> Check the steering wheel turning force for mechanical malfunction. Refer to STC-34, "Diagnosis

Procedure".

Monitor item Test condition Display value

STR ANG SPD The steering wheel is not turn-

ing. Approx. 0.0 deg/s

The steering wheel is being

turned. Displays steering angle speed

(deg/s)

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4259 of 4801

![NISSAN TEANA 2014 Service Manual

TM-44

< SYSTEM DESCRIPTION >[CVT: RE0F10D]

DIAGNOSIS SYSTEM (TCM)

SELF DIAGNOSTIC RESULTS

Display Item List

Refer to

TM-60, "DTC Index".

DTC at 1st trip and method to read DTC

• DTC (P0705, P0711 NISSAN TEANA 2014 Service Manual

TM-44

< SYSTEM DESCRIPTION >[CVT: RE0F10D]

DIAGNOSIS SYSTEM (TCM)

SELF DIAGNOSTIC RESULTS

Display Item List

Refer to

TM-60, "DTC Index".

DTC at 1st trip and method to read DTC

• DTC (P0705, P0711](/img/5/57390/w960_57390-4258.png)

TM-44

< SYSTEM DESCRIPTION >[CVT: RE0F10D]

DIAGNOSIS SYSTEM (TCM)

SELF DIAGNOSTIC RESULTS

Display Item List

Refer to

TM-60, "DTC Index".

DTC at 1st trip and method to read DTC

• DTC (P0705, P0711, P0720, etc.) is specified by SAE J2012/ISO 15031-6.

• DTC and DTC at 1st trip are displayed on “Self Diagnostic results” of CONSULT.

When DTC is currently detected, “CRNT” is displayed. If “PAST” is displayed, it shows a malfunction

occurred in the past. The trip number of drive wit hout malfunction of concerned DTC can be confirmed with

“IGN counter” inside “FFD”.

• When the DTC at the 1st trip is detected, “1t” is displayed.

DTC deletion method

NOTE:

If the ignition switch is left ON after repair, turn O FF the ignition switch and wait for 10 seconds or more. Then,

turn the ignition ON again. (Engine stop)

1. Touch “TRANSMISSION” of CONSULT.

2. Touch “Self Diagnostic Result”.

3. Touch “Erase”. (DTC memorized in TCM is erased.)

IGN counter

The ignition counter is displayed in “FFD” and the number of times of satisfied “Driving condition A” is dis-

played after normal recovery of DTC. Refer to TM-41, "DIAGNOSIS DESCRIPTION : Counter System"

.

• If malfunction (DTC) is currently detected, “0” is displayed.

• After normal recovery, every time “Driving condition A” is satisfied, the display value increases from 1 → 2 →

3...38 → 39.

• When MIL turns OFF due to the malfunction and t he counter reaches 40, the DTC is erased.

NOTE:

The counter display of “40” cannot be checked.

DATA MONITOR

NOTE:

The following table includes information (items) inapplicable to this vehicle. For information (items) applicable

to this vehicle, refer to CONSULT display items.

× : Application : Optional selection

Conditions Function

Work Support The settings for ECU functions can be changed.

Self Diagnostic Results The ECU self diagnostic results are displayed.

Data Monitor The ECU input/output data is displayed in real time.

CAN Diagnosis Support Monitor The result of transmit/receive diagnosis of CAN communication is displayed.

Active Test The ECU activates outputs to test components.

ECU Identification The ECU part number is displayed.

CALIB DATA The calibration data status of TCM can be checked.

Monitored item (Unit) Monitor item selection

Remarks

ECU IN-

PUT SIG-

NALS MAIN SIG-

NALS

VSP SENSOR (km/h or mph) ×Displays the vehicle speed calculated from the CVT out-

put shaft speed.

ESTM VSP SIG (km/h or mph) ו Displays the vehi

cle speed signal (ABS) received

through CAN communication.

• Models with ABS are displayed.

INPUT SPEED SENSOR (rpm) ×Displays the input speed calculated from the pulse signal

of the input speed sensor.

PRI SPEED SEN (rpm) ×Displays the primary pulley speed calculated from the

pulse signal of the primary speed sensor.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4260 of 4801

![NISSAN TEANA 2014 Service Manual

DIAGNOSIS SYSTEM (TCM)TM-45

< SYSTEM DESCRIPTION > [CVT: RE0F10D]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

SEC REV SENSOR (rpm) ×Displays the secondary pulley speed calculated from the

pulse signal of the NISSAN TEANA 2014 Service Manual

DIAGNOSIS SYSTEM (TCM)TM-45

< SYSTEM DESCRIPTION > [CVT: RE0F10D]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

SEC REV SENSOR (rpm) ×Displays the secondary pulley speed calculated from the

pulse signal of the](/img/5/57390/w960_57390-4259.png)

DIAGNOSIS SYSTEM (TCM)TM-45

< SYSTEM DESCRIPTION > [CVT: RE0F10D]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

SEC REV SENSOR (rpm) ×Displays the secondary pulley speed calculated from the

pulse signal of the output speed sensor.

ENG SPEED SIG (rpm) ×Displays the engine speed received through CAN com-

munication.

SEC PRESSURE SEN (V) ×Displays the signal voltage of the secondary pressure-

sensor.

PRI PRESSURE SEN (V) ×Displays the signal voltage of the primary pressuresen-

sor.

ATF TEMP SEN (V) ×Displays the signal voltage of the CVT fluid temperature

sensor.

G SENSOR* (G) ×Displays the signal voltage of the G sensor.

VIGN SEN (V) ×Displays the battery voltage applied to TCM.

PVING VOLT (V) ×Displays the backup voltage of TCM.

VEHICLE SPEED (km/h or mph) ×Displays the vehicle speed recognized by TCM.

INPUT REV (rpm) Displays the input shaft speed of CVT recognized by

TCM.

PRI SPEED (rpm) ×Displays the primary pulley speed recognized by TCM.

SEC SPEED (rpm) Displays the secondary pulley speed recognized by

TCM.

ENG SPEED (rpm) ×Displays the engine speed recognized by TCM.

SLIP REV (rpm) ×Displays the speed difference between the input shaft

speed of CVT and the engine speed.

PULLEY GEAR RATIO ×Displays the pulley gear ratio calculated from primary

pulley speed/secondary pulley speed.

G SPEED* (G) Displays the acceleration and deceleration speed of the

vehicle calculated from vehicle speed change.

ACCEL POSI SEN 1 (deg) ××Displays the estimated throttle position received through

CAN communication.

VENG TRQ (Nm) ×Display the engine torque recognized by TCM.

PRI TRQ (Nm) Display the input shaft torque of CVT.

TRQ RTO Display the torque ratio of torque converter.

SEC PRESSURE (MPa) Displays the secondary pressure calculated from the sig-

nal voltage of the secondary pressure sensor.

PRI PRESSURE (MPa) Displays the primary pressure calculated from the signal

voltage of the primary pressure sensor.

FLUID TEMP ( °C or °F) ×Displays the CVT fluid temperature calculated from the

signal voltage of the CVT fluid temperature sensor.

DSR REV (rpm) Displays the target primary pulley speed calculated from

processing of gear shift control.

TGT PLLY GR RATIO Displays the target gear ratio of the pulley from process-

ing of gear shift control.

LU PRS (MPa) Displays the target oil pressure of the torque converter

clutch solenoid valve calculated from oil pressure pro-

cessing of gear shift control.

LINE PRS (MPa) Displays the target oil pressure of the line pressure sole-

noid valve calculated from oil pressure processing of

gear shift control.

Monitored item (Unit)

Monitor item selection

Remarks

ECU IN-

PUT SIG-

NALS MAIN SIG-

NALS

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4261 of 4801

![NISSAN TEANA 2014 Service Manual

TM-46

< SYSTEM DESCRIPTION >[CVT: RE0F10D]

DIAGNOSIS SYSTEM (TCM)

TRGT PRI PRESSURE (MPa)Displays the target oil pressure of the primary pressure

solenoid valve calculated from oil pressure process NISSAN TEANA 2014 Service Manual

TM-46

< SYSTEM DESCRIPTION >[CVT: RE0F10D]

DIAGNOSIS SYSTEM (TCM)

TRGT PRI PRESSURE (MPa)Displays the target oil pressure of the primary pressure

solenoid valve calculated from oil pressure process](/img/5/57390/w960_57390-4260.png)

TM-46

< SYSTEM DESCRIPTION >[CVT: RE0F10D]

DIAGNOSIS SYSTEM (TCM)

TRGT PRI PRESSURE (MPa)Displays the target oil pressure of the primary pressure

solenoid valve calculated from oil pressure processing of

gear shift control.

TRGT SELECT PRESSURE (MPa) Displays the target oil pressure of the select solenoid

valve calculated from oil pressure processing of gear

shift control.

TRGT SEC PRESSURE (MPa) Displays the target oil pressure of the secondary pres-

sure solenoid valve calculated from oil pressure process-

ing of gear shift control.

ISOLT1 (A) ×Displays the command current from TCM to the torque

converter clutch solenoid valve.

ISOLT2 (A) ×Displays the command current from TCM to the line

pressure solenoid valve.

PRI SOLENOID (A) ×Displays the command current from TCM to the primary

pressure solenoid valve.

SEC SOLENOID CURRENT (A) ×Displays the command current from TCM to the second-

ary pressure solenoid valve.

SELECT SOLENOID CUR-

RENT (A)

×Displays the command current from TCM to the select

solenoid valve.

SOLMON1 (A) ××Monitors the command current from TCM to the torque

converter clutch solenoid valve and displays the moni-

tored value.

SOLMON2 (A) ××Monitors the command current from TCM to the line

pressure solenoid valve and displays the monitored val-

ue.

PRI SOL MON (A) ××Monitors the command current from TCM to the primary

pressure solenoid valve and displays the monitored val-

ue.

SEC SOL MON CURRENT (A) ××Monitors the command current from TCM to the second-

ary pressure solenoid valve and displays the monitored

value.

SELECT SOL MON CURRENT (A) ××Monitors the command current from TCM to the select

solenoid valve and displays the monitored value.

D POSITION SW (On/Off) ×Displays the operation status of the transmission range

switch (D position).

N POSITION SW (On/Off) ×Displays the operation status of the transmission range

switch (N position).

R POSITION SW (On/Off) ×Displays the operation status of the transmission range

switch (R position).

P POSITION SW (On/Off) ×Displays the operation status of the transmission range

switch (P position).

L POSITION SW* (On/Off) ×Displays the operation status of the transmission range

switch (L position).

DS RANGE SW (On/Off) ×Displays the operation status of the transmission range

switch (Ds position).

BRAKESW (On/Off) ××Displays the reception status of the stop lamp switch sig-

nal received through CAN communication.

IDLE SW (On/Off) ××Displays the reception status of the closed throttle posi-

tion signal received through CAN communication.

SPORT MODE SW (On/Off) ××Displays the reception status of the overdrive control

switch signal received through CAN communication.

Monitored item (Unit)

Monitor item selection

Remarks

ECU IN-

PUT SIG-

NALS MAIN SIG-

NALS

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4262 of 4801

![NISSAN TEANA 2014 Service Manual

DIAGNOSIS SYSTEM (TCM)TM-47

< SYSTEM DESCRIPTION > [CVT: RE0F10D]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

ECO MODE SW* (On/Off) ××Displays the reception status of the ECO mode switch

signal received thr NISSAN TEANA 2014 Service Manual

DIAGNOSIS SYSTEM (TCM)TM-47

< SYSTEM DESCRIPTION > [CVT: RE0F10D]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

ECO MODE SW* (On/Off) ××Displays the reception status of the ECO mode switch

signal received thr](/img/5/57390/w960_57390-4261.png)

DIAGNOSIS SYSTEM (TCM)TM-47

< SYSTEM DESCRIPTION > [CVT: RE0F10D]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

ECO MODE SW* (On/Off) ××Displays the reception status of the ECO mode switch

signal received through CAN communication.

STRDWNSW* (On/Off) ×Displays the operation status of the paddle shifter (down

switch).

STRUPSW* (On/Off) ×Displays the operation status of the paddle shifter (up

switch).

DOWNLVR* (On/Off) ×Displays the operation status of the selector lever (down

switch).

UPLVR* (On/Off) ×Displays the operation status of the selector lever (up

switch).

NONMMODE* (On/Off) ×Displays if the selector lever position is not at the manual

shift gate.

MMODE* (On/Off) ×Displays if the selector lever position is at the manual

shift gate.

TOW MODE SW* (On/Off) ×Displays the reception status of the TOW mode switch

signal received through CAN communication.

SHIFT IND SIGNAL Displays the transaxle value of shift position signal trans-

mitted via CAN communication.

CVT LAMP* (On/Off) Displays the transaxle status of the CVT warning lamp

signal transmitted through CAN communication.

SPORT MODE IND (On/Off) Displays the transaxle status of the O/D OFF indicator

lamp signal transmitted through CAN communication.

MANU MODE SIGNAL* (On/Off) Displays the transaxle status of the manual mode signal

transmitted through CAN communication.

DS RANGE SIGNAL (On/Off) Displays the shift position signal status from transmis-

sion range switch (DS position).

ECO MODE SIGNAL* (On/Off) Displays the transaxle status of the ECO mode signal

transmitted through CAN communication.

VDC ON (On/Off) ×Displays the reception status of the VDC operation signal

received through CAN communication.

TCS ON (On/Off) ×Displays the reception status of the TCS operation signal

received through CAN communication.

ABS FAIL SIGNAL (On/Off) ×Displays the reception status of the ABS malfunction sig-

nal received through CAN communication.

ABS ON (On/Off) ×Displays the reception status of the ABS operation signal

received through CAN communication.

RANGE ×Displays the gear position recognized by TCM.

M GEAR POS* ×Display the target gear of manual mode

G SEN SLOPE* (%) Displays the gradient angle calculated from the G sensor

signal voltage.

G SEN CALIBRATION* (YET/DONE) Displays the status of “G

SENSOR CALIBRATION” in

“Work Support”.

N IDLE STATUS* (On/Off) Displays idle neutral status.

ENGBRKLVL (On/Off) Displays the

setting of “ENGINE BRAKE ADJ” in “Work

Support”.

DRIVE MODE STATS* Displays the drive mode status recognized by TCM.

SNOW MODE* (On/Off) Displays whether it is the SNOW mode.

ECO MODE* (On/Off) Displays whether it is the ECO mode. Monitored item (Unit)

Monitor item selection

Remarks

ECU IN-

PUT SIG-

NALS MAIN SIG-

NALS

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4263 of 4801

![NISSAN TEANA 2014 Service Manual

TM-48

< SYSTEM DESCRIPTION >[CVT: RE0F10D]

DIAGNOSIS SYSTEM (TCM)

*: Not applicable but displayed.

WORK SUPPORT

Engine brake adjustment

Check the degradation level of the CVT fluid.

ACTIVE TEST

NORM NISSAN TEANA 2014 Service Manual

TM-48

< SYSTEM DESCRIPTION >[CVT: RE0F10D]

DIAGNOSIS SYSTEM (TCM)

*: Not applicable but displayed.

WORK SUPPORT

Engine brake adjustment

Check the degradation level of the CVT fluid.

ACTIVE TEST

NORM](/img/5/57390/w960_57390-4262.png)

TM-48

< SYSTEM DESCRIPTION >[CVT: RE0F10D]

DIAGNOSIS SYSTEM (TCM)

*: Not applicable but displayed.

WORK SUPPORT

Engine brake adjustment

Check the degradation level of the CVT fluid.

ACTIVE TEST

NORMAL MODE* (On/Off) D

isplays whether it is the NORMAL mode.

SPORT MODE* (On/Off) Displays whether it is the SPORT mode.

AIR BLDING STATE* (INCOMP/

COMP) Displays the status of “E

LECTRIC O.P. AIR BLEEDING”

in “Work Support”.

ELECTRIC OP DUTY* (%) Displays the command signal value (duty) of the electric

oil pump transmitted from TCM.

E-OP DUTY MON* (%) Monitors the status signal value (duty) transmitted from

the electric oil pump and displays the monitored value.

ELECTRIC OP RELAY* (On/Off) Displays the command status from TCM to the electric oil

pump relay.

E-OP RELAY MON* (On/Off) Monitors the command status from TCM to the oil pump

relay and displays the monitored value.

Monitored item (Unit)

Monitor item selection

Remarks

ECU IN-

PUT SIG-

NALS MAIN SIG-

NALS

Item name Description

CONFORM CVTF DETERIORTN Checks the degradation level of the CVT fluid under severe conditions.

ERASE MEMORY DATA Performs “erasing of the calibration data” and “erasing of the learned value” at the

same time.

G SENSOR CALIBRATION Compensates the G sensor.

ERASE LEARNING VALUE Erases lear ning value memorized by TCM.

ENGINE BRAKE ADJ. Although there is no malfunction on the transaxle and the CVT system, if a cus-

tomer make a complaint like “I do not feel comfortable with automatic operation of

the engine brake on downhill”, the engine brake may be cancelled with “engine

brake adjustment”.

ERASE CALIBRATION DATA Erases cali bration data memorized by TCM.

WRITE IP CHARA - REPLACEMENT AT/CVT Writes IP characteristics when transaxle assembly is replaced.

READ IP CHARA - REPLACEMENT TCM Reads IP characteristics when TCM is replaced.

WRITE IP CHARA - REPLACEMENT TCM Writes IP characteristics when TCM is replaced.

ENGINE BRAKE LEVEL

ON : Turn ON the engine brake control.

OFF : Turn OFF the engine brake control.

CVTF degradation level data

210,000 or more : Replacement of the CVT fluid is required.

Less than 210,000 : Replacement of the CVT fluid is not required.

Item name Description

CVT OIL COOLER FAN CIRCUIT Checks the operation of CVT oil cooler fan relay.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4264 of 4801

![NISSAN TEANA 2014 Service Manual

TCM

TM-49

< ECU DIAGNOSIS INFORMATION > [CVT: RE0F10D]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

ECU DIAGNOSIS INFORMATION

TCM

Reference ValueINFOID:0000000009464001

CONSULT DATA MONITOR STANDARD VALUE

• In NISSAN TEANA 2014 Service Manual

TCM

TM-49

< ECU DIAGNOSIS INFORMATION > [CVT: RE0F10D]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

ECU DIAGNOSIS INFORMATION

TCM

Reference ValueINFOID:0000000009464001

CONSULT DATA MONITOR STANDARD VALUE

• In](/img/5/57390/w960_57390-4263.png)

TCM

TM-49

< ECU DIAGNOSIS INFORMATION > [CVT: RE0F10D]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

ECU DIAGNOSIS INFORMATION

TCM

Reference ValueINFOID:0000000009464001

CONSULT DATA MONITOR STANDARD VALUE

• In CONSULT, electric shift timing or lock-up timing, i. e. operation timing of each solenoid valve, is displayed.

Therefore, if there is an obvious difference between t he shift timing estimated from a shift shock (or engine

speed variations) and that shown on the CONSULT, the mechanism parts (including the hydraulic circuit)

excluding the solenoids and sensors may be malfunctioning. In this case, check the mechanical parts follow-

ing the appropriate diagnosis procedure.

• Shift point (gear position) displayed on CONSULT slight ly differs from shift pattern described in Service Man-

ual. This is due to the following reasons.

- Actual shift pattern may vary slightly within specified tolerances.

- While shift pattern described in Service Manual indica tes start of each shift, CONSULT shows gear position

at end of shift.

- The solenoid display (ON/OFF) on CONSULT is changed at the start of gear shifting. In contrast, the gear

position display is changed at the time when gear shif ting calculated in the control unit is completed.

NOTE:

The following table includes information (items) inapplicable to this vehicle. For information (items) applicable

to this vehicle, refer to CONSULT display items.

Monitor item Condition Value/Status (Approx.)

VSP SENSOR While driving Almost same as the speedometer display.

ESTM VSP SIG While driving Almost same as the speedometer display.

INPUT SPEED SENSOR In driving (lock-up ON) Ap proximately matches the engine speed.

PRI SPEED SEN In driving (lock-up ON) Approximately matches the engine speed.

SEC REV SENSOR While driving VSP SENSOR × 40

ENG SPEED SIG Engine ru nning Almost same reading as tachometer

SEC PRESSURE SEN • After engine warm up

• Selector lever: “N” position

• At idle 1.2 – 1.3 V

PRI PRESSURE SEN • After engine warm up

• Selector lever: “N” position

• At idle 0.70 – 0.85 V

ATF TEMP SEN CVT fluid: Approx. 20

°C (68 °F) 2.01 – 2.05 V

CVT fluid: Approx. 50 °C (122 °F) 1.45 – 1.50 V

CVT fluid: Approx. 80 °C (176 °F) 0.90 – 0.94 V

G SENSOR Vehicle is level 0 V

VIGN SEN Ignition switch: ON 10 – 16 V

PVING VOLT Ignition switch: ON 10 – 16 V

VEHICLE SPEED While driving Almost sa me as the speedometer display.

INPUT REV In driving (lock-up ON) Almost same as the engine speed.

PRI SPEED In driving (lock-up ON) Approximately matches the engine speed.

SEC SPEED While driving VSP SENSOR × 40

ENG SPEED Engine running Almost same reading as tachometer

SLIP REV While driving Engine speed − Input speed

PULLEY GEAR RATIO In driving (forward) 2.70

− 0.38

In driving (reverse) 2.70

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM