ECU NISSAN TEANA 2014 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 2417 of 4801

PRECAUTIONSEXT-3

< PRECAUTION >

C

D E

F

G H

I

J

L

M A

B

EXT

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000009951571

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. Information necessary to service t he system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three mi nutes before performing any service.

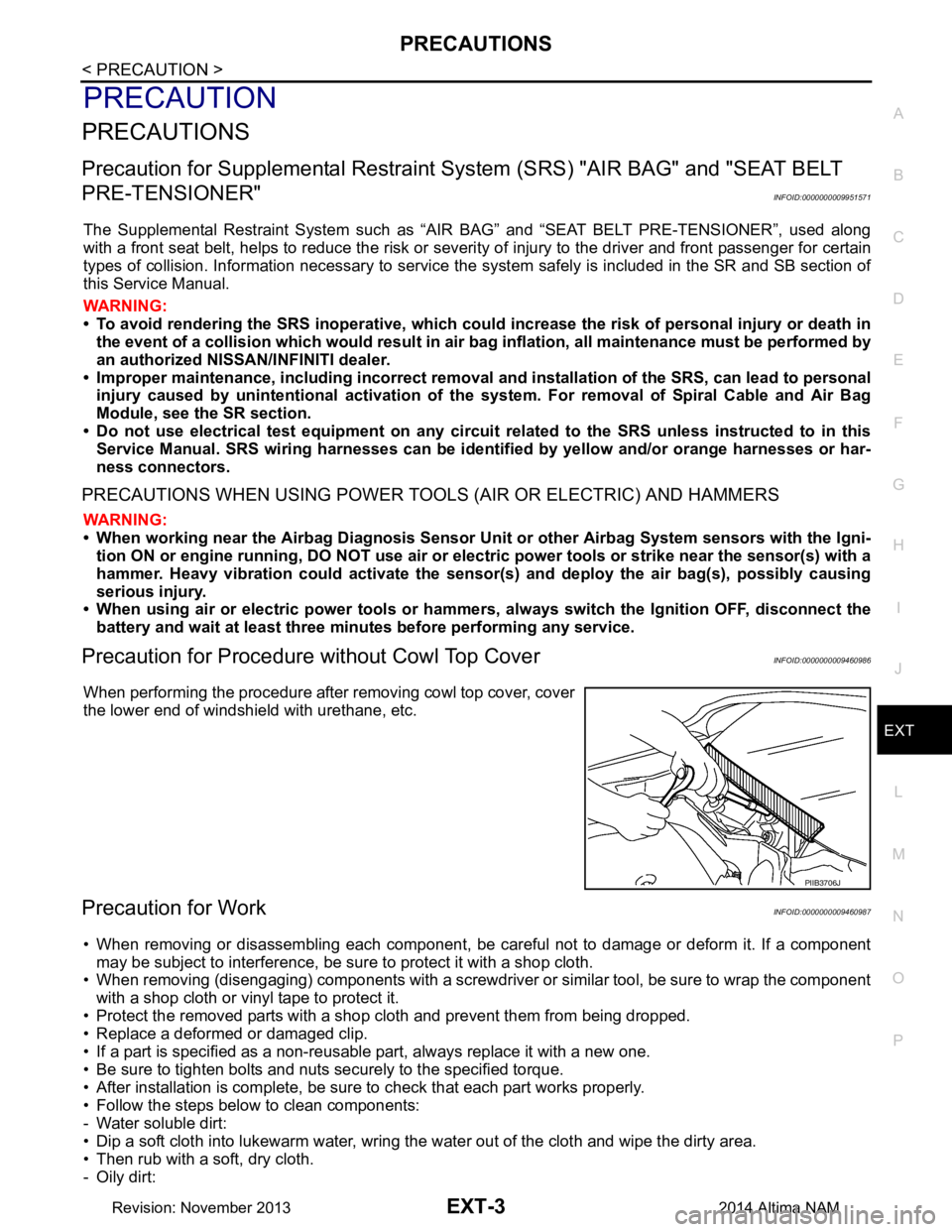

Precaution for Procedure without Cowl Top CoverINFOID:0000000009460986

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Precaution for WorkINFOID:0000000009460987

• When removing or disassembling each component, be ca reful not to damage or deform it. If a component

may be subject to interference, be sure to protect it with a shop cloth.

• When removing (disengaging) components with a screwdriver or similar tool, be sure to wrap the component with a shop cloth or vinyl tape to protect it.

• Protect the removed parts with a shop cloth and prevent them from being dropped.

• Replace a deformed or damaged clip.

• If a part is specified as a non-reusabl e part, always replace it with a new one.

• Be sure to tighten bolts and nuts securely to the specified torque.

• After installation is complete, be sure to check that each part works properly.

• Follow the steps below to clean components:

- Water soluble dirt:

• Dip a soft cloth into lukewarm water, wring the water out of the cloth and wipe the dirty area.

• Then rub with a soft, dry cloth.

-Oily dirt:

PIIB3706J

Revision: November 20132014 Altima NAM

Page 2425 of 4801

SQUEAK AND RATTLE TROUBLE DIAGNOSESEXT-11

< PERIODIC MAINTENANCE >

C

D E

F

G H

I

J

L

M A

B

EXT

N

O P

If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on

the Diagnostic Worksheet regarding the conditions or lo cation of the noise. This information can be used to

duplicate the same conditions when you confirm the repair.

If the noise can be duplicated easily during the test drive, to help identify the source of the noise, try to dupli-

cate the noise with the vehicle stopped by doing one or all of the following:

1) Close a door.

2) Tap or push/pull around the area where the noise appears to be coming from.

3) Rev the engine.

4) Use a floor jack to recreate vehicle “twist”.

5) At idle, apply engine load (electrical load, half-clutch on M/T model, drive position on CVT and A/T models).

6) Raise the vehicle on a hoist and hit a tire with a rubber hammer.

• Drive the vehicle and attempt to duplicate the conditions the customer states exist when the noise occurs.

• If it is difficult to duplicate the noise, drive the vehicle slowly on an undulating or rough road to stress the

vehicle body.

CHECK RELATED SERVICE BULLETINS

After verifying the customer concern or symptom, che ck ASIST for Technical Service Bulletins (TSBs) related

to that concern or symptom.

If a TSB relates to the symptom, follow the procedure to repair the noise.

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

1. Narrow down the noise to a general area. To help pi npoint the source of the noise, use a listening tool

(Chassis Ear: J-39570, Engine Ear: J-39565 and mechanic's stethoscope).

2. Narrow down the noise to a more specific area and identify the cause of the noise by: • removing the components in the area that you suspect the noise is coming from.Do not use too much force when removing clips and fasteners, otherwise clips and fasteners can be

broken or lost during the repair, resulting in the creation of new noise.

• tapping or pushing/pulling the component that you suspect is causing the noise.

Do not tap or push/pull the component with excessive force, otherwise the noise will be eliminated only

temporarily.

• feeling for a vibration with your hand by touching the component(s) that you suspect is (are) causing the

noise.

• placing a piece of paper between components that you suspect are causing the noise.

• looking for loose components and contact marks. Refer to EXT-11, "Generic Squeak and Rattle Troubleshooting"

.

REPAIR THE CAUSE

• If the cause is a loose component, tighten the component securely.

• If the cause is insufficient clearance between components:

- separate components by repositioning or loos ening and retightening the component, if possible.

- insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape or urethane

tape. A NISSAN Squeak and Rattle Kit (J-50397) is av ailable through your authorized NISSAN Parts Depart-

ment.

CAUTION:

Do not use excessive force as many components are constructed of plastic and may be damaged.

NOTE:

• Always check with the Parts Department for the latest parts information.

• The materials contained in the NISSAN Squeak and Rattle Kit (J-50397) are listed on the inside cover of the

kit; and can each be ordered separately as needed.

• The following materials not found in the kit can also be used to repair squeaks and rattles.

- SILICONE GREASE: Use instead of UHMW tape that will be visible or does not fit. The silicone grease will

only last a few months.

- SILICONE SPRAY: Use when grease cannot be applied.

- DUCT TAPE: Use to eliminate movement.

CONFIRM THE REPAIR

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Generic Squeak and Rattle TroubleshootingINFOID:0000000009895308

Refer to Table of Contents for specific component removal and installation information.

Revision: November 20132014 Altima NAM

Page 2427 of 4801

SQUEAK AND RATTLE TROUBLE DIAGNOSESEXT-13

< PERIODIC MAINTENANCE >

C

D E

F

G H

I

J

L

M A

B

EXT

N

O P

1. Loose harness or harness connectors.

2. Front console map/reading lamp lens loose.

3. Loose screws at console attachment points.

SEATS

When isolating seat noise it's important to note the pos ition the seat is in and the load placed on the seat when

the noise is present. These conditions should be duplic ated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of thes e incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component installed to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator installation pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine rpm or

load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Revision: November 20132014 Altima NAM

Page 2463 of 4801

FRONT DRIVE SHAFTFAX-11

< REMOVAL AND INSTALLATION >

CEF

G H

I

J

K L

M A

B

FA X

N

O P

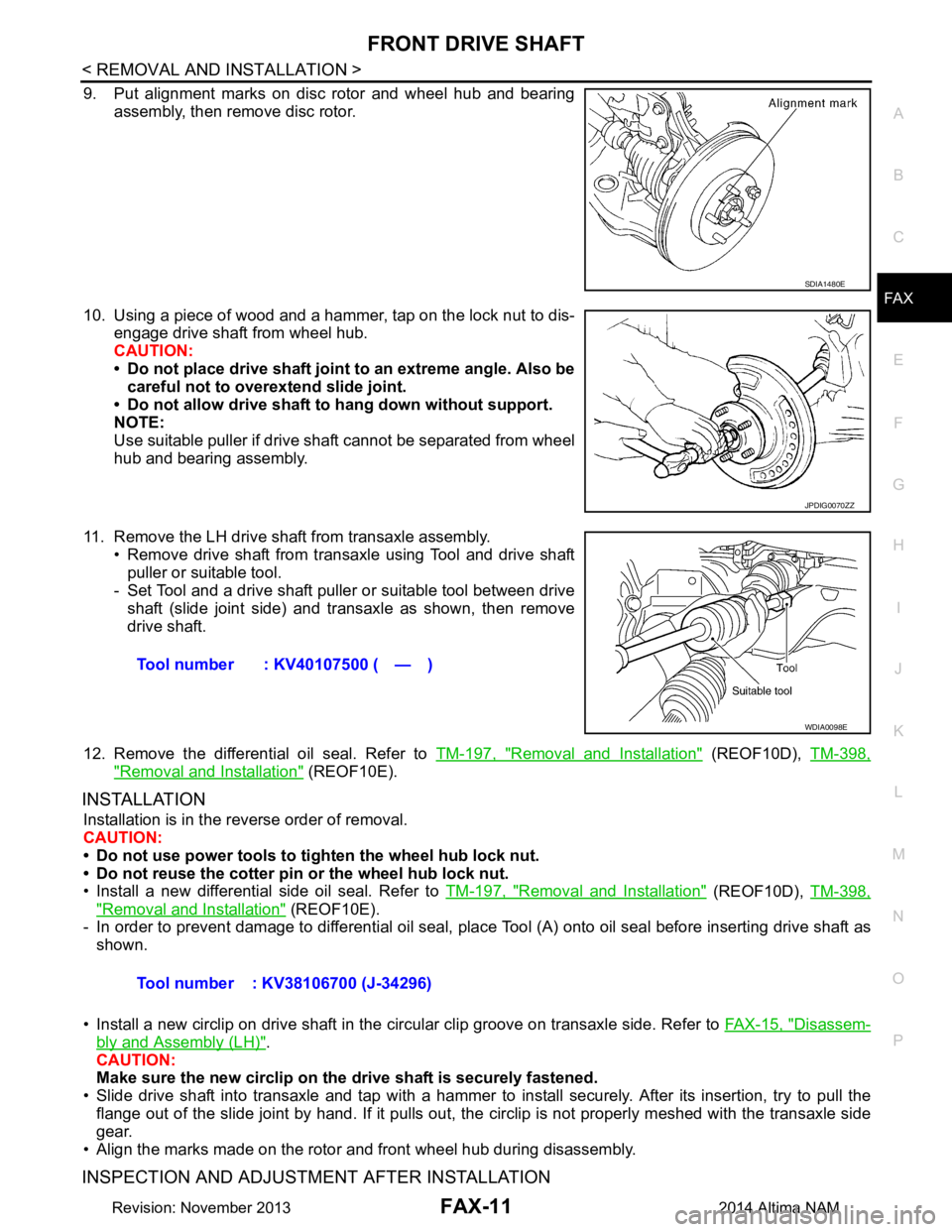

9. Put alignment marks on disc rotor and wheel hub and bearing assembly, then remove disc rotor.

10. Using a piece of wood and a hammer, tap on the lock nut to dis- engage drive shaft from wheel hub.

CAUTION:

• Do not place drive shaft joint to an extreme angle. Also be careful not to over extend slide joint.

• Do not allow drive shaft to hang down without support.

NOTE:

Use suitable puller if drive shaft cannot be separated from wheel

hub and bearing assembly.

11. Remove the LH drive shaf t from transaxle assembly.

• Remove drive shaft from transaxle using Tool and drive shaft puller or suitable tool.

- Set Tool and a drive shaft puller or suitable tool between drive

shaft (slide joint side) and transaxle as shown, then remove

drive shaft.

12. Remove the differential oil seal. Refer to TM-197, "Removal and Installation"

(REOF10D), TM-398,

"Removal and Installation" (REOF10E).

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Do not use power tools to ti ghten the wheel hub lock nut.

• Do not reuse the cotter pin or the wheel hub lock nut.

• Install a new differential side oil seal. Refer to TM-197, "Removal and Installation"

(REOF10D), TM-398,

"Removal and Installation" (REOF10E).

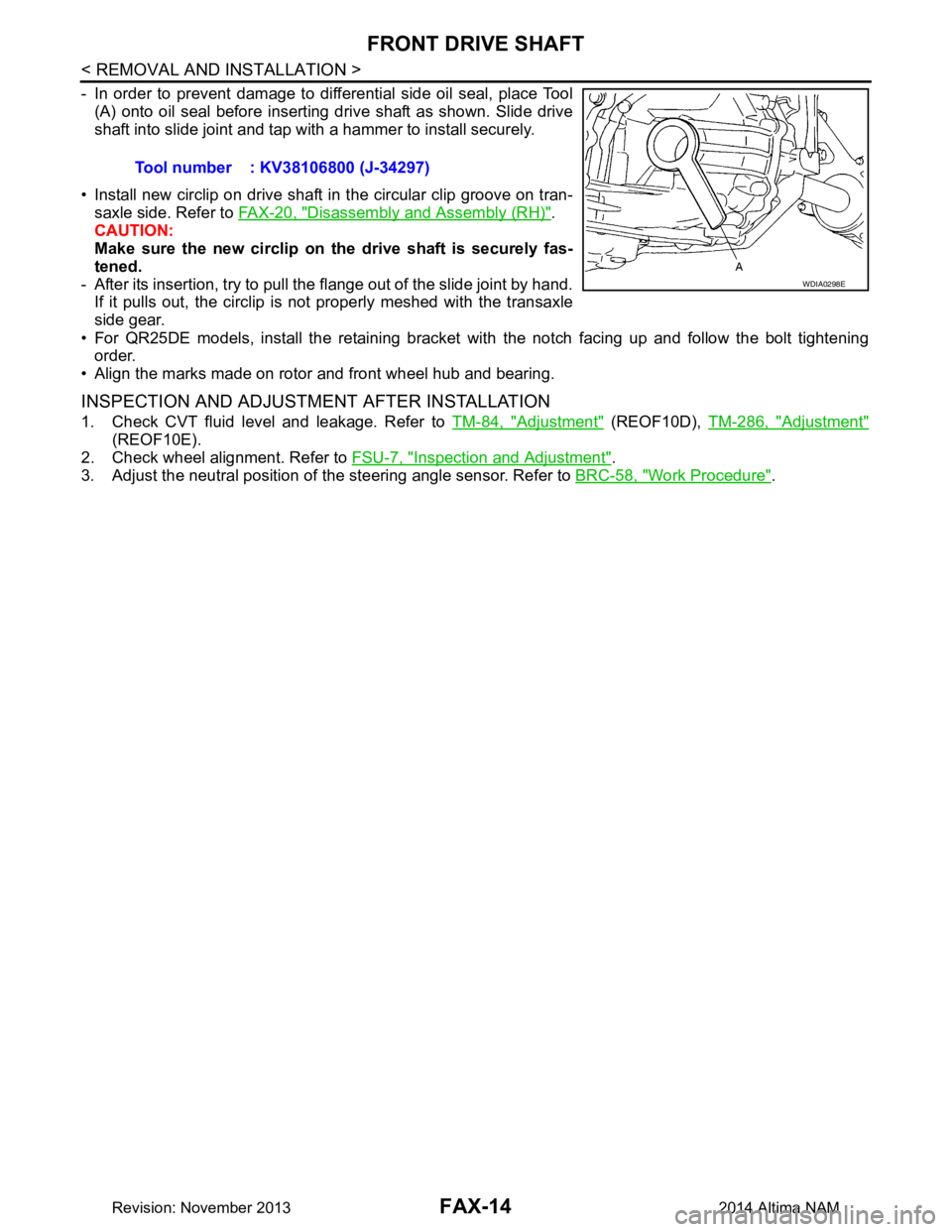

- In order to prevent damage to differential oil seal, plac e Tool (A) onto oil seal before inserting drive shaft as

shown.

• Install a new circlip on drive shaft in the circular clip groove on transaxle side. Refer to FAX-15, "Disassem-

bly and Assembly (LH)".

CAUTION:

Make sure the new circlip on the drive shaft is securely fastened.

• Slide drive shaft into transaxle and tap with a hammer to install securely. After its insertion, try to pull the

flange out of the slide joint by hand. If it pulls out, t he circlip is not properly meshed with the transaxle side

gear.

• Align the marks made on the rotor and front wheel hub during disassembly.

INSPECTION AND ADJUSTMENT AFTER INSTALLATION

SDIA1480E

JPDIG0070ZZ

Tool number : KV40107500 ( — )

WDIA0098E

Tool number : KV38106700 (J-34296)

Revision: November 20132014 Altima NAM

Page 2466 of 4801

FAX-14

< REMOVAL AND INSTALLATION >

FRONT DRIVE SHAFT

- In order to prevent damage to differential side oil seal, place Tool(A) onto oil seal before inserting drive shaft as shown. Slide drive

shaft into slide joint and tap with a hammer to install securely.

• Install new circlip on drive shaft in the circular clip groove on tran- saxle side. Refer to FAX-20, "Disassembly and Assembly (RH)"

.

CAUTION:

Make sure the new circlip on the drive shaft is securely fas-

tened.

- After its insertion, try to pull the flange out of the slide joint by hand. If it pulls out, the circlip is not properly meshed with the transaxle

side gear.

• For QR25DE models, install the retaining bracket with the notch facing up and follow the bolt tightening

order.

• Align the marks made on rotor and front wheel hub and bearing.

INSPECTION AND ADJUSTMENT AFTER INSTALLATION

1. Check CVT fluid level and leakage. Refer to TM-84, "Adjustment" (REOF10D), TM-286, "Adjustment"

(REOF10E).

2. Check wheel alignment. Refer to FSU-7, "Inspection and Adjustment"

.

3. Adjust the neutral position of the steering angle sensor. Refer to BRC-58, "Work Procedure"

.

Tool number : KV38106800 (J-34297)

WDIA0298E

Revision: November 20132014 Altima NAM

Page 2469 of 4801

FRONT DRIVE SHAFTFAX-17

< UNIT DISASSEMBLY AND ASSEMBLY >

CEF

G H

I

J

K L

M A

B

FA X

N

O P

Slide Joint Housing

• Make sure there are no compression scars, cracks or

fractures or unusual wear of ball rolling surface.

• Make sure there is no damage to shaft screws.

• Make sure there is no deformation of boot installation parts.

Ball Cage

• Make sure there are no compression scars, cracks, fractures of sliding surface.

Steel Ball

• Make sure there are no compression scars , cracks, fractures or unusual wear.

Inner Race

• Check ball sliding surface for compression scars, cracks or fractures.

• Make sure there is no damage to serrated part.

CAUTION:

If there are any irregular condit ions in the component, replace with a new set of joint sub-assembly,

ball cage, steel ball and inner race.

Damper

• Check damper for cracks or wear. Install damper with new damper bands.

ASSEMBLY

Transaxle Side

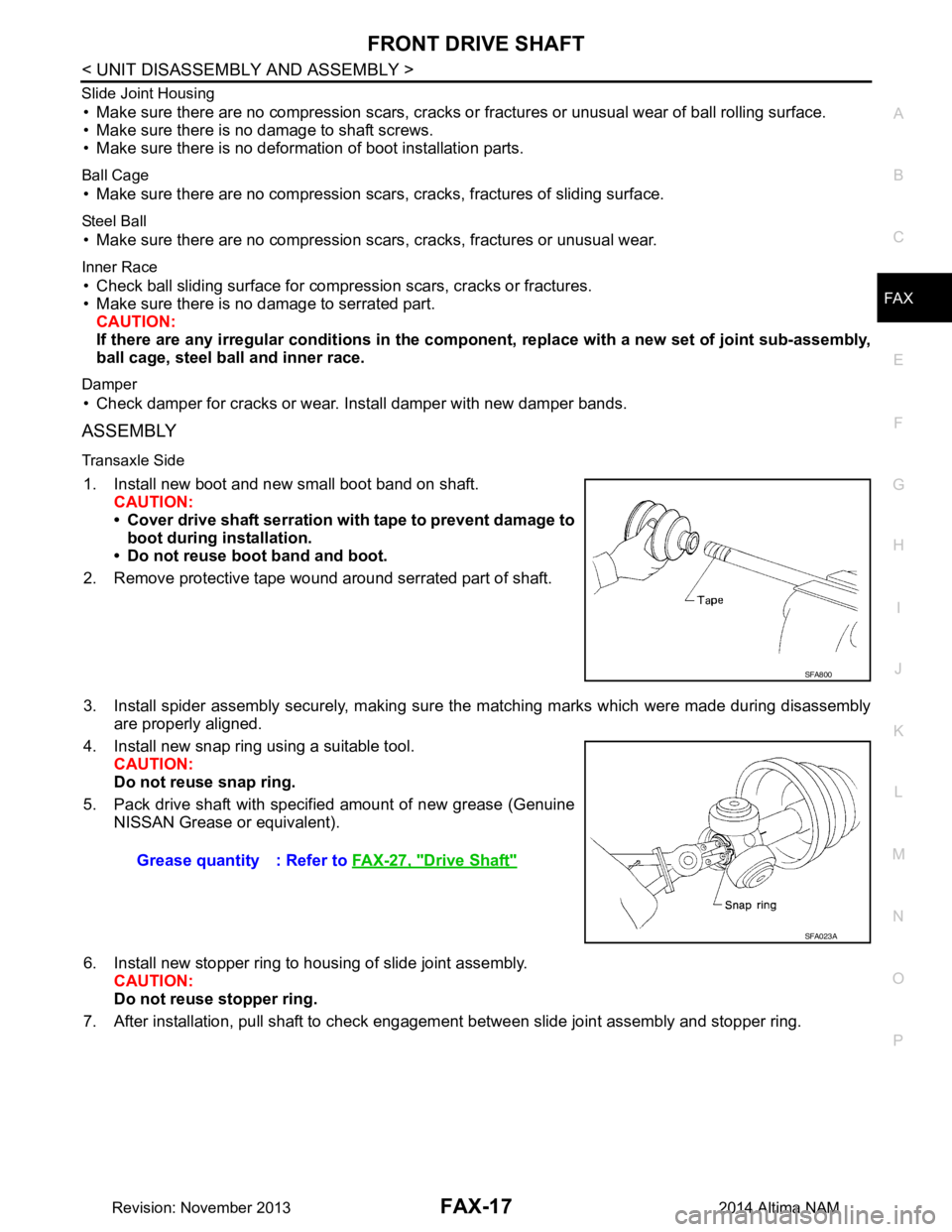

1. Install new boot and new small boot band on shaft.

CAUTION:

• Cover drive shaft serration with tape to prevent damage to boot during installation.

• Do not reuse boot band and boot.

2. Remove protective tape wound around serrated part of shaft.

3. Install spider assembly securely, making sure the matching marks which were made during disassembly are properly aligned.

4. Install new snap ring using a suitable tool. CAUTION:

Do not reuse snap ring.

5. Pack drive shaft with specified amount of new grease (Genuine NISSAN Grease or equivalent).

6. Install new stopper ring to housing of slide joint assembly. CAUTION:

Do not reuse stopper ring.

7. After installation, pull shaft to check engagement between slide joint assembly and stopper ring.

SFA800

Grease quantity : Refer to FAX-27, "Drive Shaft"

SFA023A

Revision: November 20132014 Altima NAM

Page 2470 of 4801

FAX-18

< UNIT DISASSEMBLY AND ASSEMBLY >

FRONT DRIVE SHAFT

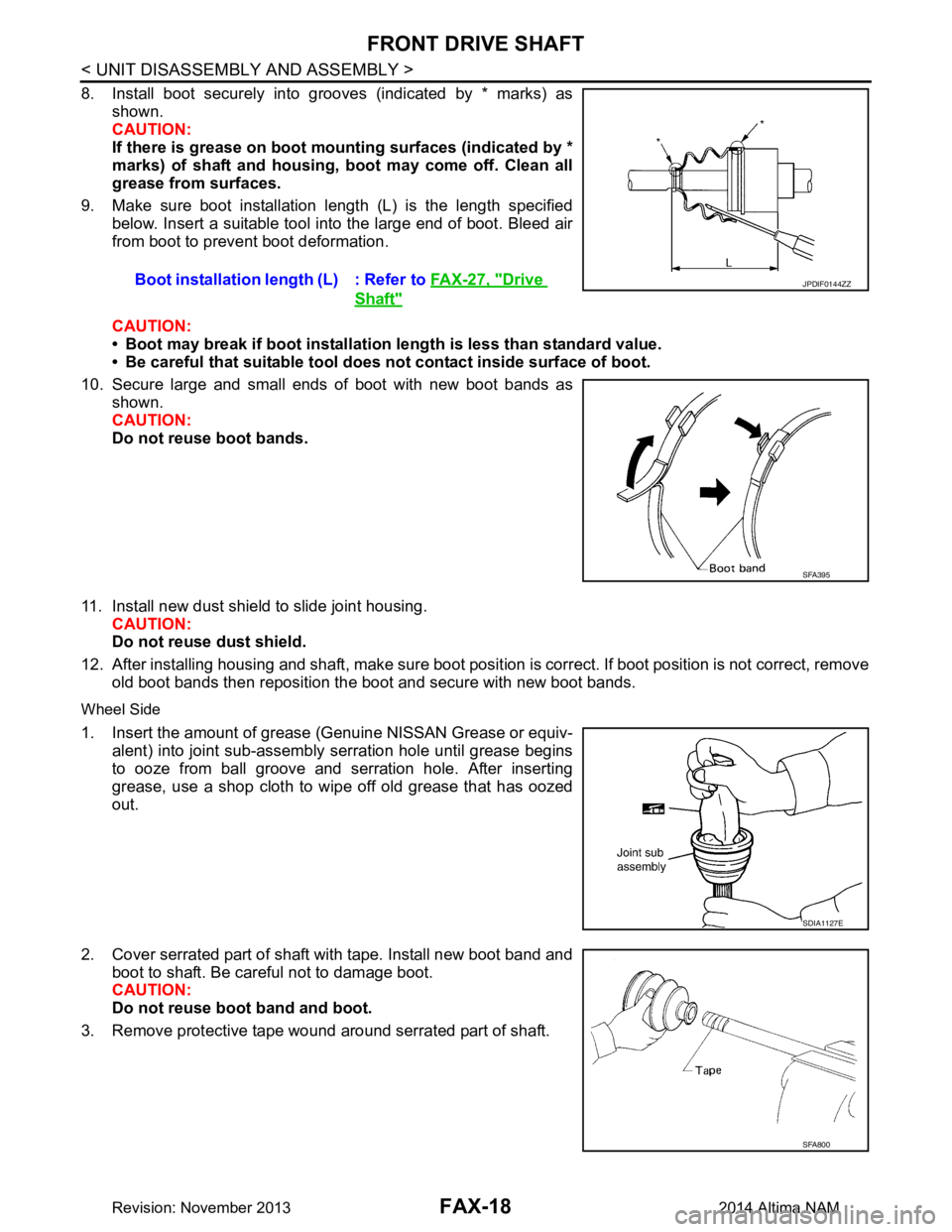

8. Install boot securely into grooves (indicated by * marks) asshown.

CAUTION:

If there is grease on boot mounting surfaces (indicated by *

marks) of shaft and housing, boot may come off. Clean all

grease from surfaces.

9. Make sure boot installation length (L) is the length specified below. Insert a suitable tool into the large end of boot. Bleed air

from boot to prevent boot deformation.

CAUTION:

• Boot may break if boot installation length is less than standard value.

• Be careful that suitable tool does not contact inside surface of boot.

10. Secure large and small ends of boot with new boot bands as shown.

CAUTION:

Do not reuse boot bands.

11. Install new dust shield to slide joint housing. CAUTION:

Do not reuse dust shield.

12. After installing housing and shaft, make sure boot posit ion is correct. If boot position is not correct, remove

old boot bands then reposition the boot and secure with new boot bands.

Wheel Side

1. Insert the amount of grease (Genuine NISSAN Grease or equiv-

alent) into joint sub-assembly serration hole until grease begins

to ooze from ball groove and serration hole. After inserting

grease, use a shop cloth to wipe off old grease that has oozed

out.

2. Cover serrated part of shaft with tape. Install new boot band and boot to shaft. Be careful not to damage boot.

CAUTION:

Do not reuse boot band and boot.

3. Remove protective tape wound around serrated part of shaft. Boot installation length (L) : Refer to

FAX-27, "Drive

Shaft"

JPDIF0144ZZ

SFA395

SDIA1127E

SFA800

Revision: November 20132014 Altima NAM

Page 2471 of 4801

FRONT DRIVE SHAFTFAX-19

< UNIT DISASSEMBLY AND ASSEMBLY >

CEF

G H

I

J

K L

M A

B

FA X

N

O P

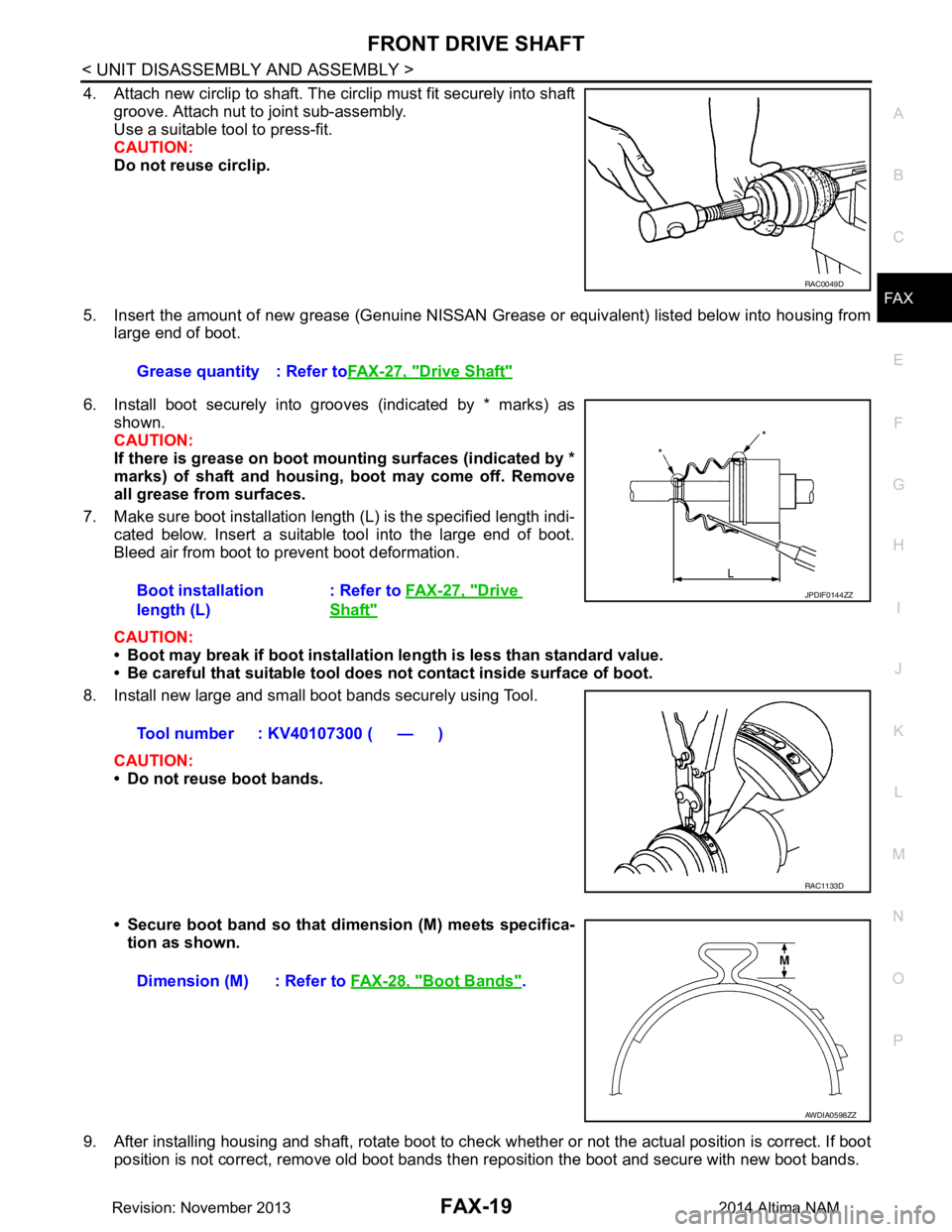

4. Attach new circlip to shaft. The circlip must fit securely into shaft groove. Attach nut to joint sub-assembly.

Use a suitable tool to press-fit.

CAUTION:

Do not reuse circlip.

5. Insert the amount of new grease (Genuine NISSAN Grease or equivalent) listed below into housing from

large end of boot.

6. Install boot securely into grooves (indicated by * marks) as shown.

CAUTION:

If there is grease on boot mounting surfaces (indicated by *

marks) of shaft and housing, boot may come off. Remove

all grease from surfaces.

7. Make sure boot installation length (L) is the specified length indi- cated below. Insert a suitable tool into the large end of boot.

Bleed air from boot to prevent boot deformation.

CAUTION:

• Boot may break if boot installation le ngth is less than standard value.

• Be careful that suitable tool does not contact inside surface of boot.

8. Install new large and small boot bands securely using Tool.

CAUTION:

• Do not reuse boot bands.

• Secure boot band so that dimension (M) meets specifica- tion as shown.

9. After installing housing and shaft, rotate boot to check whether or not the actual position is correct. If boot

position is not correct, remove old boot bands t hen reposition the boot and secure with new boot bands.

RAC0049D

Grease quantity : Refer toFAX-27, "Drive Shaft"

Boot installation

length (L) : Refer to

FAX-27, "Drive

Shaft"

Tool number : KV40107300 ( — )

JPDIF0144ZZ

RAC1133D

Dimension (M) : Refer to FAX-28, "Boot Bands".

AWDIA0598ZZ

Revision: November 20132014 Altima NAM

Page 2472 of 4801

FAX-20

< UNIT DISASSEMBLY AND ASSEMBLY >

FRONT DRIVE SHAFT

Damper

1. Use new damper bands for installation.CAUTION:

Do not reuse damper bands.

2. Install damper from stationary-joint side while holding it securely.

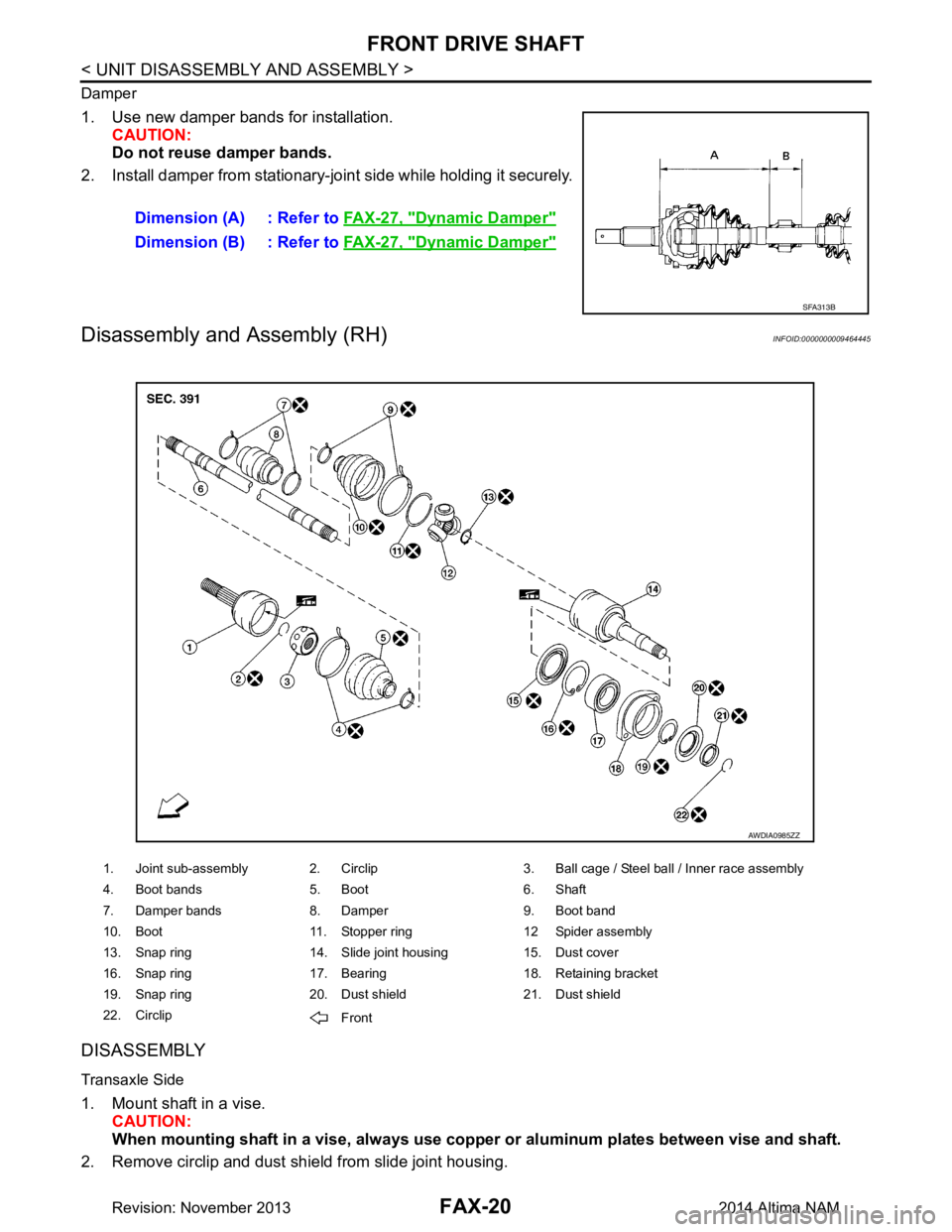

Disassembly and Assembly (RH)INFOID:0000000009464445

DISASSEMBLY

Transaxle Side

1. Mount shaft in a vise. CAUTION:

When mounting shaf t in a vise, always use copper or al uminum plates between vise and shaft.

2. Remove circlip and dust shield from slide joint housing. Dimension (A) : Refer to

FAX-27, "Dynamic Damper"

Dimension (B) : Refer to FAX-27, "Dynamic Damper"

SFA313B

1. Joint sub-assembly 2. Circlip 3. Ball cage / Steel ball / Inner race assembly

4. Boot bands 5. Boot 6. Shaft

7. Damper bands 8. Damper 9. Boot band

10. Boot 11. Stopper ring 12 Spider assembly

13. Snap ring 14. Slide joint housing 15. Dust cover

16. Snap ring 17. Bearing 18. Retaining bracket

19. Snap ring 20. Dust shield 21. Dust shield

22. Circlip Front

AWDIA0985ZZ

Revision: November 20132014 Altima NAM

Page 2475 of 4801

FRONT DRIVE SHAFTFAX-23

< UNIT DISASSEMBLY AND ASSEMBLY >

CEF

G H

I

J

K L

M A

B

FA X

N

O P

• Check damper for cracks or wear. Install damper with new damper bands.

ASSEMBLY

Transaxle Side

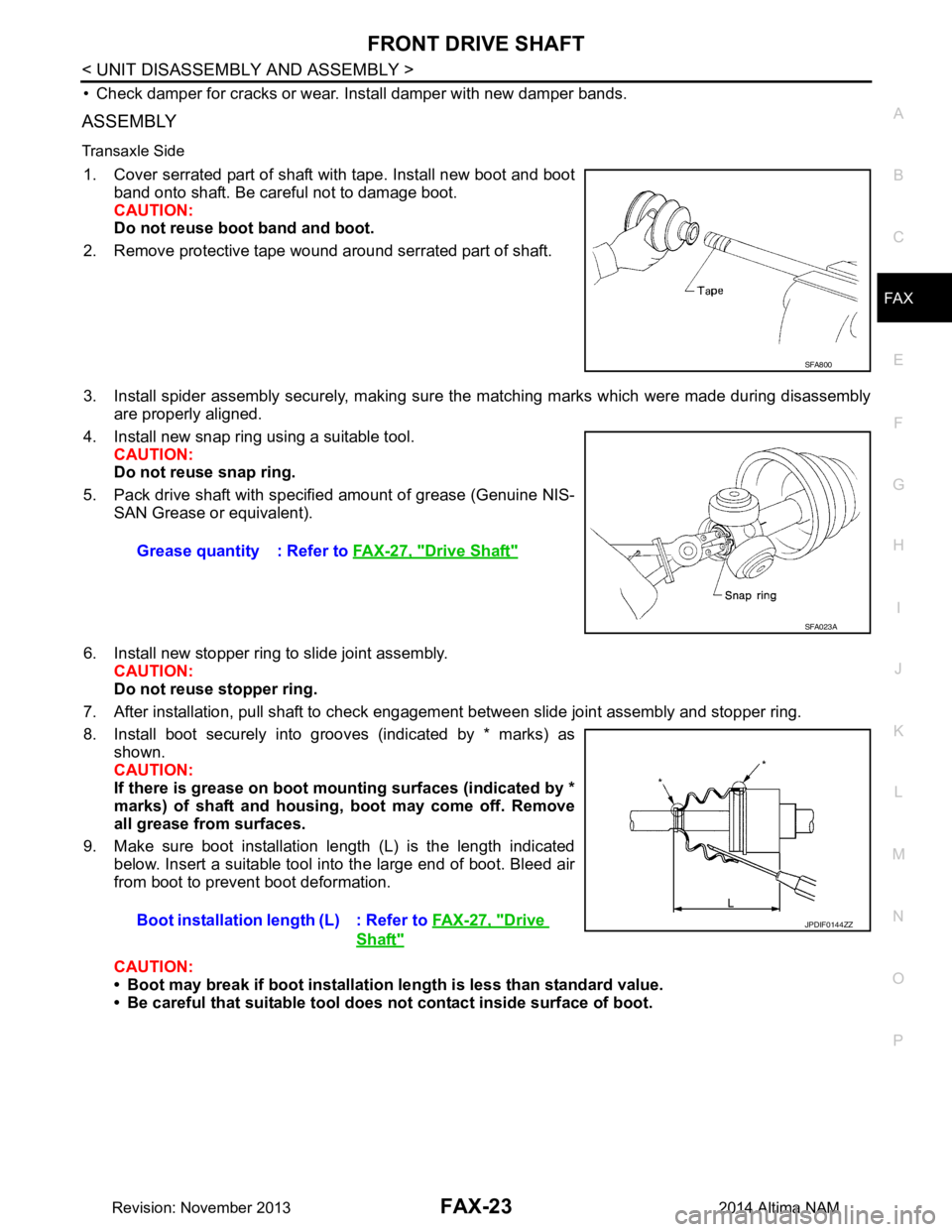

1. Cover serrated part of shaft with tape. Install new boot and boot band onto shaft. Be careful not to damage boot.

CAUTION:

Do not reuse boot band and boot.

2. Remove protective tape wound around serrated part of shaft.

3. Install spider assembly securely, making sure the matching marks which were made during disassembly are properly aligned.

4. Install new snap ring using a suitable tool. CAUTION:

Do not reuse snap ring.

5. Pack drive shaft with specifi ed amount of grease (Genuine NIS-

SAN Grease or equivalent).

6. Install new stopper ring to slide joint assembly. CAUTION:

Do not reuse stopper ring.

7. After installation, pull shaft to check engagement between slide joint assembly and stopper ring.

8. Install boot securely into grooves (indicated by * marks) as shown.

CAUTION:

If there is grease on boot mounting surfaces (indicated by *

marks) of shaft and housing, boot may come off. Remove

all grease from surfaces.

9. Make sure boot installation length (L) is the length indicated below. Insert a suitable tool into the large end of boot. Bleed air

from boot to prevent boot deformation.

CAUTION:

• Boot may break if boot installation le ngth is less than standard value.

• Be careful that suitable tool does not contact inside surface of boot.

SFA800

Grease quantity : Refer to FAX-27, "Drive Shaft"

SFA023A

Boot installation length (L) : Refer to FAX-27, "Drive

Shaft"

JPDIF0144ZZ

Revision: November 20132014 Altima NAM