stop start NISSAN TEANA 2014 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 4549 of 4801

![NISSAN TEANA 2014 Service Manual

TM-334

< DTC/CIRCUIT DIAGNOSIS >[CVT: RE0F10E]

P0779 PRESSURE CONTROL SOLENOID B

P0779 PRESSURE CONTROL SOLENOID B

DTC LogicINFOID:0000000009464288

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.P NISSAN TEANA 2014 Service Manual

TM-334

< DTC/CIRCUIT DIAGNOSIS >[CVT: RE0F10E]

P0779 PRESSURE CONTROL SOLENOID B

P0779 PRESSURE CONTROL SOLENOID B

DTC LogicINFOID:0000000009464288

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.P](/img/5/57390/w960_57390-4548.png)

TM-334

< DTC/CIRCUIT DIAGNOSIS >[CVT: RE0F10E]

P0779 PRESSURE CONTROL SOLENOID B

P0779 PRESSURE CONTROL SOLENOID B

DTC LogicINFOID:0000000009464288

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, turn ignition switch OFF and wait for at

least 10 seconds, then perform the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

1. Start the engine.

2. Drive the vehicle.

3. Maintain the following conditions for 5 seconds or more.

4. Stop the vehicle.

5. Check the first trip DTC.

Is

“P0779” detected?

YES >> Go to TM-334, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000009464289

1.CHECK CIRCUIT BETWEEN TCM AND CVT UNIT

1. Turn ignition switch OFF.

2. Disconnect TCM connector and CVT unit connector.

3. Check continuity between TCM harness connector terminal and CVT unit harness connector terminal.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace damaged parts.

2.CHECK CIRCUIT BETWEEN CVT UNIT AND GROUND

Check continuity between CVT unit harness connector terminal and ground.

DTC Trouble diagnosis name DTC detection condition Possible causes

P0779 Pressure control solenoid B

Intermittent When all of the following conditions are satis-

fied and this state is maintained for 0.2 sec-

onds:

• TCM power supply voltage: More than 11 V

• P0778 is not detected

• TCM judges that solenoid valve circuit is open or shorted to power supply. • Harness or connector

(Secondary pressure solenoid valve

circuit open or shorted to power supply)

• Secondary pressure solenoid valve

Selector lever : “D” position

Vehicle speed : 40 km/h (25 MPH) or more

TCM CVT unit Continuity

Connector Terminal Connector Terminal

F1639F4612Existed

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4551 of 4801

![NISSAN TEANA 2014 Service Manual

TM-336

< DTC/CIRCUIT DIAGNOSIS >[CVT: RE0F10E]

P0841 TRANSMISSION FLUID

PRESSURE SEN/SW A

P0841 TRANSMISSION FLUID PRESSURE SEN/SW A

DTC LogicINFOID:0000000009464290

DTC DETECTION LOGIC

DTC CONFIRM NISSAN TEANA 2014 Service Manual

TM-336

< DTC/CIRCUIT DIAGNOSIS >[CVT: RE0F10E]

P0841 TRANSMISSION FLUID

PRESSURE SEN/SW A

P0841 TRANSMISSION FLUID PRESSURE SEN/SW A

DTC LogicINFOID:0000000009464290

DTC DETECTION LOGIC

DTC CONFIRM](/img/5/57390/w960_57390-4550.png)

TM-336

< DTC/CIRCUIT DIAGNOSIS >[CVT: RE0F10E]

P0841 TRANSMISSION FLUID

PRESSURE SEN/SW A

P0841 TRANSMISSION FLUID PRESSURE SEN/SW A

DTC LogicINFOID:0000000009464290

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION:

Always drive vehicle at a safe speed.

1.PREPARATION BEFORE WORK

If another “DTC CONFIRMATION PROCEDURE” occurs just before, turn ignition switch OFF and wait for at

least 10 seconds, then perform the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

1. Start the engine.

2. Drive the vehicle.

3. Maintain the following condition for 10 seconds or more.

CAUTION:

Also keep the accelerator pedal position constant.

4. Stop the vehicle.

5. Check the first trip DTC.

Is

“P0841” detected?

YES >> Go to TM-336, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000009464291

1.CHECK INTERMITTENT INCIDENT

Refer to GI-43, "Intermittent Incident"

.

Is the inspection result normal?

YES >> Replace the transaxle assembly. Refer to TM-407, "Removal and Installation".

NO >> Repair or replace damaged parts.

DTC CONSULT screen terms

(Trouble diagnosis content) DTC detection condition Possible cause

P0841 FLUID PRESS SEN/SW A

(Transmission Fluid Pres-

sure Sensor/Switch “A” Cir-

cuit Range/Performance) When all of the following conditions are sat-

isfied and this state is maintained for 5 sec-

onds:

• TCM power supply voltage: More than 11

V

• DTC other than the applicable DTC is not detected.

• Primary pulley speed: 300 rpm or more

• Secondary pulley speed: 250 rpm or more

• Target speed for shifting: Less than 0.1

seconds

• Primary pulley pressure is outside the specified value. • Harness or connectors

(Secondary pressure sensor circuit is

open or shorted.)

• Harness or connectors

(Primary pressure sens or circuit is open

or shorted.)

• Secondary pressure sensor

Selector lever : “D” position

Vehicle speed : Constant speed of 40 km/h (25 MPH)

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4567 of 4801

![NISSAN TEANA 2014 Service Manual

TM-352

< DTC/CIRCUIT DIAGNOSIS >[CVT: RE0F10E]

P0965 PRESSURE CONTROL SOLENOID B

1.PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, turn ignition switch OFF and wa NISSAN TEANA 2014 Service Manual

TM-352

< DTC/CIRCUIT DIAGNOSIS >[CVT: RE0F10E]

P0965 PRESSURE CONTROL SOLENOID B

1.PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, turn ignition switch OFF and wa](/img/5/57390/w960_57390-4566.png)

TM-352

< DTC/CIRCUIT DIAGNOSIS >[CVT: RE0F10E]

P0965 PRESSURE CONTROL SOLENOID B

1.PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, turn ignition switch OFF and wait for at

least 10 seconds, then perform the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

1. Start the engine.

2. Drive the vehicle.

3. Maintain the following conditions for 20 seconds or more.

4. Stop the vehicle.

5. Check the first trip DTC.

Is

“P0965”detected?

YES >> Go to TM-352, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000009464309

1.CHECK INTERMITTENT INCIDENT

Refer to GI-43, "Intermittent Incident"

.

Is the inspection result normal?

YES >> Replace transaxle assembly. Refer to TM-407, "Removal and Installation".

NO >> Repair or replace malfunctioning parts.

Vehicle speed : 40 km/h (25 MPH) or more

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4573 of 4801

![NISSAN TEANA 2014 Service Manual

TM-358

< DTC/CIRCUIT DIAGNOSIS >[CVT: RE0F10E]

P2765 INPUT SPEED SENSOR B

>> GO TO 2.

2.CHECK DTC DETECTION

1. Start the engine.

2. Drive the vehicle.

3. Maintain the following conditions for 10 se NISSAN TEANA 2014 Service Manual

TM-358

< DTC/CIRCUIT DIAGNOSIS >[CVT: RE0F10E]

P2765 INPUT SPEED SENSOR B

>> GO TO 2.

2.CHECK DTC DETECTION

1. Start the engine.

2. Drive the vehicle.

3. Maintain the following conditions for 10 se](/img/5/57390/w960_57390-4572.png)

TM-358

< DTC/CIRCUIT DIAGNOSIS >[CVT: RE0F10E]

P2765 INPUT SPEED SENSOR B

>> GO TO 2.

2.CHECK DTC DETECTION

1. Start the engine.

2. Drive the vehicle.

3. Maintain the following conditions for 10 seconds or more.

4. Stop the vehicle.

5. Check the first trip DTC.

Is

“P2765” detected?

YES >> Go to TM-358, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000009464315

1.CHECK OUTPUT SPEED SENSOR POWER CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect output speed sensor connector.

3. Turn ignition switch ON.

4. Check voltage between output speed sensor harness connector terminal and ground.

Is the inspection result normal?

YES >> GO TO 2.

NO >> GO TO 6.

2.CHECK OUTPUT SPEED SENSOR GROUND CIRCUIT

Check continuity between output speed sensor harness connector terminal and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace malfunctioning parts.

3.CHECK CIRCUIT BETWEEN OUTPUT S PEED SENSOR AND TCM (PART 1)

1. Turn ignition switch OFF.

2. Disconnect TCM connector.

3. Check continuity between output speed sensor harness connector terminal and TCM harness connector

terminal.

Is the inspection result normal?

Selector lever : “D” position

Engine speed : 1,200 rpm or more

Vehicle speed : 55 km/h (34 MPH) or more

+ −Vo l ta g e

Output speed sensor

Connector Terminal F23 3 Ground 10 – 16 V

Output speed sensor —Continuity

Connector Terminal

F23 1 Ground Existed

Output speed sensor TCM Continuity

Connector Terminal Connector Terminal

F23 2 F16 34 Existed

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4590 of 4801

![NISSAN TEANA 2014 Service Manual

CVT CONTROL SYSTEMTM-375

< SYMPTOM DIAGNOSIS > [CVT: RE0F10E]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

Symptom Table 2

Symptom

Torque converter

Transmission range switch

Oil pump

Forward clutch

Reverse br NISSAN TEANA 2014 Service Manual

CVT CONTROL SYSTEMTM-375

< SYMPTOM DIAGNOSIS > [CVT: RE0F10E]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

Symptom Table 2

Symptom

Torque converter

Transmission range switch

Oil pump

Forward clutch

Reverse br](/img/5/57390/w960_57390-4589.png)

CVT CONTROL SYSTEMTM-375

< SYMPTOM DIAGNOSIS > [CVT: RE0F10E]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

Symptom Table 2

Symptom

Torque converter

Transmission range switch

Oil pump

Forward clutch

Reverse brake

Planetary gear

Bearings

Parking mechanism

Stop lamp switch

Shift lock solenoid

CVT shift selector

TM-410

TM-407BR-13TM-369TM-378

Shift Shock

Large shock (N

→ D position) 2 1

Large shock (N → R position) 2 1

Shock is too large for lock-up. 1

Slips/Will

Not Engage Vehicle cannot be started from D

position. 312

Vehicle cannot be started from R

position. 41 2 3

Does not lock-up. 1 3 2

Does not hold lock-up condition. 1 3 2

Lock-up is not released. 1 2

With selector lever in D position,

acceleration is extremely poor. 13 2

With selector lever in R position,

acceleration is extremely poor. 142 3

Slips at lock-up. 1 2

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4746 of 4801

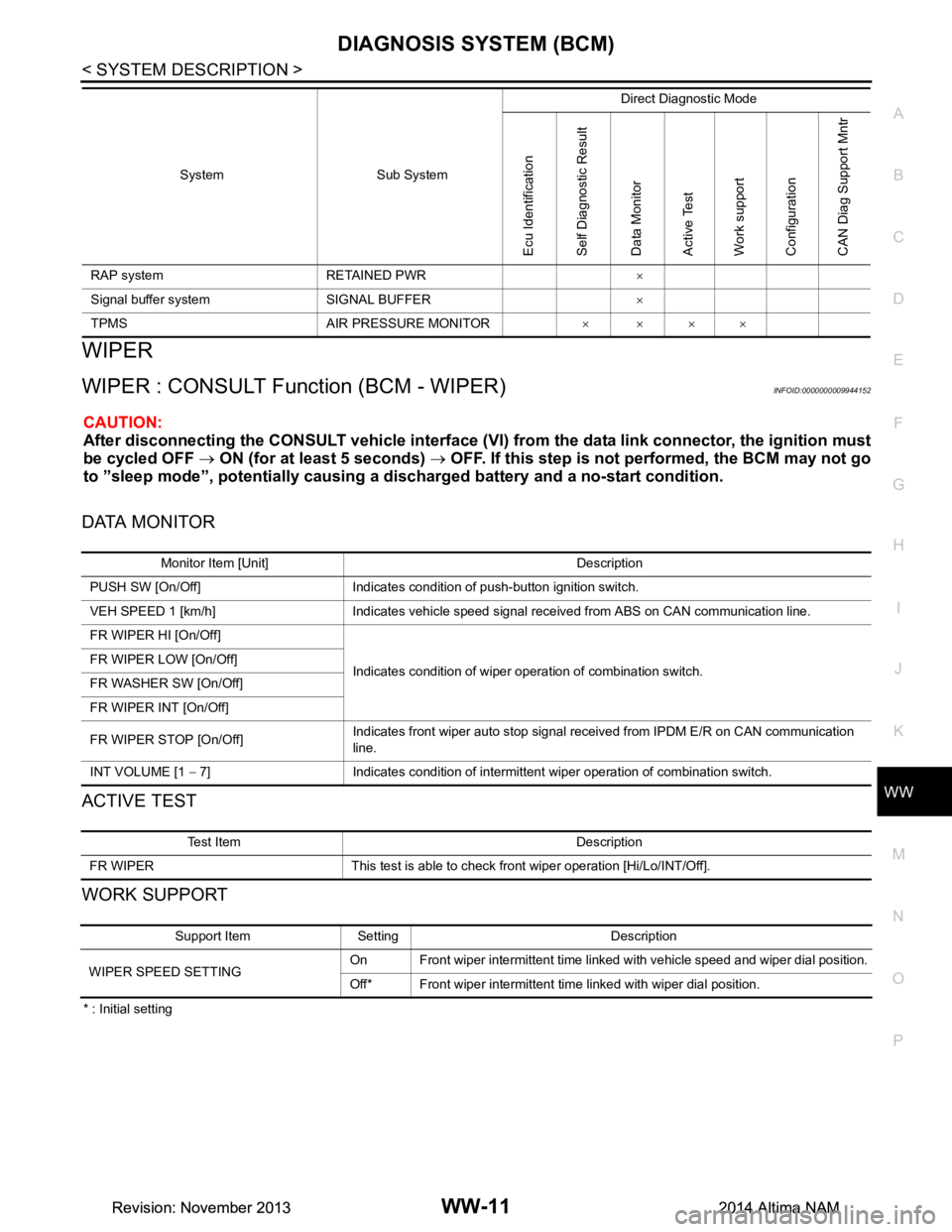

DIAGNOSIS SYSTEM (BCM)WW-11

< SYSTEM DESCRIPTION >

C

D E

F

G H

I

J

K

M A

B

WW

N

O P

WIPER

WIPER : CONSULT Func tion (BCM - WIPER)INFOID:0000000009944152

CAUTION:

After disconnecting the CONSULT vehicle interface (VI) from the data link connector, the ignition must

be cycled OFF → ON (for at least 5 seconds) → OFF. If this step is not performed, the BCM may not go

to ”sleep mode”, potentiall y causing a discharged battery and a no-start condition.

DATA MONITOR

ACTIVE TEST

WORK SUPPORT

* : Initial setting RAP system RETAINED PWR

×

Signal buffer system SIGNAL BUFFER ×

TPMS AIR PRESSURE MONITOR ××××

System Sub System

Direct Diagnostic Mode

Ecu Identification

Self Diagnostic Result

Data Monitor

Active Test

Work support

Configuration

CAN Diag Support Mntr

Monitor Item [Unit] Description

PUSH SW [On/Off] Indicates condition of push-button ignition switch.

VEH SPEED 1 [km/h] Indicates vehicle speed signal received from ABS on CAN communication line.

FR WIPER HI [On/Off]

Indicates condition of wiper operation of combination switch.

FR WIPER LOW [On/Off]

FR WASHER SW [On/Off]

FR WIPER INT [On/Off]

FR WIPER STOP [On/Off] Indicates front wiper auto stop signal received from IPDM E/R on CAN communication

line.

INT VOLUME [1 − 7] Indicates condition of intermittent wiper operation of combination switch.

Test Item Description

FR WIPER This test is able to check front wiper operation [Hi/Lo/INT/Off].

Support Item Setting Description

WIPER SPEED SETTING On Front wiper intermittent time linked with vehicle speed and wiper dial position.

Off* Front wiper intermittent time linked with wiper dial position.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

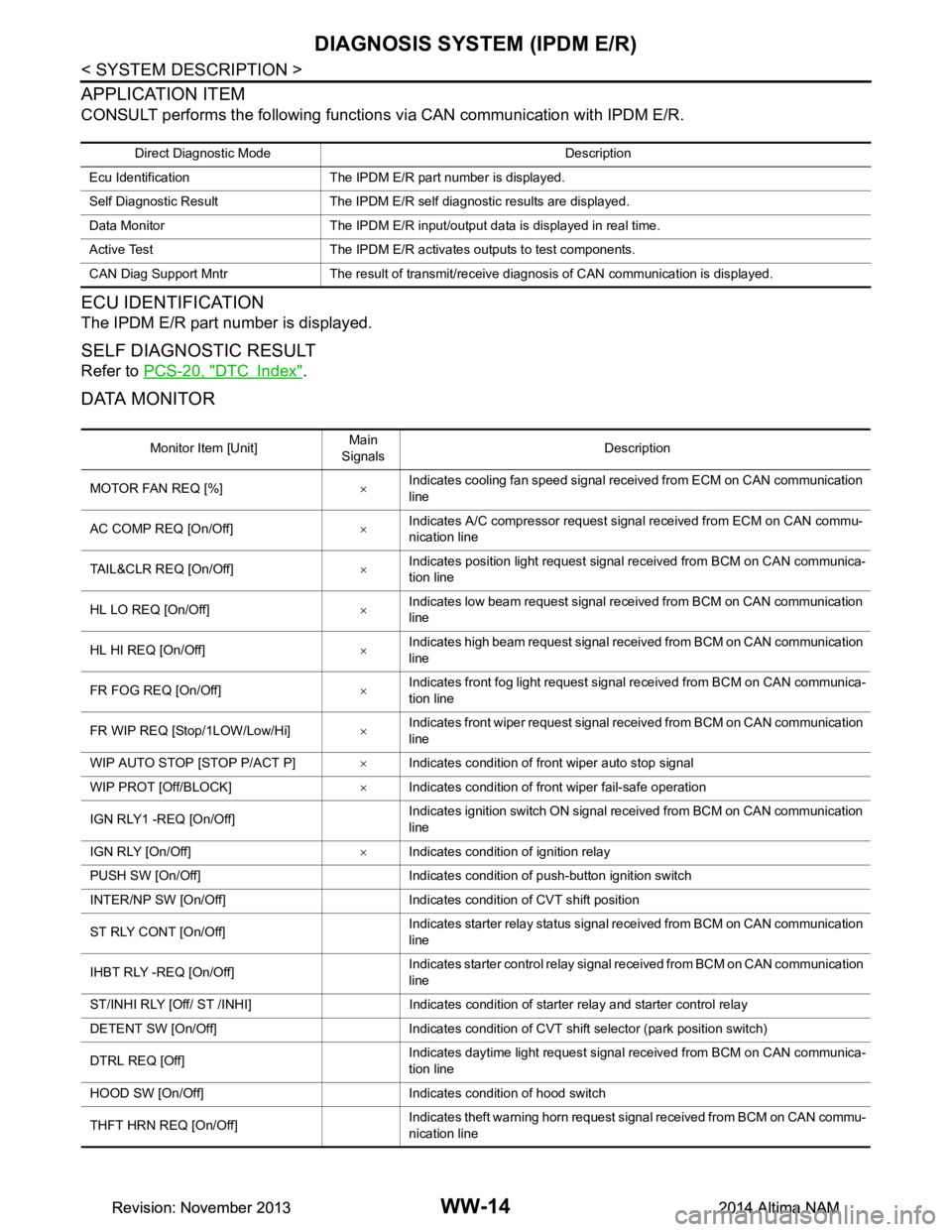

Page 4749 of 4801

WW-14

< SYSTEM DESCRIPTION >

DIAGNOSIS SYSTEM (IPDM E/R)

APPLICATION ITEM

CONSULT performs the following functions via CAN communication with IPDM E/R.

ECU IDENTIFICATION

The IPDM E/R part number is displayed.

SELF DIAGNOSTIC RESULT

Refer to PCS-20, "DTC Index".

DATA MONITOR

Direct Diagnostic Mode Description

Ecu Identification The IPDM E/R part number is displayed.

Self Diagnostic Result The IPDM E/R self diagnostic results are displayed.

Data Monitor The IPDM E/R input/output data is displayed in real time.

Active Test The IPDM E/R activates outputs to test components.

CAN Diag Support Mntr The result of transmit/receive diagnosis of CAN communication is displayed.

Monitor Item [Unit] Main

Signals Description

MOTOR FAN REQ [%] ×Indicates cooling fan speed signal received from ECM on CAN communication

line

AC COMP REQ [On/Off] ×Indicates A/C compressor request signal received from ECM on CAN commu-

nication line

TAIL&CLR REQ [On/Off] ×Indicates position light request signal received from BCM on CAN communica-

tion line

HL LO REQ [On/Off] ×Indicates low beam request signal received from BCM on CAN communication

line

HL HI REQ [On/Off] ×Indicates high beam request signal received from BCM on CAN communication

line

FR FOG REQ [On/Off] ×Indicates front fog light request signal received from BCM on CAN communica-

tion line

FR WIP REQ [Stop/1LOW/Low/Hi] ×Indicates front wiper request signal received from BCM on CAN communication

line

WIP AUTO STOP [STOP P/ACT P] ×Indicates condition of front wiper auto stop signal

WIP PROT [Off/BLOCK] ×Indicates condition of front wiper fail-safe operation

IGN RLY1 -REQ [On/Off] Indicates ignition switch ON signal received from BCM on CAN communication

line

IGN RLY [On/Off] ×Indicates condition of ignition relay

PUSH SW [On/Off] Indicates condition of push-button ignition switch

INTER/NP SW [On/Off] Indicates condition of CVT shift position

ST RLY CONT [On/Off] Indicates starter relay status signal received from BCM on CAN communication

line

IHBT RLY -REQ [On/Off] Indicates starter control relay signal received from BCM on CAN communication

line

ST/INHI RLY [Off/ ST /INHI] Indicates condition of starter relay and starter control relay

DETENT SW [On/Off] Indicates condition of CVT shift selector (park position switch)

DTRL REQ [Off] Indicates daytime light request signal received from BCM on CAN communica-

tion line

HOOD SW [On/Off] Indicates condition of hood switch

THFT HRN REQ [On/Off] Indicates theft warning horn request signal received from BCM on CAN commu-

nication line

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

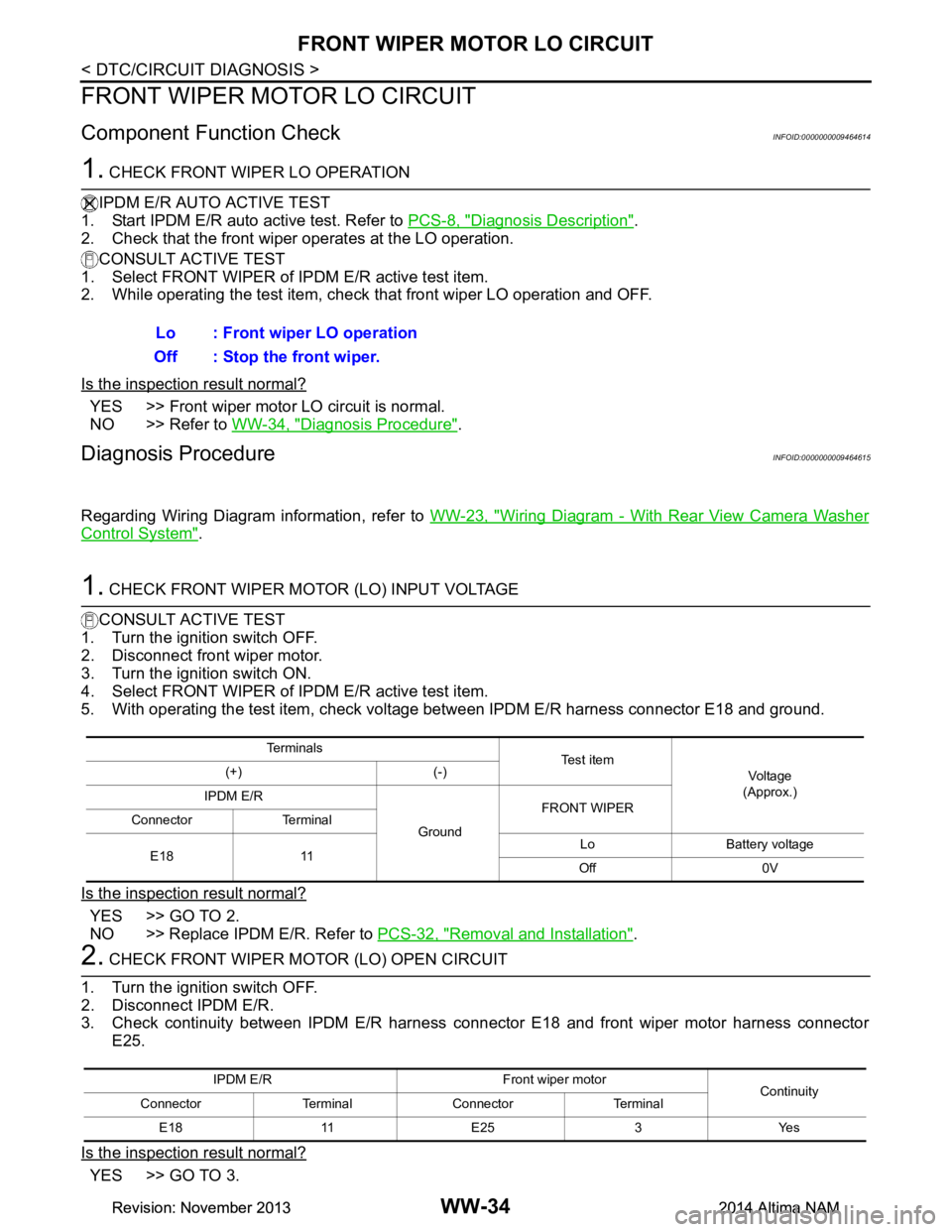

Page 4769 of 4801

WW-34

< DTC/CIRCUIT DIAGNOSIS >

FRONT WIPER MOTOR LO CIRCUIT

FRONT WIPER MOTOR LO CIRCUIT

Component Function CheckINFOID:0000000009464614

1. CHECK FRONT WIPER LO OPERATION

IPDM E/R AUTO ACTIVE TEST

1. Start IPDM E/R auto active test. Refer to PCS-8, "Diagnosis Description"

.

2. Check that the front wiper operates at the LO operation.

CONSULT ACTIVE TEST

1. Select FRONT WIPER of IPDM E/R active test item.

2. While operating the test item, check that front wiper LO operation and OFF.

Is the inspection result normal?

YES >> Front wiper motor LO circuit is normal.

NO >> Refer to WW-34, "Diagnosis Procedure"

.

Diagnosis ProcedureINFOID:0000000009464615

Regarding Wiring Diagram information, refer to WW-23, "Wiring Diagram - With Rear View Camera Washer

Control System".

1. CHECK FRONT WIPER MOTOR (LO) INPUT VOLTAGE

CONSULT ACTIVE TEST

1. Turn the ignition switch OFF.

2. Disconnect front wiper motor.

3. Turn the ignition switch ON.

4. Select FRONT WIPER of IPDM E/R active test item.

5. With operating the test item, check volt age between IPDM E/R harness connector E18 and ground.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Replace IPDM E/R. Refer to PCS-32, "Removal and Installation"

.

2. CHECK FRONT WIPER MOTOR (LO) OPEN CIRCUIT

1. Turn the ignition switch OFF.

2. Disconnect IPDM E/R.

3. Check continuity between IPDM E/R harness c onnector E18 and front wiper motor harness connector

E25.

Is the inspection result normal?

YES >> GO TO 3. Lo : Front wiper LO operation

Off : Stop the front wiper.

Te r m i n a l s Te s t i t e m

Vo l ta g e

(Approx.)

(+) (-)

IPDM E/R

GroundFRONT WIPER

Connector Terminal

E18 11 Lo Battery voltage

Off 0V

IPDM E/R Front wiper motor Continuity

Connector Terminal Connector Terminal

E18 11 E25 3 Yes

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

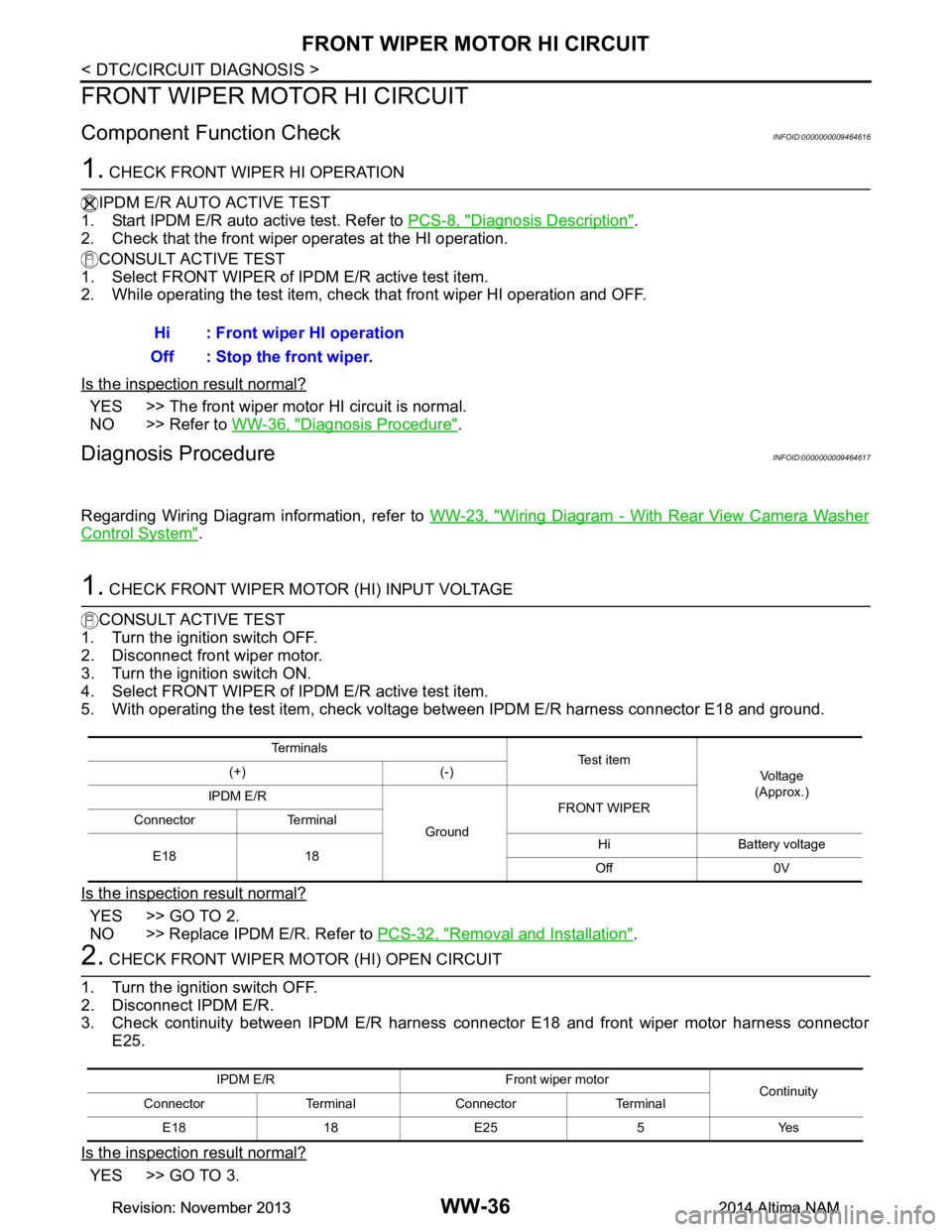

Page 4771 of 4801

WW-36

< DTC/CIRCUIT DIAGNOSIS >

FRONT WIPER MOTOR HI CIRCUIT

FRONT WIPER MOTOR HI CIRCUIT

Component Function CheckINFOID:0000000009464616

1. CHECK FRONT WIPER HI OPERATION

IPDM E/R AUTO ACTIVE TEST

1. Start IPDM E/R auto active test. Refer to PCS-8, "Diagnosis Description"

.

2. Check that the front wiper operates at the HI operation.

CONSULT ACTIVE TEST

1. Select FRONT WIPER of IPDM E/R active test item.

2. While operating the test item, check that front wiper HI operation and OFF.

Is the inspection result normal?

YES >> The front wiper motor HI circuit is normal.

NO >> Refer to WW-36, "Diagnosis Procedure"

.

Diagnosis ProcedureINFOID:0000000009464617

Regarding Wiring Diagram information, refer to WW-23, "Wiring Diagram - With Rear View Camera Washer

Control System".

1. CHECK FRONT WIPER MOTOR (HI) INPUT VOLTAGE

CONSULT ACTIVE TEST

1. Turn the ignition switch OFF.

2. Disconnect front wiper motor.

3. Turn the ignition switch ON.

4. Select FRONT WIPER of IPDM E/R active test item.

5. With operating the test item, check volt age between IPDM E/R harness connector E18 and ground.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Replace IPDM E/R. Refer to PCS-32, "Removal and Installation"

.

2. CHECK FRONT WIPER MOTOR (HI) OPEN CIRCUIT

1. Turn the ignition switch OFF.

2. Disconnect IPDM E/R.

3. Check continuity between IPDM E/R harness c onnector E18 and front wiper motor harness connector

E25.

Is the inspection result normal?

YES >> GO TO 3. Hi : Front wiper HI operation

Off : Stop the front wiper.

Te r m i n a l s Te s t i t e m

Vo l ta g e

(Approx.)

(+) (-)

IPDM E/R

GroundFRONT WIPER

Connector Terminal

E18 18 Hi Battery voltage

Off 0V

IPDM E/R Fron t wiper motor

Continuity

Connector Terminal Connector Terminal

E18 18 E25 5 Yes

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4783 of 4801

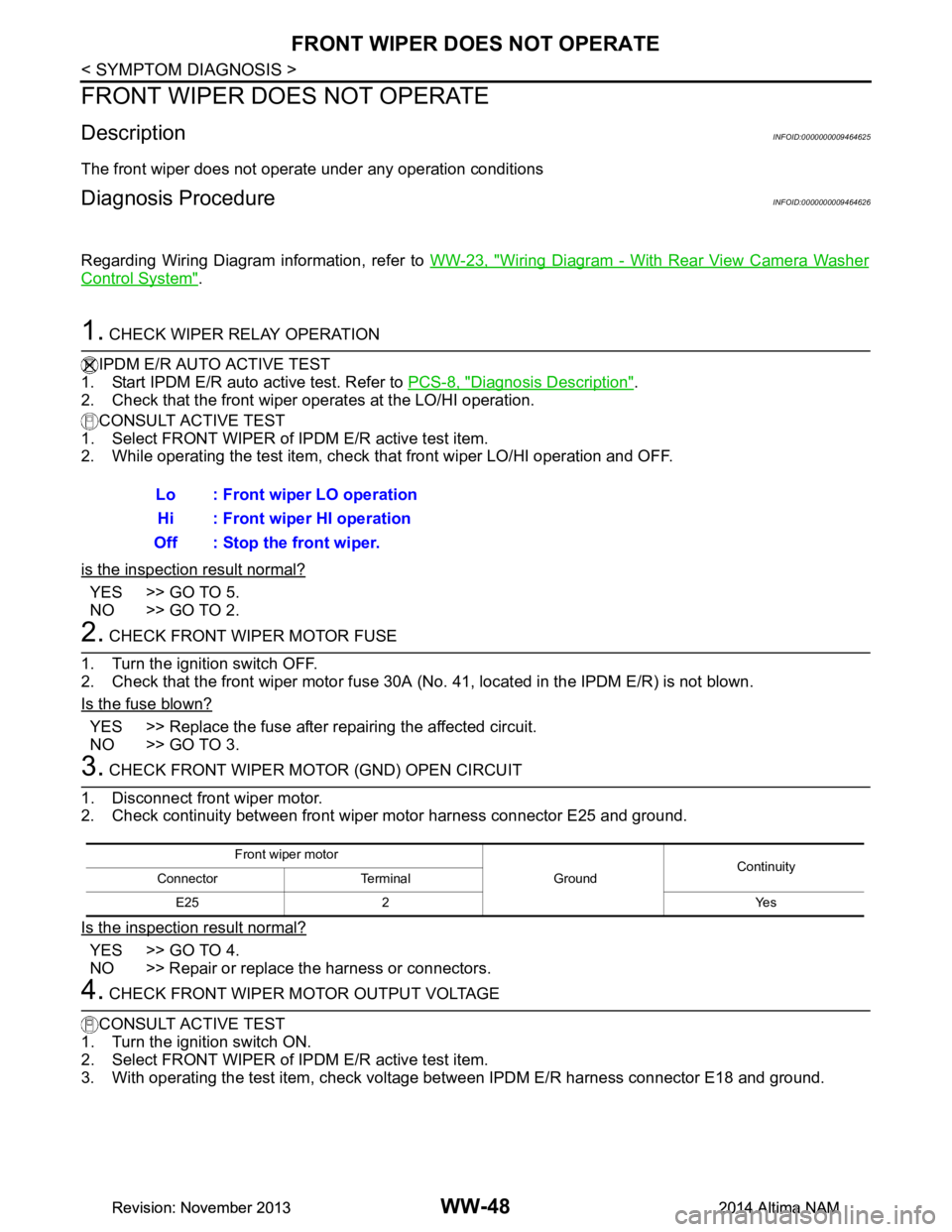

WW-48

< SYMPTOM DIAGNOSIS >

FRONT WIPER DOES NOT OPERATE

FRONT WIPER DOES NOT OPERATE

DescriptionINFOID:0000000009464625

The front wiper does not operate under any operation conditions

Diagnosis ProcedureINFOID:0000000009464626

Regarding Wiring Diagram information, refer to WW-23, "Wiring Diagram - With Rear View Camera Washer

Control System".

1. CHECK WIPER RELAY OPERATION

IPDM E/R AUTO ACTIVE TEST

1. Start IPDM E/R auto active test. Refer to PCS-8, "Diagnosis Description"

.

2. Check that the front wiper operates at the LO/HI operation.

CONSULT ACTIVE TEST

1. Select FRONT WIPER of IPDM E/R active test item.

2. While operating the test item, check that front wiper LO/HI operation and OFF.

is the inspection result normal?

YES >> GO TO 5.

NO >> GO TO 2.

2. CHECK FRONT WIPER MOTOR FUSE

1. Turn the ignition switch OFF.

2. Check that the front wiper motor fuse 30A (No. 41, located in the IPDM E/R) is not blown.

Is the fuse blown?

YES >> Replace the fuse after repairing the affected circuit.

NO >> GO TO 3.

3. CHECK FRONT WIPER MOTOR (GND) OPEN CIRCUIT

1. Disconnect front wiper motor.

2. Check continuity between front wiper motor harness connector E25 and ground.

Is the inspection result normal?

YES >> GO TO 4.

NO >> Repair or replace the harness or connectors.

4. CHECK FRONT WIPER MOTOR OUTPUT VOLTAGE

CONSULT ACTIVE TEST

1. Turn the ignition switch ON.

2. Select FRONT WIPER of IPDM E/R active test item.

3. With operating the test item, check volt age between IPDM E/R harness connector E18 and ground.

Lo : Front wiper LO operation

Hi : Front wiper HI operation

Off : Stop the front wiper.

Front wiper motor

GroundContinuity

Connector Terminal

E25 2 Yes

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM